Patents

Literature

99results about "Furnace floors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

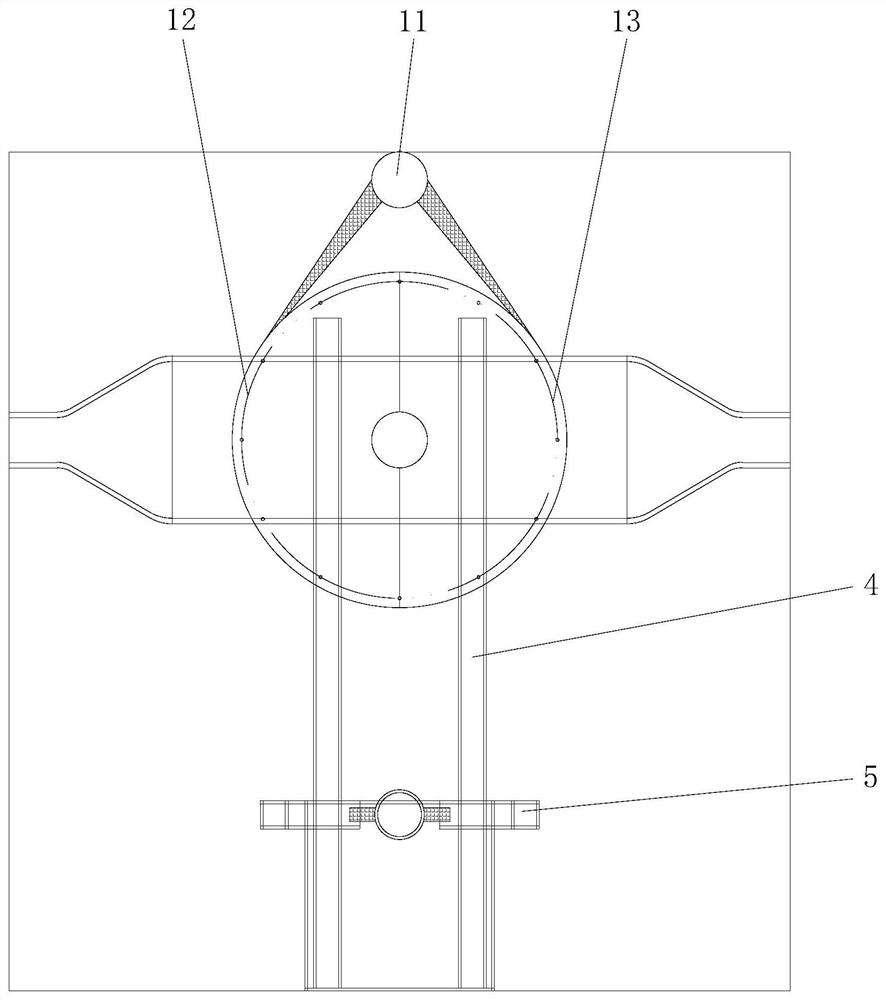

Interlocking floor brick for non-recovery coke oven

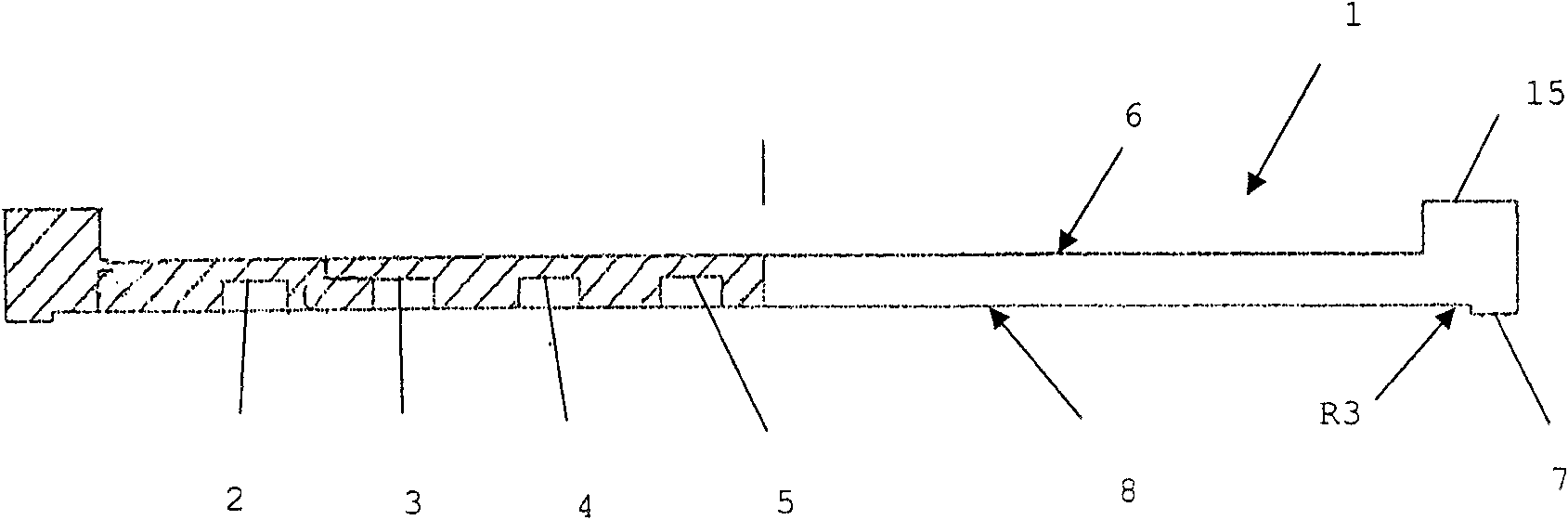

An improved non-recovery coke oven floor constructed of a single layer of refractory bricks including, for each oven sole flue, a pair of trunnion bricks and a center bridge brick spanning the width of the flue, having lower brick surfaces in the form of an arch, and joined end-to-end by a tapered tongue-and-groove joint disposed approximately perpendicular to the direction of a compression load transmitted by the center bridge brick to the trunnion bricks.

Owner:PENNSYLVANIA COKE TECH

High yield ladle bottoms

ActiveUS20120126467A1Quantity minimizationLower the volumeMelt-holding vesselsBlast furnace componentsHigh elevationMaterials science

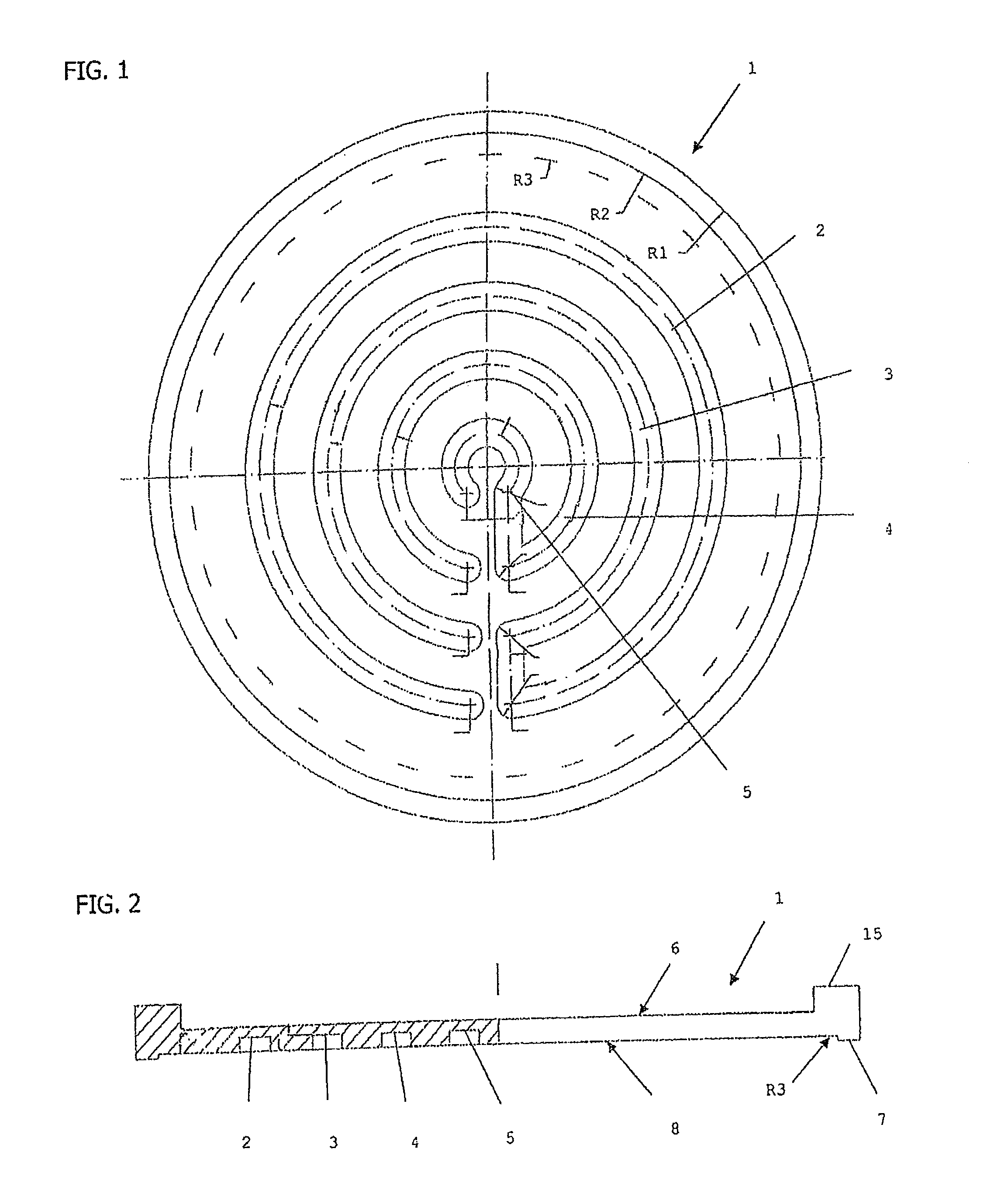

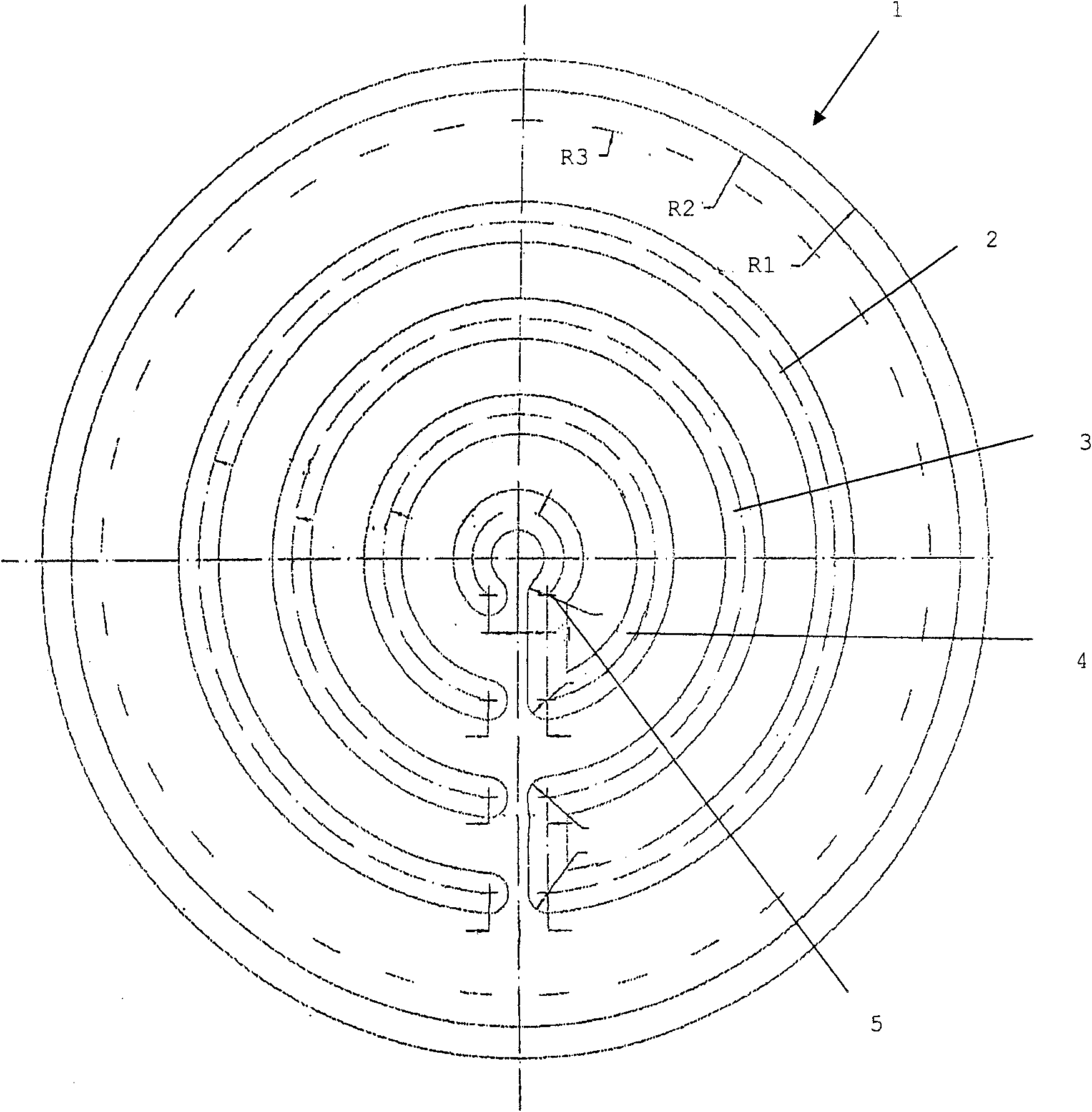

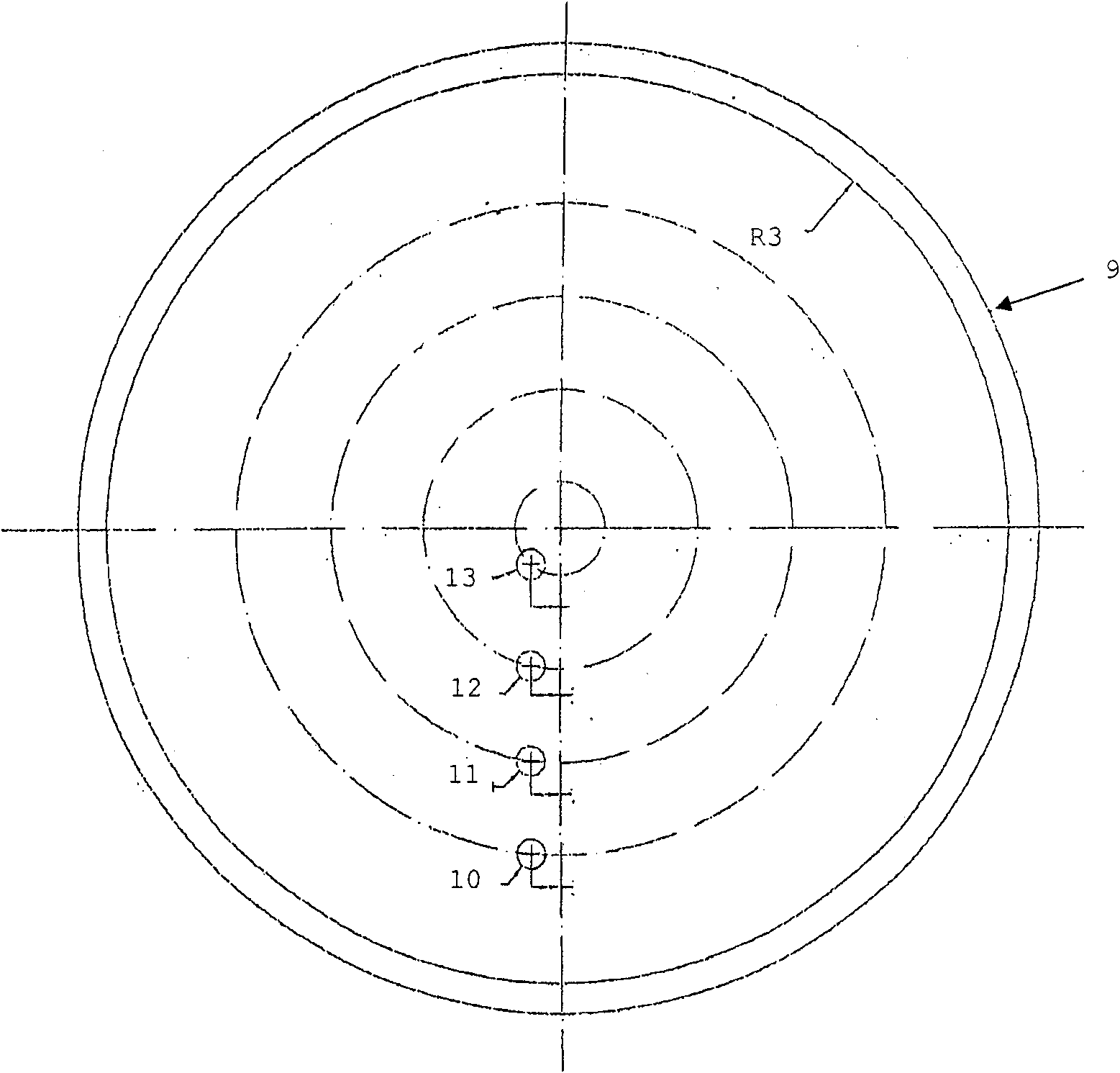

A refractory bottom lining for lining the bottom of a metallurgical vessel. The refractory bottom includes a stepped portion and an impact portion. The impact portion is formed of a first refractory material. The stepped portion is formed of a second refractory material and is disposed around the impact portion. The stepped portion includes an upper surface that has a plurality of discrete surface sections. The plurality of discrete surface sections includes an uppermost surface section, at least two intermediate surface sections and a lowermost surface section. Each surface section has a different elevation such that the uppermost surface section has a highest elevation and the lowermost surface section has a lowest elevation. The uppermost surface section, the at least two intermediate surface sections and the lowermost surface section define a continuously downward stepped path from the uppermost surface section to the lowermost surface section.

Owner:HARBISONWALKER INT INC

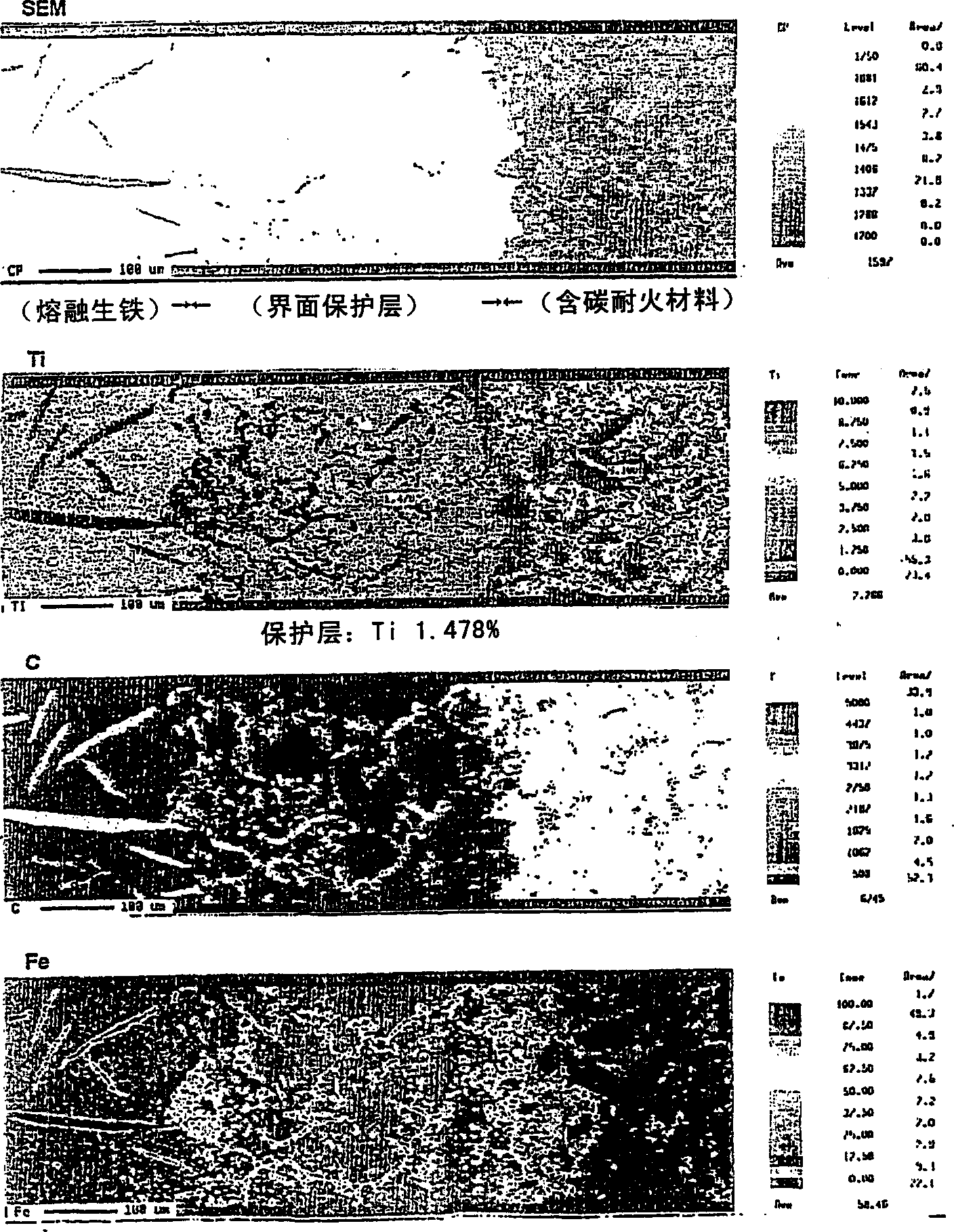

Carbonaceous refractory and method for preparing same

InactiveCN1366515AEasily wets molten ironImprove corrosion resistanceBlast furnace detailsCooling devicesTitanium nitrideCoke

Owner:NIPPON STEEL CORP +1

High yield ladle bottoms

ActiveUS20090206528A1Quantity minimizationLower the volumeMelt-holding vesselsMolten metal pouring equipmentsHigh elevationMaterials science

A refractory bottom for a metallurgical vessel comprised of a bottom lining having a bottom surface that is dimensioned to overlay a bottom of a metallurgical vessel and an upper surface. The upper surface is comprised of a plurality of discrete sections that include an uppermost section, an intermediate section and a lowermost section. Each section has an upper surface at a discrete elevation such that the upper surface of the uppermost section has a highest elevation and the upper surface of the lowermost section has a lowest elevation. The upper surface of the uppermost section, the intermediate section and the lowermost section comprise a series of successive stepped sections that define a stepped path from the uppermost section downward to the lowermost section. Each successive section of the upper surface is lower than a preceding section.

Owner:HARBISONWALKER INT INC

Method and device for the continuous melting or refining of melts

InactiveUS20110243180A1Increased energy lossEasy to useGlass furnace apparatusCharge manipulationConductive materialsContinuous production

A method for the continuous production of products from a melt is provided. The method includes heating the melt to a predetermined temperature in a skull crucible, the bottom of which is formed from electrically non-conductive, but thermally conductive material.

Owner:SCHOTT AG

Method and device for continuous melting or refining of melt

The invention relates to a method and a device for continuous melting or refining of a melt. The invention particularly relates to a method for continuously producing a product from the melt, wherein the melt is heated to a predetermined temperature in a shell crucible, and the bottom of the shell crucible is made of nonconductive heat-conducting material.

