Concrete admixture and preparation method thereof

A concrete admixture and dispersant technology, applied in the field of concrete processing, can solve the problems of poor chloride ion curing performance, poor early strength effect, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

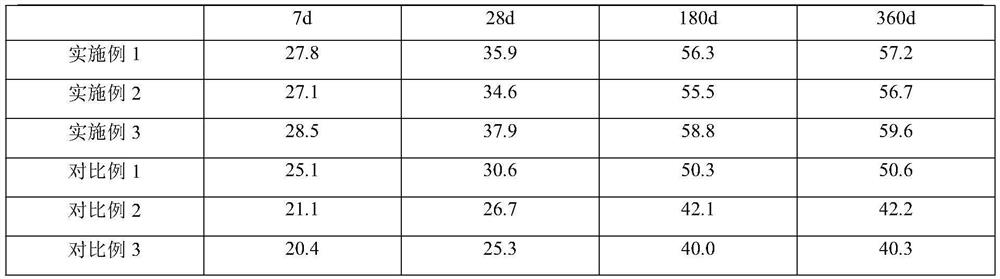

Embodiment 1

[0033] A kind of preparation method of concrete admixture, concrete steps are as follows:

[0034] (1) First add the dispersant to water and stir to mix evenly, while stirring, add magnesium nitrate aqueous solution and sodium silicate aqueous solution dropwise at the same time, stir and react for the first time to obtain a nano-magnesium silicate suspension, control the temperature to 35 ° C, and add Add cyclohexane to the nano-magnesium silicate suspension, ultrasonically oscillate to obtain a mixed solution, and then drop the mixed solution and tetraethyl orthosilicate into the premixed solution containing calcium nitrate and ammonia water at the same time, and then stir the reaction for the second time. Under the action of ammonia water, tetraethyl orthosilicate reacts with calcium nitrate and deposits on the surface of nano-magnesium silicate to obtain calcium silicate-magnesium silicate nanoparticles;

[0035] (2) Then the halloysite nanotubes are modified using N-(β-ami...

Embodiment 2

[0052] A kind of preparation method of concrete admixture, concrete steps are as follows:

[0053] (1) First add the dispersant to water and stir to mix evenly, while stirring, add magnesium nitrate aqueous solution and sodium silicate aqueous solution dropwise at the same time, stir and react for the first time to obtain nano-magnesium silicate suspension, control the temperature to 45 ° C, and add Add cyclohexane to the nano-magnesium silicate suspension, ultrasonically oscillate to obtain a mixed solution, and then drop the mixed solution and tetraethyl orthosilicate into the premixed solution containing calcium nitrate and ammonia water at the same time, and then stir the reaction for the second time. Under the action of ammonia water, tetraethyl orthosilicate reacts with calcium nitrate and deposits on the surface of nano-magnesium silicate to obtain calcium silicate-magnesium silicate nanoparticles;

[0054] (2) Then the halloysite nanotubes are modified using N-(β-amino...

Embodiment 3

[0071] A kind of preparation method of concrete admixture, concrete steps are as follows:

[0072] (1) First add the dispersant into water and stir to mix evenly, while stirring, add magnesium nitrate aqueous solution and sodium silicate aqueous solution dropwise at the same time, stir and react for the first time to obtain nano-magnesium silicate suspension, control the temperature to 40 ° C, and add Add cyclohexane to the nano-magnesium silicate suspension, ultrasonically oscillate to obtain a mixed solution, and then drop the mixed solution and tetraethyl orthosilicate into the premixed solution containing calcium nitrate and ammonia water at the same time, and then stir the reaction for the second time. Under the action of ammonia water, tetraethyl orthosilicate reacts with calcium nitrate and deposits on the surface of nano-magnesium silicate to obtain calcium silicate-magnesium silicate nanoparticles;

[0073](2) Then the halloysite nanotubes are modified using N-(β-amin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com