Patents

Literature

204 results about "Amorphous metal transformer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An amorphous metal transformer (AMT) is a type of energy efficient transformer found on electric grids. The magnetic core of this transformer is made with a ferromagnetic amorphous metal. The typical material (Metglas) is an alloy of iron with boron, silicon, and phosphorus in the form of thin (e.g. 25 µm) foils rapidly cooled from melt. These materials have high magnetic susceptibility, very low coercivity and high electrical resistance. The high resistance and thin foils lead to low losses by eddy currents when subjected to alternating magnetic fields. On the downside amorphous alloys have a lower saturation induction and often a higher magnetostriction compared to conventional crystalline iron-silicon electrical steel.

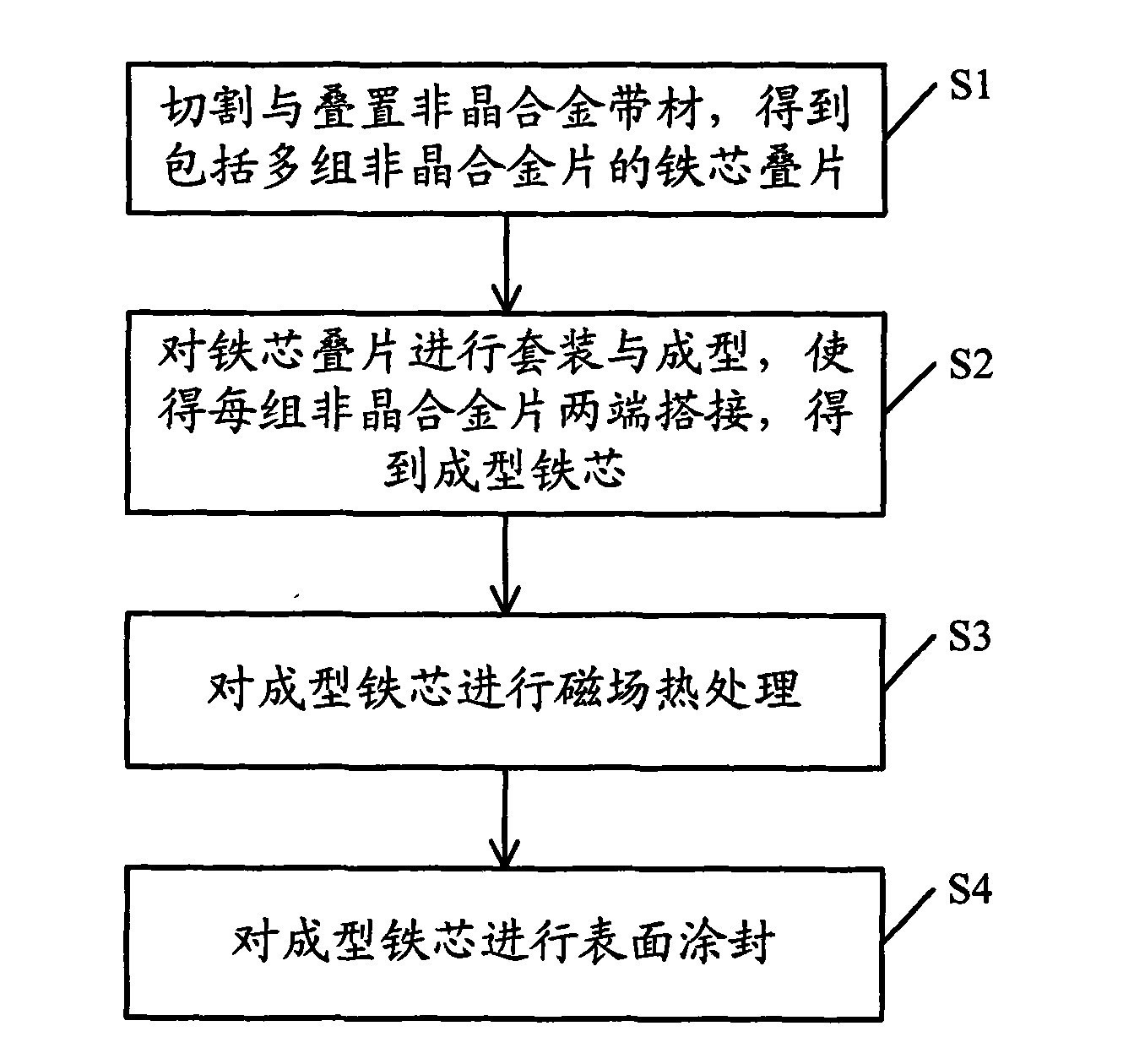

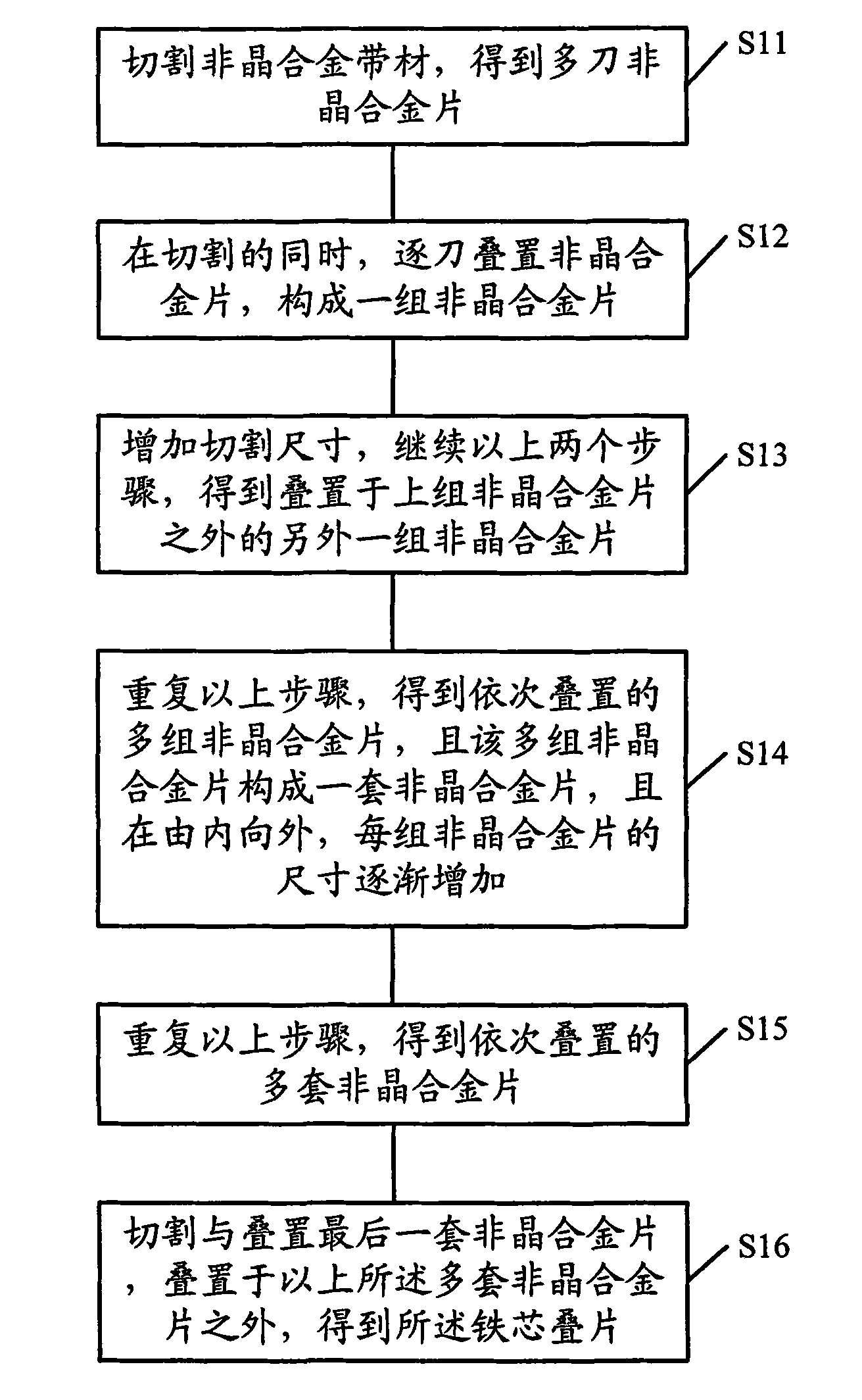

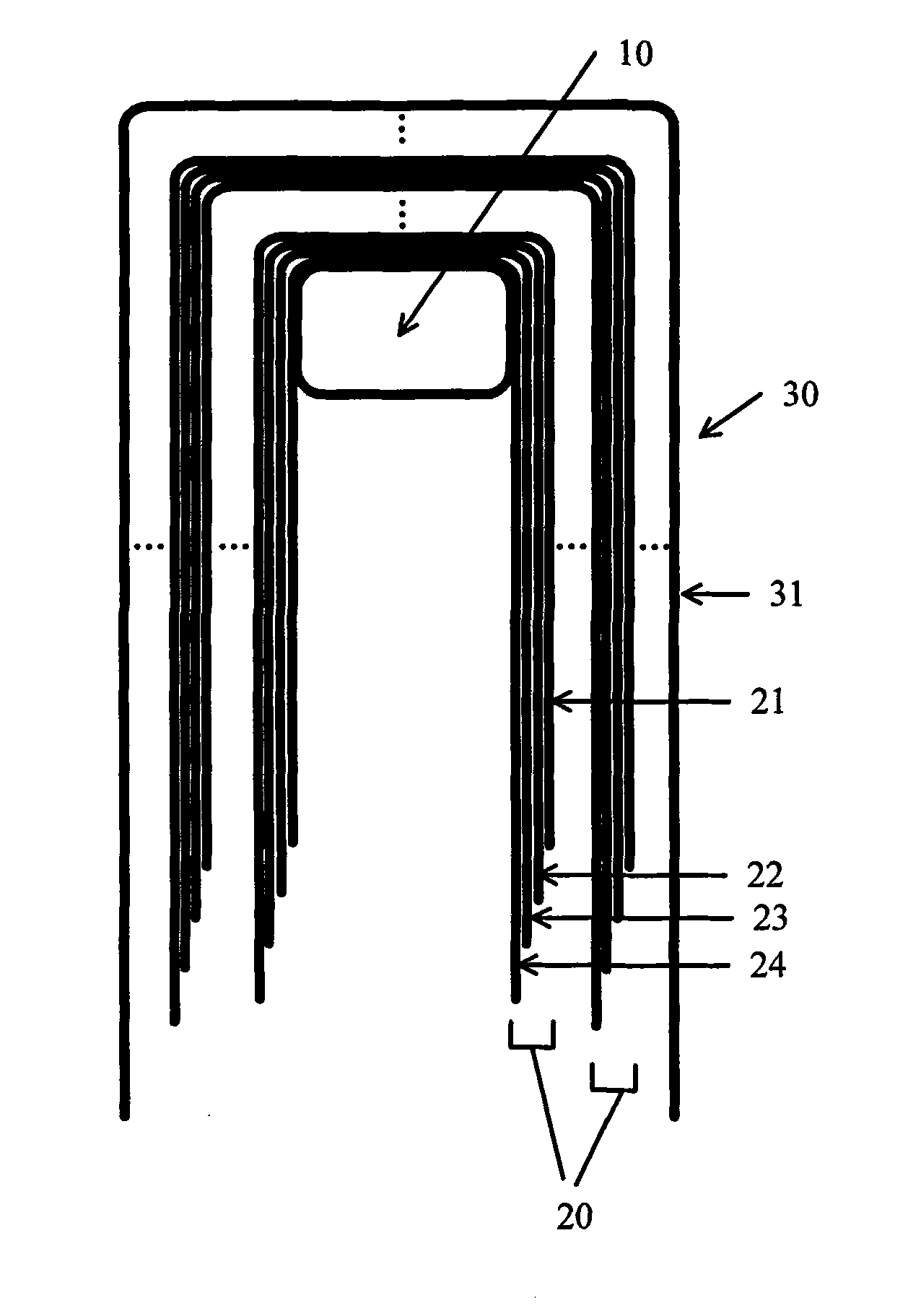

Manufacturing method of amorphous alloy iron cores

ActiveCN101887800ASuitable for mass productionEasy to operateFurnace typesTransformers/inductances magnetic coresAlloyThermal treatment

The invention discloses a manufacturing method of amorphous alloy iron cores, which comprises the following steps of: (1) cutting and overlapping an amorphous alloy belt material to obtain iron core overlapped sheets comprising multiple groups of amorphous alloy sheets; (2) suiting and molding the iron core overlapped sheets so that the two ends of the amorphous alloy sheets of each group are jointed to obtain molded iron cores; (3) carrying out magnetic heat treatment on the molded iron cores; and (4) coating the surfaces of the molded iron cores. The amorphous alloy iron cores produced by using the method can meet the requirements of the transformers with different capacities, has convenient operation and high degree of automation, is suitable for the batch production of the amorphous alloy transformer iron core, is beneficial to the popularization and application of the novel energy-saving products of the transformers, and greatly relieves the conflict of the domestic electricity overload.

Owner:SHANGHAI RIGANG ZHIXIN AMORPHOUS METAL

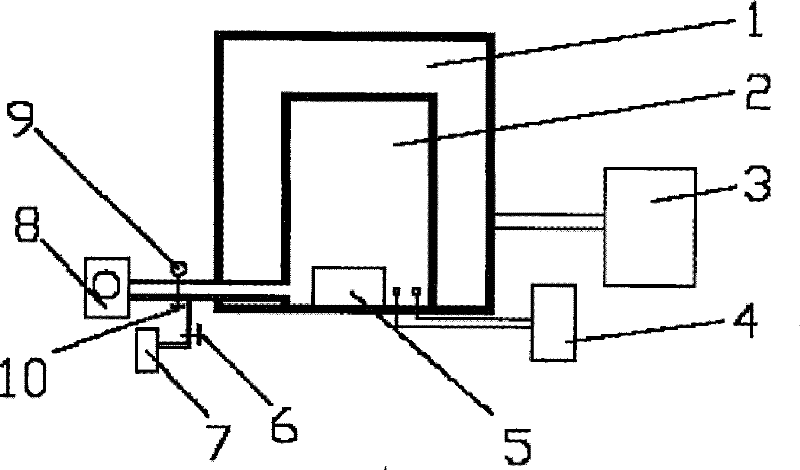

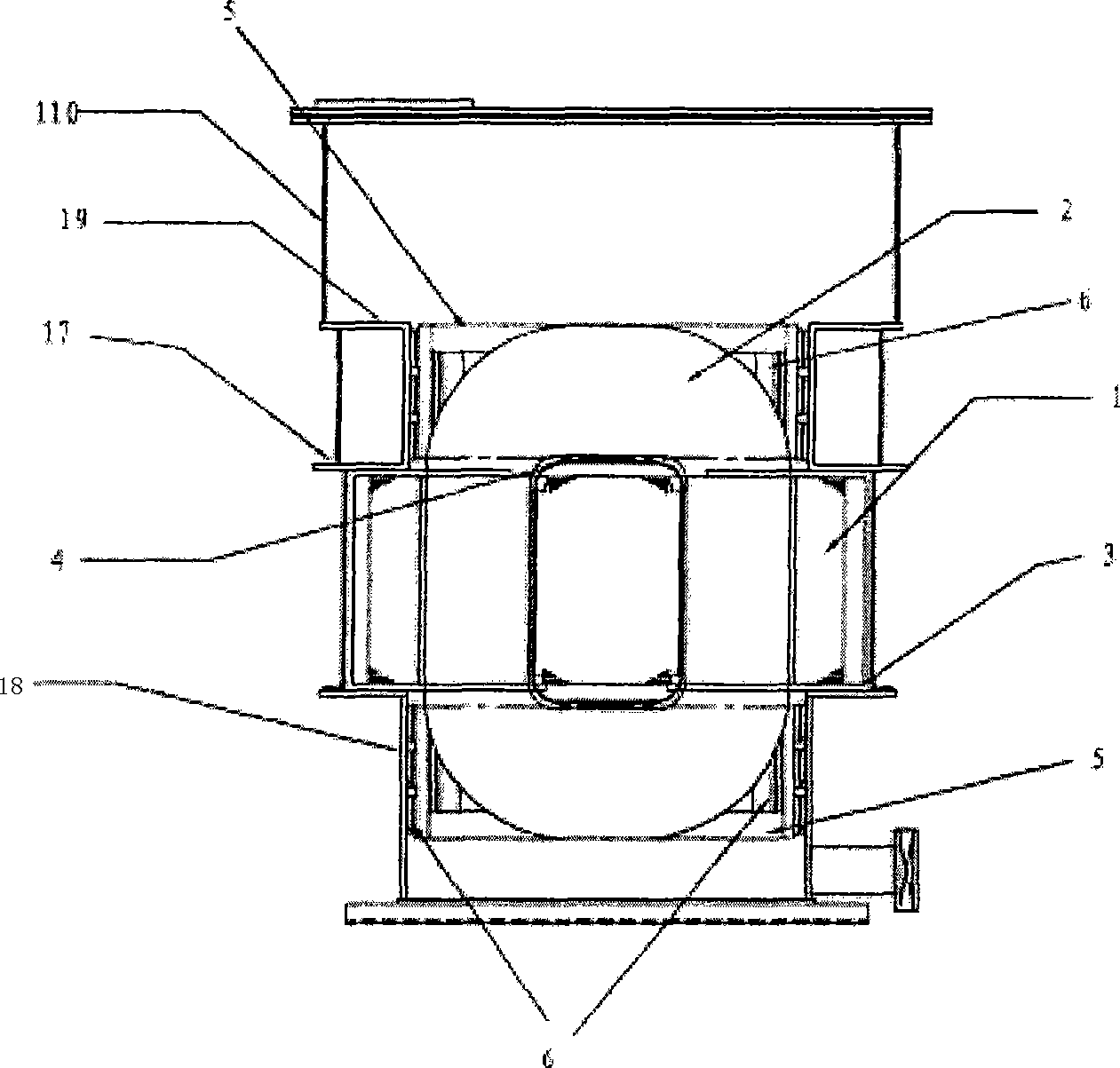

Destressing method and device for amorphous alloy transformer iron core

InactiveCN102337384AStress reliefReduce no-load lossInductances/transformers/magnets manufactureCore temperatureAlloy

The invention discloses a destressing method and device for an amorphous alloy transformer iron core, wherein the method comprises the steps of: loading an iron core to a heating furnace chamber; exhausting the air inside the furnace chamber by injecting an inert gas into the heating furnace chamber; heating up the heating furnace chamber; keeping the temperature of the heating furnace chamber when the iron core temperature reaches a keeping temperature, wherein the iron core keeping temperature is 342-348 DEG C, and the temperature keeping time is 40-50 min; cooling the iron core, wherein the cooling step comprises a step of cooling the heating furnace chamber and a step of cooling the iron core along with the furnace; and keeping to feed the inert gas into the furnace in the processes of heating up, keeping temperature and cooling the heating furnace chamber. By adopting the method and the device disclosed by the invention, the stresses of the amorphous alloy generated in the processes of fast quenching, winding, cutting, forming and the like are effectively eliminated, and no-load loss of the amorphous alloy iron core is obviously reduced.

