Damping and de-noising method for amorphous alloy transformer

An amorphous alloy and transformer technology, which is applied in the field of vibration reduction and noise reduction of amorphous alloy transformers, can solve the problems of unsatisfactory iron core vibration and noise reduction, affecting the operation safety and reliability of amorphous transformers, and achieves improved operation. Safety and reliability, reducing the generation of amorphous fragments, and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

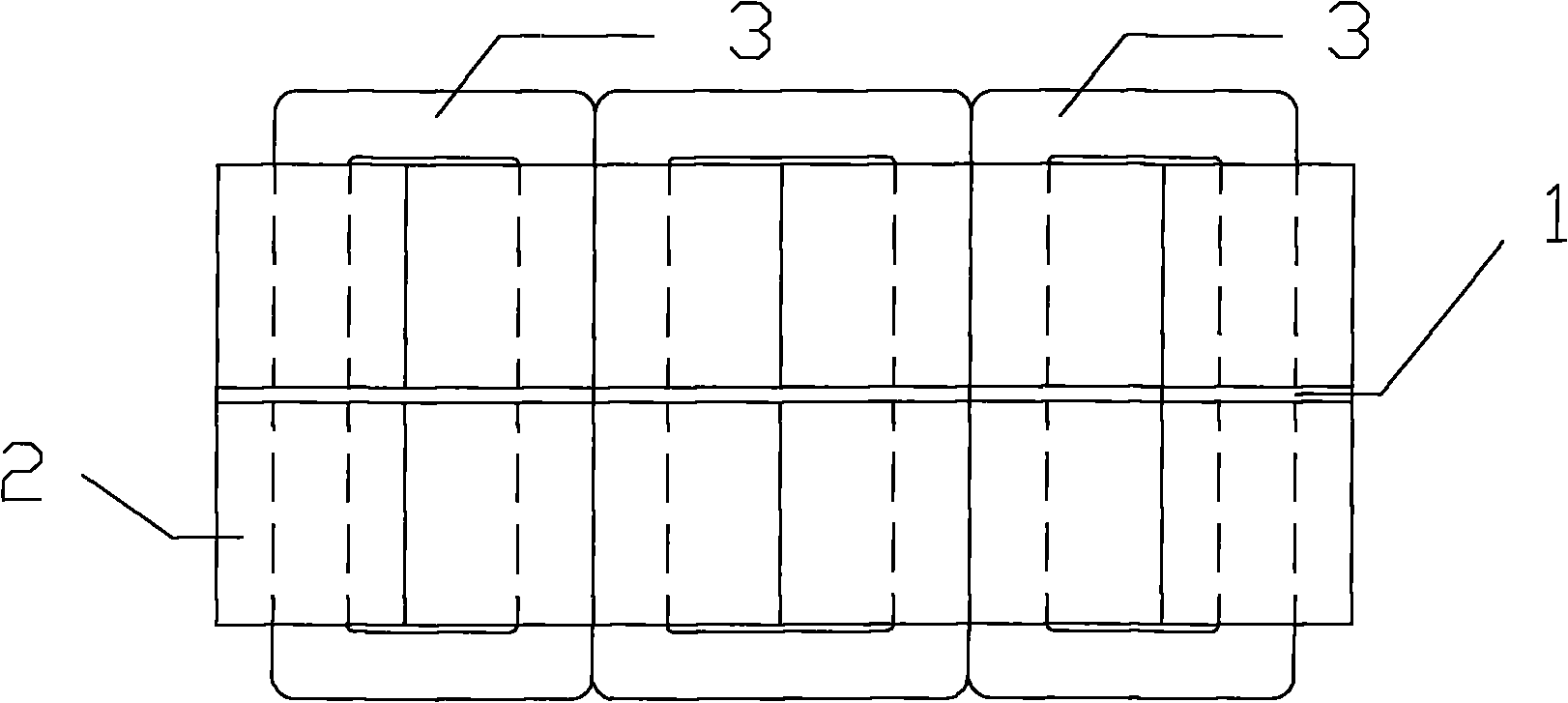

[0024] Such as Figure 1-3 As shown, after completing the window closing process of the bottom iron core according to the traditional production process of the amorphous transformer, the process improvement can be realized by following the steps below.

