Patents

Literature

117results about How to "Reduce the risk of disconnection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flexible substrate, manufacturing method thereof and display device

InactiveCN108597378AImprove flexibilityReduce bending stressFinal product manufactureIdentification meansDisplay deviceEngineering

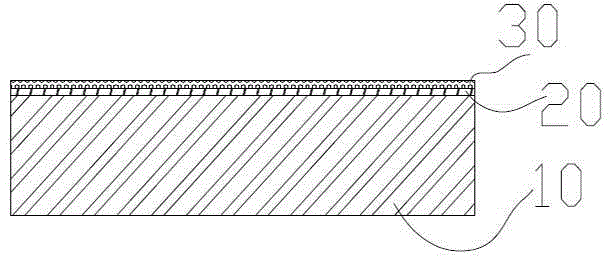

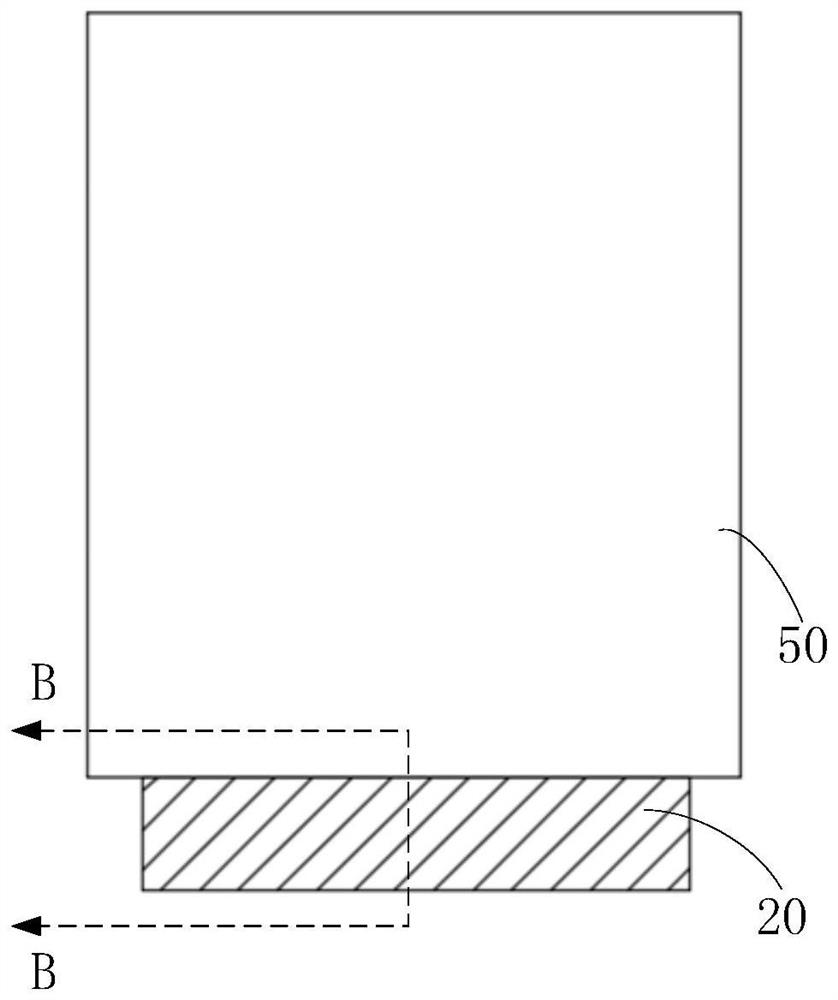

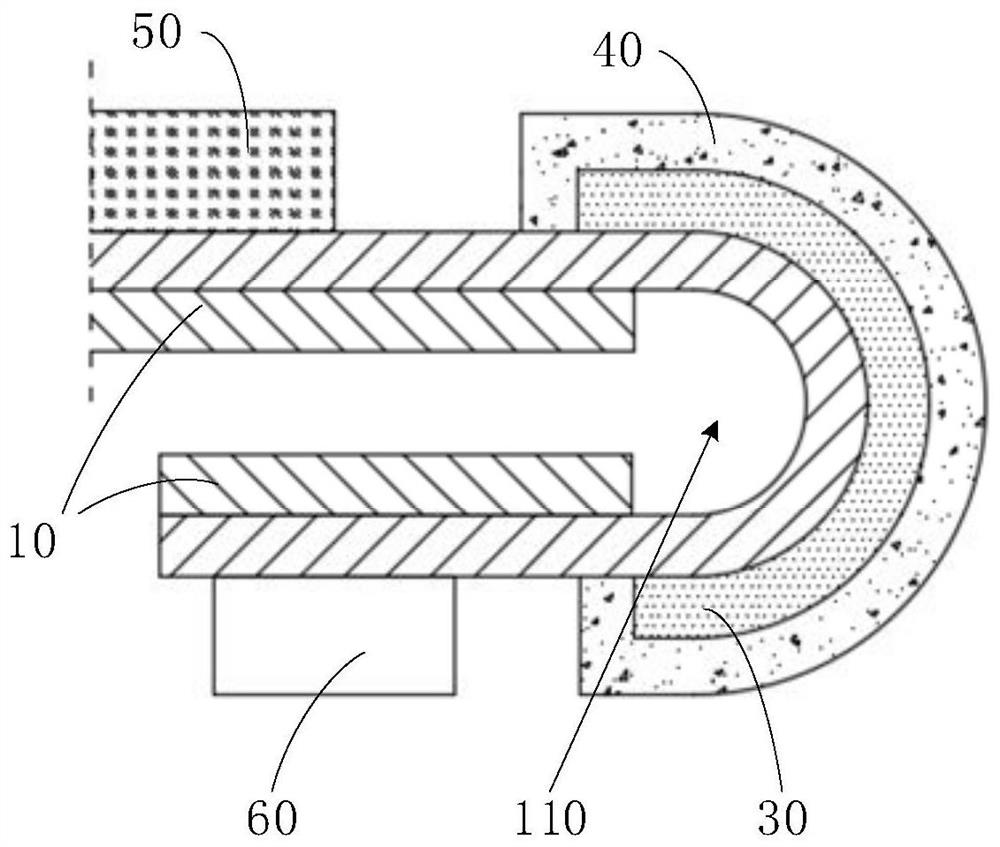

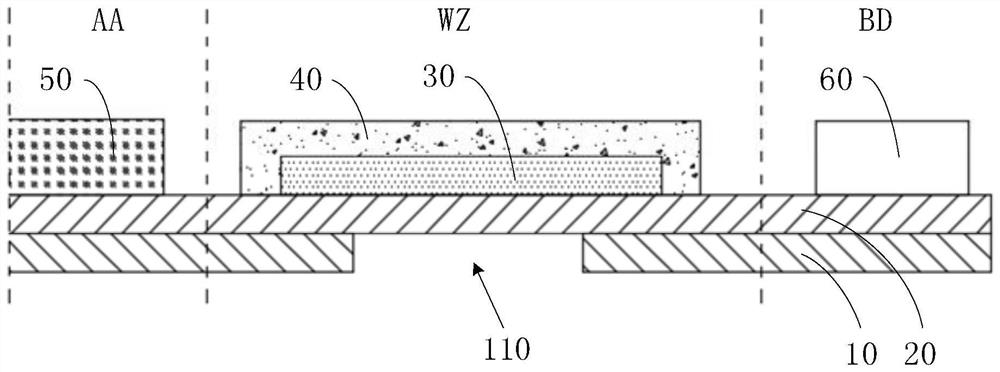

An embodiment of the invention discloses a flexible substrate, a manufacturing method thereof and a display device, relates to the technical field of display, and is used for reducing breaking risks of metal wires in the flexible substrate when the flexible substrate is bent. The flexible substrate comprises a flexible substrate body as well as a wiring layer and a back film which are arranged onthe two sides of the flexible substrate body respectively; a plane area for reserving the back film and a bending area for removing the back film are formed on one side, opposite to the wiring layer,of the flexible substrate body; a photocuring adhesive film is arranged in the bending area, elasticity modulus of the photocuring adhesive film is smaller than that of the back film. The flexible substrate, the manufacturing method thereof and the display device provided in the embodiment are applied to border narrowing of the display device.

Owner:BOE TECH GRP CO LTD +1

Array substrate, manufacturing method thereof and display panel

PendingCN107894681AImprove bending resistanceImprove reliabilityFinal product manufacturePrinted circuit aspectsStress concentrationEngineering

Owner:BOE TECH GRP CO LTD +1

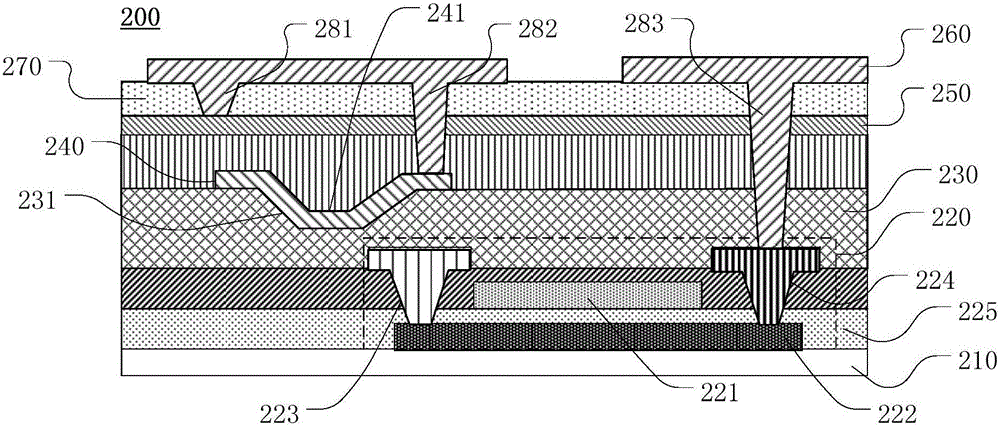

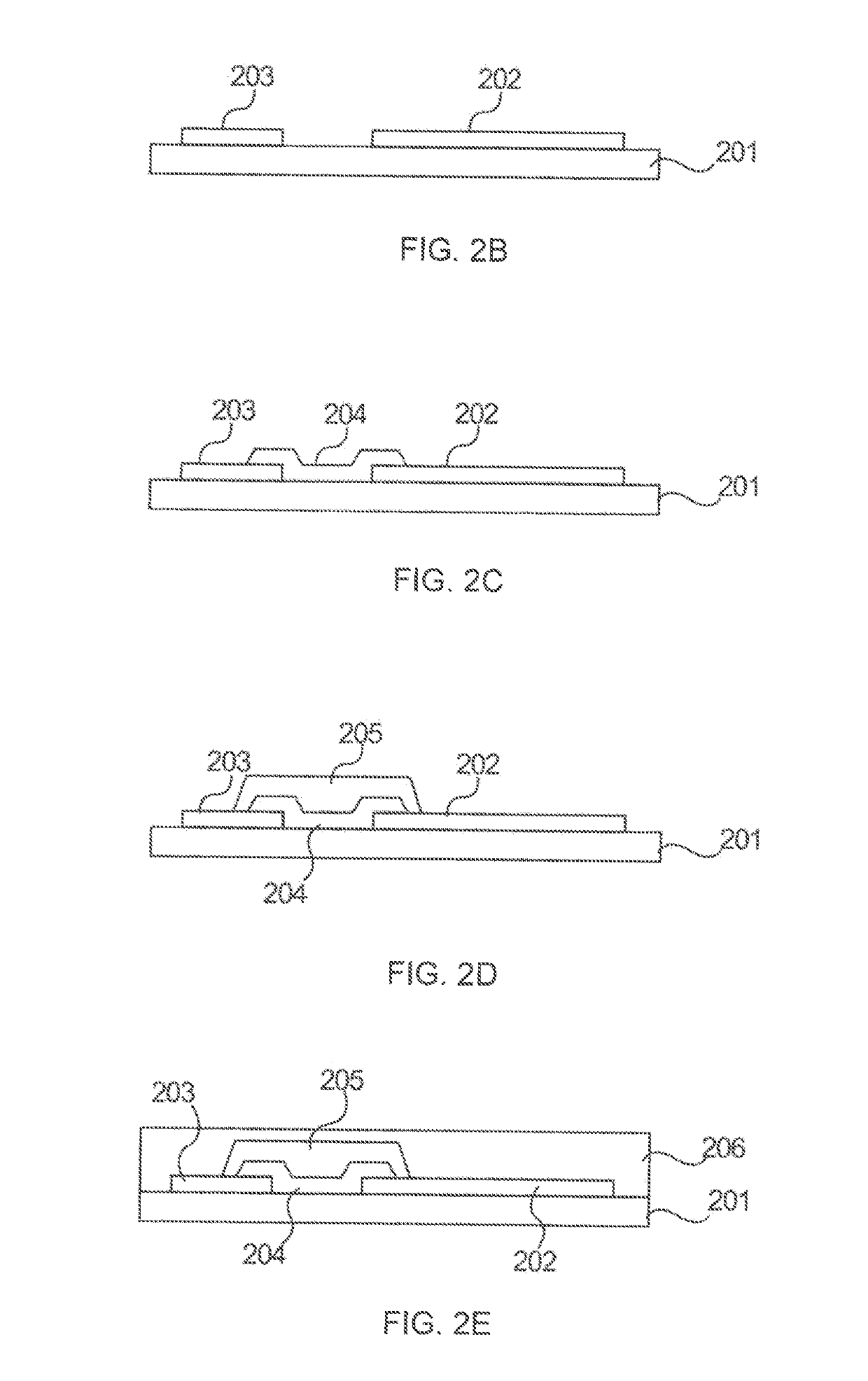

Flexible display panel and preparation method thereof and flexible display device

ActiveCN109755256AExtended service lifeReduce stressFinal product manufactureSolid-state devicesInsulation layerElectrical connection

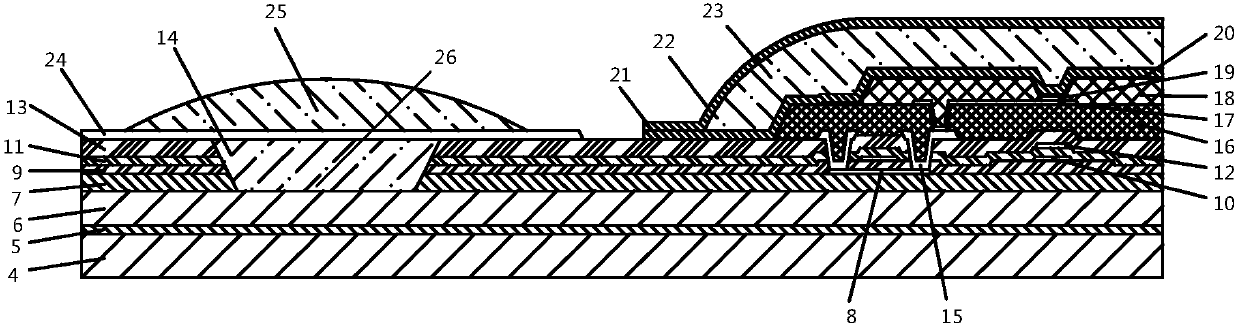

The present invention provides a flexible display panel, a preparation method thereof and a flexible display device, and belongs to the technical field of flexible display. The flexible display panelprovided by the present invention comprises: a flexible substrate which includes a bending area and a display area and a non-display area on both sides of the bending area; the display area is provided with a sub-pixel array and a signal line, and the non-display area is provided with a driving chip; an isolating insulation layer which is arranged on the flexible substrate; a trench which is located in the bending area and runs through the isolating insulation layer; a first buffer layer which is filled in the trench; a lead wire which is arranged on the isolating insulation layer of the non-display area and the first buffer layer and is used for electrical connection between the driving chip and the signal line; and a second buffer layer which is located on the lead wire and at least covers the bending area. The display panel can adjust the stress neutral layer of the bending area, reduce the stress on the lead wire and improve the folding performance.

Owner:BOE TECH GRP CO LTD

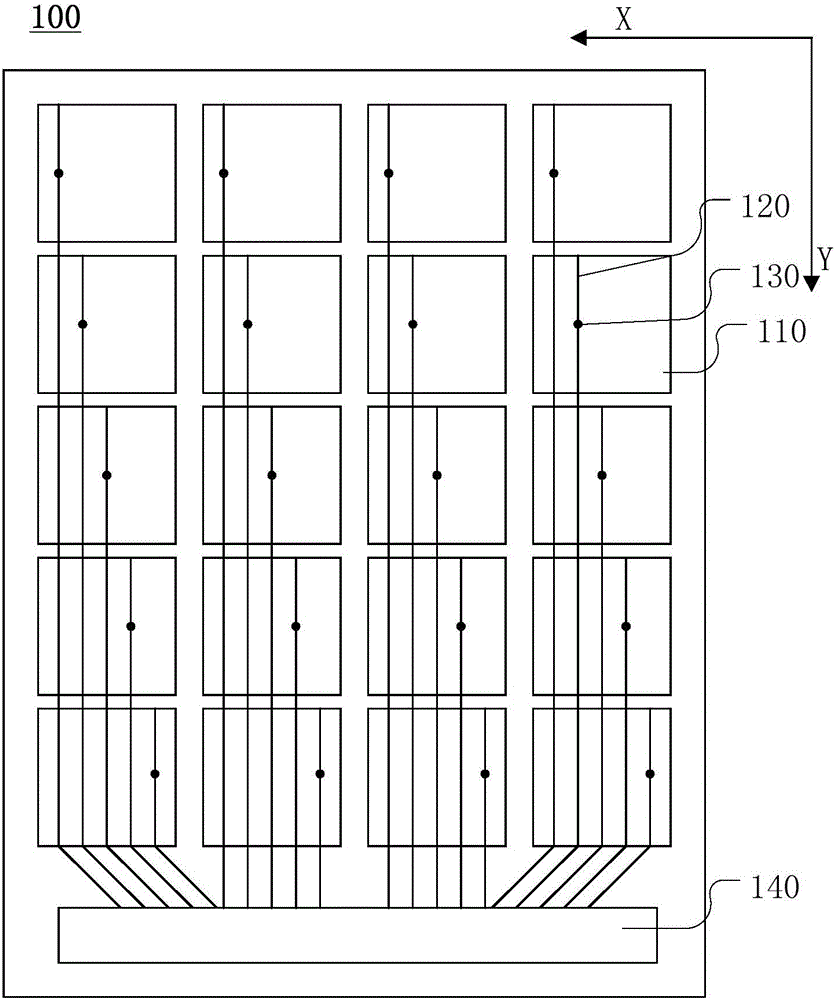

Organic light-emitting display panel and organic light-emitting display device

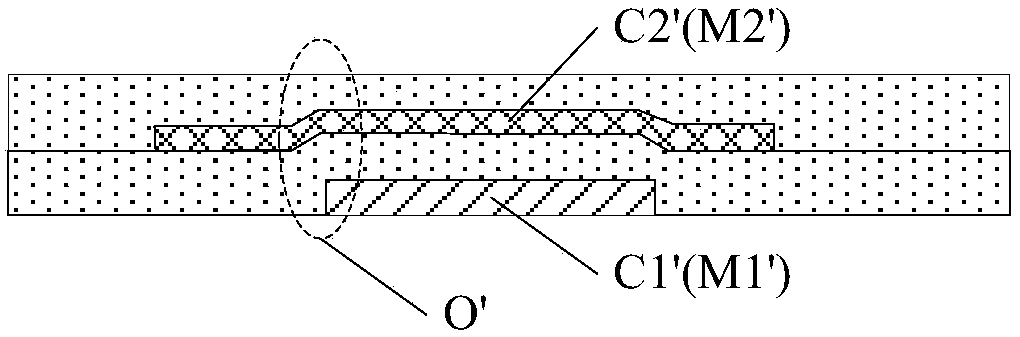

ActiveCN108538907AReduce the risk of disconnectionImprove reliabilityStatic indicating devicesSolid-state devicesCapacitanceLine width

The present invention discloses an organic light-emitting display panel and an organic light-emitting display device. The organic light-emitting display panel comprises: a substrate and organic light-emitting elements, wherein, the substrate comprises a substrate, a first metal layer, a second metal layer and a third metal layer; a plurality of drive signal lines extended in a first direction andconfigured to drive the organic light-emitting elements and located at least one layer in the three metal layers, wherein the drive signal lines comprise first drive signal lines and second drive signal lines, in the first direction, the number of the organic light-emitting elements driven by the first drive signal lines is larger than the number of the organic light-emitting elements driven by the second drive signal lines; and a plurality of compensation capacitors, wherein at least one second drive signal line is connected with the compensation capacitors, each compensation capacitor comprises one first pole wiring and a second pole wiring, each first pole wiring is located at the first metal layer, the second pole wiring is located at the second metal layer, and the line width of the first pole wiring is larger than the line width of the second pole wiring. The line breaking risk of the compensation capacitors is reduced.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

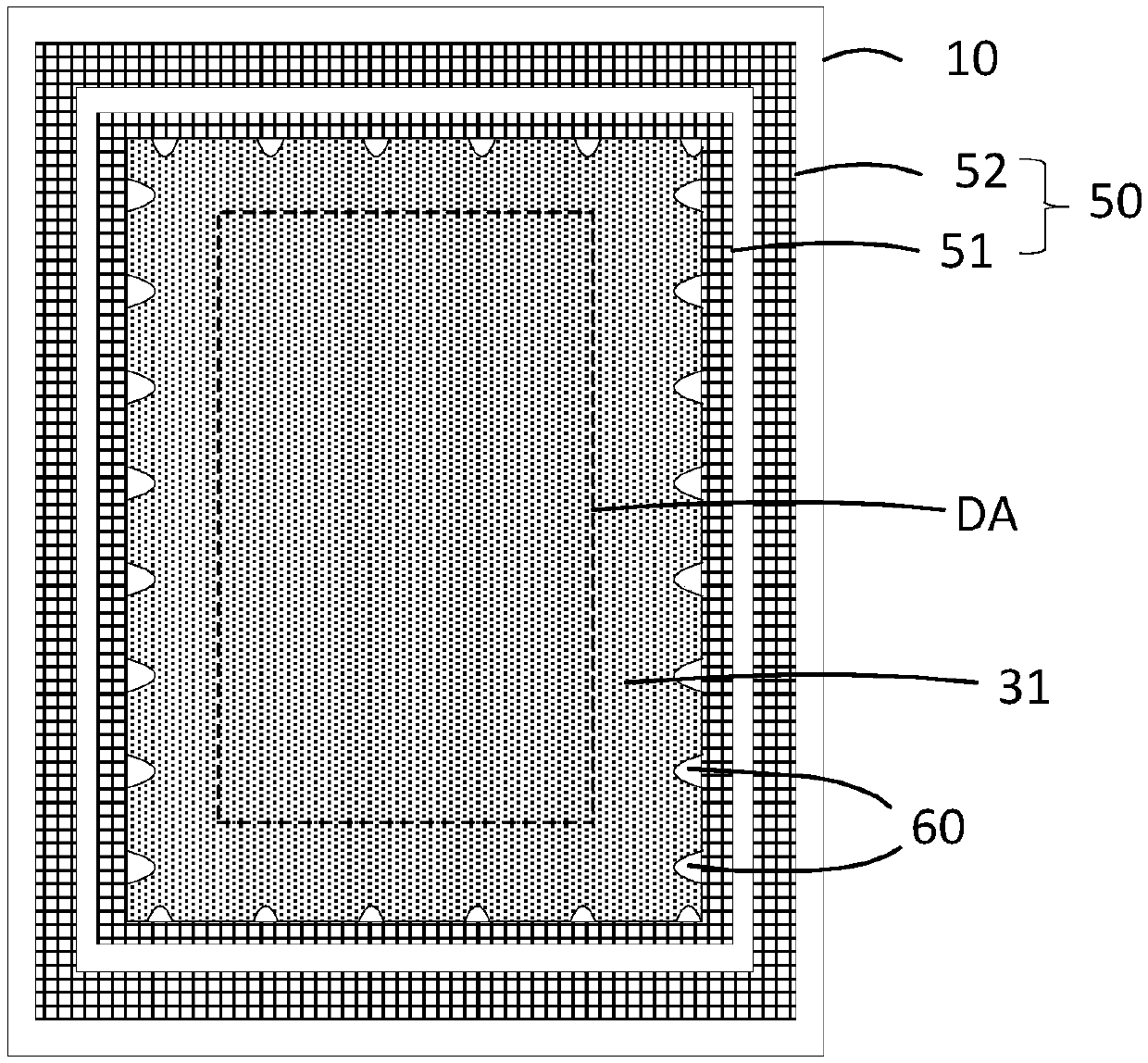

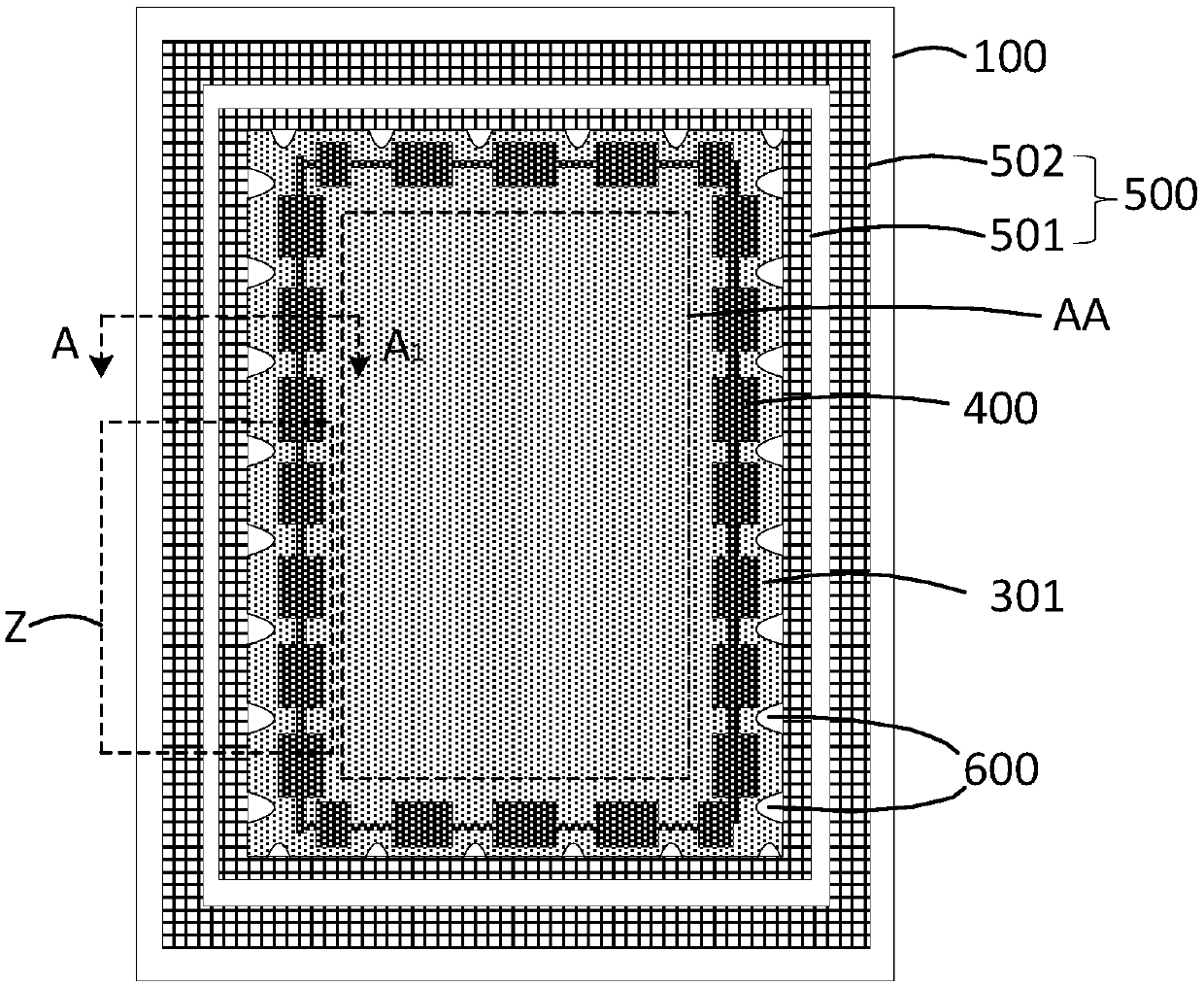

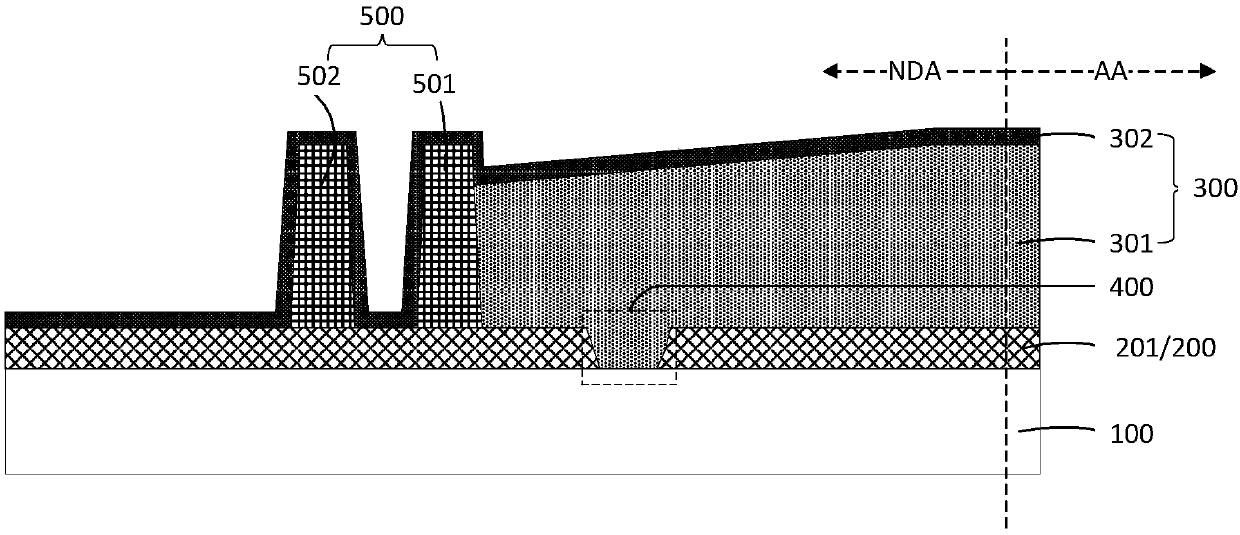

Display panel and display device

ActiveCN109585688APrevent intrusionReduce the risk of disconnectionSolid-state devicesSemiconductor/solid-state device manufacturingVertical projectionDisplay device