Owner:SHANGHAI RIGANG ZHIXIN AMORPHOUS METAL

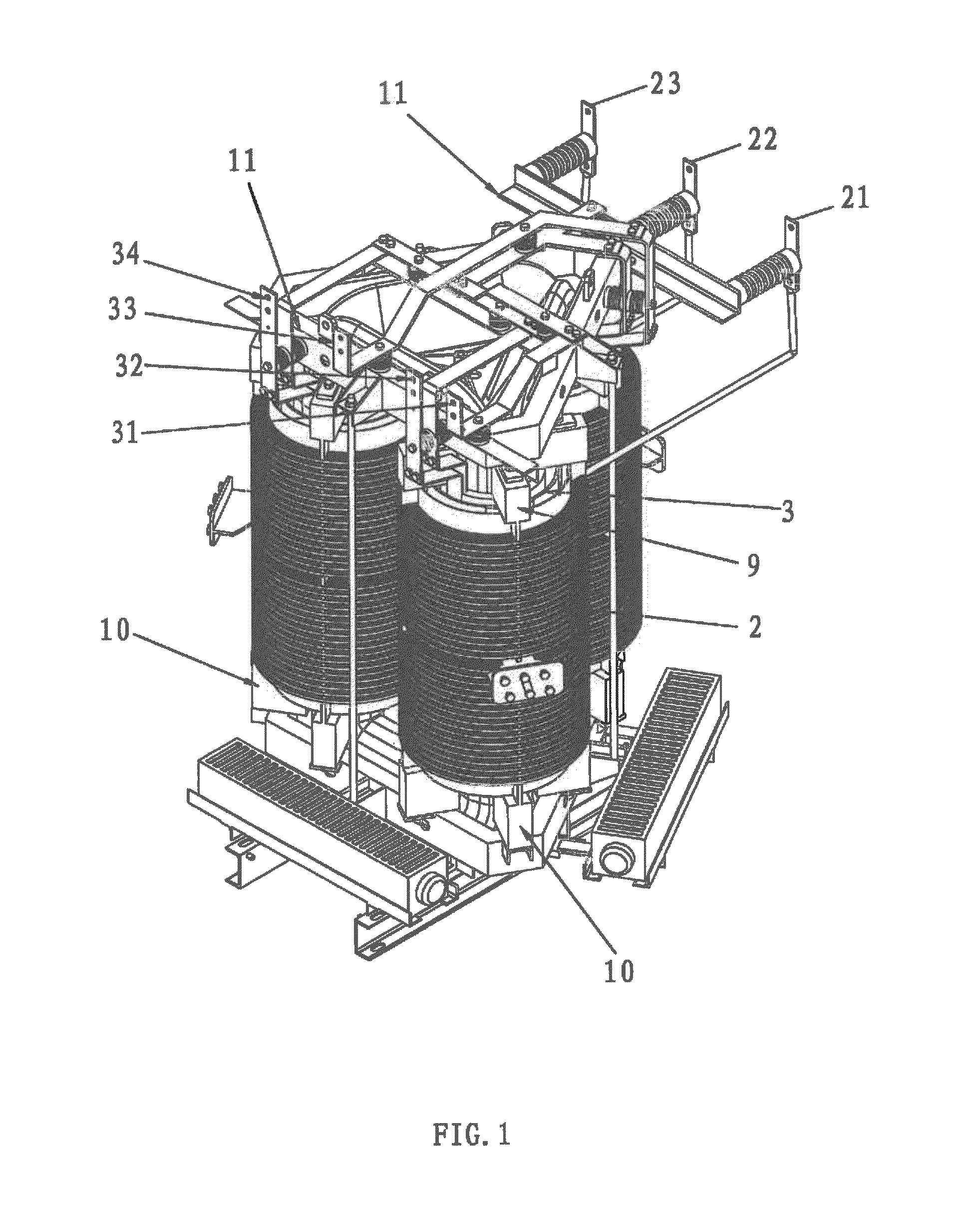

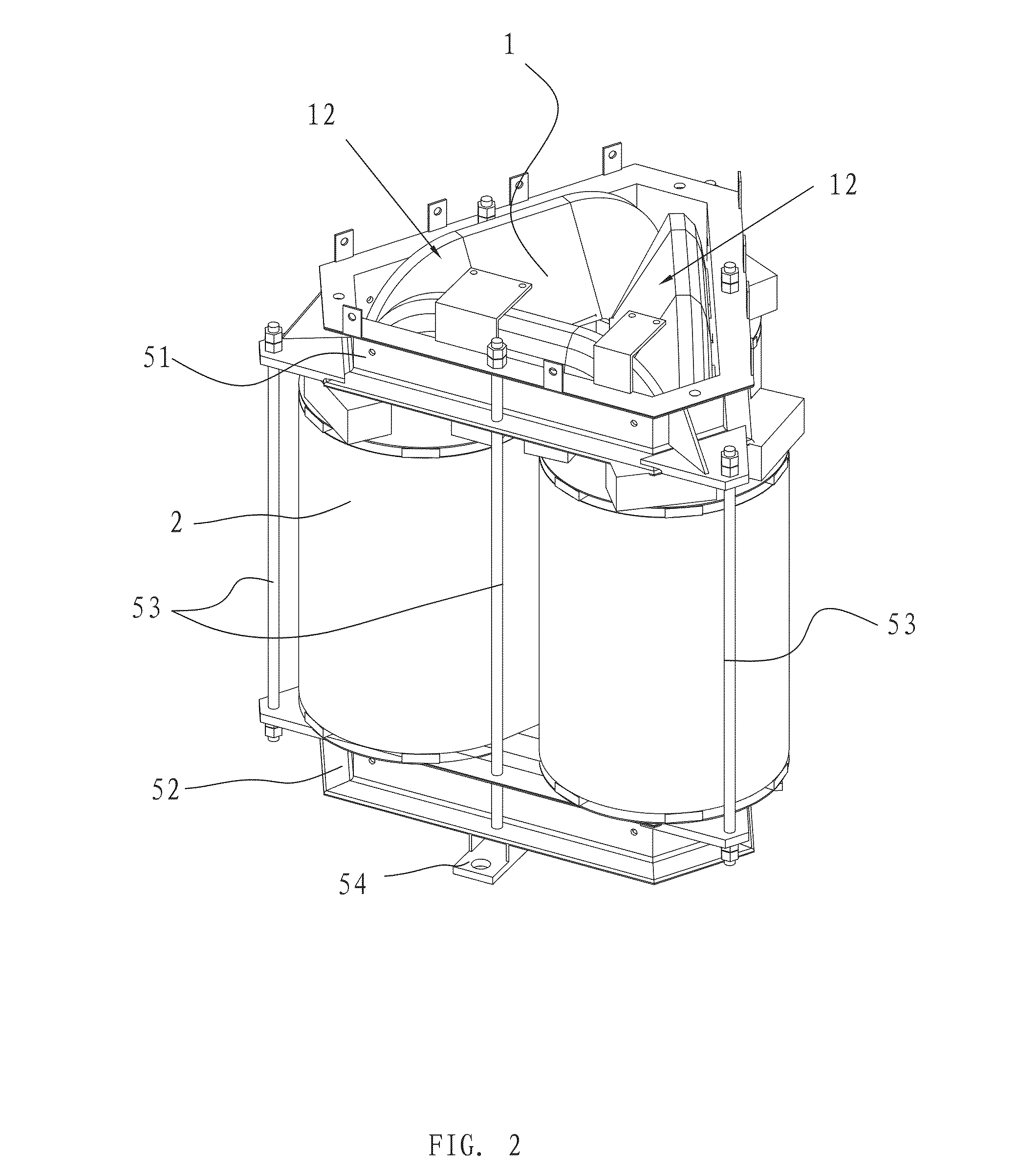

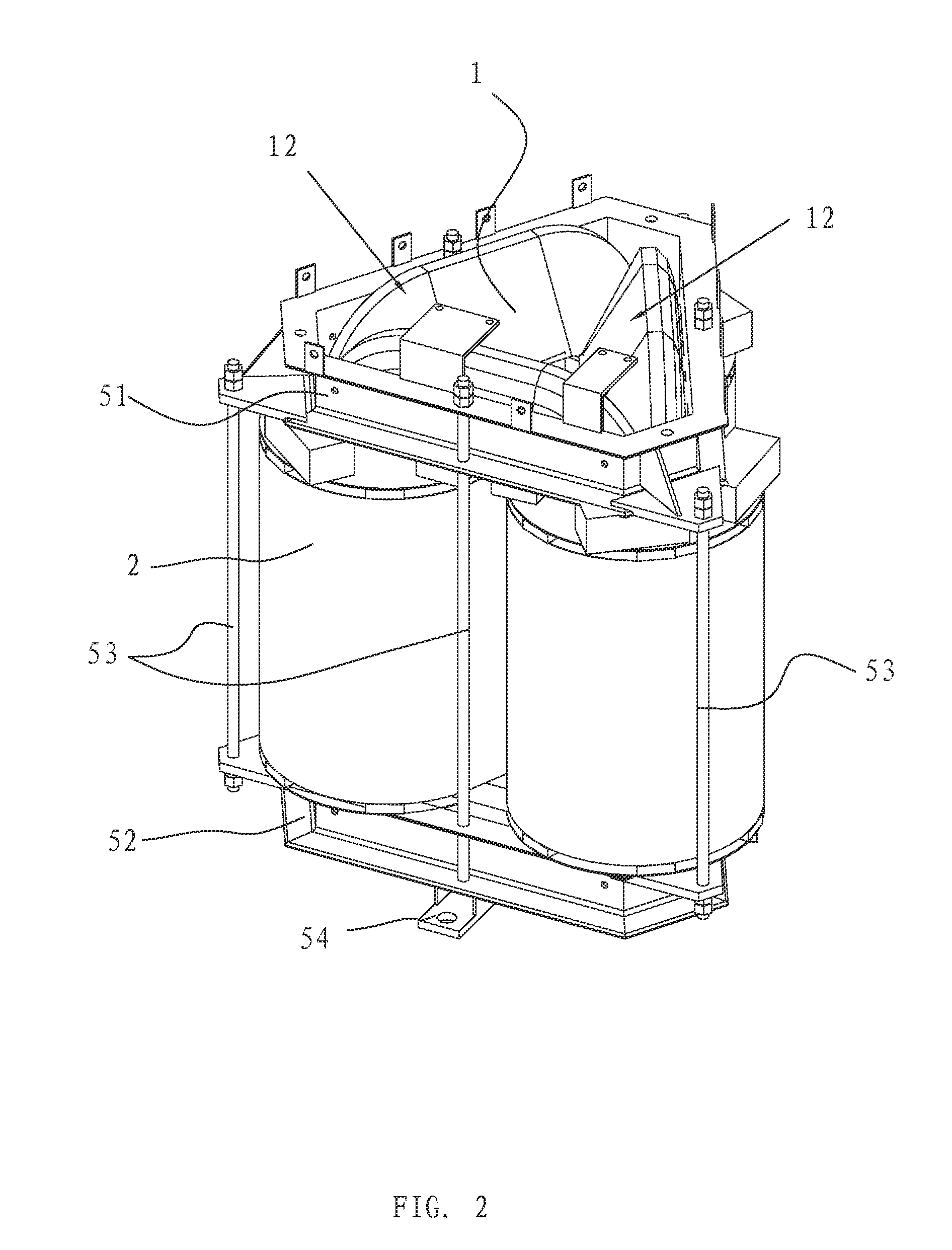

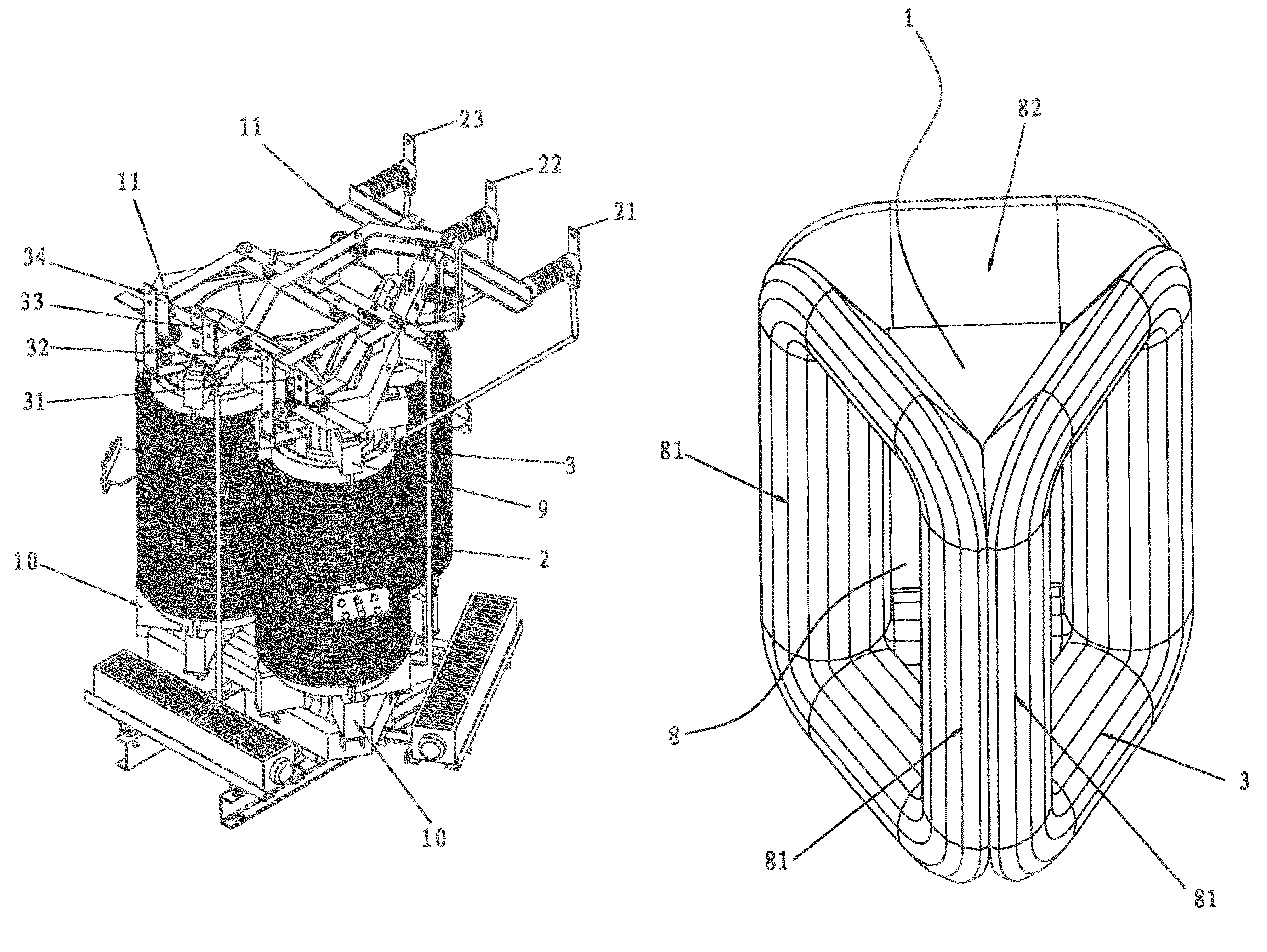

Resin-molded stereo wound-core dry-type amorphous alloy transformer

ActiveUS20140002229A1Improve abilitiesReduce working noiseTransformers/inductances magnetic coresFixed transformersNomexVacuum pressure

The patent discloses a resin-molded stereo wound-core dry-type amorphous alloy transformer, belonging to the field of power equipment. The resin-molded stereo wound-core dry-type amorphous alloy transformer disclosed is characterized in its stereo wound-core structure. Three lower yokes are provided on a welded base of a lower clamp, and an upper clamp and a lower clamp are connected with each other by press screws. Its low-voltage windings are with a foil-wound or cylindrical structure, while its high-voltage windings are wound with oxygen-free copper wires wrapped in NOMEX® paper and processed through vacuum pressure impregnation. In addition, several upper and lower padding blocks are involved to support and compress the high-voltage and low-voltage windings, so that the product is formed in a rigid stereo frame structure.

Owner:GUANGDONG HAIHONG

Amorphous alloy transformer core and manufacturing method thereof

InactiveCN101740203AAdvantages of production methodHigh bonding strengthTransformers/inductances magnetic coresInductances/transformers/magnets manufactureFiberUltimate tensile strength

The invention discloses an amorphous alloy transformer core, which comprises a rectangular core frame body formed by laminating amorphous alloy strips. An inner side of the amorphous alloy strip on the innermost layer is provided with an inner silicon-steel sheet, and an outer side of the amorphous alloy strip on the outermost layer is provided with an outer silicon-steel sheet. Grid fiber materials are adhered on the end face of the core frame body which is provided with lamination seams of the amorphous alloy strips through insulating glue. The width of the grid fiber materials is greater than the lamination thickness of the amorphous alloy strips, the inner silicon-steel sheet and the outer silicon-steel sheet, and the edges of the grid fiber materials are adhered to the inner silicon-steel sheet and the outer silicon-steel sheet. The invention also discloses a manufacturing method for the amorphous alloy transformer core. By adhering the grid fiber materials, the adhesive strength of a coating is increased; the crack of the coating is prevented; the shed of the amorphous core is prevented; and the safe operation of a transformer is guaranteed.

Owner:CHINESE ELECTRICAL EQUIP GRP CO LTD

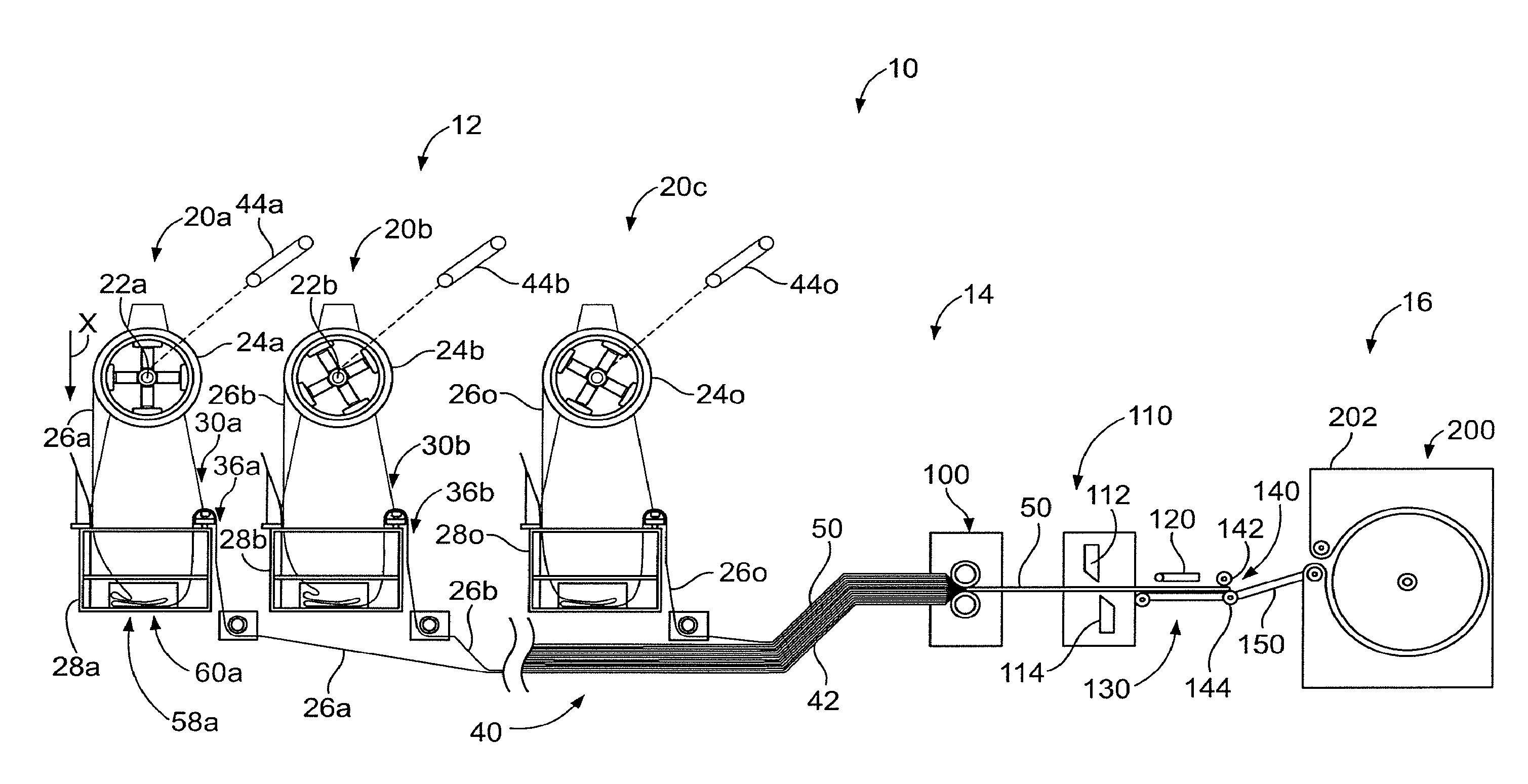

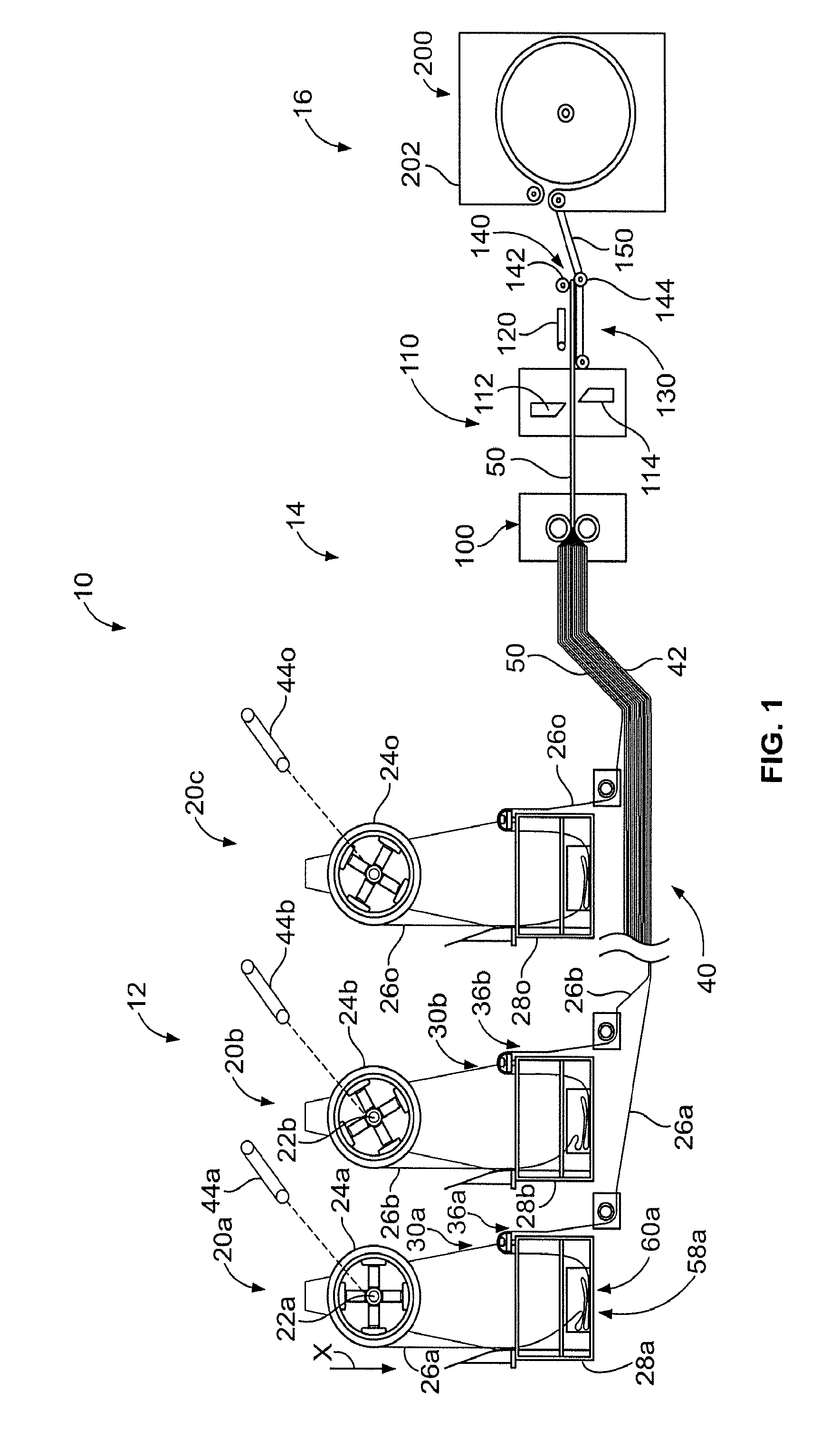

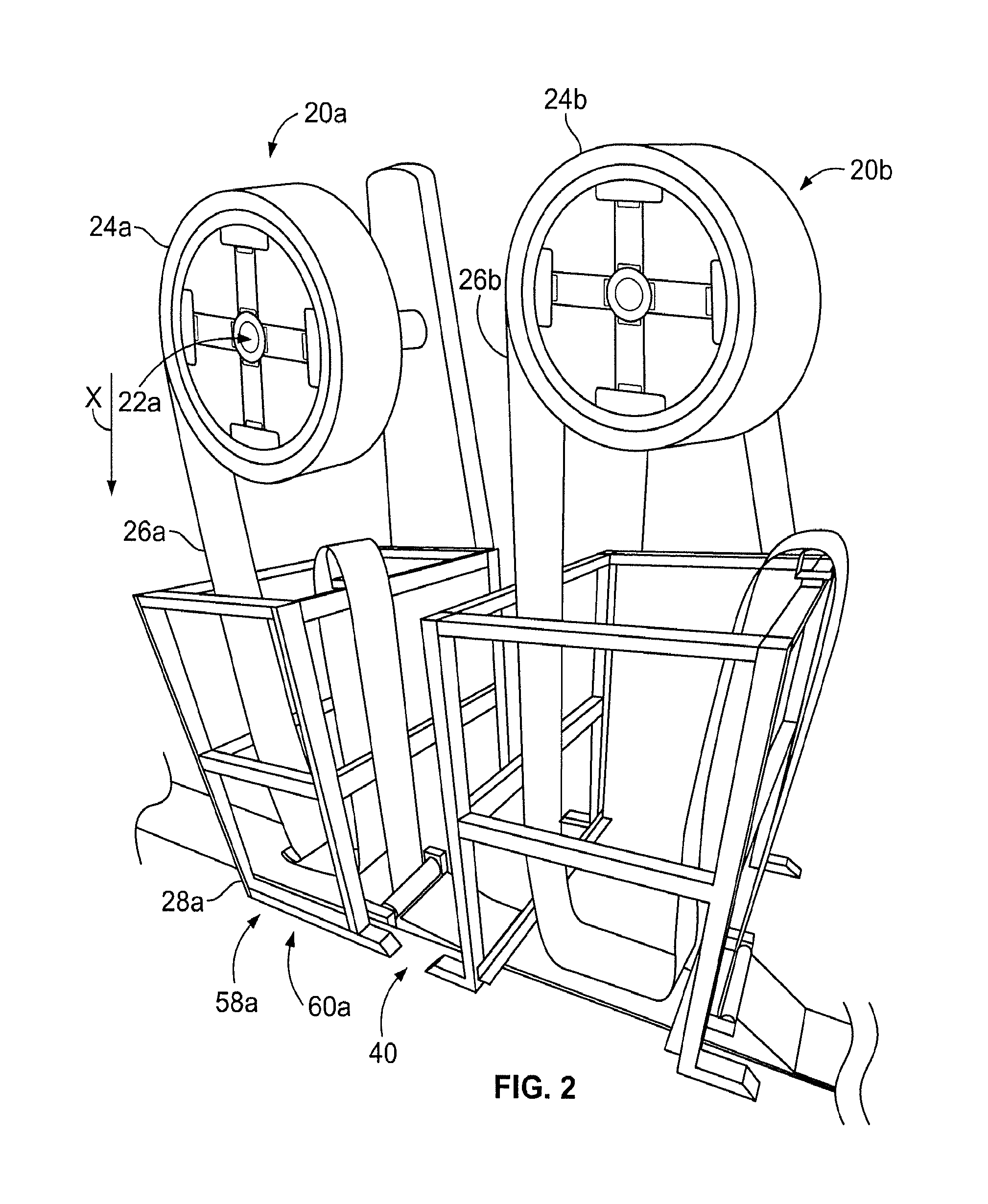

Method and apparatus for making amorphous metal transformer cores

ActiveUS20160020021A1Inductances/transformers/magnets manufactureMetal working apparatusMetallic materialsMetal

According to an exemplary embodiment, an apparatus for assembling an amorphous metallic transformer core from a plurality of amorphous metallic strip packets comprises an unwinding section comprising a plurality of uncoilers. Each of the plurality of uncoilers operated to unwind a coil comprising a single-ply continuous strip of a metallic material. A collection tray is configured to transport a composite metallic strip from the unwinding section, the composite metallic strip comprising a plurality of single ply metallic strips that are unwound from the plurality of uncoilers of the unwinding section. A shearing section operably coupled to the collection tray and configured to receive the composite metallic strip from the unwinding section, the shearing section configured to shear the composite metallic strip into a plurality of packets, the shearing section comprising an accumulator for holding the plurality of the packets of the composite metallic strips. A winding section is configured to receive the plurality of the packets of the composite metallic strips from the shearing section, the winding section forming a metallic transformer core from the plurality of packets of the composite metallic strips.

