Quantum dot color filter and manufacturing method thereof and display device

A technology of color filter and manufacturing method, which is applied in optics, nano-optics, optical components, etc., can solve the problems of high production cost, limited color gamut of color filter, affecting product display quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

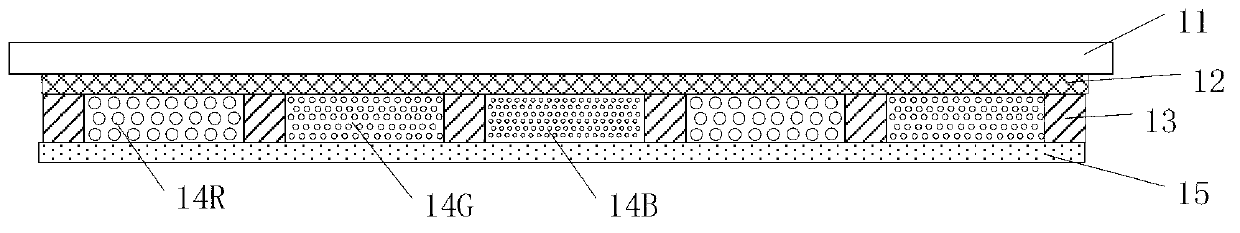

[0052] Such as figure 1 As shown, this embodiment provides a color filter, including a plurality of pixels, each pixel includes a number of color sub-pixels of different colors, and the color filter also includes:

[0053] Base substrate 11, the base substrate can be any transparent material such as glass substrate, quartz, resin;

[0054] Wherein, at least one color sub-pixel is formed of a quantum dot material, and the light generated after the quantum dot material is excited is the same color as the corresponding color sub-pixel;

[0055] The filter layer 12 is arranged in the color sub-pixel area formed by the quantum dot material, and is used for absorbing the light that does not excite the quantum dot material.

[0056] The color sub-pixel in this embodiment includes a red sub-pixel 14R, a green sub-pixel 14G and a blue sub-pixel 14B, the red sub-pixel 14R is formed of red quantum dot material, and the green sub-pixel 14G is formed of green quantum dot material; The blue...

Embodiment 2

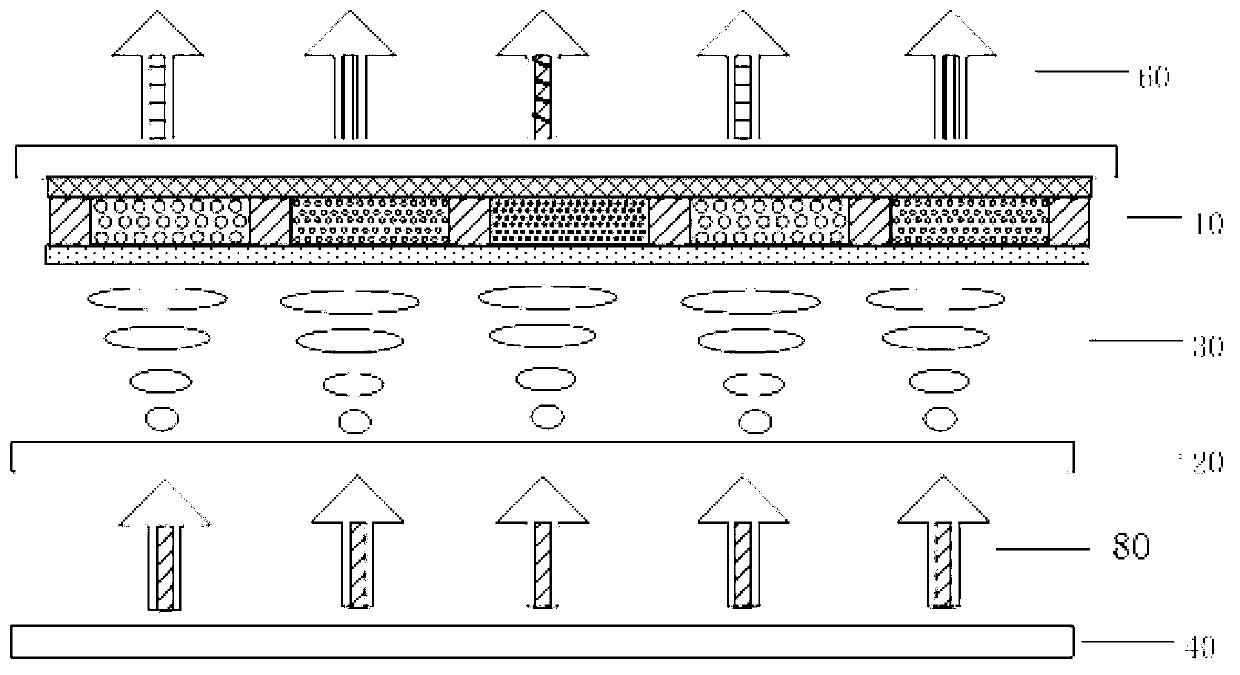

[0064] Such as image 3 As shown, this embodiment provides a display device, which includes the color filter 10 in Embodiment 1, and also includes an array substrate 20 and a backlight 40 . A liquid crystal layer 30 is disposed between the color filter 10 and the array substrate 20 to form a liquid crystal panel. Wherein, the backlight 40 is an ultraviolet backlight. In the color filter 10, the red sub-pixel 14R is formed of a red quantum dot material, the green sub-pixel 14G is formed of a green quantum dot material, and the blue sub-pixel 14B is formed of a blue quantum dot material, and each color sub-pixel area is provided with The filter layer 12 is used for absorbing ultraviolet light 80 .

[0065] It should be noted that the light from the ultraviolet backlight in this embodiment first passes through the colored sub-pixels formed by the quantum dot material, the ultraviolet light excites the quantum dot material to emit light of the corresponding color, and the ultrav...

Embodiment 3

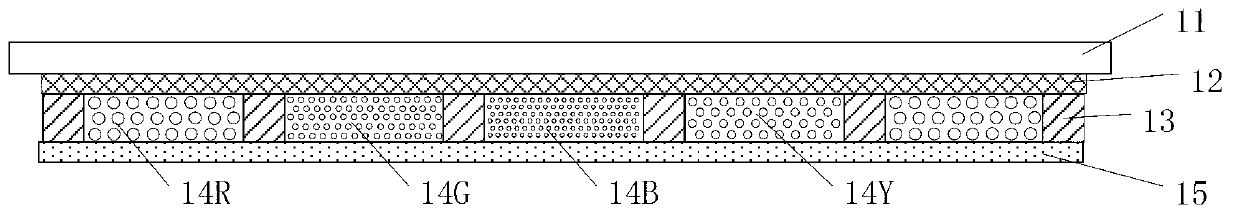

[0069] Such as Figure 4 As shown, this embodiment provides a color filter, including a plurality of pixels, each pixel includes a number of color sub-pixels of different colors, and the color filter also includes:

[0070] Base substrate 11, the base substrate can be any transparent material such as glass substrate, quartz, resin;

[0071] Wherein, at least one color sub-pixel is formed of a quantum dot material, and the light generated after the quantum dot material is excited is the same color as the corresponding color sub-pixel;

[0072] The filter layer 12 is arranged in the color sub-pixel area formed by the quantum dot material, and is used for absorbing the light that does not excite the quantum dot material.

[0073] The color sub-pixel in this embodiment includes a red sub-pixel 14R, a green sub-pixel 14G and a blue sub-pixel 14B, the red sub-pixel 14R is formed of red quantum dot material, and the green sub-pixel 14G is formed of green quantum dot material; The b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com