Owner:SCHOTT AG

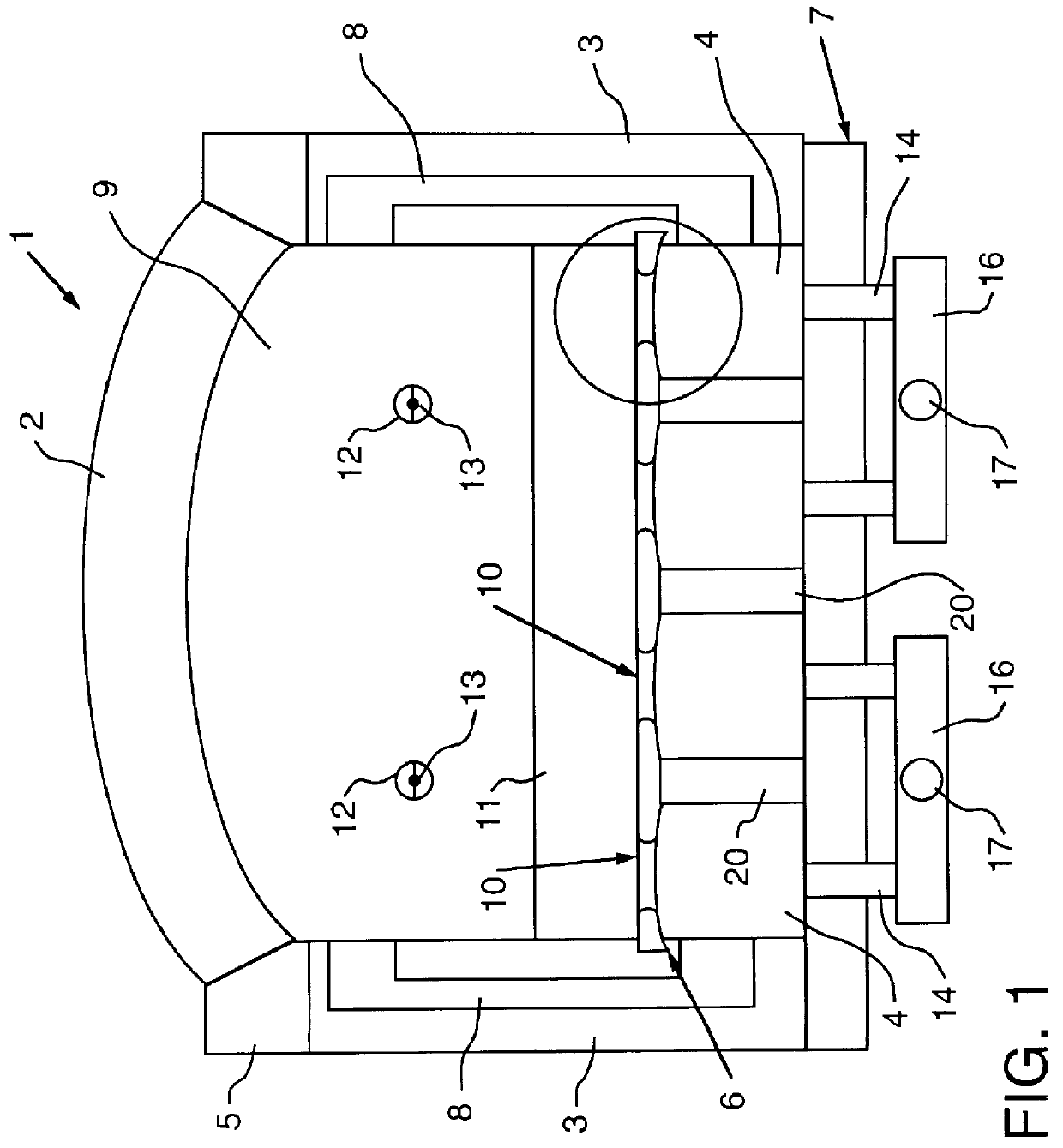

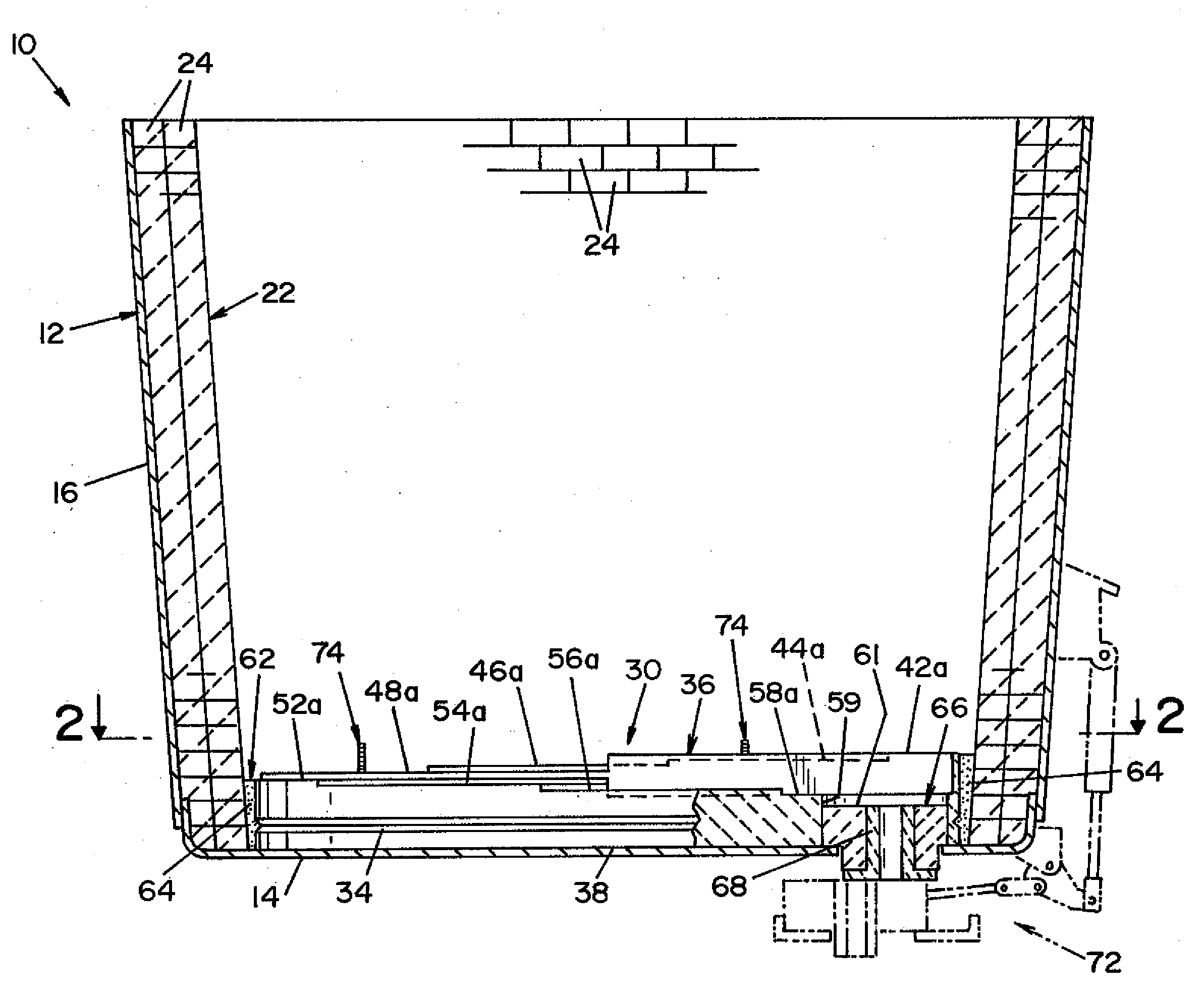

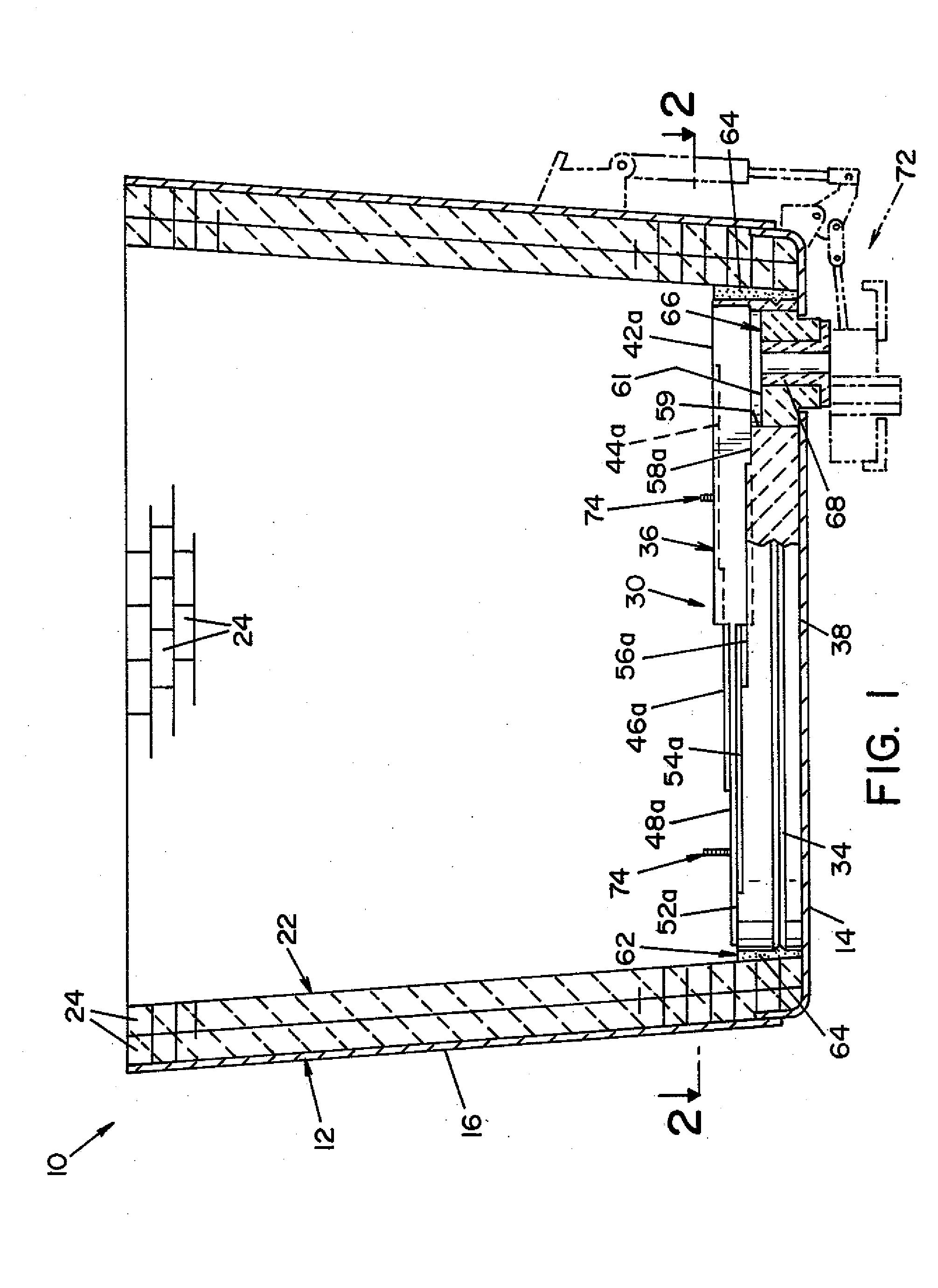

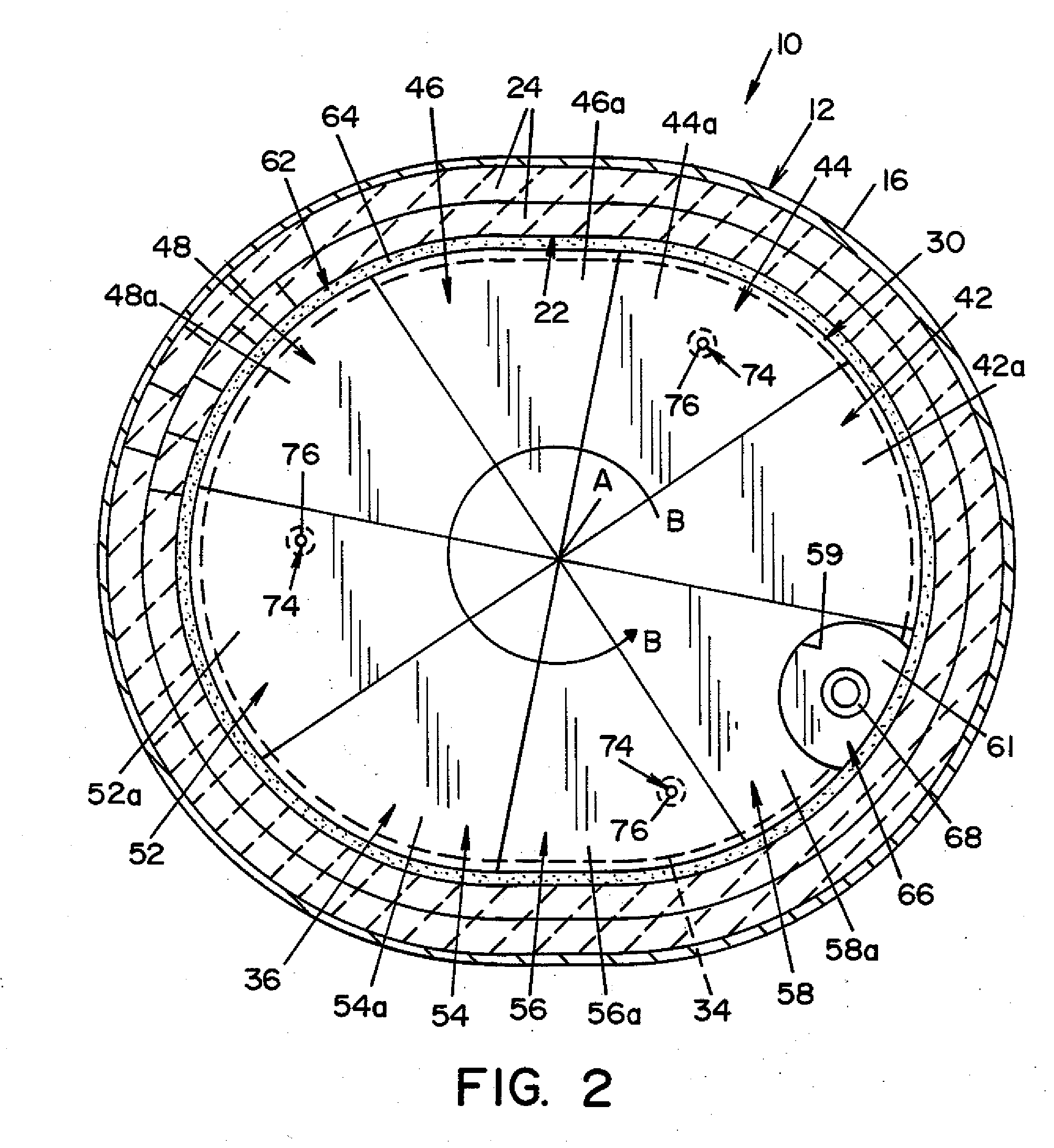

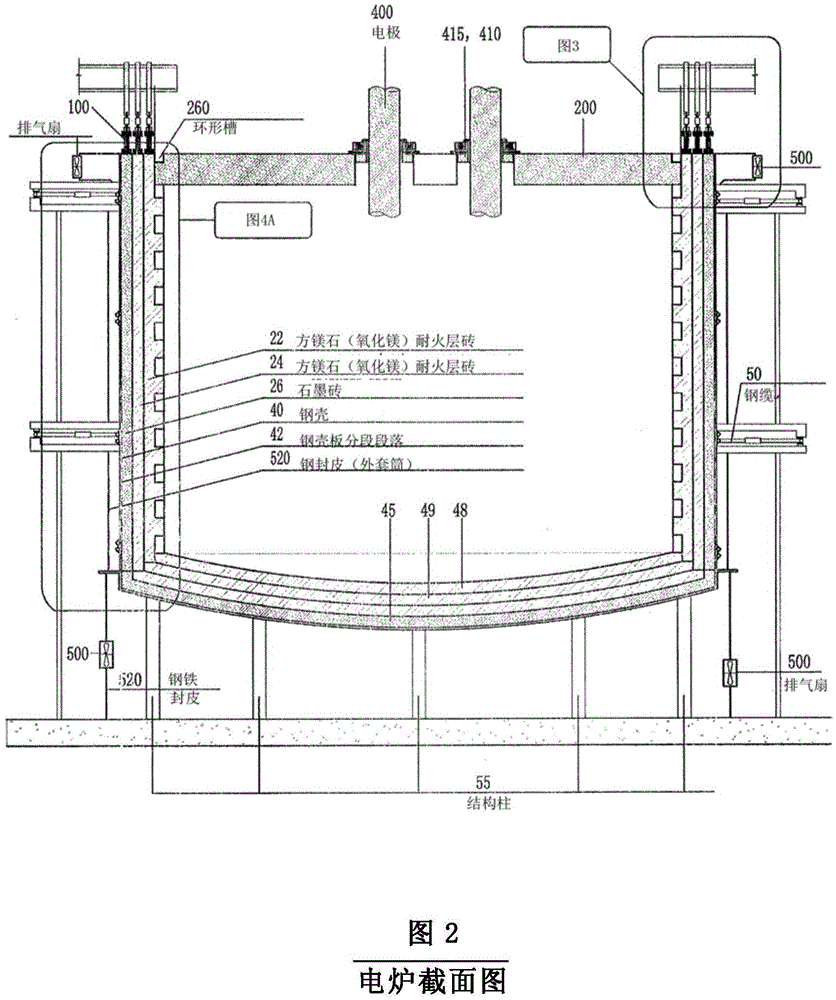

Metallurgical Furnace

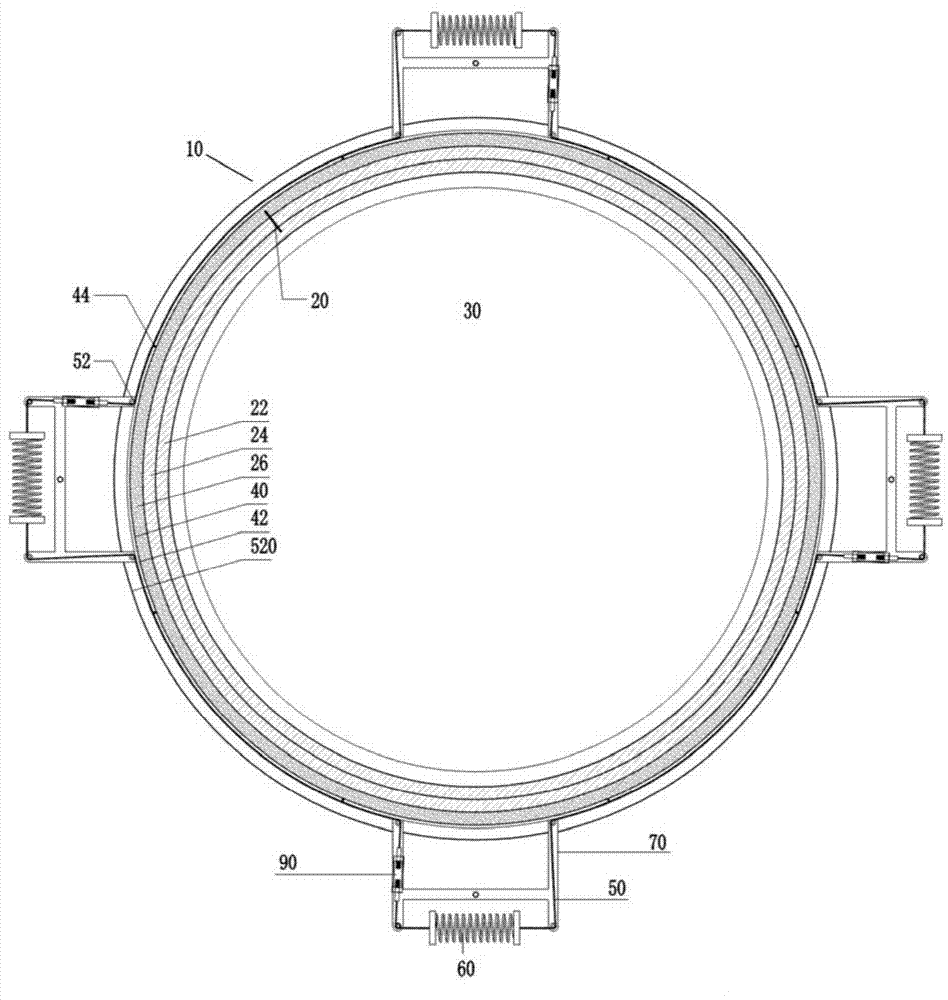

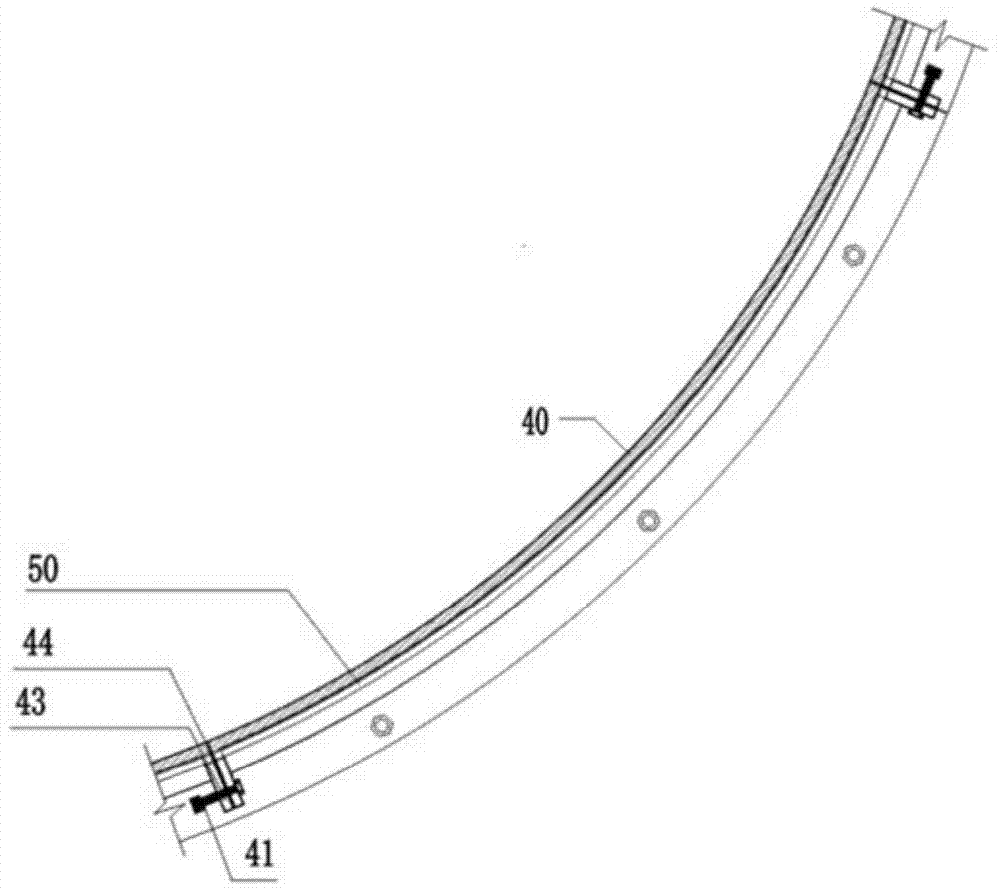

A metallurgical furnace including a refractory, which may include an inner layer, including bricks of a first type having a heat dissipation thickness, and bricks of a second type having a greater sacrificial thickness and protruding towards the furnace space. The furnace may include a force exerting member for contracting a segmented outer shell around the refractory, inward, as the refractory contracts when cooling. The force exerting member may include a tension member. The furnace may include a vertical compression member for exerting a compressive force upon the refractory, vertically compressing the refractory as it contracts. The furnace may include a cooling system, including a sleeve surrounding a layer of heated air, and air displacement members for displacing away the heated air. The furnace may include a roof, having suspension members extending therethrough, supporting an inner mesh, the inner mesh supporting insulating material. The furnace may also include an electrode seal having a plurality of shoes biased against the electrode(s).

Owner:JINZHOU TIANSHENG HEAVY IND

Oxide-bonded silicon carbide material

ActiveCN1872793AEasy to manufactureNo less strengthCharge supportsCharge manipulationFlexural strengthRefractory

There is disclosed an oxide-bonded silicon carbide material which has a more excellent strength as compared with a presently mainly available high-strength ceramic material (e.g., alumina, Si-impregnated SiC, or recrystallized SiC refractory material) and which improves mass productivity and facilitates the manufacturing of large-sized products, so that even products having complicated shapes can be easily prepared, and manufacturing costs can be largely reduced. The oxide-bonded silicon carbide material is substantially made of silicon carbide, has crystal particles of silicon carbide, grain boundaries and pores thereof, and has a structure in which the crystal particles of silicon carbide are bonded with an oxide containing silicon dioxide as a main component. A bending strength at ordinary temperature or a high temperature is 100 MPa or more, and a bulk specific gravity is 2.65 or more.

Owner:NGK INSULATORS LTD +1

High yield ladle bottoms

ActiveUS8110142B2Quantity minimizationLower the volumeMelt-holding vesselsMolten metal pouring equipmentsHigh elevationMaterials science

A refractory bottom for a metallurgical vessel comprised of a bottom lining having a bottom surface that is dimensioned to overlay a bottom of a metallurgical vessel and an upper surface. The upper surface is comprised of a plurality of discrete sections that include an uppermost section, an intermediate section and a lowermost section. Each section has an upper surface at a discrete elevation such that the upper surface of the uppermost section has a highest elevation and the upper surface of the lowermost section has a lowest elevation. The upper surface of the uppermost section, the intermediate section and the lowermost section comprise a series of successive stepped sections that define a stepped path from the uppermost section downward to the lowermost section. Each successive section of the upper surface is lower than a preceding section.

Owner:HARBISONWALKER INT INC

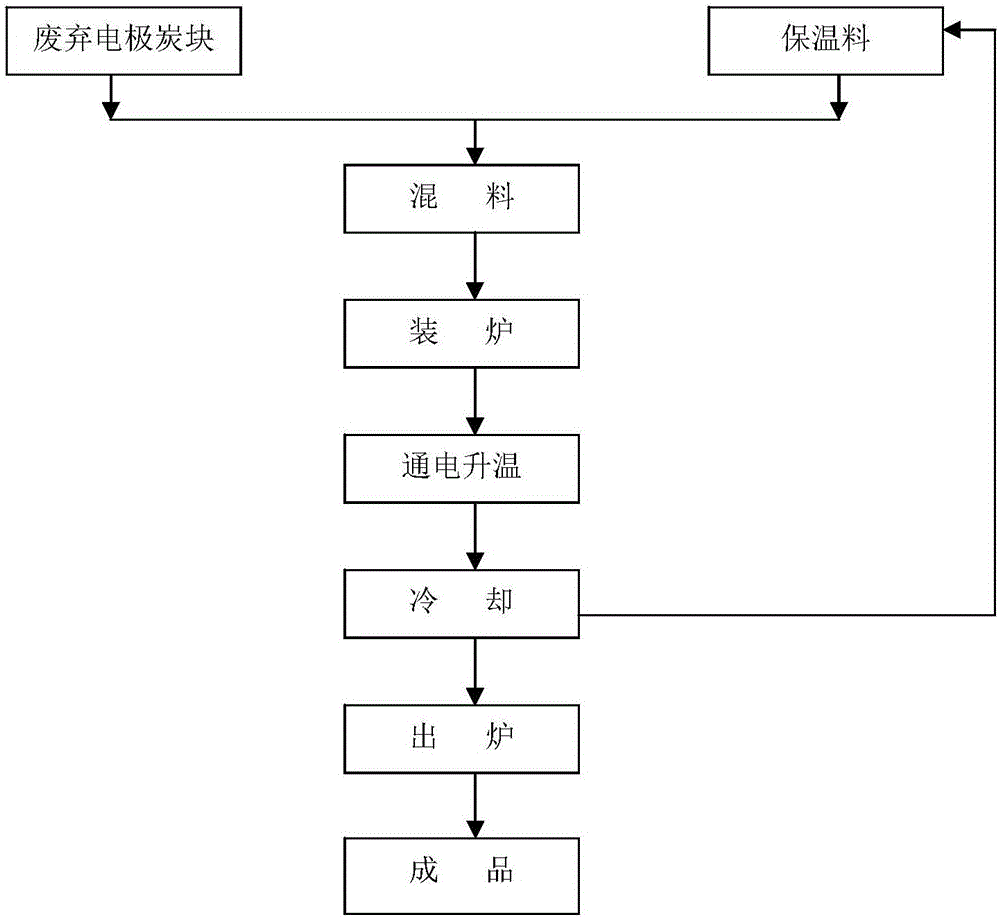

Method for producing graphite material with Acheson graphitization furnace

InactiveCN106352701AIncrease profitReduce electricity consumptionCarbon compoundsFurnace floorsEnvironmental resistanceElectricity

The invention relates to a method for production of graphite electrode with Acheson graphitization furnace, comprising the steps of using wasted electrode carbon block of steel factory or aluminum factory as raw material and producing graphite material with excellent performance index through charging furnace, electric heating, cooling, out of furnace and other steps. The method for production of graphite electrode with Acheson graphitization furnace has such advantages as fully utilizing waste, reflecting the concept of environmental protection and sustainable utilization of energy, achieving high energy utilization ratio and product yield with low power consumption, and effectively reducing the production cost of the graphite material. In addition, toxic gases are not produced in the production process, which greatly reduces the harm of production personnel and the environment, and thus has very high application value and social value.