Owner:ERMCO COMPONENTS INC

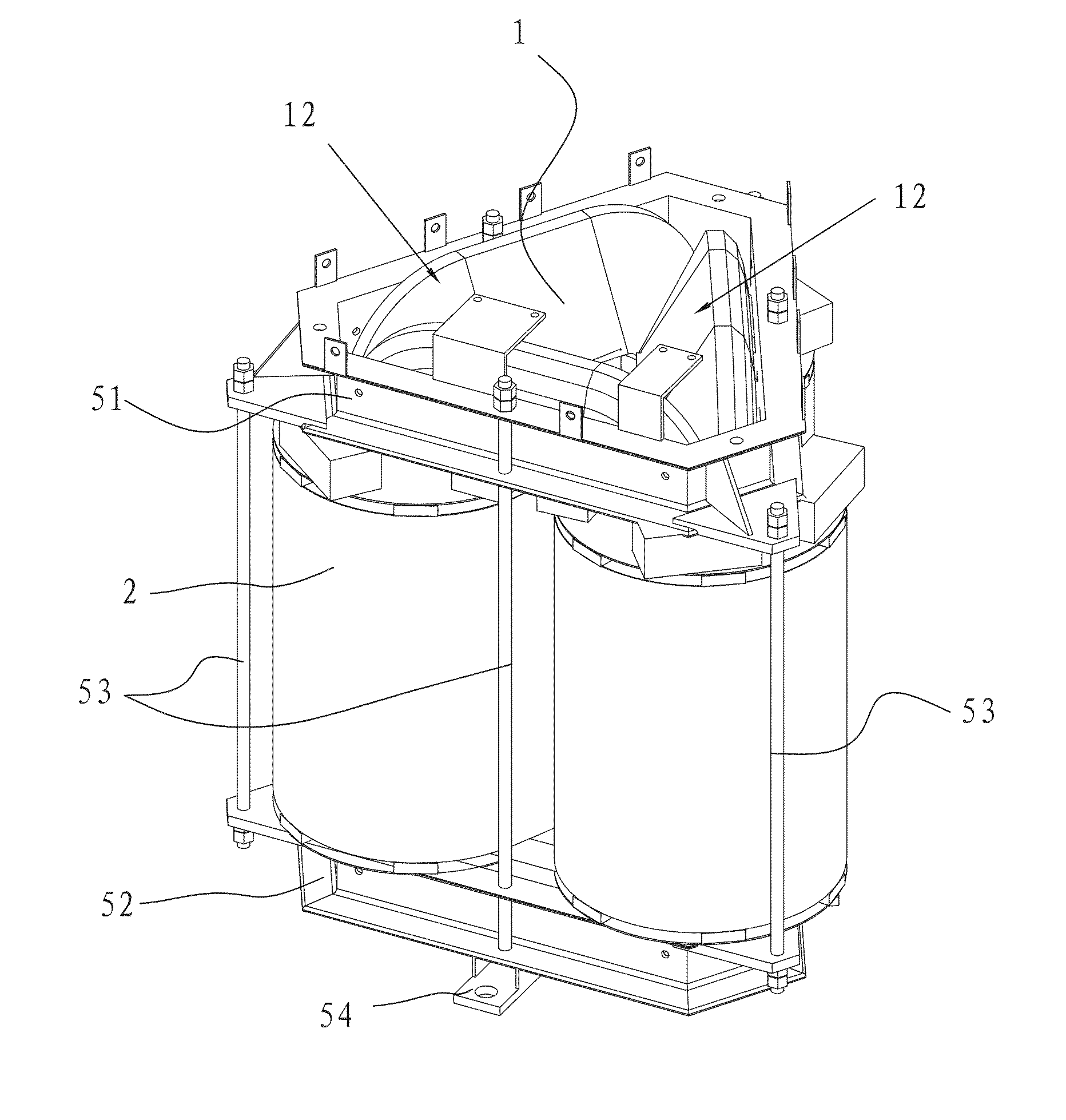

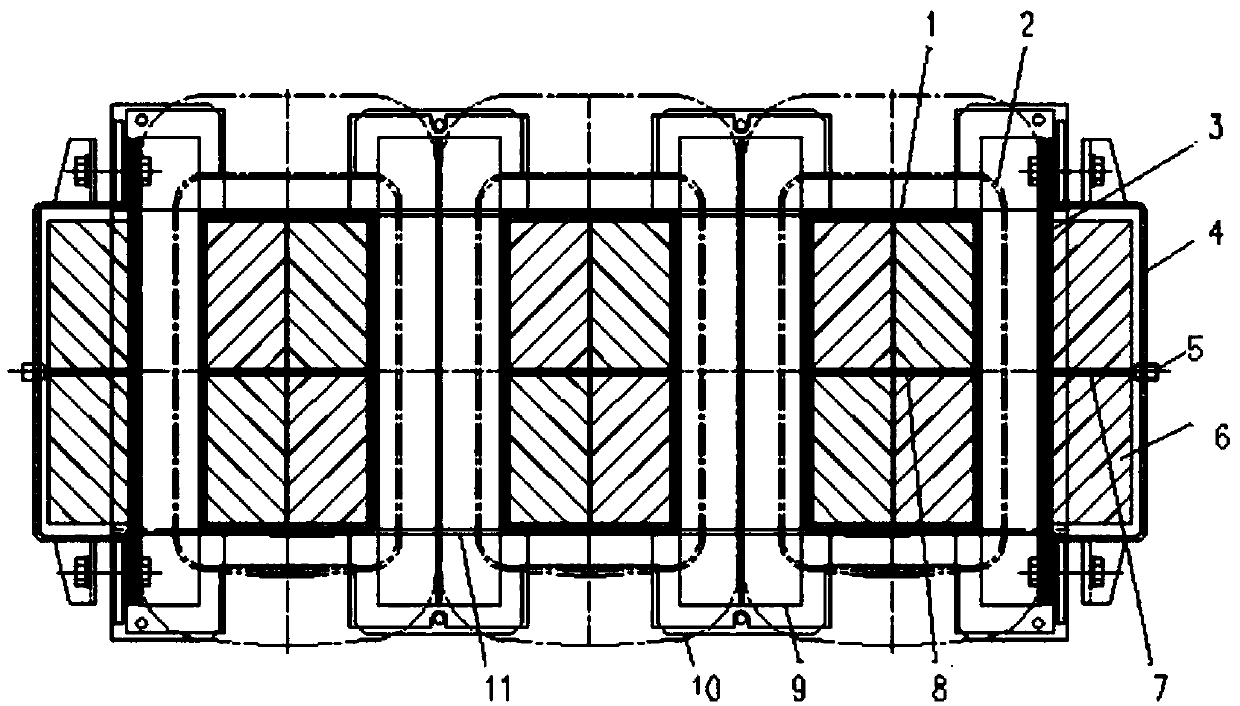

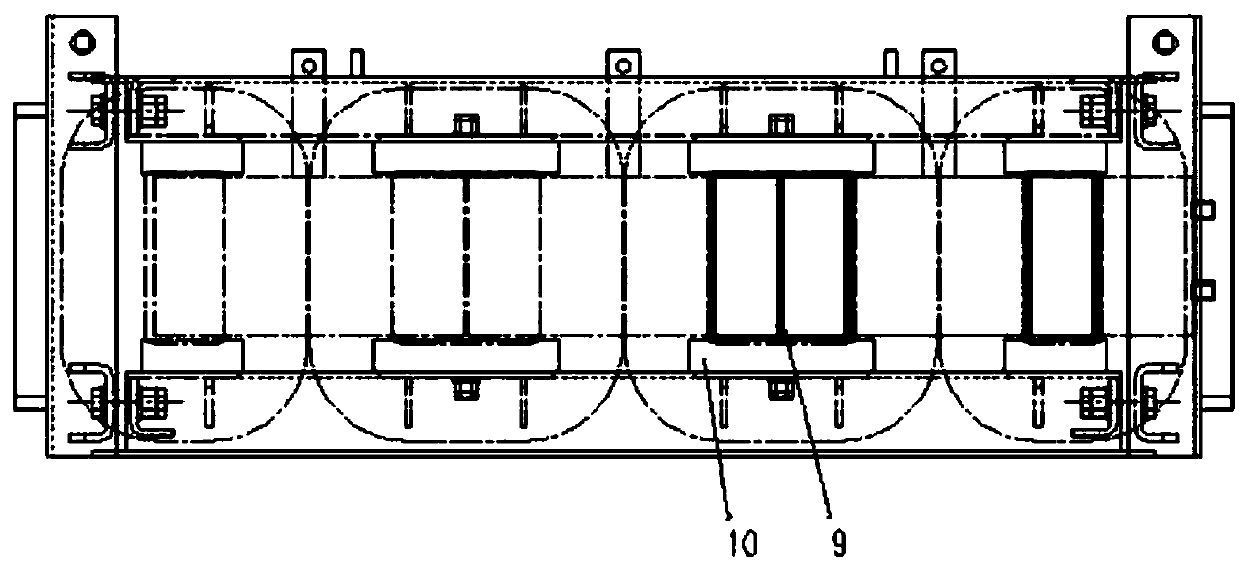

Non-encapsulated-winding stereo wound-core dry-type amorphous alloy transformer

ActiveUS20130200967A1More materialReduce noiseTransformers/inductances magnetic coresUnwanted magnetic/electric effect reduction/preventionVacuum pressureLow voltage

A non-encapsulated-winding stereo wound-core dry-type amorphous alloy transformer. The core of the transformer has a stereo structure. Three lower yokes are placed on a base of a lower clamp, and an upper clamp and the lower clamp are connected with each other by several press screws. Low-voltage windings include a foil-wound or wire-wound cylindrical structure, while its high-voltage windings are wound with oxygen-free copper wires wrapped in an insulate paper and processed through vacuum pressure impregnation. Upper and lower padding blocks support and compress the high-voltage and low-voltage windings, so that the product is formed in a rigid stereo frame structure.

Owner:HAIHONG ELECTRIC CO LTD

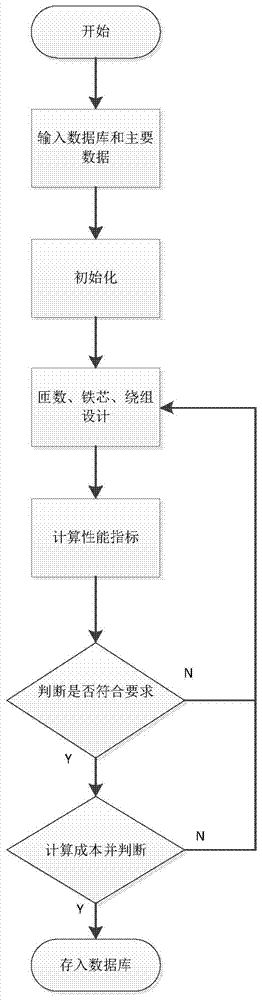

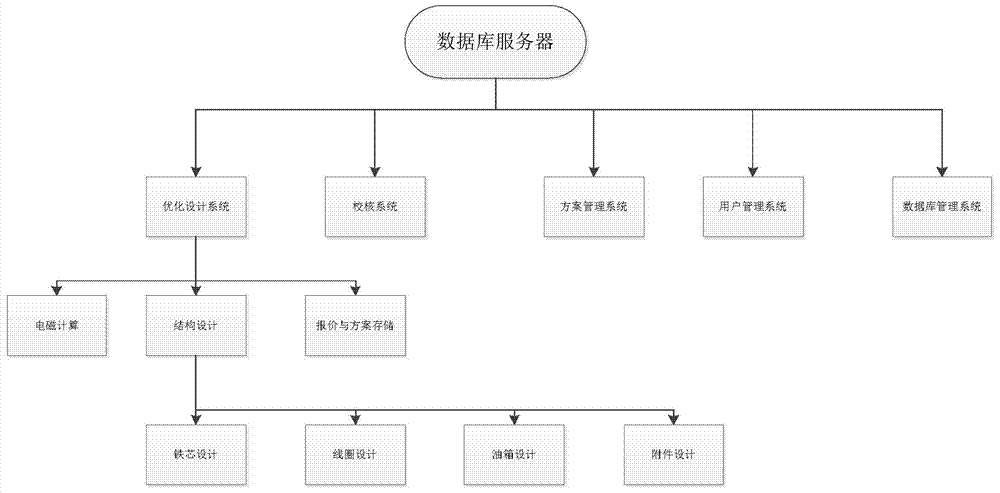

Electromagnetic design method of amorphous alloy transformer

InactiveCN104779047AReduce lossImprove reliabilityInductances/transformers/magnets manufactureSpecial data processing applicationsDistribution transformerAlloy

The invention relates to an electromagnetic design method of an amorphous alloy transformer, which designs electromagnetic parameters of the amorphous alloy transformer by utilizing a circulating traversing method, and provides a calculation method of transformer iron core parameters, no-load loss and load loss considering the characteristics of an amorphous alloy material, effectively inhibits the local magnetic saturation and reduces the loss of the transformer; moreover the search space can be reduced, the search speed can be increased, and the reliability of the design scheme can be improved. Meanwhile, since the electromagnetic design of the amorphous alloy iron core power distribution transformer involves fewer variables, the calculation requirement of the circulating traversing method can be satisfied by utilizing the existing computer, and the cost for optimizing the computer system can be reduced.