[0025] Step 1 is to prepare a sufficient amount of two millimeters thick nitrile oil-resistant rubber pads of 100mm * 500mm;

[0026] Step 2: Cutting the above-mentioned rubber pad along the outer contour of the upper surface of the underlying iron core overlap structure;

[0027] Step 3 Remove the cut rubber pad 1, and apply silicone sealant to the above-mentioned area of the bottom iron core 2;

[0028] Step 4 Cover the area coated with silicone sealant with the pre-cut rubber pad 1;

[0029] Step 5 Apply silicone sealant to the upper surface of the rubber pad 1;

[0030] After completing the above steps, continue to complete the production of the second-layer iron core according to the traditional amorphous iron core a...

Embodiment 2

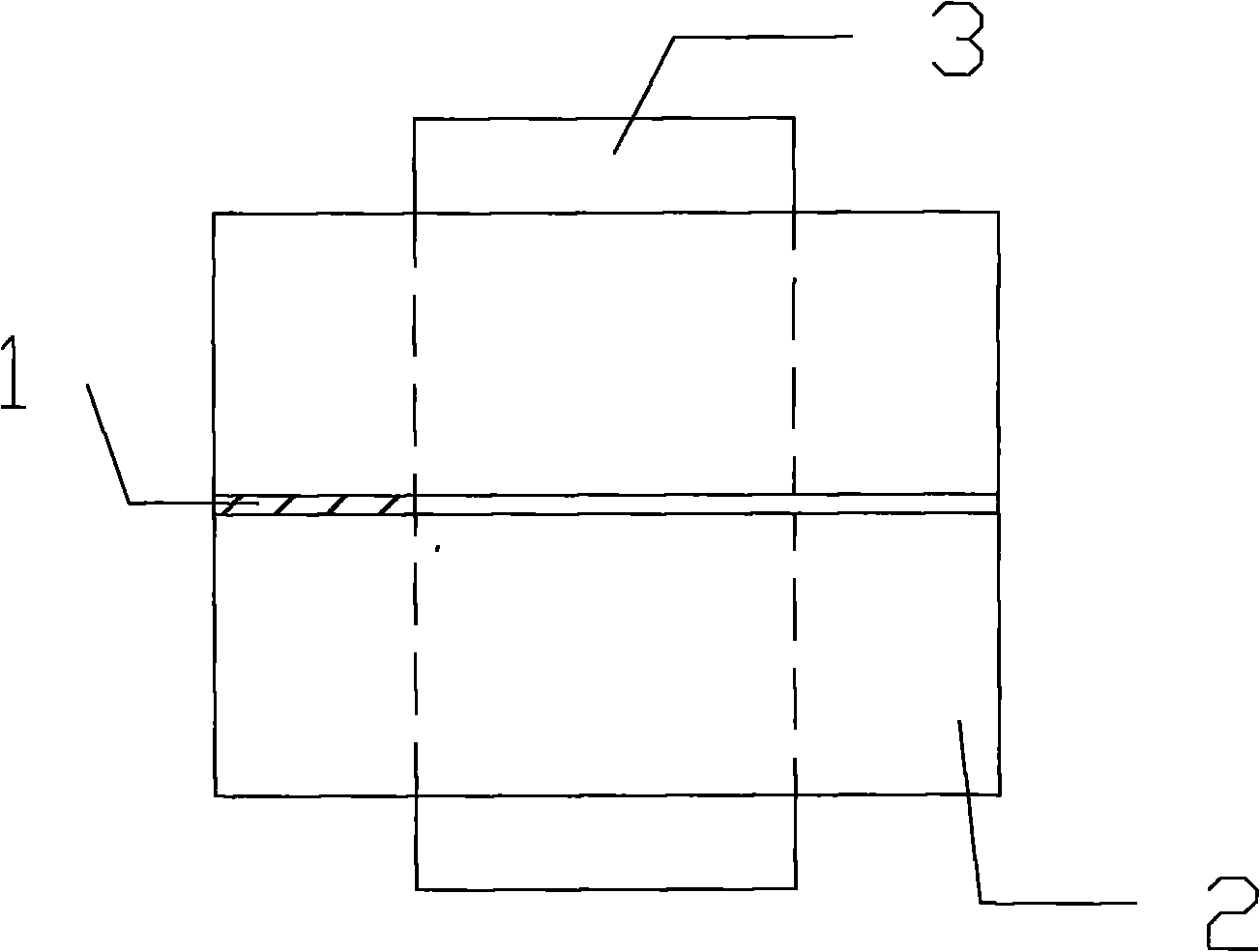

[0032] A method for reducing shock and noise with a two-layer iron core structure of an amorphous alloy transformer. The method is to perform the following steps after completing the window closing process of the bottom iron core according to the traditional production process of the amorphous transformer:

[0033] (1) Prepare enough large nitrile oil-resistant rubber pads with a length of 600mm, a width of 110mm, and a thickness of 3mm;

[0034] (2) the above-mentioned nitrile oil-resistant rubber pad is cut according to the outer contour of the upper surface of the bottom iron core overlapping structure;

[0035] (3) Apply silicone sealant to the outer contour of the upper surface of the underlying iron core overlap structure;

[0036] (4) Remove the cut nitrile oil-resistant rubber pad and cover the area coated with silicone sealant on the bottom iron core;

[0037] (5) Apply silicone sealant to the upper surface of the rubber pad;

[0038] After completing the above step...

Embodiment 3

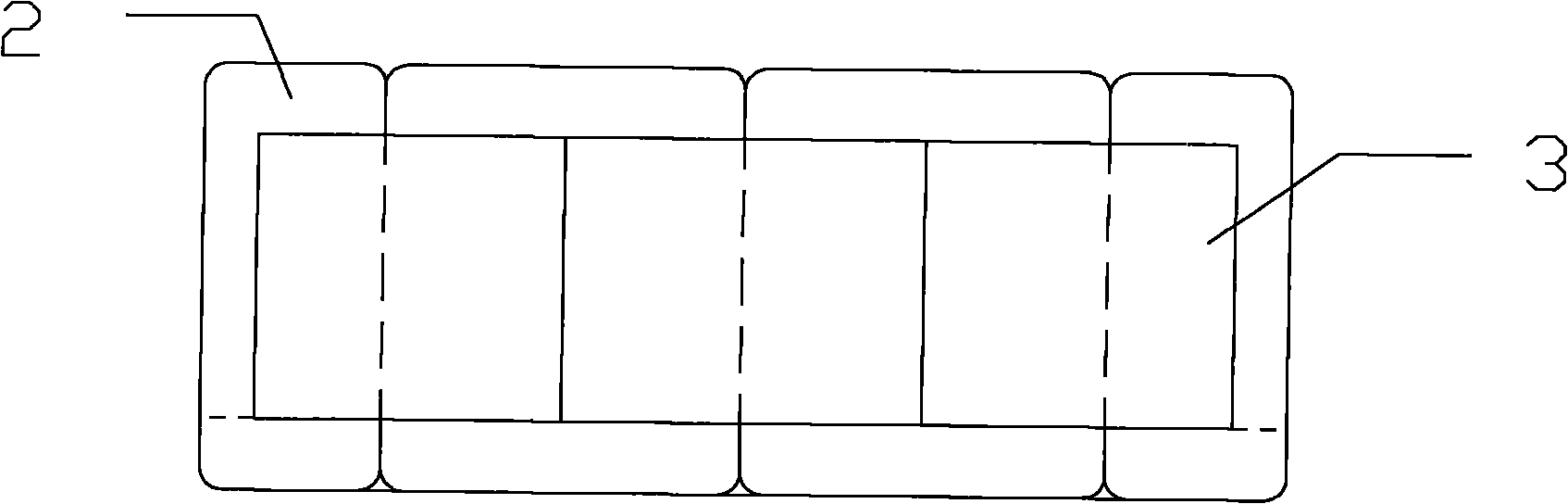

[0040] A method for reducing shock and noise of a five-layer iron core structure of an amorphous alloy transformer. The method is to perform the following steps after completing the window closing process of the bottom iron core according to the traditional production process of the amorphous transformer:

[0041] (1) Prepare enough large nitrile oil-resistant rubber pads with a length of 400mm, a width of 90mm, and a thickness of 1mm;

[0042] (2) the above-mentioned nitrile oil-resistant rubber pad is cut according to the outer contour of the upper surface of the bottom iron core overlapping structure;

[0043] (3) Apply silicone sealant to the outer contour of the upper surface of the underlying iron core overlap structure;

[0044] (4) Remove the cut nitrile oil-resistant rubber pad and cover the area coated with silicone sealant on the bottom iron core;

[0045] (5) Apply silicone sealant to the upper surface of the rubber pad;

[0046] After completing the above steps,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com