Owner:哈密胡杨林碳材料科技有限公司

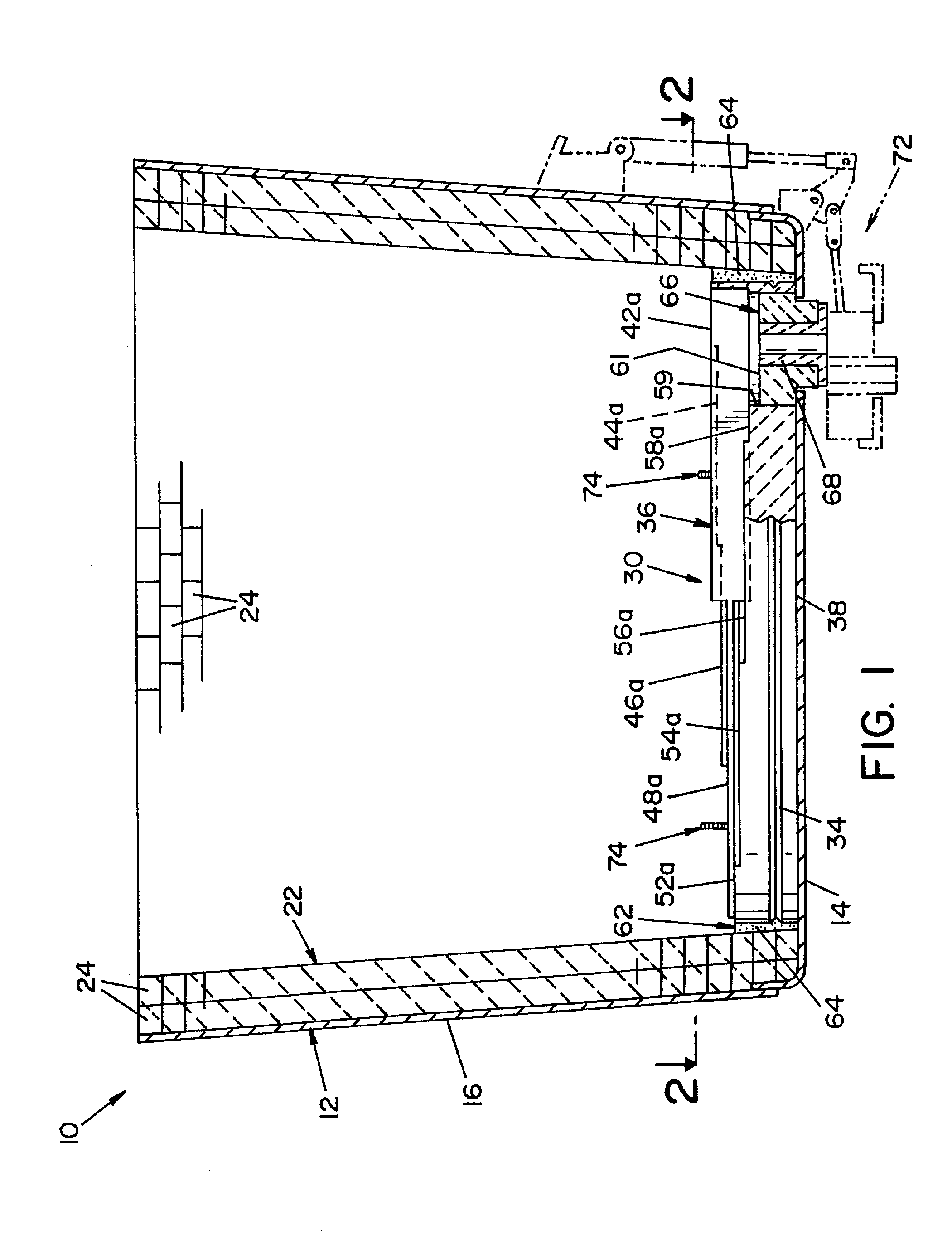

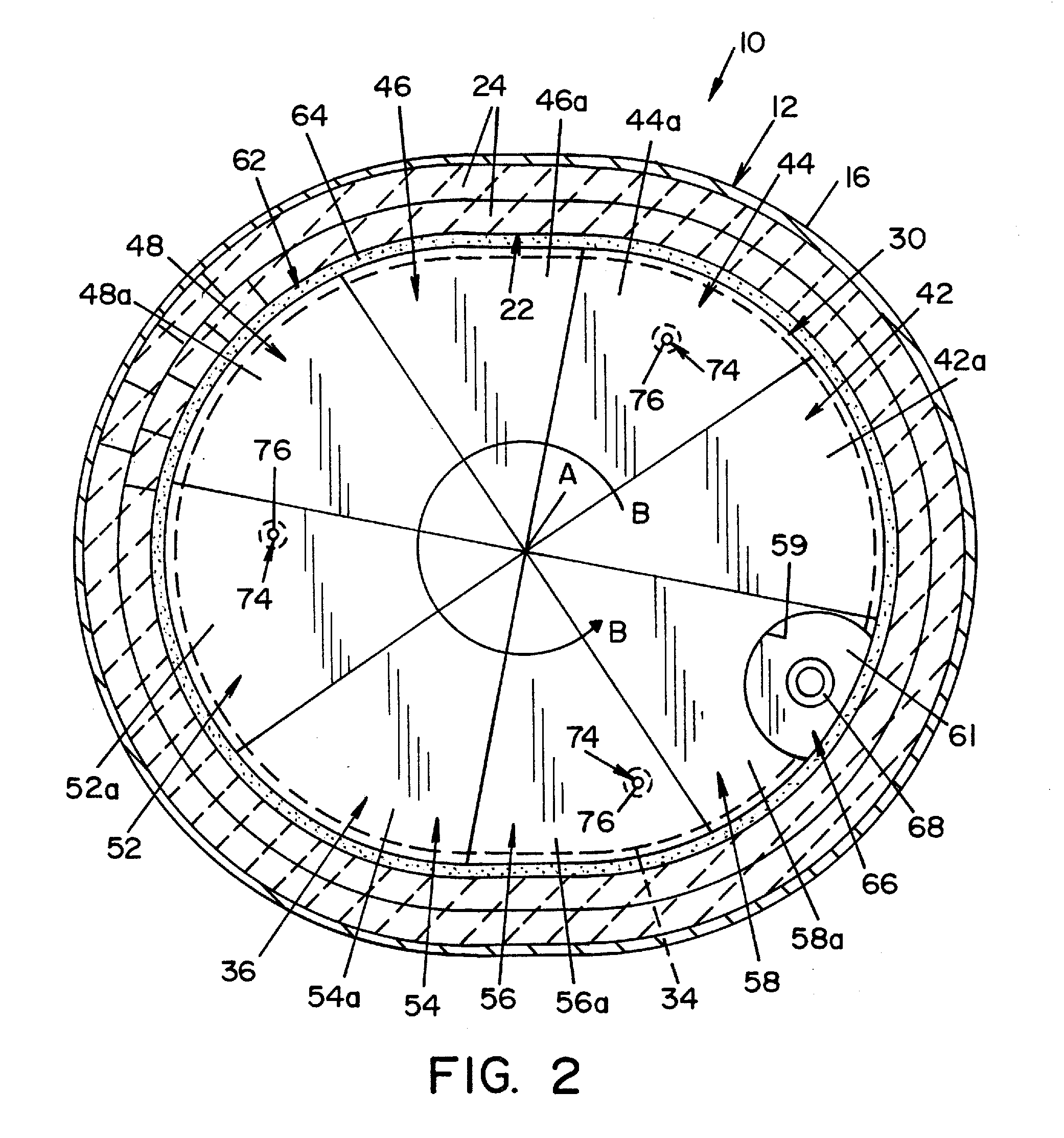

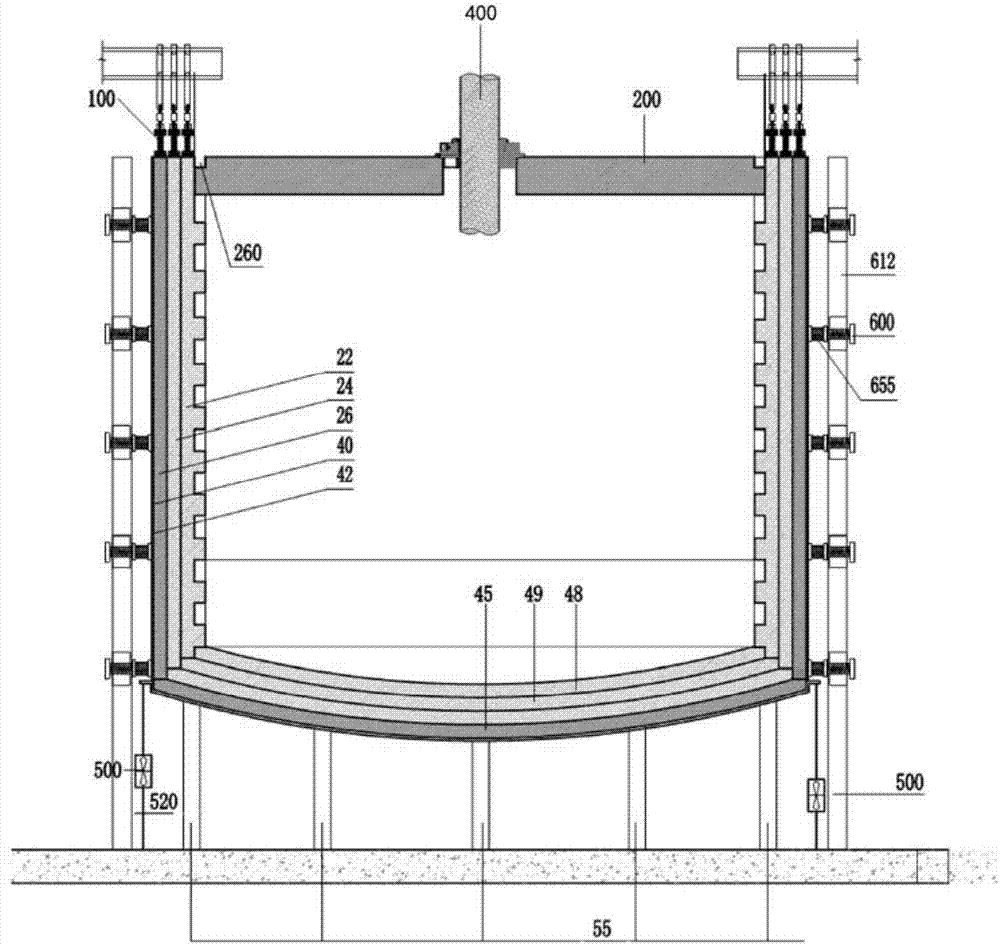

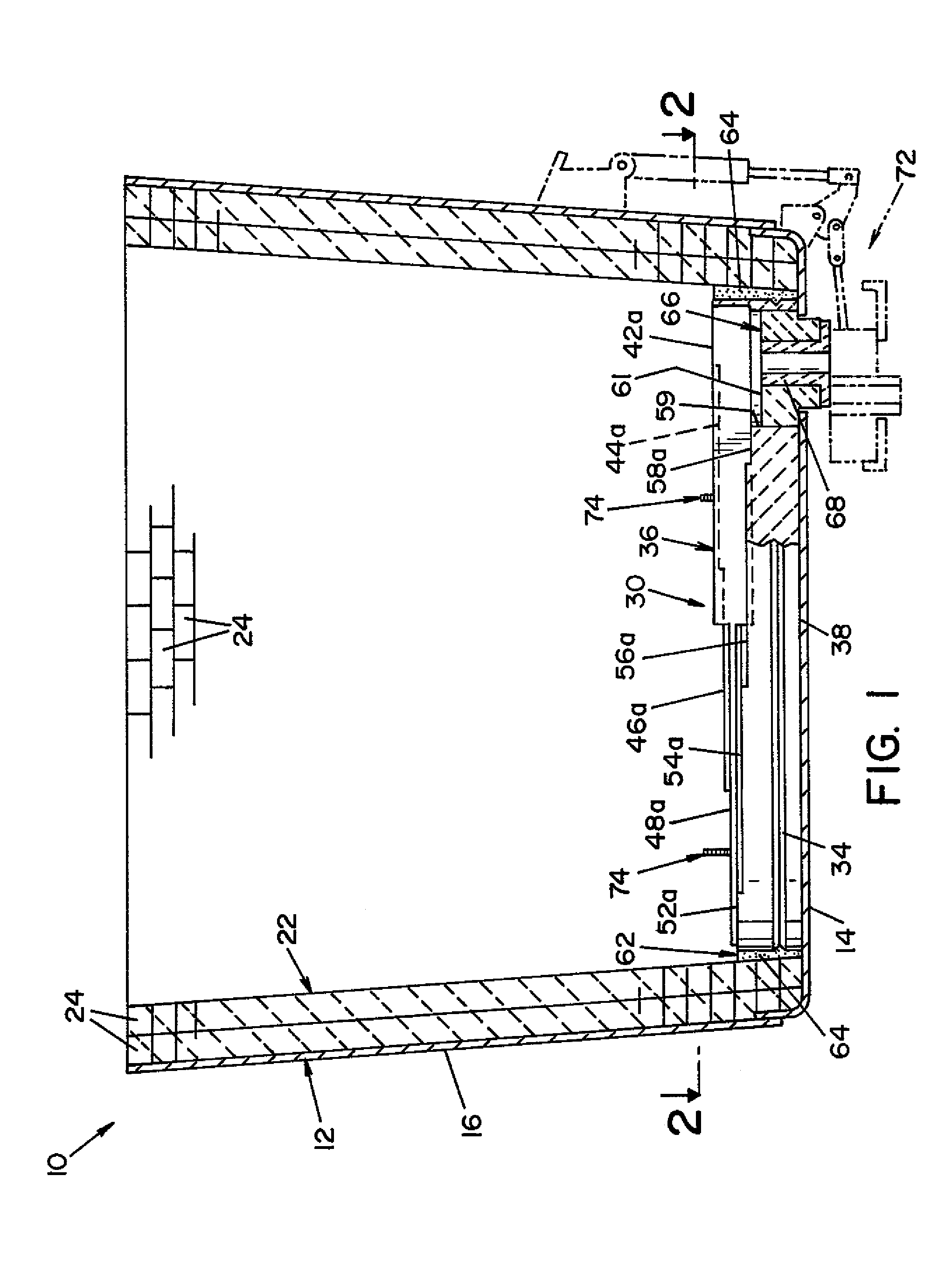

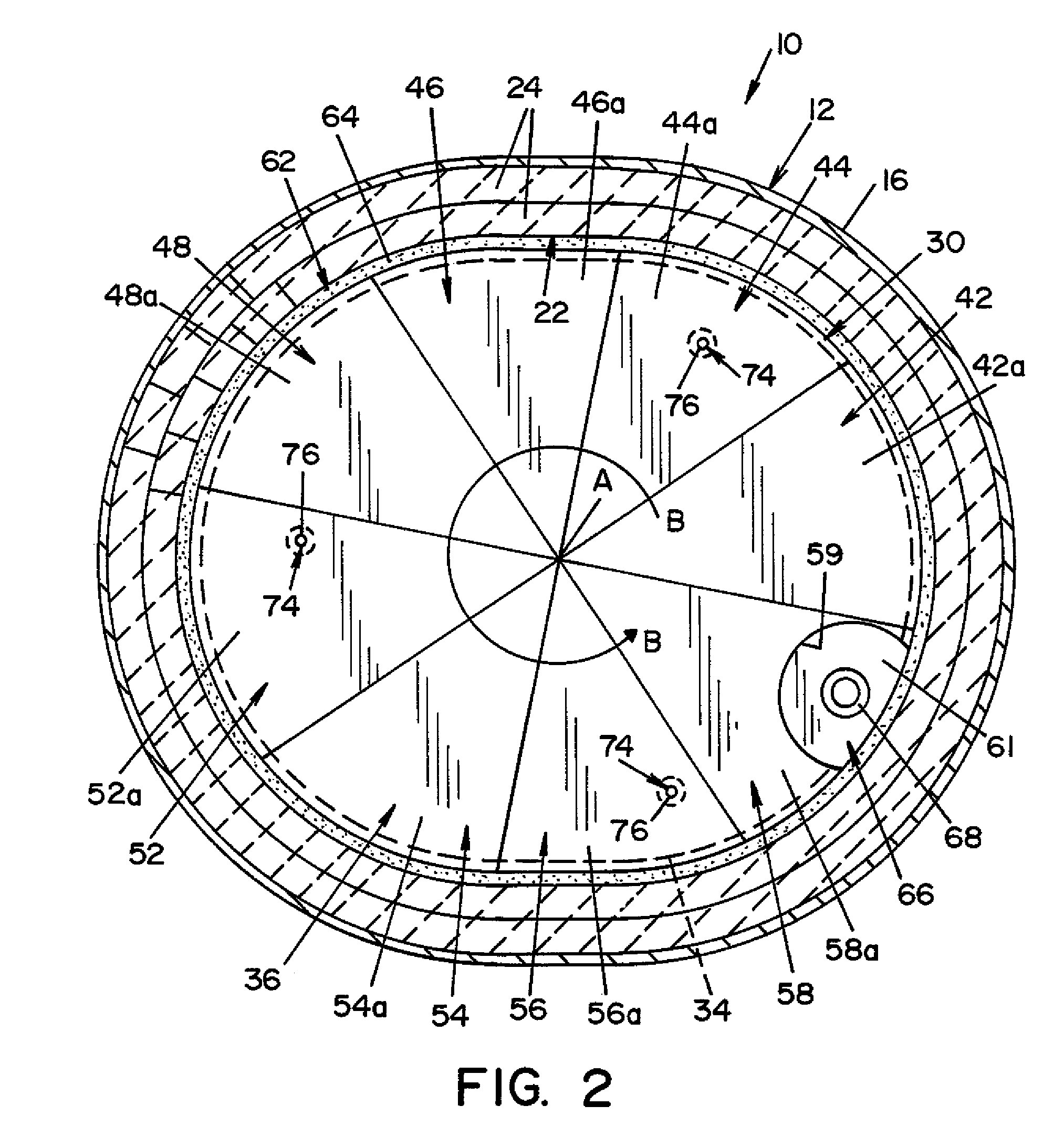

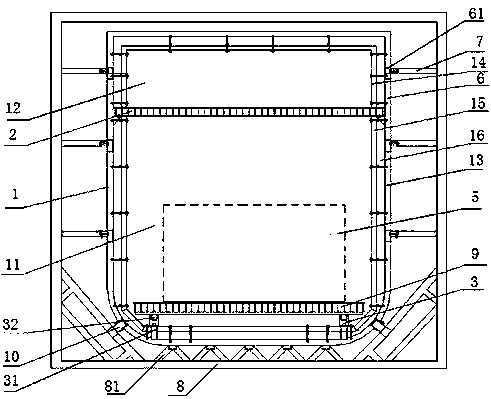

Metallurgical furnace

A metallurgical furnace including a refractory, which may include an inner layer, including bricks of a first type having a heat dissipation thickness, and bricks of a second type having a greater sacrificial thickness and protruding towards the furnace space. The furnace may include a force exerting member for contracting a segmented outer shell around the refractory, inward, as the refractory contracts when cooling. The force exerting member may include a tension member. The furnace may include a vertical compression member for exerting a compressive force upon the refractory, vertically compressing the refractory as it contracts. The furnace may include a cooling system, including a sleeve surrounding a layer of heated air, and air displacement members for displacing away the heated air. The furnace may include a roof, having suspension members extending therethrough, supporting an inner mesh, the inner mesh supporting insulating material. The furnace may also include an electrode seal having a plurality of shoes biased against the electrode(s).

Owner:JINZHOU TIANSHENG HEAVY IND

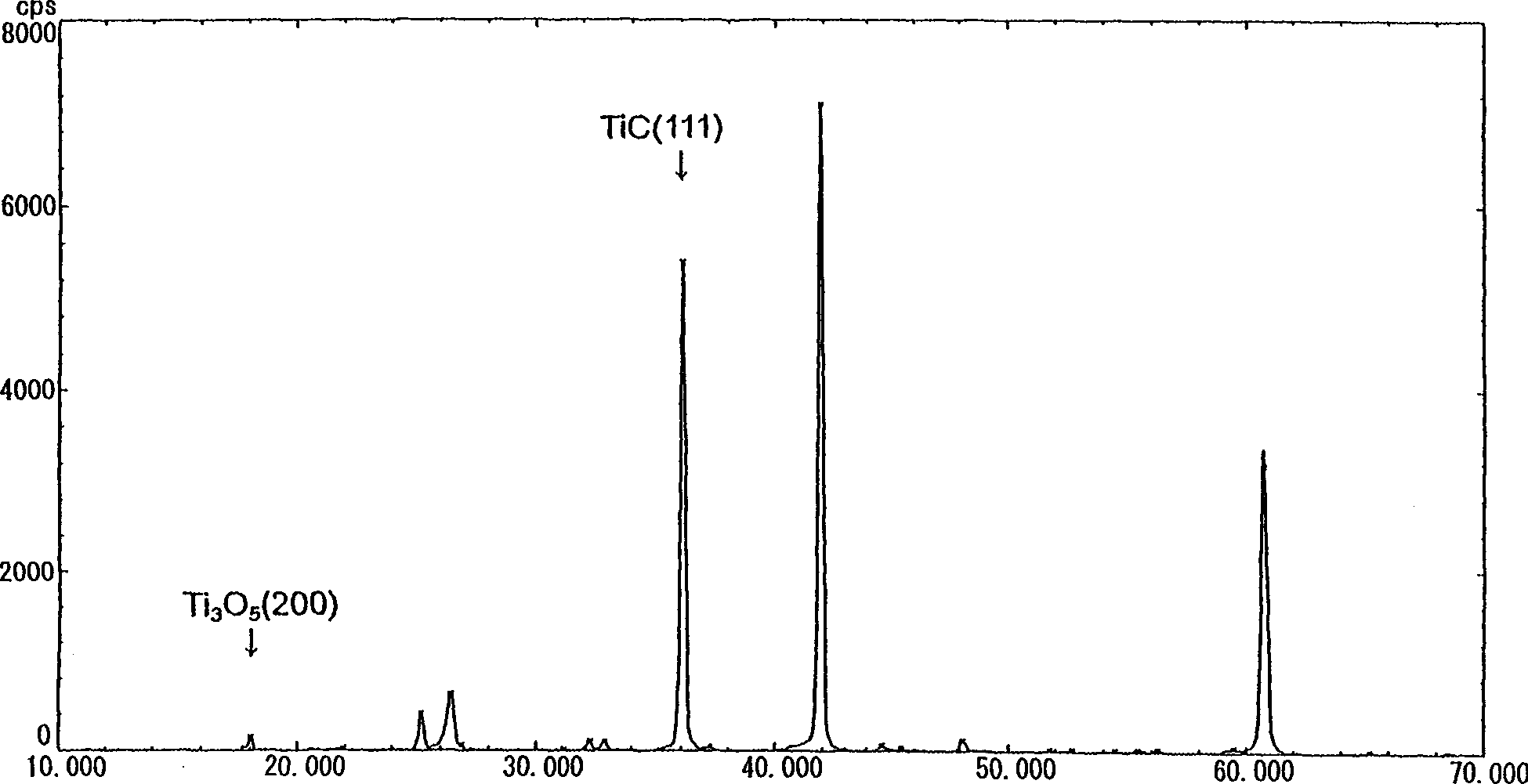

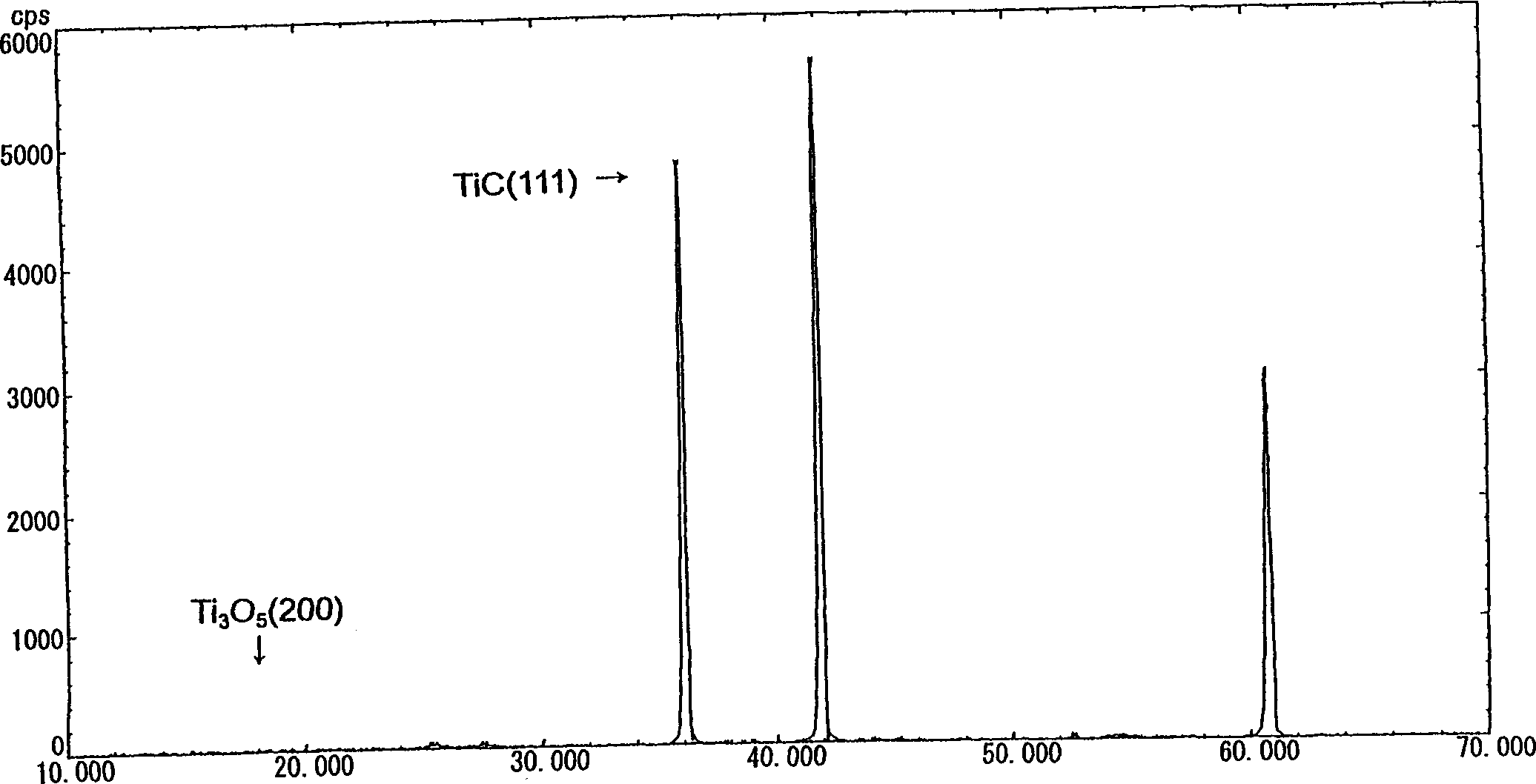

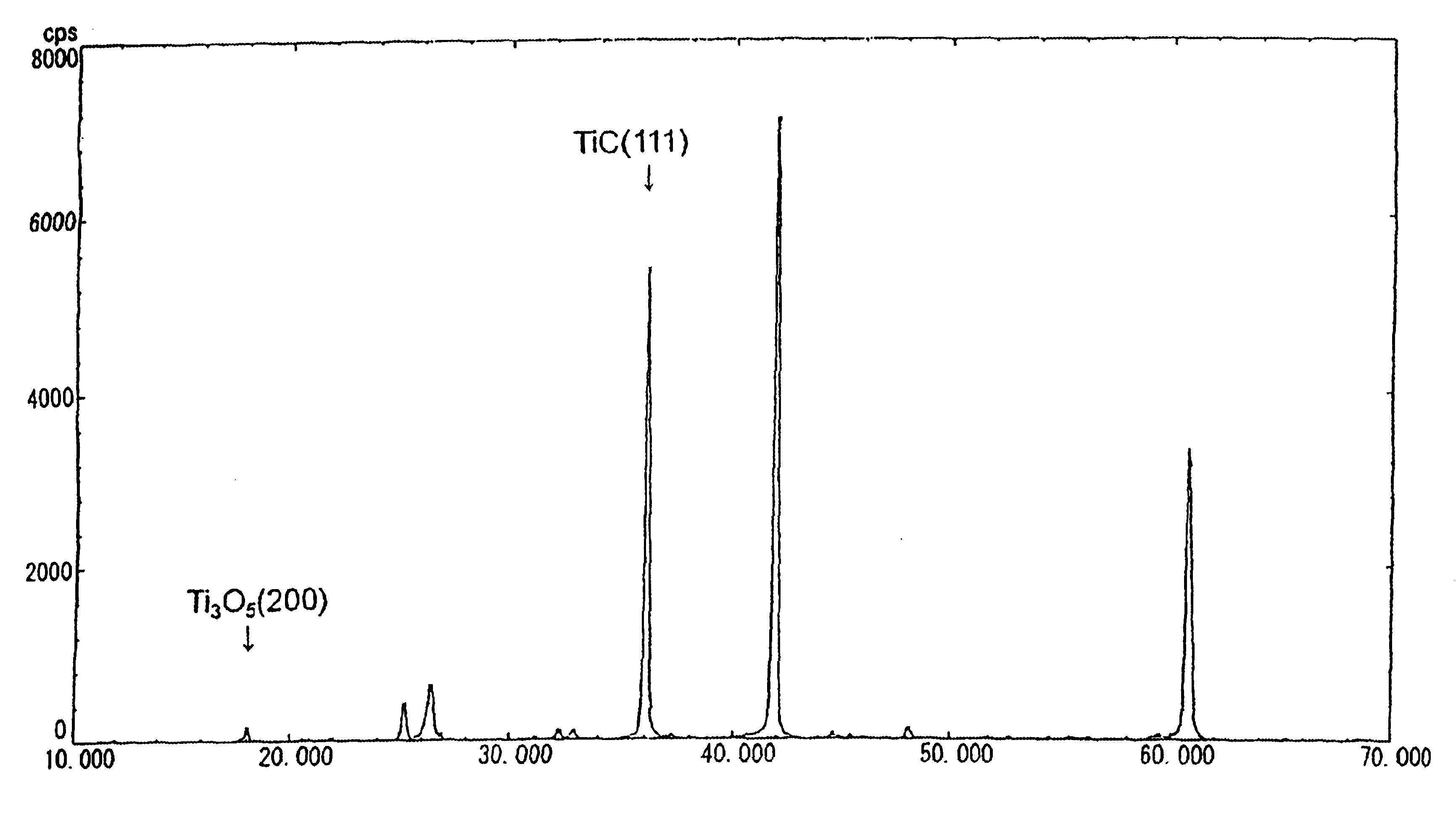

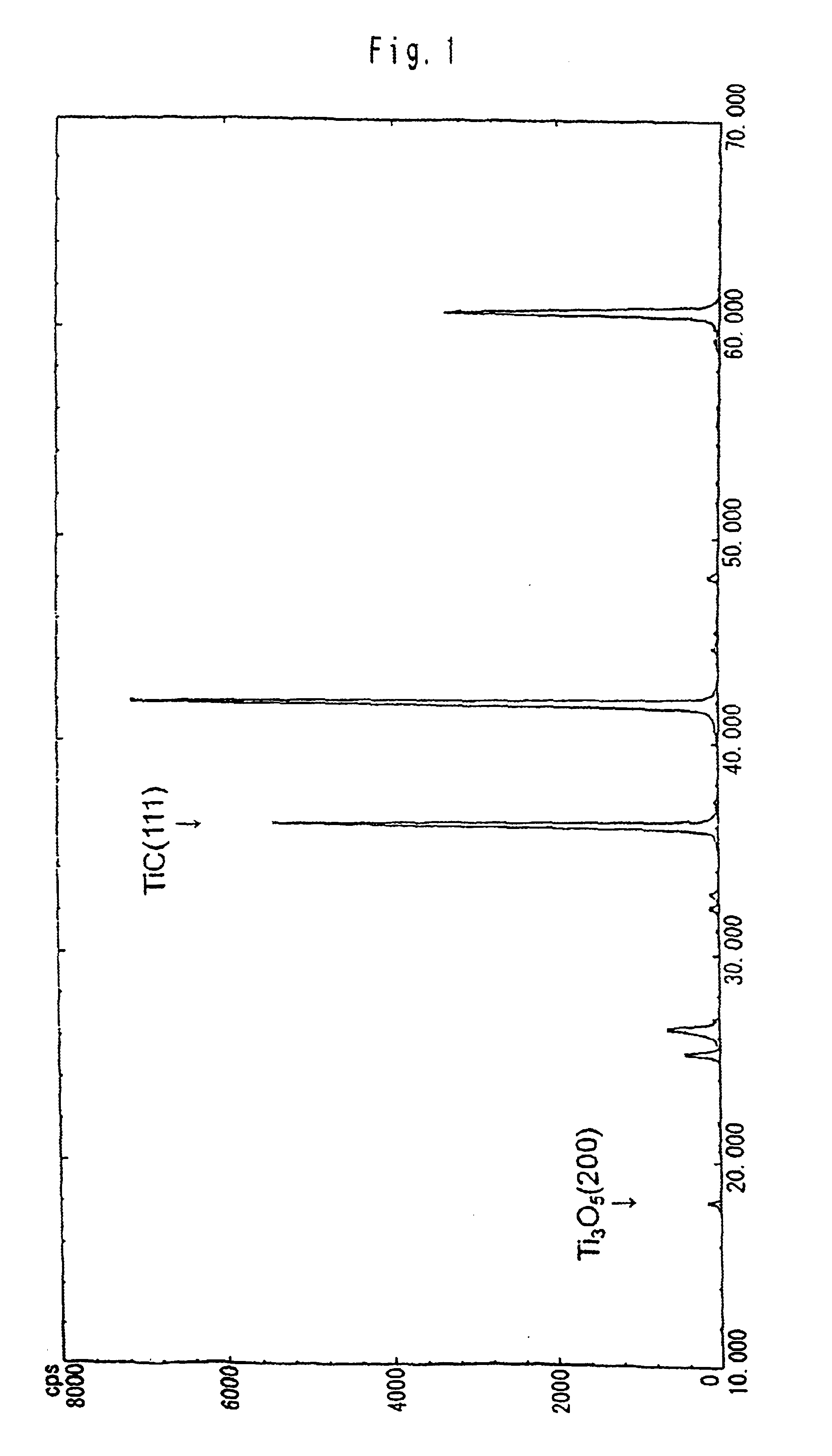

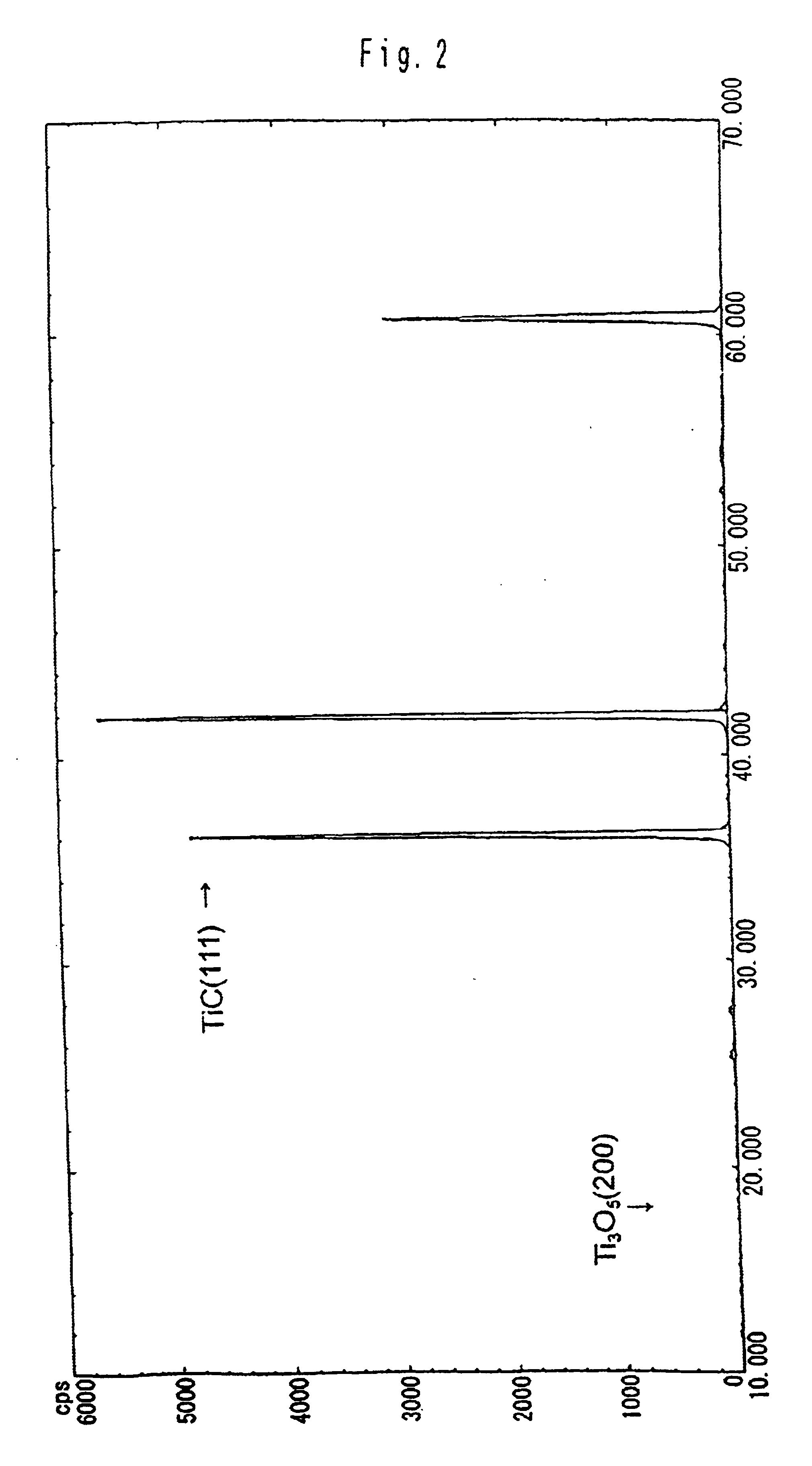

Carbonaceous refractory and method for preparing the same

InactiveUS6875716B2Satisfied with the effectLow corrosion rateBlast furnace detailsDischarge devicesTitanium nitrideTitanium carbonitride

A carbonaceous refractory material is produced by adding an organic binder to a mixture containing a carbonaceous material comprising a carbonaceous raw material comprising calcined anthracite, calcined coke, artificial graphite or natural graphite or a mixture thereof at 50 to 85% as the principal raw material, alumina particle at 5 to 15%, metal silicon particle at 5 to 15%, and one or two or more of titanium carbide powder, titanium nitride powder and titanium carbonitride powder at 5 to 20% in total, kneading and molding the resulting mixture and baking the molded article under non-oxidizing atmosphere. By using the carbonaceous refractory material as the inner lining material for the side wall and bottom of blast furnace hearth, the consumption of the inner lining material due to the dissolution thereof in melted pig iron can be decreased, and simultaneously, the abrasion due to the flow of melted pig iron can be decreased, which works to prolong the life of the blast furnace.

Owner:NIPPON STEEL CORP +1

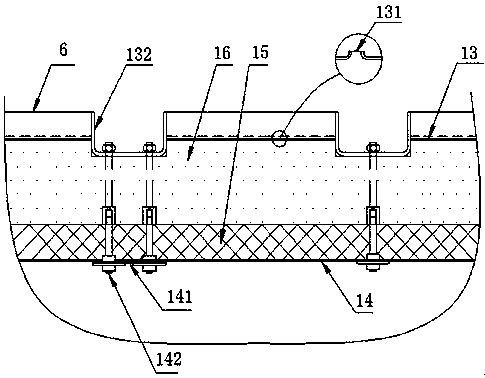

Energy-saving hearth provided with air thermal insulating layer and thermal radiation reflecting layer and preparation method thereof

The invention discloses an energy-saving hearth provided with an air thermal insulating layer and a thermal radiation reflecting layer and a preparation method thereof. The energy-saving hearth is composed of a refractory lining, the air thermal insulating layer, the thermal radiation reflecting layer and a thermal insulating layer from inside to outside, wherein the refractory lining is preparedfrom ceramic fiber or / and graphite fiber or / and hollow ceramic microspheres through pouring or die-casting forming method;and the thermal radiation reflecting layer is composed of a metal polishing plate with the infrared ray total reflection capacity, a glass pane film coating plate, and a ceramic microsphere coating. According to the energy-saving hearth, the air thermal insulating layer and thethermal radiation reflecting layer are arranged between the refractory lining and the thermal insulating layer, so that thermal radiation and loss of heat conduction energy of the energy-saving hearth to the outside world are reduced to the maximum, and the energy-saving effect is remarkably improved. The preparation method of the energy-saving hearth is simple in technology, and the combined structure is convenient to maintain and can prolong the service life.