Owner:浙江环联电力设备有限公司

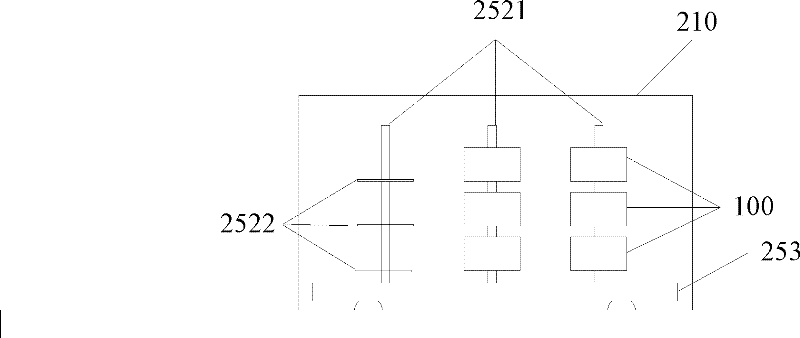

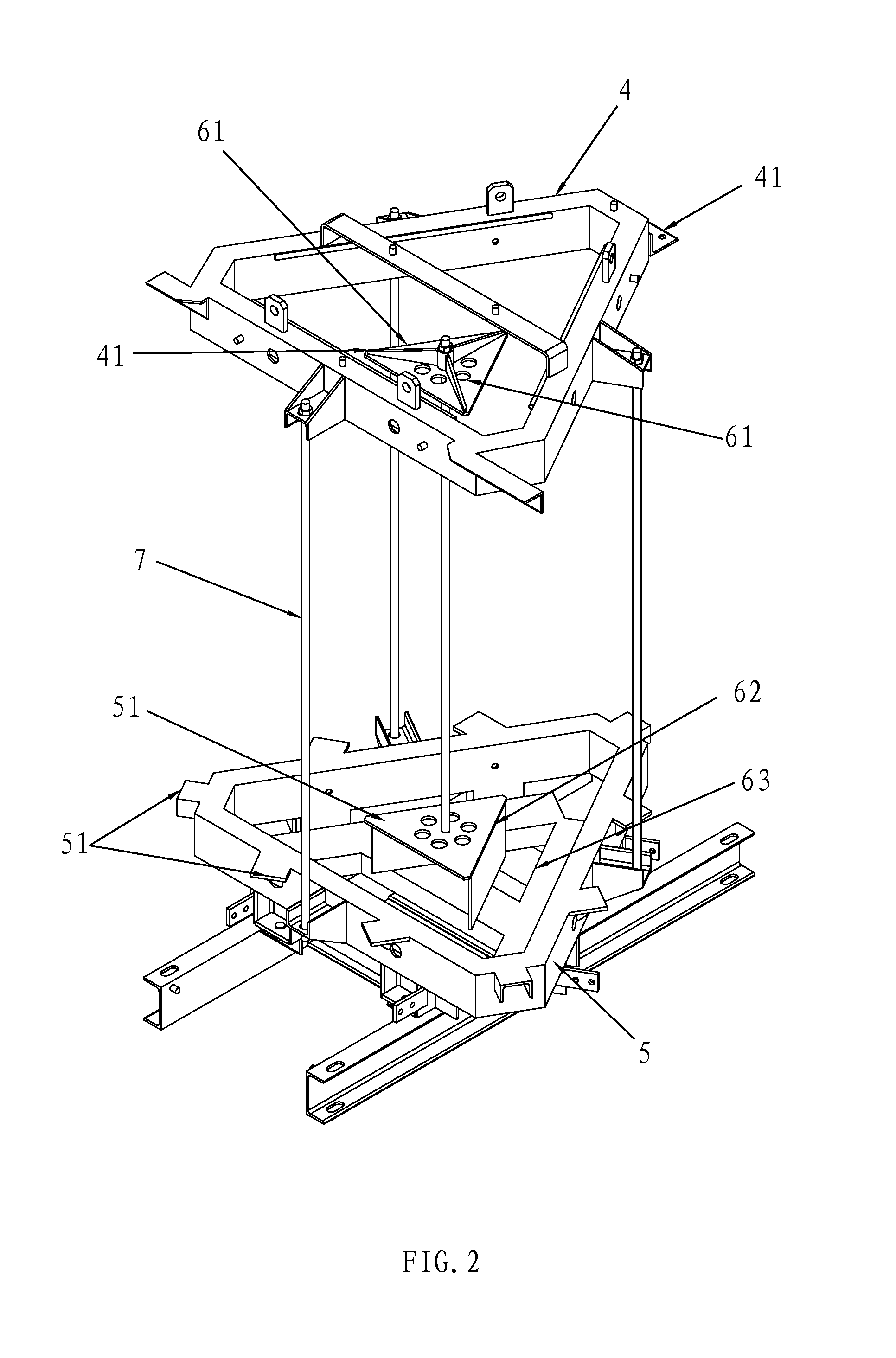

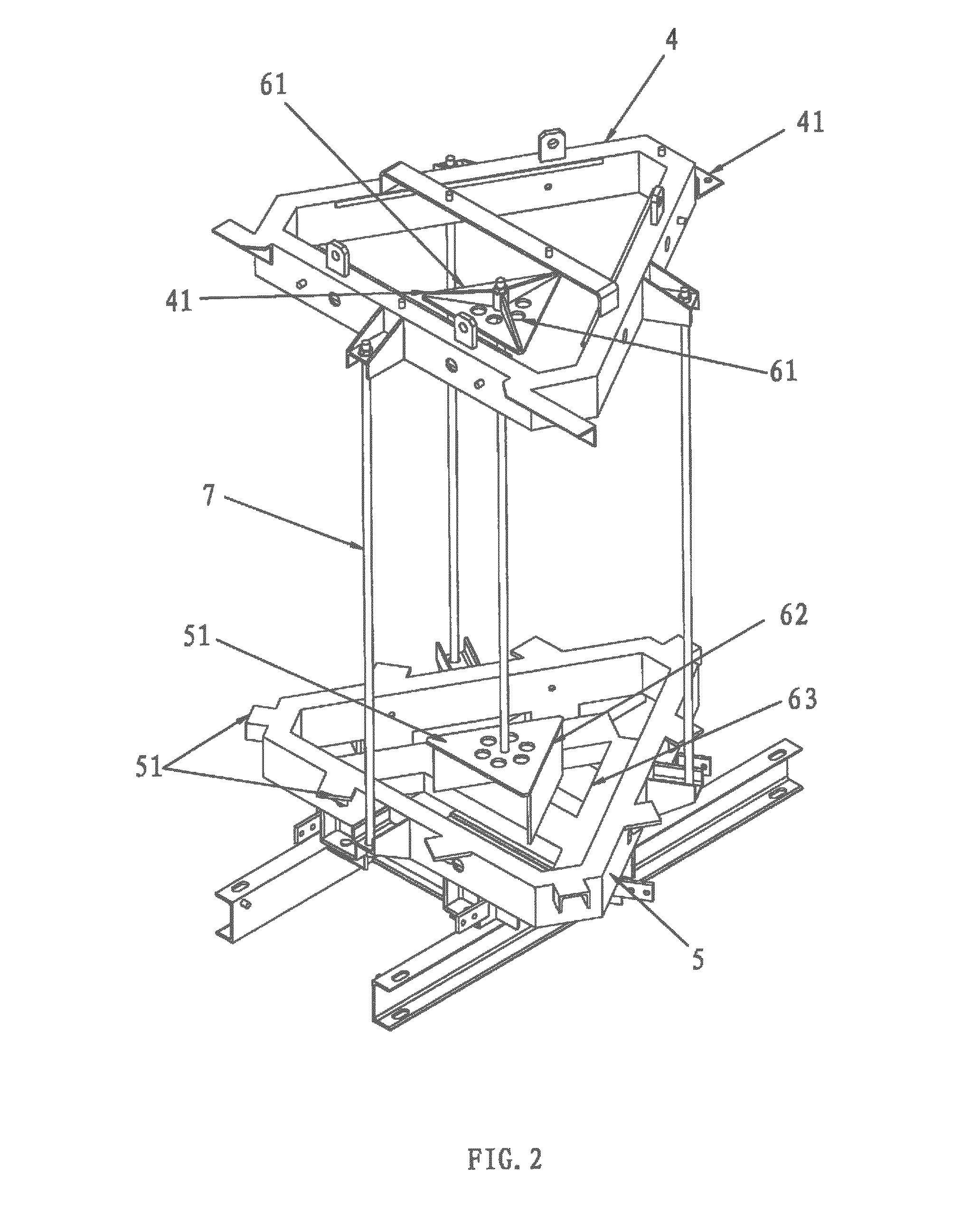

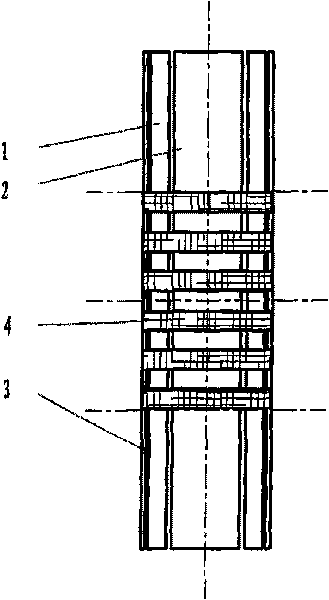

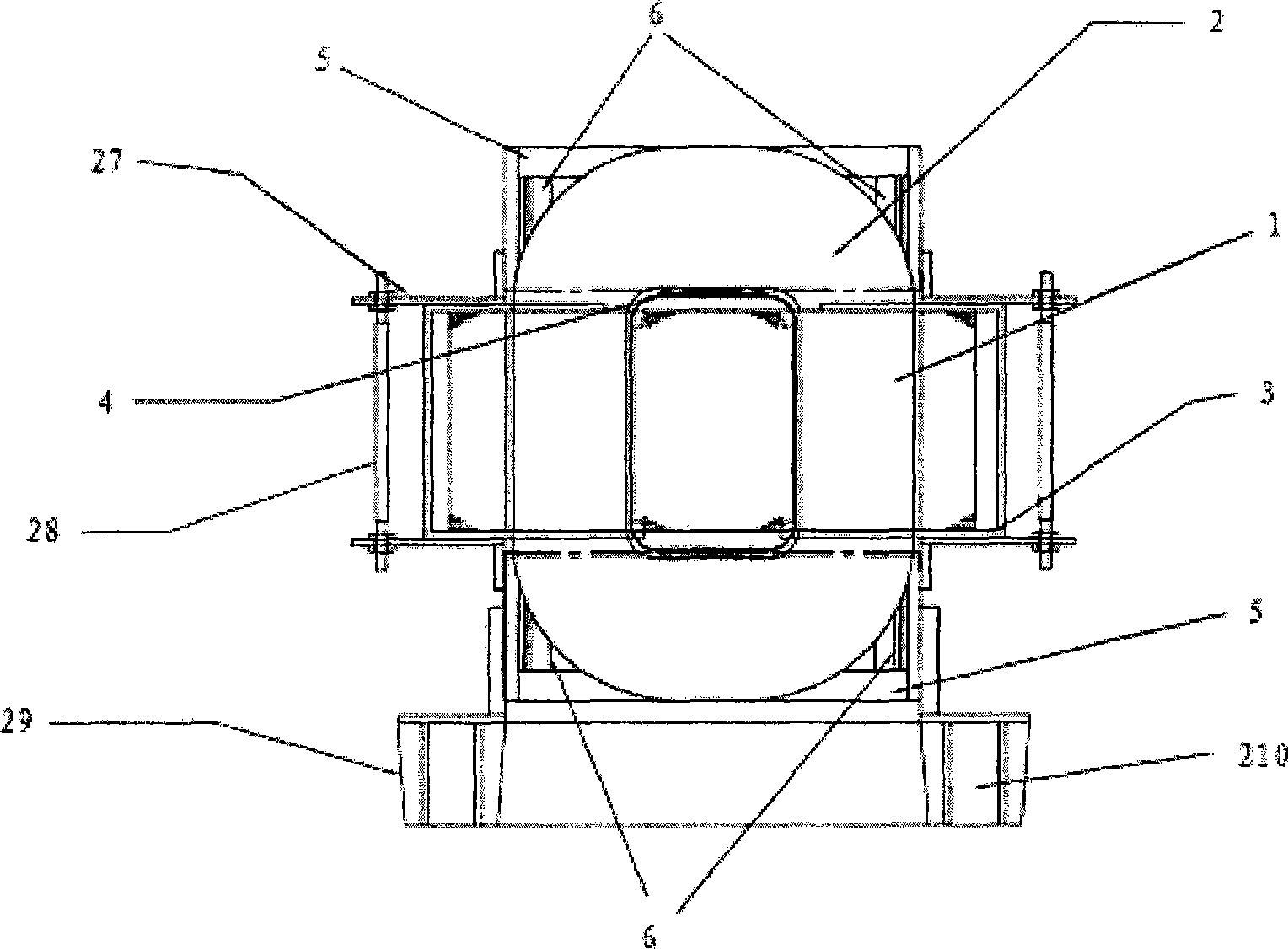

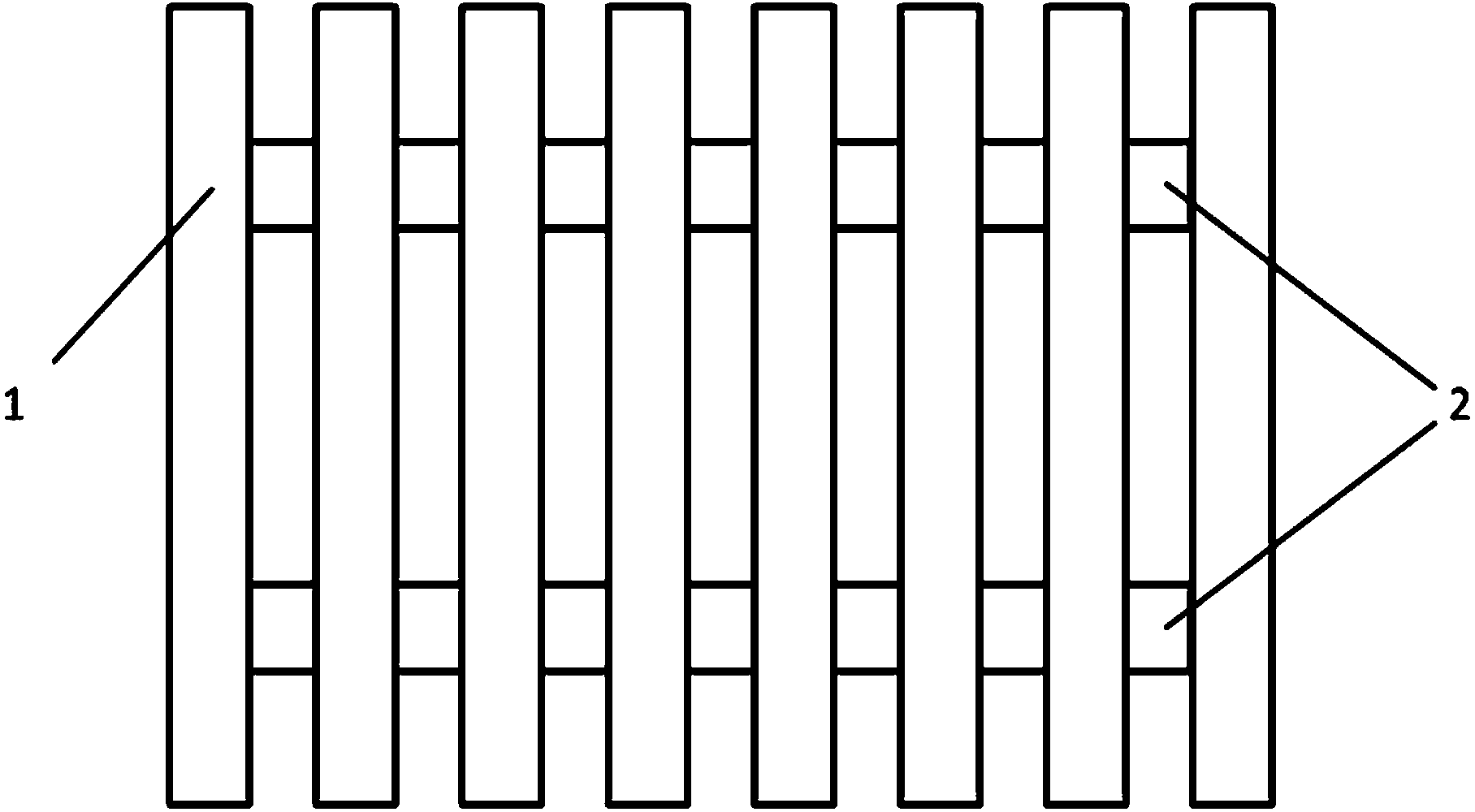

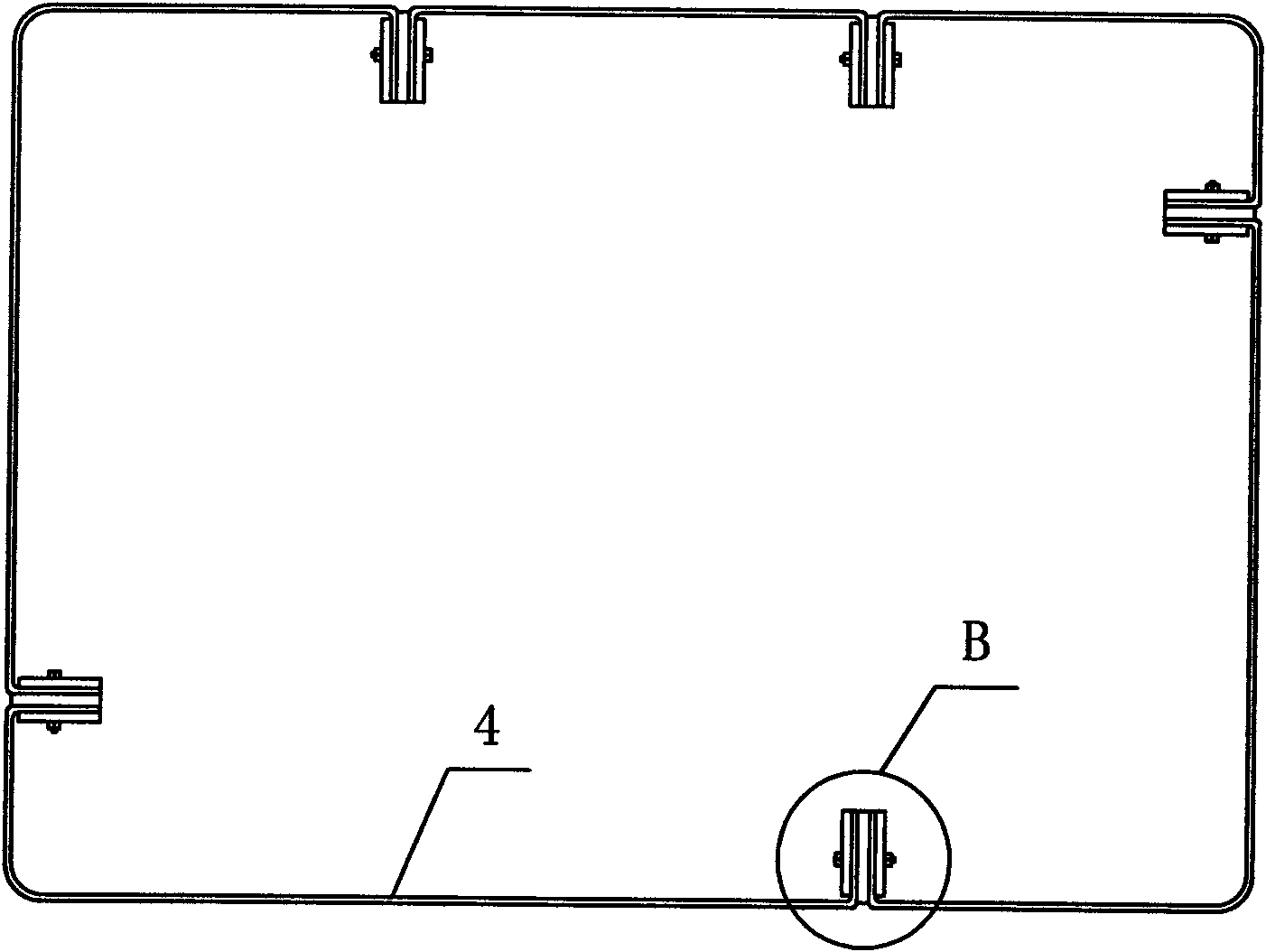

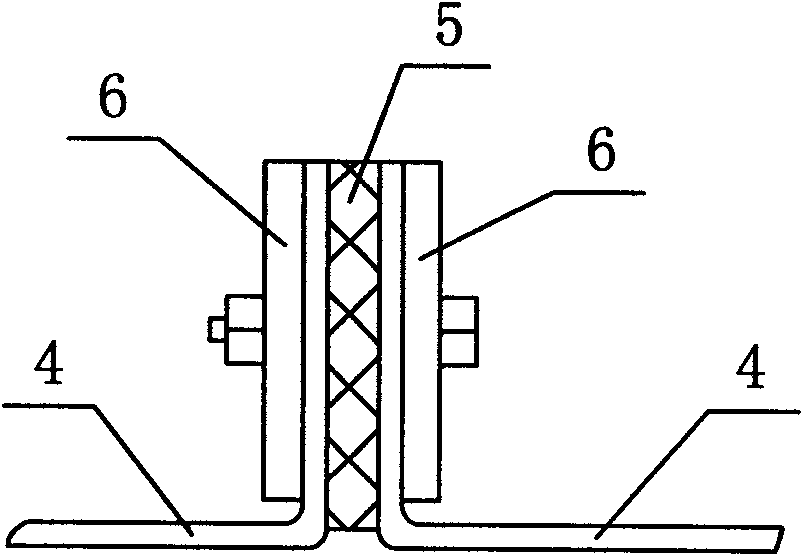

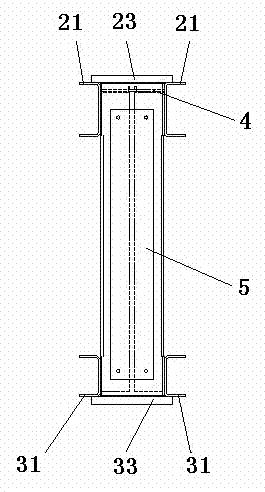

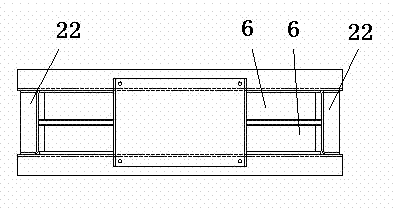

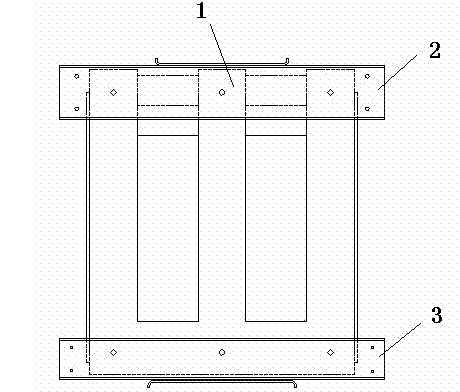

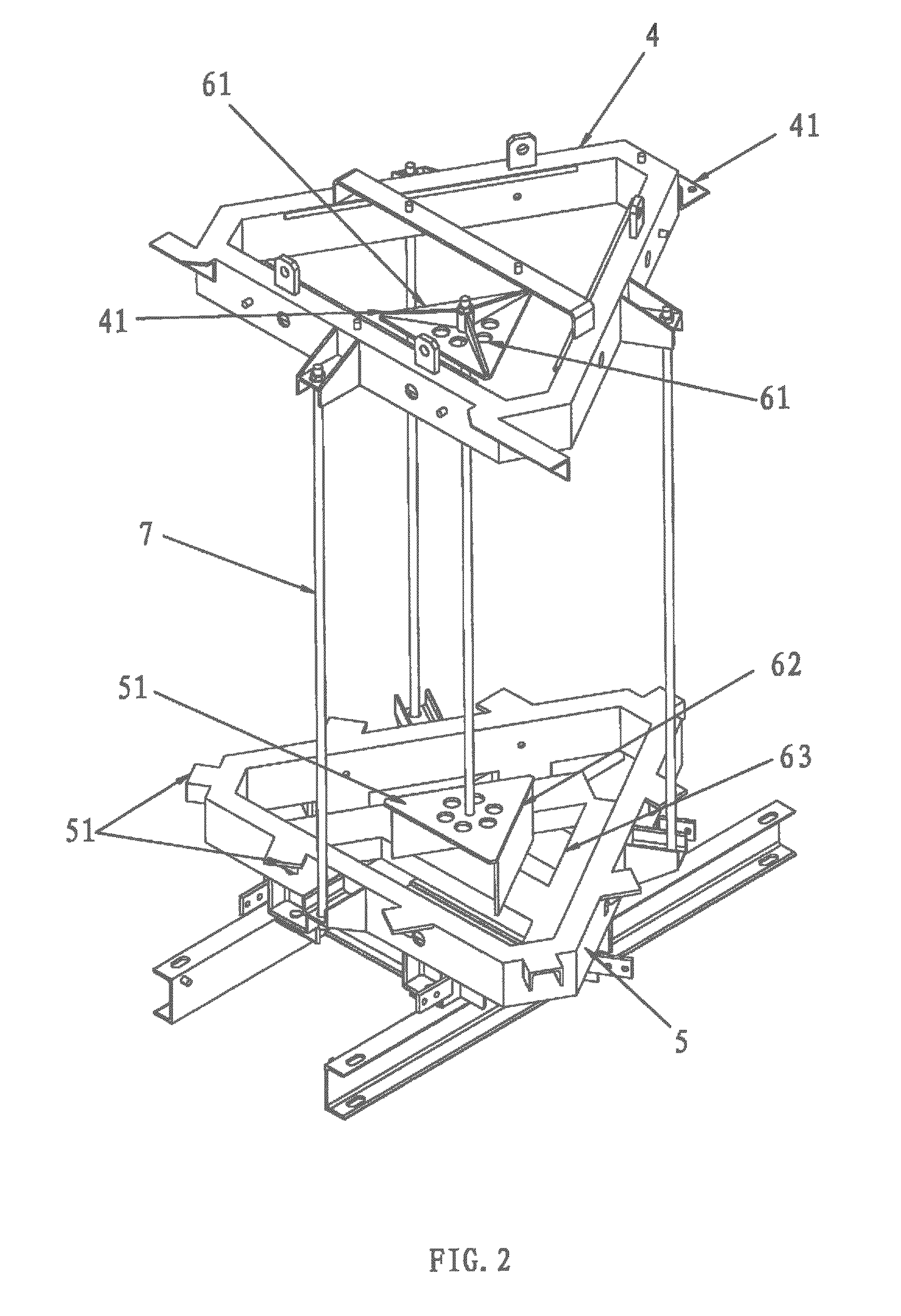

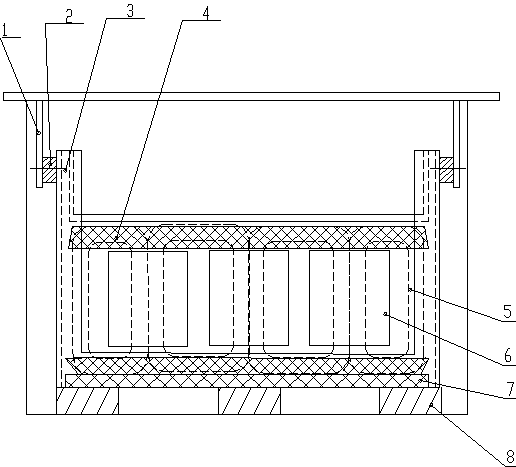

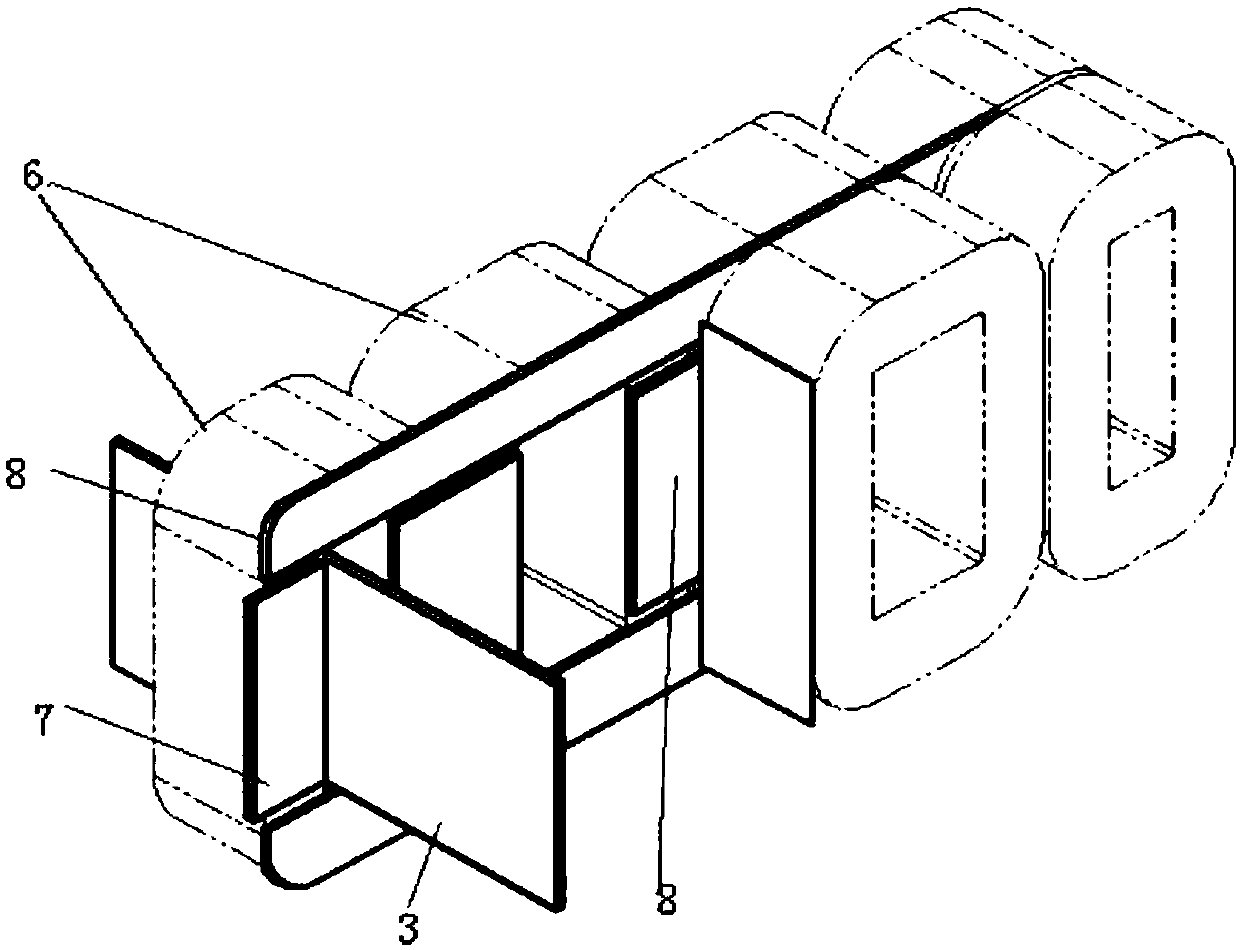

Structure for fastening amorphous alloy transformer body and method for assembling transformer body

InactiveCN101692389AAvoid forceAvoid electric powerTransformers/inductances coils/windings/connectionsInductances/transformers/magnets manufactureLow voltageAlloy

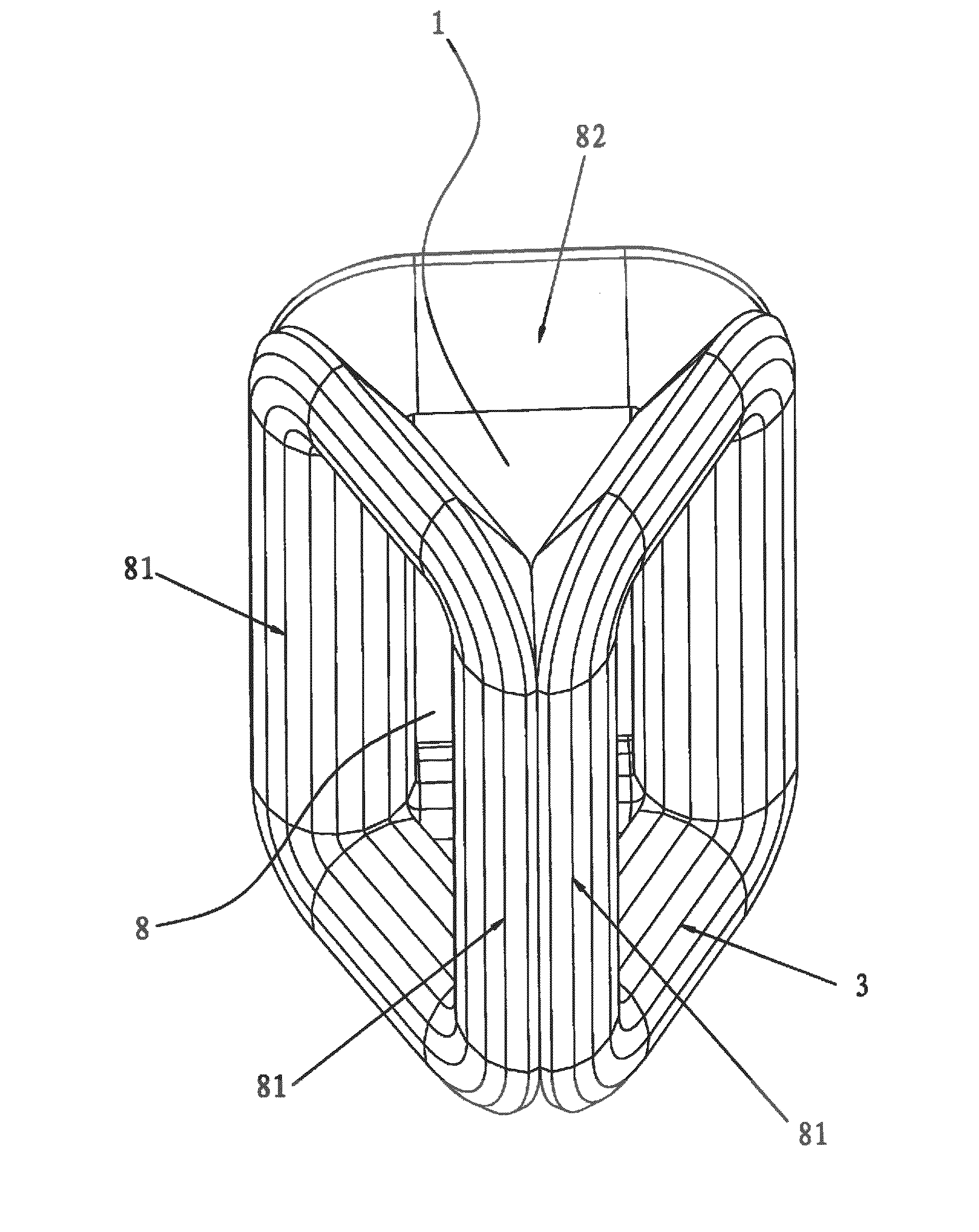

The invention provides a structure for fastening an amorphous alloy transformer body. A low-voltage coil (1) and a high-voltage coil (2) in a phase winding of the transformer body are distributed in a staggered manner; a clamp plate (3) is arranged on the outer side of the end part of the phase winding of the transformer body; one or a plurality of phase windings are sleeved on a core limb (5); the phase windings are fastened by a binding tape (4); and the upper parts and the lower parts of the coils in the phase windings are embedded in the grooves of a lower fixture (6) and an upper fixture (7) respectively. The method for assembling the transformer body comprises the following steps: winding the low-voltage coil (1) and the high-voltage coil (2) respectively; assembling the coils into a single phase winding; tightly pressing the phase windings inwards by the clamp plate (3); binding up the phase windings and the clamp plate (3) by the binding tape (4); sleeving the bound phase windings on the core limb (5); mounting the phase windings together with the core limb (5) on the upper fixture (7) and the lower fixture (6); and plugging cushion blocks between the clamp plate (3) and the walls of the upper fixture (7) and the lower fixture (6).

