Optical film set and backlight module employing same

A backlight module and optical film technology, applied in optics, nonlinear optics, electric light sources, etc., can solve the problems of adding a backlight module 100 manufacturing trouble, installation and manufacturing difficulty, etc., to simplify the manufacturing and assembly process, and improve the problem of light leakage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

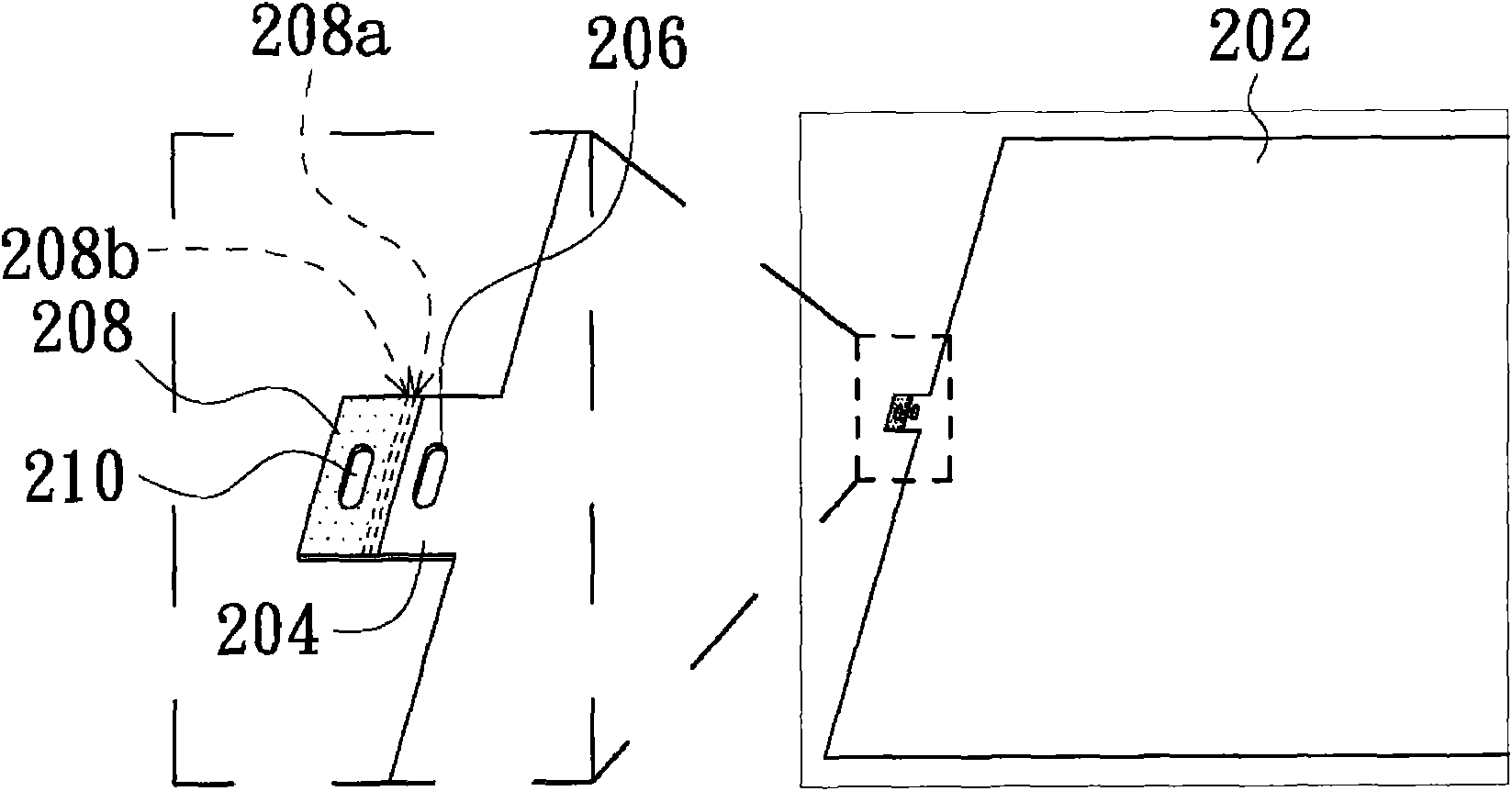

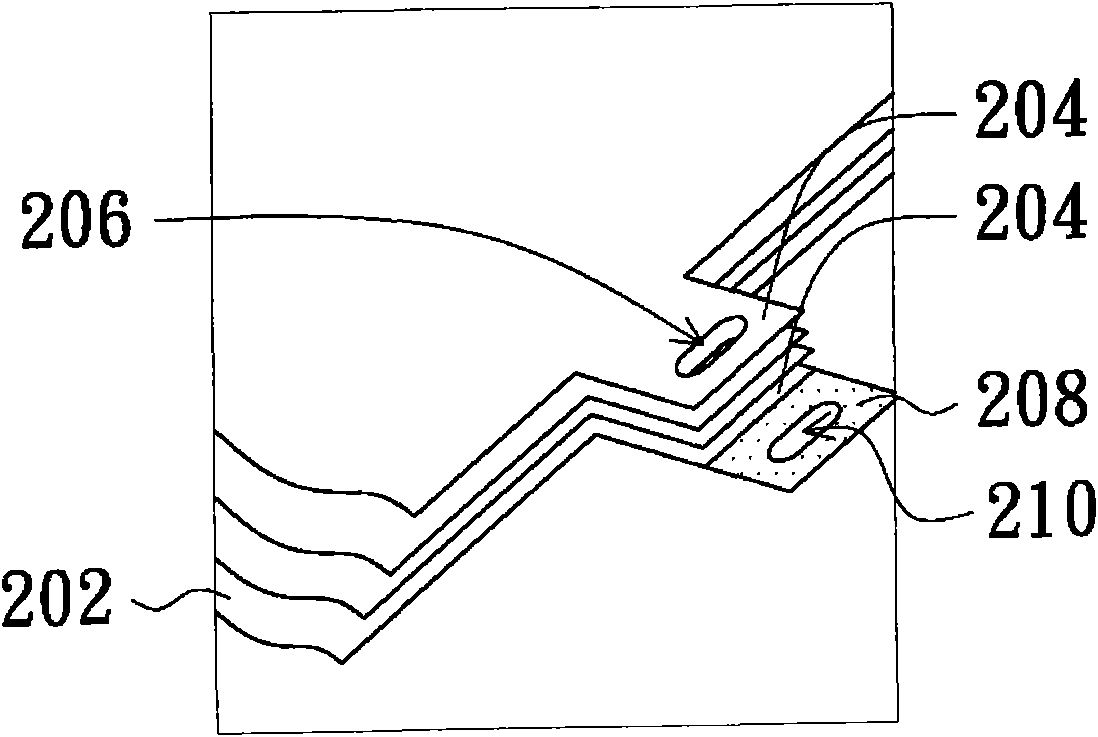

[0052] Please refer to Figure 2A , Figure 2A It is a partial appearance schematic diagram of the first embodiment of the present invention. Such as Figure 2A As shown, the optical film 202 of the first embodiment of the present invention has four sides (not shown in the figure), which are the upper side, the lower side, the left side and the right side. The four sides make the optical film 202 roughly in a rectangular shape. For the convenience of explanation, Figure 2A Only the upper side, lower side, and left side are shown in the middle.

[0053] A protruding portion 204 extending outward and a light shielding portion 208 extending outward from the edge of the protruding portion 204 are formed at a specific position on the left side of the optical film 202 . The protruding portion 204 and the light shielding porti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com