Owner:SUZHOU DINGAN ELECTRONICS TECH

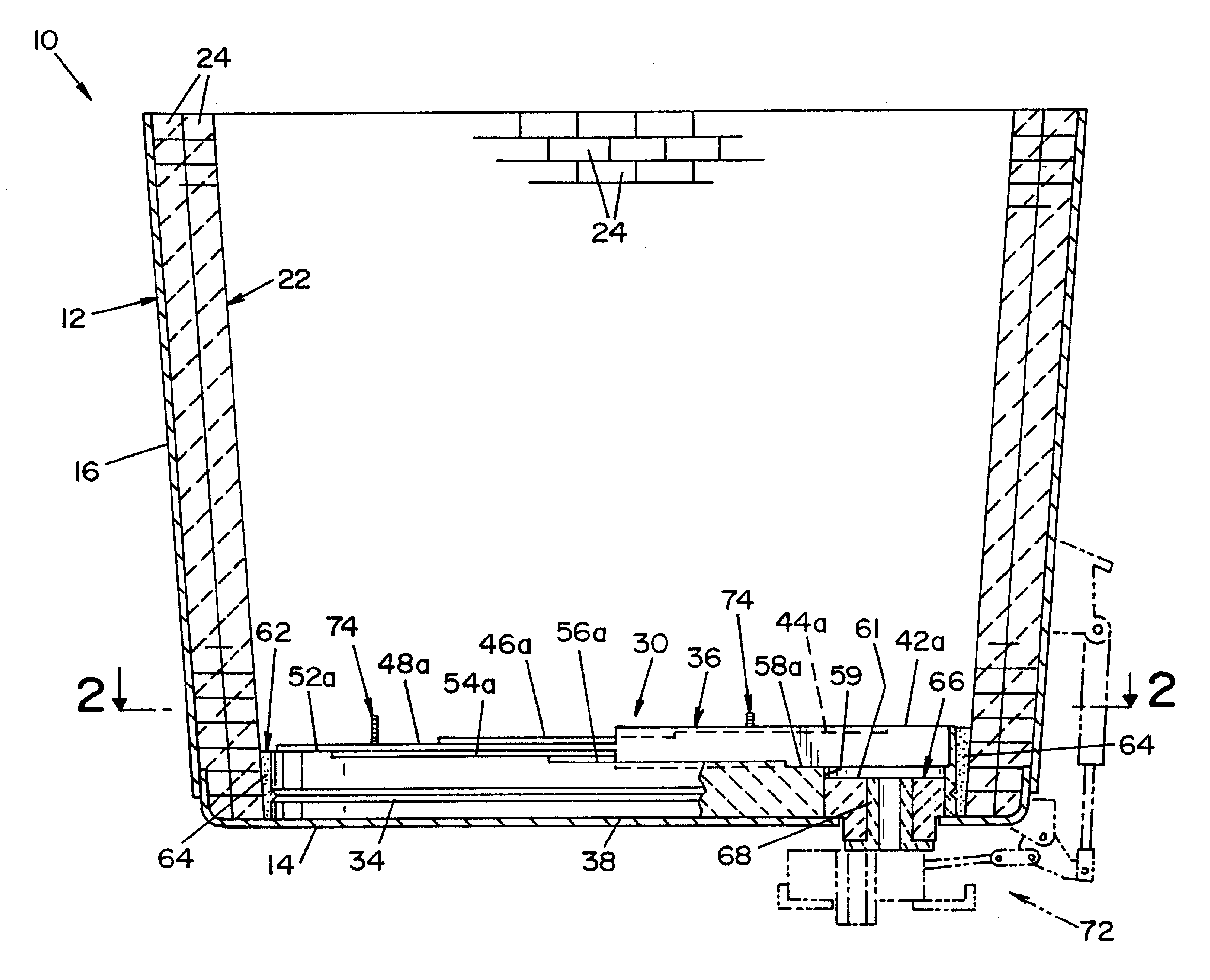

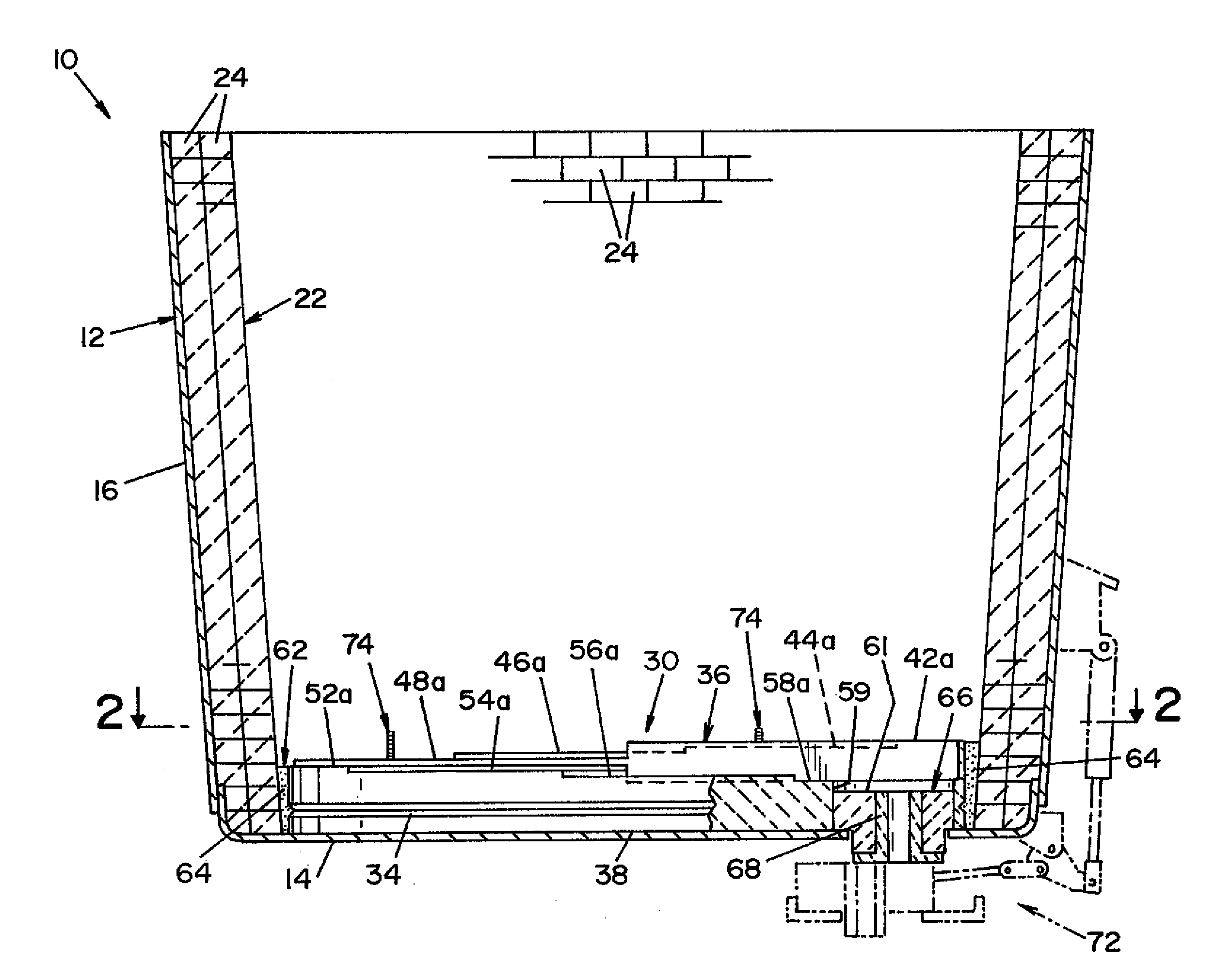

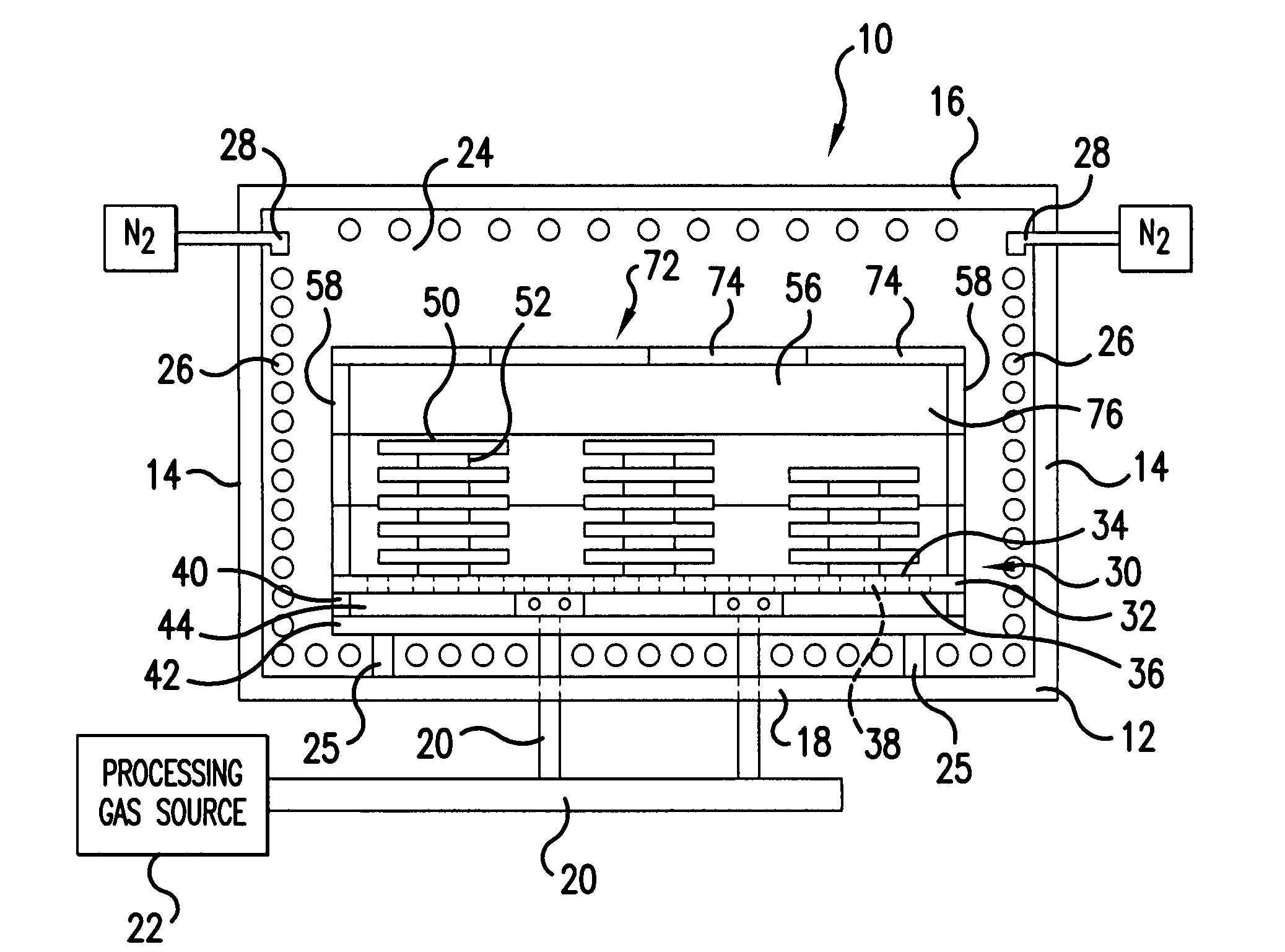

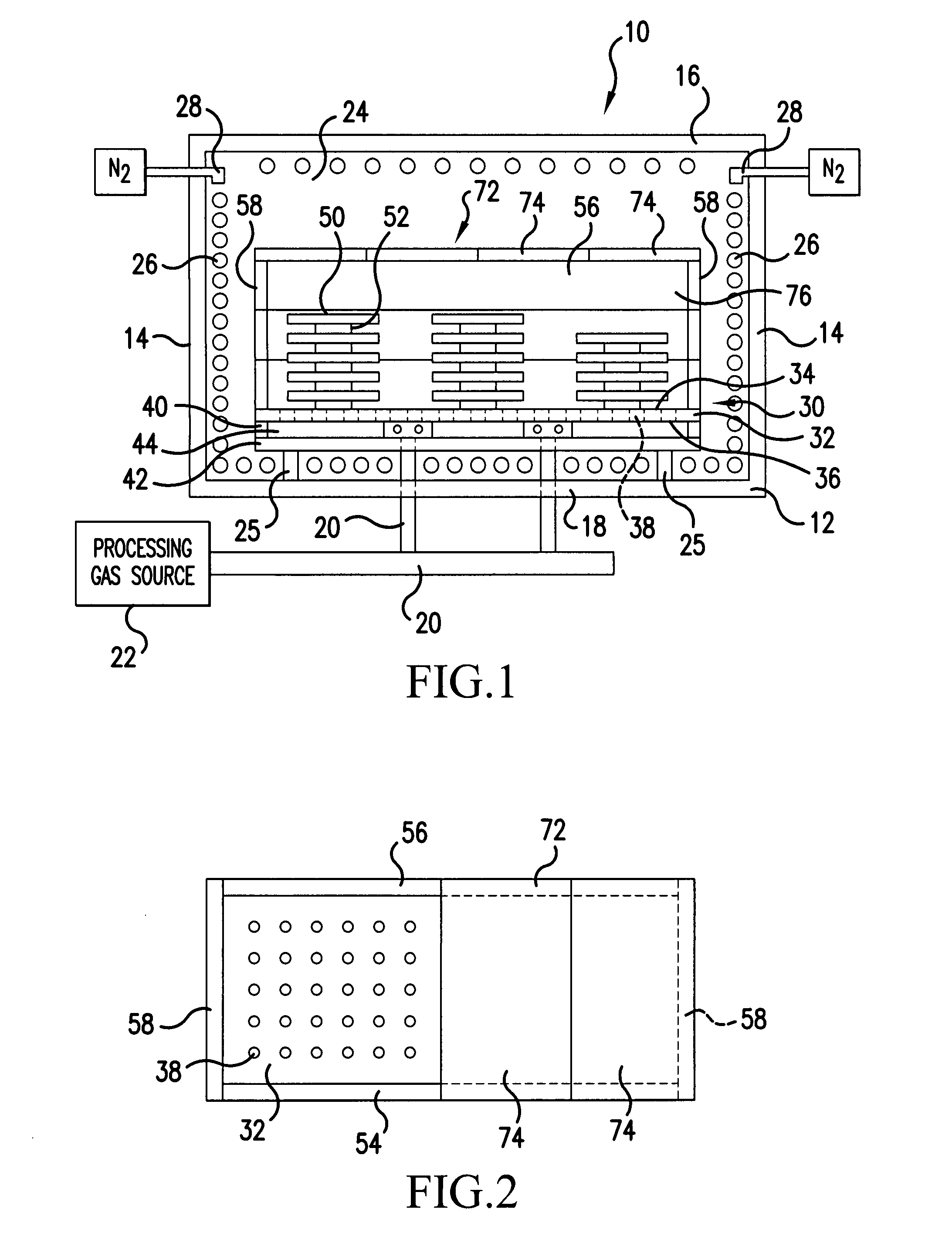

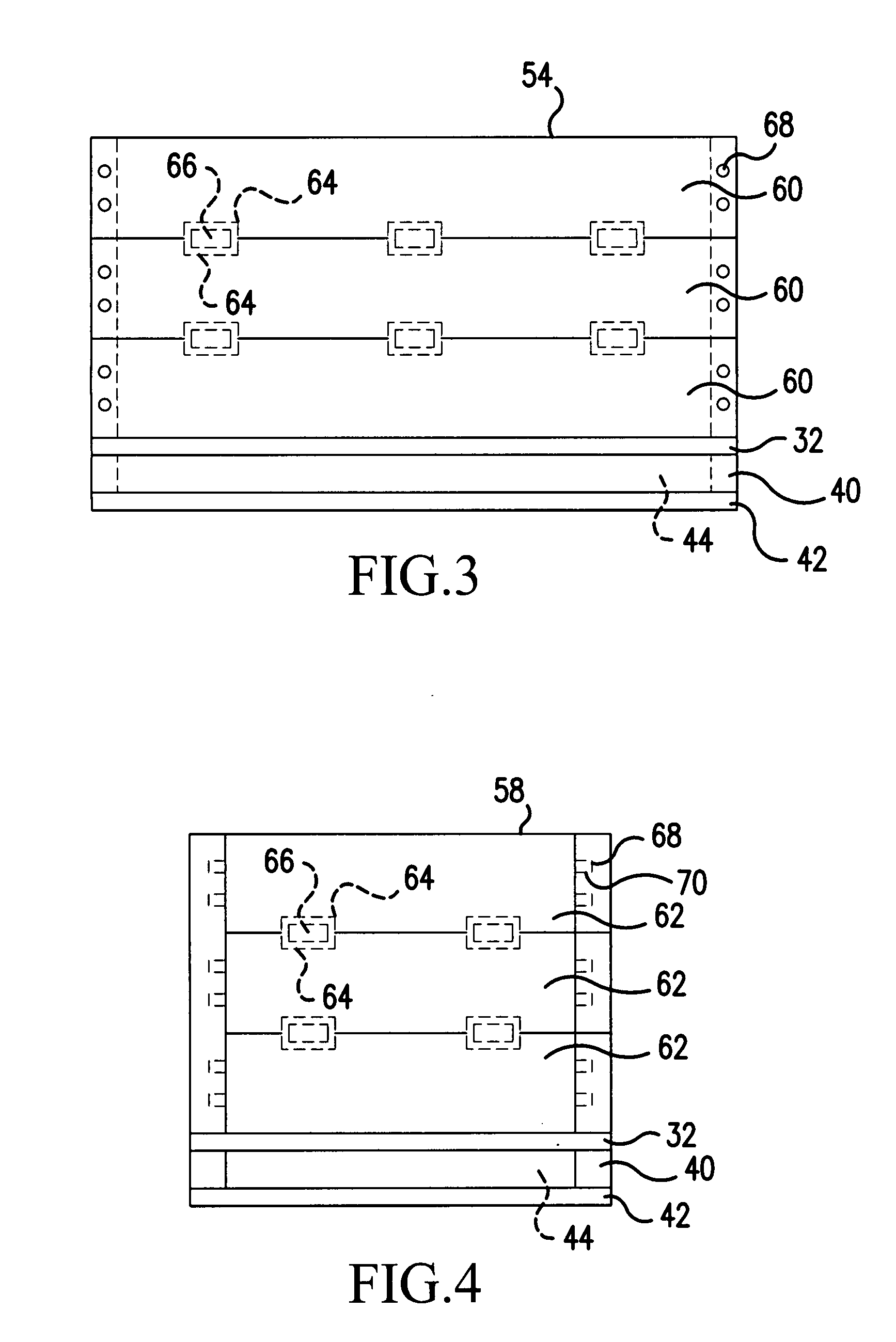

Hearth plate including side walls defining a processing volume

A hearth plate (30) includes a flat rectangular plate (32) having a top surface (34), a bottom surface (36), and a plurality of through openings (38) between the top surface (34) and bottom surface (36), four support walls (40) having top edges connected around the periphery of the bottom surface (36) and bottom edges and a bottom wall (42) connected to the bottom edges of the support walls (40). A preheater structure (46) is mounted in the space (44) defined by the four support walls (40), flat rectangular plate (32) and bottom wall (42), and a rectangular enclosure comprising four interconnected graphite walls (54, 56, 58) is mounted around the peripheral edge of the top surface (34) to define a processing volume for receiving objects (50) to be processed. A graphite lid (72) is removably supported by the rectangular enclosure.

Owner:HONEYWELL INT INC

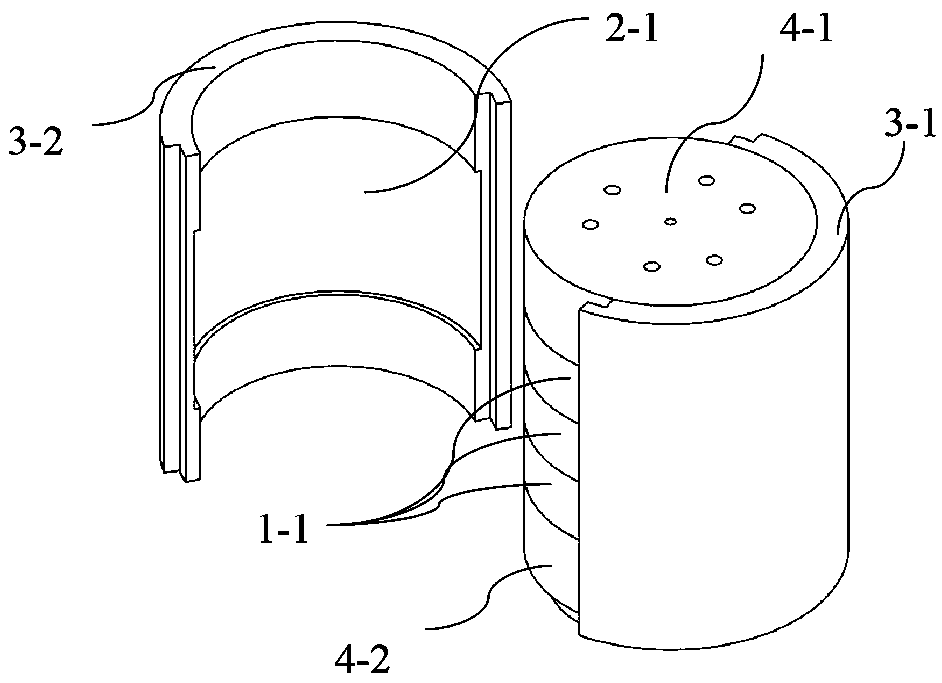

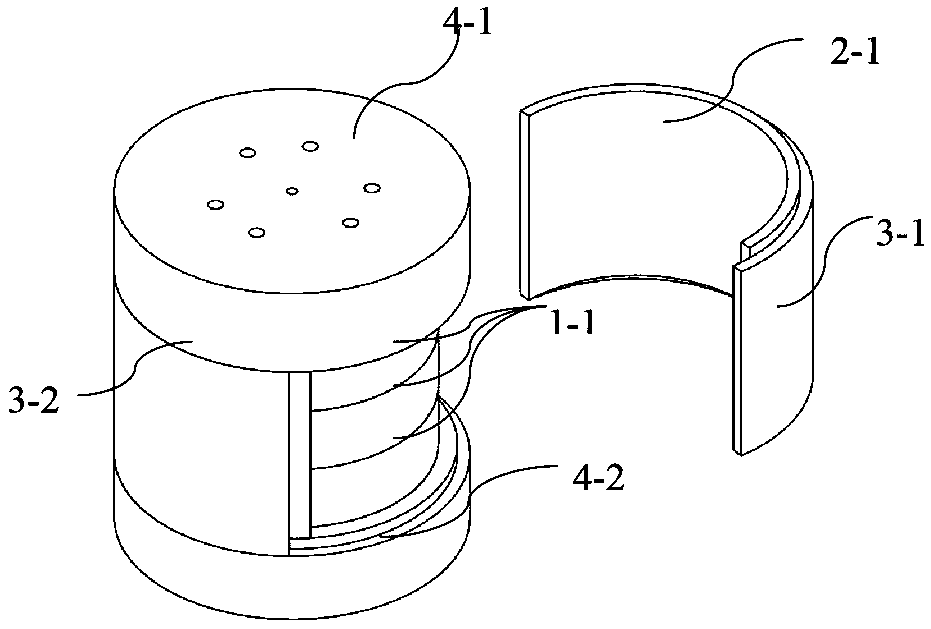

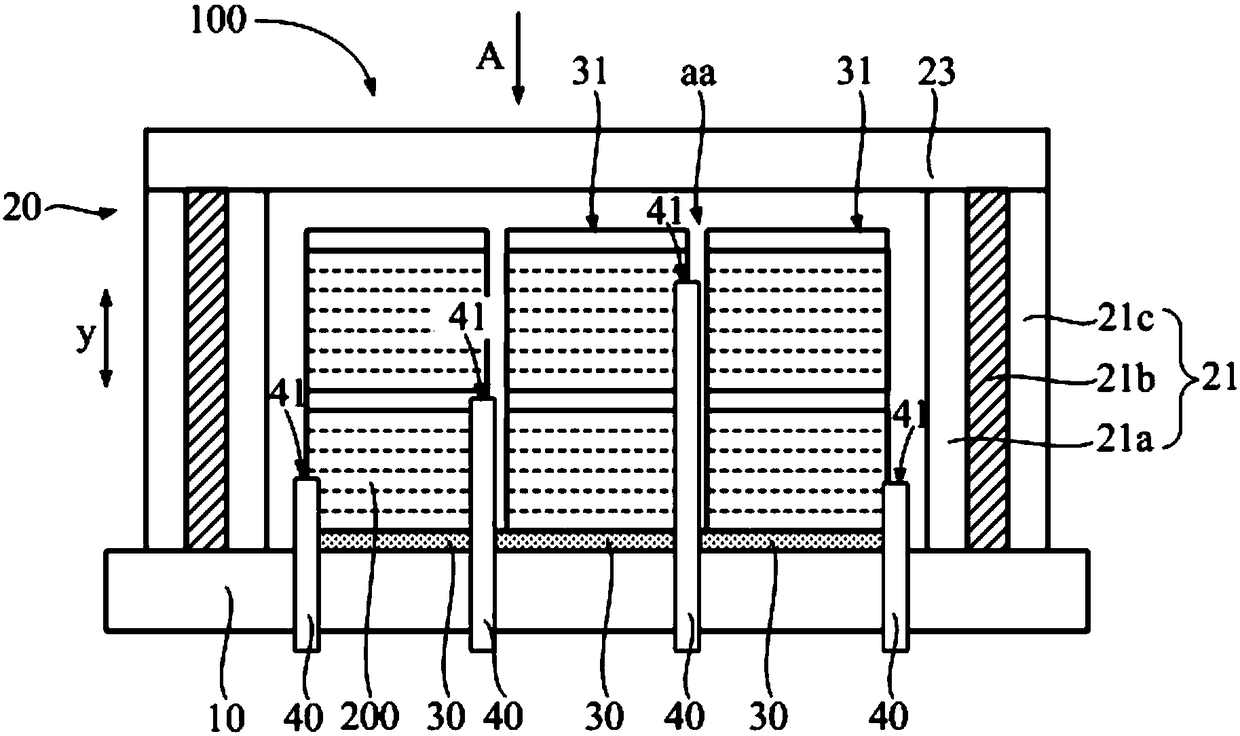

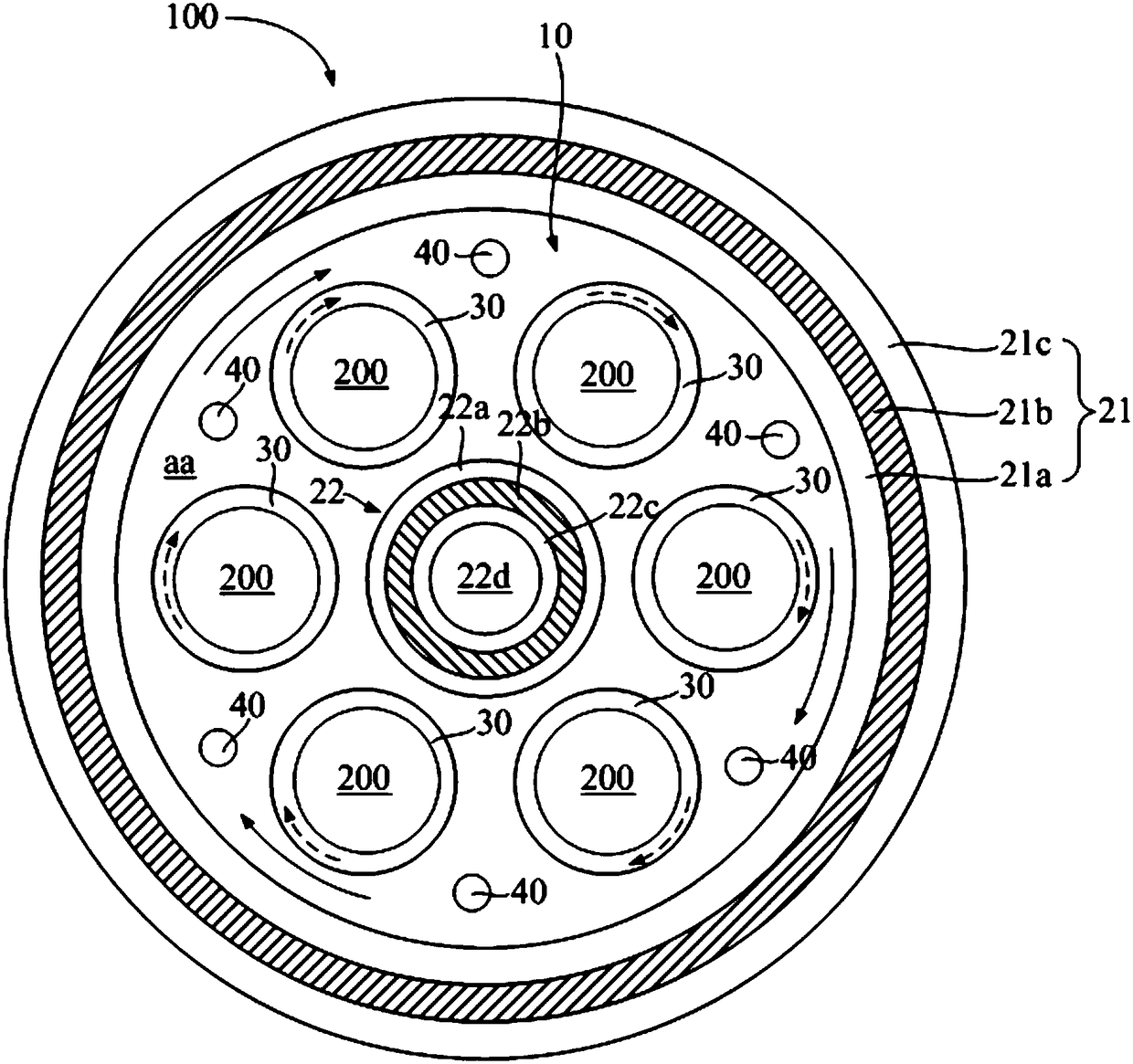

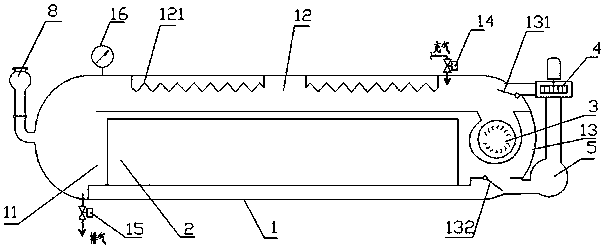

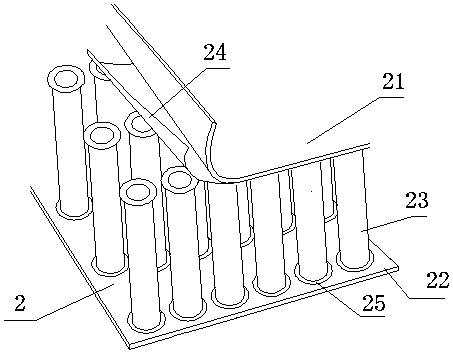

Furnace tube device

ActiveCN108088247ALower the altitudeReduce distanceCharge supportsFurnace typesTherapeutic effectEngineering

A furnace tube device comprises a base and a shell, a furnace tube cavity for containing wafers is defined by the base and the shell, multiple trays used for containing the wafers is formed in the surface, facing the furnace tube cavity, of the base. The multiple trays are arranged on the base, the wafers can be placed on the trays in a dispersed manner, and therefore the height of the furnace tube cavity can be reduced. When the height of the furnace tube cavity is reduced, it means that the distance between the wafers at the two ends in the height direction is reduced, the process conditionsof the wafers are close, each wafer has the quite close treatment effect, and the product yield is improved.