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI +1

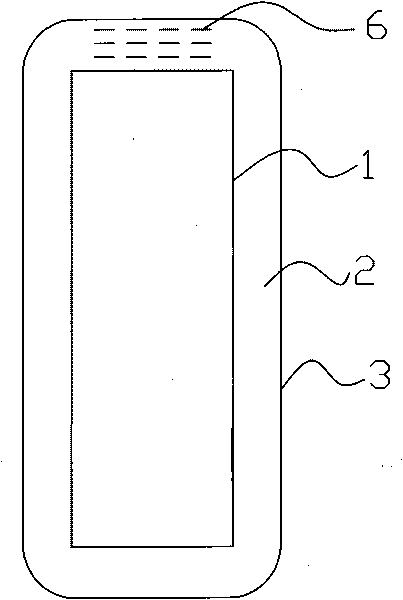

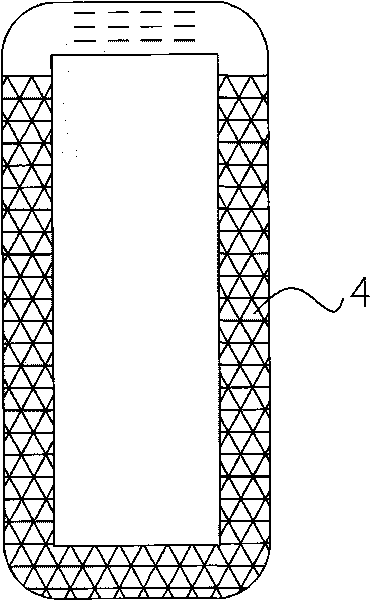

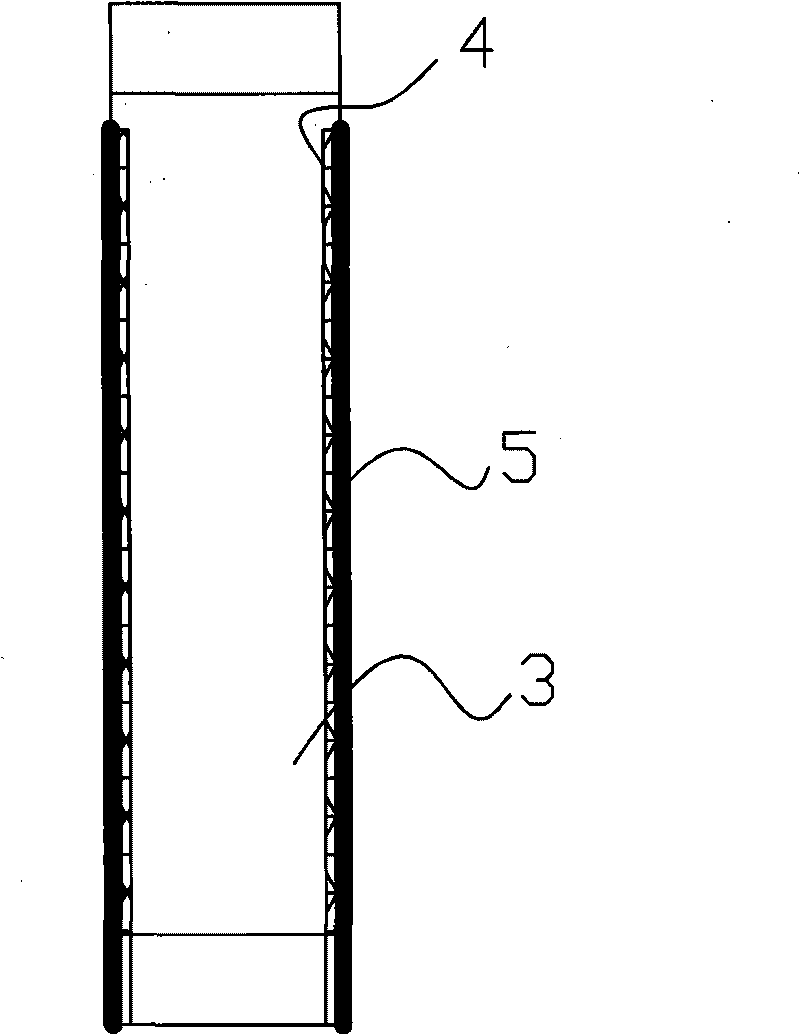

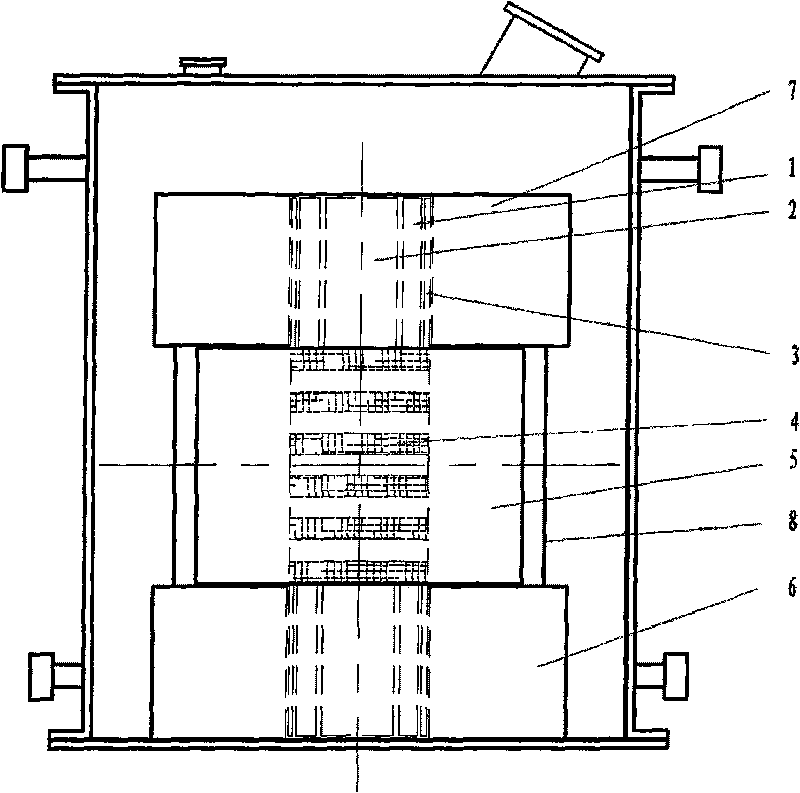

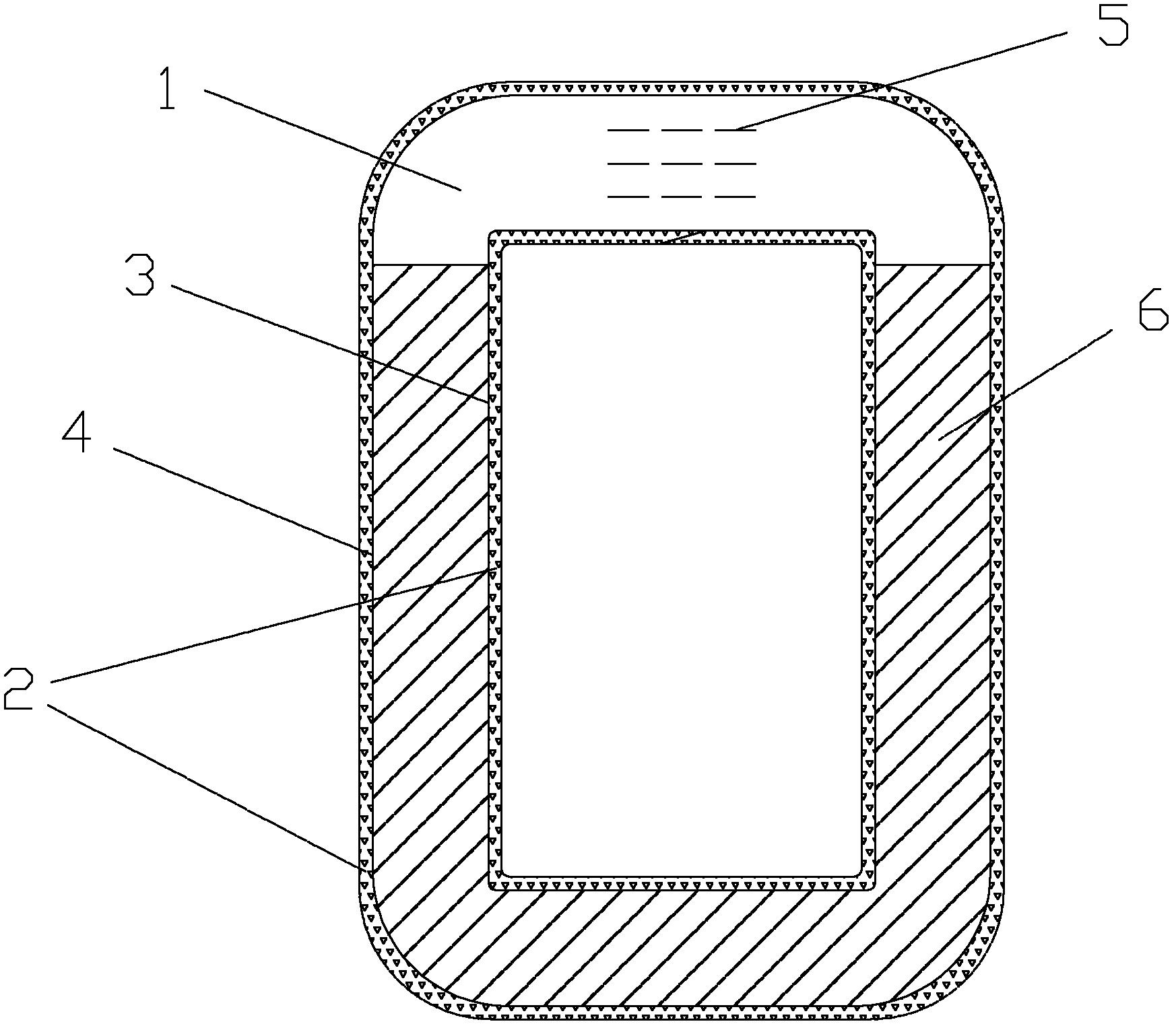

Body of shell type amorphous alloy transformer

InactiveCN101388279AImprove short circuit resistanceReduce leakage fluxTransformers/inductances casingsTransformers/inductances coils/windings/connectionsFuel tankAmorphous metal transformer

A body of a shell type amorphous alloy transformer comprises an amorphous alloy shell type iron core (1) and rectangular coils which are alternatively arranged, and a U-shaped epoxy resin insulating clamp (3) is arranged outside an iron yoke (31) of the amorphous alloy shell type iron core (1). Square type frameworks (5) are respectively arranged on the upper portion and the lower portion of the iron core (5) outside each phase winding (2), and the phase winding is clamped by the square type frameworks (5) through an insulating plate (6). An intermediate section of box body and a lower section of box body in a transformer with an oil box or a gas box can stretch the square type framework (5) of each phase winding through a breast beam and box walls, thereby facilitating the short-circuit force of the phase winding to transfer to the square type framework (5) and the oil box walls. A coil support plate (4) which is formed by insulating elements is arranged on the inner side of the phase winding (2), which can lead the crosswise force of a coil not to press the amorphous alloy shell type iron core (1) when the coil is in short-circuit. The intermediate section of box body and the lower section of box body are used to position the iron core through the U-shape clamp (3). A dry transformer is used to fix the iron core (1) through an upper location press plate and a lower location press plate (27).

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

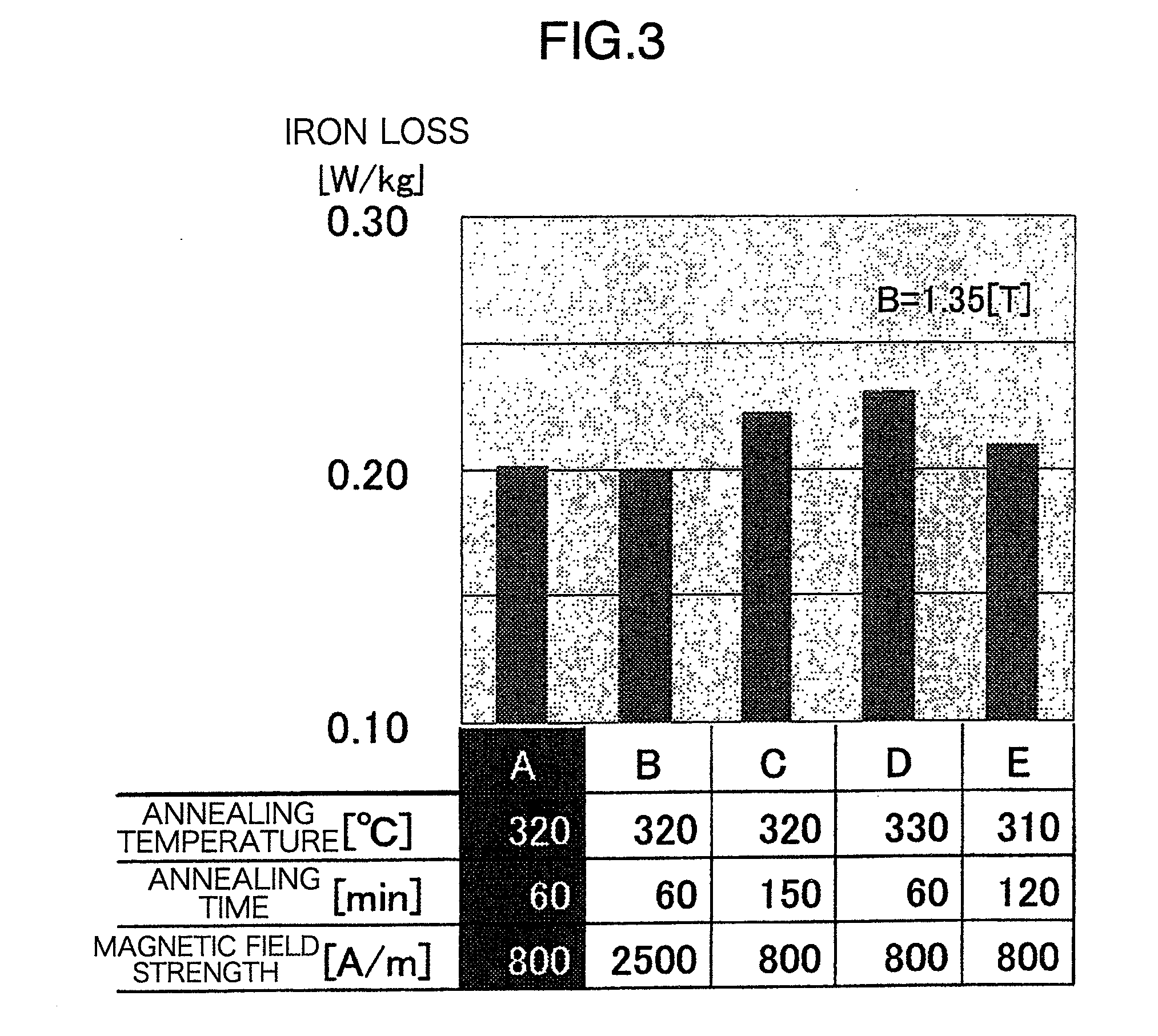

Annealing process of amorphous alloy transformer core

InactiveCN102676757ASolving the problem of annealingImprove stabilityFurnace typesHeat treatment furnacesMagnetizationAlloy

The invention discloses an annealing process of an amorphous alloy transformer core. The process comprises hanging a formed core on an annealing stand, and closing a furnace door; hanging an annealing furnace in a vacuum hood, closing the vacuum hood, and vacuuming the vacuum hood; powering on the annealing furnace, starting heating, and recording time and an ambient temperature; filling nitrogen gas in the vacuum hood, starting recording temperatures of tested points, and recording once every 15min; turning on a magnetization current; holding at the temperature for 40-75min when the temperatures of at least 50% of the tested points reach 370-380 DEG C; closing a nitrogen gas controlling valve, and opening the furnace door; and taking out the core by using a forklift, and finishing. The invention effectively solves the annealing problem of cores, effectively controls two critical parameters of core loss and excitation power of cores, and greatly improves core annealing stability.

Owner:中兆培基(北京)电气有限公司

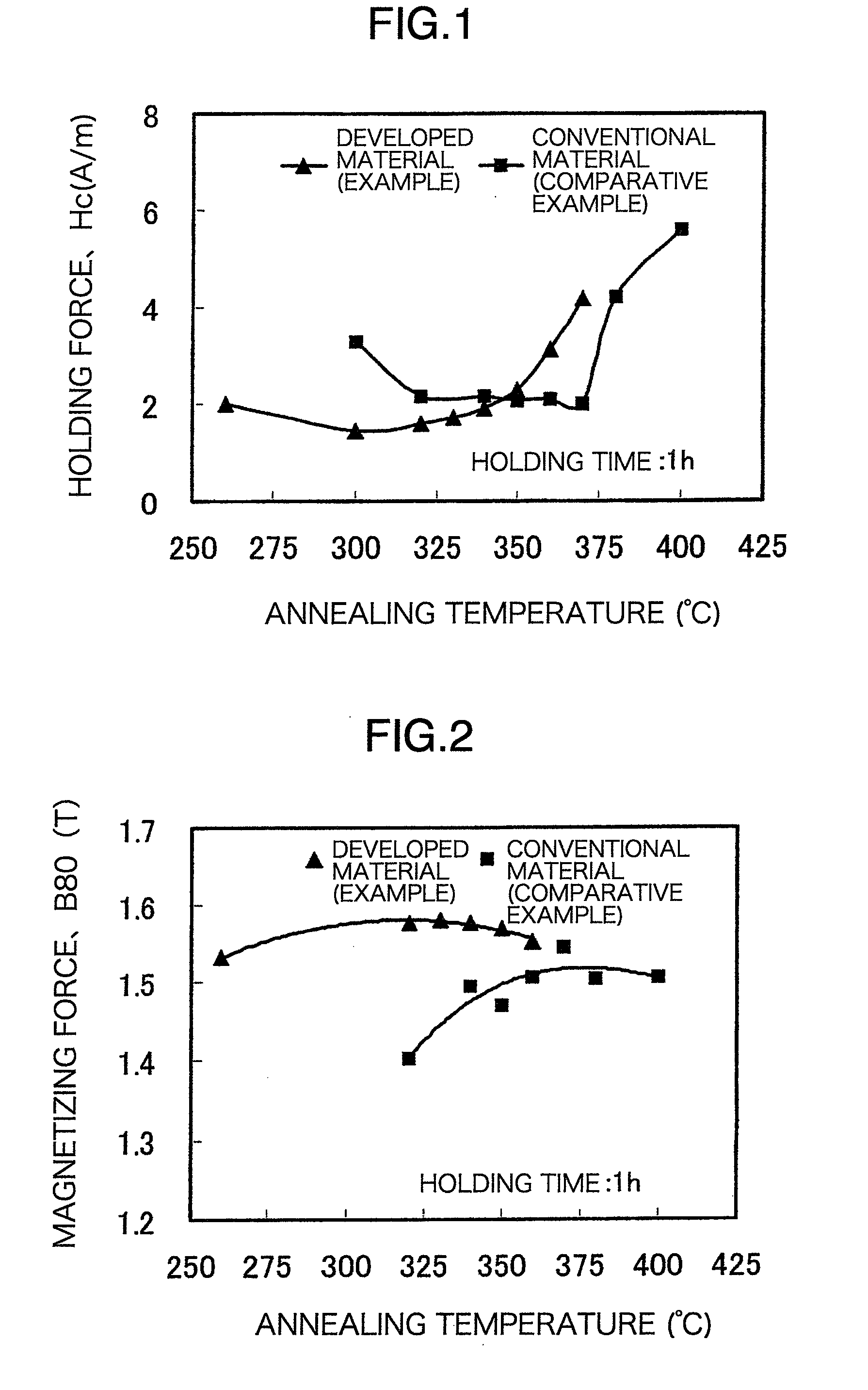

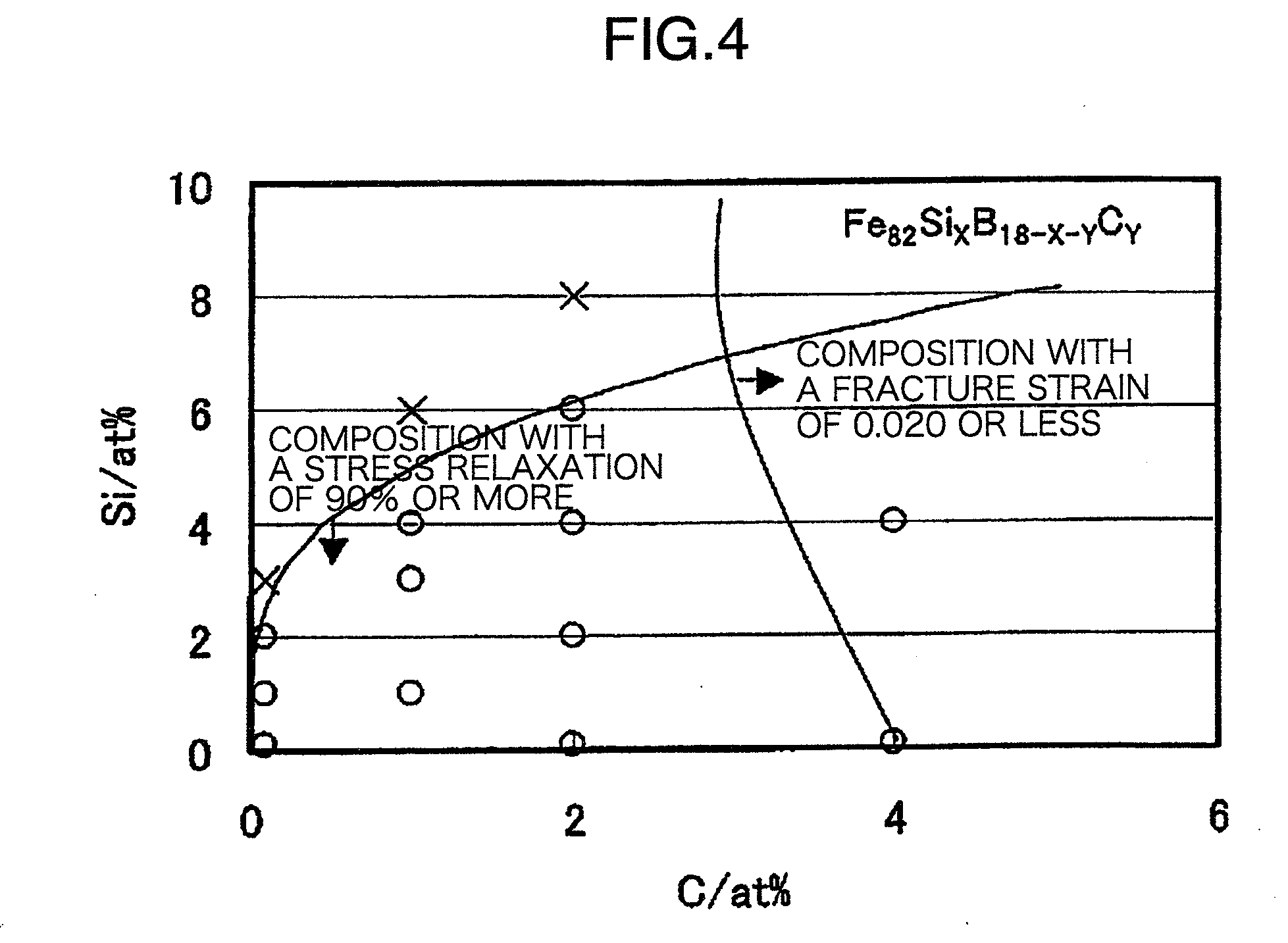

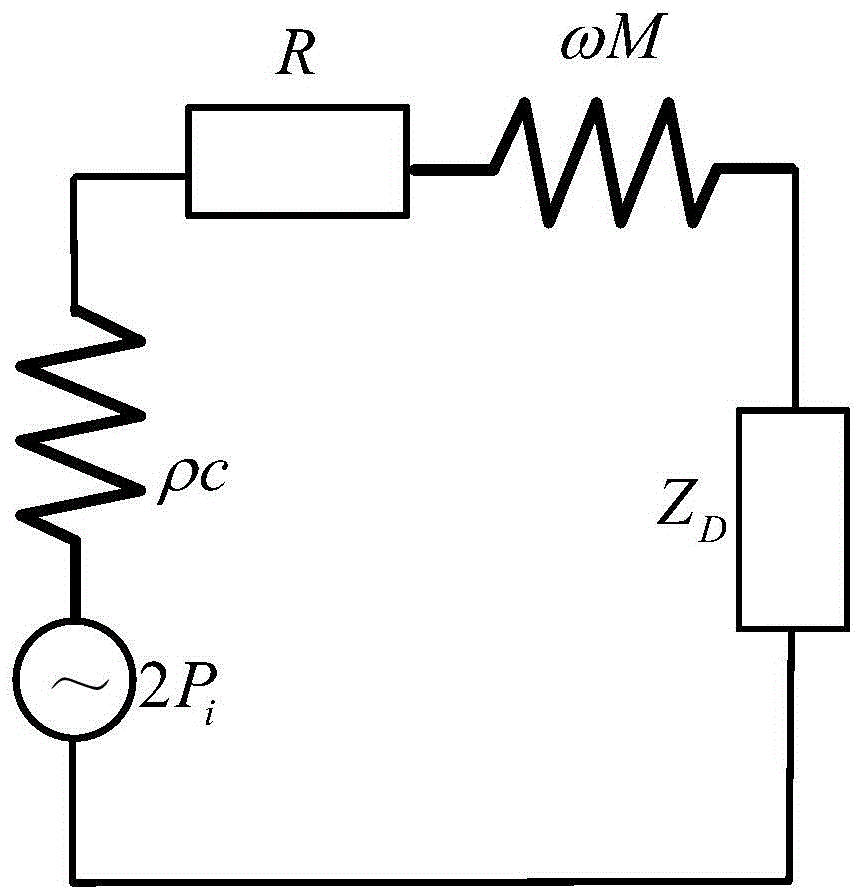

Amorphous transformer for electric power supply

InactiveUS20090189728A1High saturated magnetic flux densityReduce lossInorganic material magnetismInductances/transformers/magnets manufactureConductor CoilUltimate tensile strength

This invention provides an amorphous transformer for electric power supply, using a magnetic core formed of an amorphous alloy material, which, as compared with the conventional amorphous alloy material, has a lower annealing temperature and a higher level of magnetic properties. The amorphous transformer for electric power supply is provided with a magnetic core of a thin band of an amorphous alloy and a winding wire. The iron core has been annealed under such conditions that the iron core center part temperature during annealing after iron core molding is 300 to 340° C. and the holding time is not less than 0.5 hr. Further, for the iron core, the magnetic field intensity during annealing after the iron core molding is not less than 800 A / m.

