Cement clinker doped with tailing slag and ash slag and preparation method thereof

A technology of cement clinker and production method, which is applied in the direction of cement production, etc., which can solve the problems of affecting the economic benefits of cement enterprises, rising limestone costs, and high limestone consumption, so as to achieve the effects of ensuring strength, improving flammability, and alleviating resource pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1. Preparation of raw meal: The raw meal is weighed according to the following raw materials by weight: limestone 79.0%, high-silica sandstone 4.8%, low-silica sandstone 10.7%, smelting slag 2.0%, tailing slag 2.0%, ash 1.5%, all raw materials Grinding, 0.08mm sieve fineness control ≤17%, 0.2mm sieve fineness ≤2.0%;

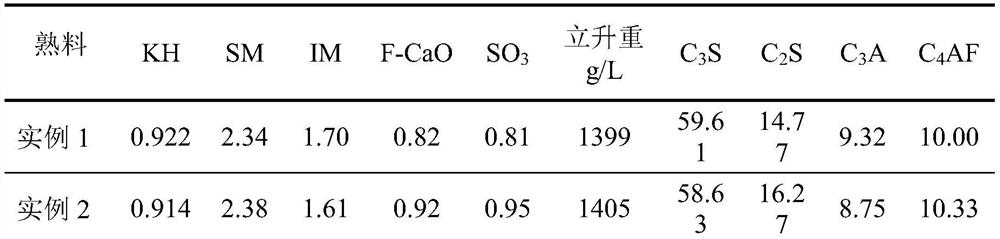

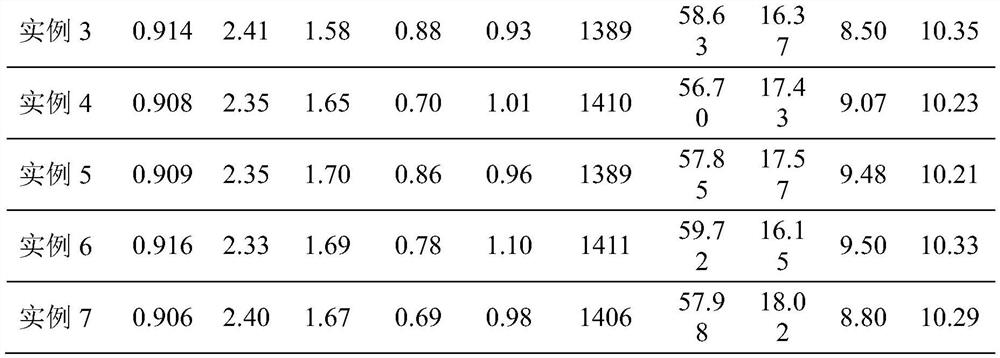

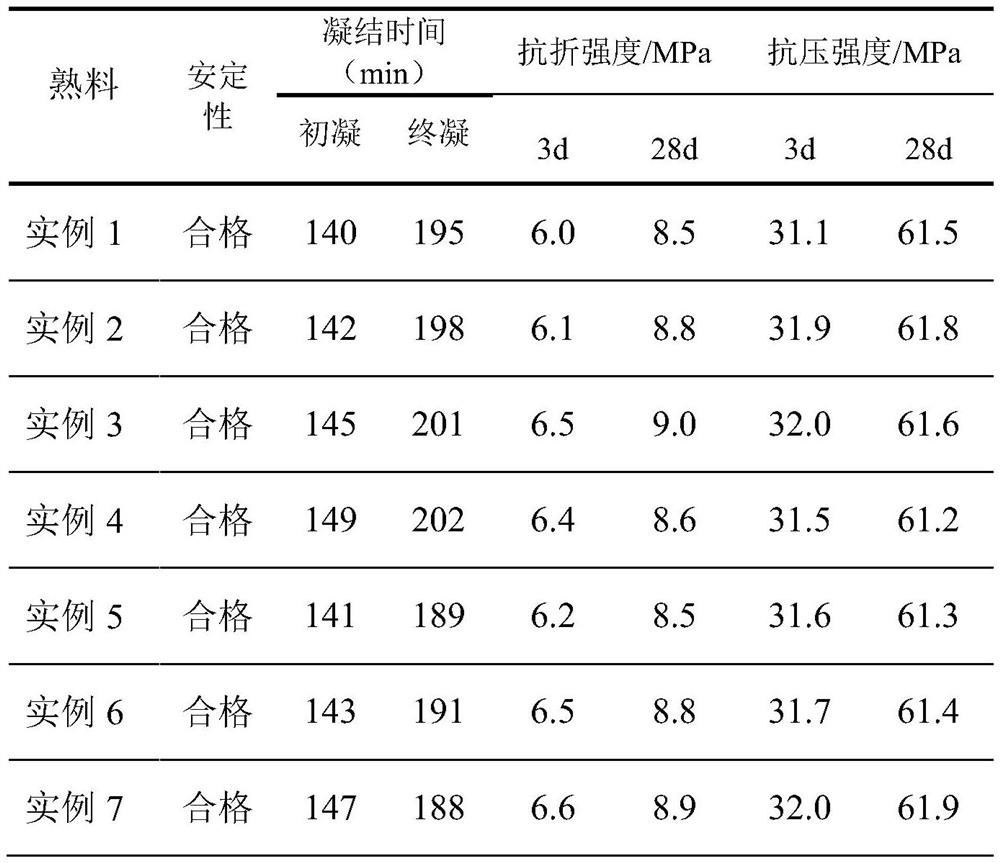

[0039]2. Clinker firing: the raw meal powder is preheated and decomposed for 60s to a temperature of 700°C and then fed into the rotary kiln. With the help of the inclination and rotation of the kiln, it slowly moves to the kiln head, and the kiln head coal is used in the firing zone. The burner provided by the powder sinters it into cement clinker for 25 minutes, and the sintered high-temperature clinker leaves the kiln and falls into the grate cooler. After crushing, it is unloaded on the chain bucket conveyor, and then transported by the chain bucket conveyor to the clinker yard of the combined warehouse. The rate range of clinker is shown in Table 1, ...

Embodiment 2

[0041] 1. Preparation of raw meal: The raw meal is weighed according to the following raw materials by weight: limestone 78.0%, high-silica sandstone 4.0%, low-silica sandstone 11.3%, smelting slag 2.5%, tailing slag 2.2%, ash slag 2.0%, all raw materials Grinding, 0.08mm sieve fineness control ≤17%, 0.2mm sieve fineness ≤2.0%;

