Diamond wire cutting liquid for large-size silicon wafer

A technology of diamond wire cutting and silicon wafer cutting fluid, which is applied in the direction of lubricating composition and petroleum industry, etc. It can solve the problems of poor surface quality of silicon wafers, large amount of cutting fluid, high wire breakage rate, etc., achieves strong cleaning ability and reduced consumption , the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

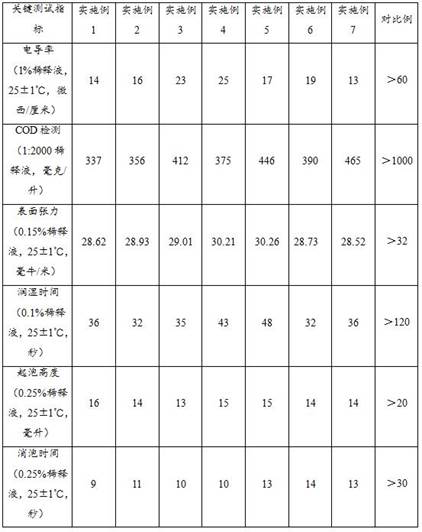

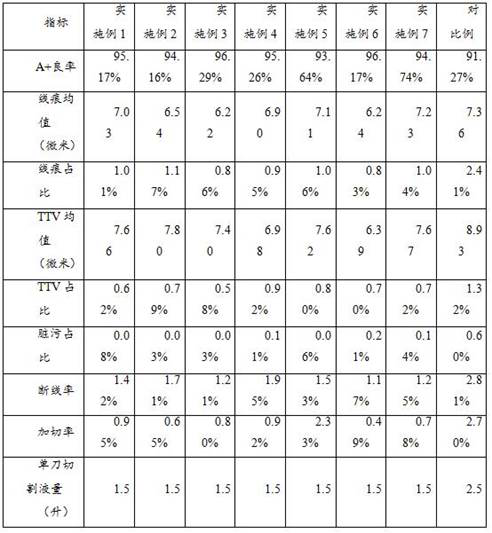

Examples

Embodiment 1

[0033] This embodiment provides a diamond wire cutting fluid for large-sized silicon wafers, which consists of 15 parts of solubilizer polyethylene glycol, 25 parts of surfactant alkylphenol polyoxyethylene ether, and 100 parts by total mass. 12 parts of defoaming agent acetylene glycol polyether, 1.5 parts of defoaming agent GPE type polyoxyethylene polyoxypropylene glyceryl ether, 10 parts of penetrant isomeric tridecyl alcohol polyoxyethylene ether, emulsifier sorbitan monooleic acid 2 parts of ester, 5 parts of polyoxyethylene sorbitan monostearate as emulsifier, 0.5 part of acrylic acid homopolymer as dispersant, 0.5 part of methyl benzotriazole as antirust agent, and 0.5 part of fungicide lauryl trimethyl Add 1 part of ammonium chloride in turn to the stirring tank, stir for 20 minutes, then add the remaining amount of deionized water, mix and stir for 60 minutes, and obtain a large-size silicon wafer diamond wire cutting fluid.

Embodiment 2

[0035] This embodiment provides a diamond wire cutting fluid for large-sized silicon wafers, which consists of 10 parts by mass of the total mass parts: 10 parts of polyethylene glycol as a solubilizer, and 30 parts of allyl alcohol polyoxyalkyl ether as a surfactant , 15 parts of dodecynediol defoamer, 1.5 parts of GP glycerol polyether defoamer, 12 parts of isooctyl alcohol polyoxyethylene ether phosphate penetrant, 2 parts of sorbitan monooleate emulsifier , emulsifier polyoxyethylene sorbitan monostearate 3 parts, dispersant acrylic acid homopolymer 0.5 part, antirust agent methyl benzotriazole 0.5 part, fungicide dodecyl trimethyl chloride Add 1 part of ammonium into the stirring tank in turn, stir for 30 minutes, then add the remaining amount of deionized water, and mix and stir for 60 minutes to obtain a large-size silicon wafer diamond wire cutting fluid.

Embodiment 3

[0037] This embodiment provides a diamond wire cutting fluid for large-sized silicon wafers, which is composed of 100 parts by total mass: 12 parts of propylene glycol, and 30 parts of surfactant six-carbon to eight-carbon fatty alcohol polyoxyethylene polyoxypropylene ether 13 parts, defoamer acetylene glycol polyether 13 parts, defoamer GPE type polyoxyethylene polyoxypropylene glyceryl ether 1.5 parts, penetrant isomeric tridecyl alcohol polyoxyethylene ether 14 parts, emulsifier monoglyceride fatty acid glyceride 1 part, emulsifier sorbitan monooleate 5 parts, dispersant phosphonocarboxylic acid copolymer 0.5 part, antirust agent methyl benzotriazole 0.5 part, fungicide dodecyl trimethyl chloride Add 1 part of ammonium chloride into the stirring tank in turn, stir for 25 minutes, then add the remaining amount of deionized water, and mix and stir for 60 minutes to obtain a large-size silicon wafer diamond wire cutting fluid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com