Metallurgical Furnace

A metallurgical furnace and furnace cavity technology, applied in the field of metallurgical furnaces, can solve the problems of toxic gas leakage, electrocution, and the inability of the furnace cover to insulate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

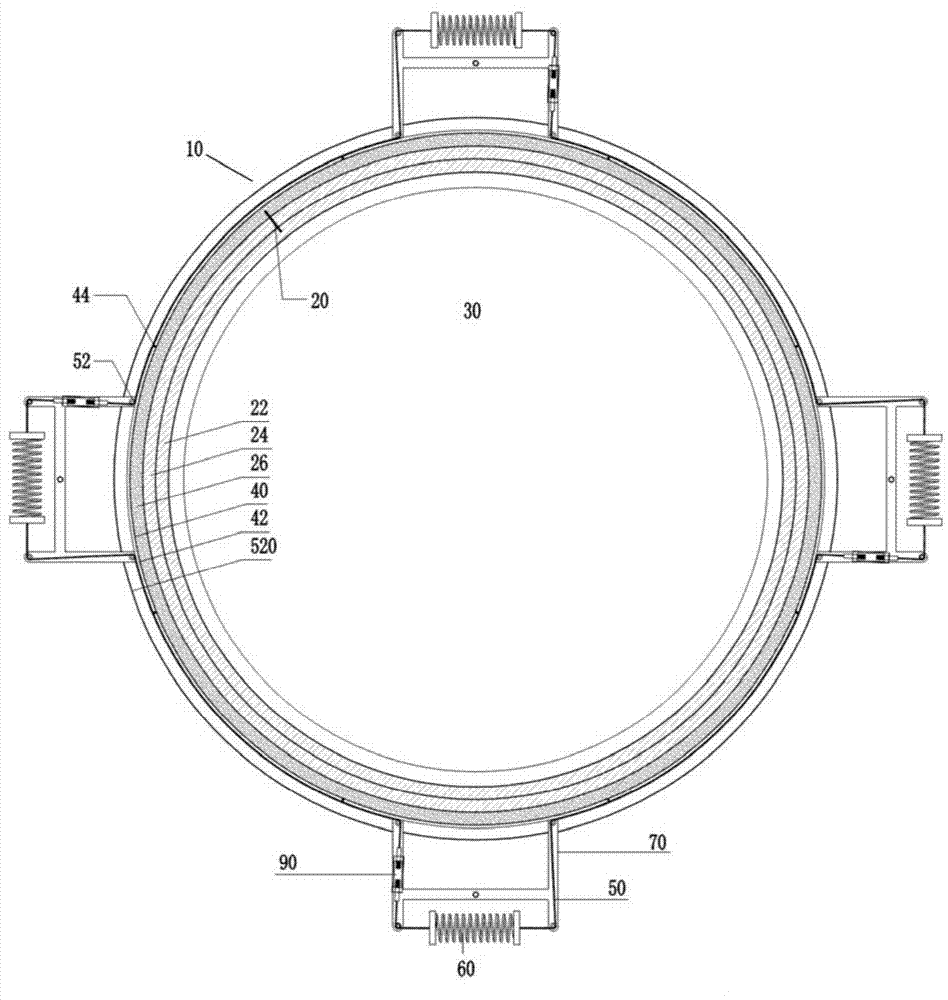

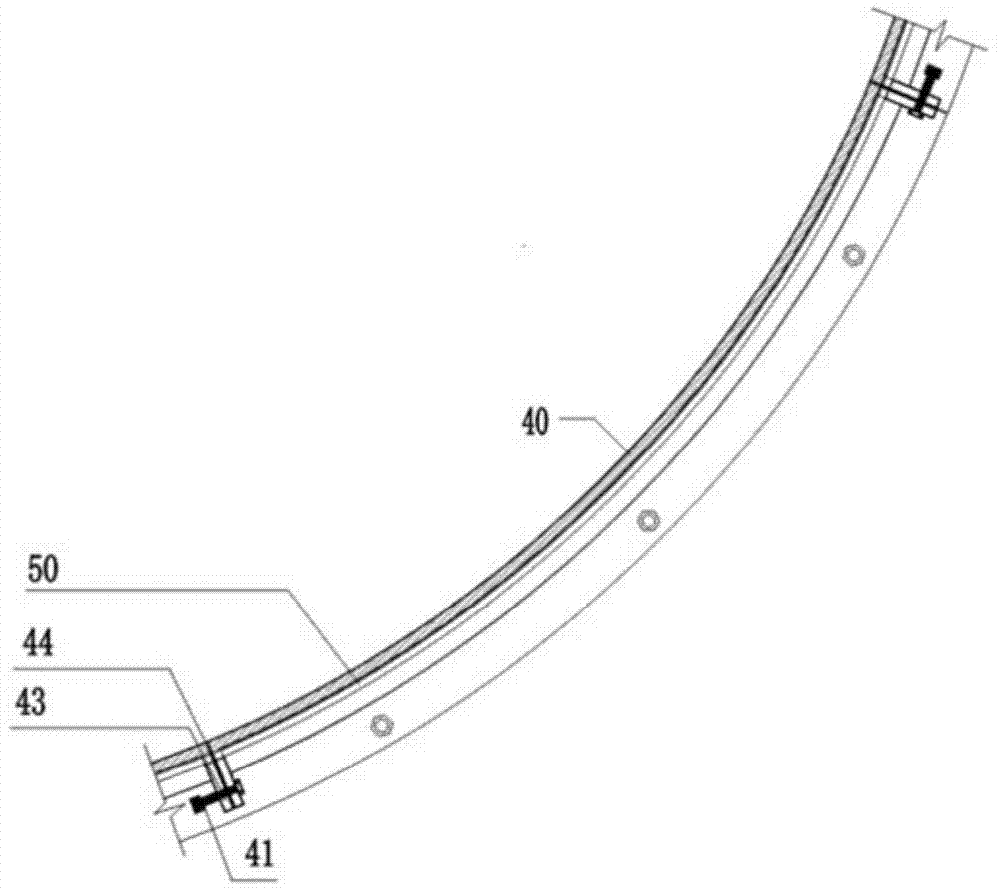

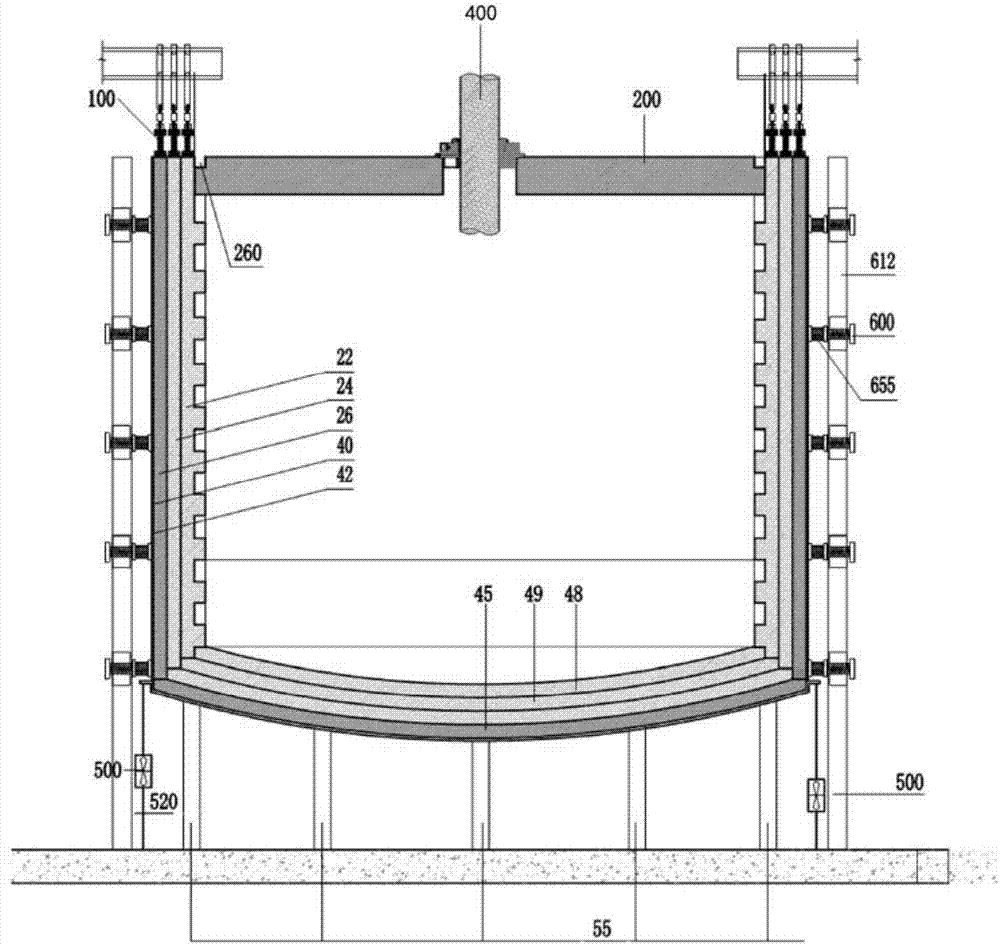

[0213] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the metallurgical furnace proposed according to the present invention and its specific implementation methods, steps, structures, features and its Efficacy in detail.

[0214] Different embodiments address different aspects of furnace design. It will be appreciated that not all aspects of furnace design discussed herein need be employed to address at least some of the disadvantages involved with existing designs. In some cases, a single aspect described herein may independently address at least some of the known disadvantages. While there are synergies between the various exemplary embodiments, this embodiment would be expected to be used with other conventional furnace designs (e.g., conventional brick refractory and / or electrodes and / or external cooling systems and / or furnace cover design).

[0215] The invention relates to metallur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com