The invention describes a display panel and a display device. The display panel comprises a substrate, a display function layer, a thin film encapsulation layer, at least one retaining wall and at least one groove, wherein the substrate is provided with a display area and a non-display area; the display function layer is located on the substrate, and the display function layer comprises at least one inorganic insulating layer; the thin film encapsulation layer is located on one side of the display function layer away from the substrate, and the thin film encapsulation layer comprises at leastone organic layer and at least one inorganic layer; the at least one retaining wall is located in the non-display area and on the same side as the display function layer, and the inorganic layer at least covers the retaining wall; the at least one groove is located on one side of the inorganic insulating layer away from the substrate and is arranged in the non-display area between the retaining wall and the display area, the groove accommodates the organic layer, the vertical projection of the groove on the substrate has different widths in the first direction, and the first direction is a direction that the display area points to the non-display area. According to the scheme of the invention, the risk of disconnection caused by forming touch electrode lines on the retaining wall and the risk of cracking caused by film layer peeling can be reduced, and the reliability of encapsulation can be improved.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

Light emitting diode display panel and method for producing same

InactiveCN103794617AEffective protectionEffective Diffusion EffectSolid-state devicesSemiconductor devicesLight-emitting diodePhysics

The invention provides a light emitting diode display panel and a method for producing same. The dielectric pattern of the light emitting diode display panel is formed on a substrate after a light emitting diode element is formed on the substrate, and wraps the sidewall of the corresponding light emitting diode element and an electrode of the corresponding light emitting diode element is exposed. The top surface of the dielectric pattern and the electrode of the light emitting diode element are roughly in a same plane. A connecting electrode disposed on the dielectric pattern is electrically connected with the electrode and the signal line of the light emitting diode element.

Owner:AU OPTRONICS CORP

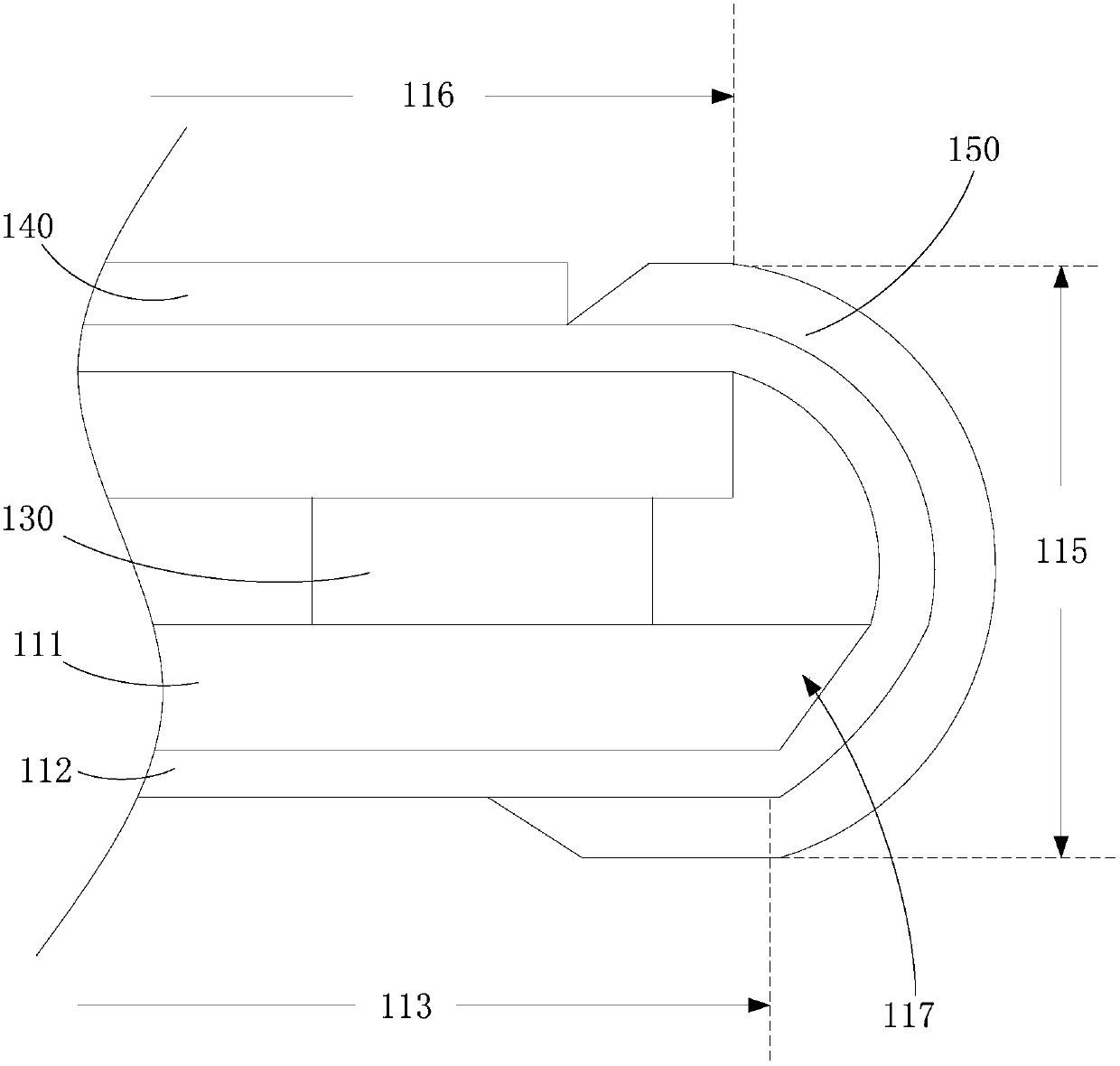

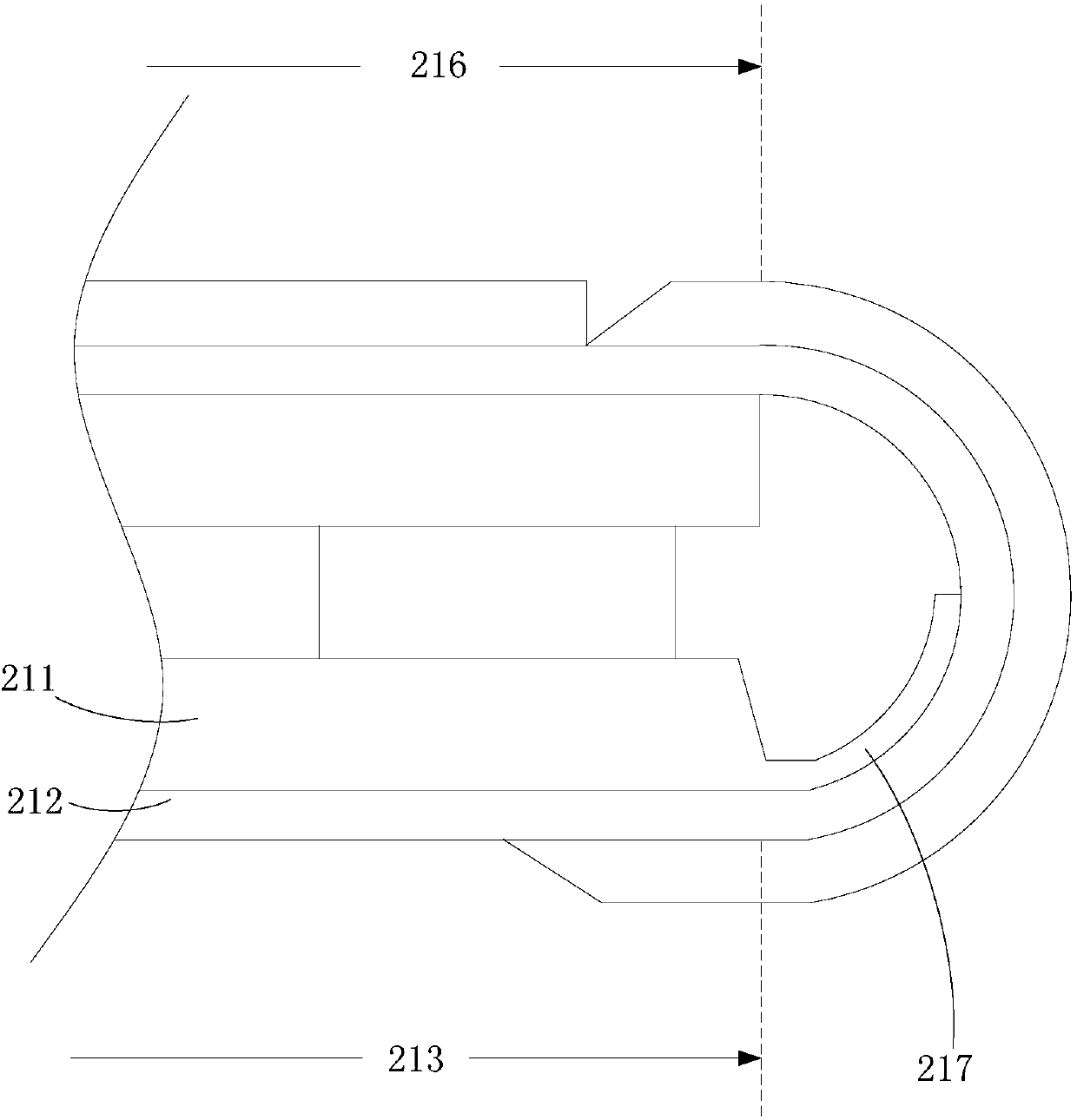

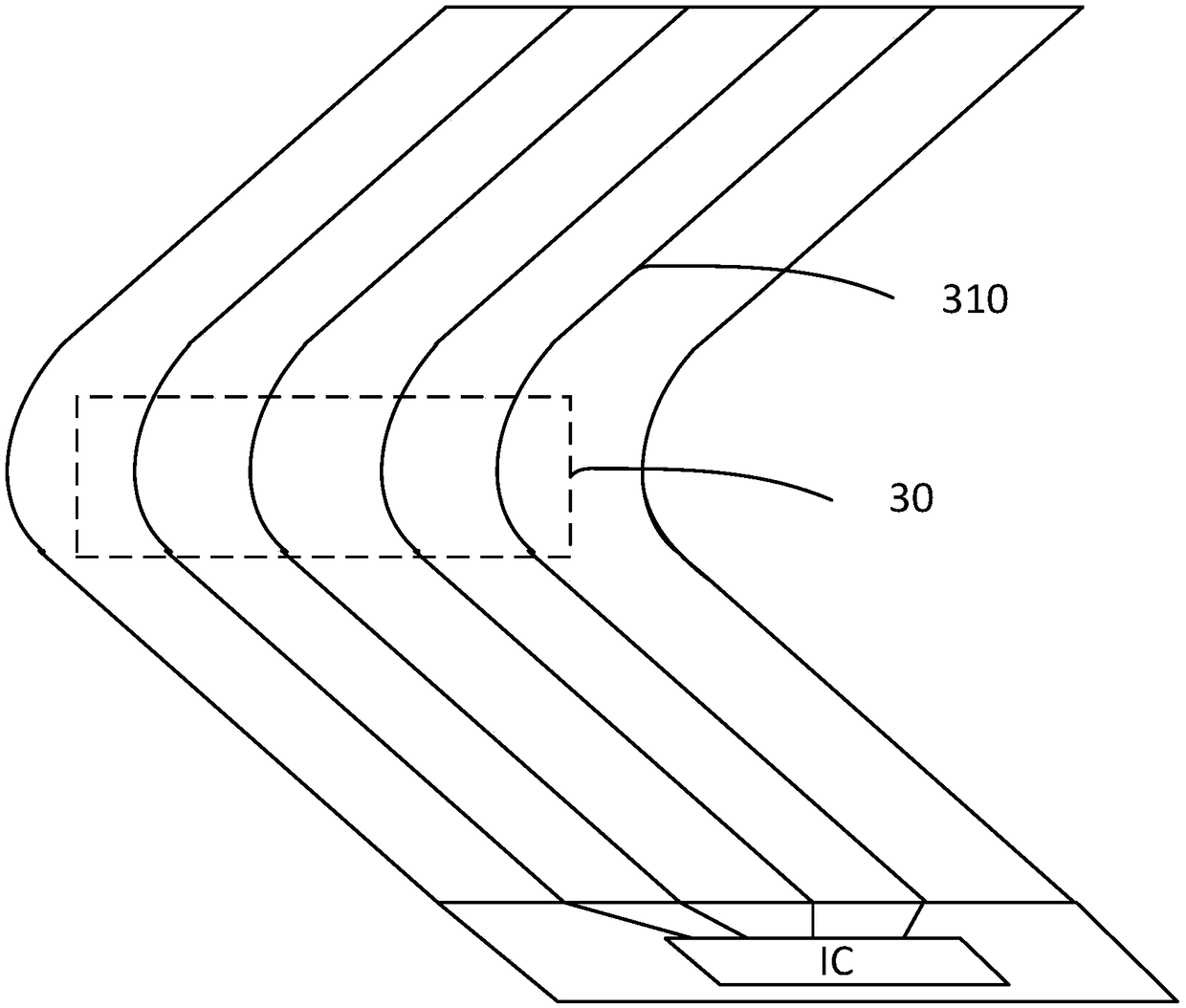

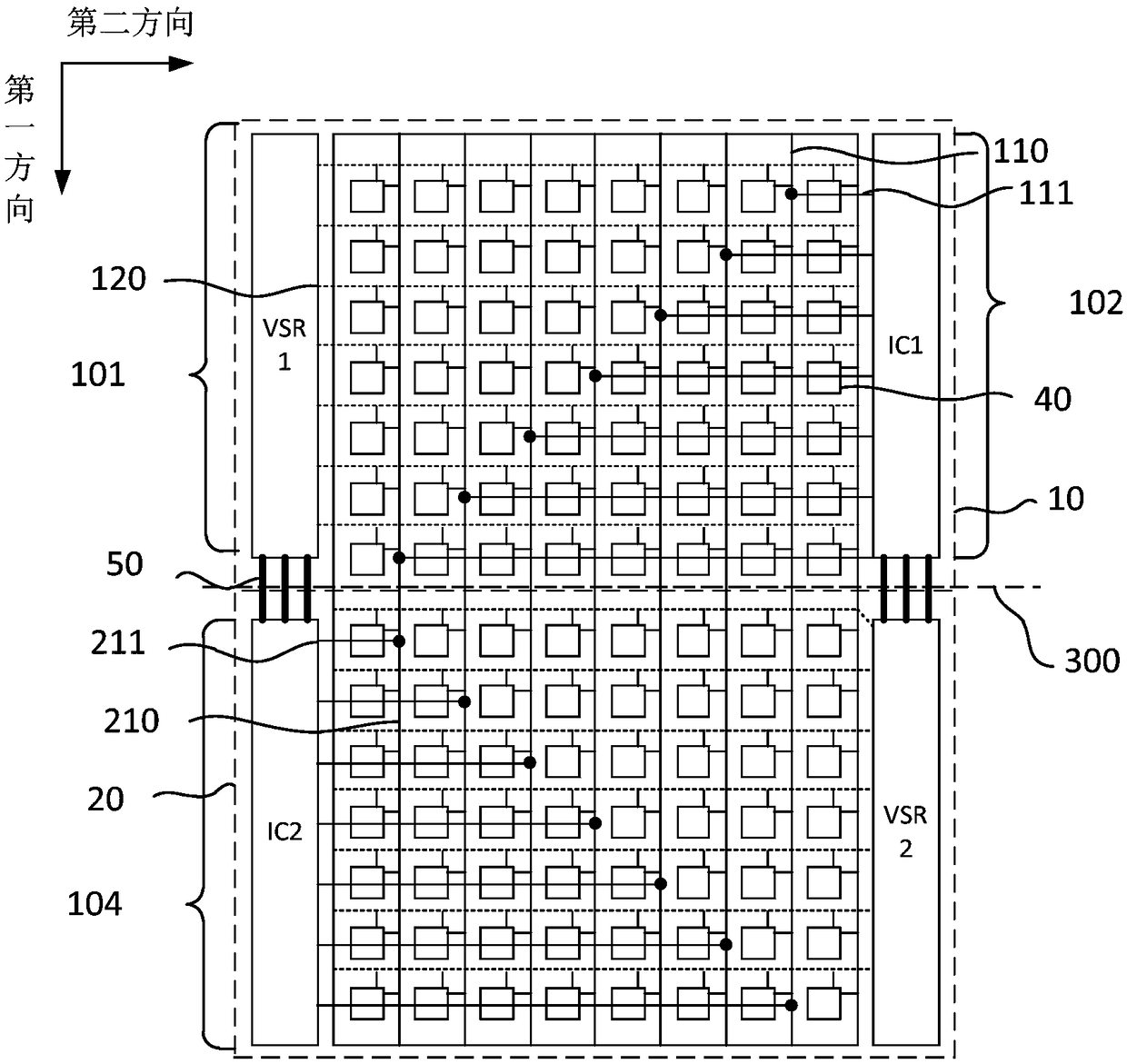

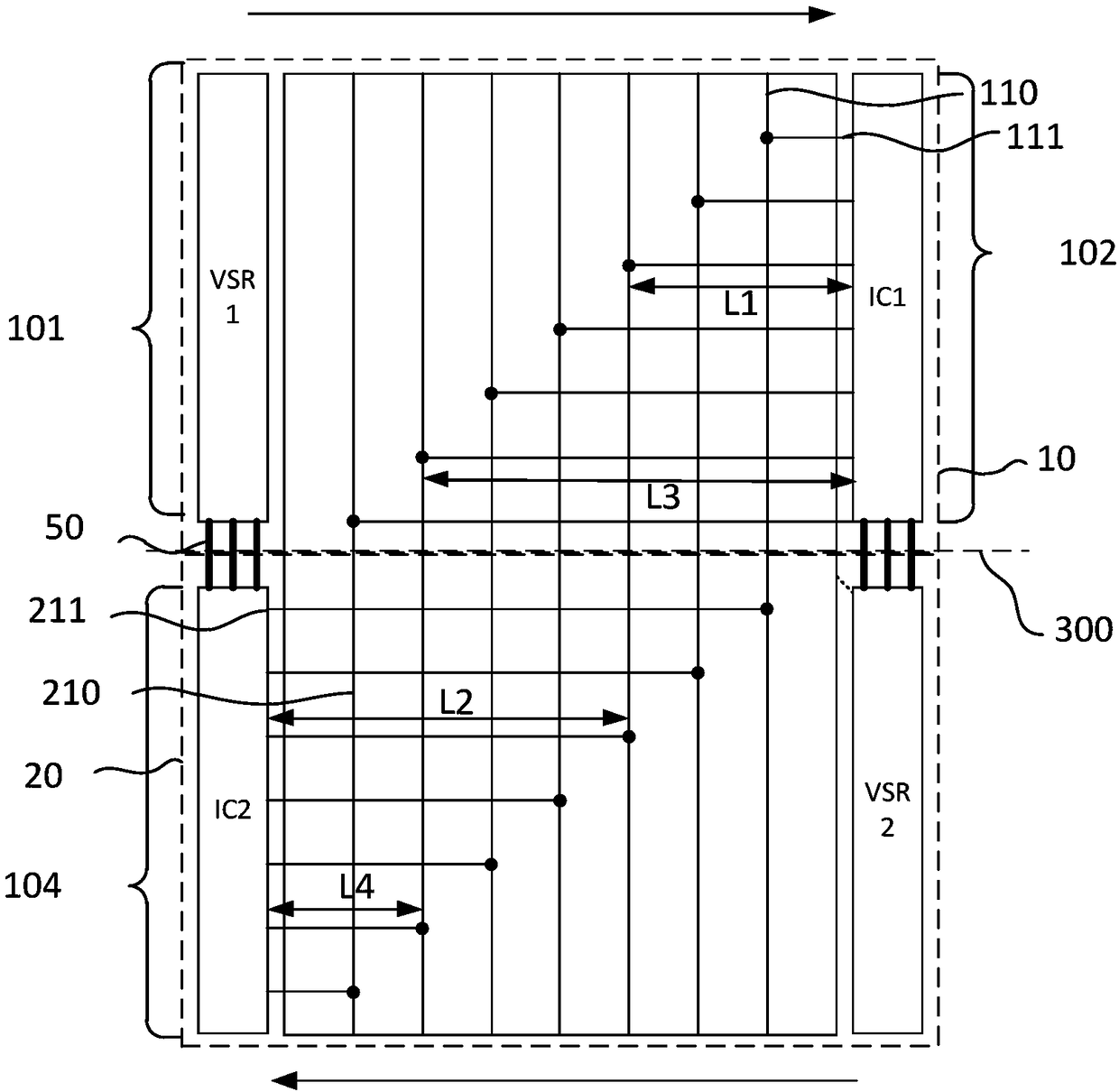

Foldable display panel and display device

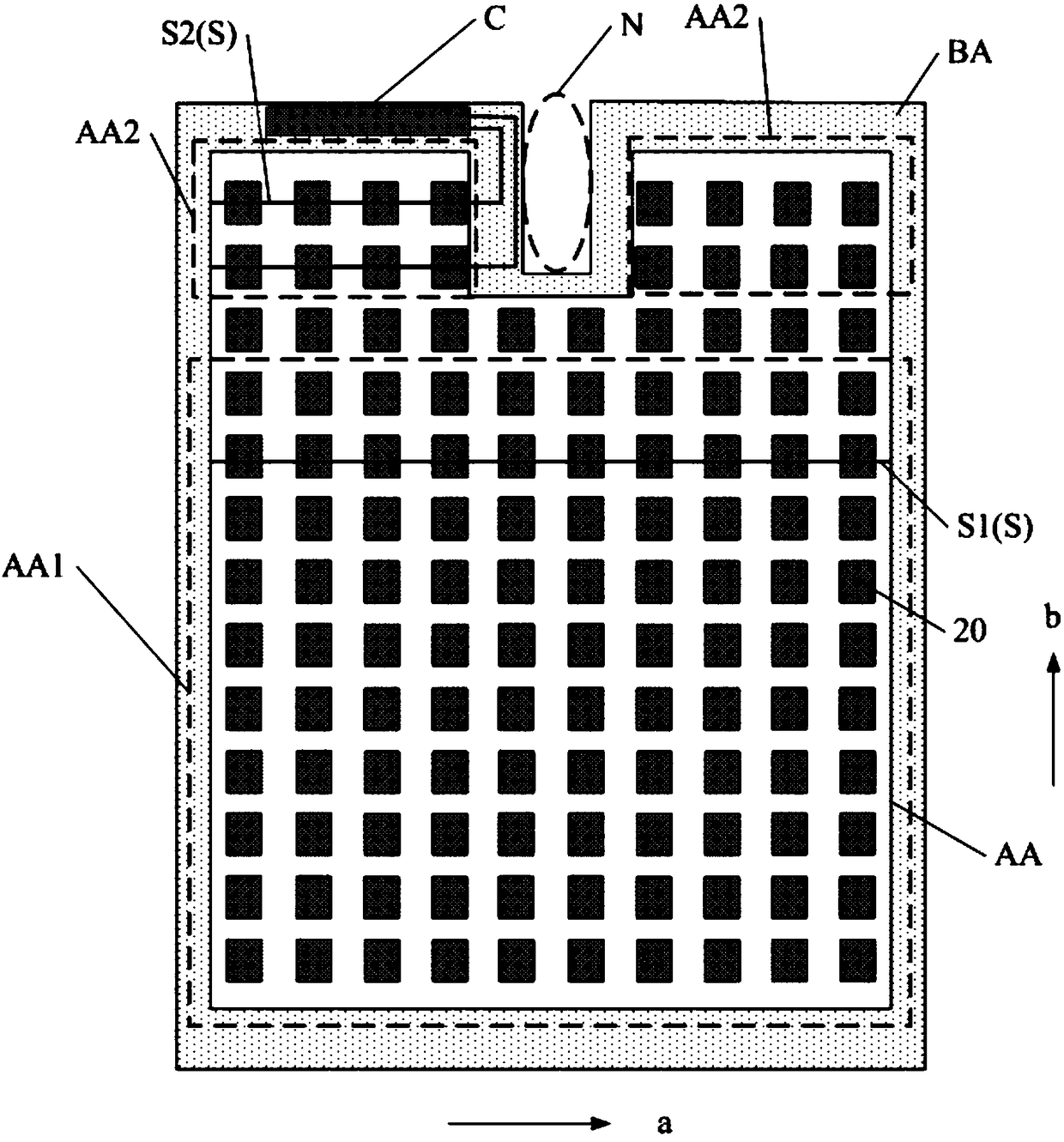

ActiveCN108877535AReduce the risk of disconnectionImprove driving abilityStatic indicating devicesIdentification meansDisplay deviceEngineering

The invention discloses a foldable display panel, which comprises a first display area and a second display area, wherein a folding shaft is arranged between the first display area and the second display area; the first display area comprises a first side edge which is crossed with the folding shaft and a second side edge which is opposite to the first side edge; a first driving circuit is arranged on the first side edge, and a first driving chip is arranged on the second side edge; the second display area comprises a third side edge which is crossed with the folding shaft and a fourth side edge which is opposite to the third side edge; a second driving circuit is arranged on the third side edge, and a second driving chip is arranged on the fourth side edge; the first side edge is alignedwith the fourth side edge, and the second side edge is aligned with the third side edge. By applying the folding display panel, the risk of disconnection can be reduced, the driving capability is improved, and the display effect and the display stability are enhanced.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

Array substrate and touch display panel

ActiveCN106020581AReduce color mixingLower resistanceInput/output processes for data processingInsulation layerEngineering

The invention provides an array substrate and a touch display panel comprising the array substrate. The array substrate comprises a substrate, multiple switch elements located above the substrate, a first insulation layer located above the switch elements and provided with an upper surface having at least one recess, a touch-control electrode layer located above the switch elements and provided with multiple touch-control electrodes, and a touch-control wiring layer located above the first insulation layer and provided with multiple touch-control wiring. Each touch-control wiring is electrically connected with each touch-control electrode correspondingly and used for connecting a corresponding touch-control electrode to a driving circuit. At least one touch-control wiring comprises at least one protrusion arranged in a corresponding recess. The array substrate and the touch display panel comprising the array substrate help improve display effect.

