Laminated structure and preparation method thereof

A technology of laminated structure and material layer, applied in the direction of semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as disconnection and difficulty in climbing, and achieve the effect of improving product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] It should first be noted that, unless the context clearly dictates otherwise, as used herein and in the appended claims, the singular includes the plural and vice versa. Thus, when referring to the singular, the plural of the corresponding term will generally be included. Similarly, the words "comprise" and "include" are to be interpreted as being inclusive and not exclusive. Likewise, the terms "include" and "or" should be construed as inclusive, unless such an interpretation is expressly prohibited herein. Where the term "example" is used herein, particularly when it follows a group of terms, said "example" is exemplary and explanatory only, and should not be considered to be exclusive or inclusive .

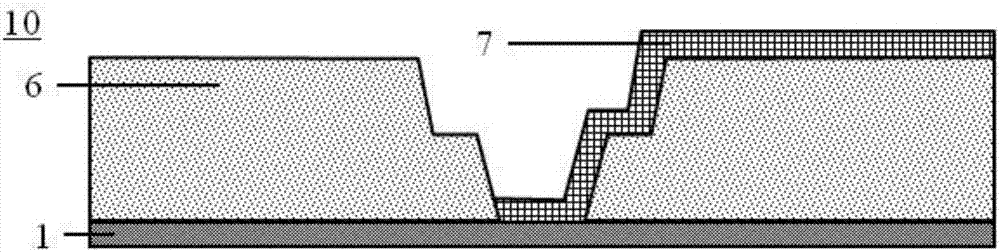

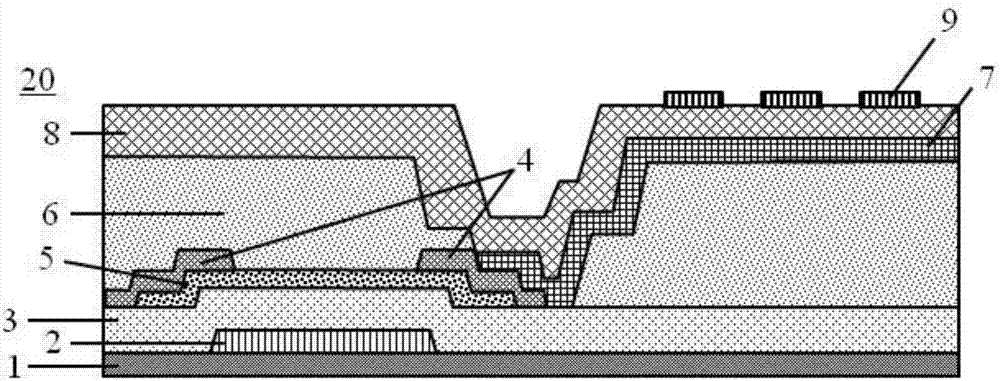

[0037] Also, in the drawings, the thicknesses and regions of layers are exaggerated for clarity. It will be understood that when a layer, region, or component is referred to as being “on” another component, it can be directly on the other component or other component...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com