Owner:上海昭帆智能科技有限公司

Production method of high-quality AlV55 alloy

ActiveCN114015874AImprove qualityImprove appearance qualityMaintainance of heating chambersProcess efficiency improvementAlloyMixed materials

The invention relates to the field of metallurgy, and discloses a production method of a high-quality AlV55 alloy. The method comprises the following steps: (1) adding V2O5 of which the purity is greater than or equal to 99.5 mass percent, metal Al of which the purity is greater than or equal to 99.7 mass percent and CaO of which the purity is greater than or equal to 98.5 mass percent into a charging bucket according to a mass ratio of 1: (0.88 to 0.90): (0.12 to 0.16), and mixing; (2) filling the mixed material into a reaction furnace in 3 to 5 times, and compressing and exhausting after filling the material each time; (3) initiating the material to carry out aluminothermic reaction by adopting an ignition agent; (4) after the reaction is stable, pushing the reaction furnace body into a vacuum chamber, vacuumizing, and introducing argon; and (5) disassembling the furnace after cooling, and obtaining the high-quality AlV55 alloy. The AlV55 alloy prepared by the method disclosed by the invention is high in yield, low in impurity element content and high in quality.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Ferronickel electric furnace with magnesium-carbon composite furnace lining

PendingCN110906740AStop erosionAvoid erosion damageLinings repairCharge manipulationCarbon compositesBrick

The invention provides a ferronickel electric furnace with a magnesium-carbon composite furnace lining. The electric furnace comprises a furnace bottom and a furnace wall, wherein an iron notch and aslag notch are formed on the furnace wall, a graphite ramming mass is arranged on the furnace wall close to the furnace shell, and graphite bricks are arranged close to the graphite ramming mass on ahot surface of the furnace wall. The electric furnace is advantaged in that a slag shell can be formed on the furnace wall graphite brick hot surface of the ferronickel electric furnace to prevent molten iron from eroding and damaging the furnace wall, brick joints are reduced by adopting large masonry, and the molten iron is prevented from eroding the furnace wall along the brick joints, the magnesia carbon bricks are adopted in the upper and lower circumferential areas of the iron notch, so molten iron corrosion resistance of the furnace lining is improved, and defects of easy expansion andeasy peeling of magnesia bricks are overcome; the service life of the ferronickel electric furnace is prolonged to 5-10 years or even longer from original 2-3 years, the overall service life of the furnace lining is greatly prolonged, moreover, maintenance cost is reduced, production efficiency is improved, and economic benefits are remarkable.

Owner:鲁山县方圆工程技术有限公司

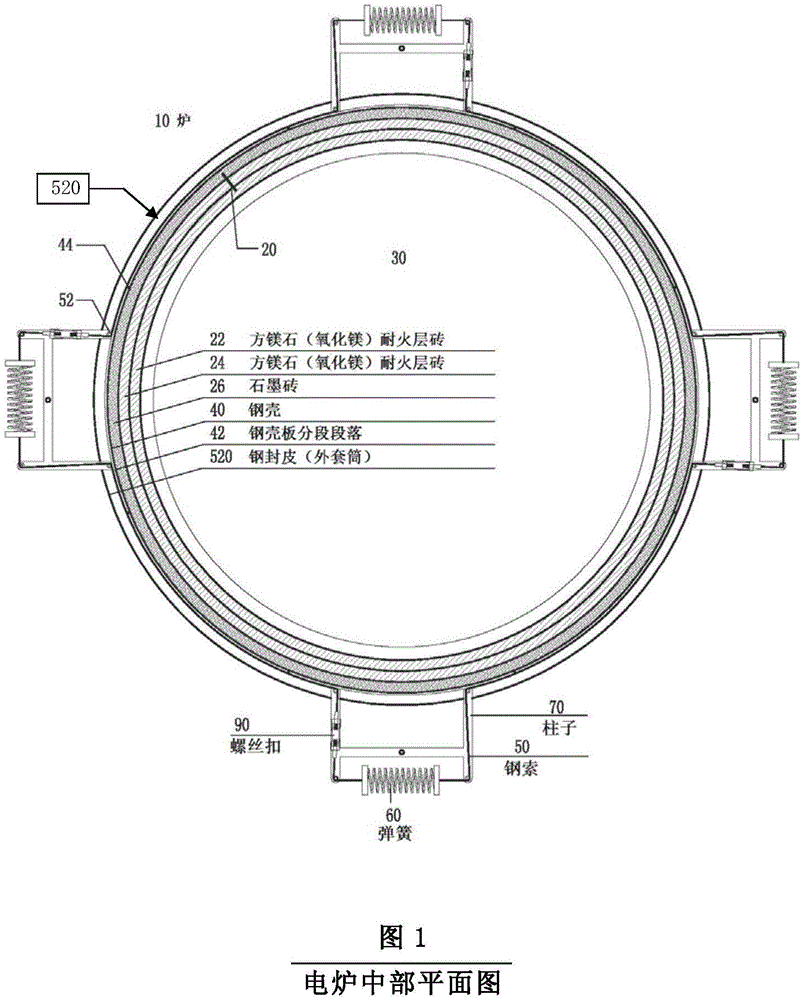

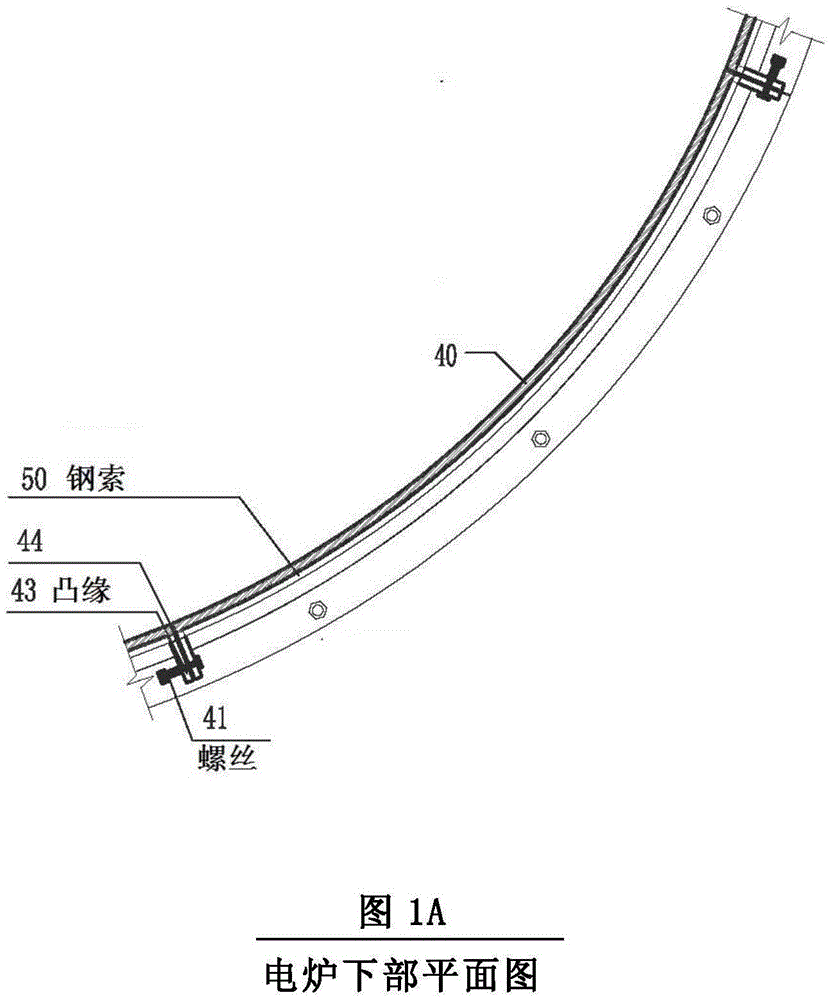

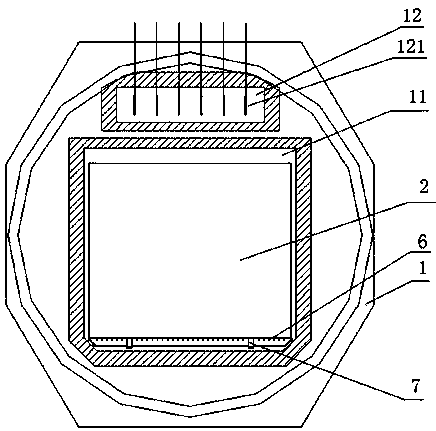

Electric furnace

PendingCN113048785AAvoid deformationAvoid failureCrucible furnacesFurnace floorsEngineeringMechanical engineering

The invention discloses an electric furnace. The electric furnace comprises a furnace body, wherein a furnace chamber is formed in the furnace body; the furnace chamber comprises an upper chamber and a molten pool positioned below the upper chamber; the furnace body comprises a bottom wall and a peripheral wall; the cross section of the peripheral wall is circular; the peripheral wall of the molten pool comprises a lining brick layer and a furnace shell positioned on the outer side of the lining brick layer; the furnace shell comprises a plurality of shell sections; the bottom ends of the shell sections are connected with the bottom wall; the shell sections are arranged in sequence along the circumferential direction of the peripheral wall; and the end parts of two adjacent shell sections are connected through an expansion regulator. The furnace shell of the electric furnace can keep a hooping effect on the lining brick layer, and can be adaptively regulated along with the expansion effect of the lining brick layer, so that deformation and failure of the furnace shell are avoided.