Owner:XIAMEN TIANMA MICRO ELECTRONICS +1

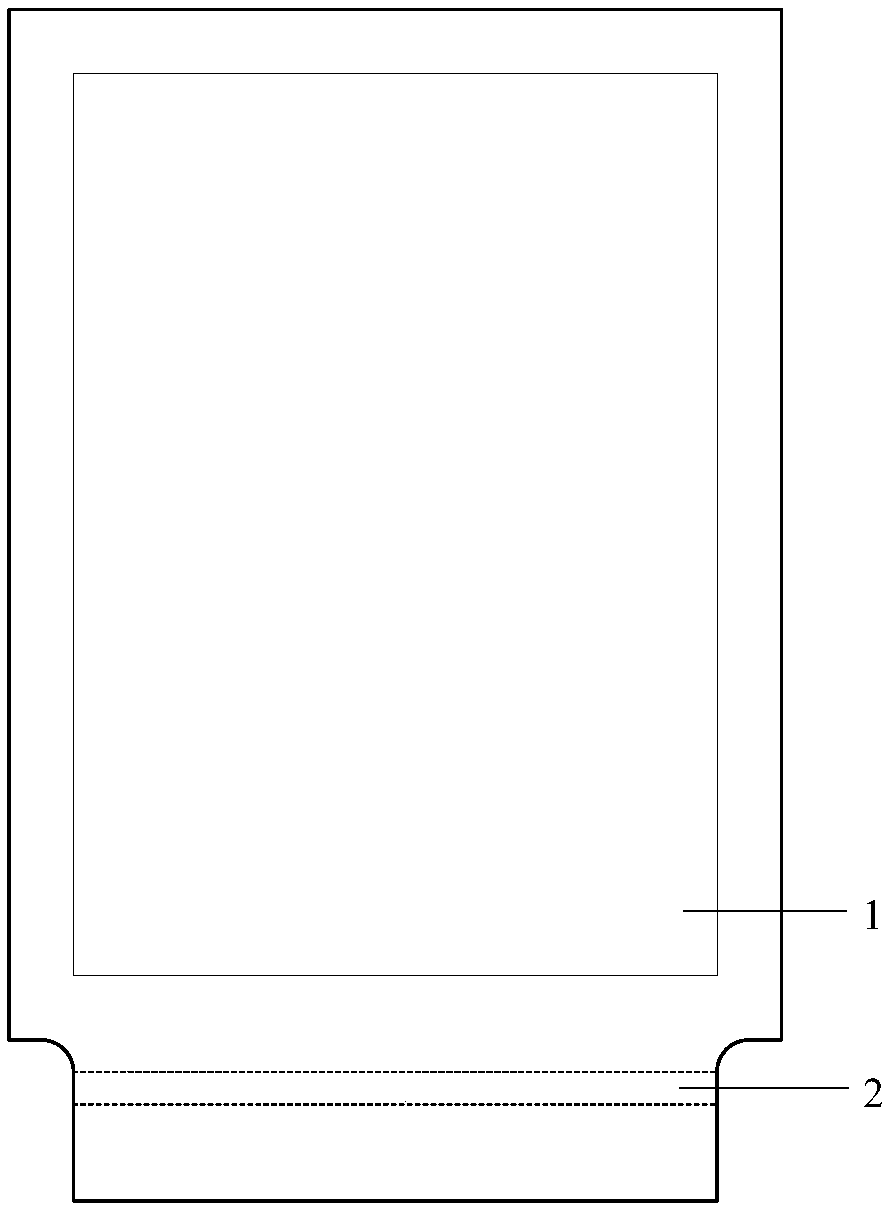

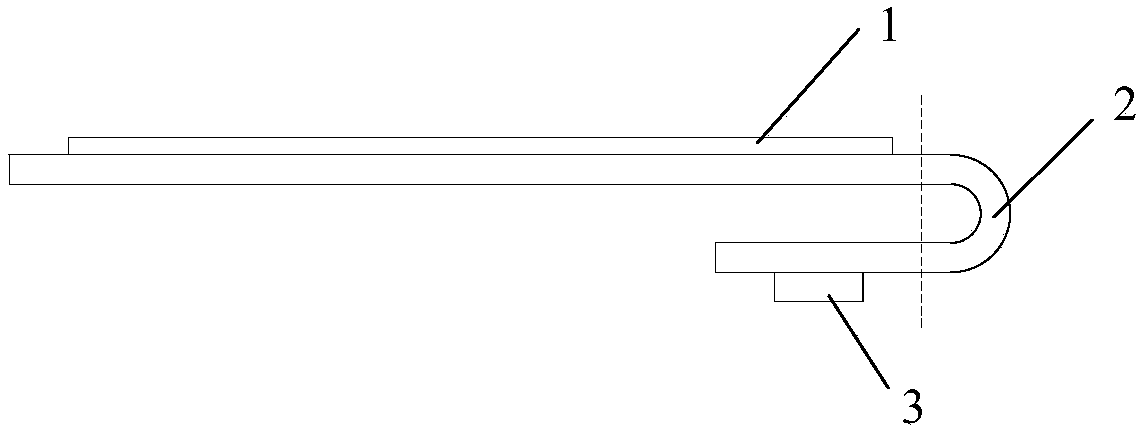

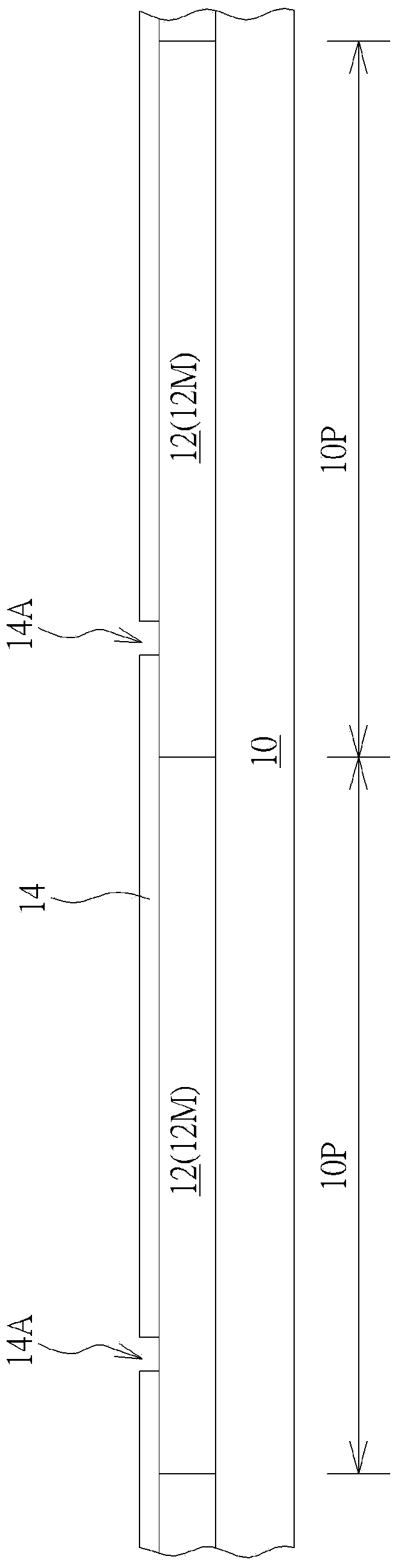

Display module

InactiveCN103489369AEasy to useImprove display qualityStatic indicating devicesIdentification meansFlexible circuitsEngineering

A display module comprises a display panel, a printed circuit board, a flexible circuit board and a driving chip. The display panel comprises a first bent lateral edge and a first electric connection part at the bent lateral edge. The printed circuit board comprises a second electric connection part. The flexible circuit board comprises a first side edge and a second side edge which are opposite to each other. A first joint part is disposed on the first side edge of the flexible circuit board and is contacted and electrically connected with the first electric connection part. A second joint part is disposed on the second side edge of the flexible circuit board and is contacted and electrically connected with the second electric connection part. The flexible circuit board comprises an enclosed broken hole which is between the first joint part and the second joint part. The driving chip is disposed on the flexible circuit board and is between the first joint part and the second joint part.

Owner:AU OPTRONICS CORP

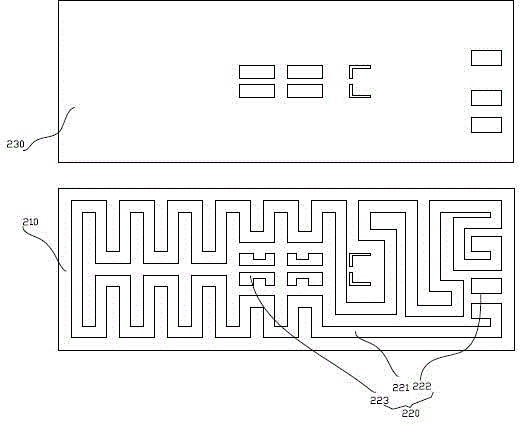

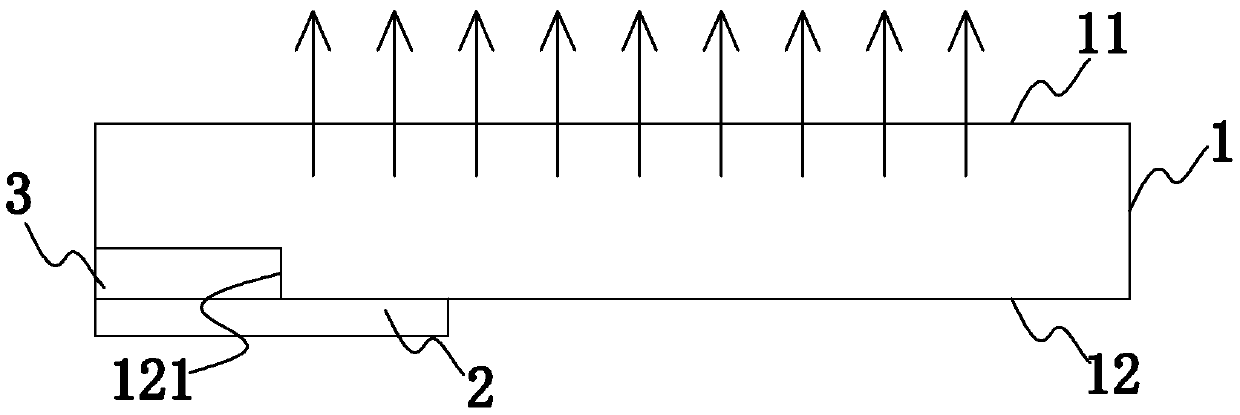

A mask plate and a flexible display panel

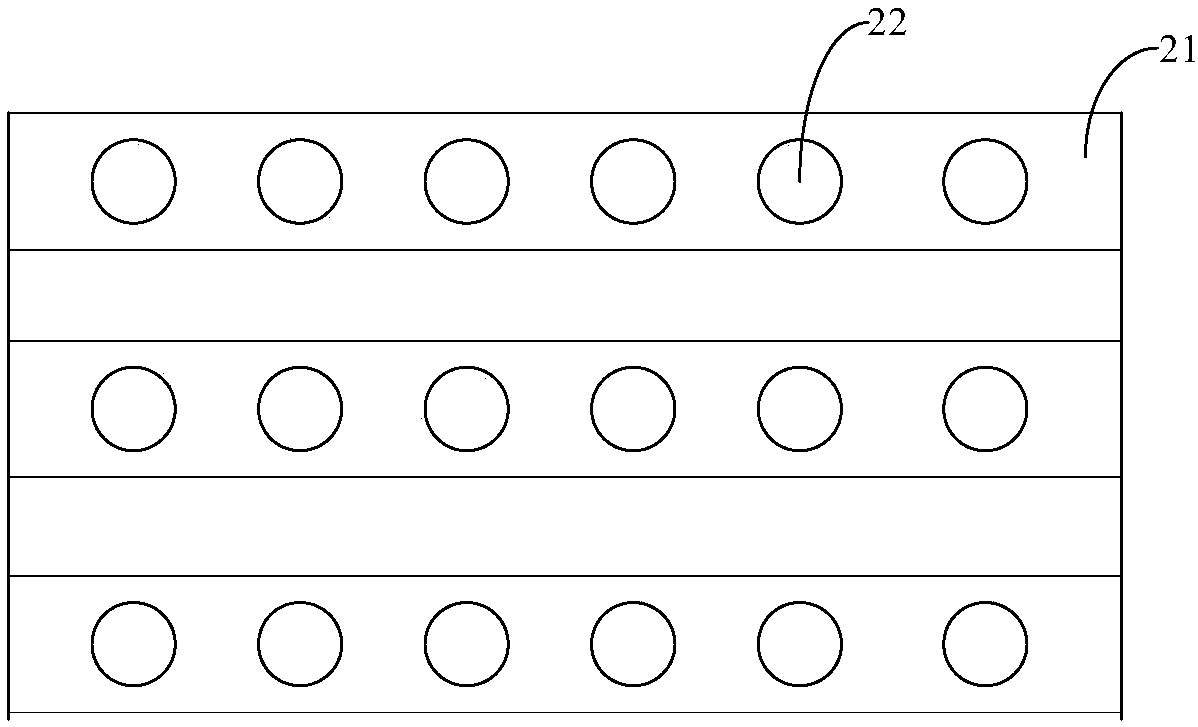

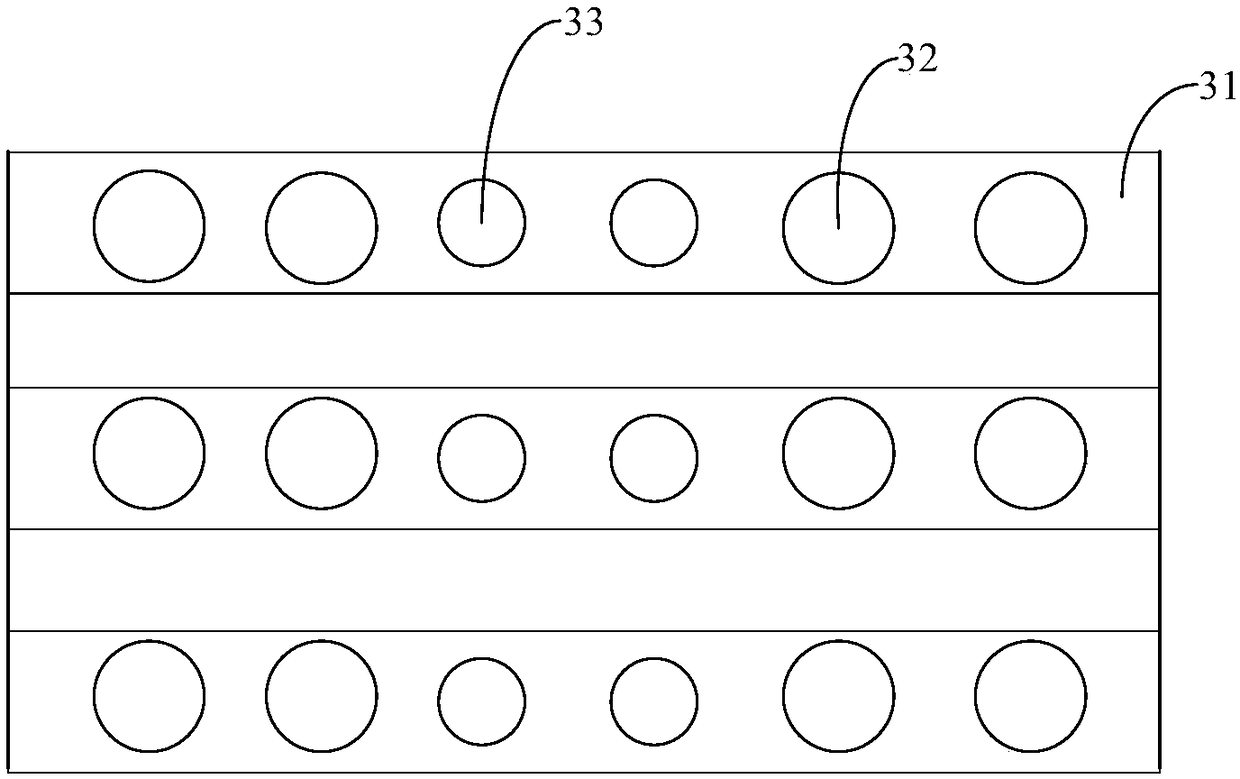

InactiveCN109100914AReduce the risk of disconnectionImprove display qualitySolid-state devicesOriginals for photomechanical treatmentEngineeringFlexible display

A mask plate and a flexible display panel are disclosed. The mask plate is provided with a plurality of strip portions spaced apart, and the strip portions are provided with a plurality of through hole spaced apart along the length direction of the strip portions. The area ratio of the through holes per unit area at both ends of the strip portions is smaller than that of the through holes per unitarea in the middle of the strip portions. The metal traces formed by using the mask plate have the same widths at the metal traces at the through-holes formed in the first and second portions havingdifferent heights, thereby reducing the risk of wire breakage of the metal traces and improving the display quality.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

