Vapor deposition method and manufacturing device of vapor deposition thin film, vapor deposition thin film and display device8

An evaporation thin film and evaporation technology, which is applied in vacuum evaporation plating, sputtering plating, ion implantation plating, etc., can solve problems such as color mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] In the above, the relative distance between the first evaporation pattern 101 and the second evaporation pattern 102 is adjusted by modifying the original distance H1 between the first evaporation pattern 101 and the second evaporation pattern 102 in the evaporation unit of the original evaporation film. Locations include: (reference Figure 4 )

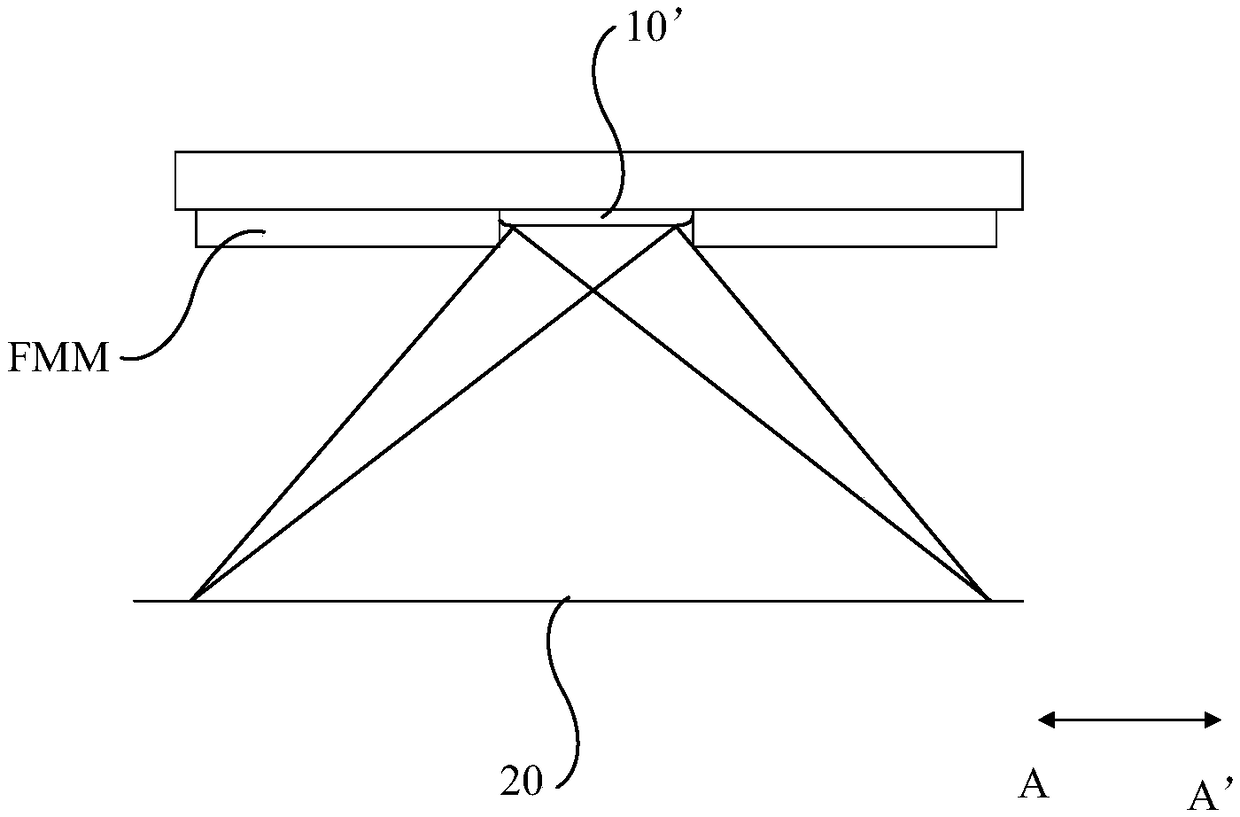

[0052] Step S101, refer to Figure 5 (a) of Figure 4 The schematic cross-sectional view of the first vapor deposition pattern 101' along the O1-O1' position in , measuring the mask shadow pattern of the vapor deposition pattern 10' in the original vapor deposition film along the first direction AA', one side A dimension (L1); Of course, the vapor deposition pattern 10' here can be Figure 2a Any one of the first vapor deposition pattern 101', the second vapor deposition pattern 102', and the third vapor deposition pattern 103' in the original vapor deposition film shown in Figure 4 The illustration is only schematically ...