Owner:CHINA ENFI ENGINEERING CORPORATION

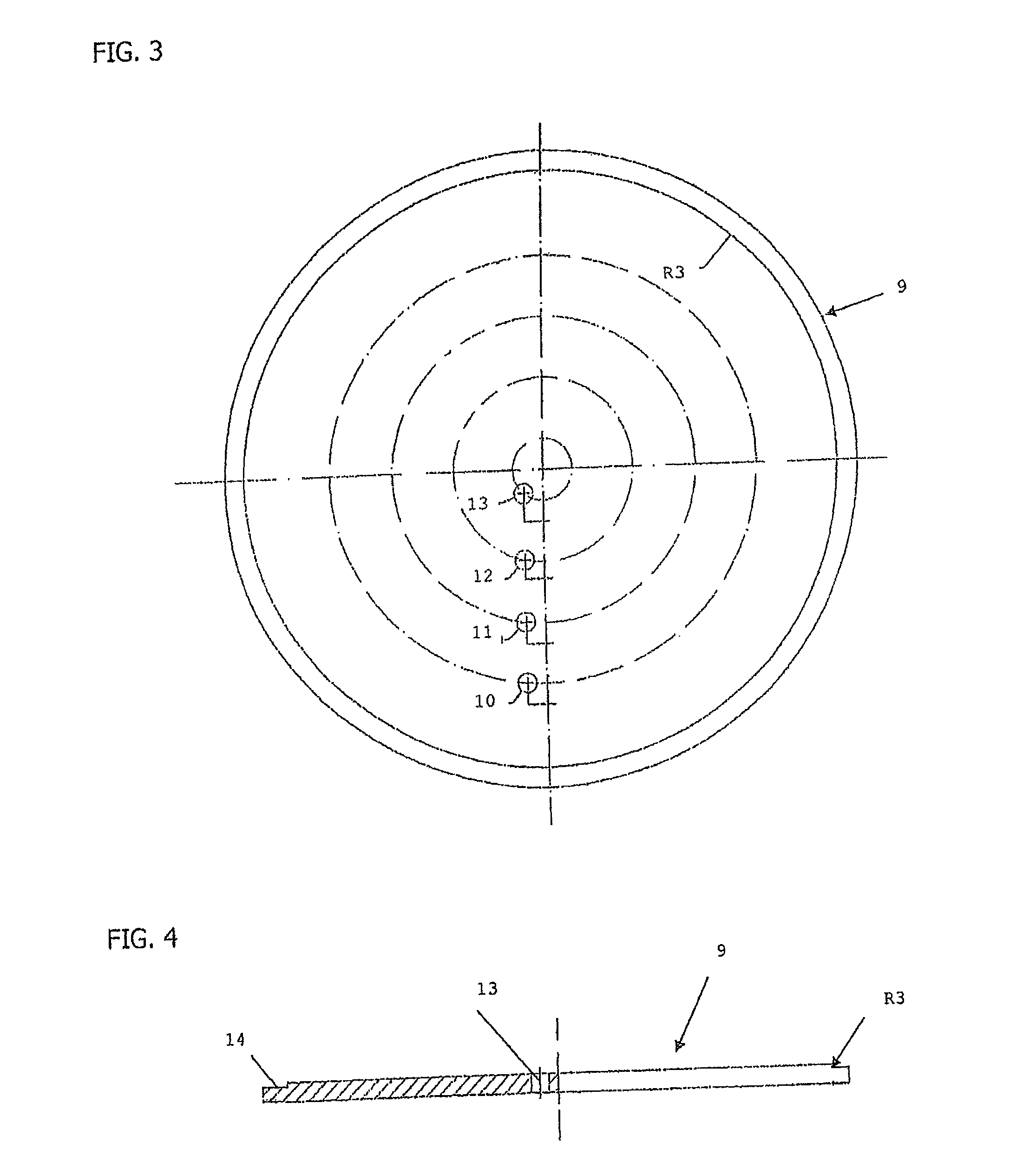

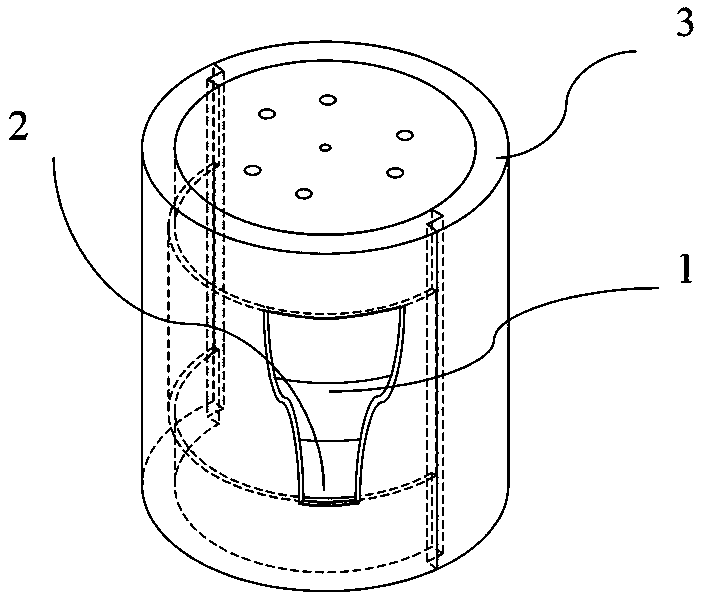

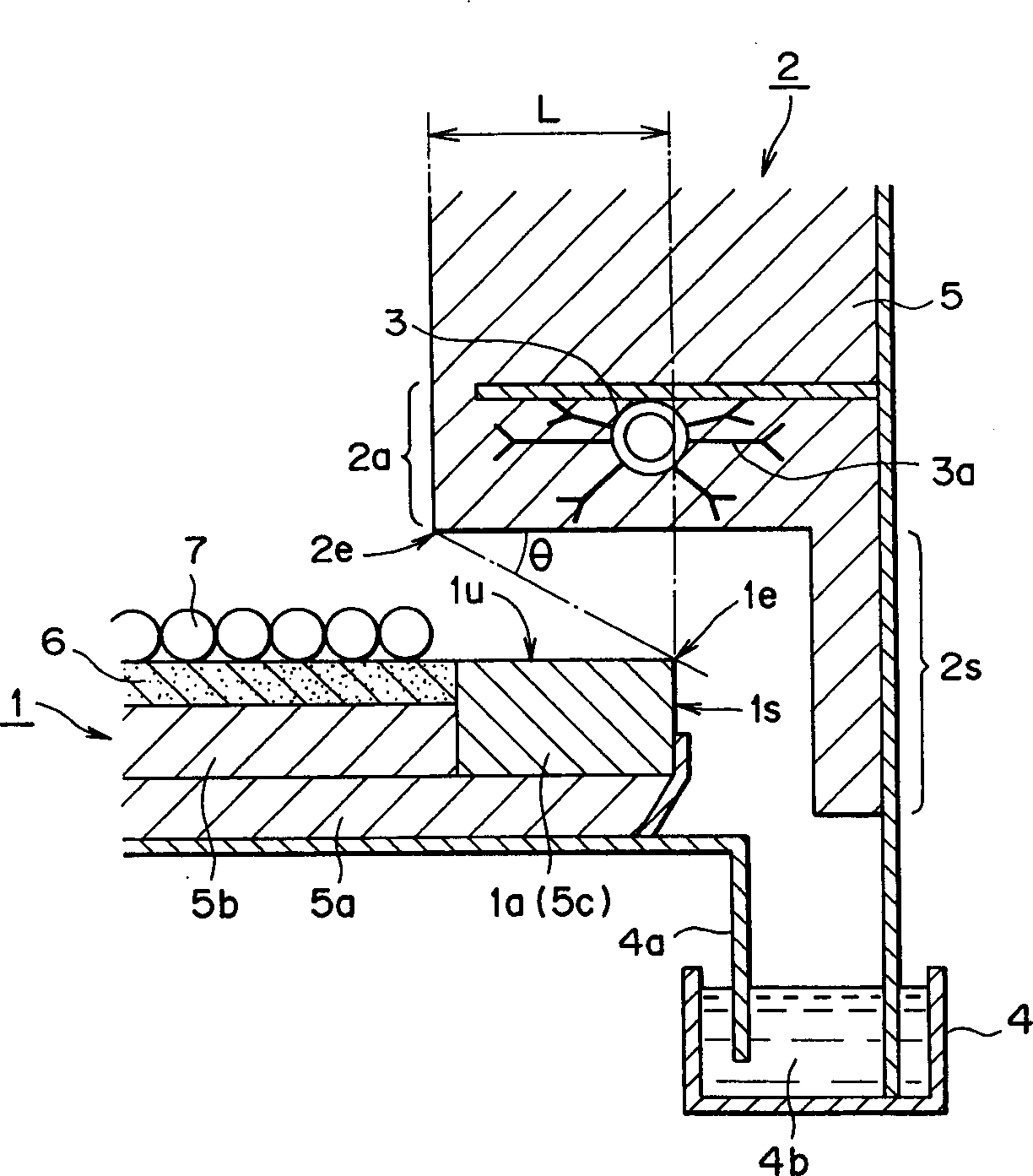

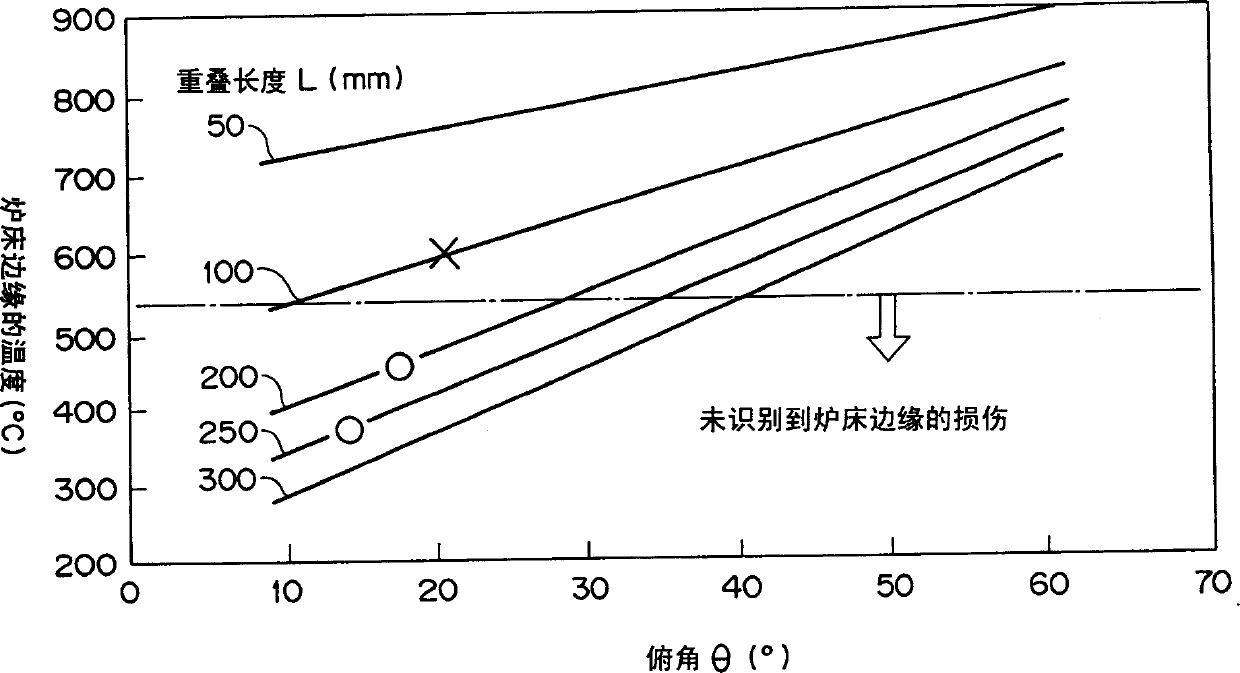

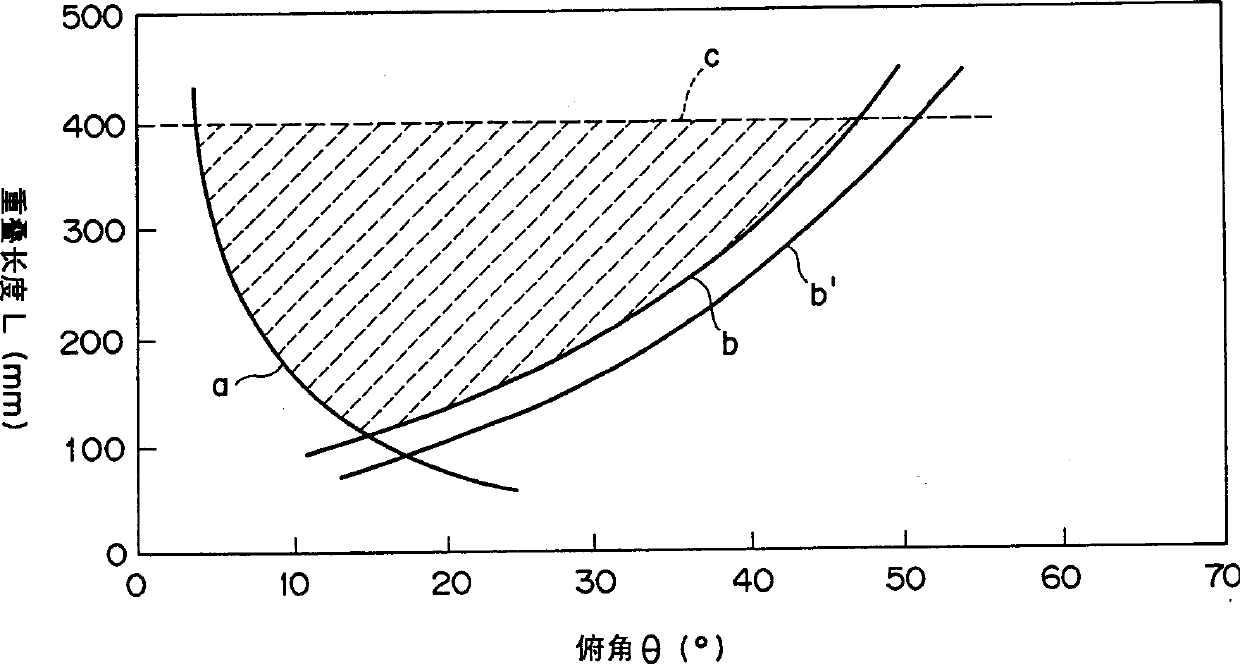

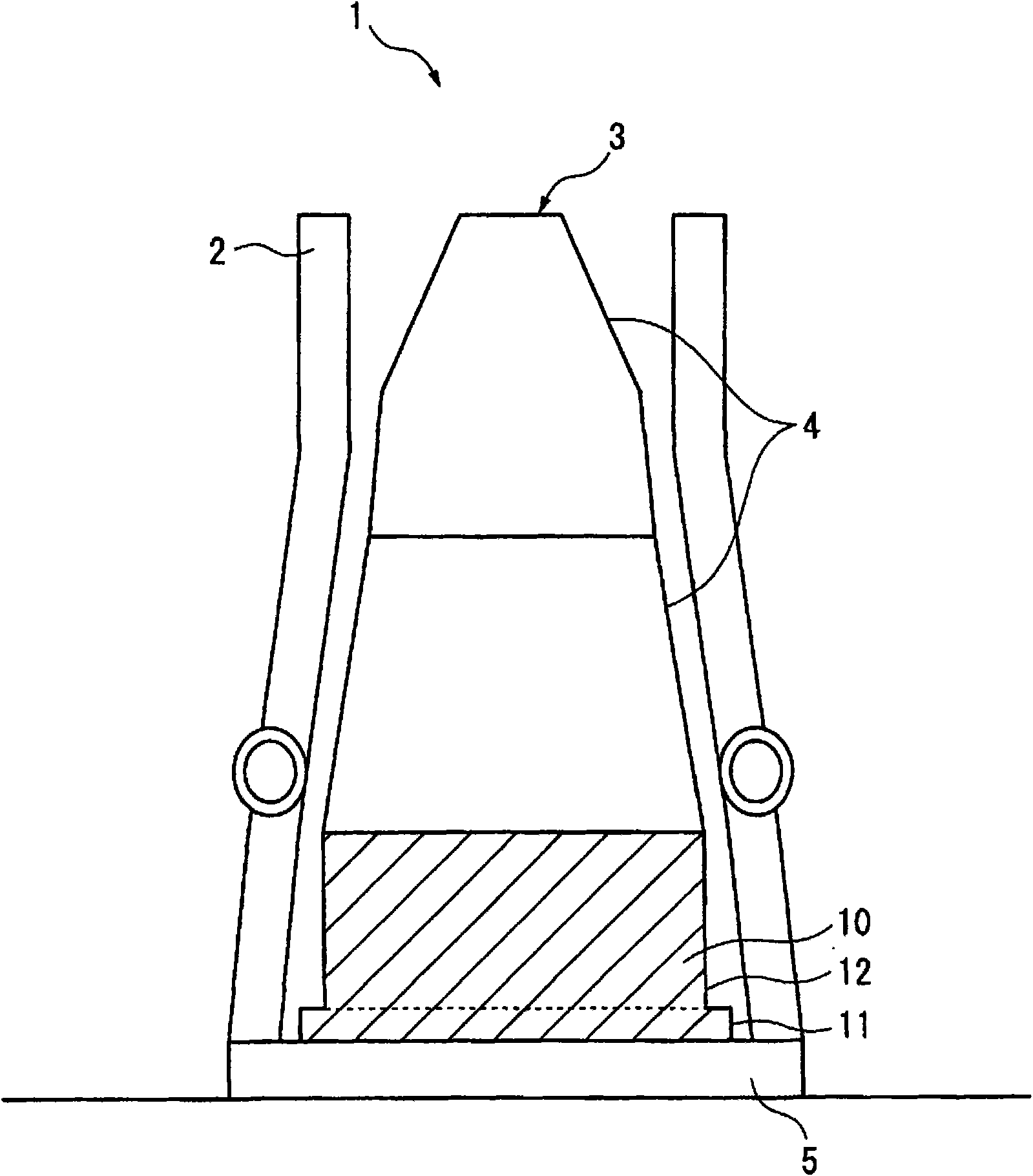

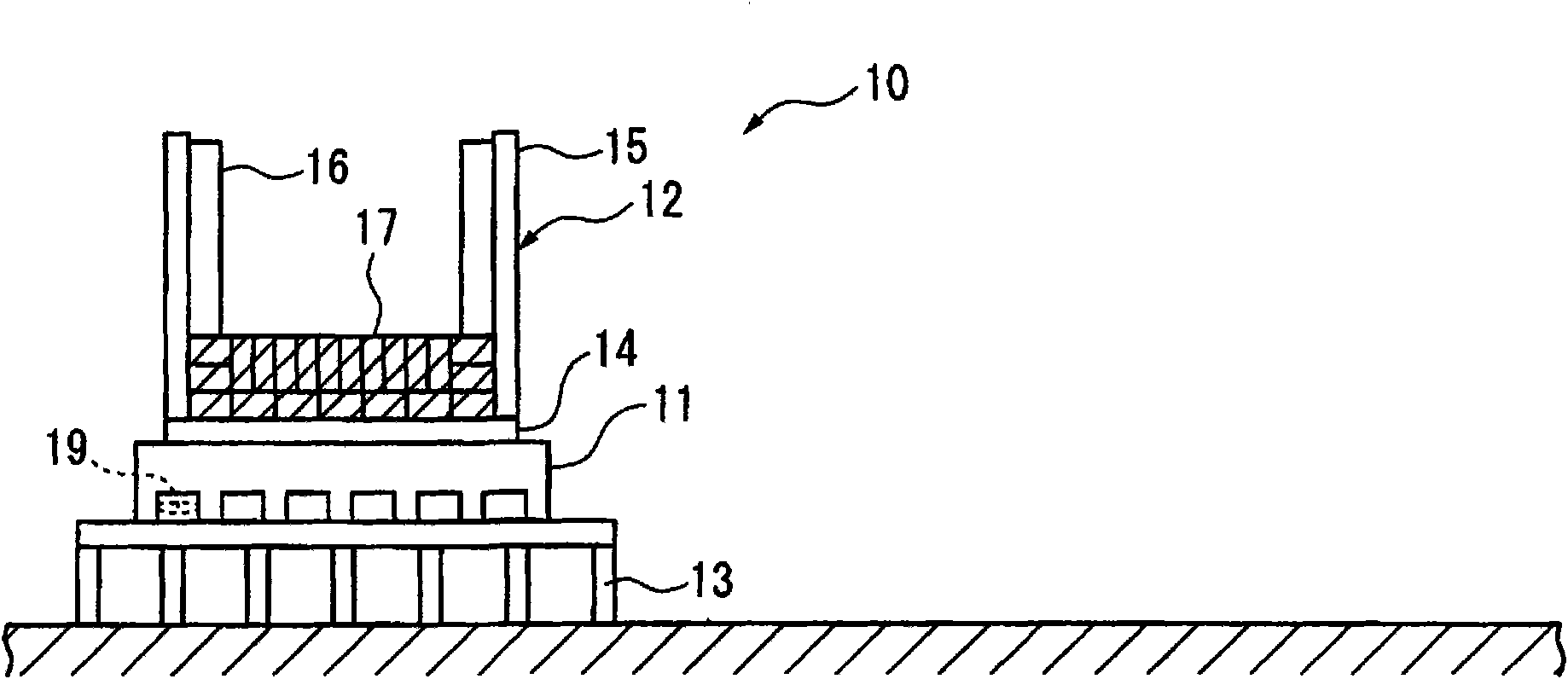

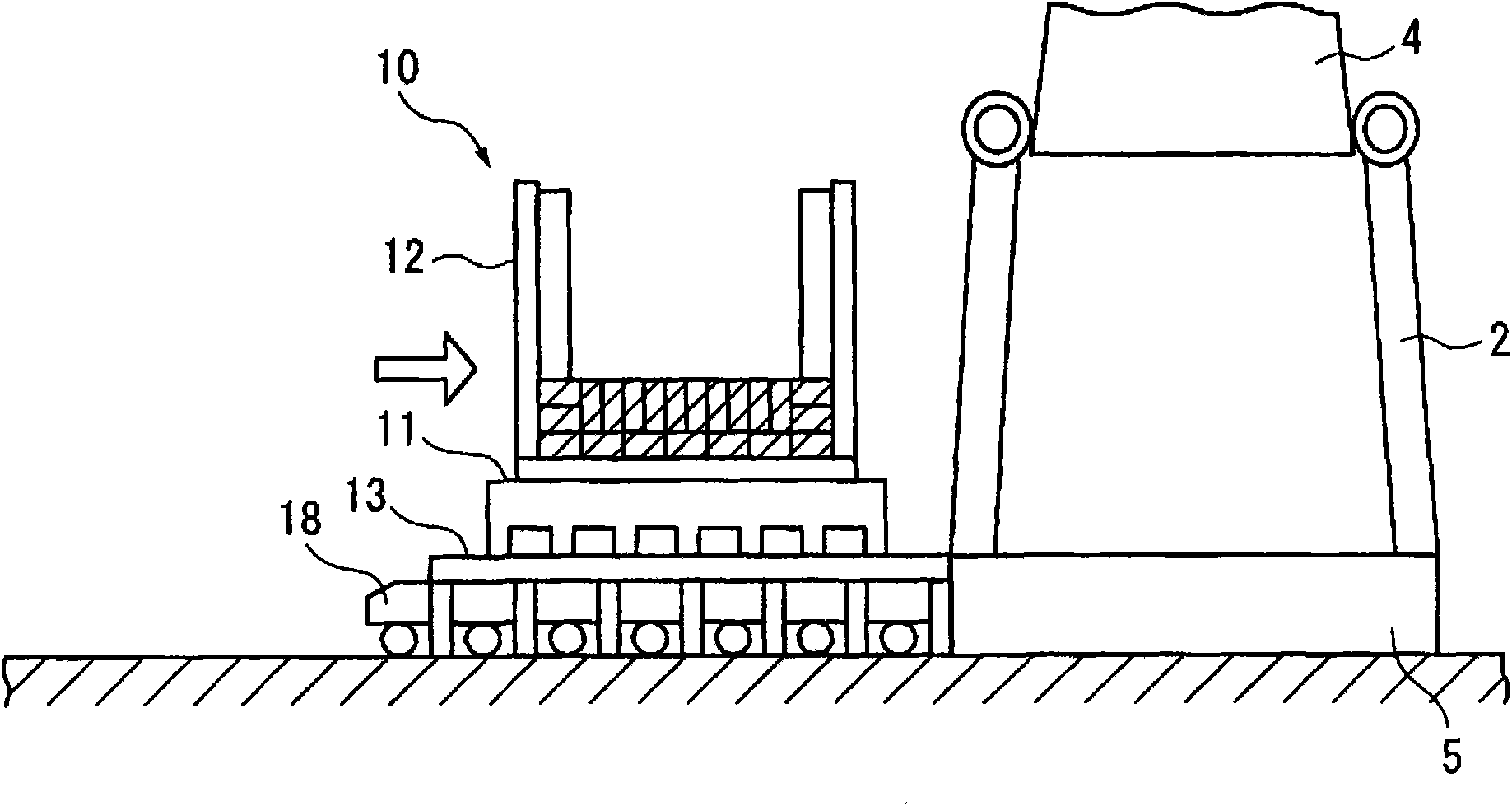

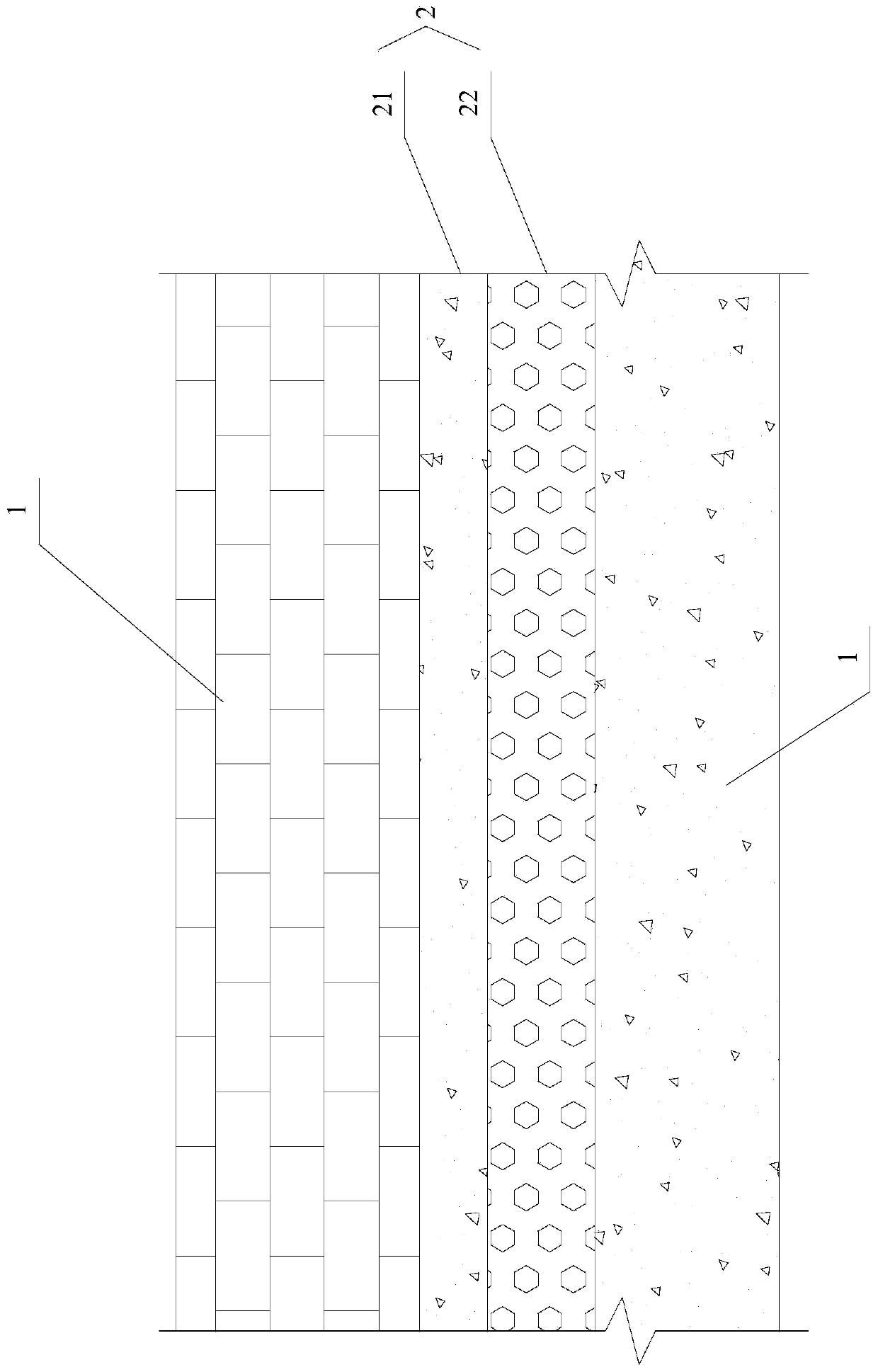

Rotary hearth furnace and method for producing reduced metal

InactiveCN1360061AReduce the extent to which spallation cannot occurDoes not interfere with rotationRotary drum furnacesFurnace cooling arrangementsRefractoryHearth

In a rotary hearth furnace for producing reduced metal through heating and reducing carbon containing materials composed of at least metal oxide-containing material and carbon-containing reduction material, a hearth structure is provided by which a refractory in a hearth lateral end is not damaged and carbon containing materials do not fall down to a water sealing section of the rotary hearth furnace. The upper part of a hearth lateral end (1a) is covered with the lower end (2a) of a side wall (2) of a hood covering the whole hearth, and a cooling means (3) is installed in the side wall lower end (2a).

Owner:KOBE STEEL LTD

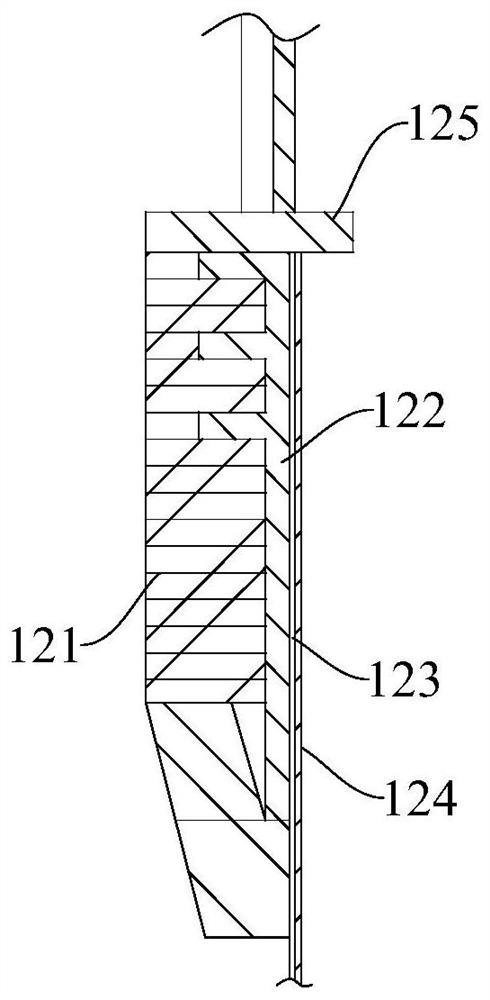

Internal structure of furnace body

InactiveCN109425221AIncrease temperatureEvenly heatedPump componentsMaintainance of heating chambersEngineeringHigh pressure

The invention provides an internal structure of a furnace body. The internal structure comprises a liner; chamber bodies of the liner are connected with a partition plate; the partition plate is usedfor dividing the liner into at least two chamber bodies; one chamber body is a working chamber; an internal rolling wheel mechanism is arranged inside the working chamber; a workpiece is placed on theinternal rolling wheel mechanism; and a fan is arranged at one side of the liner. On one hand, the internal structure provided by the invention can realize uniform heating or cooling of the workpiece; and on the other hand, the inside of the liner is made from a high temperature resisting material and can resist a temperature larger than or equal to 450 DEG C, so the internal structure is especially applicable to places which can bear strong burning and high pressure.

Owner:张跃

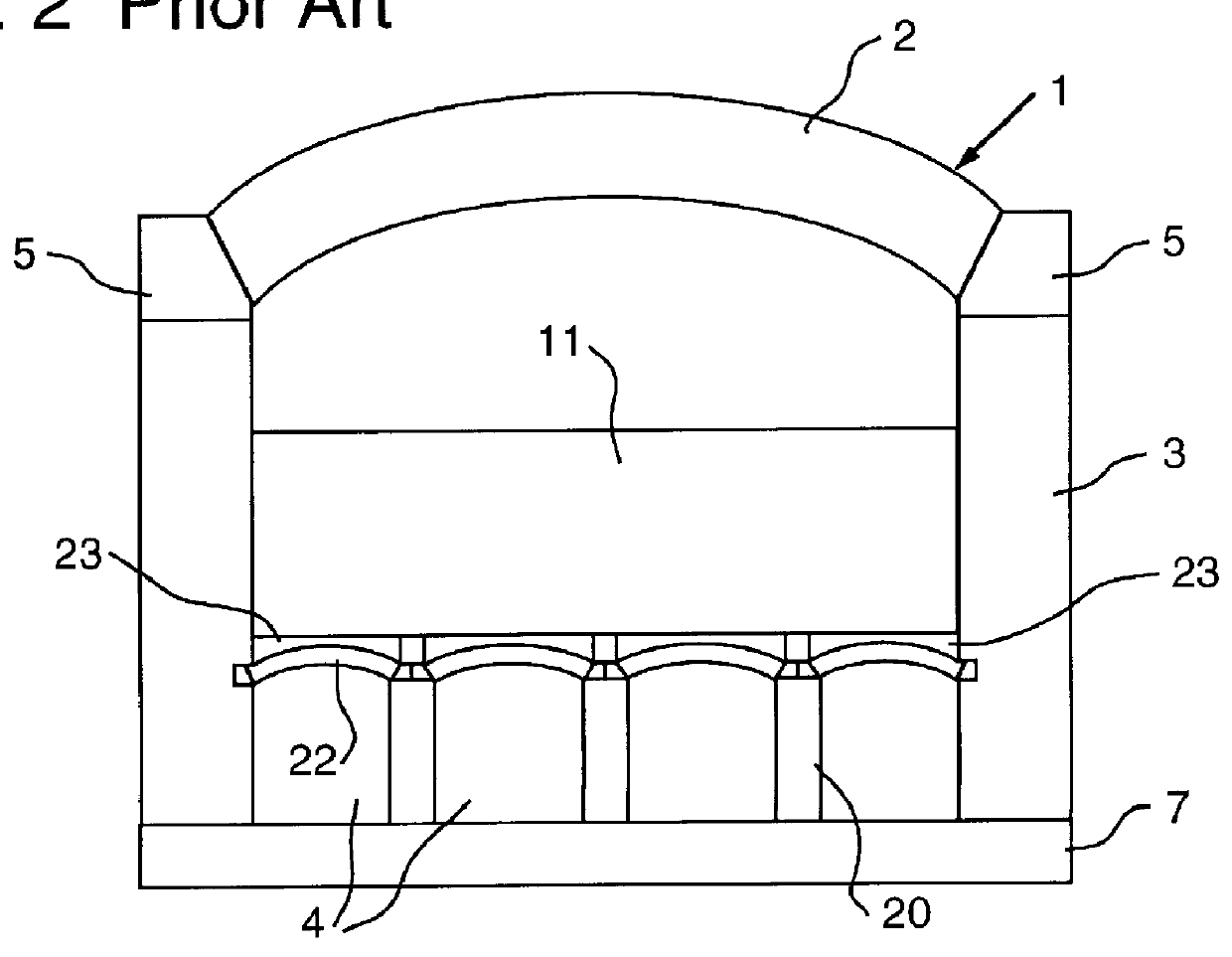

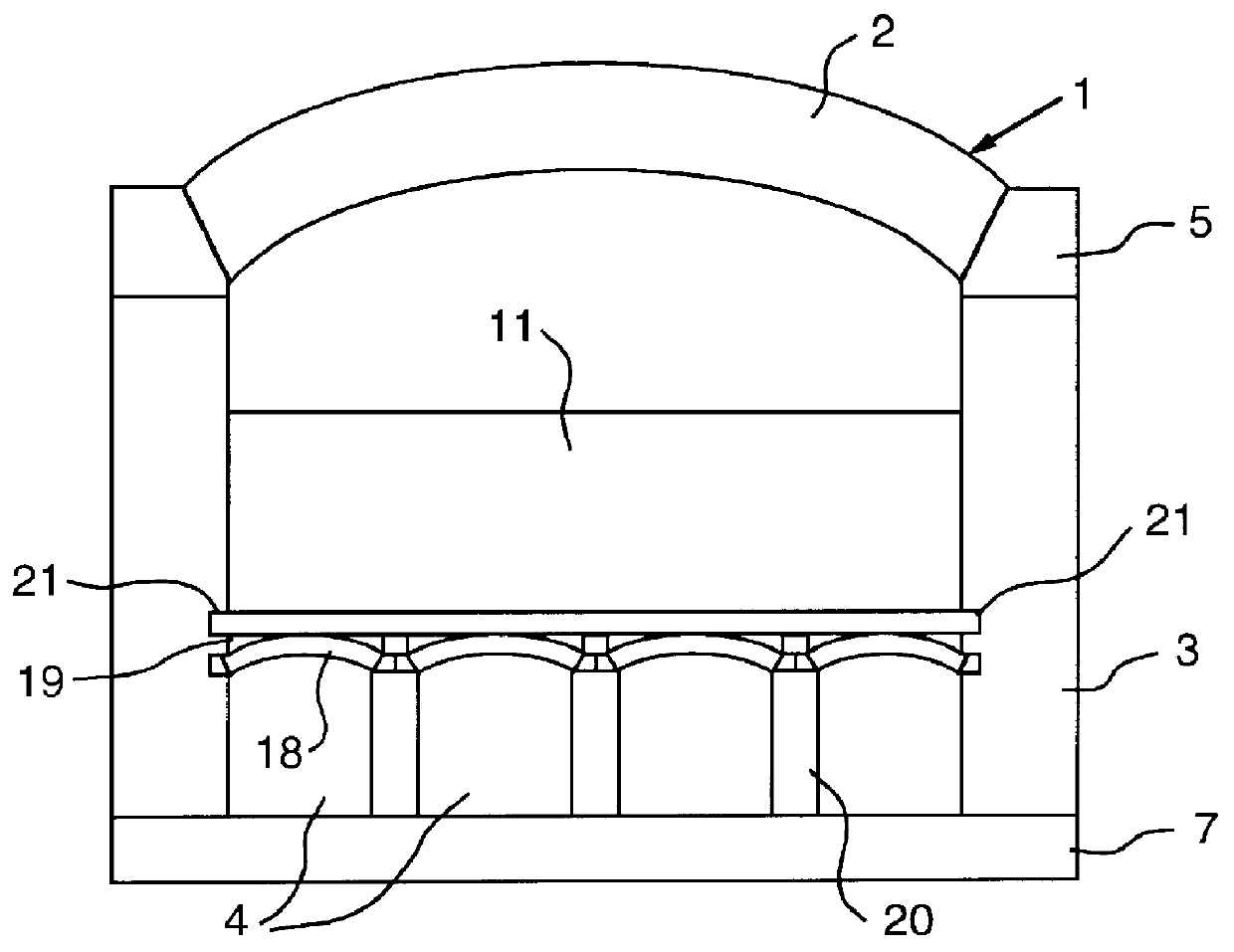

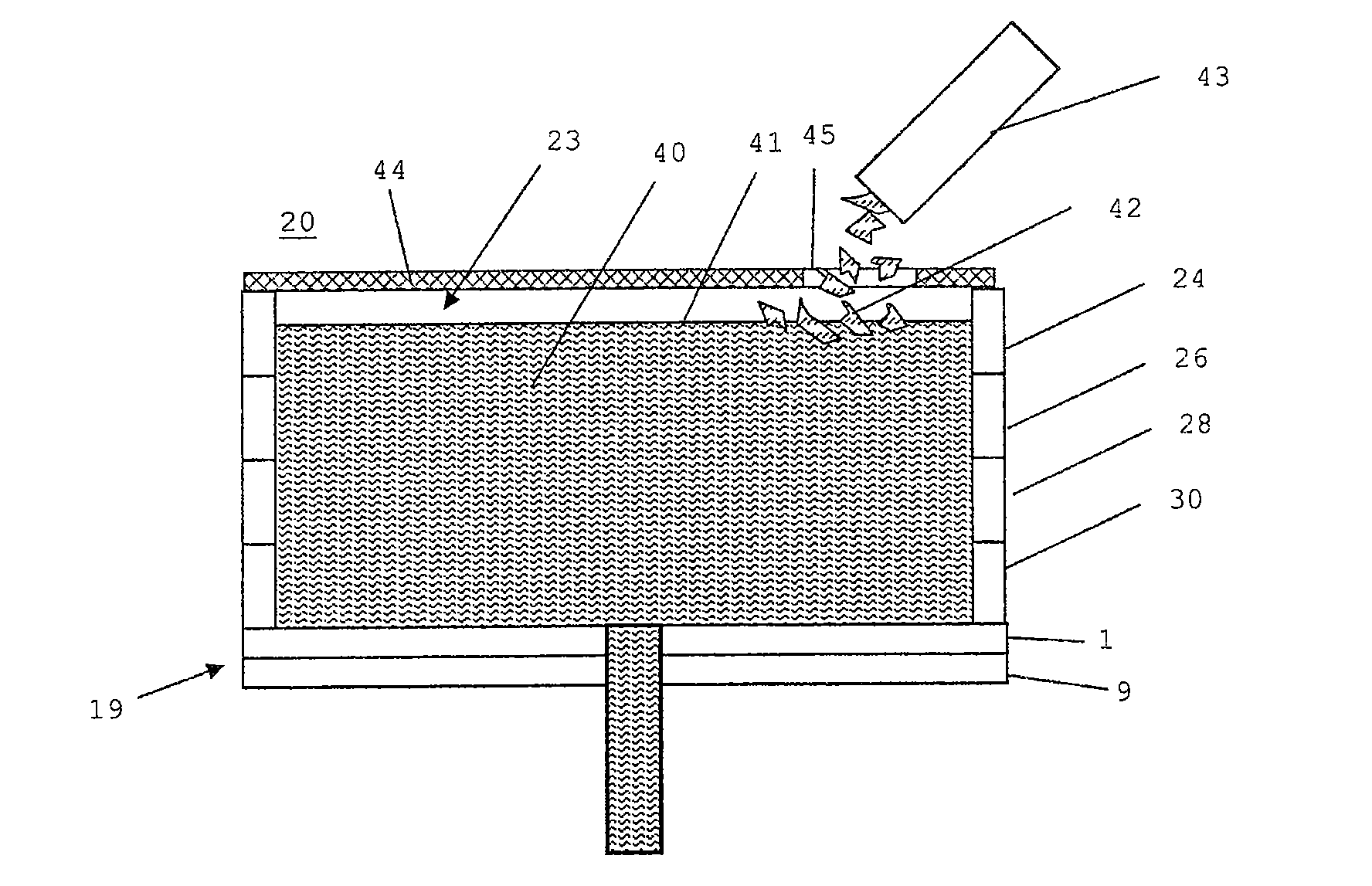

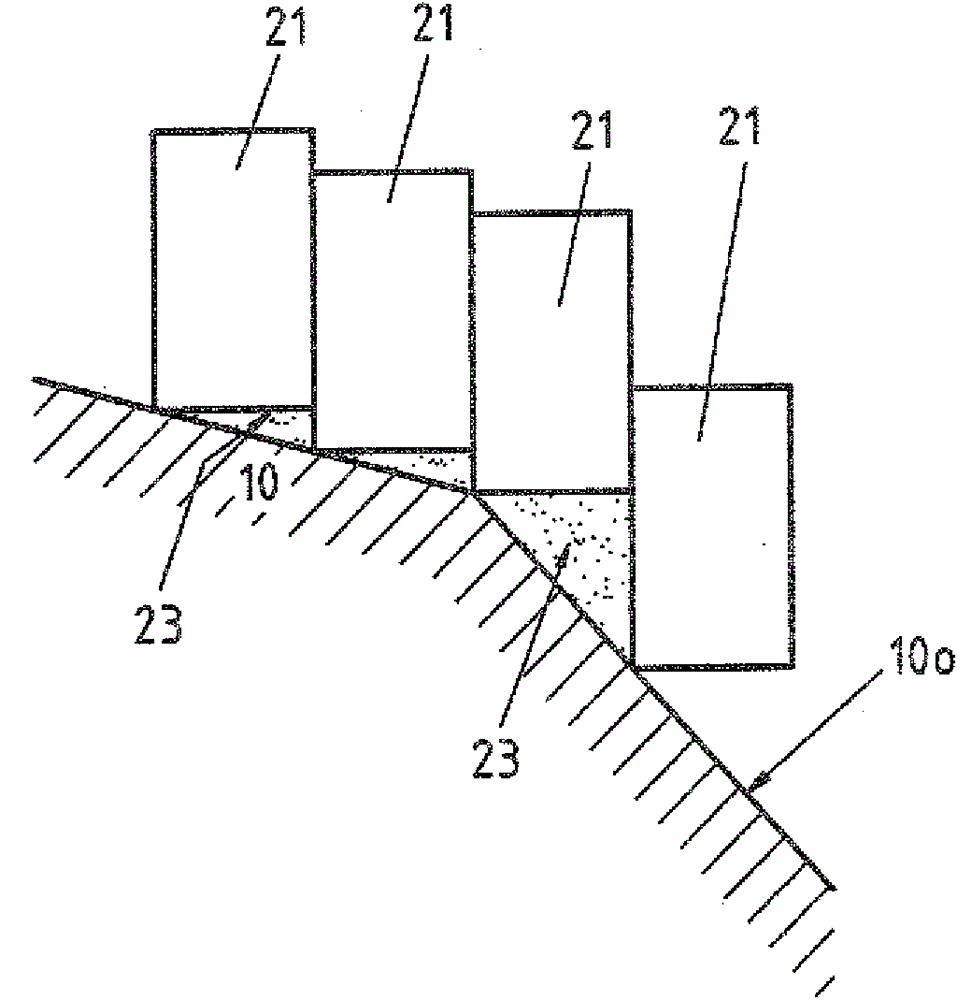

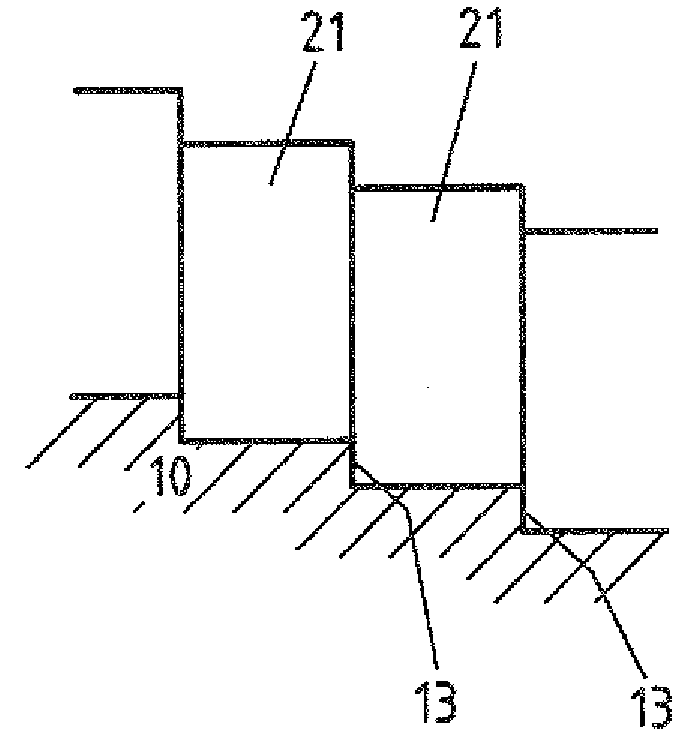

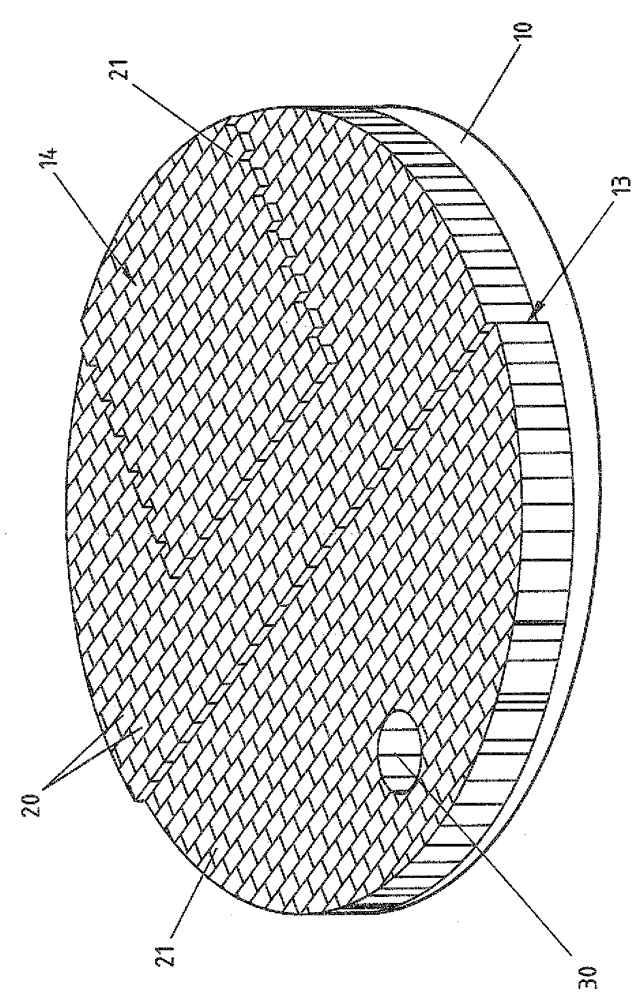

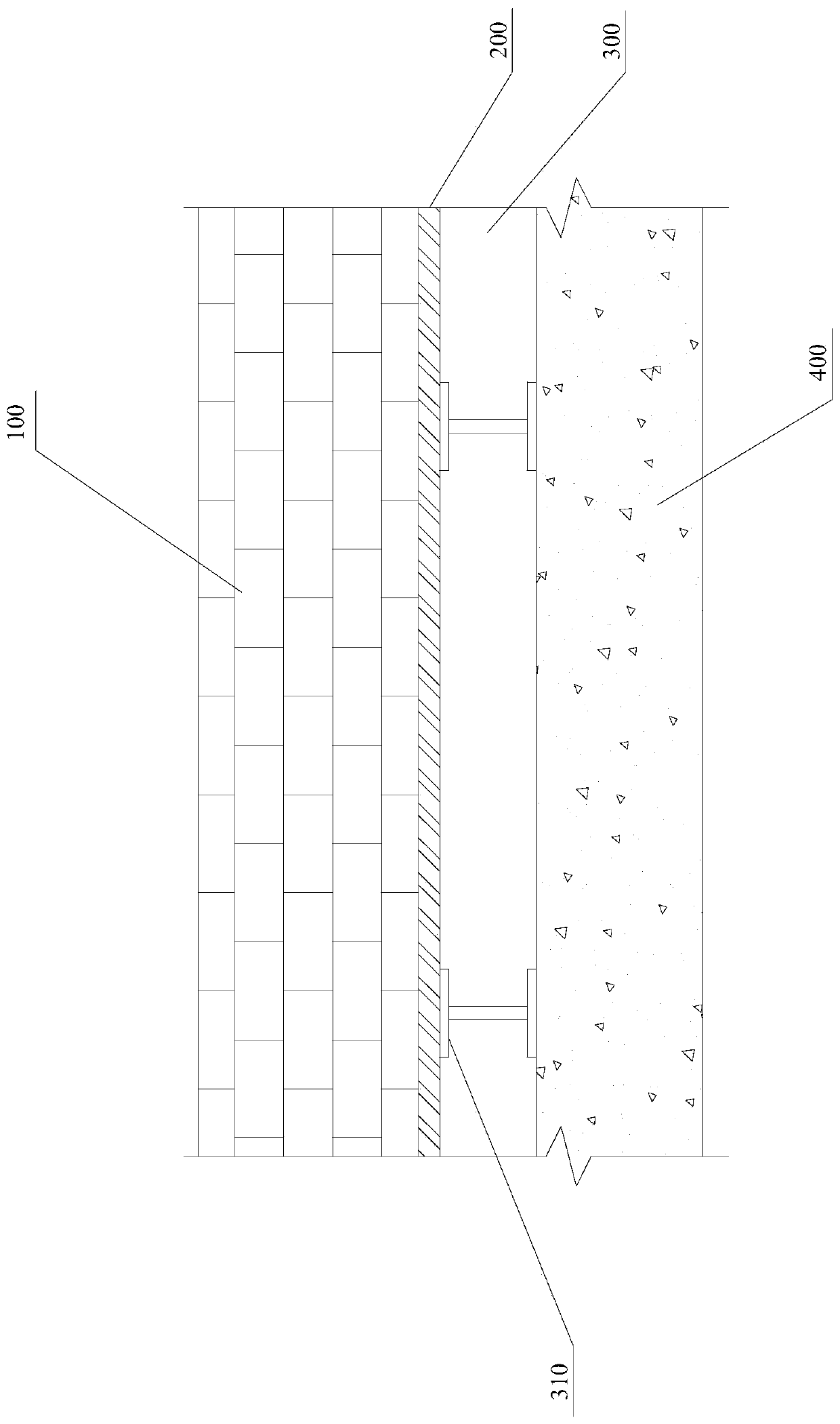

Fireproof ceramic bottom

The floor has a base that includes a lower layer of a refractory ceramic outer lining and a top layer of a refractory ceramic wearing lining (20). The outer lining has an upper surface (20o) with a three-dimensional design which is partially inclined to a horizontal by more than one adjacent to the wearing lining. The wearing lining consists of a refractory ceramic solid brick (21). The outer lining and the wearing lining include an interruption for forming a common outlet for a high-temperature melt.

