Ferronickel electric furnace with magnesium-carbon composite furnace lining

A technology of magnesium carbon and furnace lining, which is applied in the direction of furnace, furnace bottom, furnace, etc., can solve the problems of general corrosion resistance of molten iron, environmental pollution, cracking of furnace shell steel plate, etc., and achieves improved corrosion resistance of molten iron, significant economic benefits, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be noted that the "connection" mentioned in this application and the words used to express "connection", such as "connected", "connected", etc., include not only the direct connection between a certain component and another component, but also the direct connection of a certain component. One part is connected to another part through other parts.

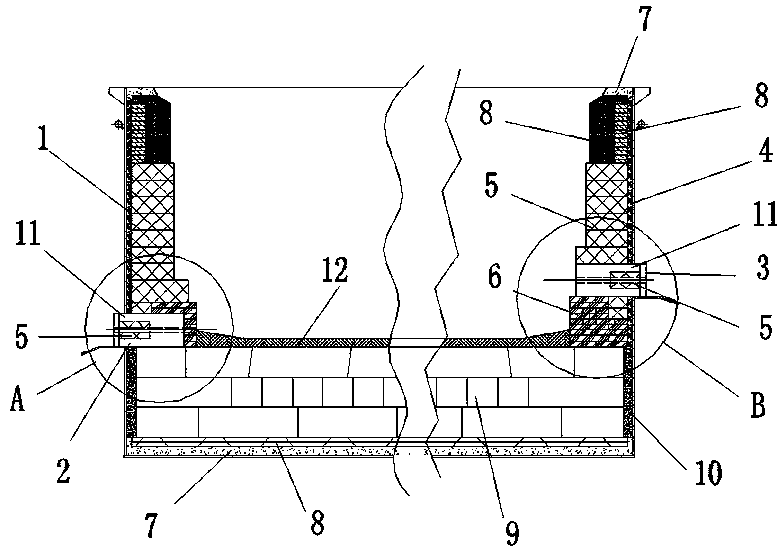

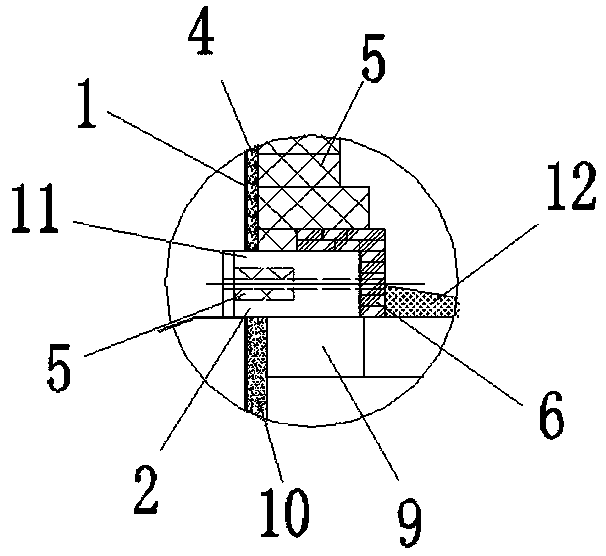

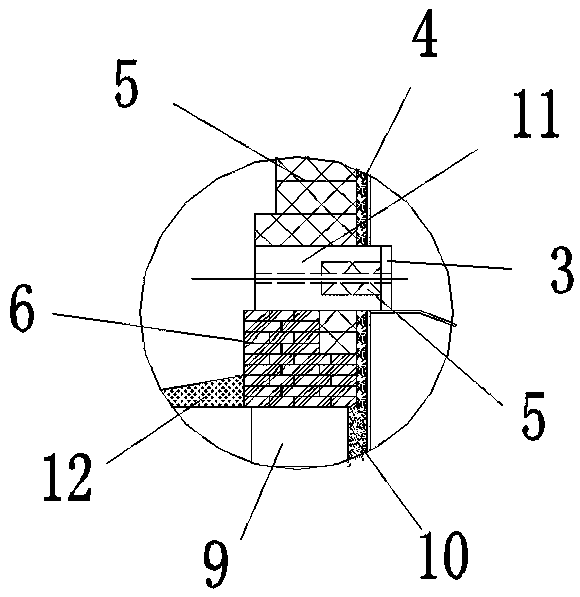

[0015] like figure 1 - As shown in 3, a nickel-iron electric furnace with a magnesium-carbon composite lining, including a furnace bottom and a furnace wall, the furnace wall is provided with an iron port 2 and a slag port 3; the furnace wall is provided with a graphite ramming material 4 close to the furnace shell ; Arrange graphite bricks 5 close to the graphite ramming material 4 on the hot surface of the furnace wall. A spray cooling system is installed outs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com