Hot air circulation brazing furnace

A technology of hot air circulation and brazing furnace, applied in furnace, furnace cooling, furnace charge and other directions, can solve the problems of not suitable for high temperature brazing and brazing of large workpieces, save the internal space of the furnace body, and achieve remarkable brazing effect. , the effect of uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

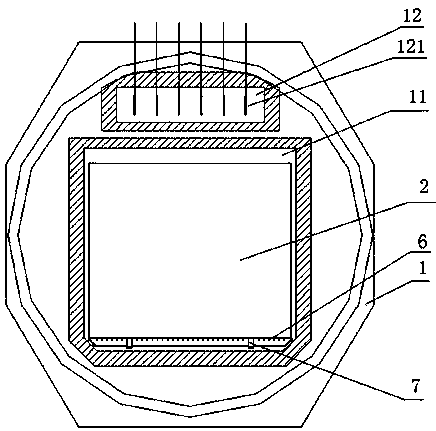

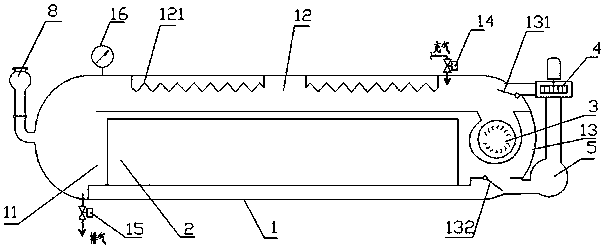

[0027] Such as figure 1 and figure 2 Shown: a hot air circulation brazing furnace, including a furnace body 1, the furnace body 1 is provided with a heating chamber 12 and a working chamber 11, the heating chamber 12 and the working chamber 11 are separate chambers, and the heating chamber 12 and the working chamber The cavities 11 are connected; one side of the furnace body 1 is provided with a main fan 3, through which the gas passing through the heating chamber 12 is introduced into the working chamber 11 to form a hot air circulation channel.

[0028] A resistance heater 121 is arranged in the heating chamber 12 . The gas outlet of the heating chamber 12 is connected with the gas inlet of the workpiece 2, and the gas inlet of the heating chamber 12 is connected with the gas outlet of the workpiece. The furnace body 1 is provided with an inlet valve 14 and an exhaust valve 15 .

[0029] The main fan 3 is a high temperature resistant centrifugal fan. In this embodiment,...

Embodiment 2

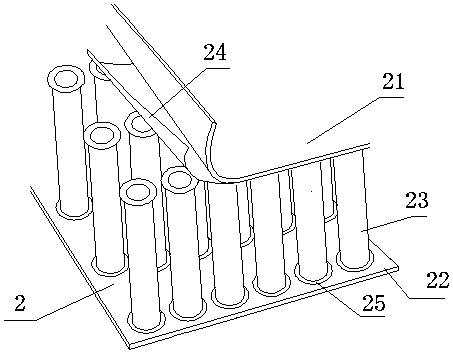

[0037] Such as Figure 4 Shown: The difference from Embodiment 1 is that the workpiece 2' includes a first panel 21', a second panel 22' and a plurality of core plates 23' between them. Core board 23' can be corrugated core board, corrugated core board, rib core board, straight core board etc. The core board 23' of this embodiment is preferably a corrugated core board. A plurality of core plates 23' are arranged at intervals to form a through air channel. Tin solder is provided between the core board 23' and the panel. The hot gas penetrates the inner cavity of the workpiece and contacts with each core plate 23', so that the temperatures of the upper, lower, left, right, front and rear ends of the workpiece are close to each other, and the temperature uniformity is greatly improved.

[0038] Other structures are with embodiment 1.

Embodiment 3

[0040] The difference from Embodiment 1 is that the impeller of the main fan and a part of the motor shaft are arranged in the furnace body, the motor and another part of the motor shaft are arranged outside the furnace body, and the part of the motor shaft extending into the furnace body is wrapped by a water-cooled jacket. The outer side of the water-cooled jacket is provided with an insulating layer.

[0041] Other structures are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com