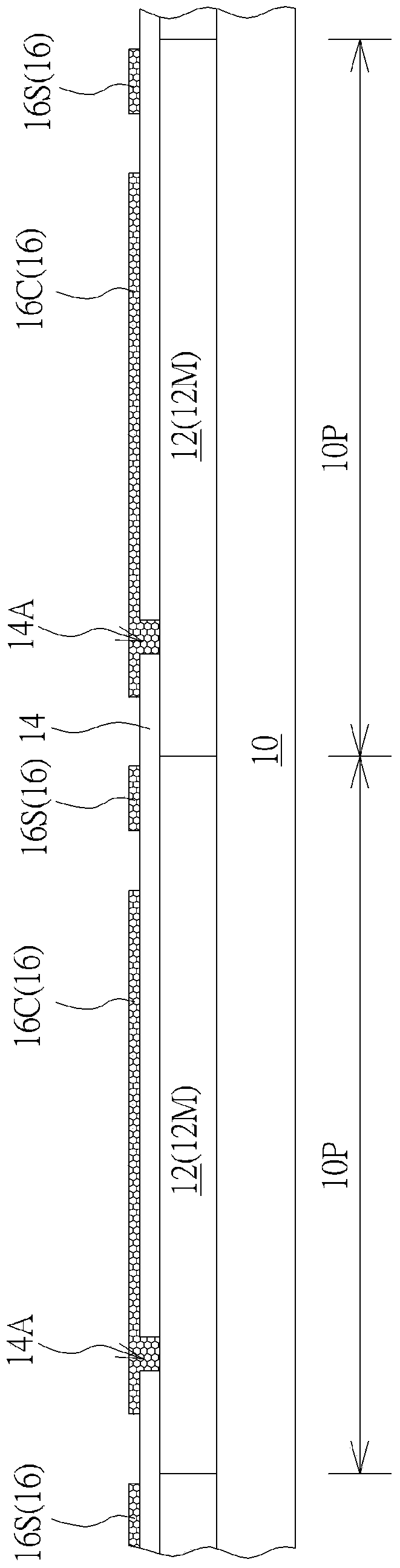

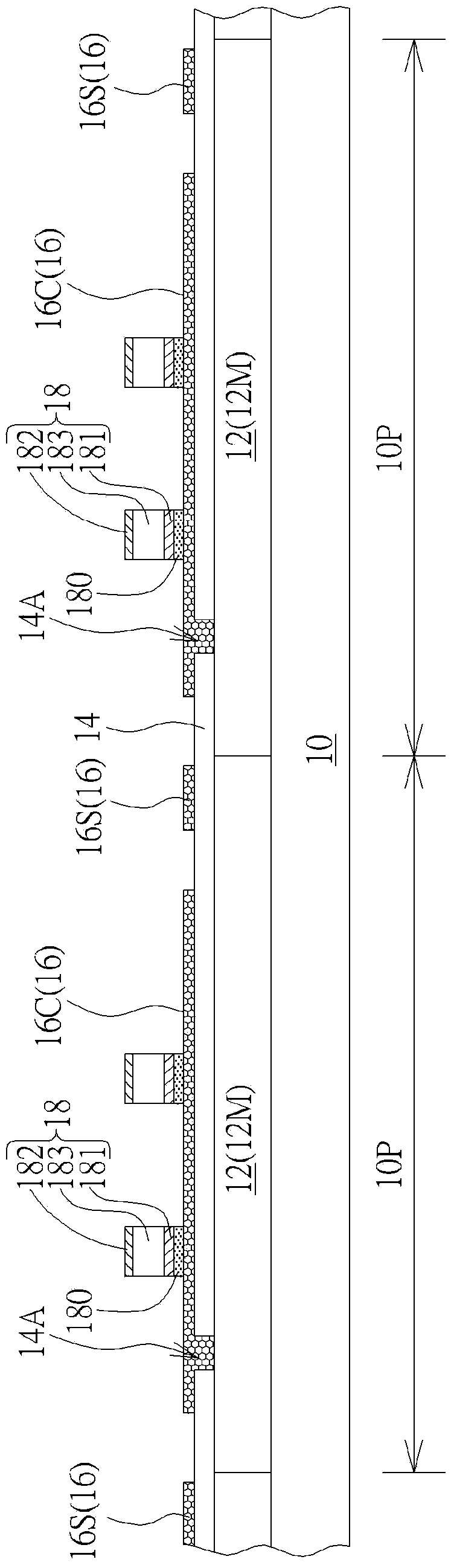

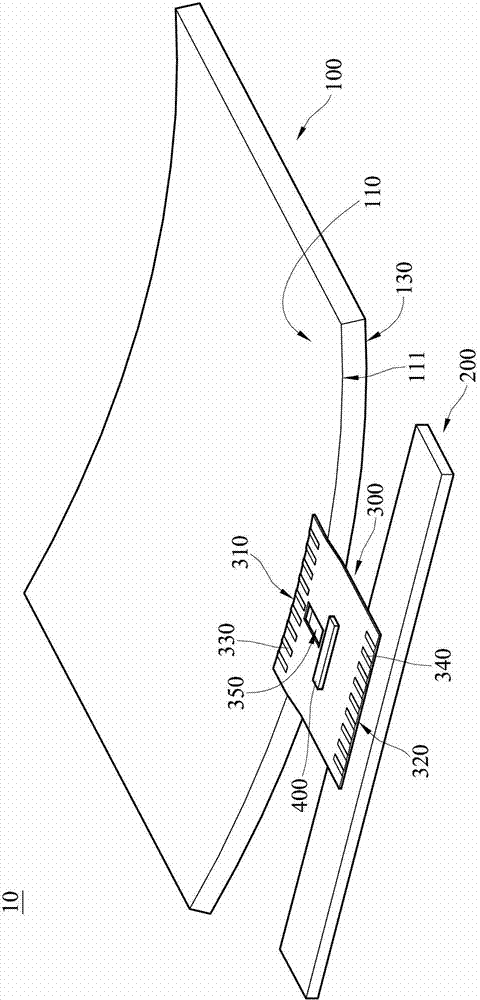

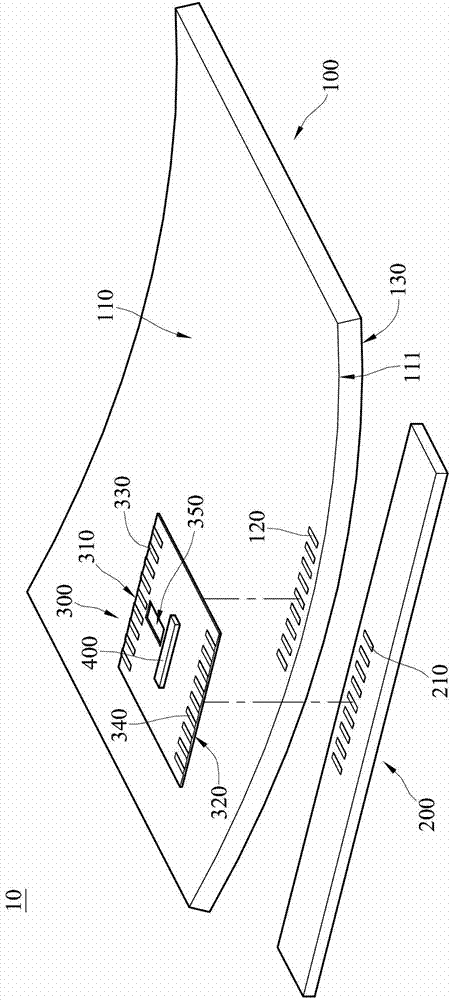

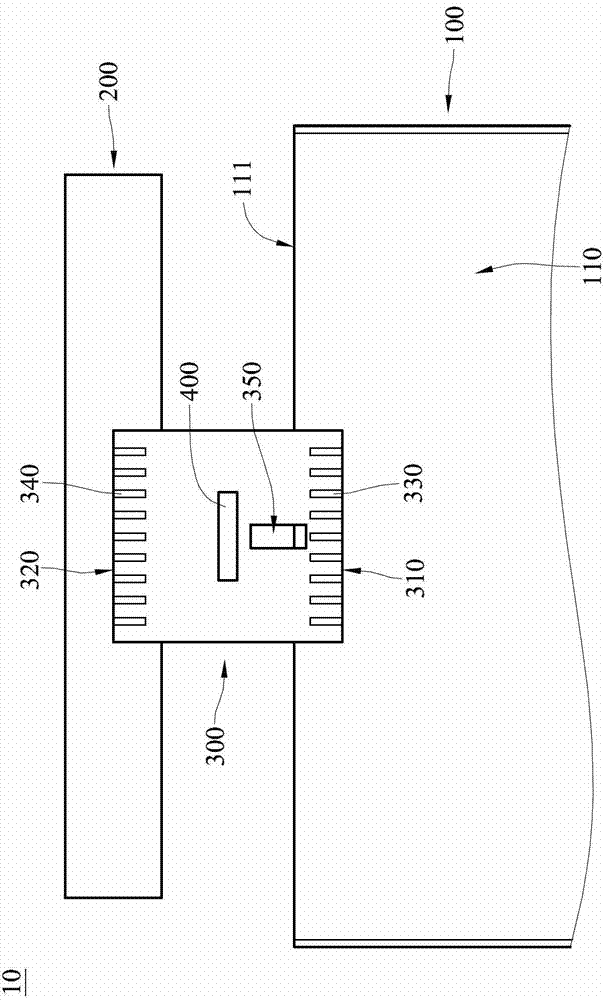

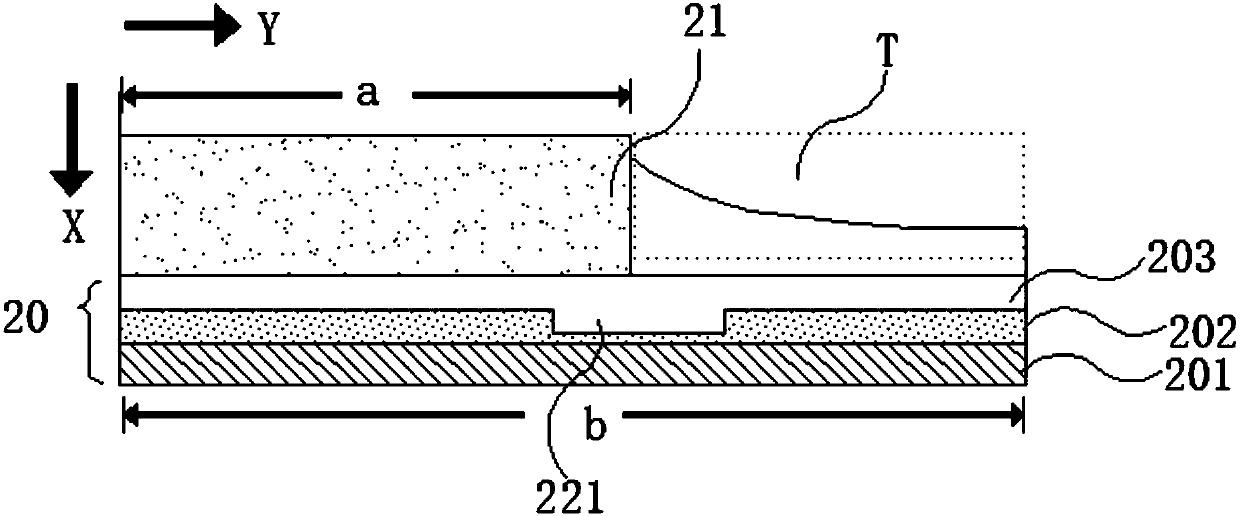

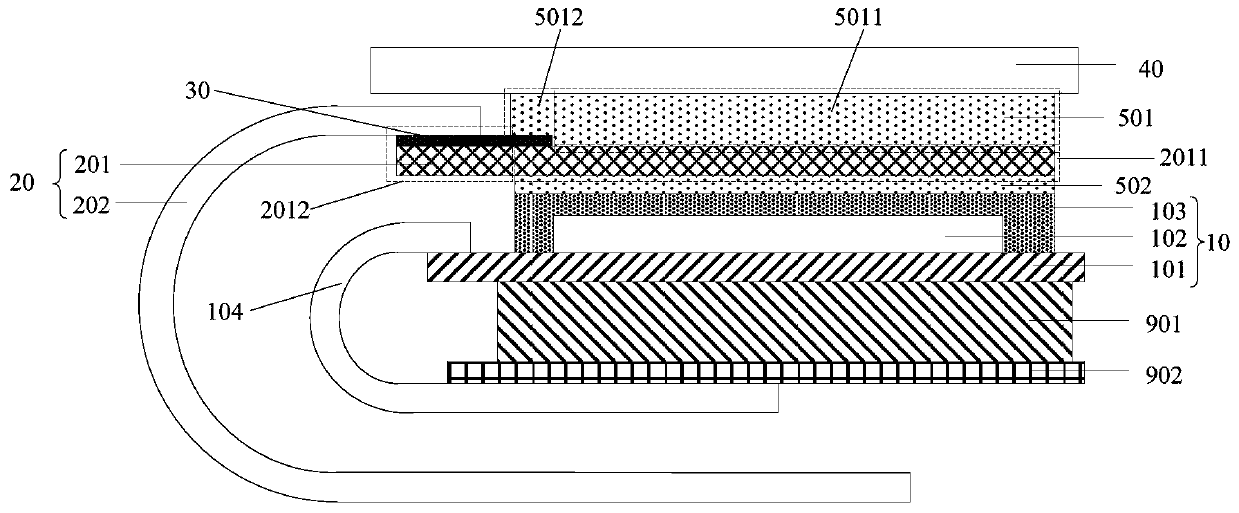

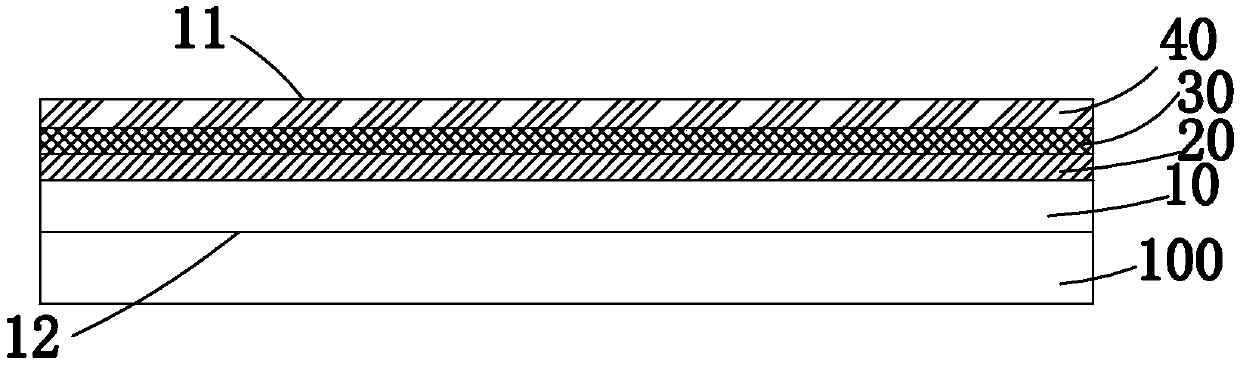

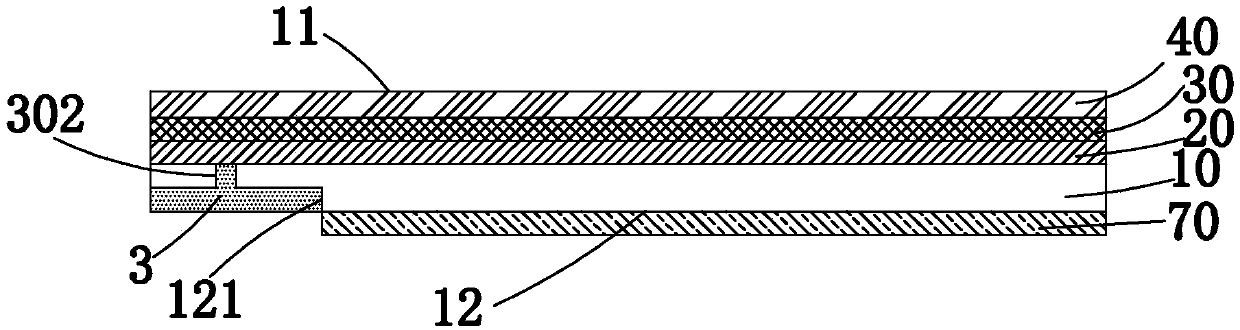

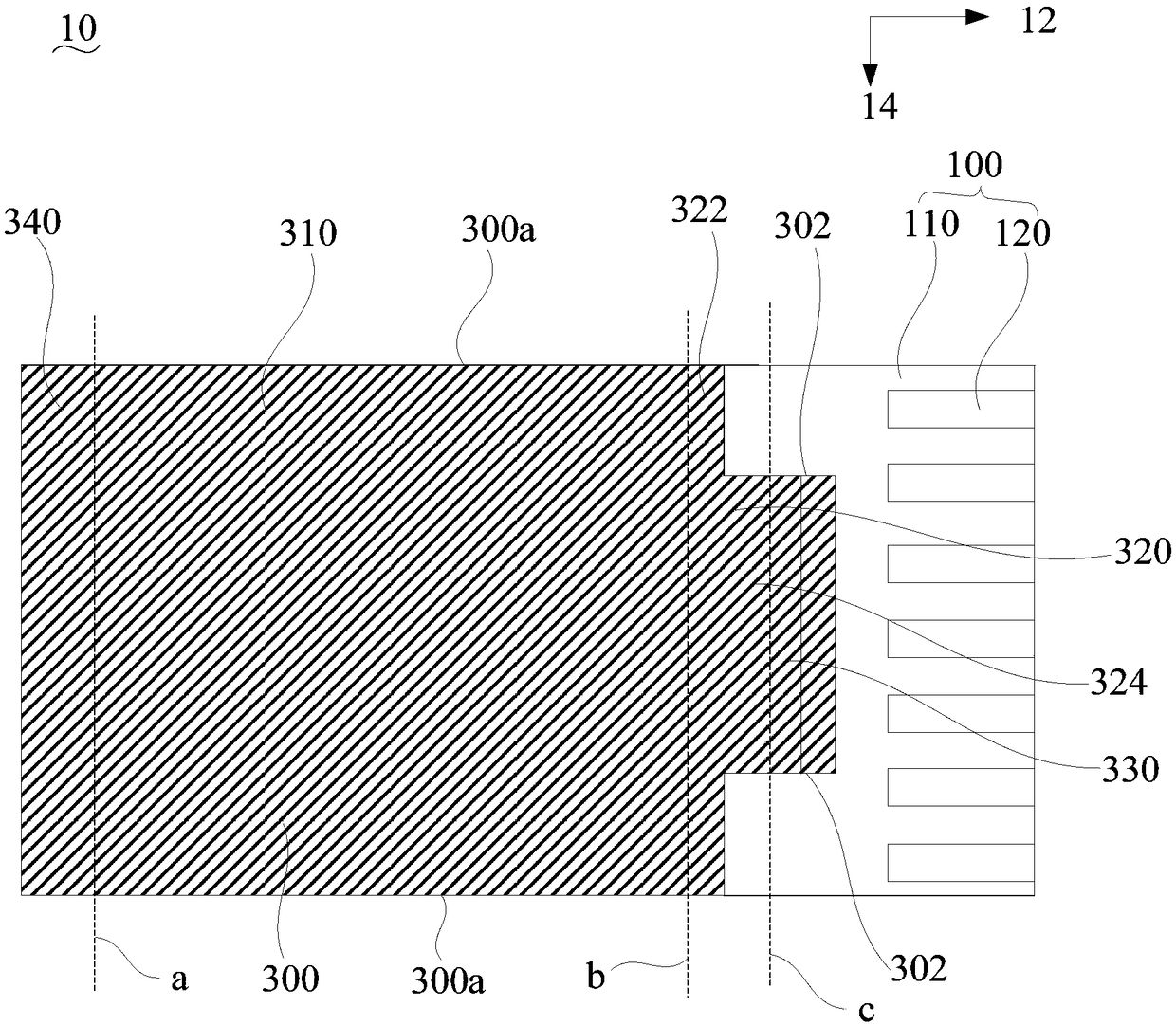

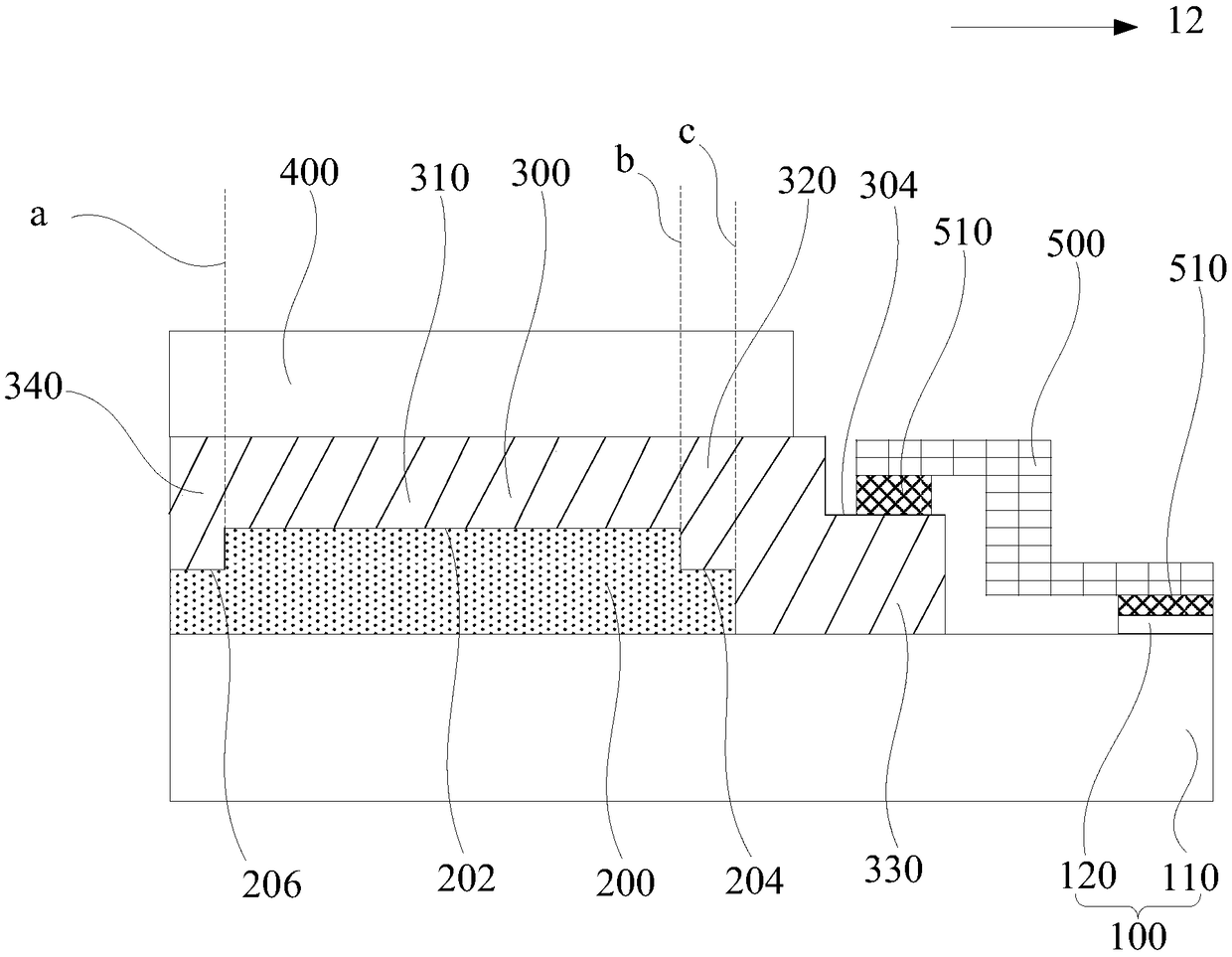

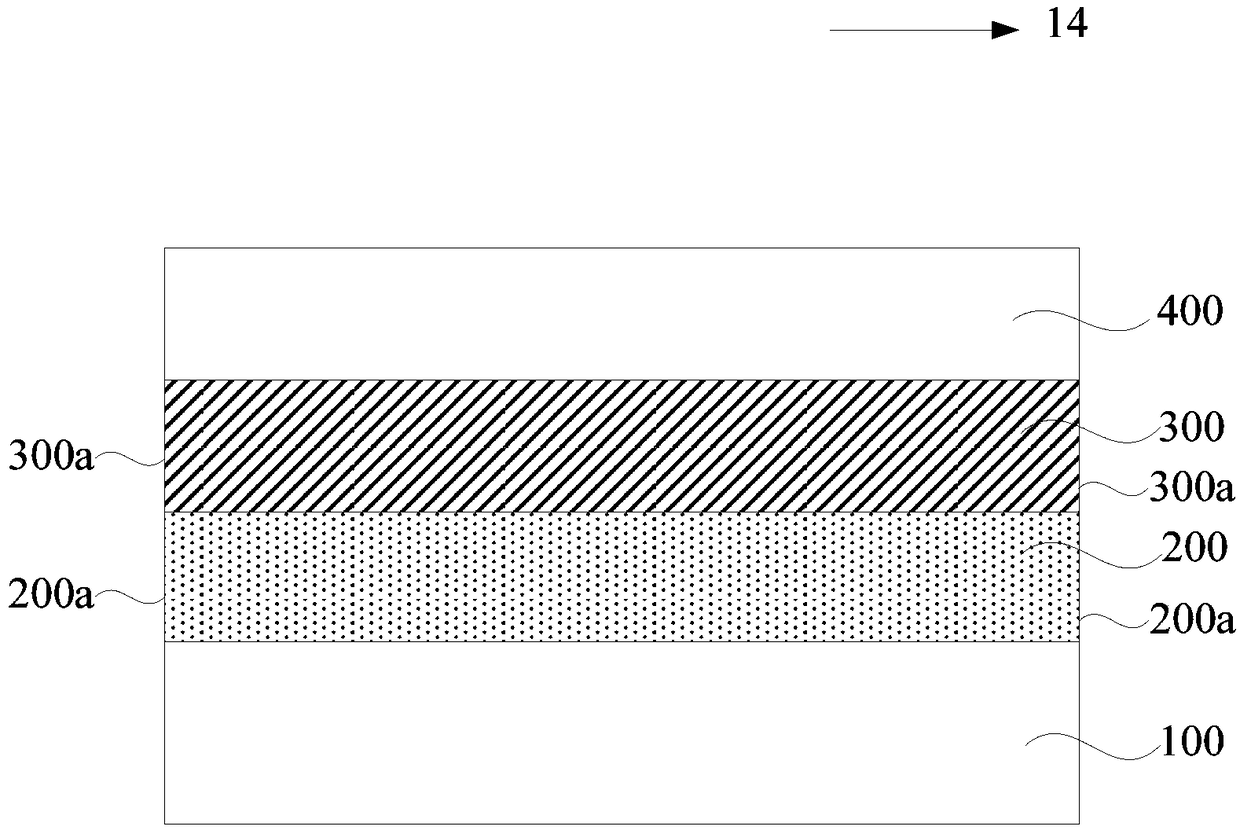

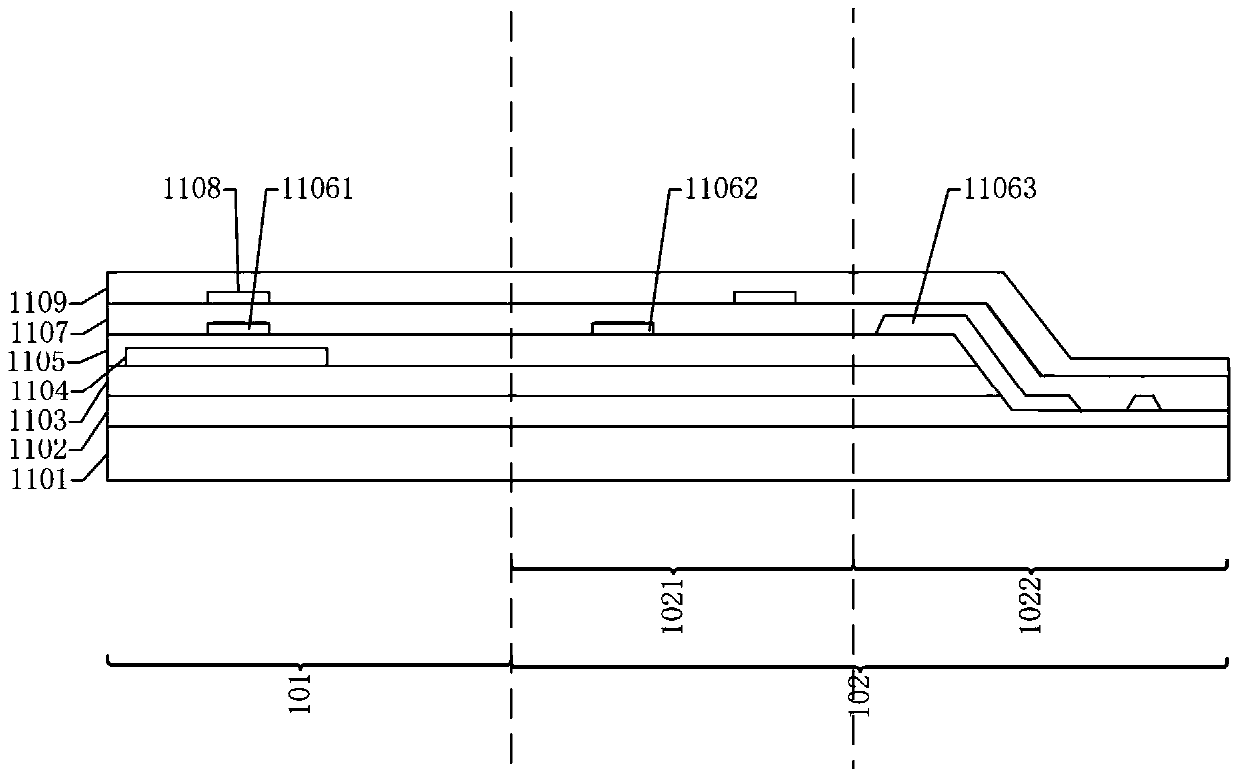

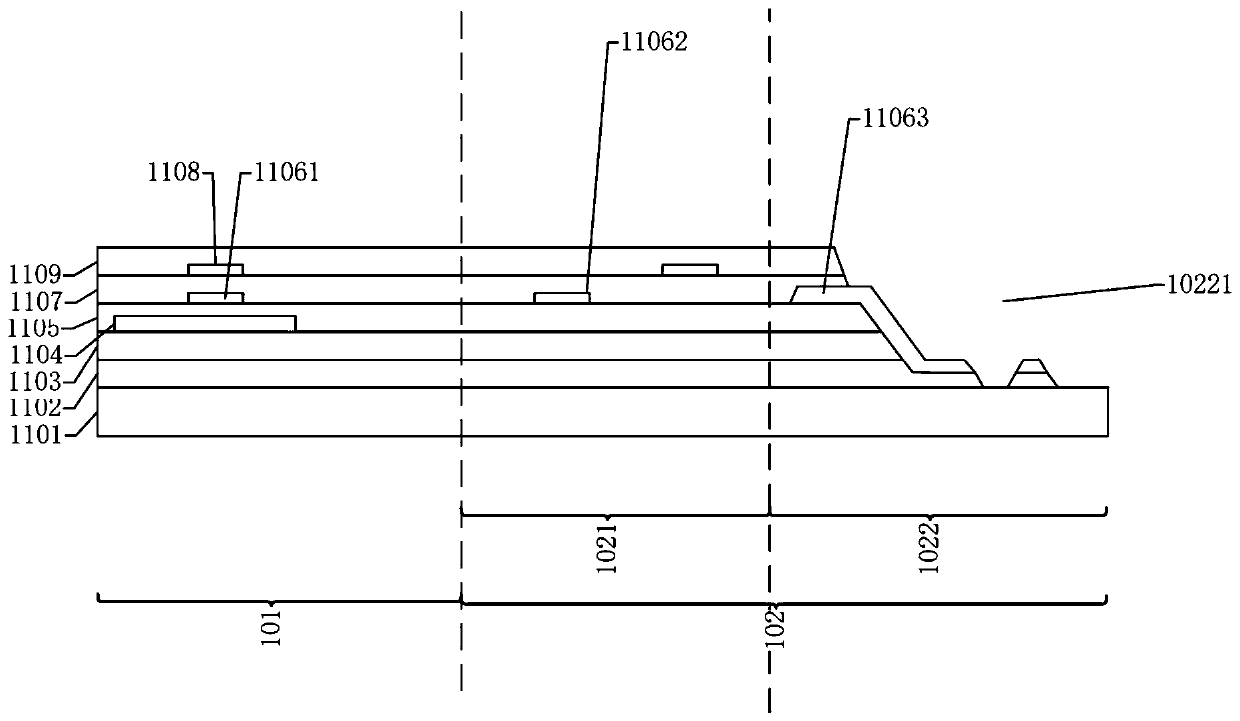

Module structure of flexible display device and flexible touch display device

ActiveCN107706214AReduced risk of cracksReduce the risk of disconnectionSolid-state devicesInput/output processes for data processingDisplay deviceInsulation layer

The present invention discloses a module structure of a flexible display device and a flexible touch display device. The module structure of the flexible display device comprises: a first film layer and a second film layer group oppositely arranged with the first film layer in a first direction, wherein the second film layer group comprises a flexible substrate layer, an inorganic insulation layerlocated between the flexible substrate layer and the first film layer and a conductive layer located between the inorganic insulation layer and the first film layer, the length of the first film layer is smaller than the length of the flexible substrate layer in a second direction to form a step structure, the inorganic insulation layer has a groove, a projection of the groove at a first plane covers at least part of a projection of a step side of the step structure at the first plane, and the first direction is perpendicular to the first plane and the second direction. According to the invention, a risk of wire disconnection in a module structure can be reduced.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

