Silica gel interface adhesion strength testing device and quantitative testing method thereof

A technology for interfacial adhesion and strength testing, applied in the field of silicone gel, which can solve the problems of uneven sample preparation, uncontrollable sample preparation integrity, affecting the stability of results, etc., and achieve the effect of being beneficial to quantitative calculation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with accompanying drawing.

[0039] The invention provides a silicone gel interface adhesion strength testing device, comprising:

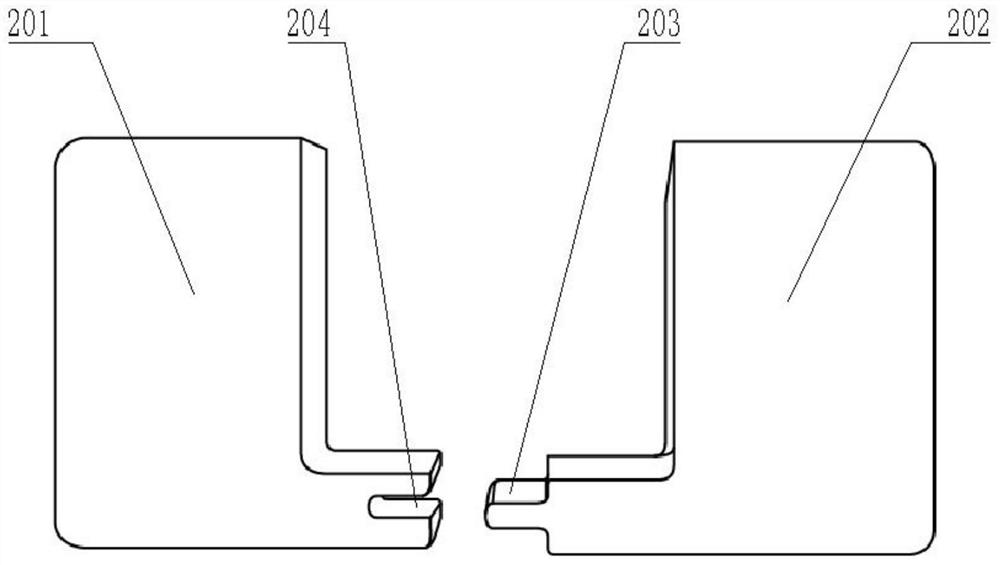

[0040] A sample preparation component, which has a cavity for containing the silicone gel, one side of the cavity has an opening, and the opposite sides of the cavity respectively have templates constituting the cavity wall;

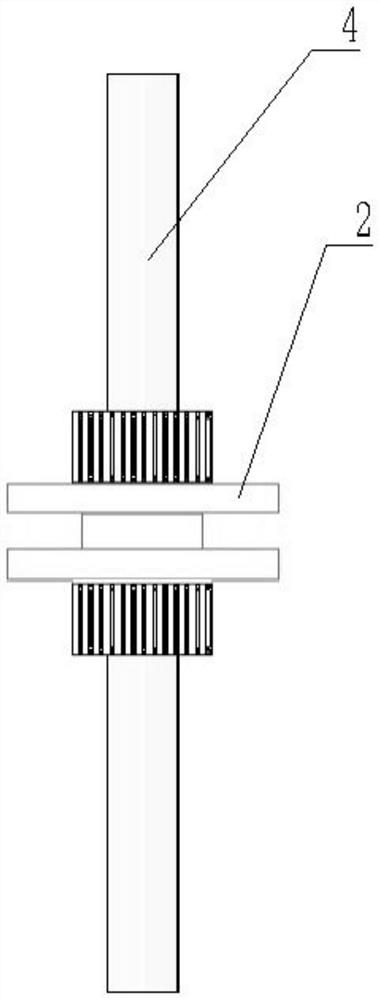

[0041] The test component is used for testing the test piece made of the template and the cured and molded silicone gel, and the test component includes two test ends arranged oppositely;

[0042] Wherein, the two test ends can be respectively fixedly connected to the two templates, so as to respectively drive the two templates to move in directions away from each other.

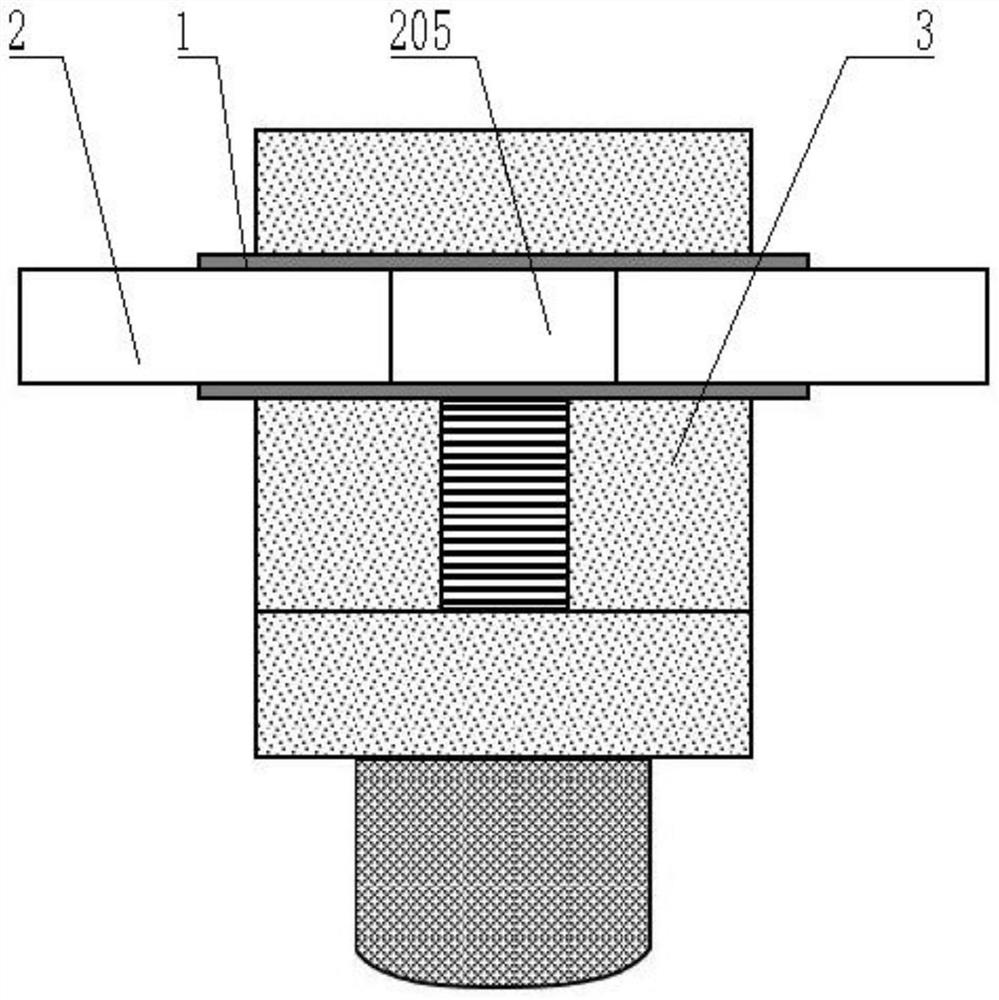

[0043] Specifically, such as figure 1 and image 3 As shown, the sample preparation assembly has a cavity 205 for accommodating silicone gel, one side of the cavity has an openi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com