Owner:REFRACTORY INTELLECTUAL PRORERTY GMBH & CO KG

Blast furnace bottom structure

InactiveCN101835910APrevent spoilagePrevent heat transferBlast furnace detailsCooling devicesEngineeringCooling pipe

Owner:NIPPON STEEL & SUMIKIN ENG CO LTD +1

Tank-cover-free type forevacuum heat treatment furnace

PendingCN114410905AAchieve heat treatmentImprove uniformityMaintainance of heating chambersSolid state diffusion coatingExhaust valveEngineering

The invention belongs to the field of metallurgical equipment, and particularly relates to a tank-cover-free type forevacuum heat treatment furnace. Comprising a furnace bottom and a furnace cover detachably mounted on the furnace bottom, and a closed space is formed after the furnace cover covers the furnace bottom; the furnace bottom is composed of a substrate and a furnace lining which is arranged above the substrate and completely located within the range of the substrate, a heating body is arranged on the furnace lining, and a supporting bottom is further arranged on the periphery of the substrate; the furnace cover is composed of an outer cover and a lining, a heating piece is arranged on the inner side wall of the lining, and after the furnace cover is closed, the outer cover is buckled downwards to abut against the supporting bottom. The furnace cover is provided with an exhaust valve used for vacuumizing, and the exhaust valve is externally connected with a vacuum pump to work, so that vacuumizing treatment of the heat treatment furnace is achieved. According to the invention, large-batch plate heat treatment can be quickly and efficiently realized, the size of the furnace body can be adjusted according to actual use requirements, and heat treatment of materials with different specifications and sizes can be realized.