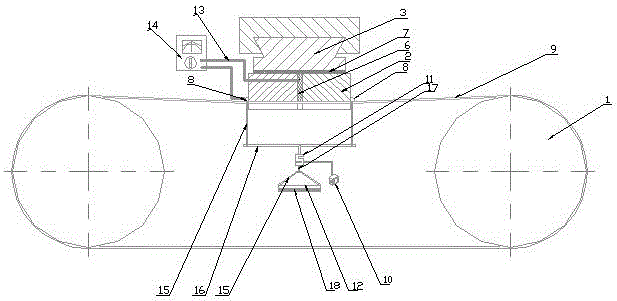

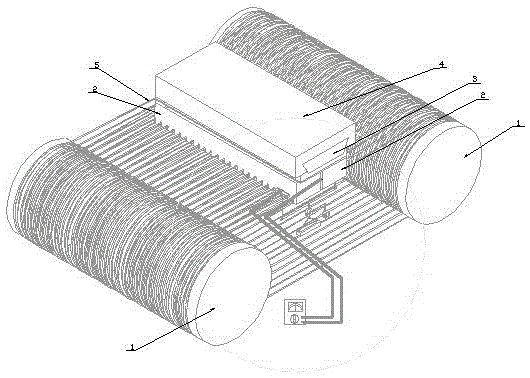

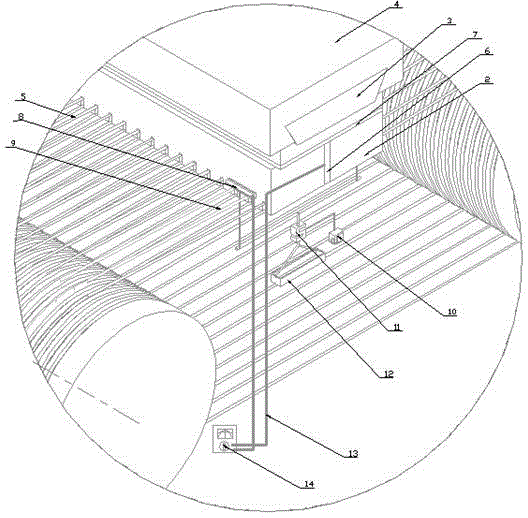

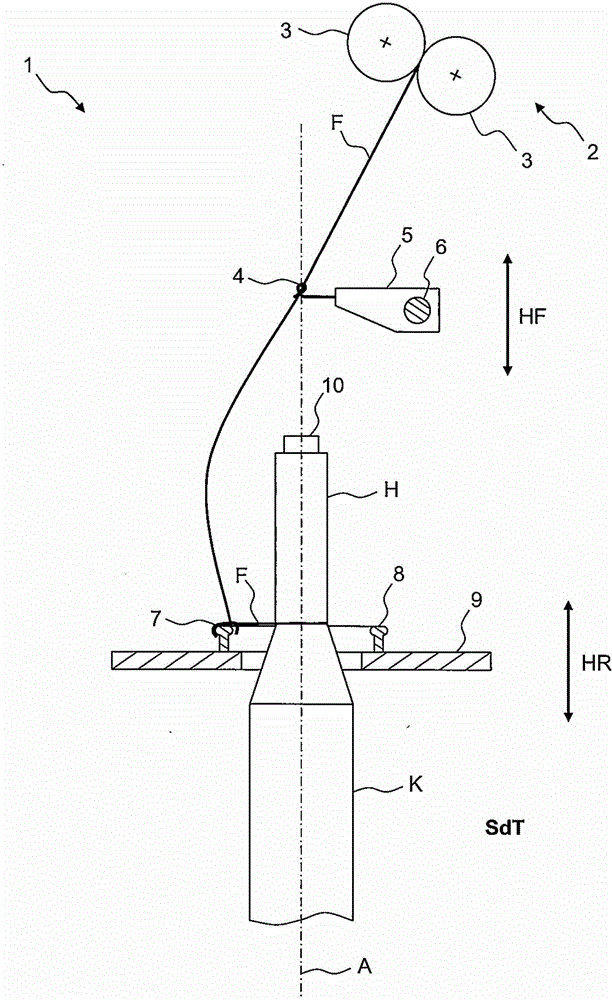

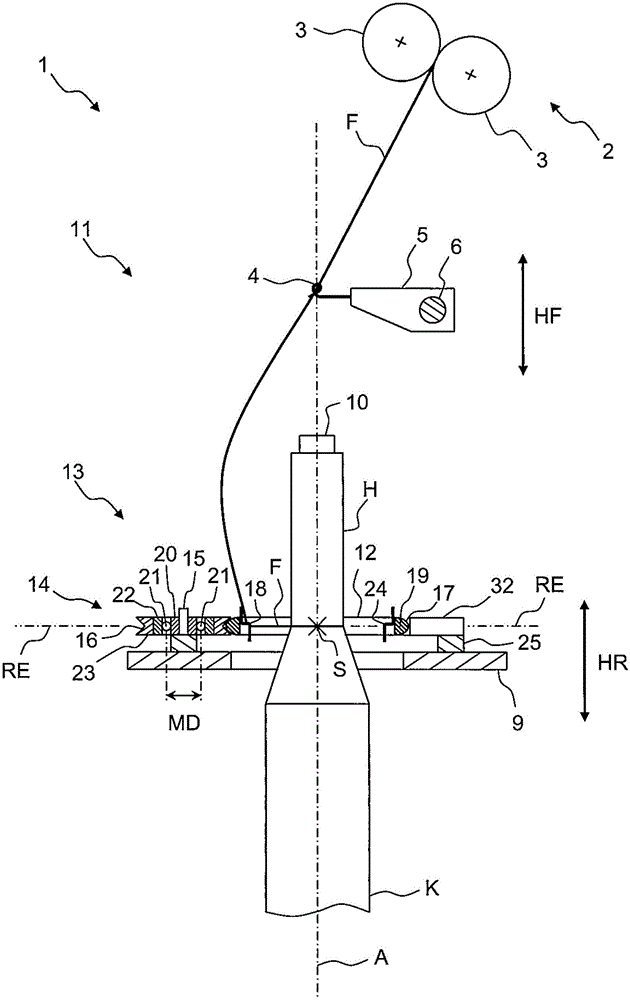

Device and method for measuring tension of wire mesh of multi-wire cutting machine

InactiveCN106313351AReduced impact on cut qualityReduce the risk of disconnectionFine working devicesTension measurementWire cuttingIngot

The invention discloses a device and a method for measuring tension of a wire mesh of a multi-wire cutting machine. The tension is an important parameter in the process that the multi-wire cutting machine machines a crystal ingot, and the tension of the wire mesh is changing and is difficult to measure by an ordinary tension detection tool. According to the measuring principle of the measuring device, the tension of wires is calculated on the basis that the force of the measured wires is balanced in the vertical direction and the measurable gravity is equivalent to the pressure applied by the crystal ingot on the measured wires; and the device comprises measuring stand columns, a T-shaped connecting rod, a pressure sensor, connecting wires, a long box, a counterweight liquid, a multi-meter and the crystal ingot with a conductive sheet sandwiched. The tension of the wires in different positions is measured, and the distribution condition of the tension of the wire mesh can be obtained. With the device and the method, the tension of the wire mesh in the cutting process is measured, and the scientific basis is provided for technological adjustment.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE +1

Ceramic heating slice

The invention relates to a ceramic heating slice. The ceramic heating slice comprises a ceramic substrate and a printing circuit which are burned together under high temperature; the ceramic is used as a supporting structure and has excellent insulation and heat-conducting performance; a heating circuit is used as a heating function element and placed between at least two layers o ceramic substrates; each of the ceramic substrates comprises a 0.4-1.2 mm thick aluminum oxide ceramics substrate and a 3-100 miu m transparent protecting film covering on the printing circuit. The invention further provides a corresponding preparation technique. Through the 3-100 miu m transparent protecting film, heating lines are clear and visible; for reducing the thickness of an upper ceramic, the temperature raising speed is obviously improved and can meet the rapid temperature raising requirement at about 300 DEG C in rapid food detection and medical treatment. Meanwhile, for the upper mm grade aluminum oxide ceramics of the prior art is improved, the material cost is lower. Furthermore, for there is no relative thick aluminum oxide ceramics at the upper layer, the risk of heating circuit disconnection caused by heat loss and rupture of the upper aluminum oxide ceramics in the prior art is reduced, and the service life of the ceramic heating slice is improved.

Owner:张耿荻

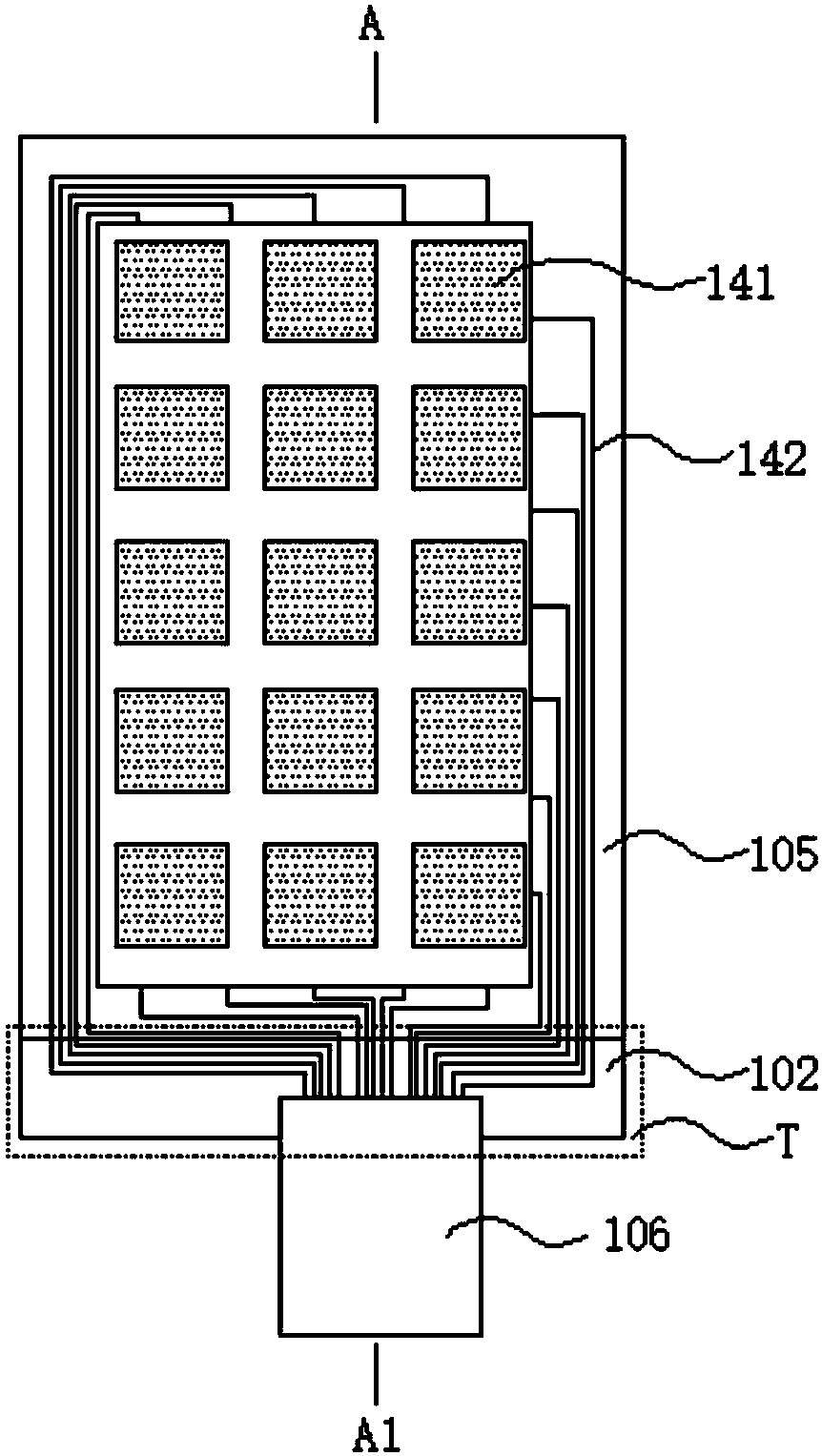

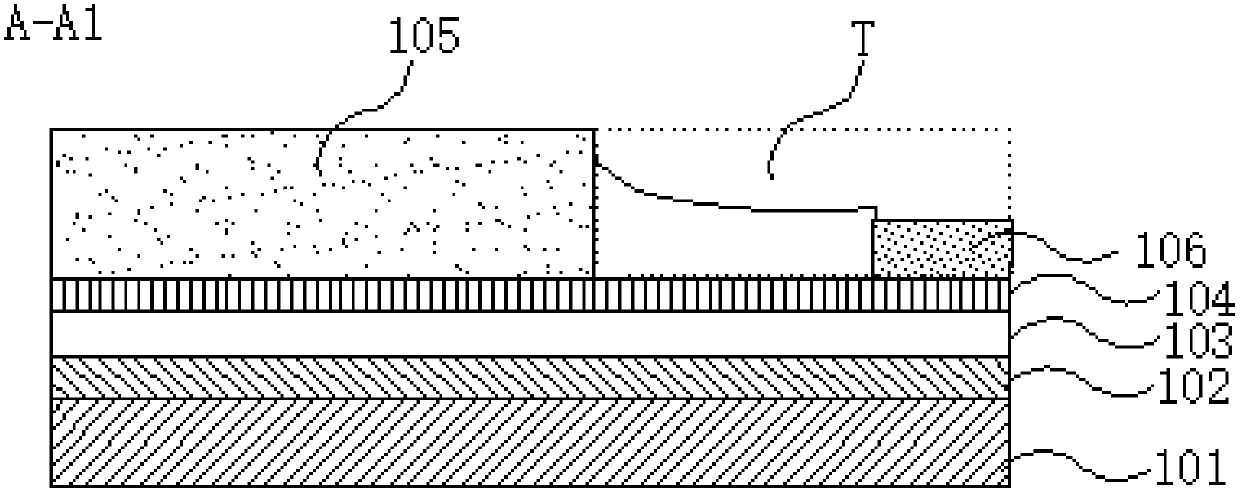

Display panel, display equipment and preparation method of display panel

ActiveCN111338511AReduce the risk of disconnectionImprove reliabilityPhotovoltaic energy generationInput/output processes for data processingComputer hardwareFlexible circuits

The invention discloses a display panel, a display device and a preparation method of the display panel, the display panel comprises a display substrate and a touch module, and the display substrate defines a display area and a non-display area; the touch module comprises a touch layer and a touch flexible circuit board, the touch layer is located on the light emitting side of the display substrate, the touch layer is provided with a touch area and a bonding area, the touch area covers the display area, and the touch flexible circuit board is bonded to the side, away from the display substrate, of the touch layer of the bonding area; the touch control flexible circuit board is electrically connected with the touch control layer of the bonding area in a bonding mode through conductive adhesive, and the conductive adhesive is arranged on the touch control layer of the bonding area, extends to the touch control area and covers part of the touch control layer of the touch control area. Bymeans of the mode, the probability that the touch layer circuit is damaged can be reduced, and the reliability of the product is improved.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

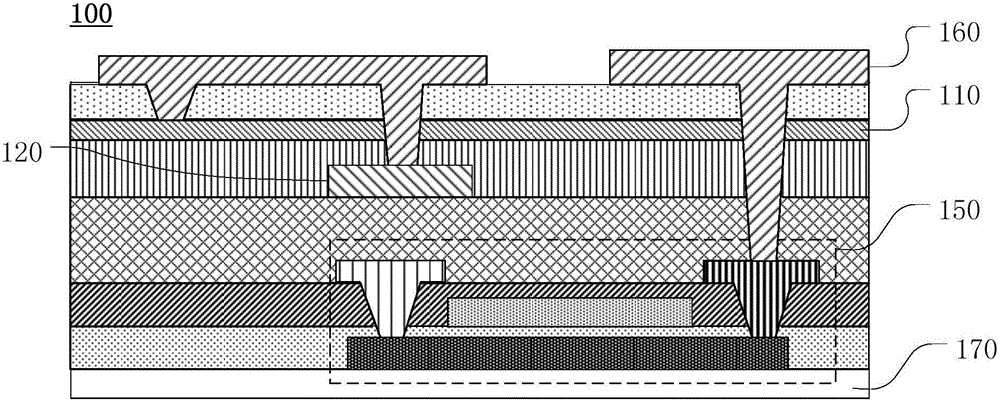

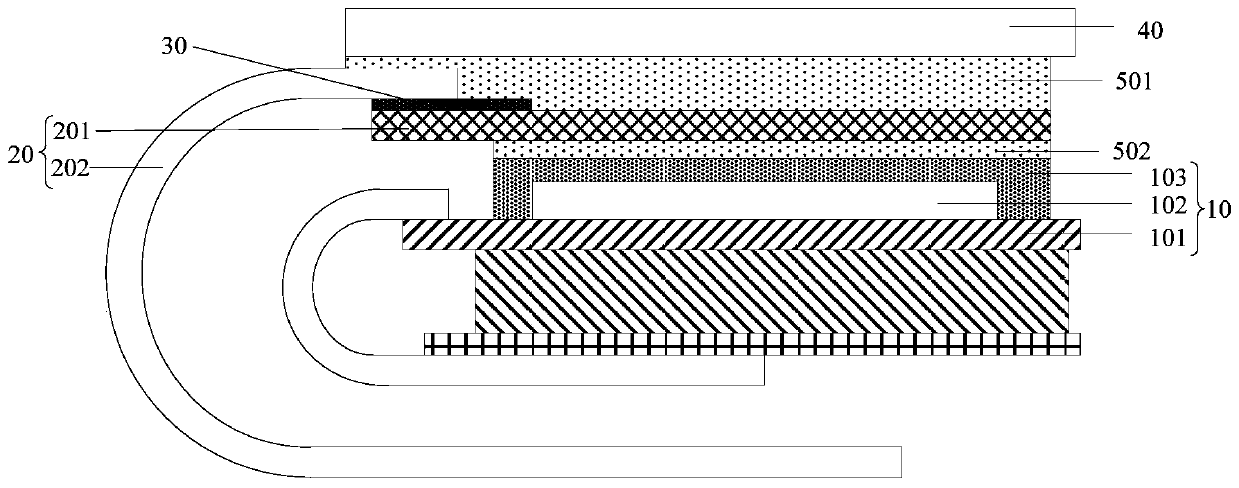

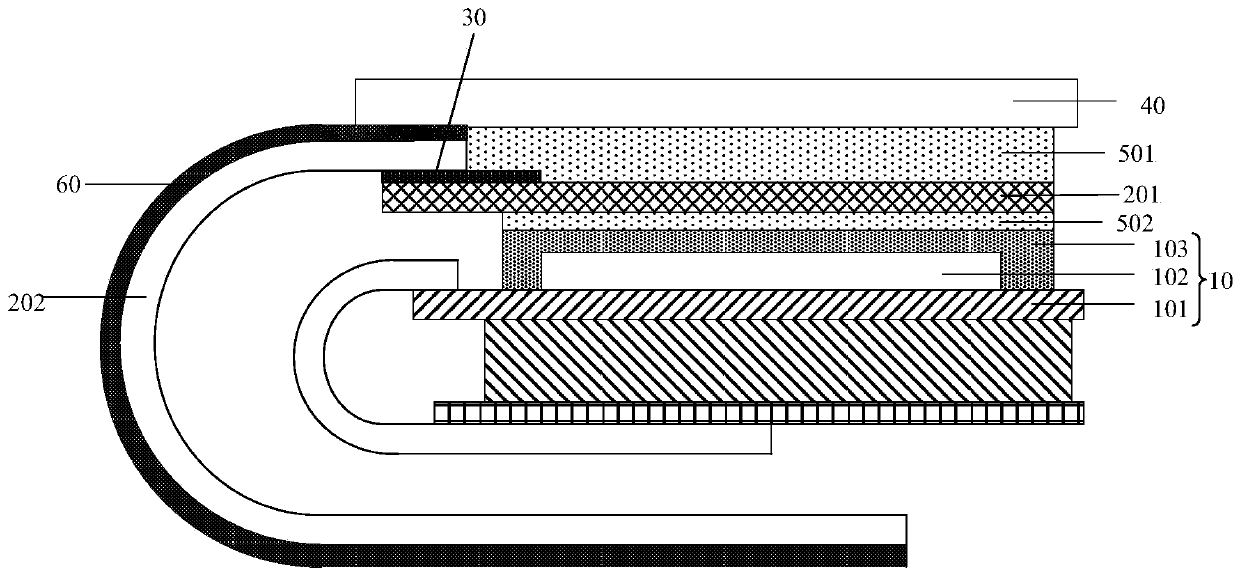

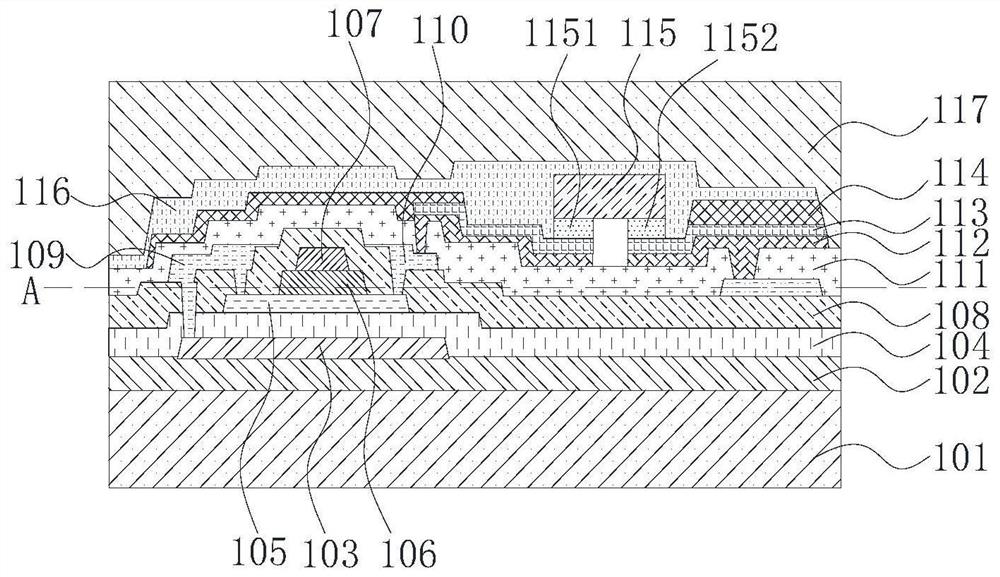

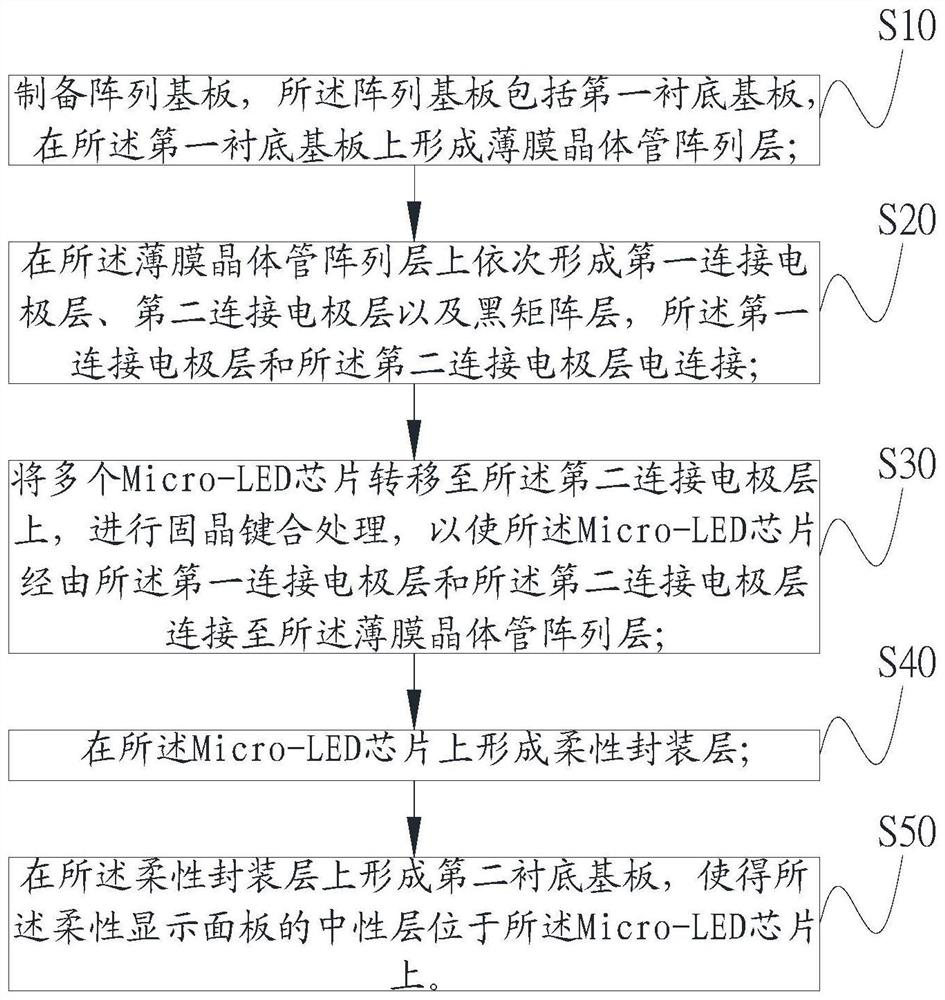

Flexible Micro-LED display panel and manufacturing method thereof

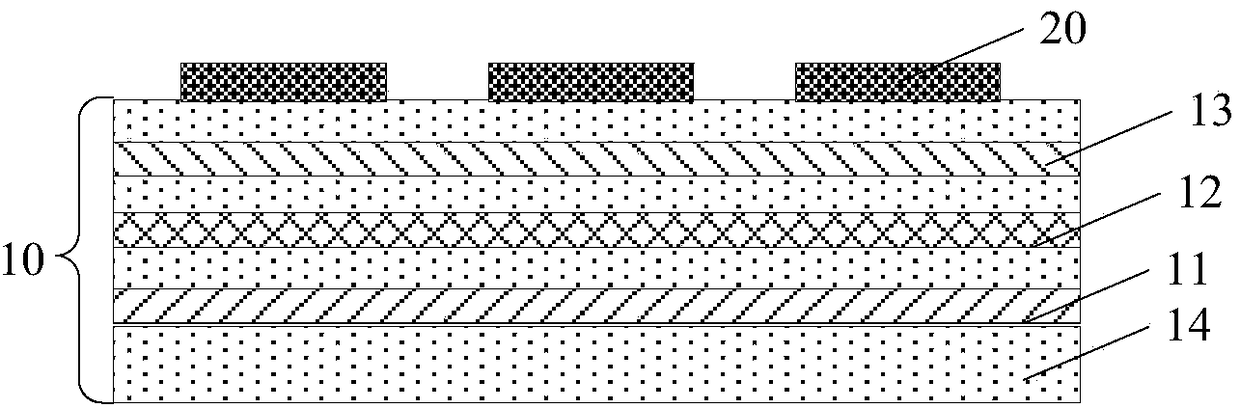

ActiveCN111710691AReduce the risk of disconnectionHigh transparencySolid-state devicesSemiconductor devicesEngineeringFlexible display

The invention provides a flexible Micro-LED display panel and a manufacturing method thereof. The flexible Micro-LED display panel comprises a first substrate, a thin film transistor array layer, a first connecting electrode layer and a second connecting electrode layer which is arranged on the first connecting electrode layer, a plurality of Micro-LED chips, a flexible packaging layer, and a second substrate arranged on the flexible packaging layer. The first substrate and the second substrate are both flexible base plates. By arranging the second substrate on the flexible packaging layer covering the Micro-LED chip, the neutral layer of the flexible display panel is located on the thin film transistor array layer, so that the risk of line breakage is reduced, and flexible display of theMicro-LED display panel is realized.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

OLED (Organic Light Emitting Diode) display device and manufacture method thereof

ActiveCN109599421AReduce border widthIncrease the screen ratioStatic indicating devicesFinal product manufactureDisplay deviceLine Break

The invention provides an OLED (Organic Light Emitting Diode) display device and a manufacture method thereof. The OLED display device comprises an OLED display panel, a driving module and a binding terminal, wherein the OLED display panel is provided with a light emitting surface and a non-light-emitting surface opposite to the light emitting surface; the binding terminal is arranged on the non-light-emitting surface; the driving module is bound to the binding terminal; the binding terminal is arranged on the non-light-emitting surface of the OLED display panel; and the driving module is bound to the binding terminal of the non-light-emitting surface. Compared with the prior art, the OLED display device is characterized in that: since the binding terminal is positioned on the non-light-emitting surface of the OLED display panel, the bound driving module does not need to be bent, so that border width is reduced to a maximum degree, and a line breaking risk is lowered while a screen-to-body ratio is improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Liquid crystal display panel

ActiveCN101833183AHigh light transmittanceLower impedanceNon-linear opticsLiquid-crystal displayEngineering

The invention discloses a liquid crystal display panel comprising an array basal plate and at least one connecting wire. The connecting wire is arranged at the peripheral area of the array basal plate and comprises a first straight-line segment and a second straight-line segment connected with the first straight-line segment. At least one side edge of the first straight-line segment is arranged along a first direction, at least one side edge of the second straight-line segment is arranged along a second direction, and the first direction is not parallel to the second direction. The first straight-line segment comprises a plurality of first slits arranged along the first direction, and the second straight-line segment comprises a plurality of second slits arranged along the second direction.