[0042] 2. Clinker firing: the raw meal powder is preheated and decomposed for 50s to a temperature of 700 °C and then fed into the rotary kiln. With the help of the inclination and rotation of the kiln, it slowly moves to the kiln head, and the kiln head coal is used in the firing zone. The burner provided by the powder sinters it into cement clinker for 30 minutes, and the sintered high-temperature clinker leaves the kiln and falls into the grate cooler. After crushing, it is unloaded on the chain bucket conveyor, and then transported by the chain bucket conveyor to the clinker yard of the combined warehouse. The rate range of clinker is shown in Ta...

Embodiment 3

[0044] 1. Preparation of raw meal: Raw meal is weighed according to the following raw materials by weight: limestone 78.5%, high-silica sandstone 4.0%, low-silica sandstone 10.8%, smelting slag 2.0%, tailing slag 2.2%, ash slag 2.5%, all raw materials Grinding, 0.08mm sieve fineness control ≤17%, 0.2mm sieve fineness ≤2.0%;

[0045] 2. Clinker firing: the raw meal powder is preheated and decomposed for 55s to a temperature of 700°C and then fed into the rotary kiln. With the help of the inclination and rotation of the kiln, it slowly moves to the kiln head, and the kiln head coal is used in the firing zone. The burner provided by the powder sinters it into cement clinker for 28 minutes, and the sintered high-temperature clinker leaves the kiln and falls into the grate cooler. After crushing, it is unloaded on the chain bucket conveyor, and then transported by the chain bucket conveyor to the clinker yard of the combined warehouse. The rate range of clinker is shown in Table 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| curing time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com