Embodiment 2

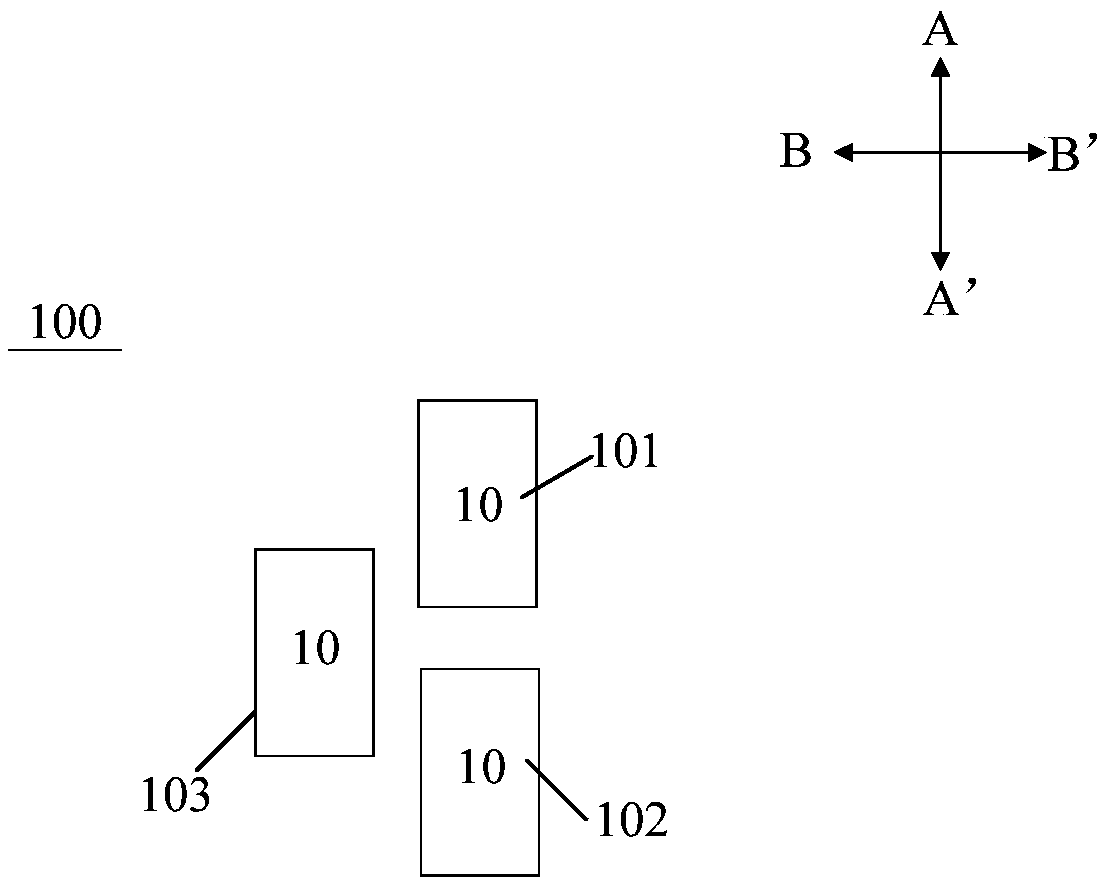

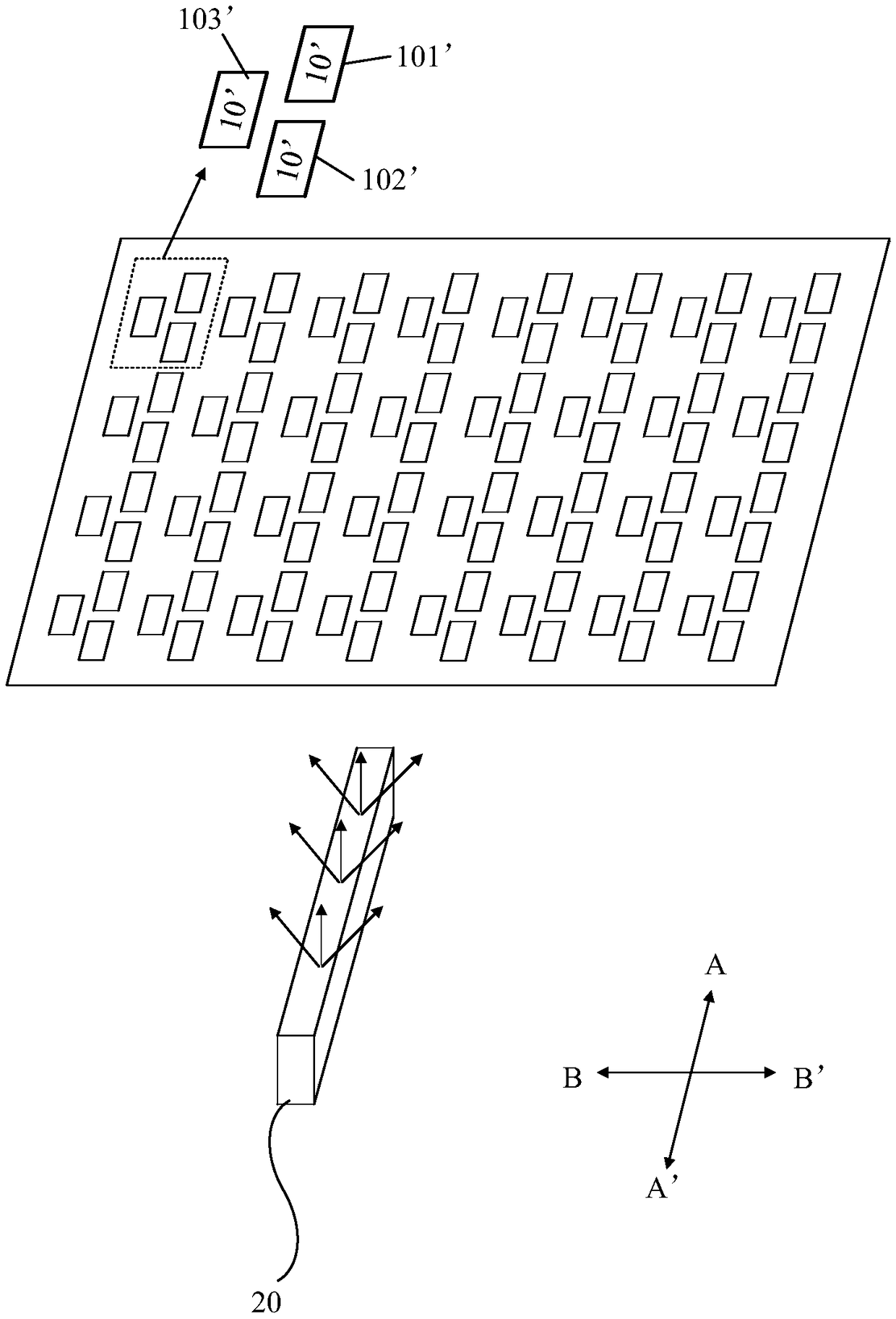

[0066] As can be seen from the foregoing, in practice, when using Figure 2a In the evaporated film formed by the evaporation method shown in , the mask shadow (Shadow) along the first direction A-A' will be significantly larger than the mask shadow along the second direction B-B' (refer to image 3 , Figure 4 , Figure 5 ), so that the risk of offset aliasing between the first vapor deposition pattern 101 and the second vapor deposition pattern 102 arranged side by side along the first direction A-A' is high, resulting in a high risk of color mixing.

[0067] Based on this, in this embodiment, the relative position of the first vapor deposition pattern 101 and the second vapor deposition pattern 102 is adjusted by adjusting the movement of the linear vapor deposition source 20 relative to the first vapor deposition pattern 101 and the second vapor deposition pattern 102 Including: (reference Figure 7 )

[0068] Using the first linear evaporation source 201 moving along ...

Embodiment 3

[0075] The aforementioned adjustment of the relative positions of the first vapor deposition pattern and the second vapor deposition pattern by adjusting the alignment method of the mask includes:

[0076] moving the first reticle along the first direction AA' and the second direction BB' (perpendicular to the first direction), and rotating the first reticle along the central axis of the first reticle, in the first reticle When the error of the distance from the stencil to the target position along the vertical first direction is within the standard error range, the error of the distance from the first mask to the target position along the first direction is minimized to form the first vapor deposition pattern 101 .

[0077] moving the second reticle along the first direction AA' and the second direction BB', and rotating the second reticle along the central axis of the second reticle, when the second reticle reaches the target position When the error of the distance along the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com