Grouting Binder and Its Performance Parameter Testing Method

A binder and grouting technology, which is applied in the direction of analyzing materials, measuring devices, instruments, etc., can solve the problems of harsh construction environment, long construction time, difficult repair, etc., and achieve the effect of improving mechanical properties and high early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

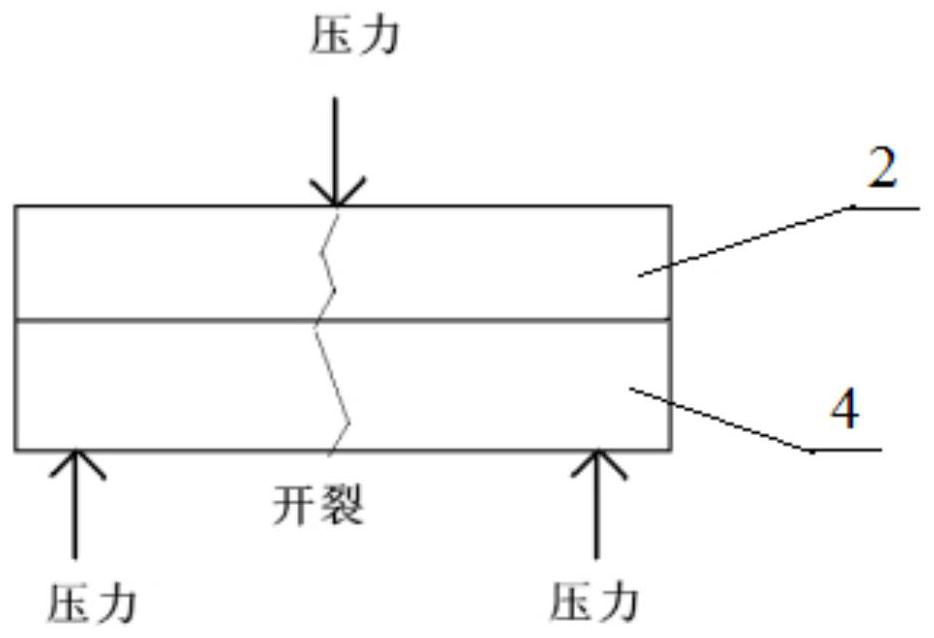

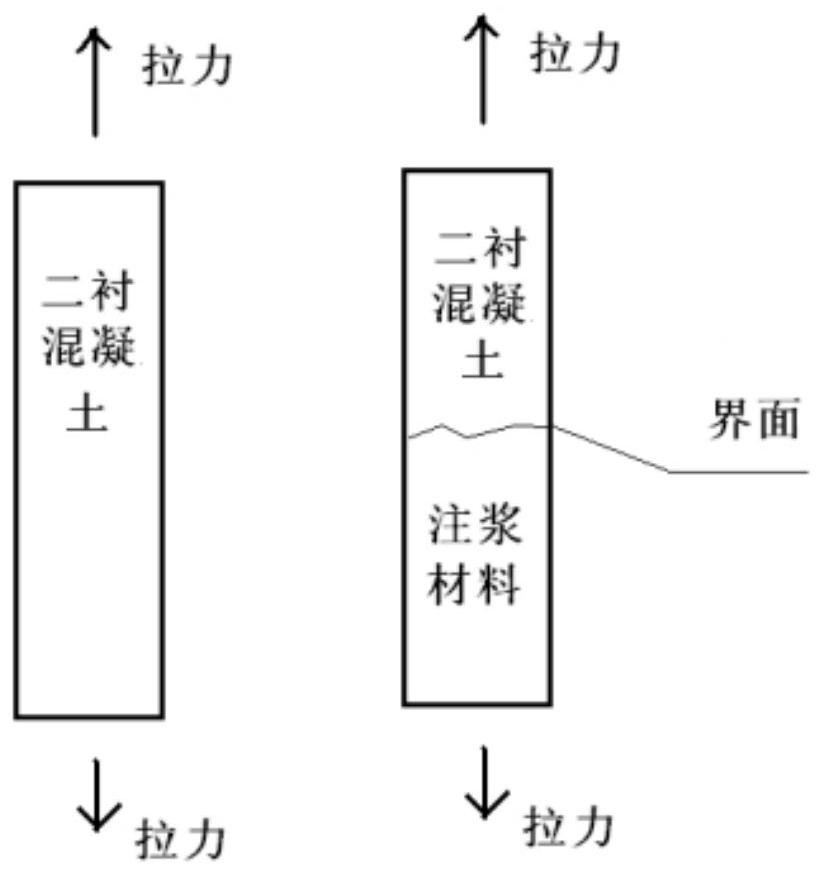

Problems solved by technology

Method used

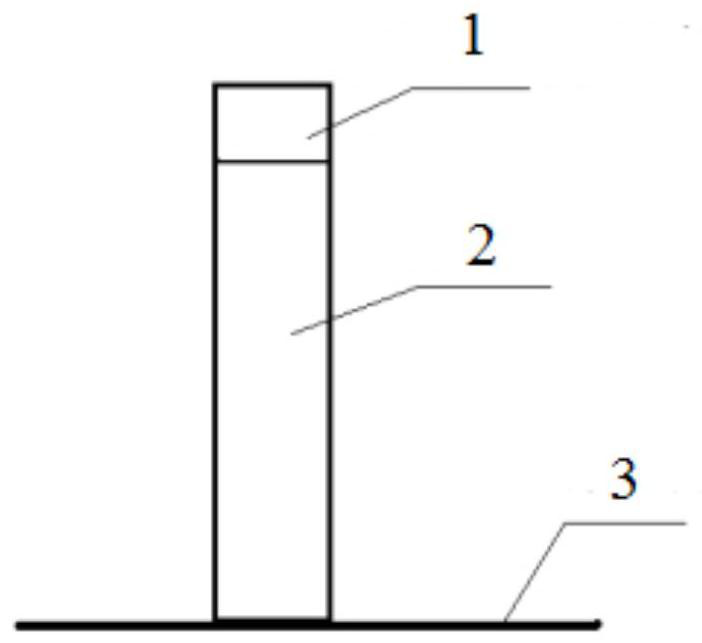

Image

Examples

Embodiment 1

[0041] This embodiment provides a grouting binder (standard type), and its components are by weight: 500-1500 parts of cement, preferably 700-1200 parts; 500-3000 parts of aggregate, preferably 1000-2000 parts; 10-150 parts of admixture, preferably 40-110 parts; 5-150 parts of rubber powder, preferably 30-100 parts; 1-20 parts of superplasticizer, preferably 5-15 parts; 1-10 parts of anti-cracking capsule, Preferably 4-8 parts; 0.1-5 parts of defoamer, preferably 1-3 parts; 0.02-2 parts of plastic expansion agent, preferably 0.1-1 part; 20-150 parts of hardening expansion agent, preferably 50-110 parts; early strength 0.5-10 parts of agent, preferably 1-6 parts; 0.5-5 parts of slump-retaining agent, preferably 1-4 parts; 0.5-5 parts of fiber, preferably 1-4 parts; mixing water is powder (the total amount of the above-mentioned materials weight) 0.10-0.35 times.

[0042] Through the above proportions, a standard grouting binder can be formed, which has very high early strength...

Embodiment 2