Owner:HITACHI IND EQUIP SYST CO LTD

Amorphous alloy transformer coil winding method

The invention discloses a production method for windings of an amorphous alloy transformer, which comprises the following steps: making a low-voltage winding: fixing start leads in rows with an assistant tool and locking inside a rabbet of an insulating cylinder, winding the start leads without tension, and removing the assistant tool after the start lead winding is completed and regulating the size; making the low-voltage winding under tension: winding while knocking the surface of a copper foil, compressing the low-voltage winding to the specified size after the low-voltage die is removed, drying and painting; winding a high-voltage winding on the low-voltage winding to obtain an amorphous alloy transformer winding. Based on the combination of low-voltage and high-voltage windings, the invention can eliminate the influence of positive deviation of the low-voltage winding and ensure the insulation distance between the low-voltage and high-voltage windings.

Owner:CHINESE ELECTRICAL EQUIP GRP CO LTD

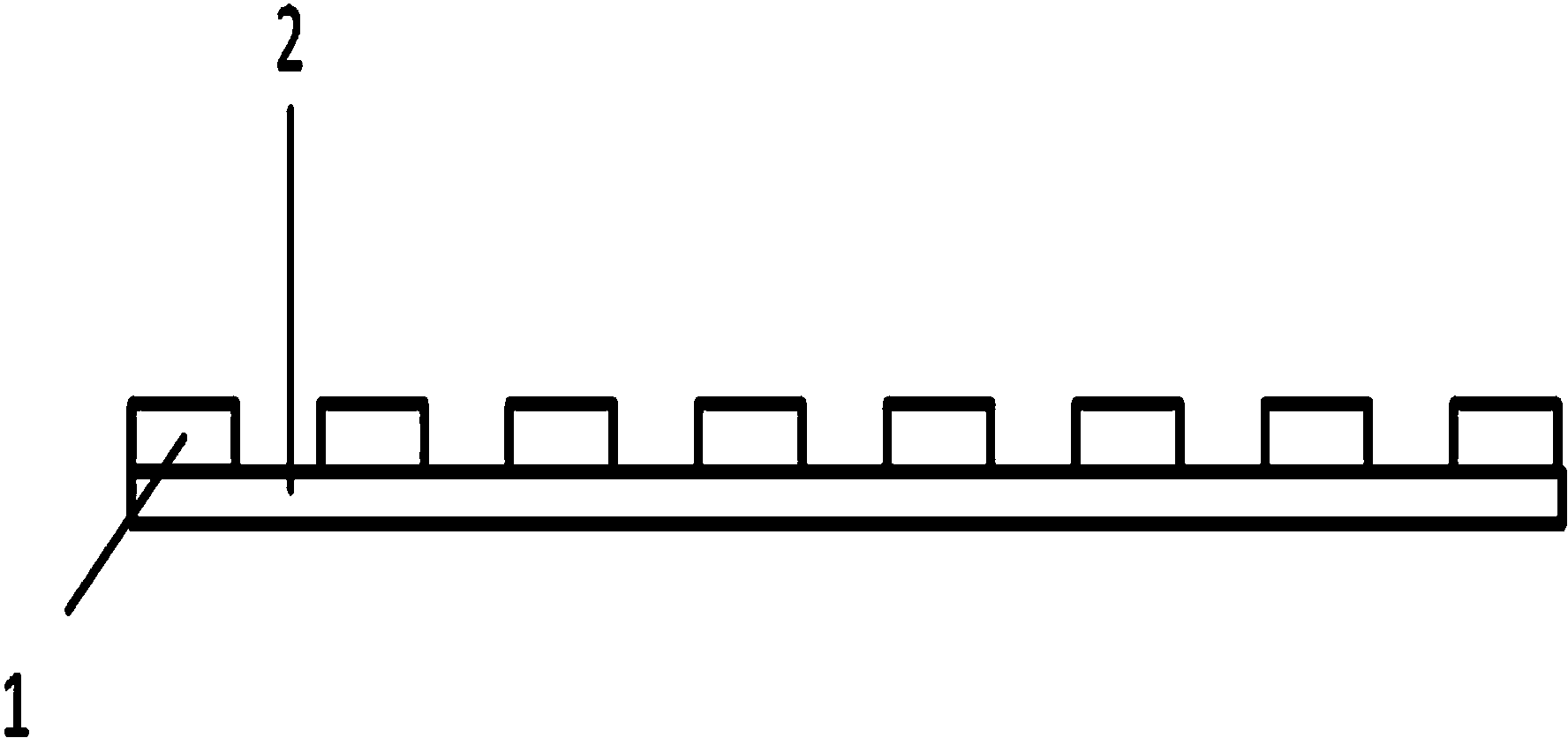

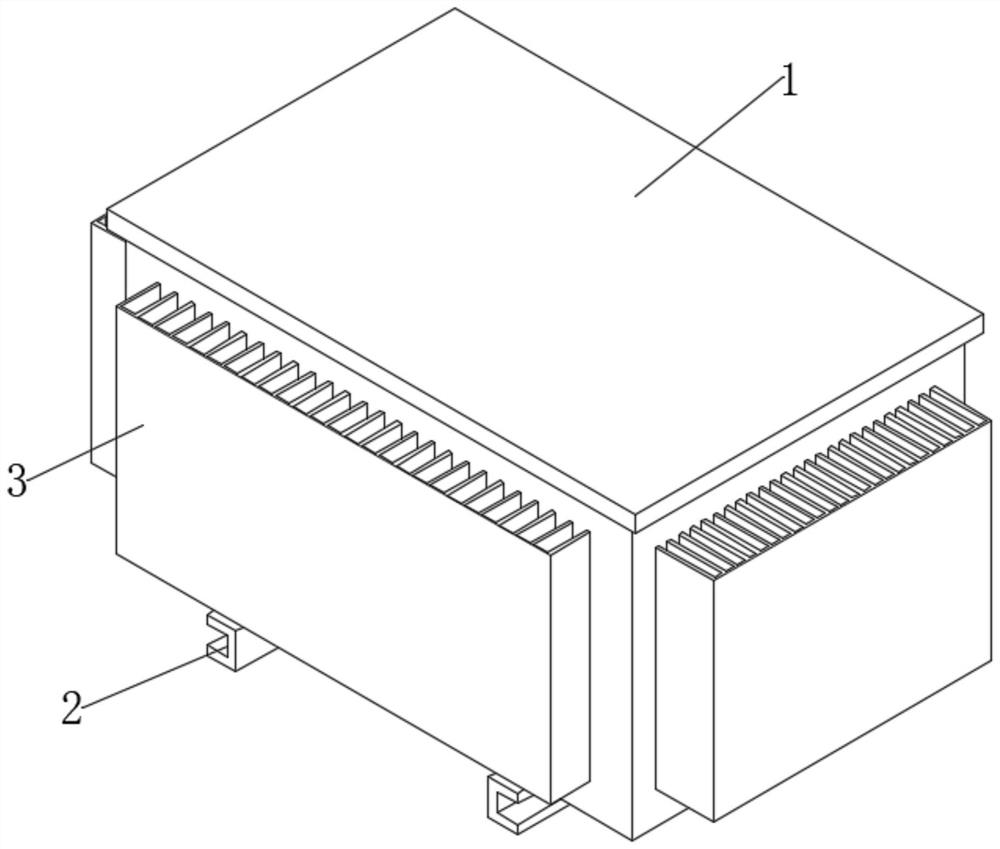

Supporting bar favorable for dissipating heat of oil-immersing amorphous alloy transformer

InactiveCN103545088AImprove cooling effectHigh heat dissipation coefficientTransformers/inductances coolingTransformers/inductances coils/windings/connectionsManufacturing technologyCopper wire

The invention belongs to the technical field of amorphous alloy iron core manufacturing, and particularly relates to a supporting bar favorable for dissipating heat of an oil-immersing amorphous alloy transformer. Temperature rising of the transformer is reduced through optimizing the oil-immersing amorphous alloy transformer. The supporting bar comprises supporting bar bodies, glue applying straps are connected to the lower surfaces of the supporting bar bodies, and the number of the glue applying straps is more than one. The thickness of the supporting bar bodies in an oil channel of the transformer is increased, the area of the oil channel can be increased, the supporting strength of the supporting bar bodies is improved, a breakdown voltage is increased, and the heat dissipating effect of the transformer is improved. The two narrow-piece glue applying straps are adopted to paste a fence-type structure of the supporting bar bodies, not only is full contact between oil and copper wires facilitated and thus is the temperature rising of the transformer reduced, but also machining difficulty of the transformer is favorable for being reduced, the transformer can be machined faster and more conveniently, and the temperature of the transformer is lowered. Thus, the remarkable advantages that the heat dissipating coefficient is improved and the temperature rising of the transformer is reduced are achieved, and the supporting bar is simple and reasonable in structure, obvious in effect and favorable for being widely promoted and applied.

Owner:STATE GRID CORP OF CHINA +1

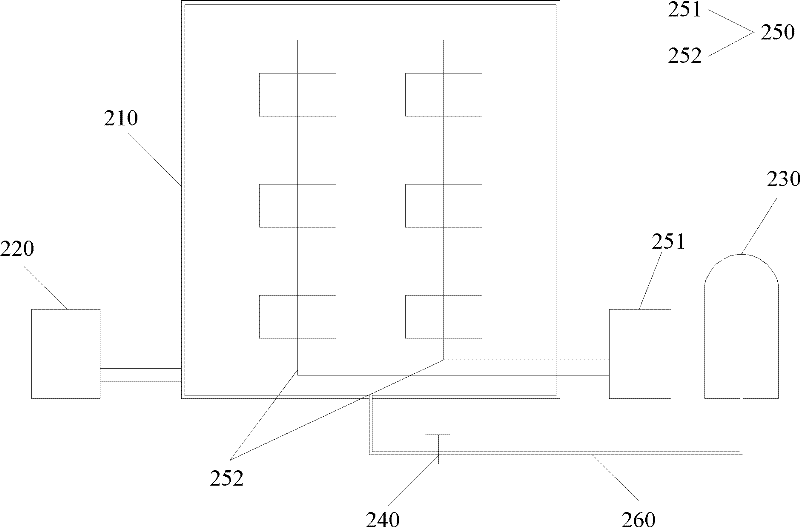

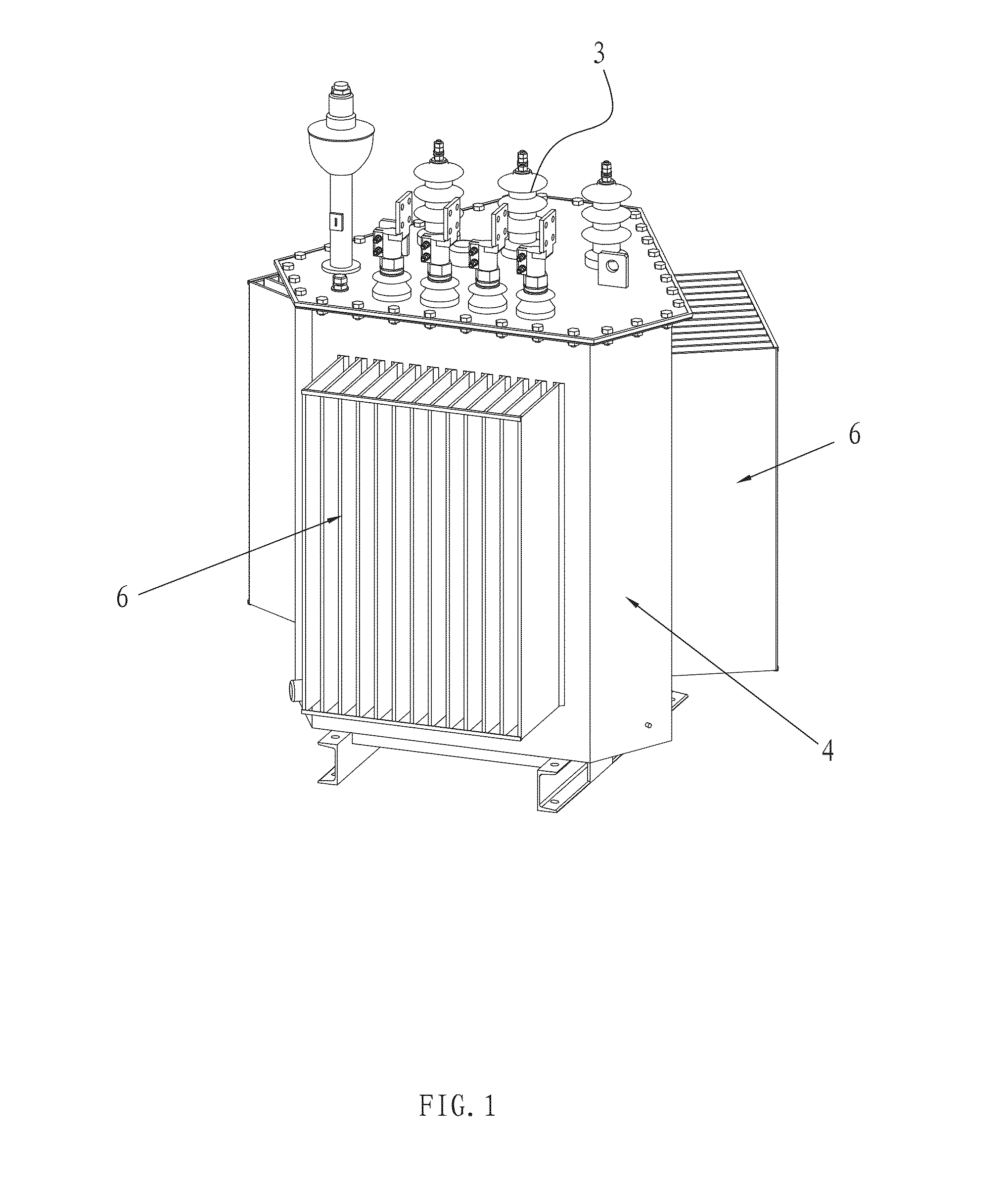

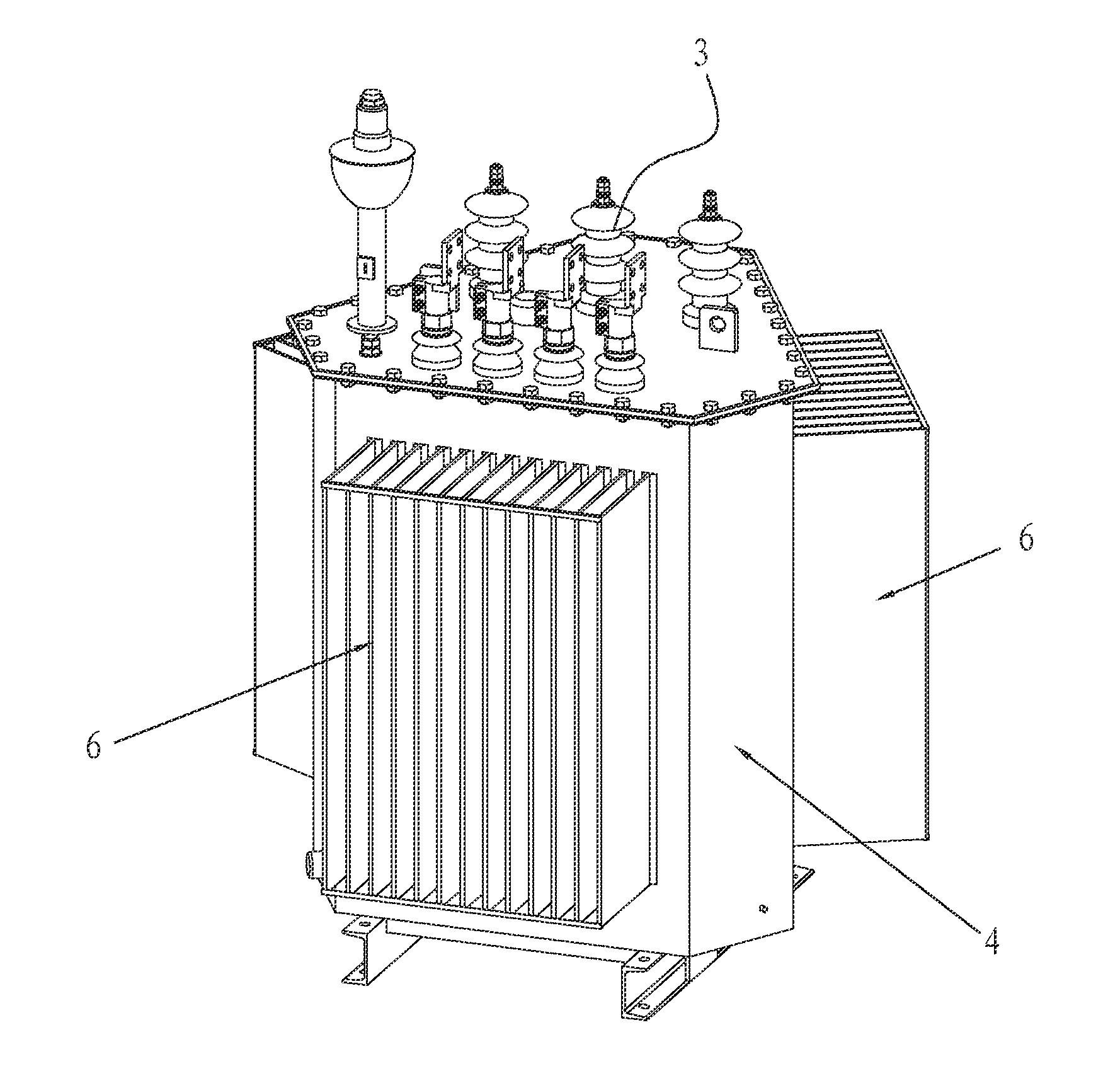

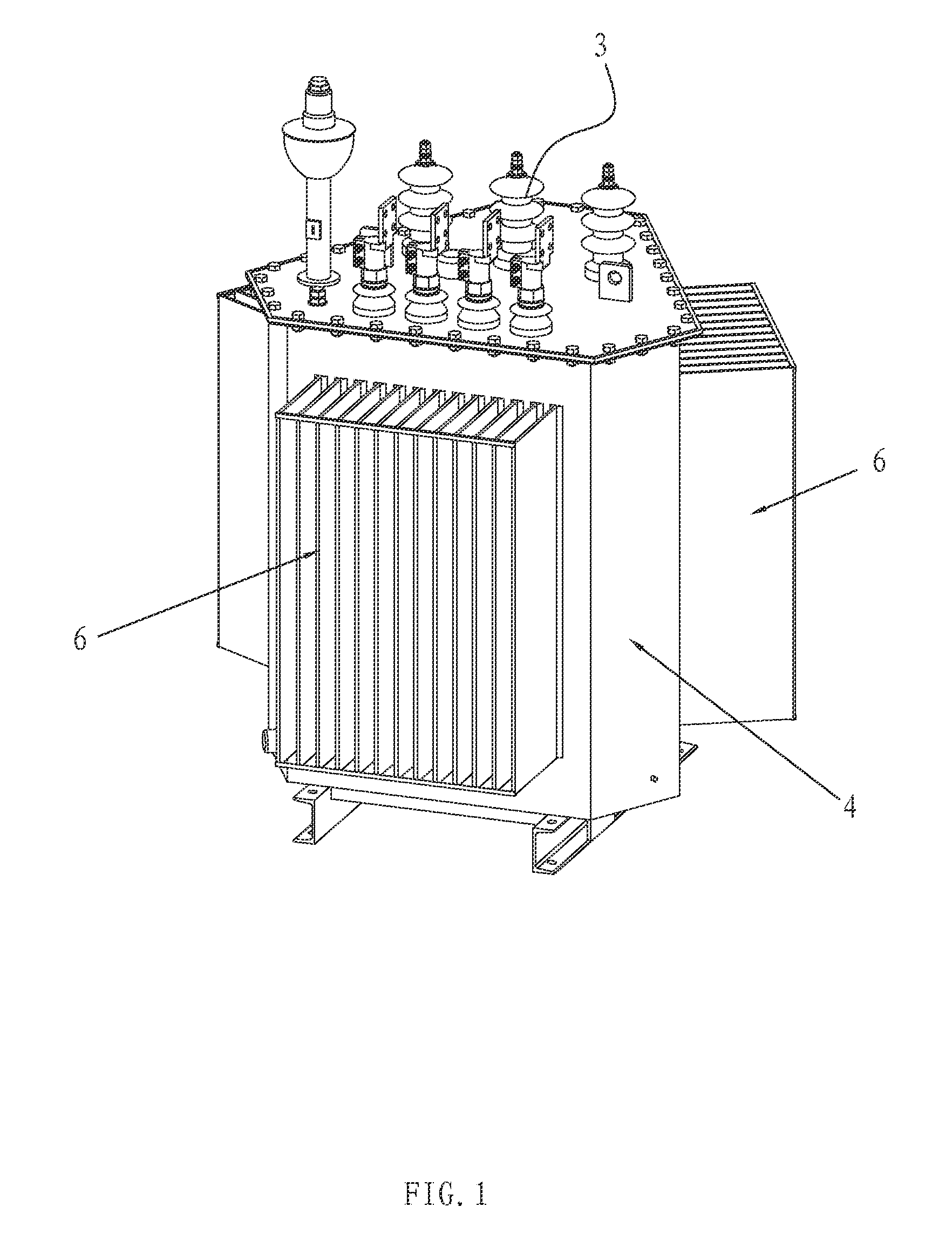

Oil immersed stereo wound-core amorphous alloy transformer

ActiveUS8963677B2Save energyReduce processTransformers/reacts mounting/support/suspensionTransformers/inductances coolingLow voltageFuel tank

Owner:GUANGDONG HAI HONG

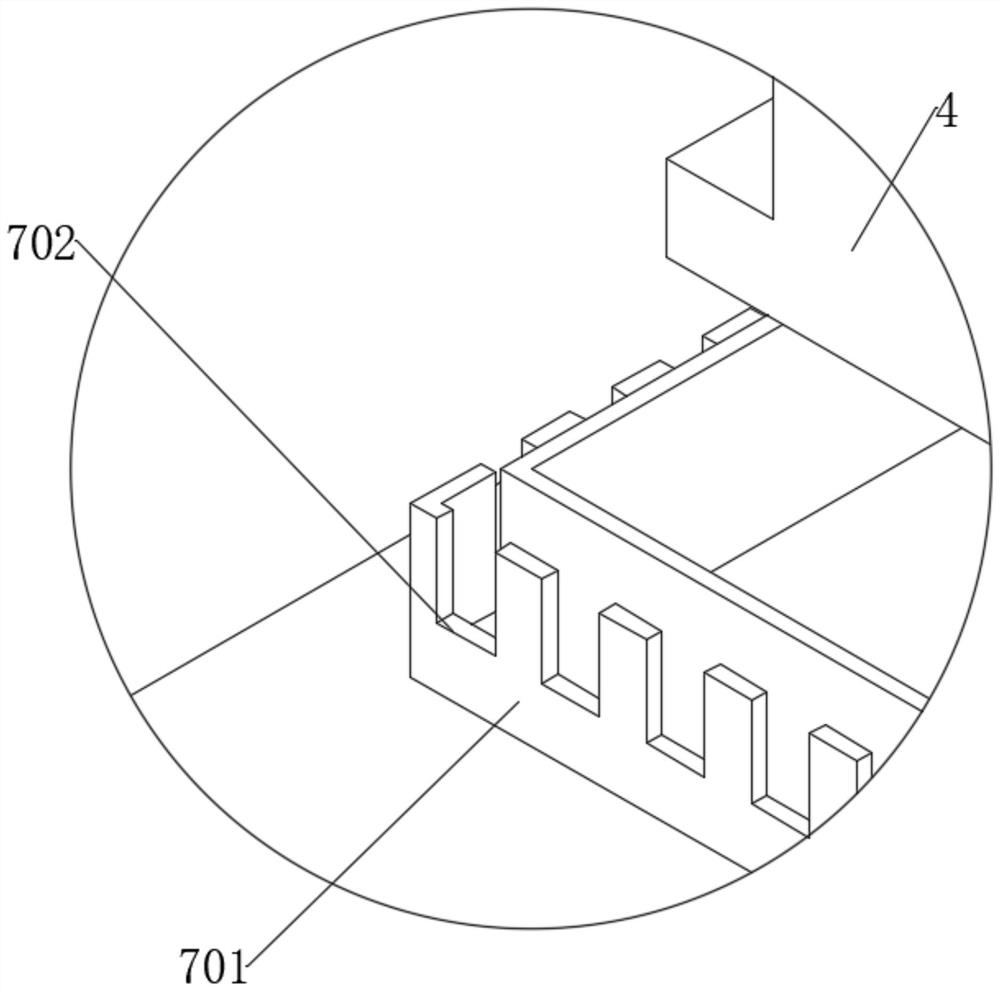

Framework structure of amorphous alloy transformer

InactiveCN102664091ASave assembly timeReduce the impactTransformers/inductances magnetic coresAlloyElectromotive force

The invention discloses a framework structure of an amorphous alloy transformer. The framework structure of the amorphous alloy transformer is a hollow barrel, the section shape of an inner cavity of a framework matches with the section shapes of iron core columns used for sleeving each phase of coils, each iron core column is formed by splicing of a plurality of iron core column units which have the same shape and the same dimensions, and the inner cavity of the framework is partitioned into a plurality of space units through partitions according to the number and the shape of the iron core column units, so that each of the iron core column units can be inserted in one of the space units of the framework correspondingly. Each iron core column cannot be subjected to mutual friction and extrusion to produce stress, so that no-load loss is reduced. Additionally, rigid strength of the framework is enhanced, so that resistance to electromotive force produced by the coils can be strengthened when the transformer is short-circuited unexpectedly, increasing of the no-load loss caused by extra-stress of iron cores is prevented, and time for assembling a transformer body is greatly shortened by the preprocessed framework.

