Method and device for preparing high-silicon silicon steel sheet in static magnetic field with powder sintering method

A technology of high-silicon steel sheet and sintering method, which is applied in the direction of magnetic materials, magnetic objects, inorganic materials, etc., to achieve high orientation and anisotropy, good magnetic properties, and ensure the effect of purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The following are specific embodiments of the present invention.

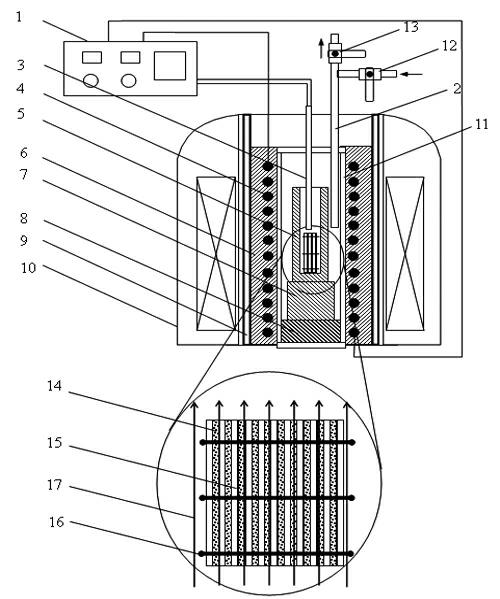

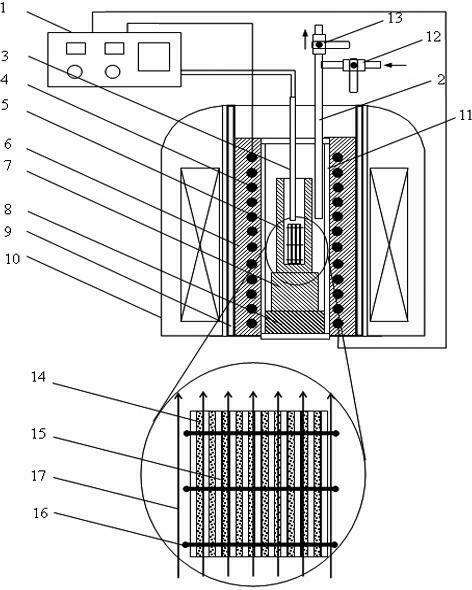

[0024] A preferred embodiment of the present invention is: see appended figure 1 .

[0025] Weigh 18700g of micron-sized iron powder and 1300g of nano-sized pure silicon powder according to the ratio of silicon weight content of 6.5%, and put them into a V-shaped mixer for mixing. The mixing speed is 70r / min, and the mixing time is 10h. , During the mixing process, argon protection is passed through the mixer. After the mixing is completed, take out the uniformly mixed Fe-Si powder, and press-roll it into multiple pieces of Fe-6.5wt%Si powder slabs with a size of 80mm×80mm×50mm.

[0026] In the method for preparing 6.5% high-silicon silicon steel sheet by powder sintering under a constant magnetic field, the sintering process is realized by an atmosphere / vacuum protection high-temperature sintering device under a constant magnetic field. see figure 1 . The atmosphere / vacuum sintering device under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com