A kind of coagulation-promoting early-strength polycarboxylate superplasticizer and preparation method thereof

A superplasticizer, a technology of accelerating coagulation and early strength, used in concrete admixtures, the preparation of polycarboxylate superplasticizers, the preparation of coagulation-promoting early-strength polycarboxylate superplasticizers, and the preparation of coagulation-promoting early-strength type Polycarboxylate superplasticizer, the field of polycarboxylate superplasticizer, can solve the problems of shortening the setting time of concrete, high price of styrene sulfonic acid, and no guidance plan, saving steam curing energy consumption, shortening setting time, The effect of faster template turnaround

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

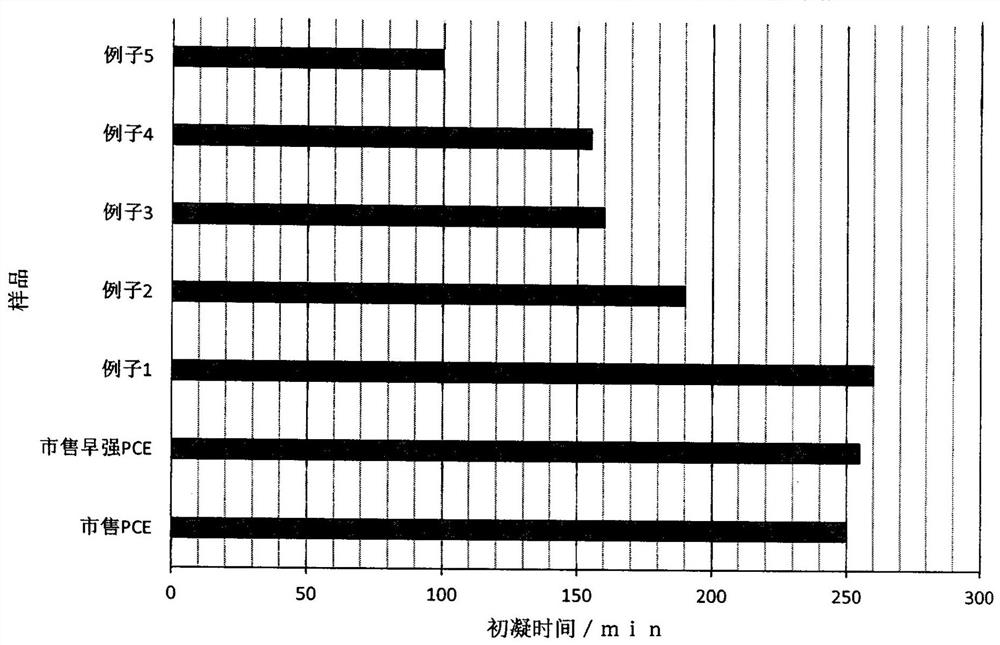

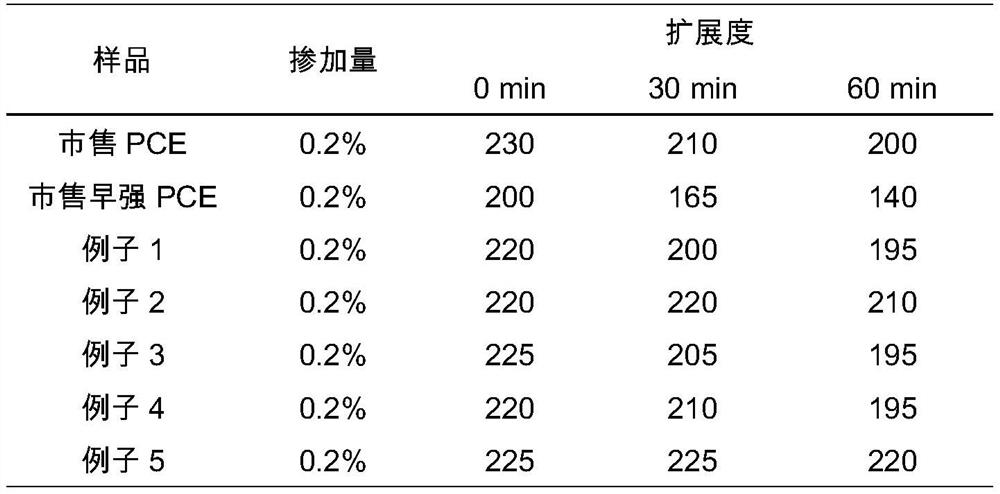

Examples

Embodiment 1

[0019] Embodiment 1: the coagulation-accelerating early-strength polycarboxylate superplasticizer of the present invention is made of the following raw materials in parts by mass: polyoxyethylene ether macromonomer is isopentenol polyoxyethylene ether (TPEG4000) 72 parts, reducing agent ferrous sulfate 0.009 part, aqueous initiator namely hydrogen peroxide (30% mass percent concentration, hydrogen peroxide 30%) 1.2 parts, deionized water 45 parts, A feed liquid, B feed liquid. The above-mentioned A material liquid is mixed by 8.6 parts of acrylic acid, 0.4 part of unsaturated alcohol amine ester, i.e. triethanolamine trimethacrylate, 0.5 part of unsaturated amide, i.e. acrylamide, and 20 parts of deionized water; It is prepared by mixing 0.09 part of L-ascorbic acid, 0.3 part of mercaptopropionic acid as a chain transfer agent, and 20 parts of deionized water.

[0020] The preparation method of described coagulation-accelerating early-strength polycarboxylate superplasticizer ...

Embodiment 2

[0021] Embodiment 2: The coagulation-accelerating early-strength polycarboxylate superplasticizer of the present invention is made of the following raw materials in parts by mass: polyoxyethylene ether macromonomer is isopentenol polyoxyethylene ether (TPEG4000) 76 parts, reducing agent ferrous sulfate 0.012 parts, aqueous initiator namely hydrogen peroxide (30%) 1.5 parts, deionized water 48 parts, A material liquid, B material liquid. The above-mentioned material solution A is mixed by 9 parts of acrylic acid, 1 part of triethanolamine trimethacrylate, 0.2 parts of methacrylamide, and 22 parts of deionized water; the material solution of B is made of 0.12 parts of reducing agent L-ascorbic acid, chain transfer The agent is 0.32 parts of mercaptopropionic acid and 25 parts of deionized water mixed.

[0022] The preparation method of described coagulation-accelerating early-strength polycarboxylate superplasticizer comprises the following process steps: 1. 76 parts of polyoxye...

Embodiment 3

[0023] Embodiment 3: the coagulation-accelerating early-strength polycarboxylate superplasticizer of the present invention is made of the following raw materials in parts by mass: polyoxyethylene ether macromonomer is isopentenol polyoxyethylene ether (TPEG6000) 72 parts, reducing agent ferrous sulfate 0.015 parts, aqueous initiator namely hydrogen peroxide (hydrogen peroxide 30%) 1.5 parts, deionized water 46 parts, A feed liquid, B feed liquid. The above-mentioned A feed liquid is mixed by 8 parts of acrylic acid, 1 part of triethanolamine maleate, 0.5 parts of acrylamide, and 21 parts of deionized water; the B feed liquid is made of 0.15 parts of reducing agent L-ascorbic acid, chain transfer agent It is prepared by mixing 0.32 parts of mercaptopropionic acid and 22 parts of deionized water.

[0024] The preparation method of described coagulation-accelerating early-strength polycarboxylate superplasticizer comprises the following process steps: 1. 72 parts of polyoxyethyle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com