[0073] This embodiment provides a kind of grouting binder (high bonding type), and its components are by weight: 500-1500 parts of cement, preferably 700-1200 parts; 500-1500 parts of aggregate, preferably 700-1200 parts 10-150 parts of admixture, preferably 40-110 parts; 1-5 parts of rubber powder, preferably 2-3 parts; 1-20 parts of superplasticizer, preferably 5-15 parts; 1-10 parts of anti-crack capsule parts, preferably 4-8 parts; 0.1-5 parts of defoamer, preferably 1-3 parts; 0.1-2 parts of plastic expansion agent, preferably 0.1-1 part; 20-150 parts of hardening expansion agent, preferably 50-110 parts; 0.5-10 parts of early strength agent, preferably 1-6 parts; 0.5-5 parts of slump retaining agent, preferably 1-4 parts; 0.5-5 parts of fiber, preferably 1-4 parts; 5-150 parts of emulsion, preferably 20-110 parts parts; the mixing water is 0.10-0.25 times of the powder.

[0074] In this embodiment, the cement is Portland cement or ordinary Portland cement with a strengt...

Embodiment 3

[0101] The present embodiment provides a kind of grouting binder (high bonding type), and the main component of high bonding type is by weight: cement (425) 1000 parts; Aggregate 1000 parts; Admixture (silica fume) 60 parts; rubber powder (5010N) 1 part; superplasticizer (PC1030) 2 parts; anti-crack capsule 1 part; defoamer (organosiloxane) 0.3 part; plastic expansion agent (aluminum powder) 0.1 part; 20 parts of expansion agent (HCSA); 1 part of early strength agent (sodium carbonate); 0.1 part of slump retaining agent (sodium gluconate); 2 parts of fiber (basalt fiber); 100 parts of emulsion (S623); 350 parts of mixing water.

[0102] The performance parameters of the grouting binder of the present embodiment are shown in the following table by the above-mentioned formula:

[0103]

[0104] The high-adhesive grouting binder of this embodiment, through the above ratio, has super strong mechanical properties, that is, the 28d compressive strength reaches 65MPa, the 28d flex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com