Array substrate and touch display panel

An array substrate and substrate technology, applied in the field of array substrates and touch display panels, can solve the problems of signal attenuation, increase in thickness of touch traces 120, time increase, etc., and achieve the effect of alleviating color shift in color mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

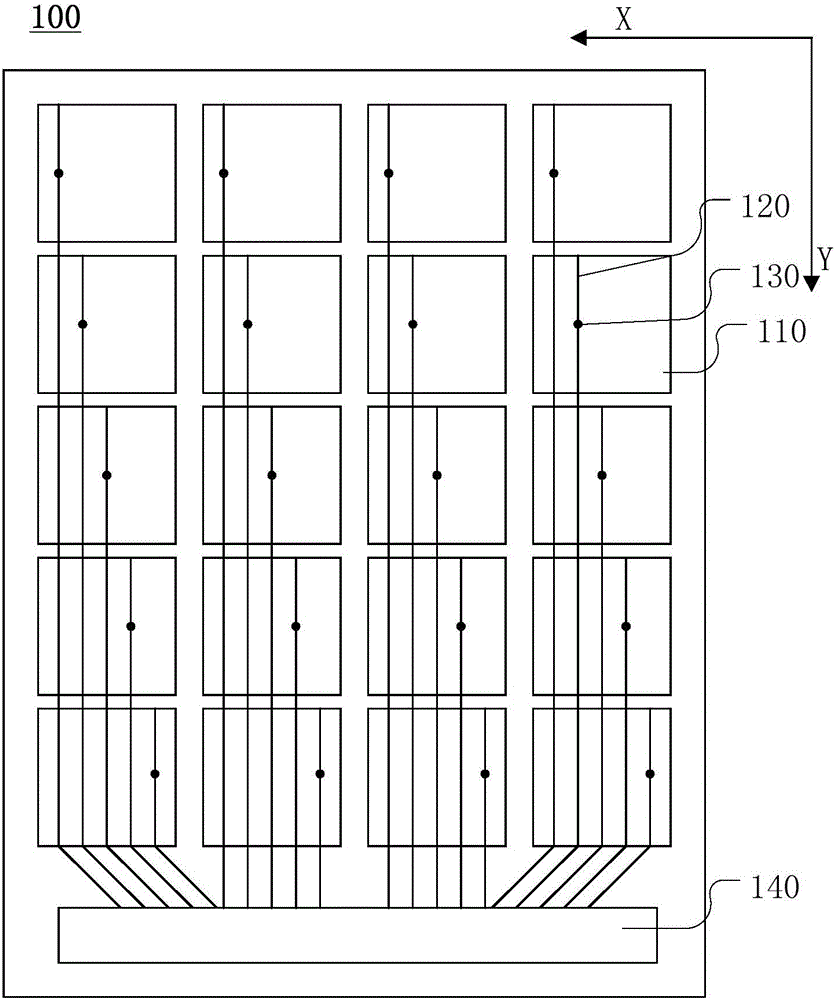

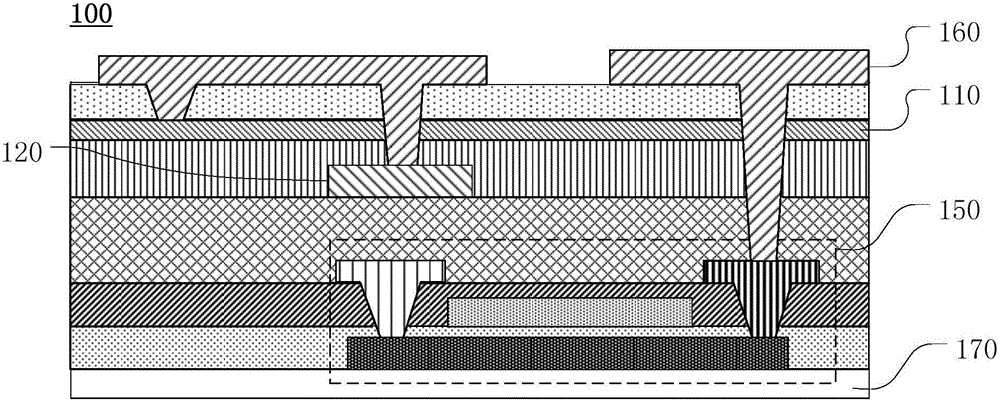

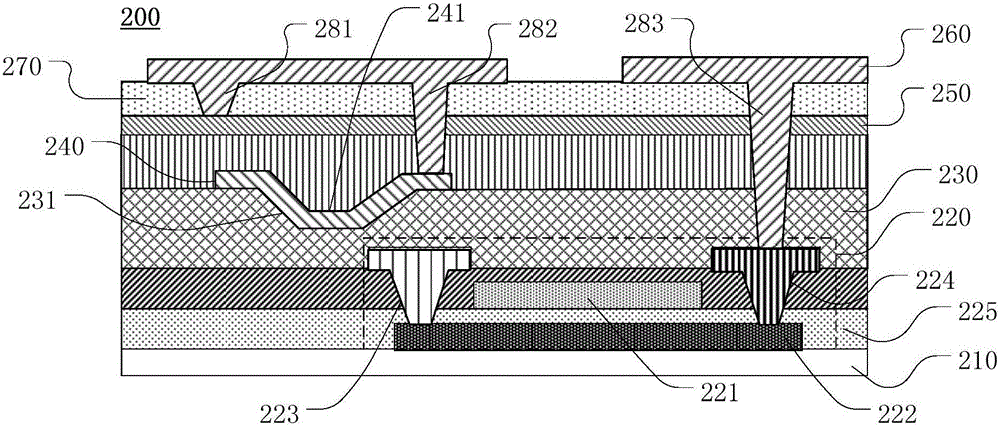

[0033] see first image 3 and Figure 4 , image 3 Showing a cross-sectional view of the array substrate 200 according to the first embodiment of the present invention, Figure 4 show image 3 A partial enlarged view of the array substrate 200 of FIG.

[0034] The array substrate 200 includes: a substrate 210 , a plurality of switch elements 220 , a first insulating layer 230 , a touch electrode layer and a touch wiring layer.

[0035] A plurality of switching elements 220 are located above the substrate 210 . The switching element 220 may be a thin film transistor. For example, in image 3 In the illustrated embodiment, the switch element 220 is a top-gate thin film transistor. Each top-gate TFT 220 includes an active layer 222 , a gate insulating layer 225 , a gate 221 , a source 223 , and a drain 224 sequentially on the substrate 210 . The source electrode 223 and the drain electrode 224 are located on the same layer. The switch element 220 can also be a bottom-gat...

no. 2 example