Owner:SHANGHAI ZHIXIN ELECTRIC AMORPHOUS +2

Amorphous alloy transformer assembly method

InactiveCN101145441AEliminate hidden dangersReduce noiseInductances/transformers/magnets manufactureEpoxyAlloy

The invention discloses an method of assembling an amorphous alloy transformer, which comprises placing an upper fastening plate and an upper compression plate; vertically placing iron core frames, opening the iron core frame and placing an iron core insulator inside; covering coils on an iron core column with the coil outlet being faced downward; placing a lower iron yoke insulator in a way that the rabbet thereof is aligned to an iron core window; fixing supporting plates, in the same number as the coils, inside the coils, closing the iron core, taking out the fragments in time; placing iron core disks, in multi-stage mode, on the lower iron yoke insulator, closing the iron core, adhering with adhesive tape, connecting grounded disks to connect iron core frames and sealing the joint seams with epoxide resin; placing an insulator and a lower compress plate; turning the transformer body and drying the body; and assembling lead lines to obtain an amorphous alloy transformer. The invention can eliminate the potential danger that the iron core chips fall into the coils during the operation of the transformer, and reduce the noise and loss of the transformer.

Owner:CHINESE ELECTRICAL EQUIP GRP CO LTD

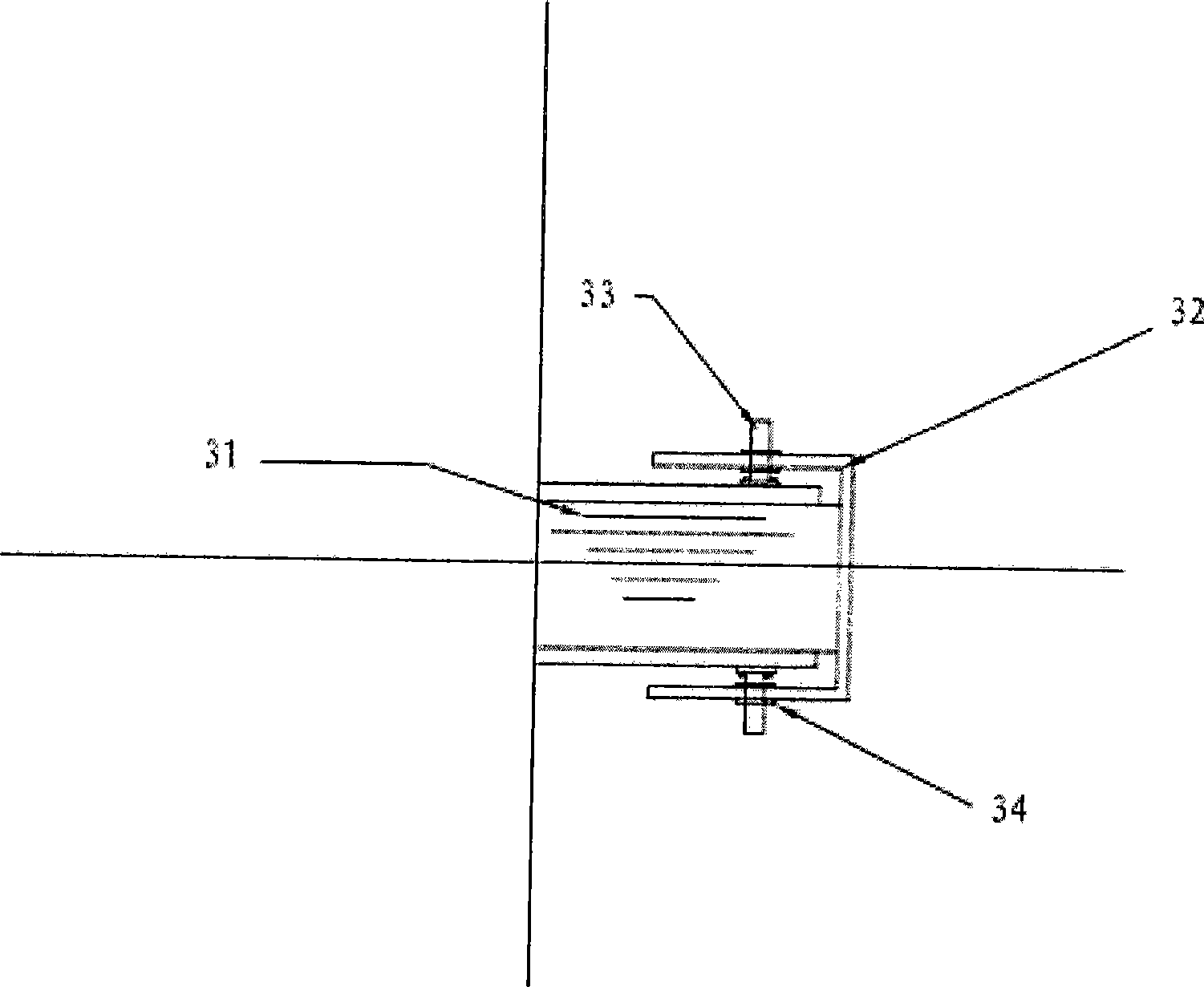

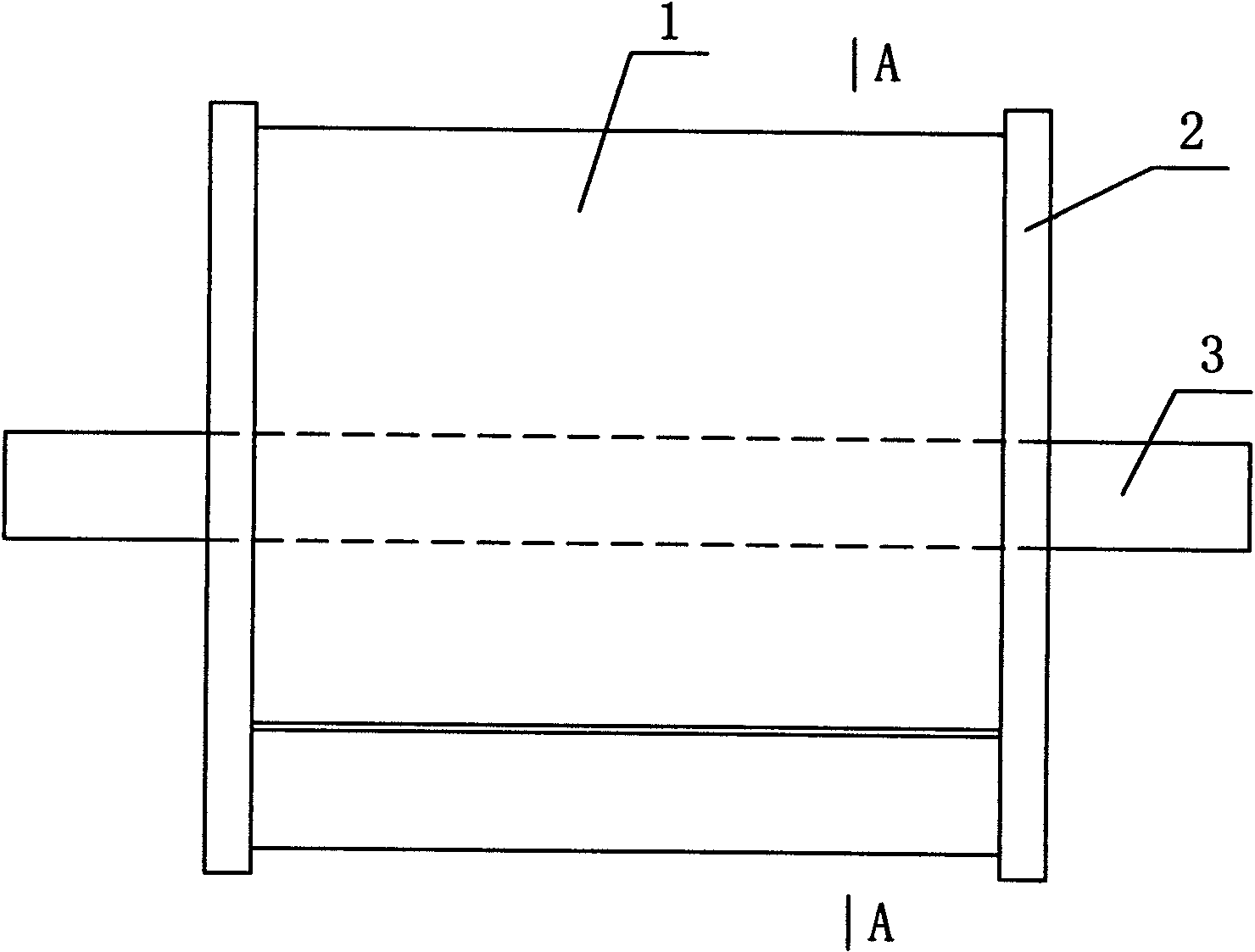

Winding mould used in transformer coil

The invention relates to a coil winding mould, in particular to a winding mould used in a dry type amorphous alloy transformer coil, comprising a rectangular inner mould, end supporting plates arranged at two ends of the rectangular inner mould and a winding shaft arranged in the middle of the rectangular inner mould, wherein, the rectangular inner mould is constituted by a plurality of steel plates which are connected end to end; the two ends of the steel plates bend inwards to form a right angle with the steel plate surface; a silicon rubber plate is nipped between the two buckling ends of two adjacent steel plates; the outsides of the two buckling ends are respectively arranged with a reinforcement plate; and the two reinforcement plates, two buckling ends and the silicon rubber plate are fastened through bolts. The invention has simple structure, few mould opening materials, low cost, adjustable mould size and higher popularity.

Owner:济南西电特种变压器有限公司

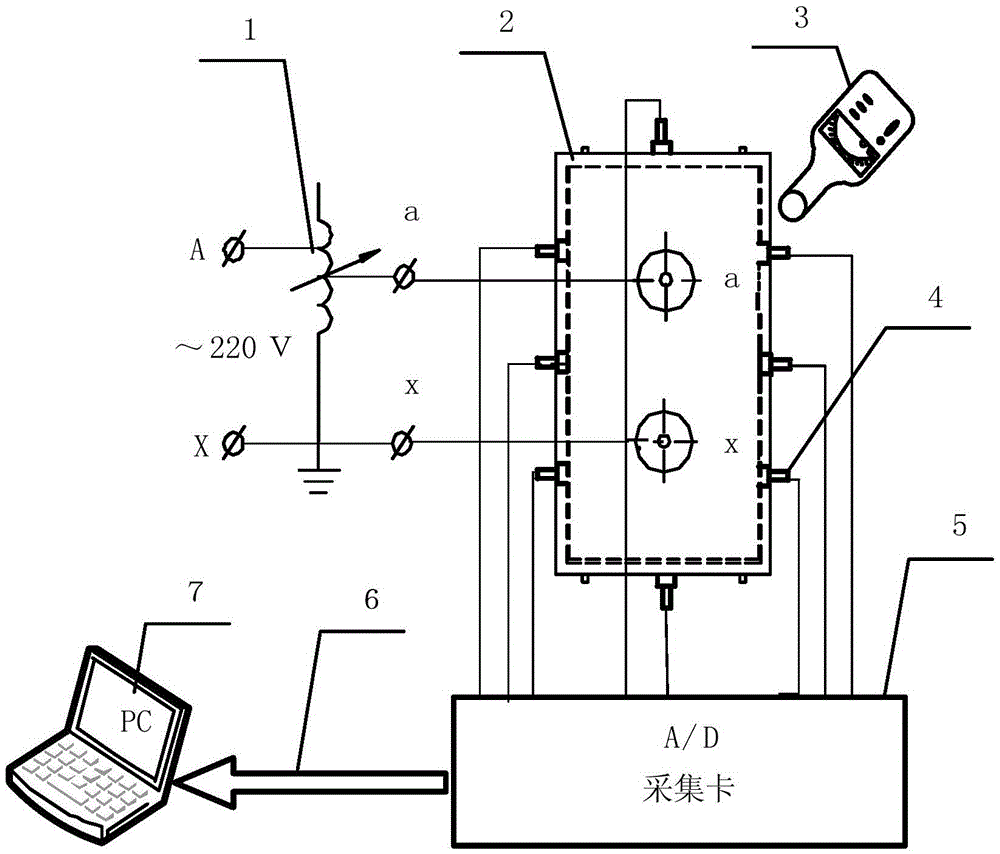

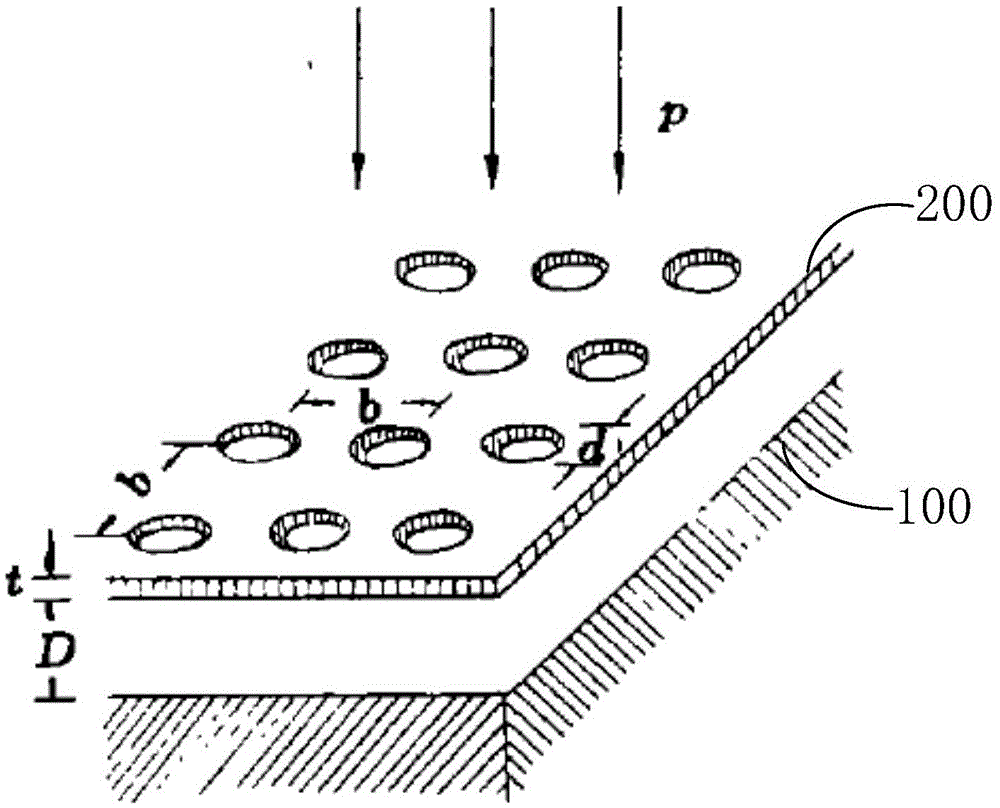

Amorphous alloy oil-immersed transformer employing micro-perforated panels

ActiveCN105609264AReduce no-load lossCoordinated operationTransformers/inductances coolingTransformers/inductances noise dampingLow voltageHelmholtz resonator

The invention provides an amorphous alloy oil-immersed transformer employing micro-perforated panels. The amorphous alloy oil-immersed transformer comprises a specially designed transformer oil tank, the micro-perforated panels, a hollow cavity, shock pads and a high-voltage bushing, a low-voltage bushing and a high-voltage tap switch, wherein the specially designed micro-perforated panels are arranged in the oil tank; the hollow cavity is used for serving as an acoustic impedance; one shock pad is arranged between a transformer body and the tank bottom; the other shock pad is arranged between a hanger plate and a clamp; transformer oil is used as an insulating and cooling medium; the high-voltage bushing, the low-voltage bushing and the high-voltage tap switch are arranged on a tank cover; and a sound absorber comprises one or more micro-perforated panels and the single hollow cavity or a plurality of hollow cavities. The micro-perforated panels form a helmholtz resonant cavity after being installed on the inner side wall of the amorphous alloy oil-immersed transformer oil tank, can absorb energy of vibration caused by iron core magnetostriction and coil vibration caused by electrodynamic force, and finally reduce the noise. Due to the adoption of an amorphous alloy iron core, the amorphous alloy oil-immersed transformer can save more energy than a traditional transformer; the oil tank provided with the micro-perforated panels can absorb vibration of the maximum amplitude corresponding to the iron core vibration frequency; and the noise of the micro-perforated panels is reduced.

Owner:JIANGXI UNIV OF SCI & TECH

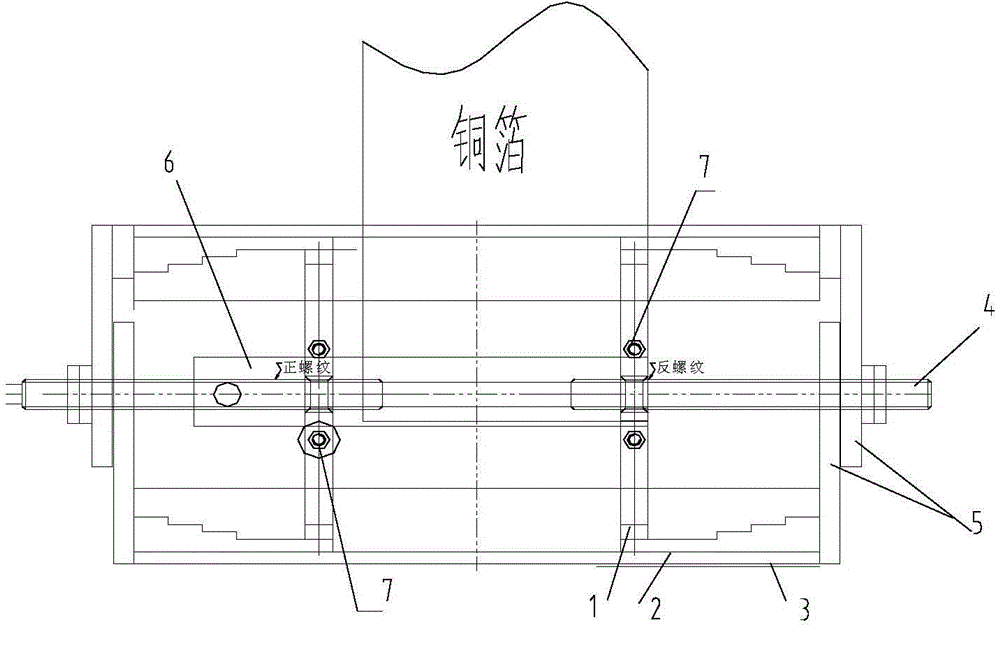

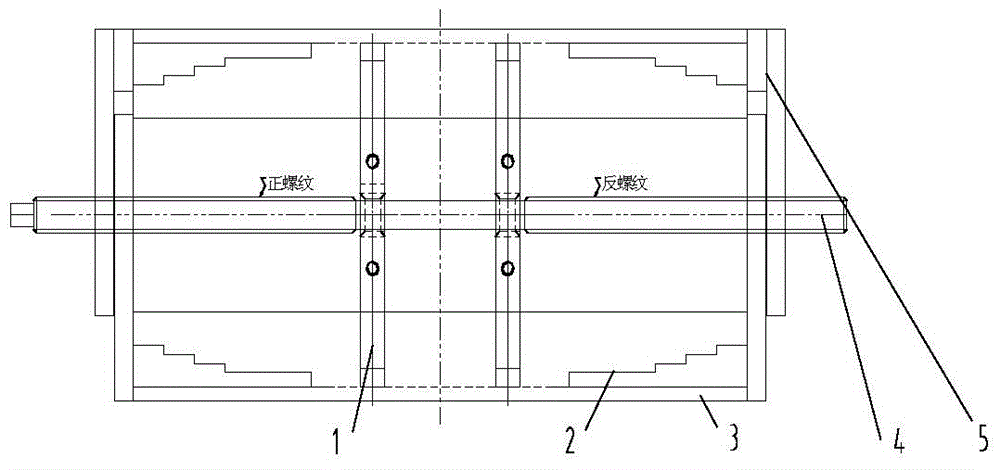

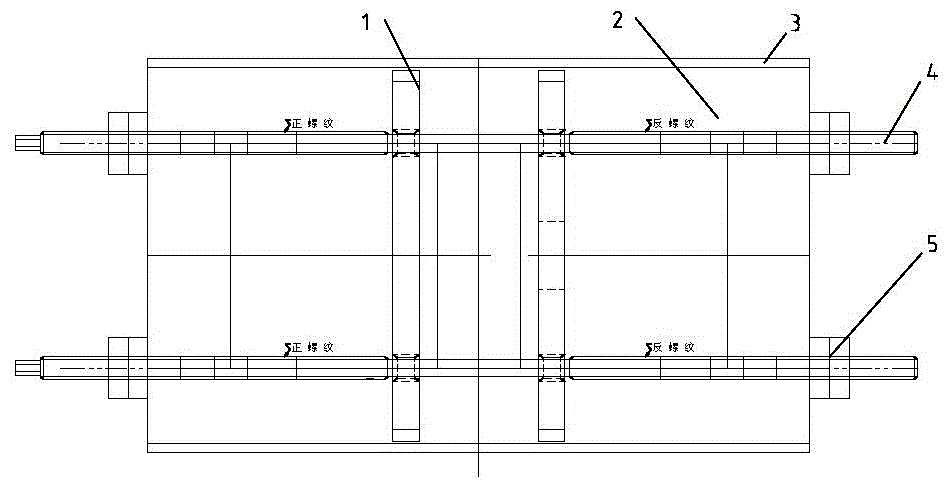

Adjustable type amorphous alloy transformer winding die and manufacturing and use method

The invention relates to an adjustable type amorphous alloy transformer winding die and a manufacturing and use method. The adjustable type amorphous alloy transformer winding die comprises an adjustable low-voltage winding die, a high-voltage support die and shaping wood square blocks, and is characterized in that the adjustable low-voltage winding die structure consists of a panel, a cushion block and a fixing plate; two parallel support plates are vertically arranged in the middle part of the wide side of the panel, a positive thread rod and a reverse thread rod penetrate through the two parallel support plates, two assemblies are vertically buckled, each support plate is adjusted onto a cushion block step with the coil size by the positive thread rod and the reverse thread rod, and is tightened by a nut, and then the adjustable low-voltage winding die is formed; the support die for winding a high-voltage line adopts a wood framework, and has the same shape as an inner cavity of a coil; during shaping, the building block type wood square blocks are arranged, and are filled into an inner cavity space of the low-voltage winding die. The adjustable type amorphous alloy transformer winding die has the advantages that the adjustable low-voltage winding die can be alternatively used with the high-voltage support die and the shaping wood square blocks, the die is immediately removed after the winding, and the winding die in a warehouse is not needed; a foil winding machine only needs to be equipped with five to six winding dies for standby, and the requirement of large-batch production of full series of products can be met; the cost is reduced, and the production efficiency is improved.