Owner:AU OPTRONICS CORP

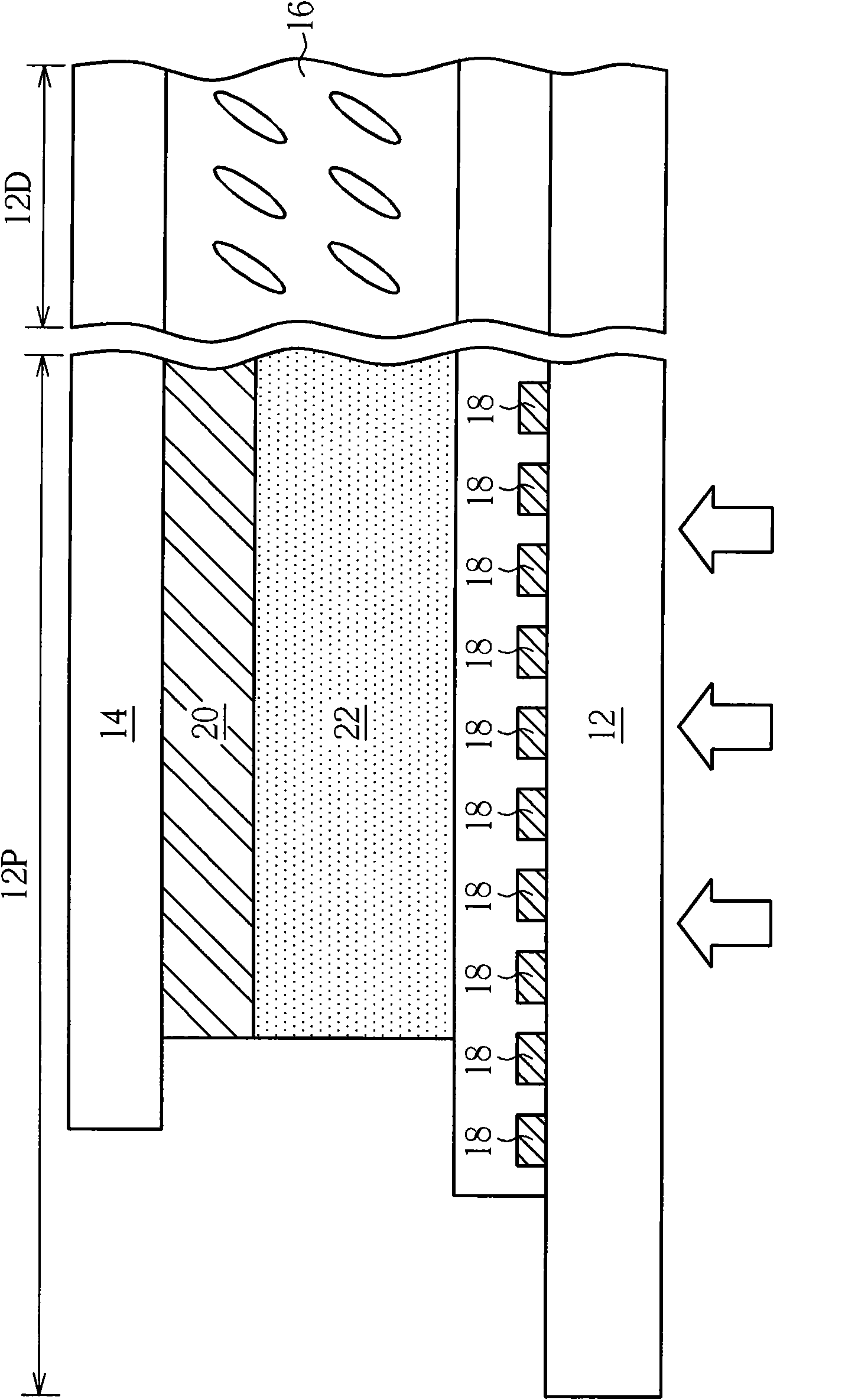

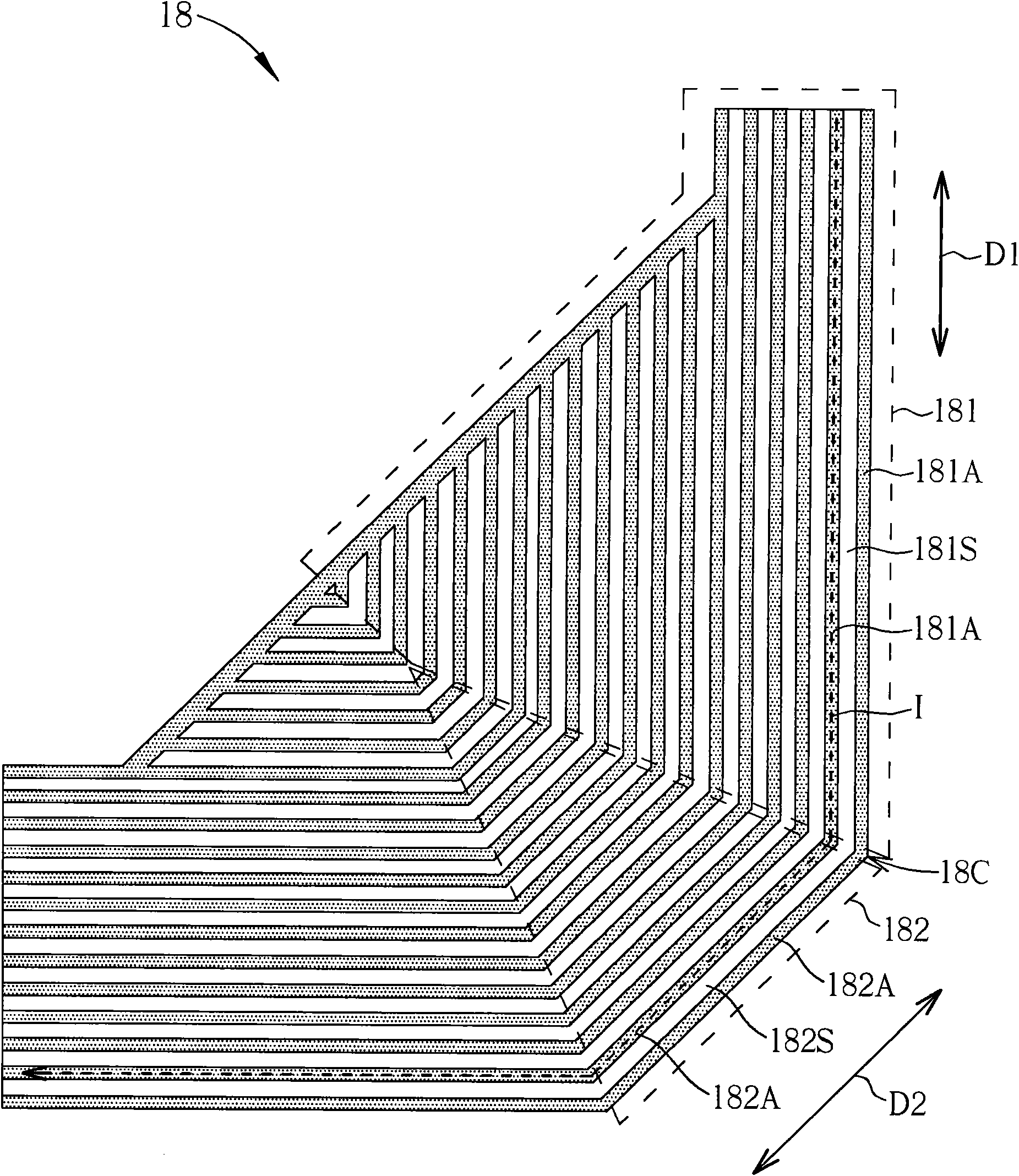

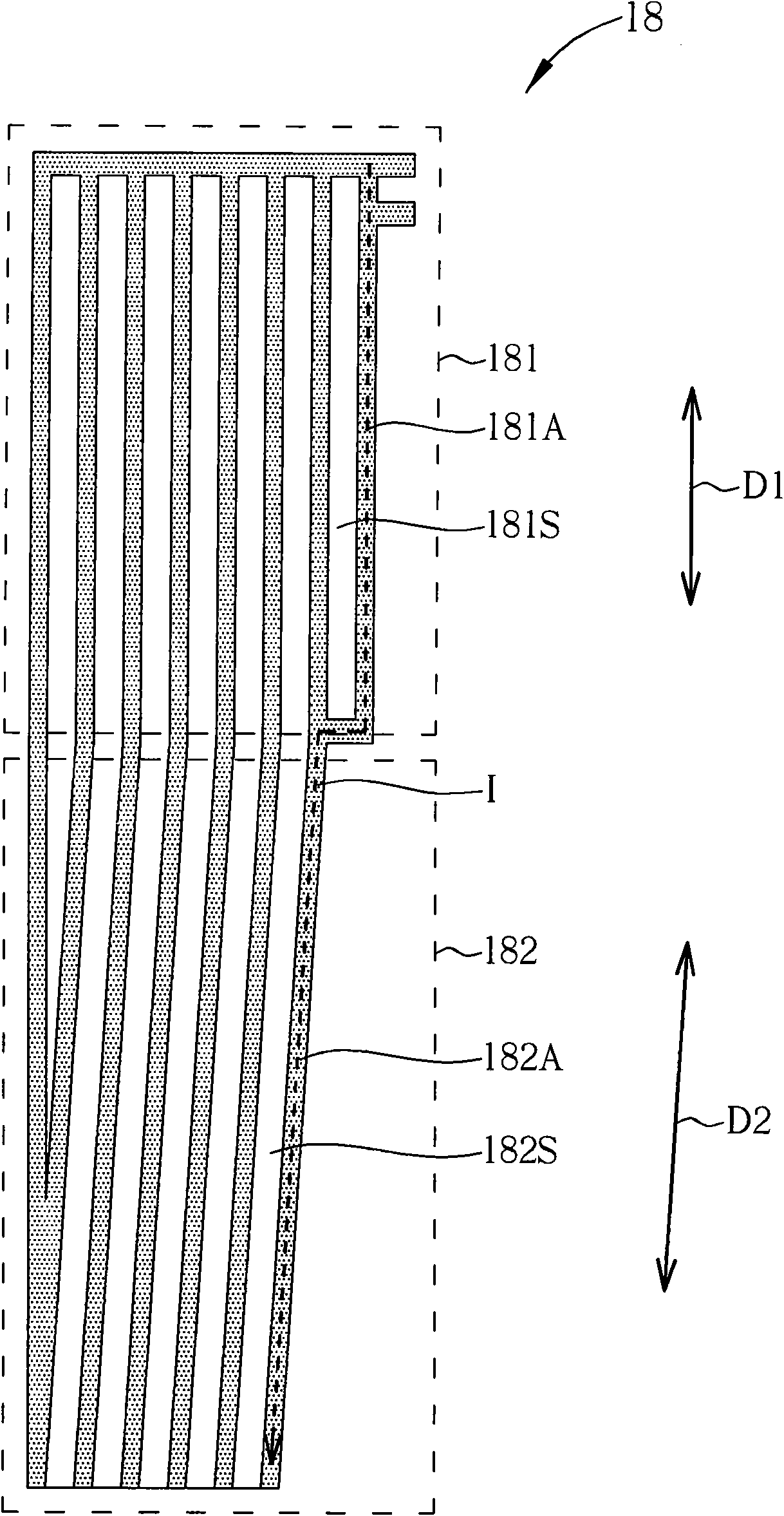

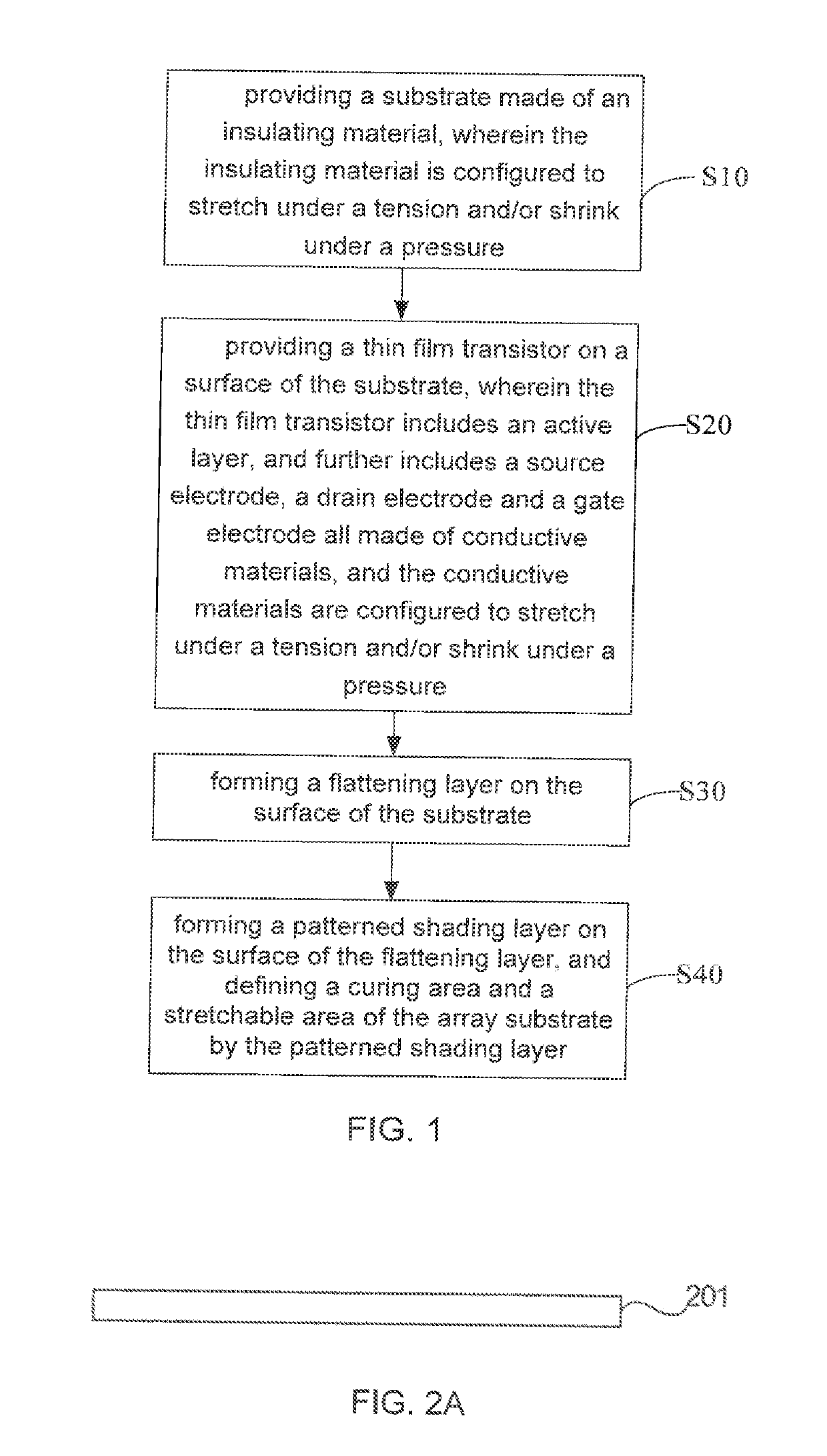

Array substrate and manufacturing method thereof

ActiveUS20190181154A1Reduce the risk of disconnectionAffect qualitySolid-state devicesPhotovoltaic energy generationConductive materialsEngineering

A method of manufacturing an array substrate is provided. The method divides an array substrate into a curing area and a stretchable area. A metal wiring corresponding to the stretchable area is made of a flexible conductive material, so as to reduce disconnection risk of the display panel during bending.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

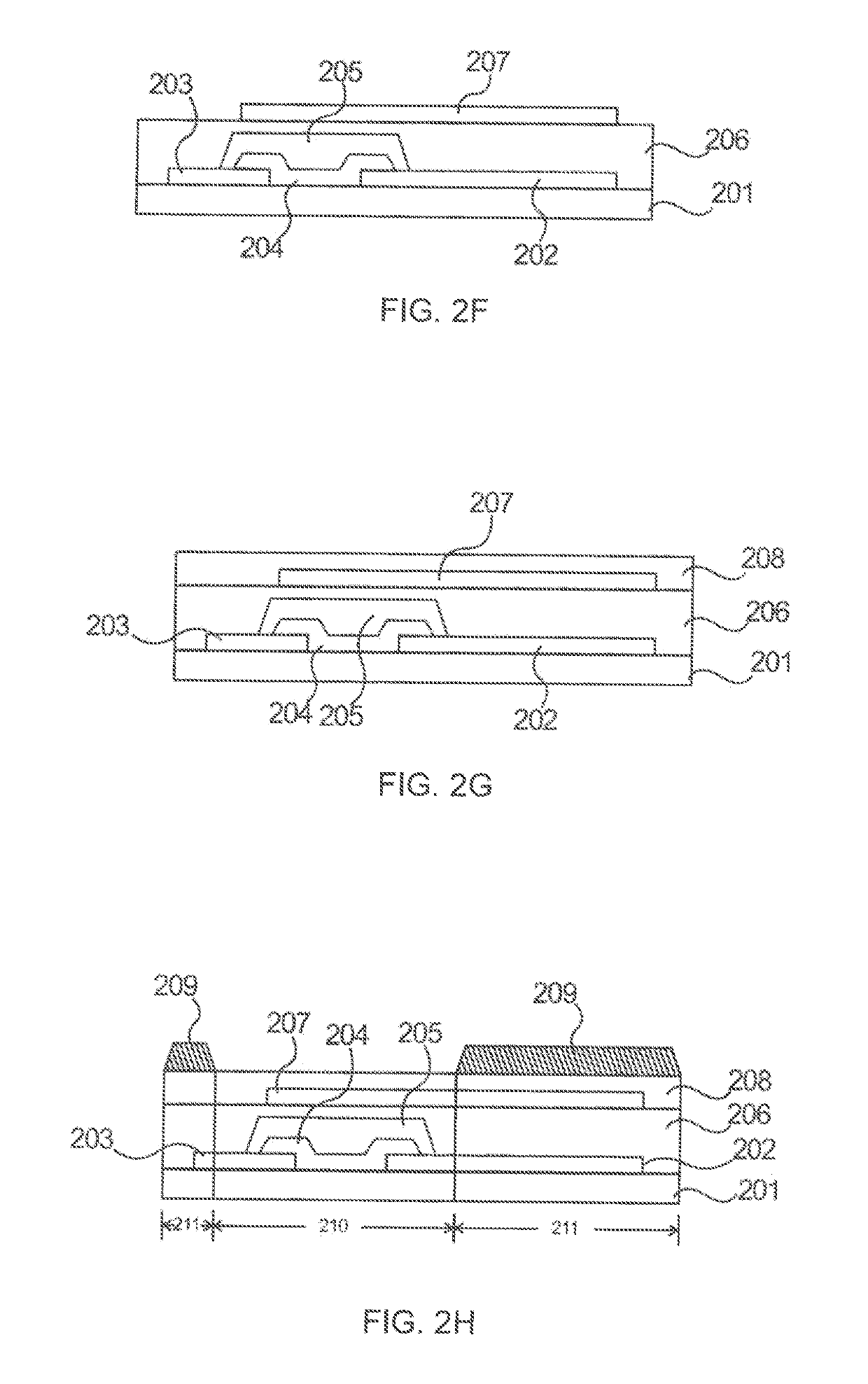

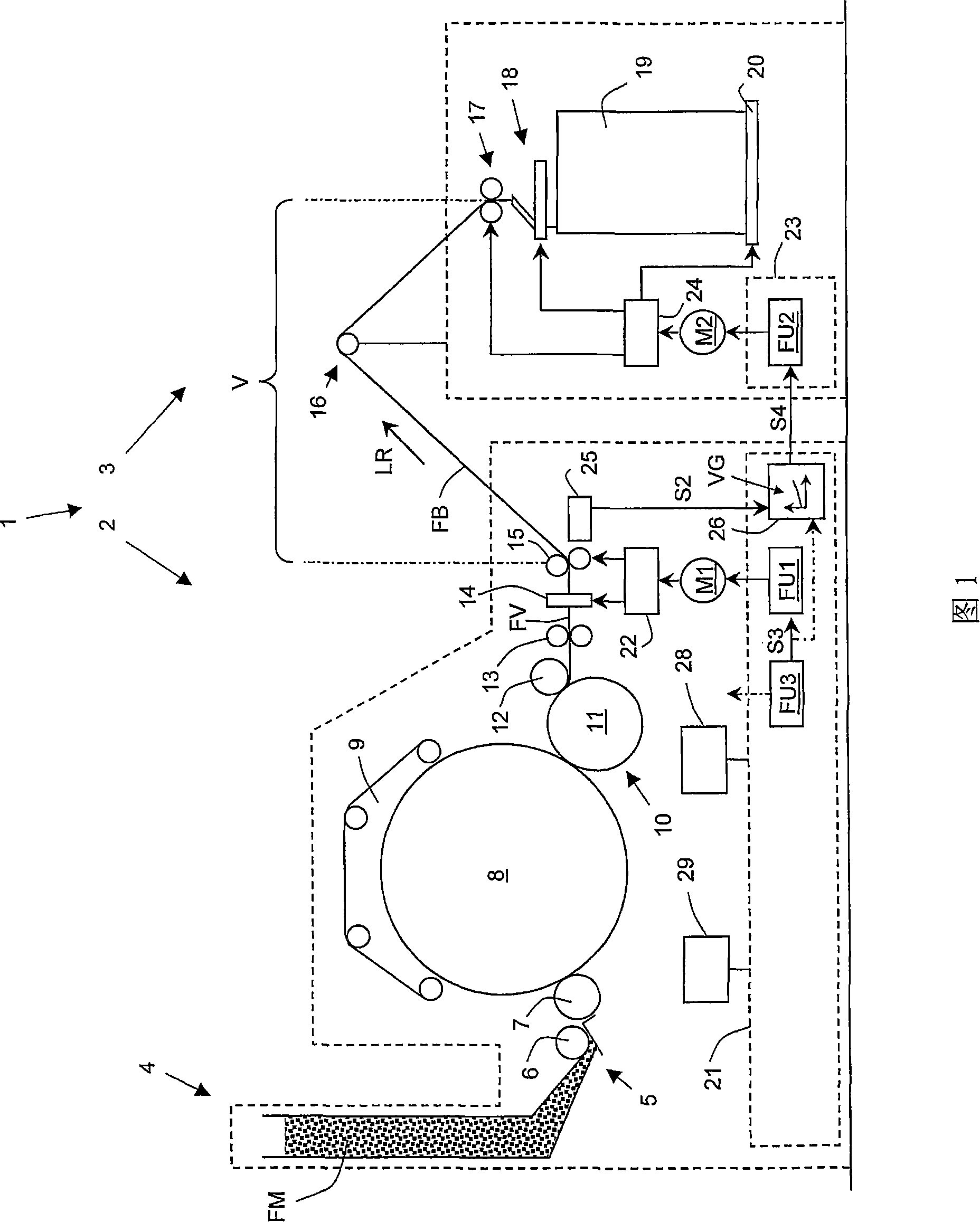

Method for plaiting a fibre web control device and textile machine combination

InactiveCN101243219APrevent draftingReduce output speedFilament handlingFibre feedersFiberEngineering

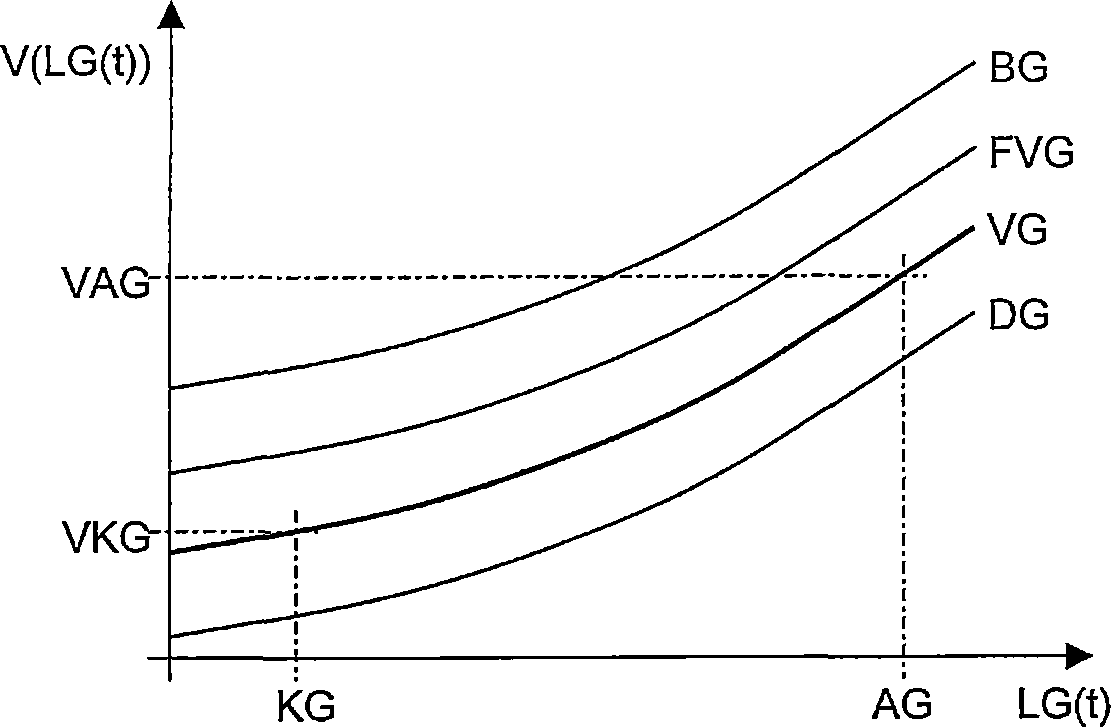

The invention discloses a method for placing a fiber sliver (FB) output by a spinning preparation machine (2), such as a carding machine (2), combing machine or drafting machine, by means of The fiber sliver (FB) is placed in the fiber sliver container (19) at the fiber sliver placement device (3), wherein the fiber sliver (FB) runs from the output device (15) located at the outlet of the spinning preparation machine (2) to the drawing-in device (17) at the entrance of the sliver depositing device (3) and thus undergoes a draft (V) corresponding to the drawing-in speed and output of the drawing-in device (17) The ratio of the output speed (LG) of the device (15). During the placement of the fiber sliver (FB), said draft (V) is automatically and variably controlled by means of a previously defined standard function (VG), which control depends on the output speed of the output device (15) ( LG). The invention also discloses a control device (26) for implementing the above method and a textile machine combination (1) with the control device (26).