Owner:浙江精瑞工模具有限公司

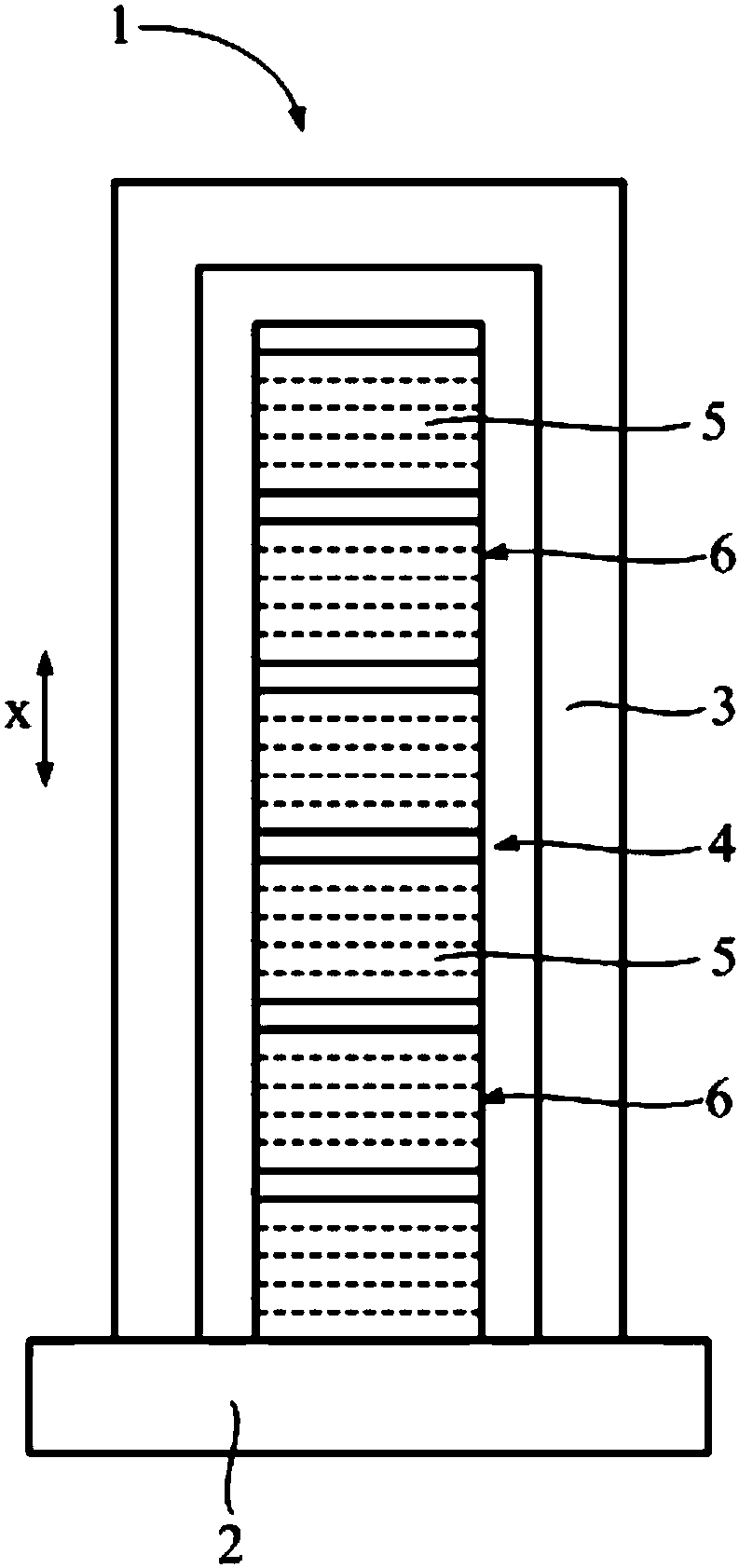

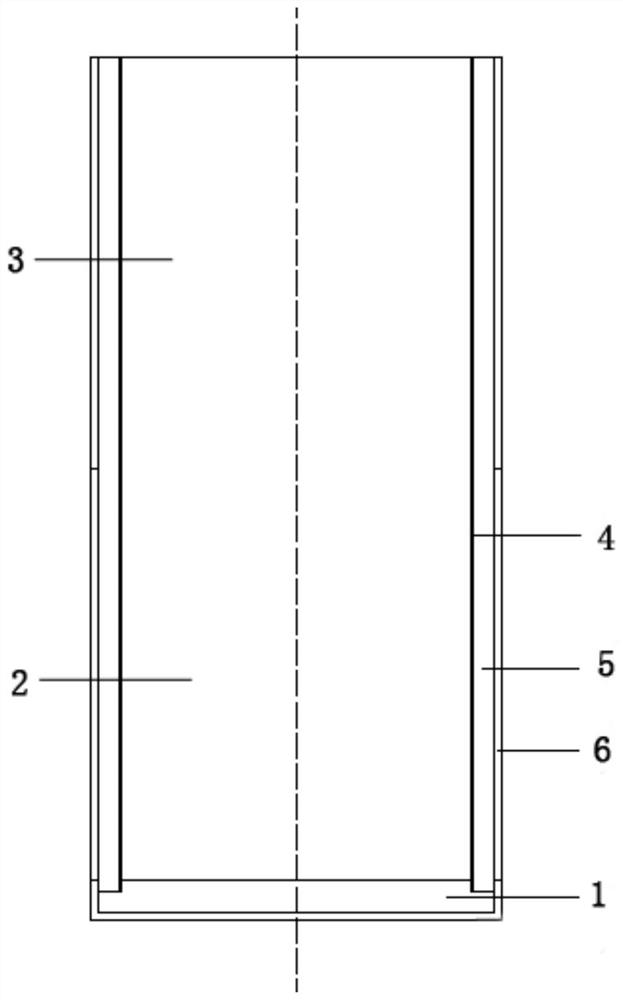

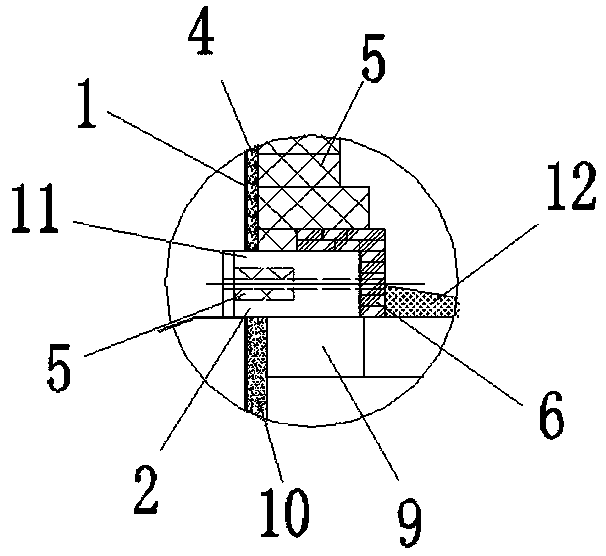

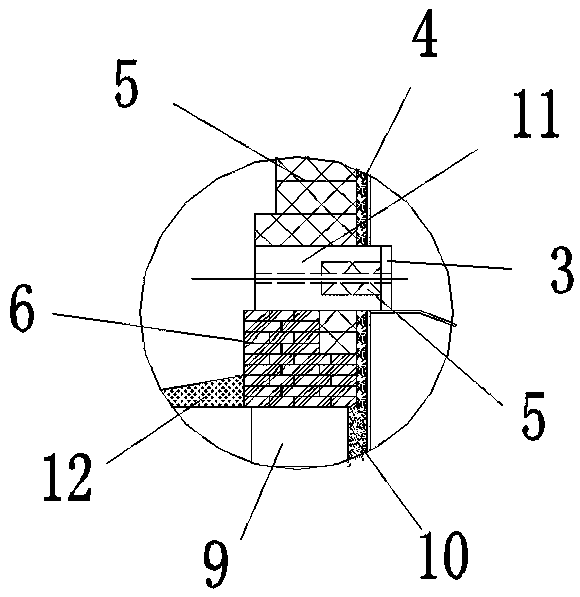

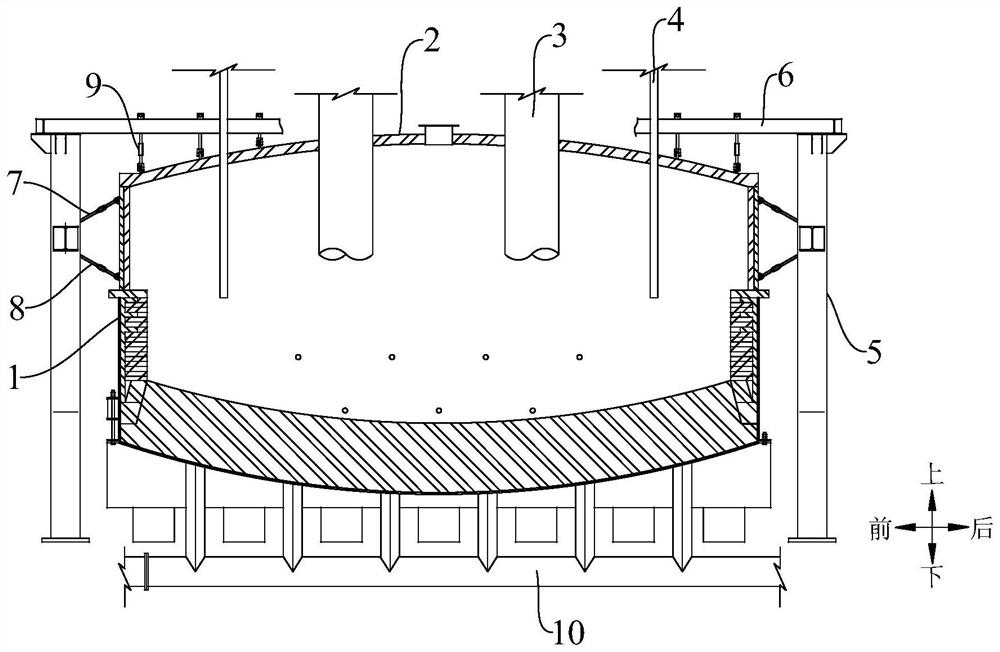

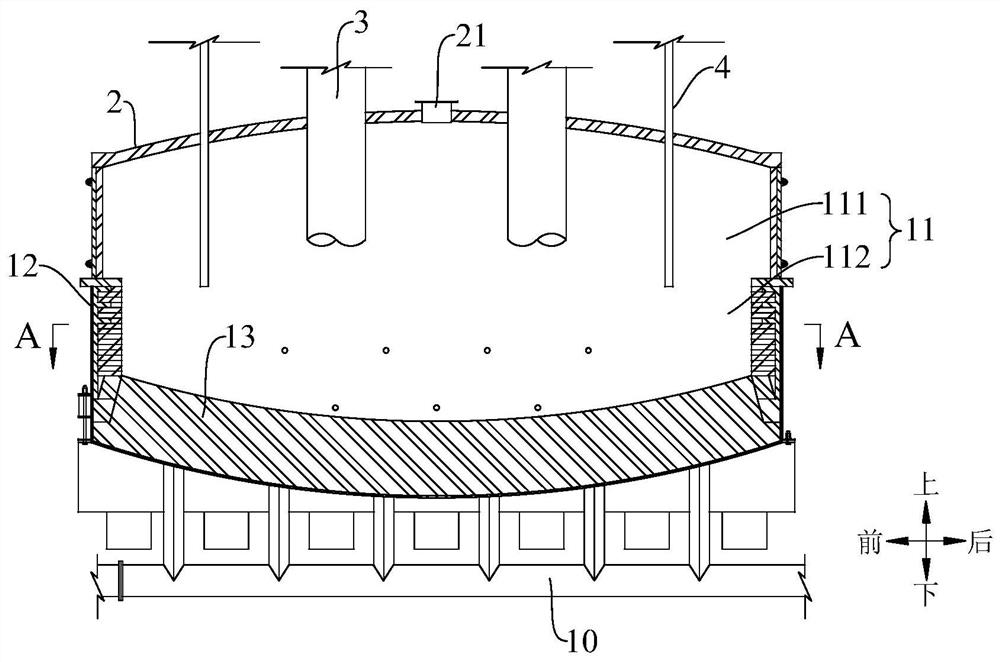

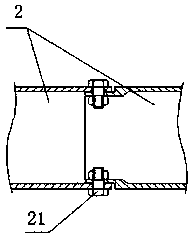

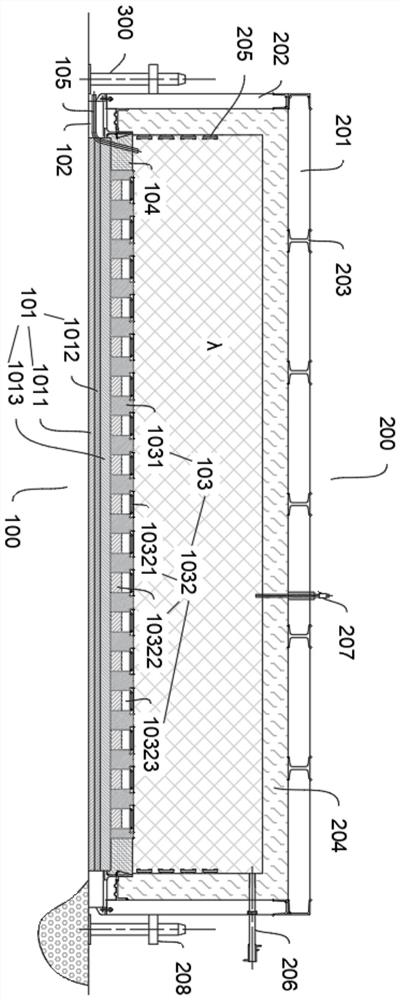

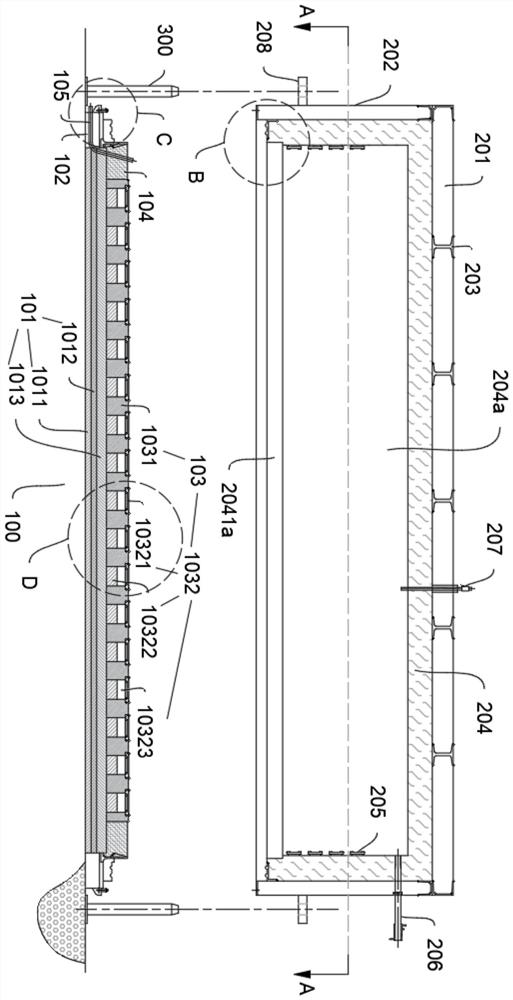

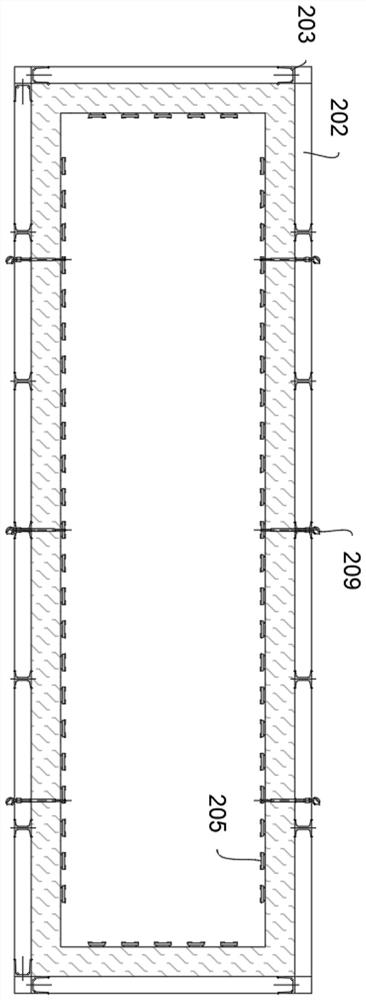

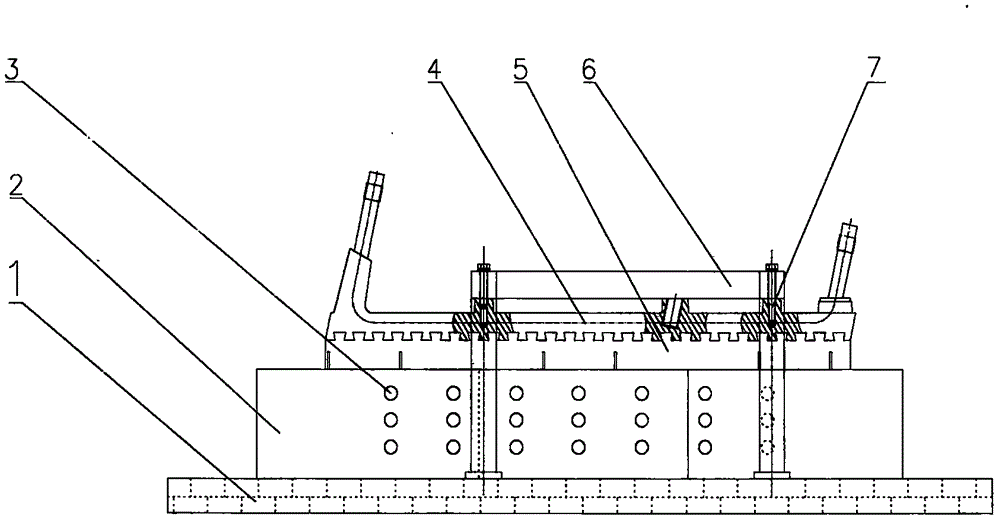

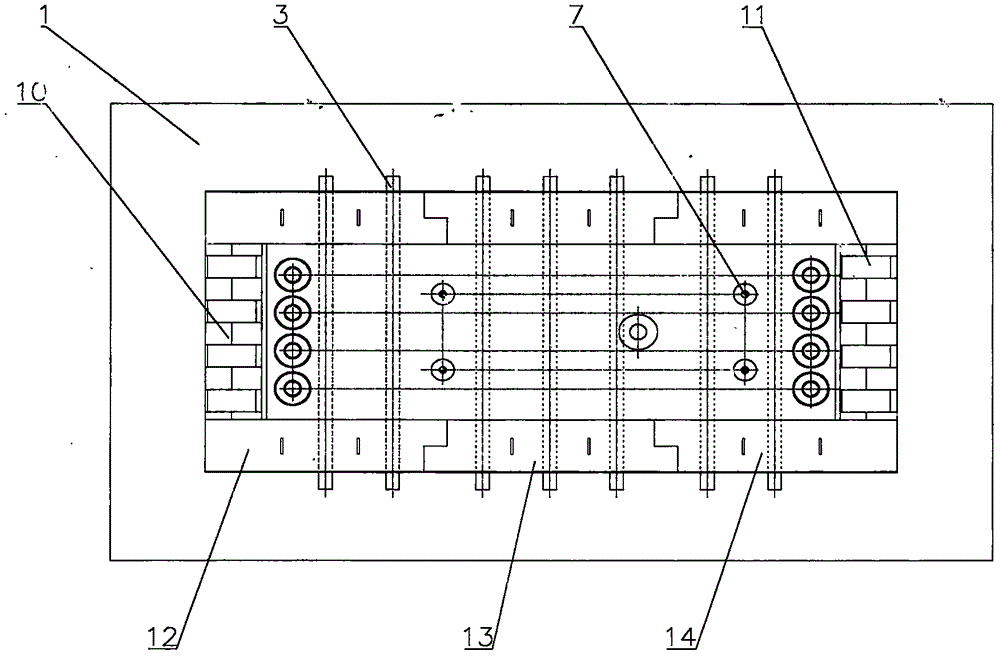

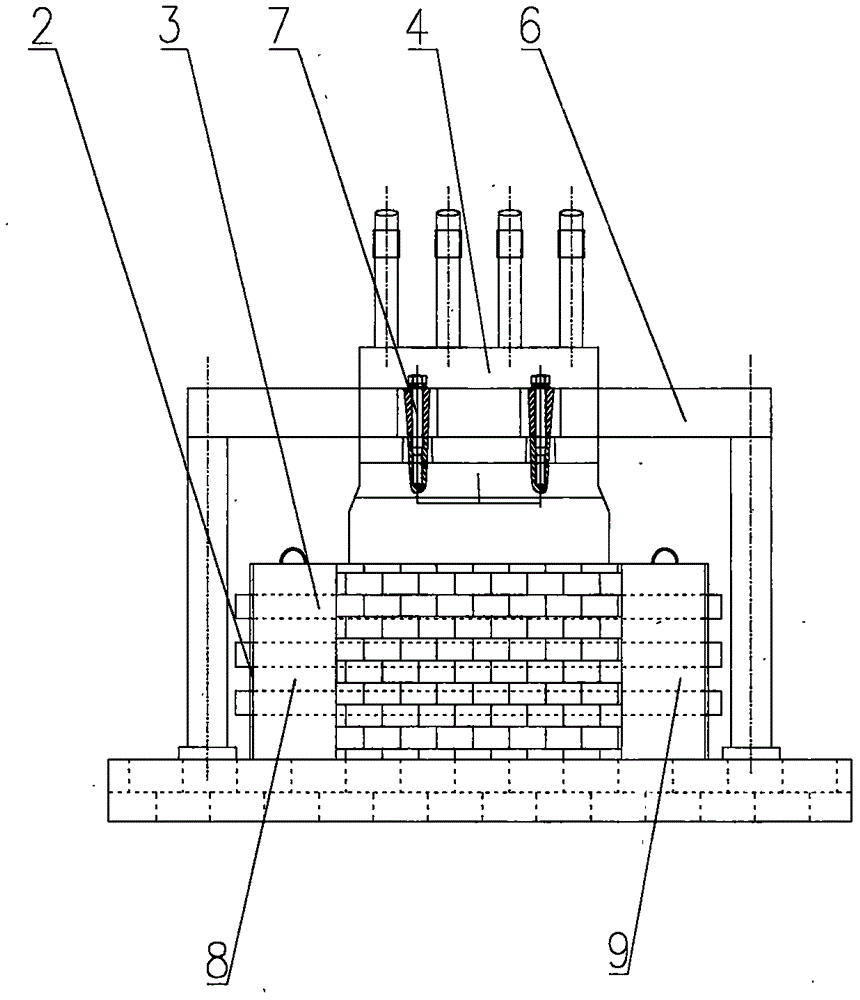

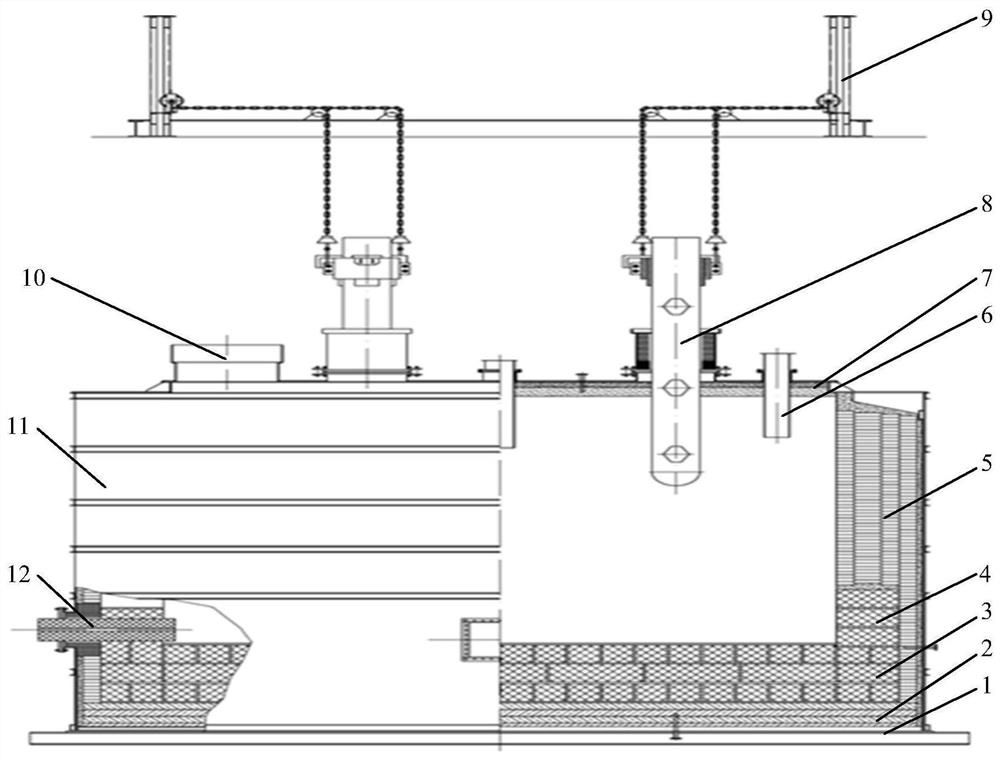

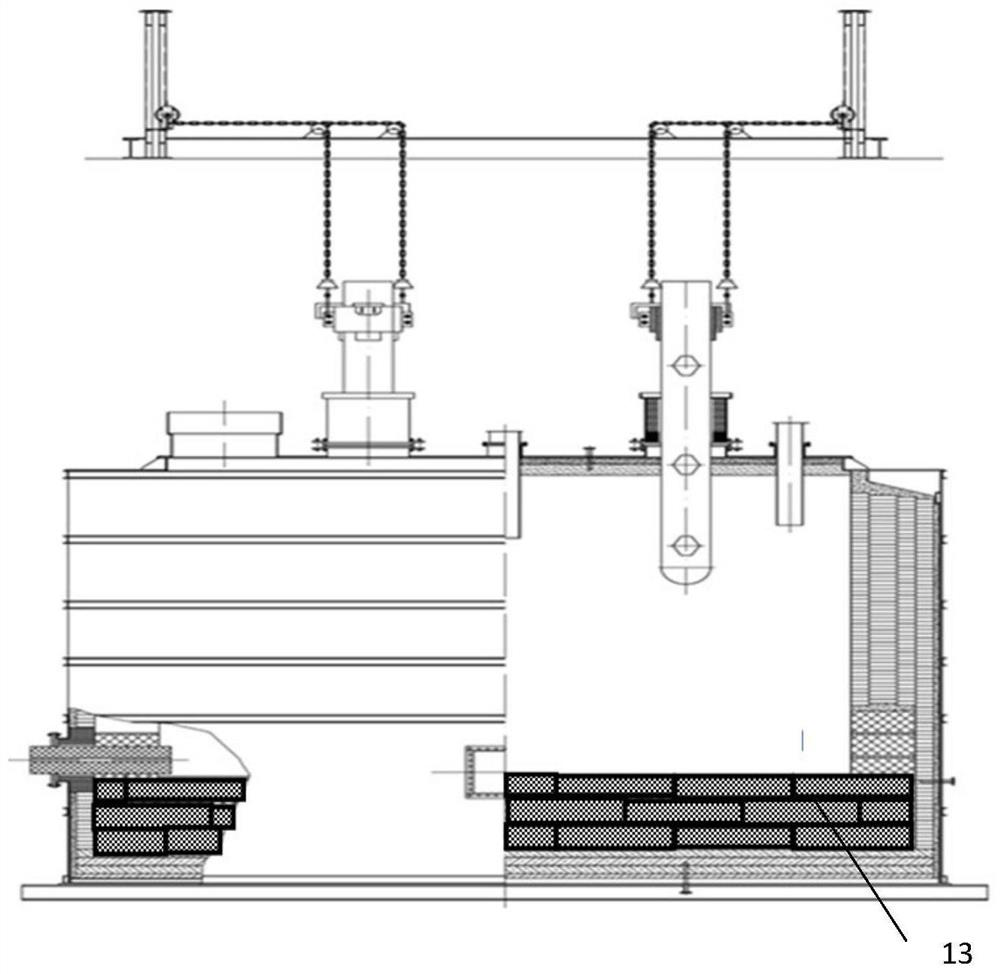

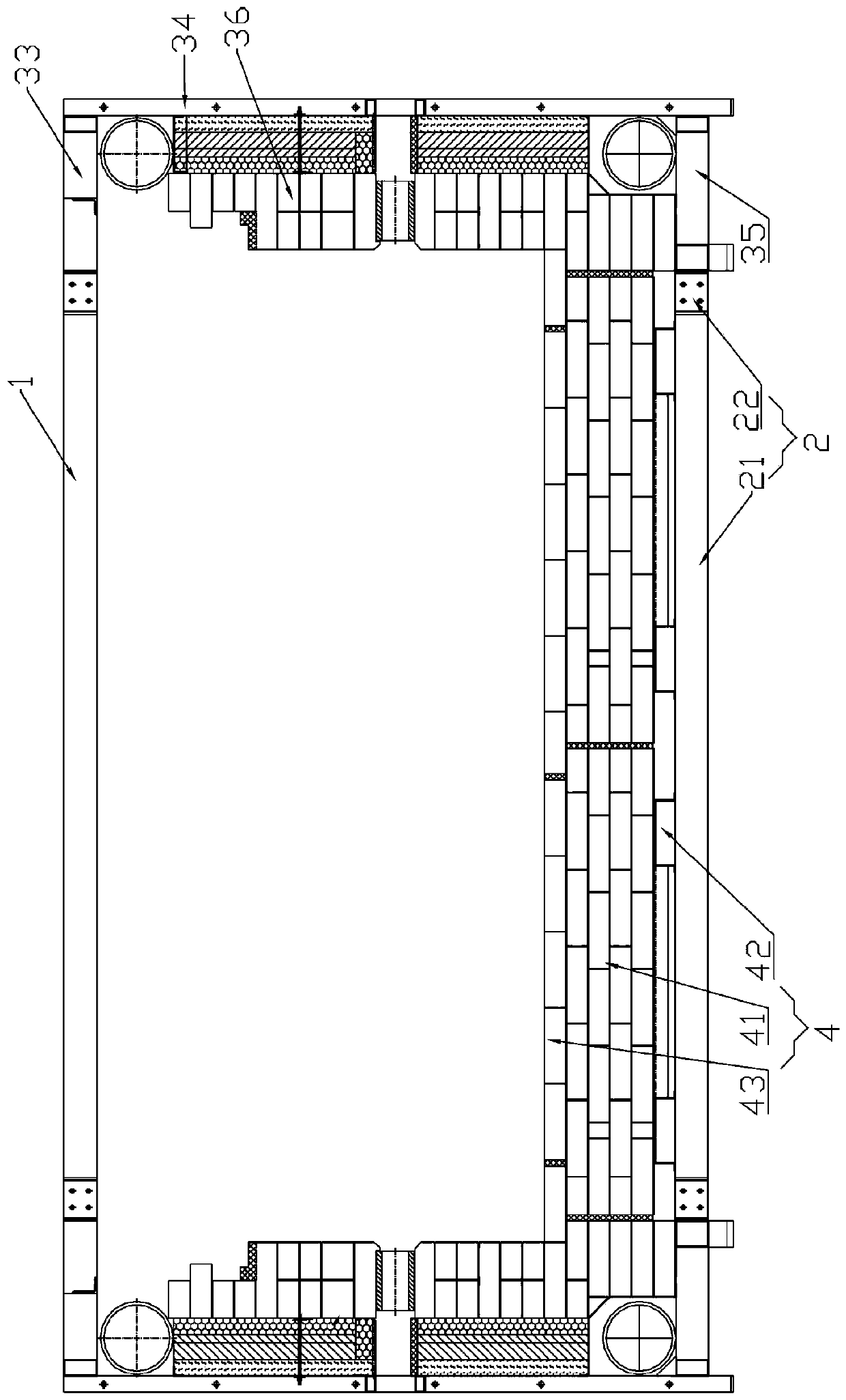

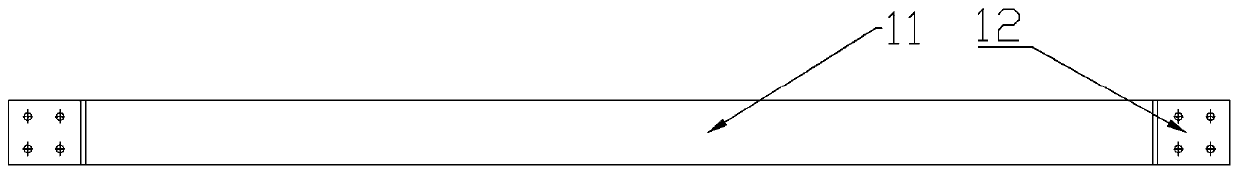

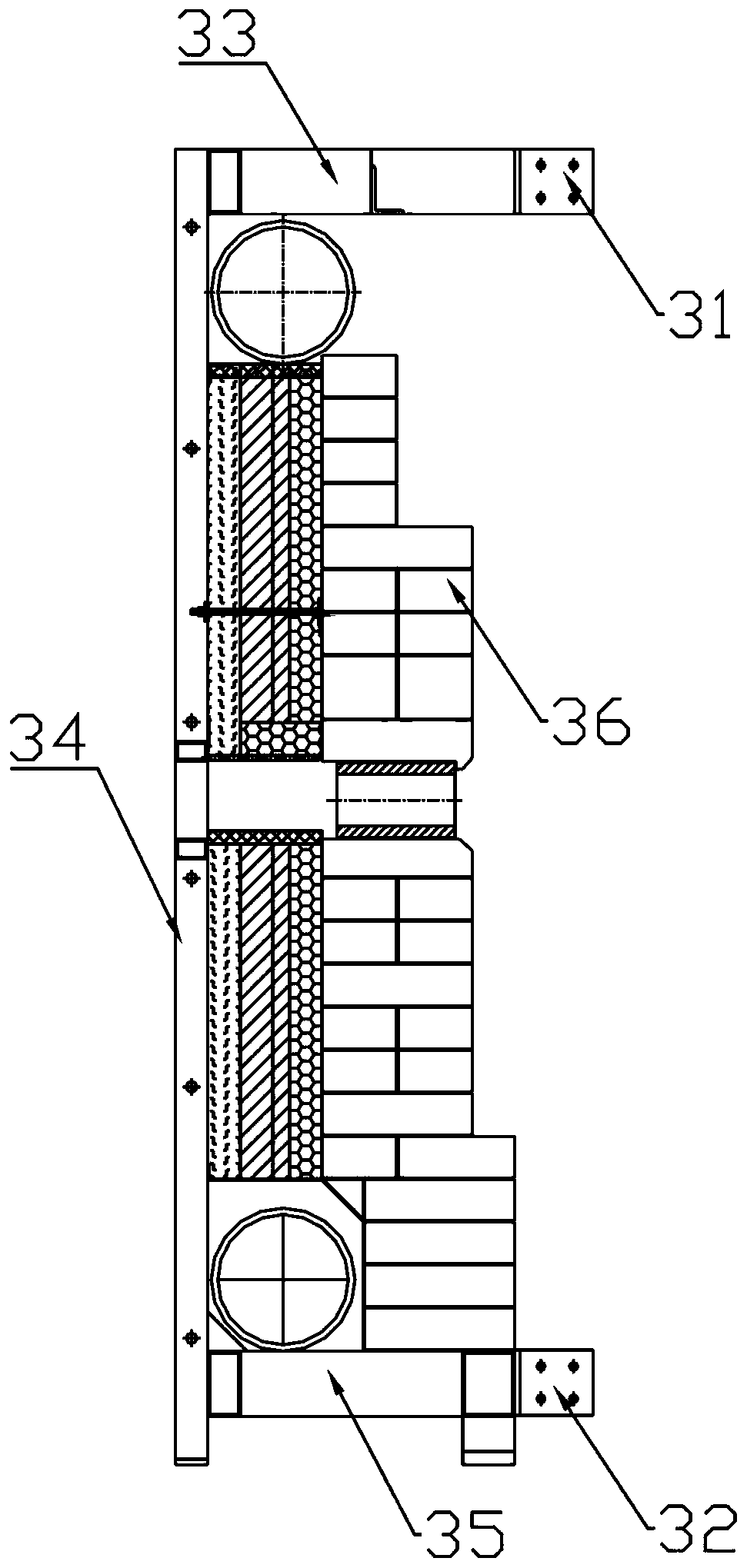

Electric furnace applicable to thermal state experiment of blast-furnace cooling staves with different sizes

ActiveCN106091692AEasy to controlLower the altitudeFurnace typesFurnace liningsElectricityThermal state

The invention relates to an electric furnace applicable to a thermal state experiment of blast-furnace cooling staves with different sizes. The technical scheme is as follows: the electric furnace applicable to the thermal state experiment of the blast-furnace cooling staves with different sizes consists of a furnace bottom (1), a furnace wall (2), a group of heating pipes (3), a cooling stave (4), an embedded brick (5) and a bearing frame (6), wherein the furnace wall (2) is a combined furnace wall with adjustable lengths and widths; the group of heating pipes (3) are installed in through holes of the furnace wall (2); the cooling stave (4) is installed on the bearing frame (6) by bolts (7) and forms a hearth together with the furnace wall (2). The electric furnace is applicable to cooling staves with different sizes, and has the characteristics of accurately controlling experimental temperature, being convenient to operate, safe and environmentally-friendly, and the like by adoption of electrical heating.

Owner:WUHAN UNIV OF SCI & TECH

Hot air circulation brazing furnace

InactiveCN109420813AEvenly heatedImprove brazing qualityPump componentsMaintainance of heating chambersHeating timeMetallurgy

The invention provides a hot air circulation brazing furnace. The hot air circulation brazing furnace comprises a furnace body. A heating cavity and a working cavity are formed in the furnace body andcommunicate with each other. A main draught fan is arranged on one side of the furnace body, gas passing through the heating cavity is introduced into the working cavity through the main draught fan,and a hot air circulation channel is formed. The gas is introduced into an inner cavity of a workpiece, and a through gas way is formed in the inner cavity of the workpiece. On one hand, a thermal circulation heating manner is combined with the workpiece with the hollow inner cavity, and the heating time can be shortened; the inner cavity of the workpiece can be directly filled with the hot gas,the temperature differences between all the positions of the workpiece are approximate, the workpiece is more evenly heated, and the brazing quality of the workpiece is greatly improved; the brazing effect is very remarkable; and on the other hand, the hot air circulation brazing furnace can be suitable for brazing, namely the occasions with the brazing atmospheres higher than 450 DEG C.

Owner:张跃

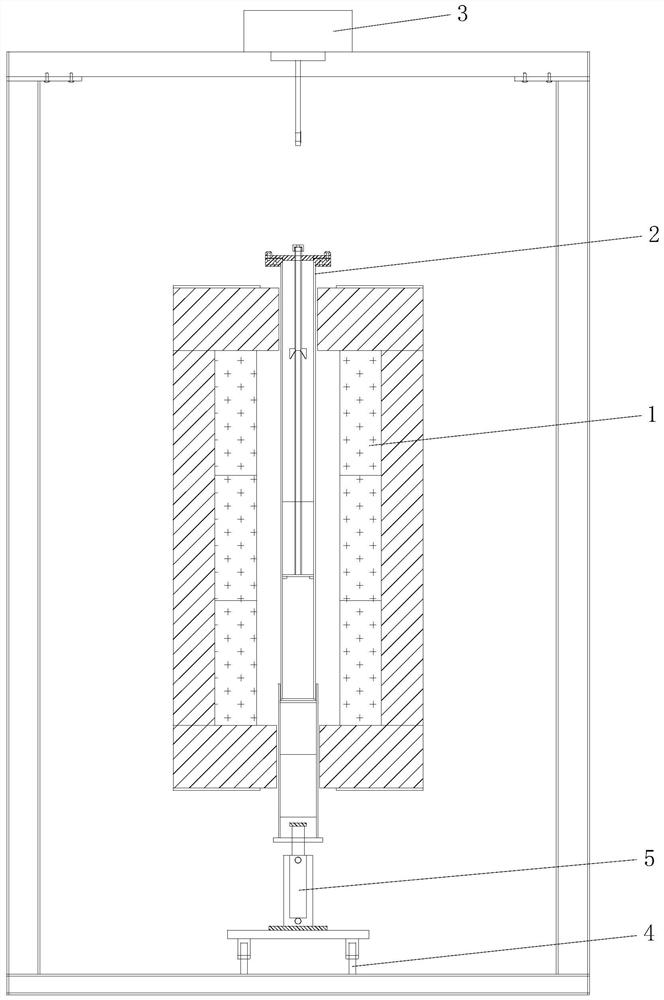

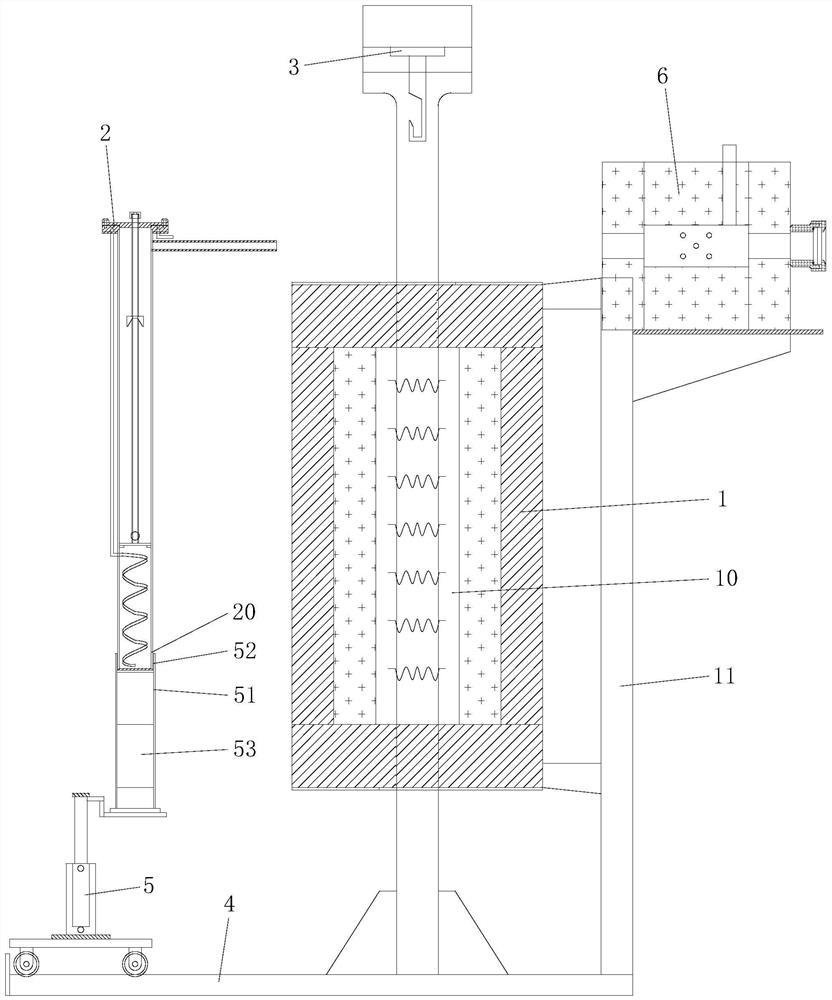

Reduction furnace

ActiveCN111692883ARealize loading and unloadingEasy loading and unloadingCharge supportsFurnace typesProcess engineeringHearth

The invention discloses a reduction furnace. The reduction furnace comprises a heating furnace, a reduction tank and a hanging-type weighing device, wherein the heating furnace is provided with a hearth capable of being opened and closed; and the hanging-type weighing device is fixedly arranged above the hearth and used for hanging the reduction tank in the hearth. The reduction furnace further comprises a tank loading-unloading device used for moving the reduction tank into the hearth and hanging the reduction tank onto the hanging-type weighing device, and taking down the reduction tank fromthe hanging-type weighing device and moving the reduction tank out of the hearth. The reduction furnace has the advantages of being long in service life, high in treatment efficiency, high in weighing stability and accuracy, convenient to overhaul and maintain, and the like.

Owner:CENT SOUTH UNIV

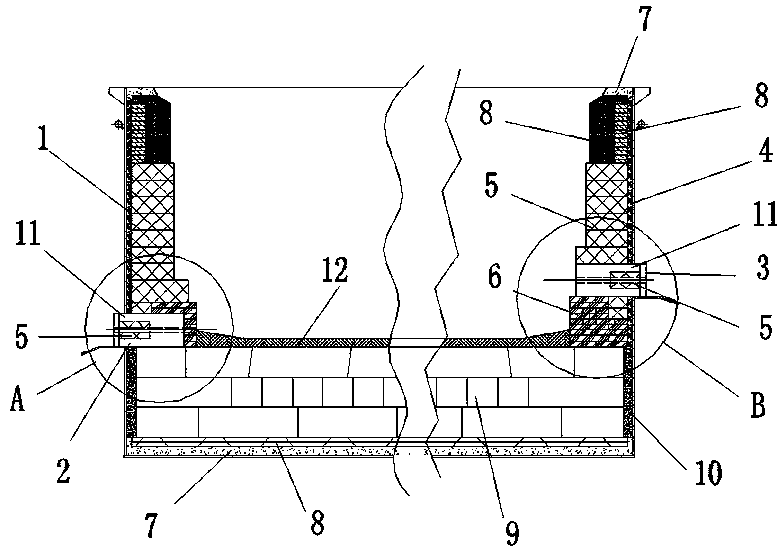

Furnace bottom structure of regenerative pusher type reheating furnace

PendingCN110849147AAvoidance of damageAvoid overheating damageFurnace typesFurnace floorsSolid structureHeating furnace

The invention provides a furnace bottom structure of a regenerative pusher type reheating furnace. The furnace bottom structure of the regenerative pusher type reheating furnace comprises a refractoryheat preserving layer, a heat insulating structure and a supporting structure from top to bottom in sequence; the heat insulating structure is of a solid structure; the upper surface of the heat insulating structure is connected with the lower surface of the refractory heat preserving layer; and the lower surface of the heat insulating structure is connected with the upper surface of the supporting structure. According to the furnace bottom structure of the regenerative pusher type reheating furnace provided by the invention, a furnace bottom steel plate in the furnace bottom structure in theprior art is cancelled, so that the situation that a furnace body steel structure is damaged because of the deformation of the furnace bottom steel plate when the refractory heat preserving layer isburnt through is avoided fundamentally; meanwhile, the heat insulating structure of the solid structure is arranged between the refractory heat preserving layer and the supporting structure, so that the supporting structure can be effectively subjected to heat insulating protection through the heat insulating structure when the refractory heat preserving layer is burnt through; and therefore, thesituation of overheating damage of the supporting structure is effectively avoided.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

Construction method of yellow phosphorus electric furnace bottom

ActiveCN112097524AImprove machining accuracyProblems in Realizing Construction Quality Control AccuracyElectric heating for furnacesFurnace floorsGraphite electrodeGraphite

The invention relates to a construction method of a yellow phosphorus electric furnace bottom. The construction method comprises the following steps of connecting a plurality of graphite electrodes toobtain the assembled graphite electrodes, laying a plurality of layers of assembled graphite electrodes at the furnace bottom, and filling electrode paste into gaps between every two adjacent layersof graphite electrodes. According to the method, the problem of control precision of the construction quality of a carbon material at the furnace bottom is solved, and the problem of furnace bottom burn-through accidents caused by improper material selection, masonry and baking of the carbon material of the yellow phosphorus electric furnace bottom is successfully solved.

Owner:SCEGC EQUIP INSTALLATION GRP COMPANY

Detachable single kiln body of roller kiln

PendingCN111207590ASave shipping spaceReduce shipping costsFurnace typesFurnace crowns/roofsIndustrial engineeringKiln

The invention discloses a detachable single kiln body of a roller kiln. The detachable single kiln body comprises a kiln top connecting beam, a kiln bottom unit and a kiln wall unit, wherein the kilntop connecting beam comprises first angle steel; the kiln bottom connecting beam comprises second angle steel; the kiln wall unit comprises third angle steel and fourth angle steel; the third angle steel is arranged at the top of the kiln wall unit; the fourth angle steel is arranged at the bottom of the kiln wall unit; the first angle steel and the third angle steel are connected through a bolt;the second angle steel and the fourth angle steel are connected through a bolt; and the kiln bottom unit is arranged at the top of the kiln bottom connecting beam. The single kiln body of the roller kiln is of a detachable structure, so that the space occupied during transportation can be greatly reduced, and the transportation cost is reduced; and moreover, the detachable single kiln body does not need to be assembled in a factory, so that the space of a factory building can be saved, and the utilization rate of the production space of the factory building is improved.

Owner:MODENA TECH LTD

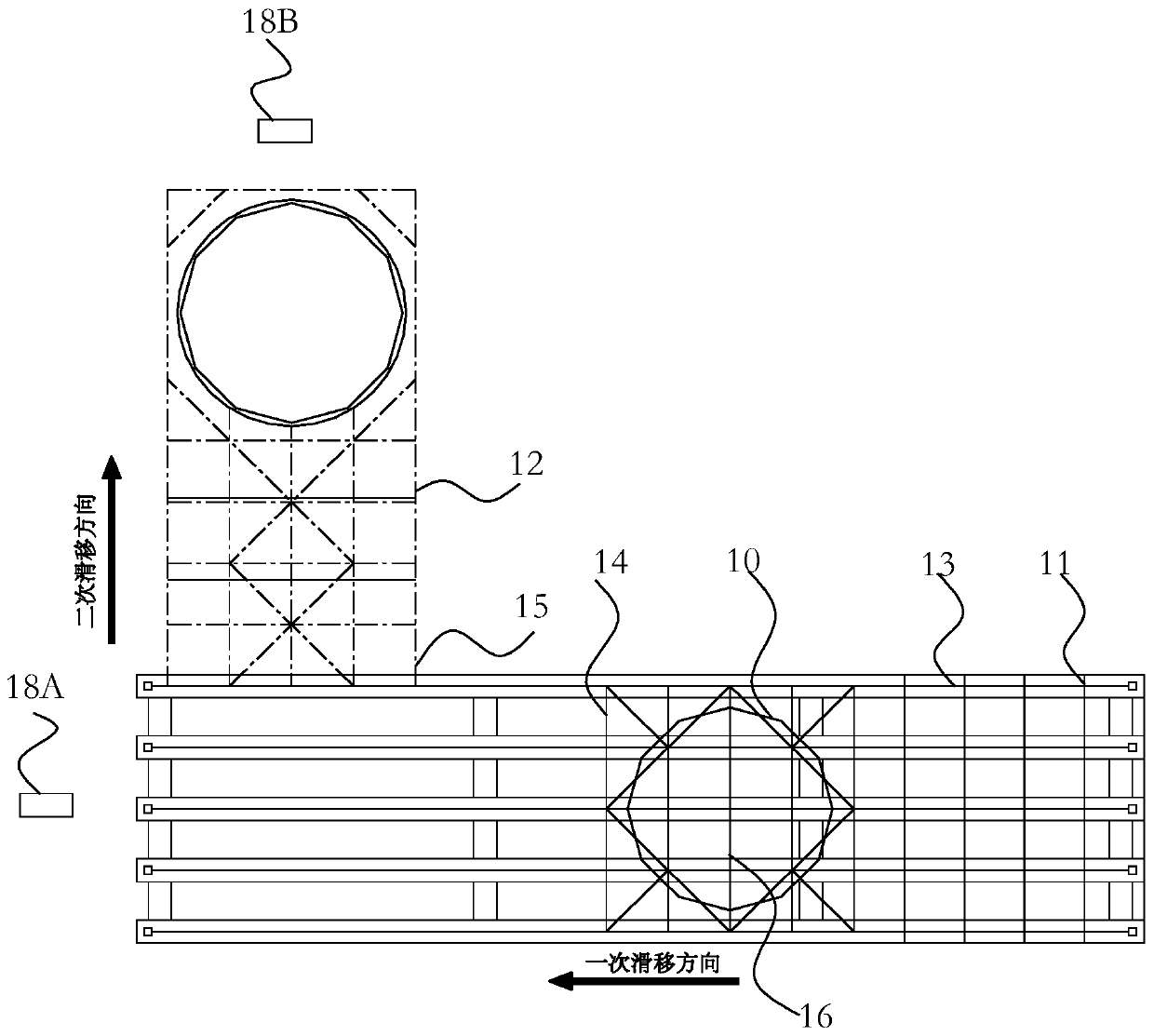

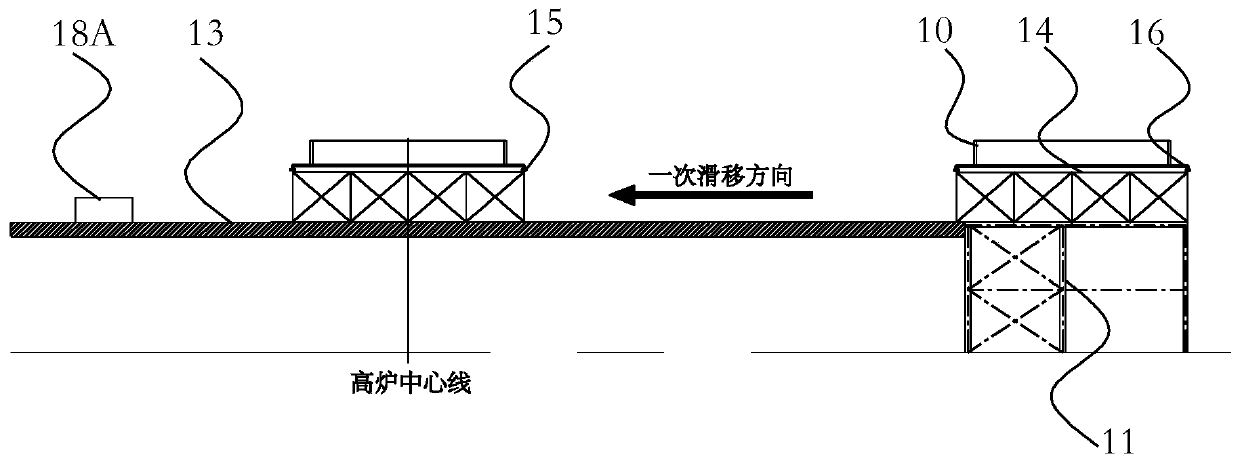

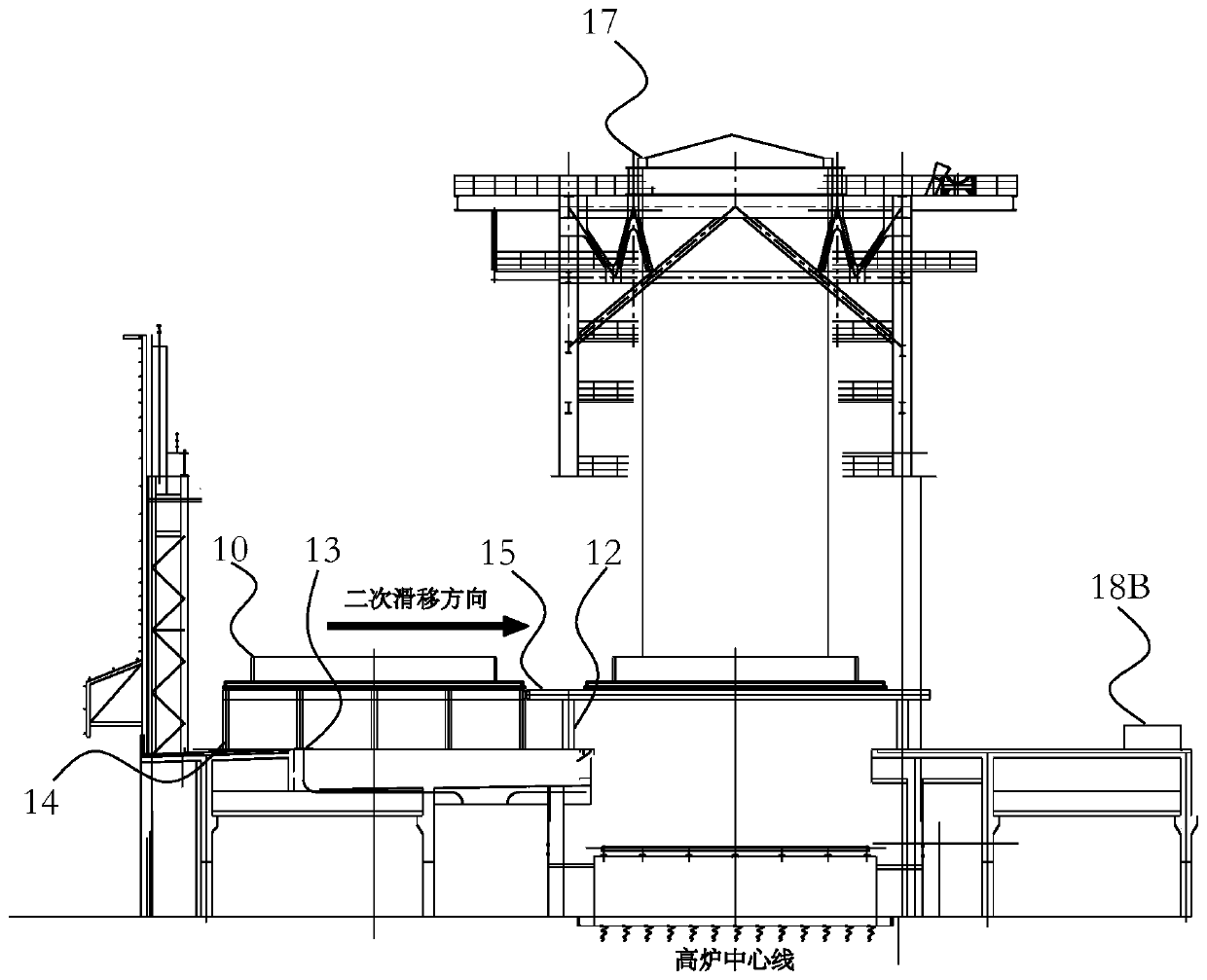

Transportation system and method for blast furnace shell

InactiveCN110592300AEasy to installFlexible operationBlast furnace componentsBlast furnace detailsMechanical engineeringBuilding construction

The invention relates to a transportation system and method for a blast furnace shell. The transportation system comprises a material receiving platform arranged outside a casting house and a furnacebody surrounding frame arranged at the periphery of the center of a casting house furnace body frame, wherein a primary sliding rail is arranged on the material receiving platform and a casting houseplatform, a sliding truss is arranged on the primary sliding rail, a secondary sliding rail is arranged above the sliding truss and the furnace body surrounding frame, the extending direction of the primary sliding rail is intersected with the extending direction of the secondary sliding rail, a sliding vehicle is arranged on the sliding truss, and the sliding vehicle transports the furnace shellfrom the material receiving platform to the mounting position on the secondary sliding rail through the primary sliding rail. The system and method have the advantages of low construction cost and high safety.

Owner:SHANGHAI BAOYE CONSTR INDAL FURNACE ENG TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com