Preparation method of delayed coagulation type water reducing agent

A production method and technology of a water reducing agent, which are applied in the field of concrete admixtures, can solve the problems such as the mismatch between the type of retarder and the cement, the short setting time of concrete, and the poor adaptability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: A kind of preparation method of retarding type superplasticizer

[0031] Add 471 grams of water, 163 grams of p-aminobenzenesulfonic acid, 150 grams of salicylic acid, and 20 grams of glucose in a four-necked flask equipped with a reflux condenser, agitator, and a thermometer, and neutralize to a pH of 10 with sodium hydroxide. The temperature was raised to 90°C, and 180 grams of formaldehyde solution was added dropwise for 4 hours, followed by a constant temperature reaction for 5 hours.

Embodiment 2

[0032] Embodiment 2: A kind of preparation method of retarding type superplasticizer

[0033] Add 575 grams of water, 220 grams of sodium sulfanilate, 171 grams of sodium salicylate, and 30 grams of glucose into a four-necked flask equipped with a reflux condenser, agitator, and a thermometer, and neutralize with sodium hydroxide until the pH is 10. Raise the temperature to 90°C, add 180 grams of formaldehyde solution dropwise for 4 hours, and react at constant temperature for 5 hours.

Embodiment 3

[0034] Embodiment 3: performance test

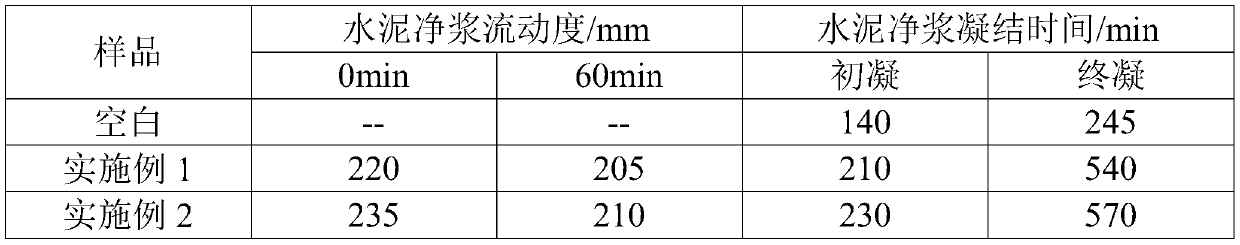

[0035] 1. Determination of the fluidity of cement paste and the setting time of cement paste: the samples synthesized in the above examples are tested according to GB / T8077-2012 "Concrete Admixture Homogeneity Test Method" and "Cement Standard Consistency Water Consumption, Setting Time , Stability Test Method" to test, the dosage of the retarded water reducer prepared by the present invention is 1.8%, the results are shown in Table 1.

[0036] Table 1

[0037]

[0038] Note: "--" in the table means no pulp fluidity.

[0039] It can be seen from the above test data that the retarded water reducer synthesized by the present invention has a good retarding effect.

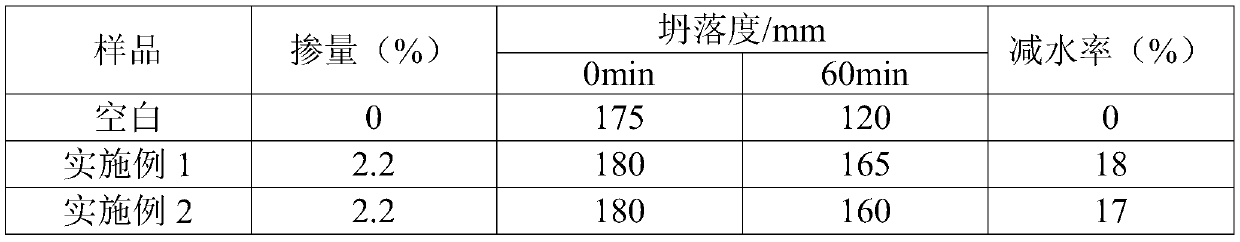

[0040] 2. Concrete performance test: Test with reference to GB8076-2008 "Concrete Admixtures", the results are shown in Table 2.

[0041] Table 2

[0042]

[0043] It can be seen from the above test data that the retarded water reducer synthesized by the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com