Fair-faced concrete

A technology of fair-faced concrete and cement, which is applied in the field of building materials and can solve the problems of reducing the durability of fair-faced concrete, poor crack resistance, and poor durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] The preparation method of the fair-faced concrete is not particularly limited in the present invention, and it can be prepared by a preparation method well known to those skilled in the art.

[0060] In order to further illustrate the present invention, below in conjunction with example the fair-faced concrete provided by the present invention is described in detail, but they can not be interpreted as the limitation of protection scope of the present invention.

[0061] Raw materials used:

[0062] Alkaline electrolyzed water: by K 2 CO 3 The electrolyte solution is electrolyzed in a fully automatic diaphragm electrolyzed water machine, and the permeability of the ion exchange membrane in the electrolyzed water machine is 0.2cc / cm 2 Min, the power supply for electrolysis is pulsed direct current, the voltage is 380V, 50Hz, the current is 19A, the temperature of the incoming water is 20°C, the flow rate of the incoming water is 25L / h, and the electrolysis time is 15min...

Embodiment 1

[0071] Fair-faced concrete mix ratio design research scheme of the present invention is as follows:

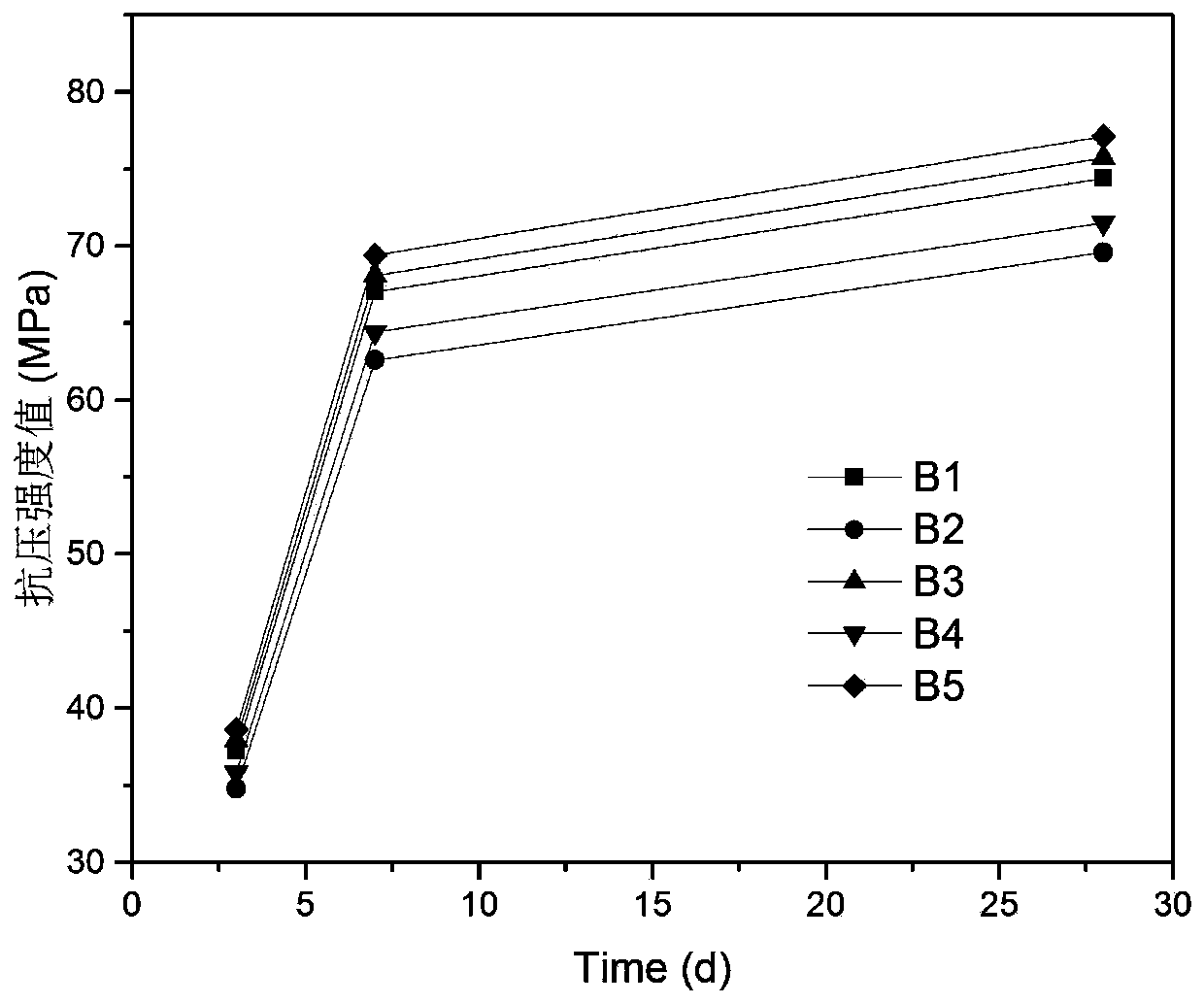

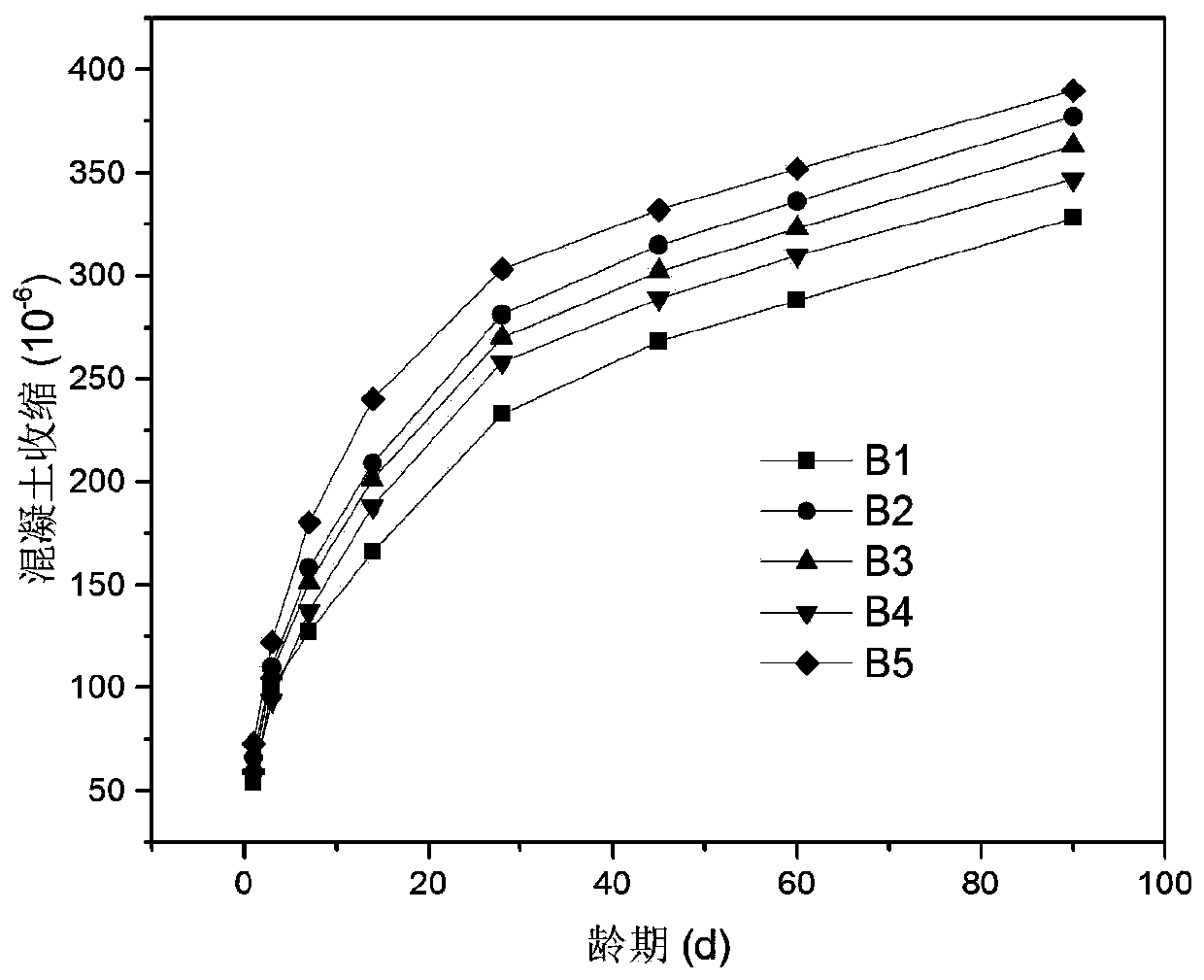

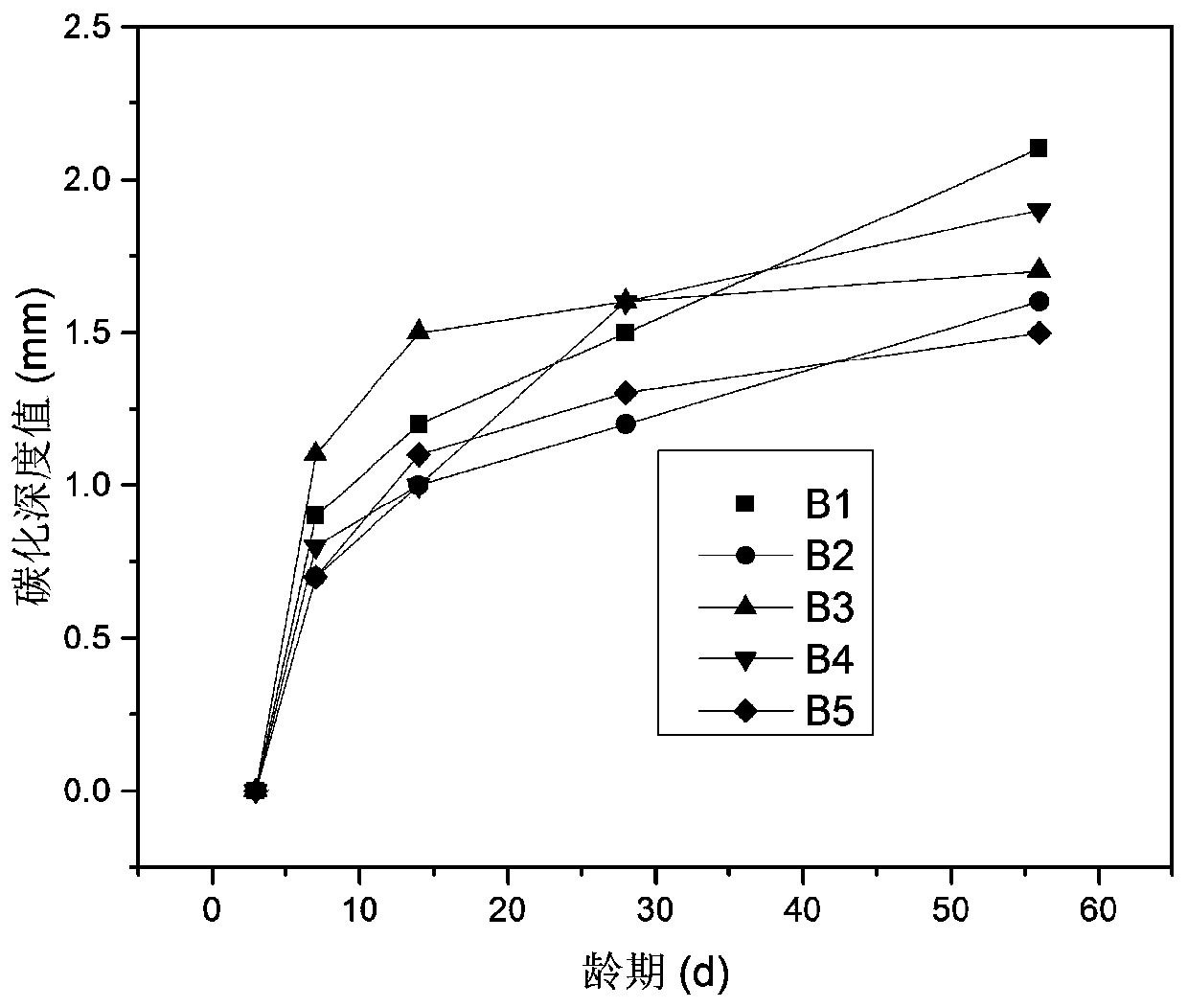

[0072] (1) Preliminarily adopt different cementitious material systems, and determine the test water consumption by controlling the slump, so as to prepare a fair-faced concrete system with a strength grade of C60.

[0073] (2) According to the "Technical Regulations for the Application of Fair-faced Concrete" (JGJ169-2009), a reasonable cementitious material system was designed. Due to comprehensive factors such as crack resistance and color difference, the test adopted both a large-volume mineral admixture system and a The system using only mineral admixture and pure cement is shown in Table 6.

[0074] Table 6 cementitious material system

[0075]

[0076] On the basis of analyzing the existing design method of fair-faced concrete mix ratio, according to the characteristics of clear-water concrete and the design idea of fair-water concrete mix ratio, a special design ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com