High corrosion-resistant Portland cement early strength agent and preparation method thereof

A technology of portland cement and early strength agent, which is applied in the field of materials, can solve the problems of insufficient early strength promotion and cannot well meet the early strength requirements of high-corrosion portland cement, so as to promote early hydration, Meet the needs of erosive environment and construction conditions, and accelerate the effect of dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

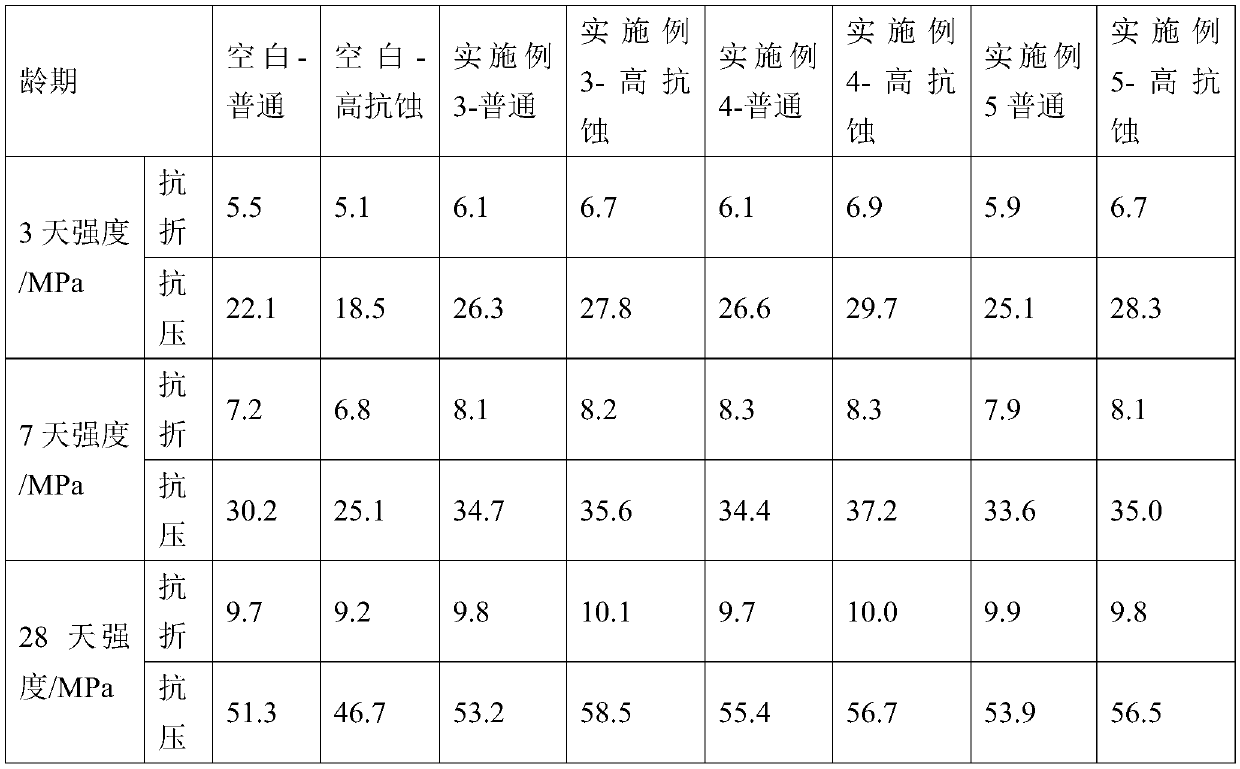

Examples

Embodiment 1

[0027] A high corrosion resistant Portland cement early strength agent, the components and parts by mass are as follows: 40 parts of gypsum; 20 parts of quicklime; 15 parts of sodium sulfate; 5 parts of aluminum sulfate; 5 parts of triethanolamine; 10 parts of alcohol amine; 5 parts of calcium formate.

Embodiment 2

[0029] A high corrosion resistant Portland cement early strength agent, the components and parts by mass are as follows: 20 parts of gypsum; 10 parts of quicklime; 20 parts of potassium sulfate; 10 parts of sodium sulfate; 10 parts of aluminum sulfate; 10 parts of diethylene triamine Parts; 10 parts of triisopropanolamine.

Embodiment 3

[0031] A high corrosion resistance Portland cement early strength agent, the components and mass parts are as follows: 20 parts of gypsum; 10 parts of quicklime; 15 parts of sodium sulfate; 5 parts of magnesium sulfate; 15 parts of triisopropanolamine; 10 parts of ethanolamine; 5 parts of polyvinyl ammonium phosphate; 10 parts of sodium citrate; 10 parts of calcium formate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com