[0047] see Figure 5 , Figure 5 A cross-sectional view of an array substrate 300 according to a second embodiment of the present invention is shown. Figure 5 The structure of the array substrate 300 shown is the same as image 3 The illustrated array substrate 200 has a similar structure. and image 3 The difference of the array substrate 200 shown is that the concave portion 331 of the array substrate 300 is perpendicular to the cross-section of the extending direction of the touch trace 340 (eg Figure 5 The section shown) is V-shaped. The V-shaped concave portion 331 can not only alleviate the problem of light leakage, but also alleviate the problem of color shift in color mixing.

no. 3 example

[0049] see Figure 6 , Figure 6 A cross-sectional view of an array substrate according to a third embodiment of the present invention is shown. Figure 6 The structure of the array substrate 400 shown is the same as image 3 The illustrated array substrate 200 has a similar structure. and image 3 The difference of the array substrate 200 shown is that the fourth surface 443 of the convex part 441 of the touch trace 440 of the array substrate 400 away from the substrate 410 is not lower than the upper surface 432 of the first insulating layer 430 on the edge of the concave part (convex out of the third surface of portion 441 with image 3 The first surface 242 shown is the same, being in contact with the inner wall of the recess). M3 is made into a buried structure. Figure 6 In the illustrated embodiment, in addition to reducing the resistance of the touch wire 440 , it can also prevent the touch wire 440 from falling off on the first insulating layer 430 and reduce th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com