Method and device for continuous melting or refining of melt

A melt and pre-melt technology, applied in glass melting devices, lighting and heating equipment, furnace types, etc., can solve problems such as short service life, and achieve the effects of easy processing, rapid refining and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

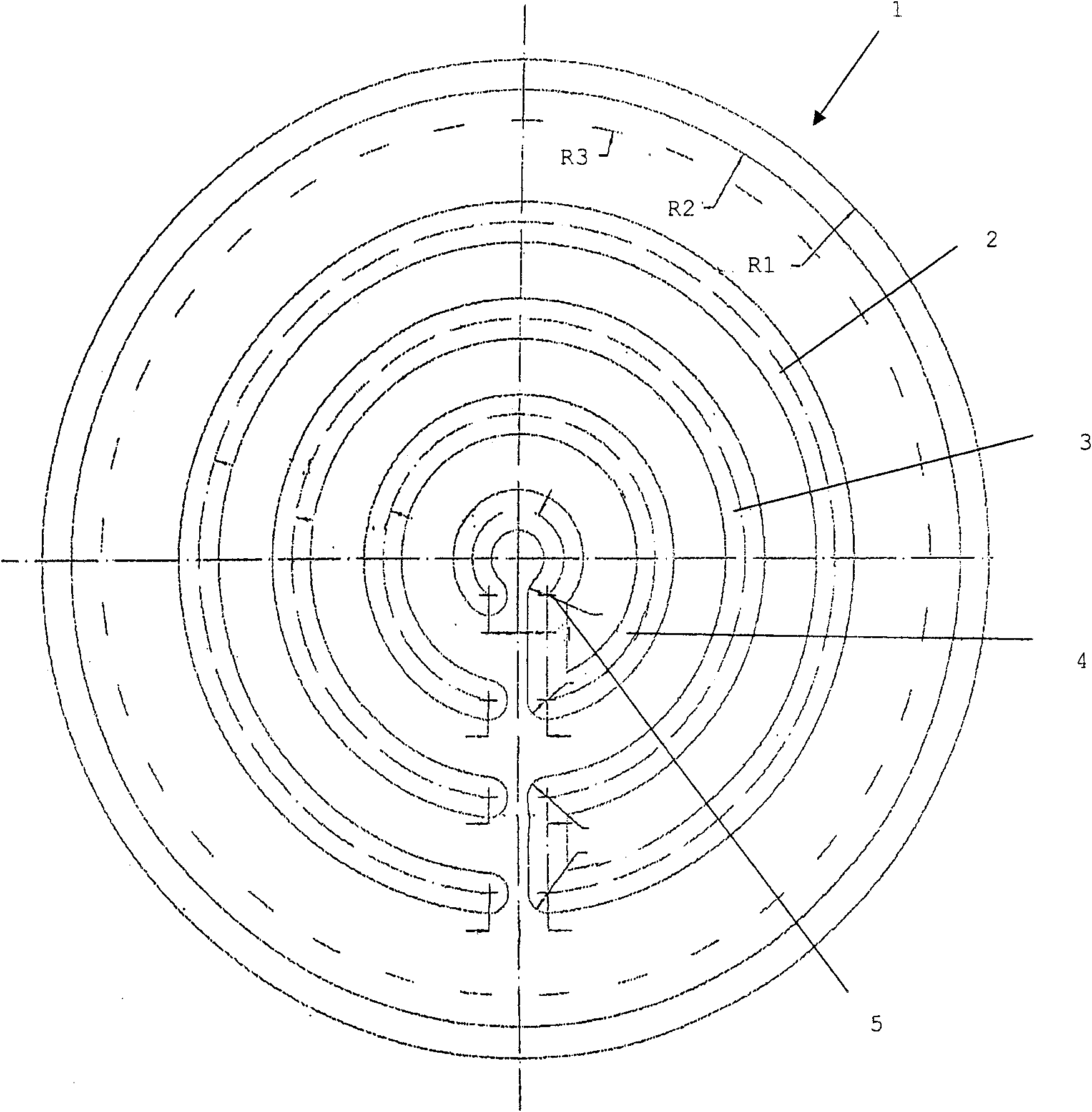

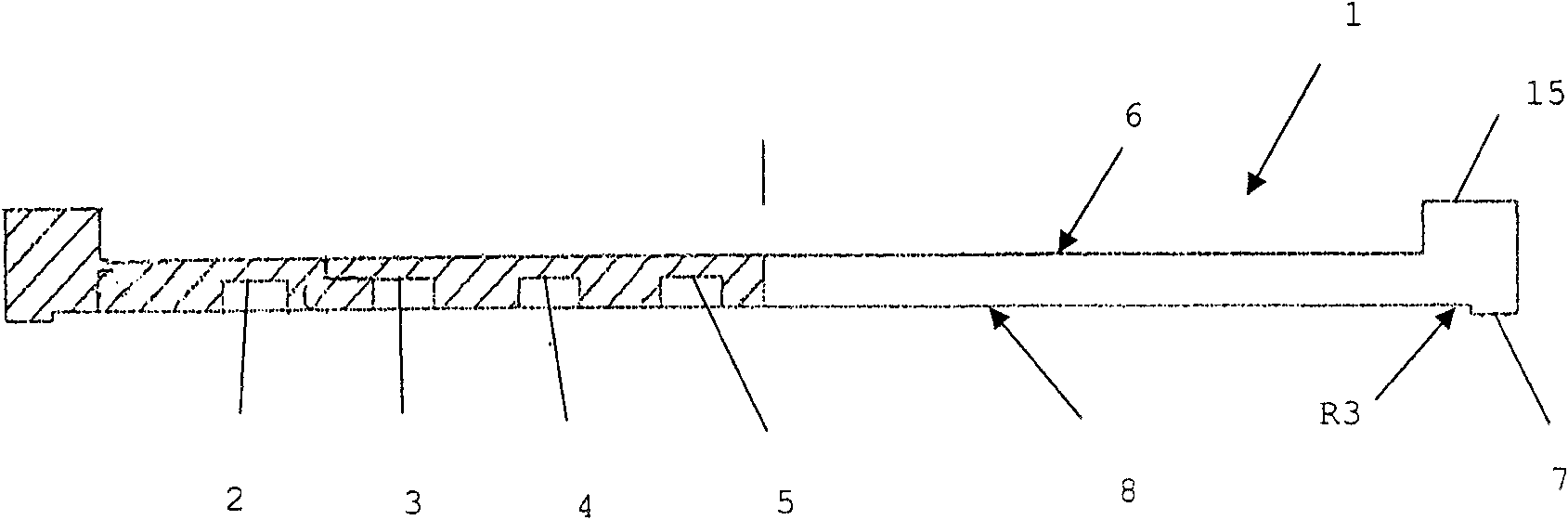

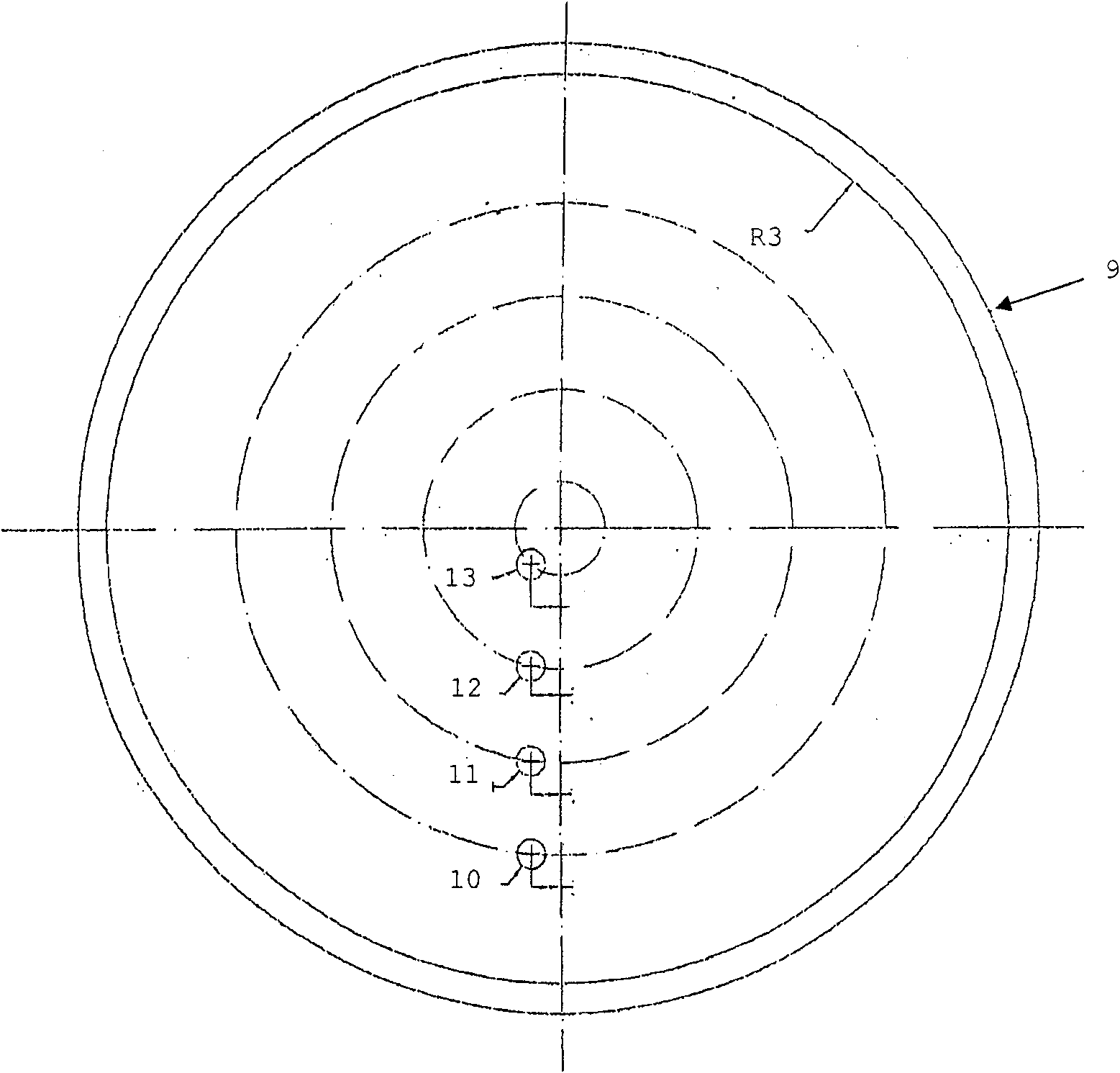

Method used

Image

Examples

Embodiment 1

[0230] The composition and typical material properties of Example 1 are shown in Table 1.

[0231] Due to the high concentration of B 2 o 3 and ZnO and because of the low viscosity of this material, melting in conventional ceramic refractory materials such as eg quartz glass is completely ruled out, since these materials will completely dissolve in the melt in a very short time.

[0232] Therefore, the unit will be completely destroyed.

[0233] It may also not be possible to conduct smelting in vessels made of precious metals, since leached metals would interfere or eliminate the electrical properties of the product.

[0234] Although the melting process in a conventionally used shell-crucible high-frequency unit would avoid said disadvantages and provide a satisfactory glass quality, however, in addition to the previously described technical disadvantages of said units (two cooling circuits, spark discharge , no-load power losses at the tube and shell crucibles, complex a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com