Owner:MASCHINENFABRIK RIETER AG

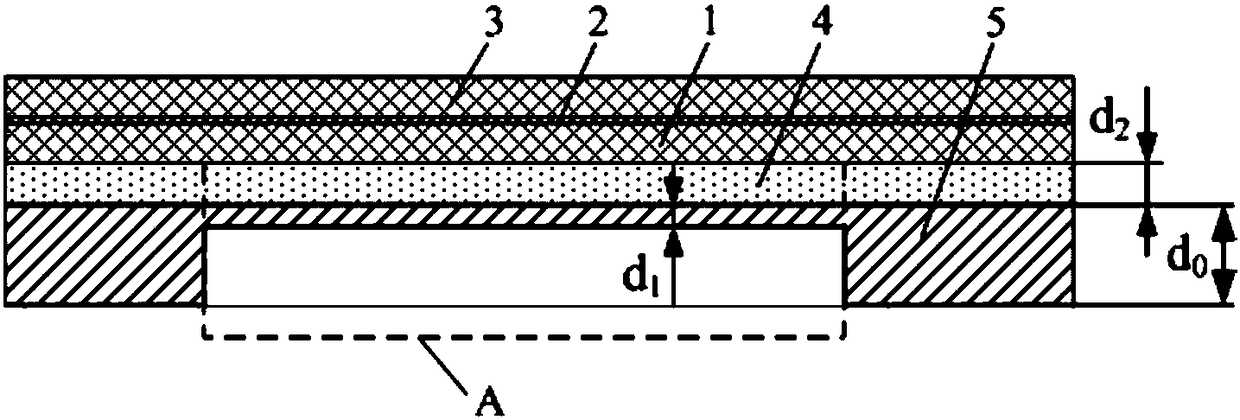

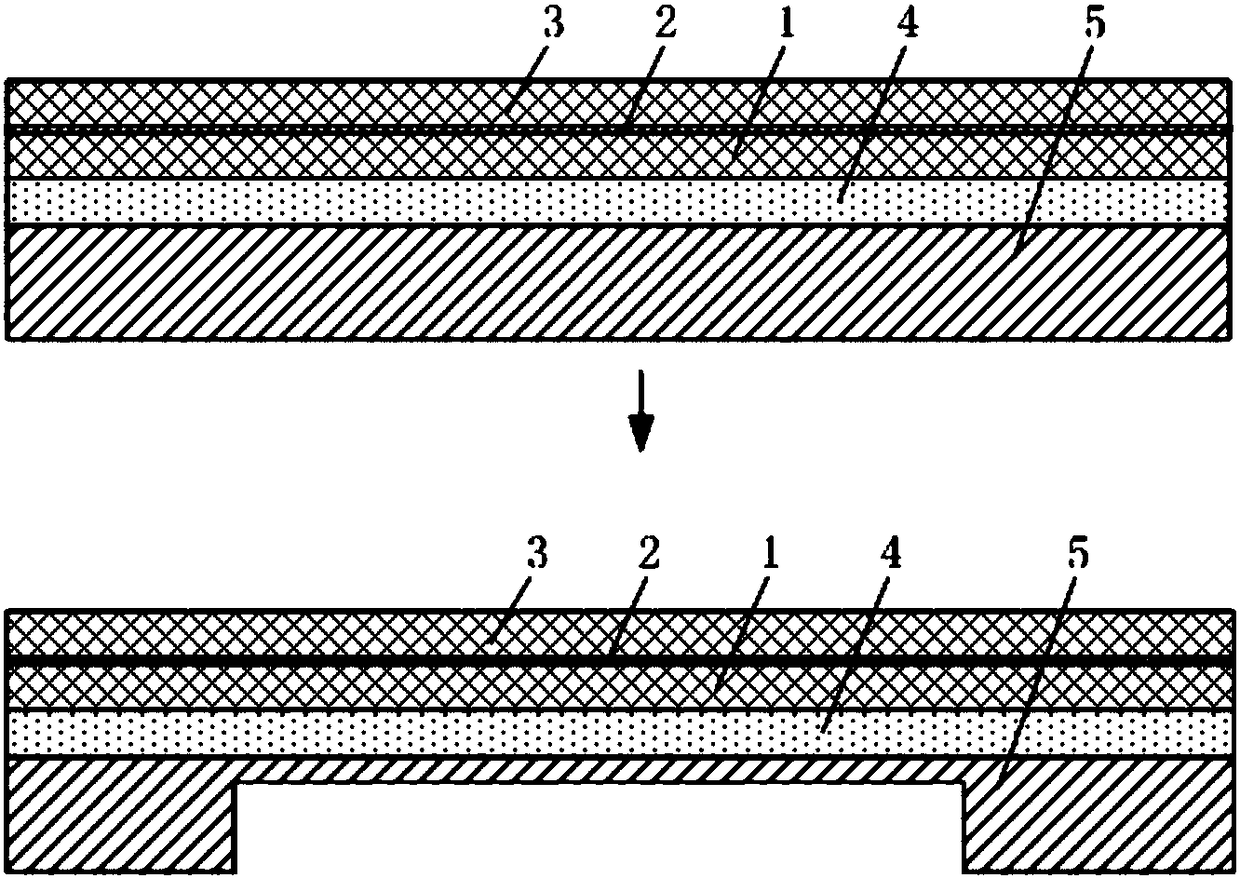

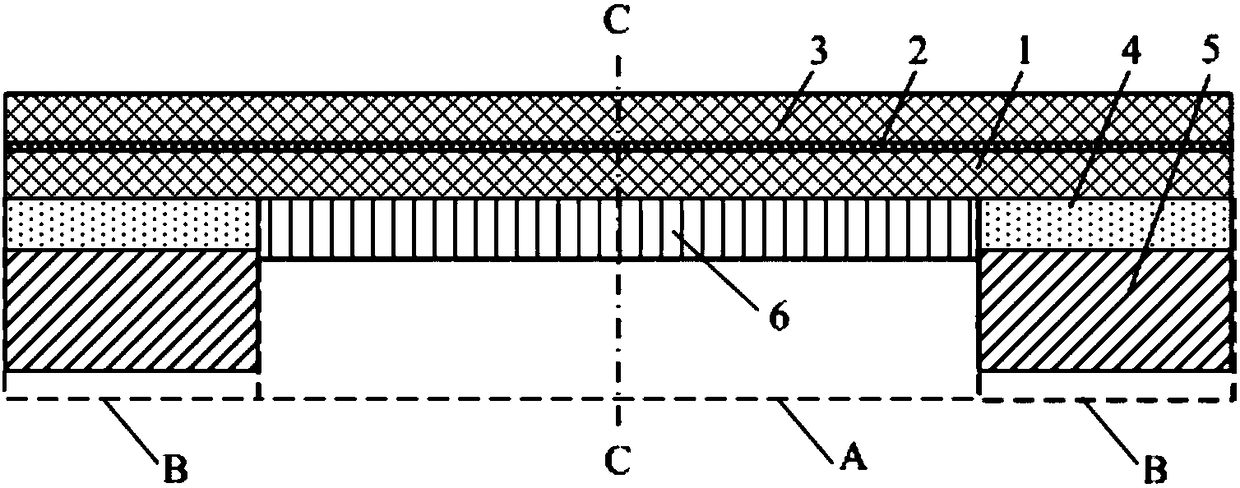

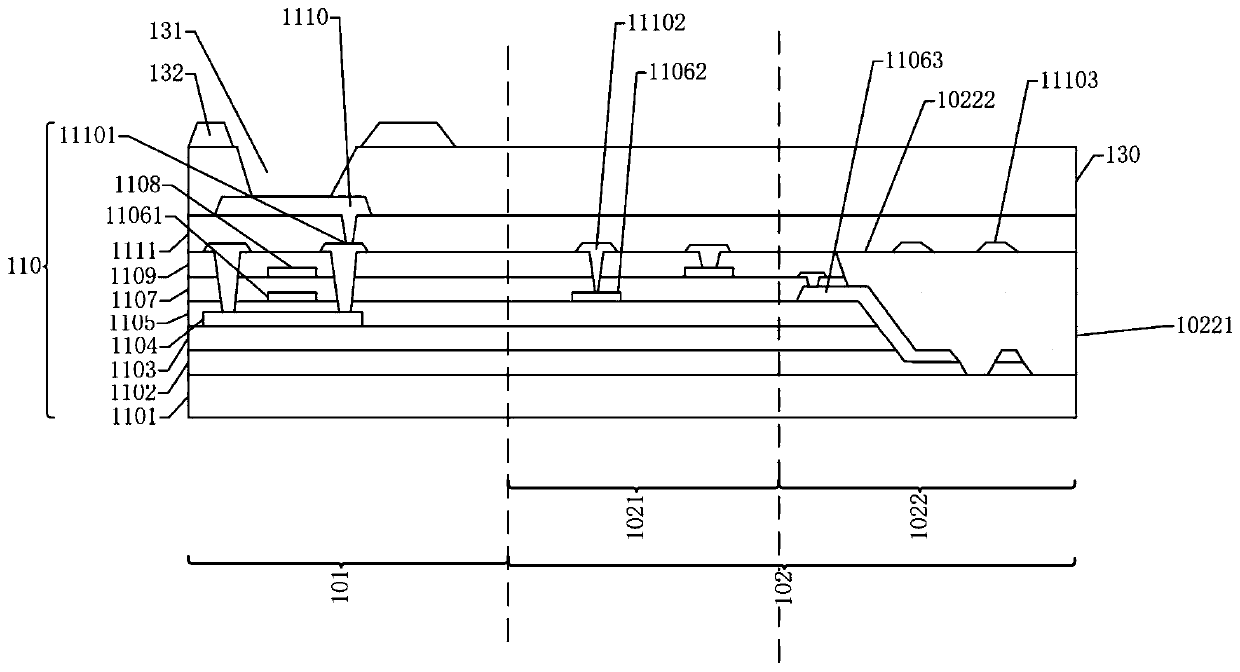

Display panel, manufacturing method of display panel and display device

PendingCN112164712AImprove yieldImprove impact resistanceFinal product manufactureSolid-state devicesDisplay deviceEngineering

The invention provides a display panel, a manufacturing method of the display panel and a display device. The display panel comprises a supporting layer, a display function layer, an adjusting layer and a buffer layer, and the supporting layer comprises a through hole; the display function layer is arranged on one side of the supporting layer, the display function layer comprises a display area, abending area and a bonding pad area, and the through holes correspond to the bending area in position; the adjusting layer is arranged on the side, deviating from the supporting layer, of the displayfunction and corresponds to the bending area in position; the buffer layer is arranged on the side, away from the display function layer, of the adjusting layer, and the elasticity modulus of the buffer layer is smaller than that of the adjusting layer. According to the display panel provided by the invention, the metal wires of the display function layer can be located in the stress neutral layer, and the wire breakage risk is reduced.

Owner:BOE TECH GRP CO LTD

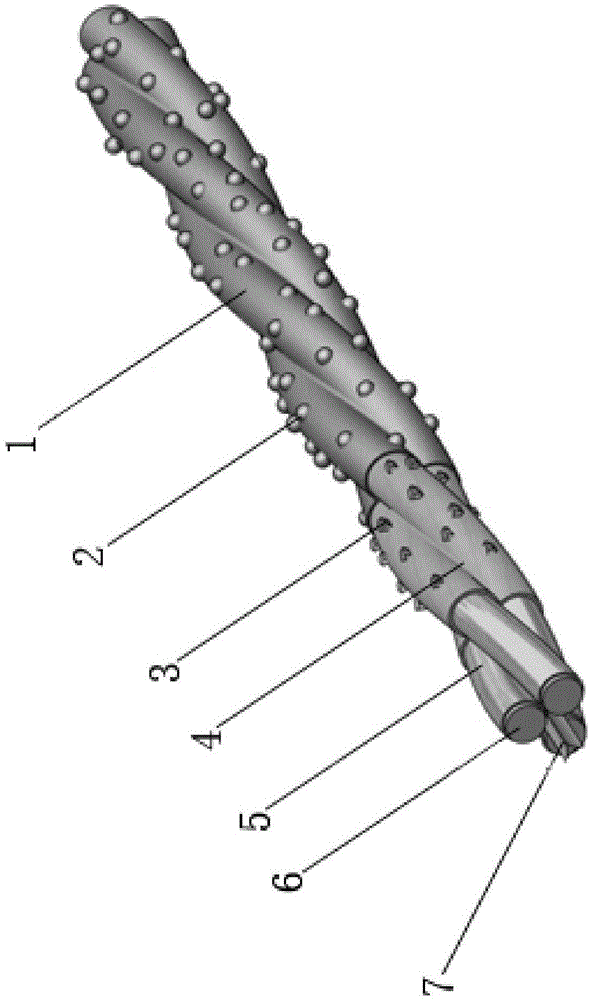

Novel composite metal fixed abrasive diamond rope and production process thereof

InactiveCN105459281AReduce mutual frictionLimit slipFine working devicesCoatingsCopper platingPre treatment

The invention relates to the technical field of diamond ropes, in particular to a novel composite metal fixed abrasive diamond rope. The novel composite metal fixed abrasive diamond rope comprises a core rope which is prepared by twisting a plurality of copper-plated steel wires and a soft polymer filling strip, wherein an attaching nickel layer for attaching diamond particles is deposited at the outer side of the core rope; the diamond particles are deposited on the attaching nickel layer on the surface of the core rope; and a packaging nickel layer for covering the diamond particles is deposited on the surfaces of the diamond particles. The invention further discloses a production process for the novel composite metal fixed abrasive diamond rope, wherein the production process comprises the following steps: compounding the core rope; carrying out surface pre-treatment; depositing the attaching nickel layer; attaching diamond; and depositing the packaging nickel layer. After the process is adopted, the core part of the core rope is free of a remarkable gap, so that a water-phase electrolyte solution is not remained in the space of the rope core, and therefore, corrosion is avoided; after the rope core is filled with soft stuffing, the diamond rope fracture risk is reduced; besides, by virtue of a buffer layer, slippage among steel wires is restricted, and coating is integrated, so that the coating fracture risk is reduced, and therefore, the line breakage risk in use is further reduced.

Owner:盛利维尔(常州)金属材料有限公司

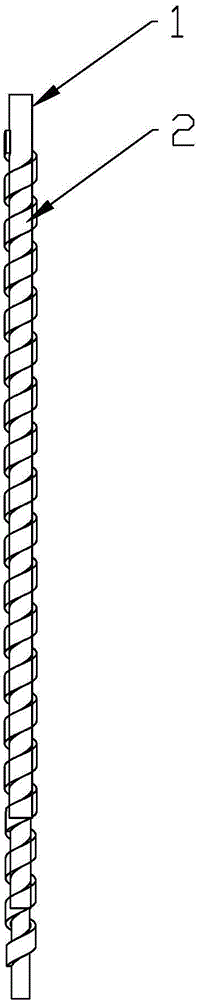

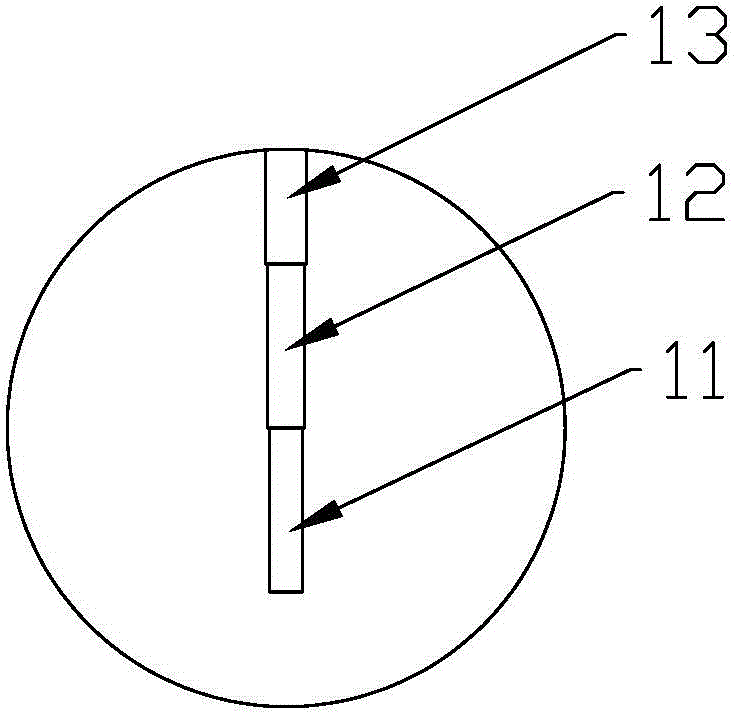

Trunk line

InactiveCN104900303ASimple structureImproved bending fatigue resistanceConductive layers on insulating-supportsSingle bars/rods/wires/strips conductorsElastomerHigh rate

The invention discloses a trunk line which comprises an elastic body and a winding line, wherein the elastic body is arranged in the center, the winding line is spirally wound around the elastic body, the elastic body comprises an elastic line which is arranged in the center, an insulating layer is wrapped on the elastic line, and a glue layer which is used for bonding the elastic body and the winding line each other is wrapped on the insulating layer. According to the technical scheme of the trunk line, the structure of the trunk line is simple, and the winding line is spirally wound around the elastic body of the trunk line, so that the bending fatigue resistance, the heat resistance and the high-temperature and high-humidity resistance of the trunk line can be increased, the tension resistance of the trunk line is increased, the service life of the trunk line is prolonged, a voice coil with the trunk line can bear higher rated power, and the risk of disconnection is reduced.

Owner:XIEKANGLI MOTOR SHENZHEN CO LTD

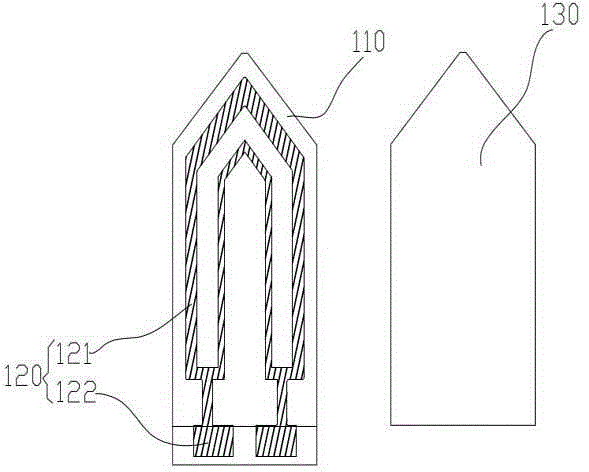

Ultrasonic fingerprint recognizing module and manufacturing method thereof

ActiveCN108921074AReduce the risk of disconnectionIncrease the climbing rangePrint image acquisitionFingerprintWire breakage

The invention relates to an ultrasonic fingerprint recognizing module and a manufacturing method thereof. The ultrasonic fingerprint recognizing module comprises: a substrate, a piezoelectric layer, aconducting layer and an electrode layer, wherein the piezoelectric layer is arranged on the substrate; the surface, which is far away from the substrate, of the piezoelectric layer is a function surface; a first step groove is arranged in the edge of the function surface; the conducting layer comprises a main body part arranged on the function surface, a first filling part arranged at the first step groove and a connecting part arranged on the surface, which is provided with the piezoelectric layer, of the substrate; the main body part, the first filling part and the connecting part are sequentially integrated; the connecting part is used for connecting with a power supply line; and the electrode layer is arranged on the surface, which is far away from the substrate, of the main body part. The ultrasonic fingerprint recognizing module has the advantages that the climbing amplitude of the conducting layer can be mitigated by utilizing the first step groove, so that the wire breakage risk of the conducting layer is reduced; an ox horn can be removed while the first step groove is arranged at the same time, so that the clamping amplitude of the conducting layer is avoided being increased by the ox horn and the wire breakage risk of the conducting layer is reduced; and therefore, the ultrasonic fingerprint recognizing module has better performance and higher manufacturing yield.

Owner:RECO TECH CHENGDU CO LTD

Array substrate and preparation method thereof

InactiveCN111106130AImprove conductivityImprove featuresSolid-state devicesSemiconductor/solid-state device manufacturingThin membraneElectronic conductivity

The invention discloses an array substrate and a preparation method thereof. The array substrate comprises a display area and a non-display area. The non-display area is provided with a bonding area and a fan-out area. The fan-out area is arranged between the display area and the bonding area. The array substrate further comprises a thin film transistor structure layer which comprises a grid electrode layer and a source-drain electrode layer. The grid electrode layer and the source-drain electrode layer are made of at least one of titanium, aluminum and titanium-aluminum alloy. The array substrate and the preparation method thereof, which are provided by the invention, have the beneficial effects that the grid electrode layer and the source-drain electrode layer on the array substrate aremade of the same material such as low-resistance and bending-resistant metal such as aluminum, titanium and titanium-aluminum alloy; the conductivity and the bending characteristic of metal wires areimproved; in the bonding area of the array substrate, the grid electrode layer is arranged below an organic layer and is closer to a neutral surface, and thus the risk of wire breakage of the bondingarea is reduced; and the grid electrode layer is used as a mask plate for inorganic film layer patterning, which saves the cost , and meanwhile solves the problem that adhesion of metal wires to the etched flexible substrate is poor.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

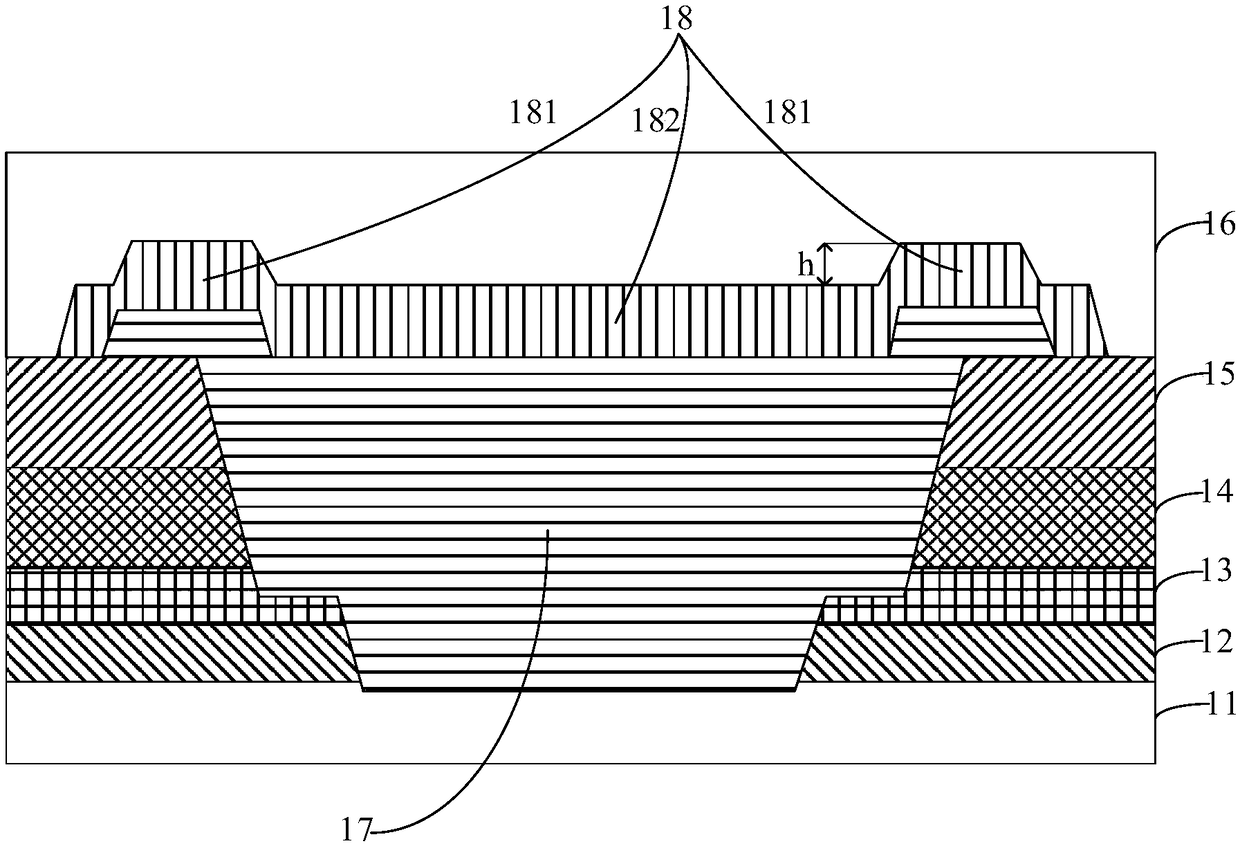

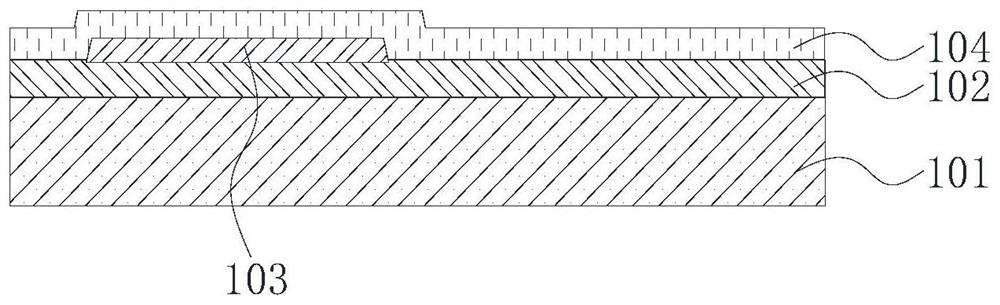

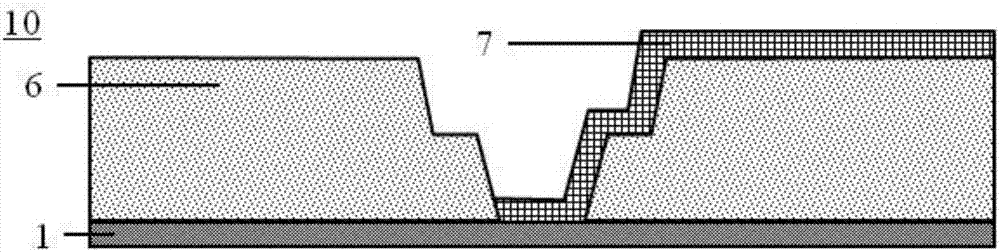

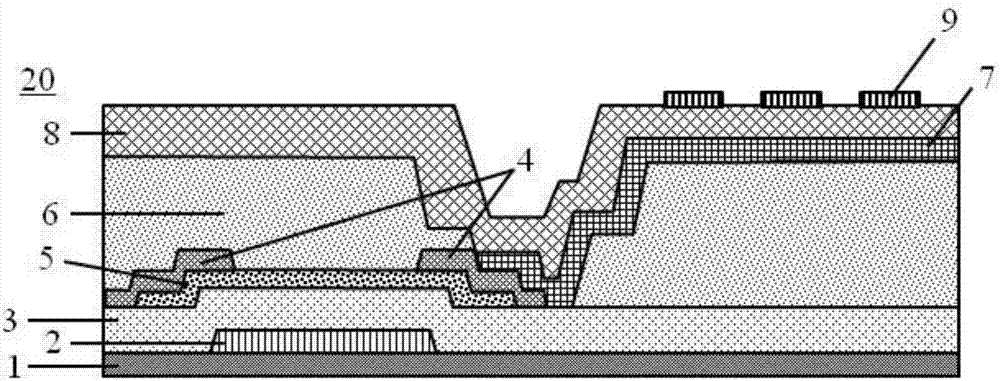

Laminated structure and preparation method thereof

InactiveCN106952927AReduce the risk of disconnectionImprove yieldSolid-state devicesSemiconductor/solid-state device manufacturingMaterials scienceWire breakage

The invention relates to a laminated structure and a preparation method thereof. The laminated structure comprises a substrate, at least one material layer positioned on the substrate, and a through hole penetrating through at least part of the at least one material layer, wherein the through hole is provided with a stepped side surface. The laminated structure further comprises another material layer conformally covering the side surface of the through hole. A ratio of the thickness of the at least one material layer to that of the other material layer is greater than 10. The laminated structure provided by the invention can reduce a risk of wire breakage due to difficult material climbing when a material covers the through hole, so that a product yield is improved.

