Noise isolation sheet

A technology of sound insulation panels and sound-absorbing materials, applied in sound-proof doors/windows, sound-generating devices, instruments, etc., can solve problems such as unsatisfactory noise and unsatisfactory absorption, and achieve the effect of improving waterproof performance and effective waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

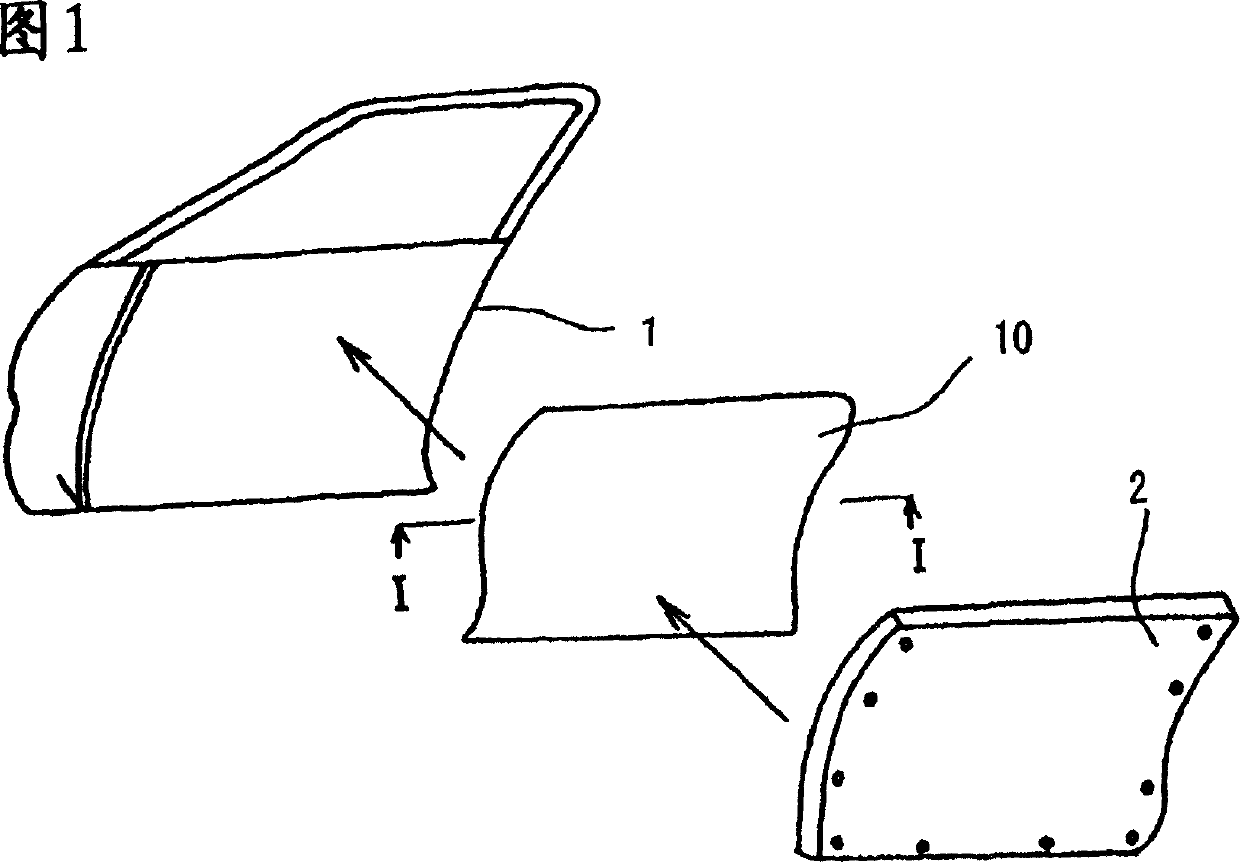

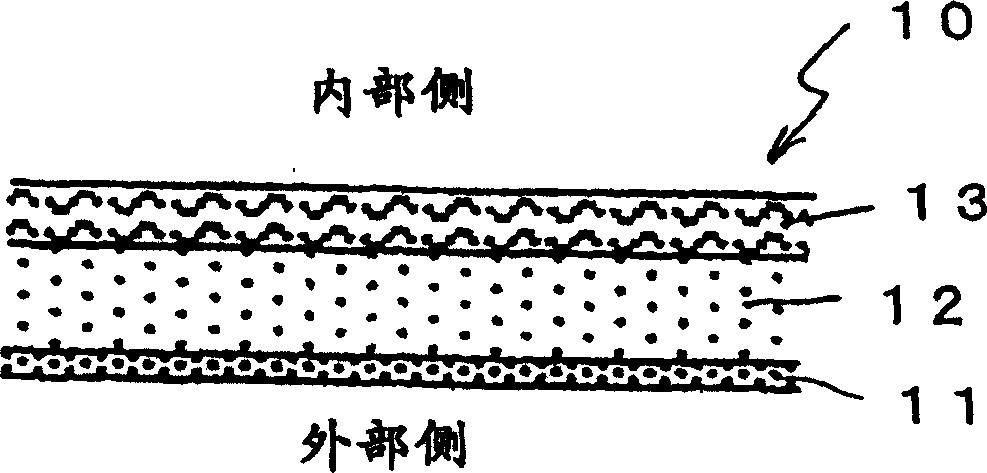

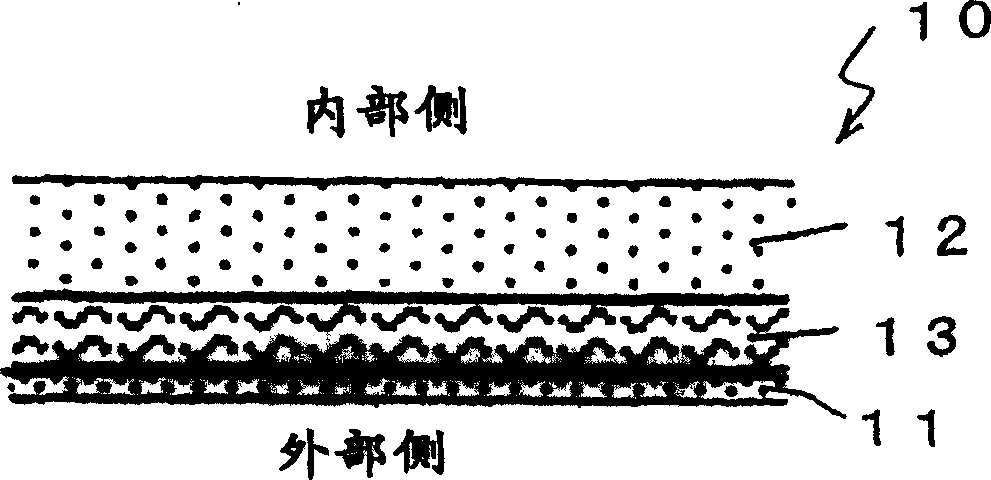

[0047] A sound insulation panel 10 according to a first preferred embodiment of the present invention will be described below with reference to FIGS. 1-6. Fig. 1 is an exploded perspective view showing the acoustic panel 10 in an installed state. Each of FIGS. 2-6 is a sectional view showing the sound insulation panel 10 taken along line I-I of FIG. 1 .

[0048] Each of these sound insulation panels 10 is installed between the door inner panel 1 and the inner door trim 2 of the vehicle, completely or partially covering the inner side of the door inner panel 1 . The sound insulation board 10 is composed of a closed-cell foam layer 11 , an open-cell foam layer 12 , and a fiber sound-absorbing material 13 .

[0049] The closed-cell foam layer 11 and the open-cell foam layer 12 can be made of synthetic rubber such as EPDM, CR, SBR and NBR, and in this preferred embodiment, they are made of EPDM because its specific gravity can be easily controlled. The fiber sound absorbing mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com