Owner:HEFEI BOE OPTOELECTRONIC TECH CO LTD +1

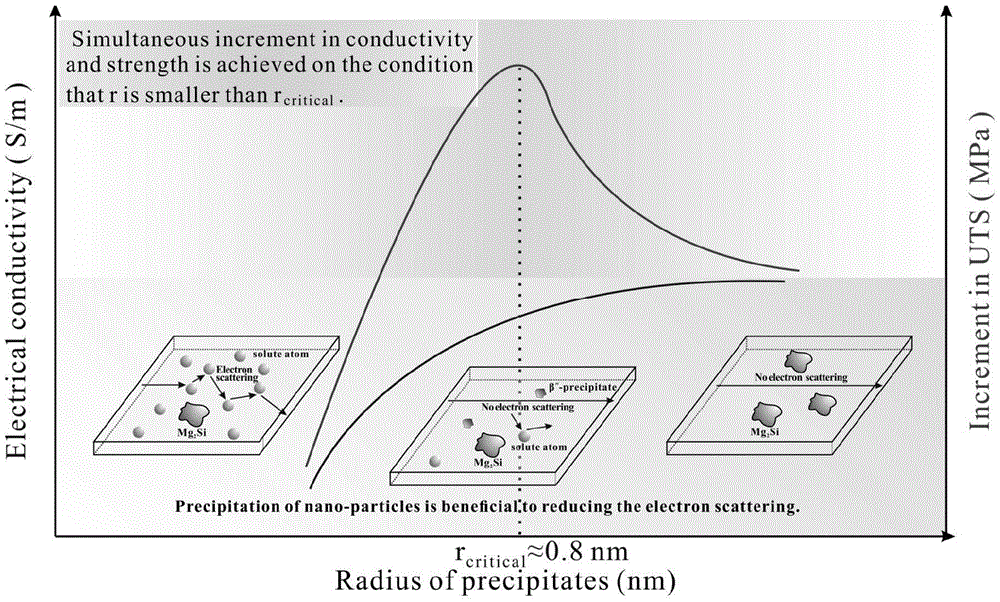

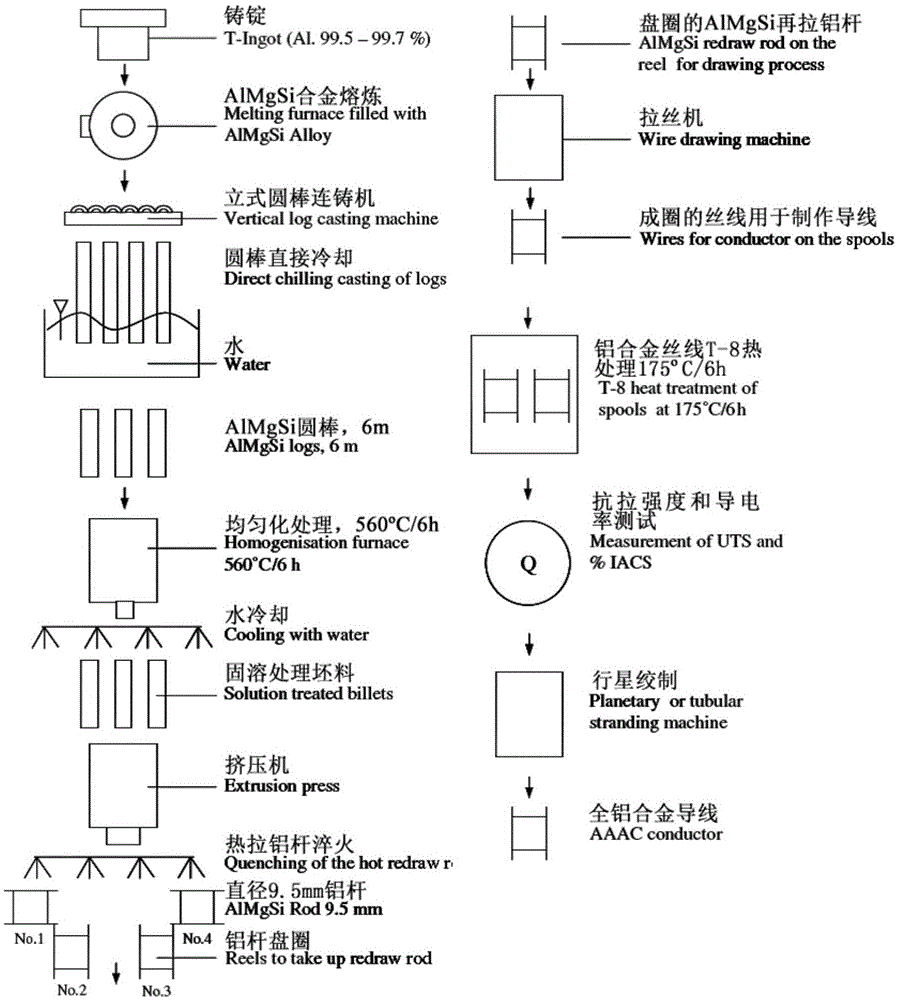

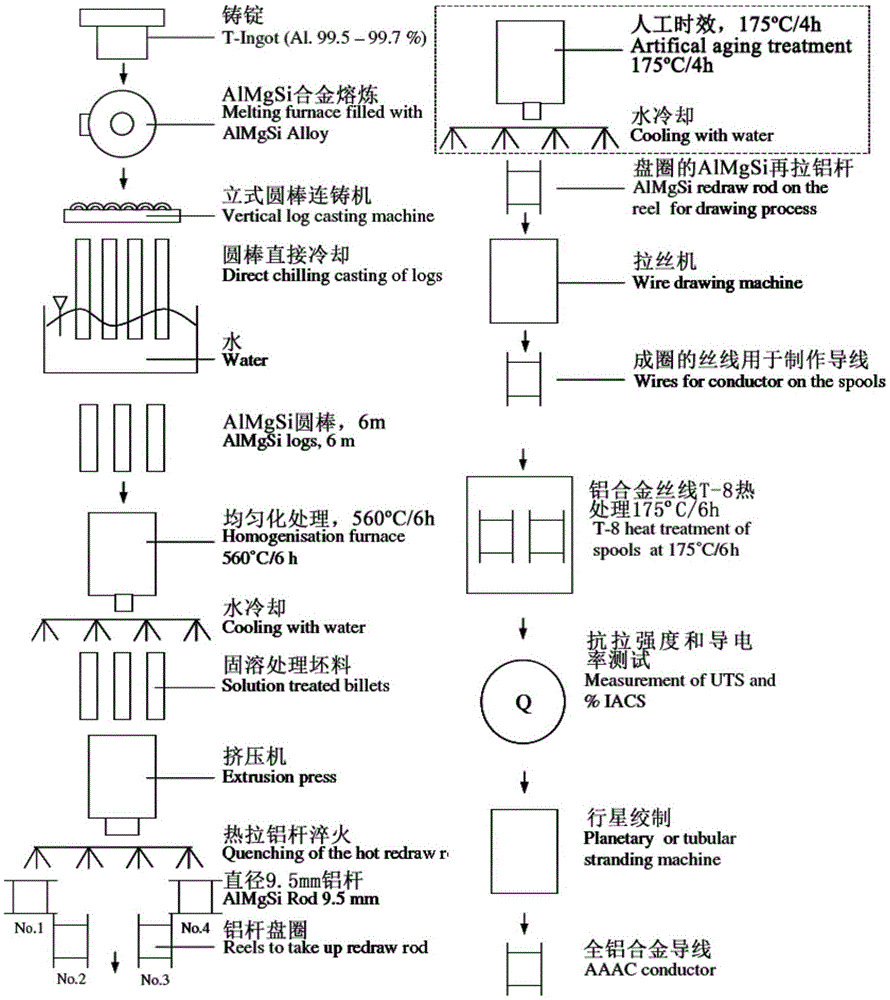

Method for preparing nanophase containing aluminum-magnesium-silicon alloy wire

ActiveCN105568189AHigh strengthImprove conductivityConductive materialMetal/alloy conductorsSolution treatmentSilicon alloy

The invention discloses a method for preparing a nanophase containing aluminum-magnesium-silicon alloy wire, and belongs to the technical field of alloy materials. The method comprises the steps that an aluminum-magnesium-silicon alloy bar is rolled after solution treatment; and artificial aging heat treatment is carried out, heat treatment is carried out after wire drawing, and the finished product is obtained. According to solution treatment, gradient temperature rise is carried out within the range of 400 DEG C to 500 DEG C, heat preservation is carried out for 3-15 minutes at each gradient, solution treatment is carried out at the temperature of 500 DEG C to 580 DEG C, heat preservation is carried out for 0.5-8.0 hours, and cold water quenching is immediately carried out. According to aging treatment, theoretical calculation is carried out, the size range of nano precipitated phase particles is determined, gradient temperature rise is carried out within the range of 100 DEG C to 160 DEG C, and heat preservation is carried out for 5-10 minutes at each gradient; and artificial aging heat treatment is carried out within the range of 160 DEG C to 190 DEG C, heat preservation is carried out for 0.5-6 hours, and cold water quenching is immediately carried out. The strength and conductivity of the nanophase containing aluminum-magnesium-silicon alloy wire are synchronously improved. Energy consumption is remarkably reduced, and meanwhile reliability is improved. Solution treatment and aging treatment are combined, operation is easy, and a newly-added technological link is low in cost and remarkable in effect.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

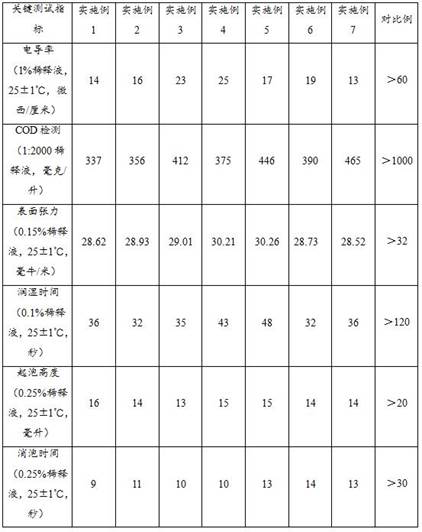

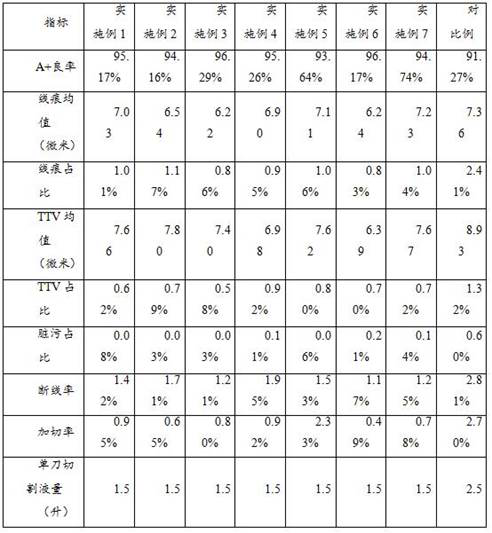

Diamond wire cutting liquid for large-size silicon wafer

ActiveCN113549488AEffective defoamingImprove performanceLubricant compositionActive agentWire cutting

The invention discloses diamond wire cutting liquid for a large-size silicon wafer. The diamond wire cutting liquid comprises the following components in parts by mass: 20-60 parts of a surfactant, 10-40 parts of a penetrating agent, 0.5-20 parts of a defoaming agent, 5-30 parts of a solubilizer, 3-10 parts of an emulsifier, 0.1-2 parts of a dispersing agent and the balance of deionized water. The large-size silicon wafer cutting fluid has the advantages that the large-size silicon wafer cutting fluid has excellent permeation, lubrication and cleaning effects, a stable oil-in-water system can be formed after the large-size silicon wafer cutting fluid is dissolved in water, the silicon powder can be efficiently dispersed, silicon powder cuttings and organic residues can be prevented from being gathered in equipment, adhesion and pipe blockage are prevented, the usage amount of the cutting liquid can be reduced, and the difficulty of silicon wafer cleaning and wastewater treatment can be effectively reduced.

Owner:江苏捷捷半导体新材料有限公司

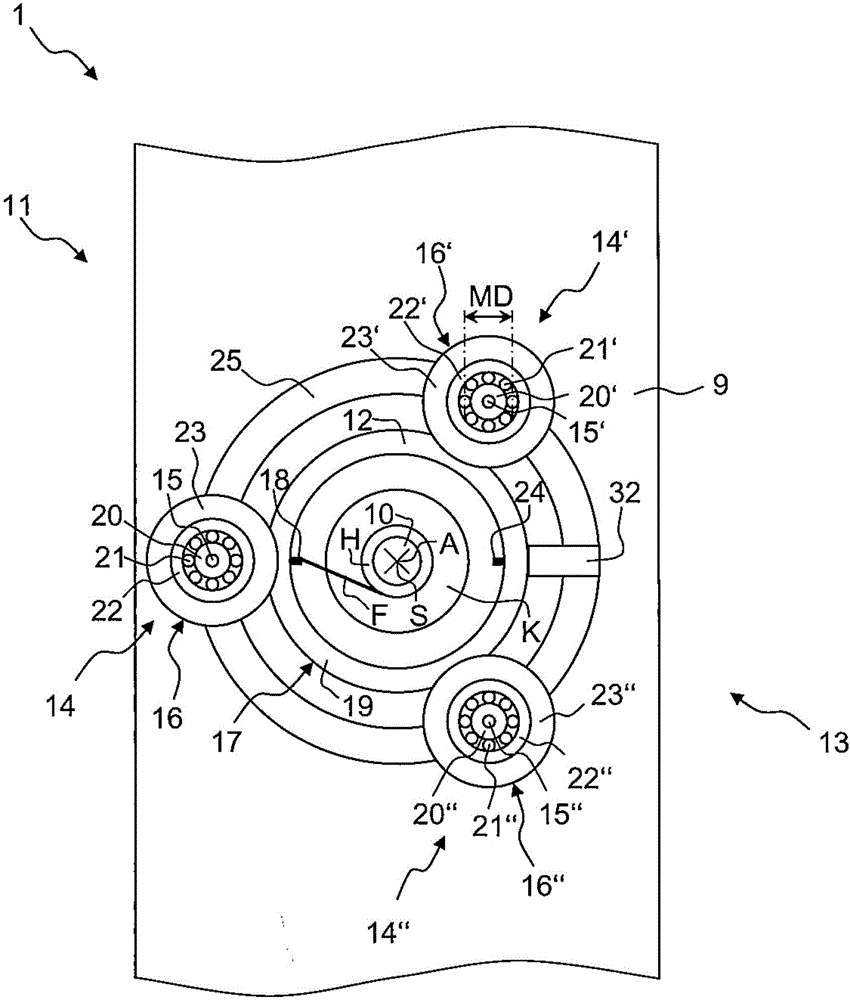

Thread guidance device for a textile machine, in particular for a ring spinning machine

The invention relates to a thread guidance device for a textile machine. The Thread guiding device for the textile machine is arranged between a stretching unit for supplying thread and a rotary driven spindle for winding the thread to a spindle. Rotation of the threads exist between the stretching device and the spindle. A movement portion device is also arranged. The movement portion device is mounted by means of a bearing device at a support device portion moving in an axial direction relative to a spindle in an axial direction. The support device portion has three support rollers, which are mounted around a roller axis extended parallel to an axis of the spindle. The bearing arrangement has a contour on its periphery. The contour extends in the corresponding matched contour externally constructed for the movement portion device to enable the movement portion device to be rotary in a mode of being coaxial with the spindle. The movement portion device is with a reversing device used for reversing the threads. The revering device is arranged in such a way that the threads which get away the reversing device are pulled to the tape reel in a tagent line direction, thereby arranging the movement portion device in the rotation.

Owner:DITF DEUT INST FUR TEXTIL UND FASERFORSCHUNG DENKENDORF

Soybean protein fiber and graphene-containing synthetic fiber blended knitted fabric

InactiveCN112064181AImprove performanceReduce the risk of disconnectionElectroconductive/antistatic filament manufactureWeft knittingEpoxyYarn

The invention discloses a soybean protein fiber and graphene-containing synthetic fiber blended knitted fabric. The knitted fabric is characterized by being formed by weaving blended yarns of soybeanprotein fibers and graphene-containing synthetic fibers, and the mass percent of the soybean protein fibers in the blended yarns is 60%-70%; the transverse density of the knitted fabric is (68-75) / 10cm; the longitudinal density is (35-42) / 10 cm; the graphene-containing synthetic fibers are prepared from the following components in parts by weight of 60-80 parts of 2,6-diaminopurine riboside / dihydro-2,4,6-trioxo-1,3,5-triazinyl-1,3(2H,4H) dipropionic acid polycondensate, 10-20 parts of PA66, 0.3-0.8 part of 1,3,5-tri[3-(trimethoxysilyl)propyl]-1,3,5-triazinyl-2,4,6(1H,3H,5H)-triketone, 1-3 parts of graphene, 1-2 parts of pumice powder and 3-5 parts of epoxy-terminated hyperbranched poly(amine-ester). The invention further discloses a preparation method of the fabric. The fabric disclosed by the invention is good in moisture absorption and sweat releasing effect, excellent in wearing comfort and antibacterial property, high in fastness to washing and good in performance stability.

Owner:CHENGDU ZHIA TECH CO LTD

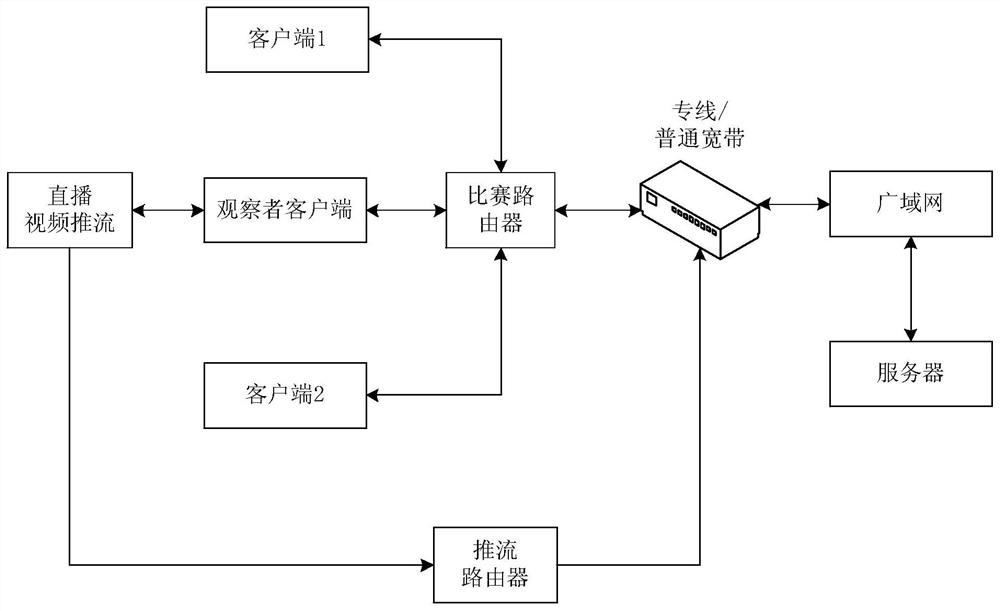

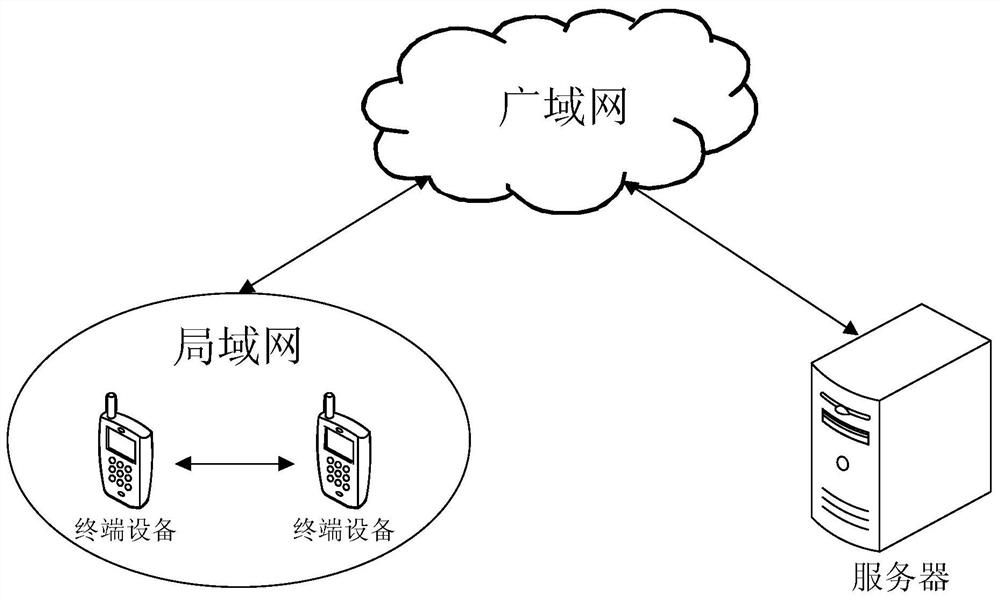

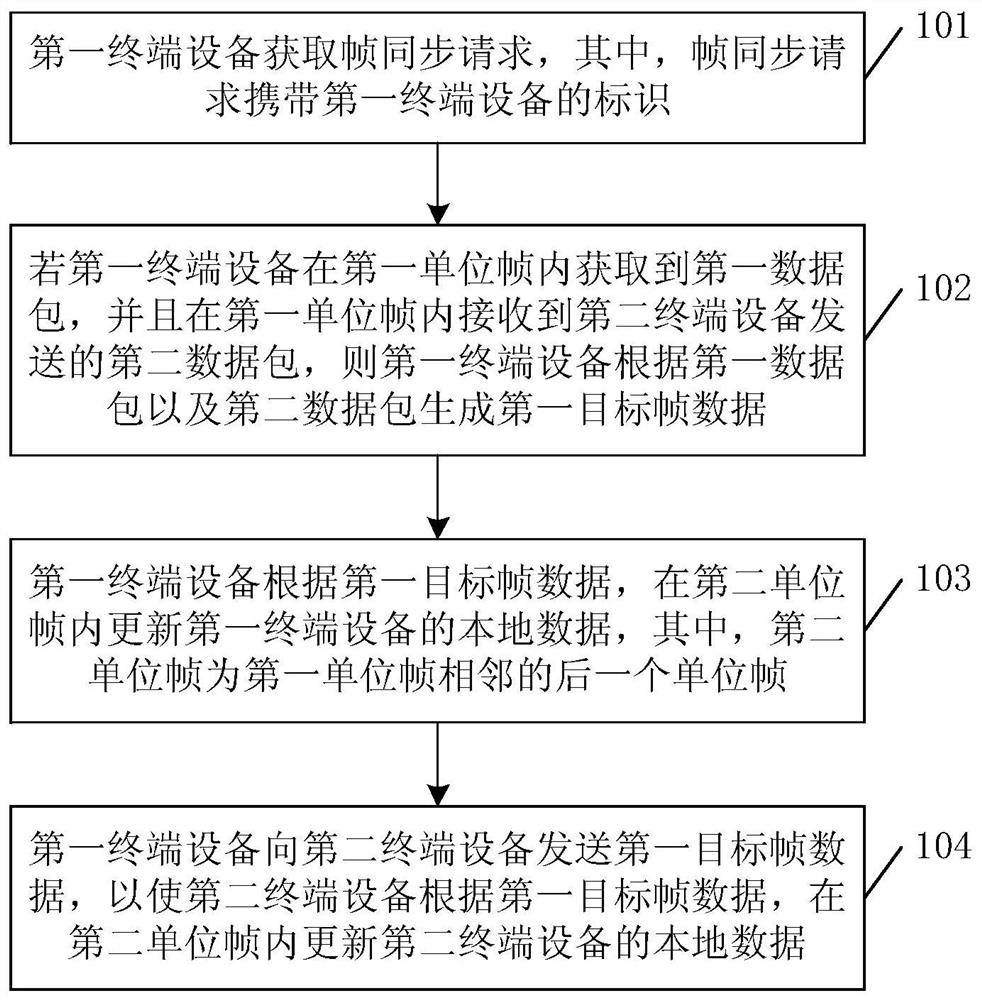

Data synchronization method, device and equipment and storage medium

ActiveCN111917866AReduce the risk of disconnectionImprove real-time performanceConnection managementTransmissionData synchronizationData pack

The invention discloses a data synchronization method, and the method is applied to a data synchronization system. The data synchronization system at least comprises a first terminal device and a second terminal device, wherein the first terminal device and the second terminal device establish a local area network connection. The method comprises the following steps: obtaining a frame synchronization request; if the first data packet is obtained in the first unit frame and the second data packet sent by the second terminal device is received in the first unit frame, generating first target frame data according to the first data packet and the second data packet; updating local data of the first terminal equipment in the second unit frame according to the first target frame data; and sending the first target frame data to the second terminal device. The embodiment of the invention further provides a related device, the frame synchronization logic in the server is deployed on the terminal equipment side, the purpose of data synchronization is achieved through the local area network, the risks of network jitter and network disconnection are reduced, and therefore the real-time performance of data transmission is improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com