Owner:SHENYANG TIANTONG ELECTRIC POWER EQUIP

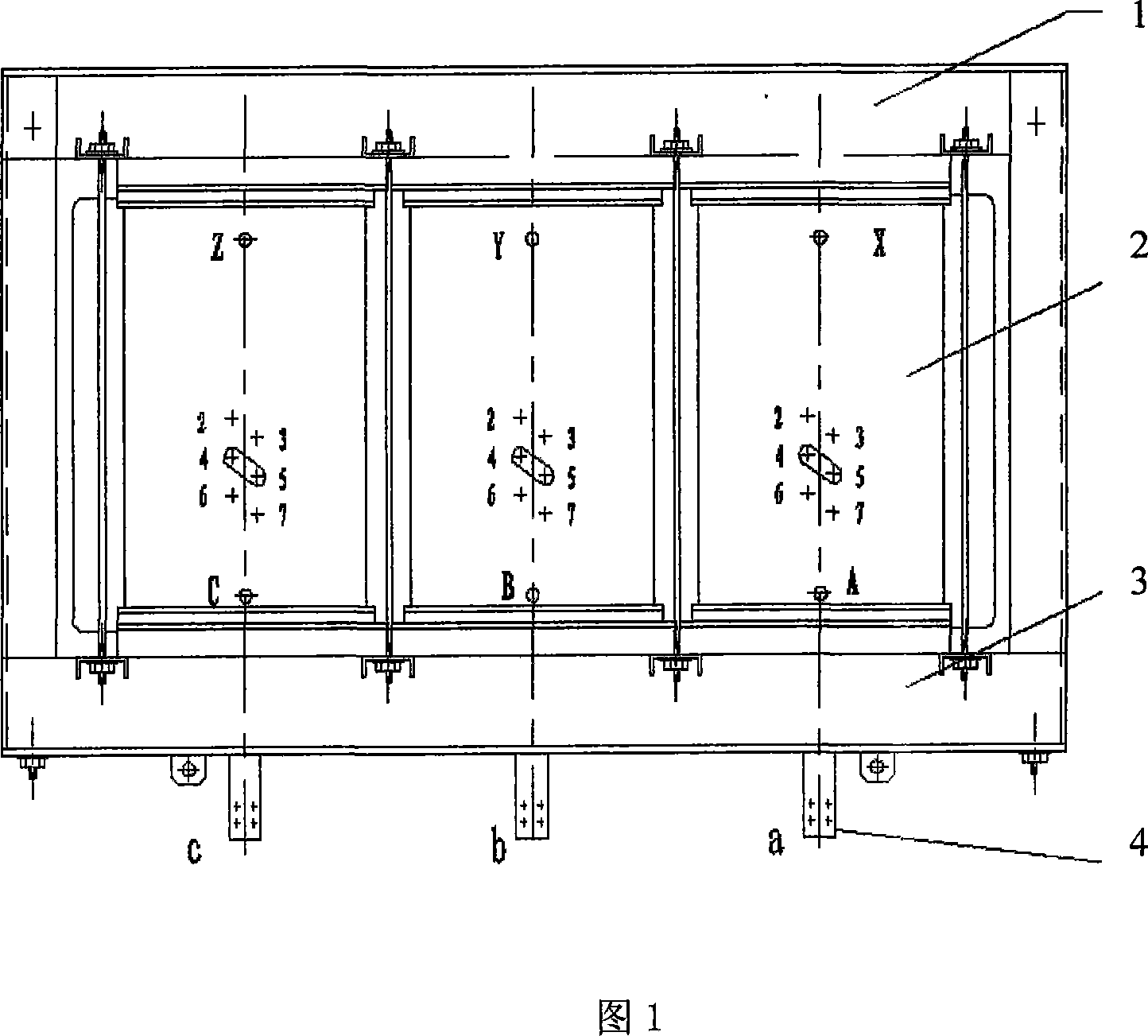

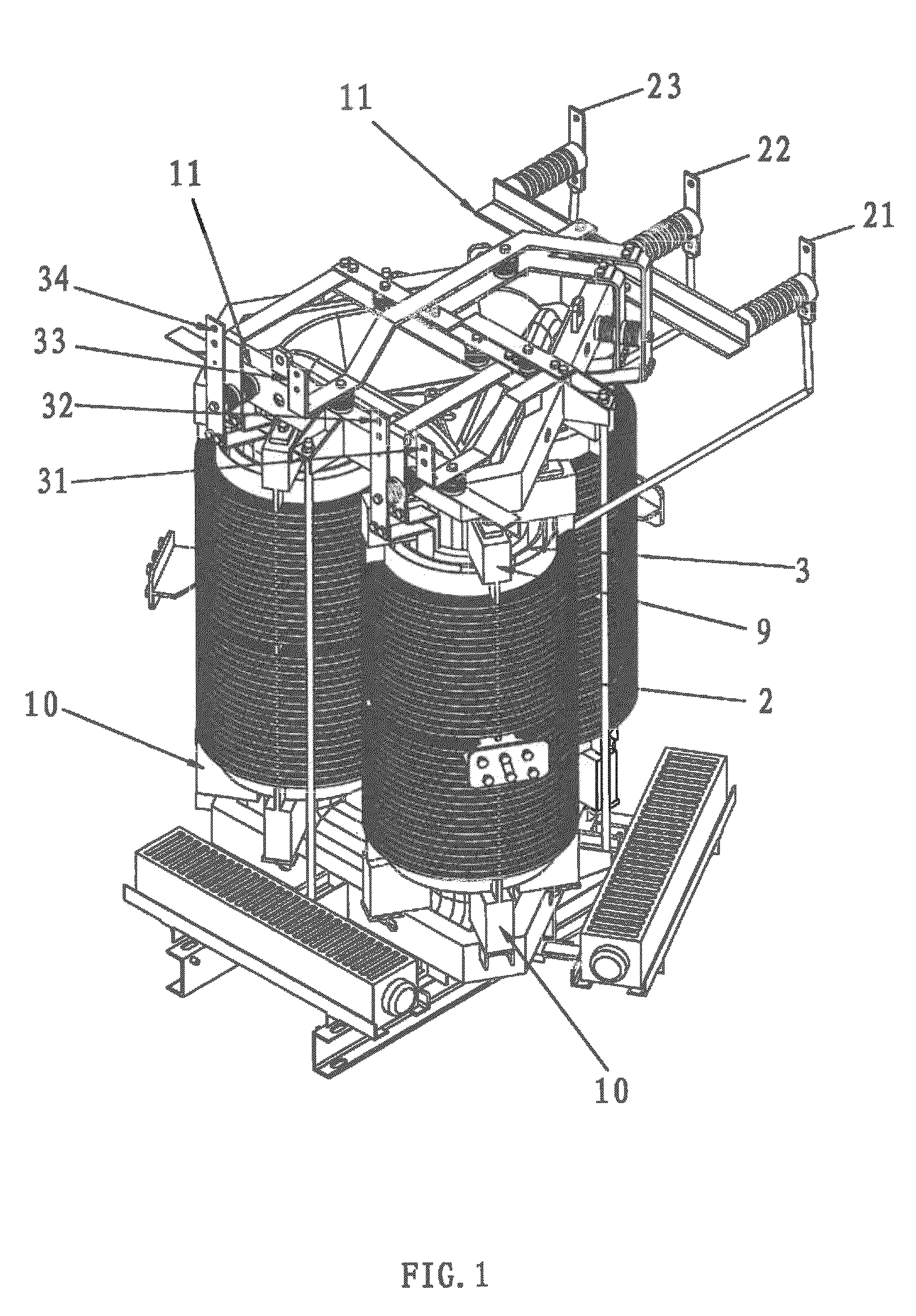

Amorphous alloy transformer with three-dimensional antitorque clamp and iron core parallel independent distribution structure

InactiveCN102651271AImprove stabilityReduce no-load lossTransformers/inductances magnetic coresStress distributionAlloy

The invention relates to an amorphous alloy transformer with a three-dimensional antitorque clamp and an iron core parallel independent distribution structure. The amorphous alloy transformer comprises two pulling plates and an iron core group, and is characterized by also comprising an upper frame clamp component and a lower frame clamp component, wherein a side clamp component is connected between the upper end clamp component and the lower end clamp component; the tops of the pulling plates are connected with the inner side surface of an upper clamp component in the upper frame clamp component; the bottoms of the pulling plates are connected with the inner side surface of a lower clamp component in the lower frame clamp component; and a clearance is formed between the two pulling plates. The amorphous alloy transformer has the advantages that the structure is simple, the stressed state of the iron core in a product is greatly improved, the stressed distribution of the iron core is perfected, the no-load loss of the amorphous alloy transformer is relatively and greatly reduced, and the stability of an energy0saving index is greatly improved. At the same time, the high requirement on an assembling process in a product manufacturing process is reduced, so that the management of product manufacture can be reduced, and the yield of the product is improved to a relatively large extent.

Owner:SHANGHAI SUPERCONDUCTOR ENERGY EQUIP

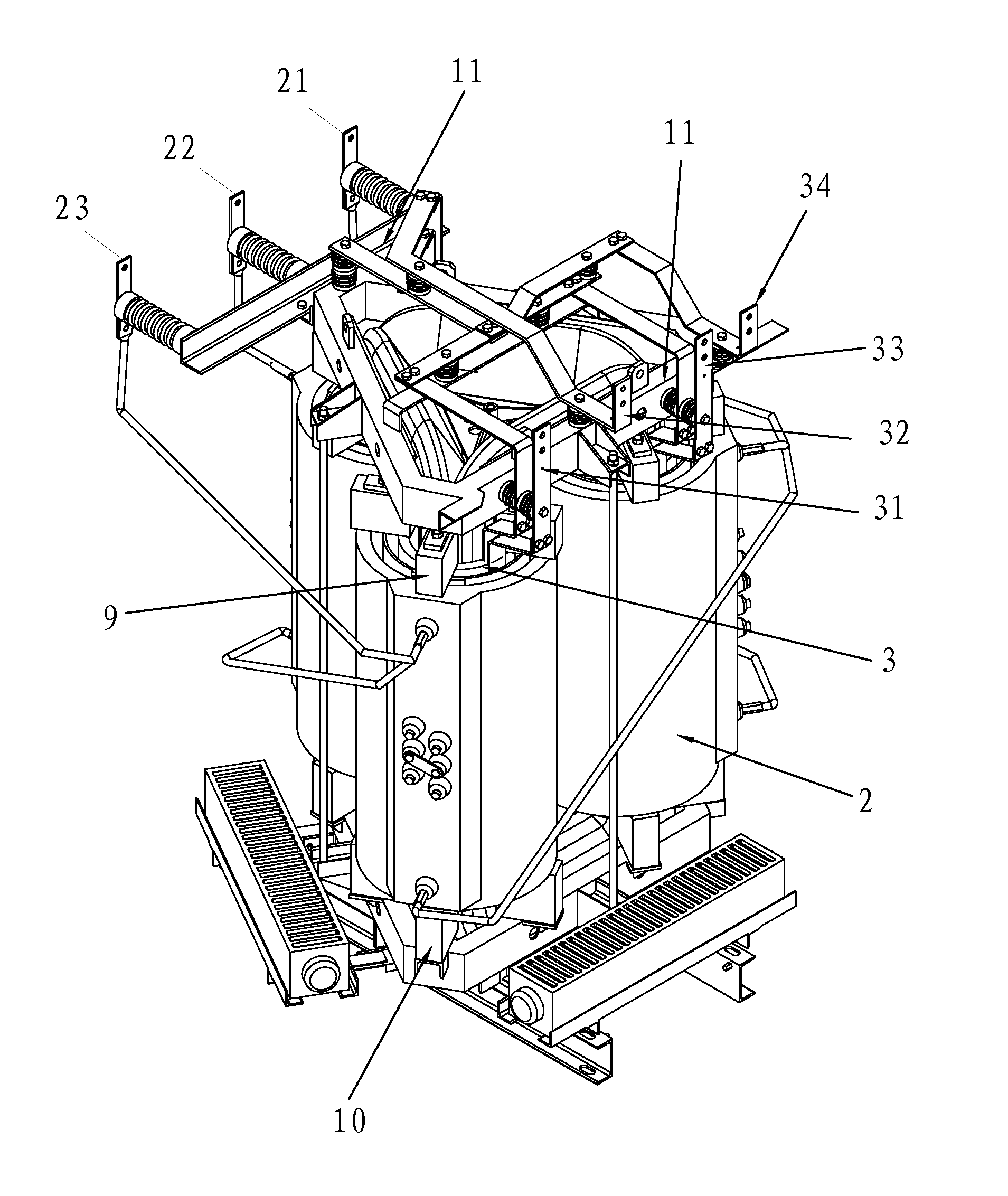

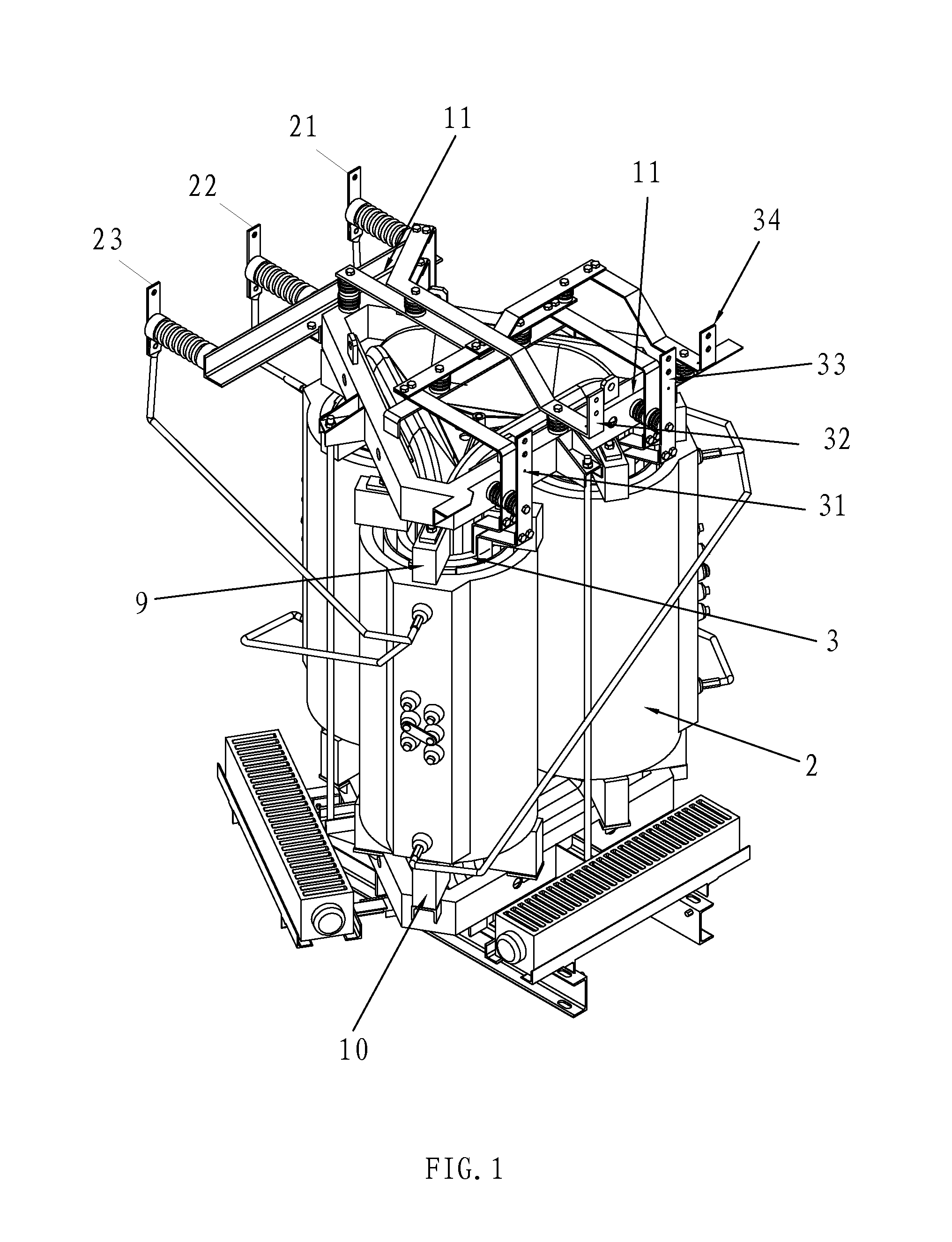

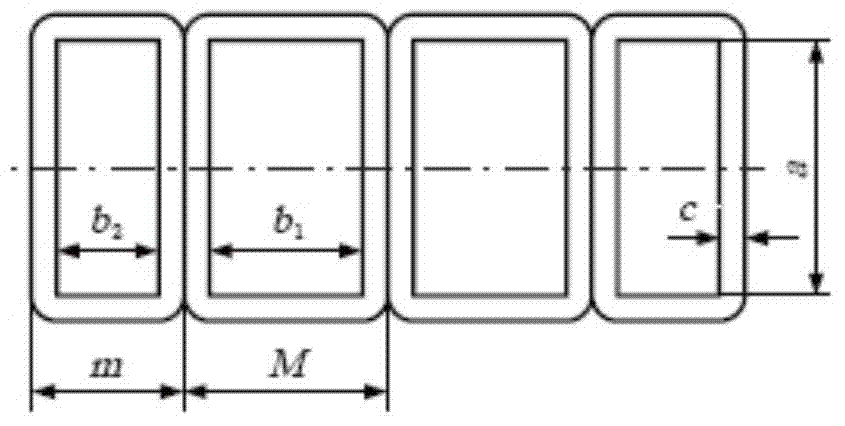

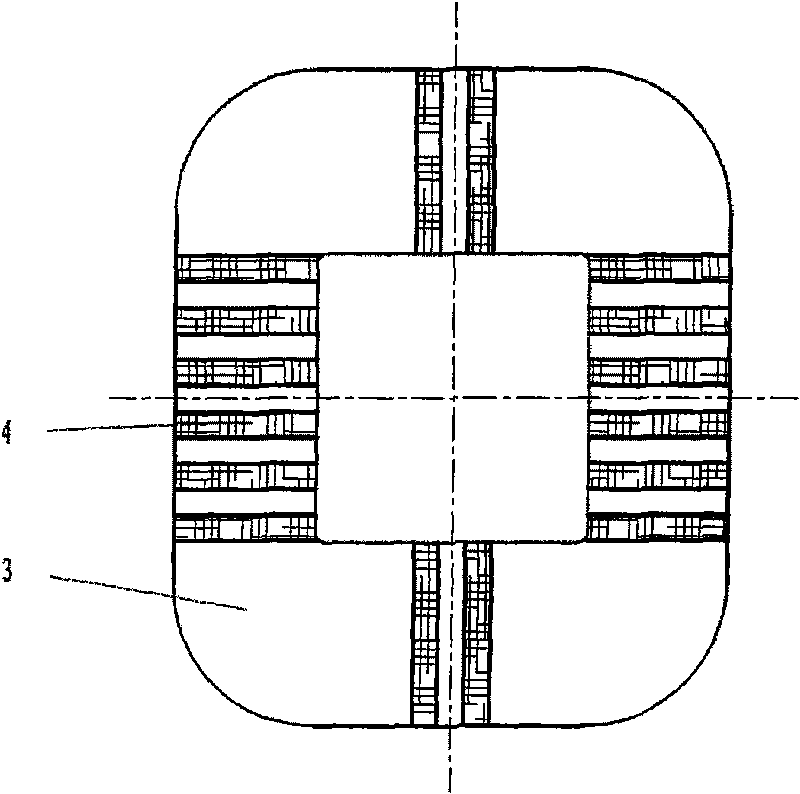

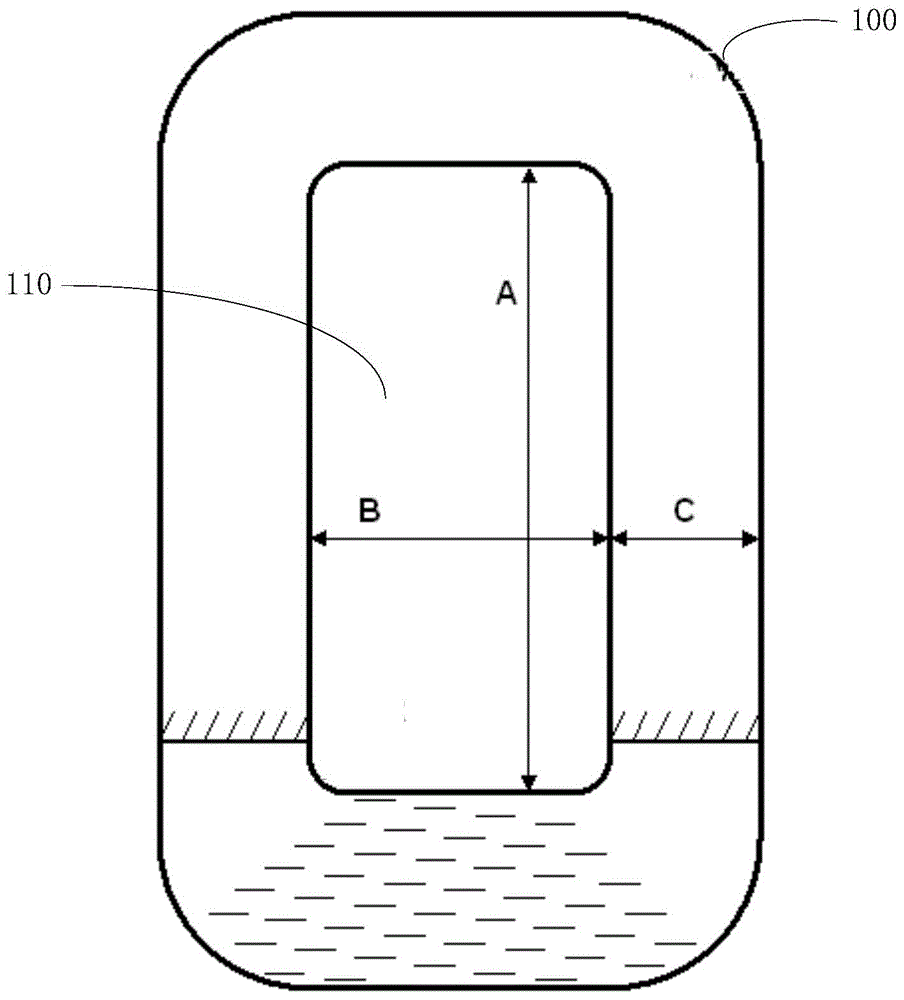

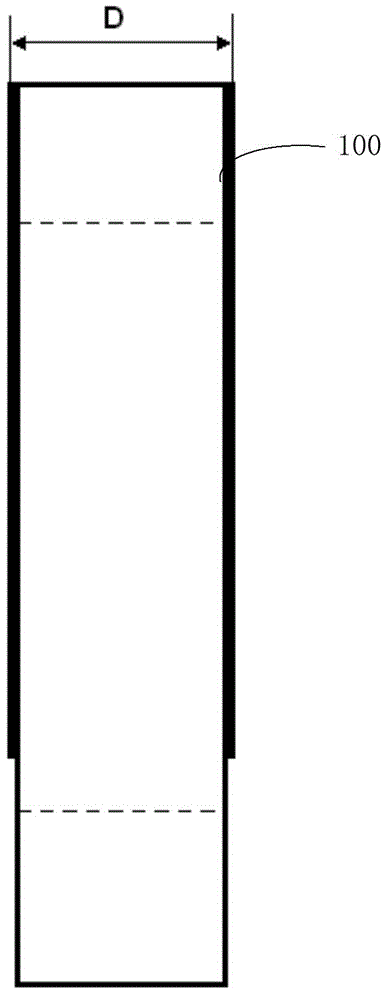

Oil immersed stereo wound-core amorphous alloy transformer

ActiveUS20130162381A1Few process stepsIncrease productivityTransformers/reacts mounting/support/suspensionTransformers/inductances coolingLow voltageFuel tank

An oil immersed stereo wound-core amorphous alloy transformer, comprising an iron core, a high-low voltage winding, leads and a tank. The core comprises three single frames made of amorphous alloy strips by winding and are identical in structure, and the single frames have a rectangular shape; the vertical sides of every two adjacent frames fit together fixedly to form a core pillar, and the horizontal sides of the single frame form iron yokes; the cross sections of the core pillars have an approximately circular or polygonal shape; the transformer further comprises a clamp, comprising a quasi-triangular upper and lower clamp, and posts, the lower clamp is provide with three food pads; the iron yokes in the lower portion of the iron core are located on the foot pads, and the high-low voltage winding is wound on the core pillars;

Owner:GUANGDONG HAI HONG

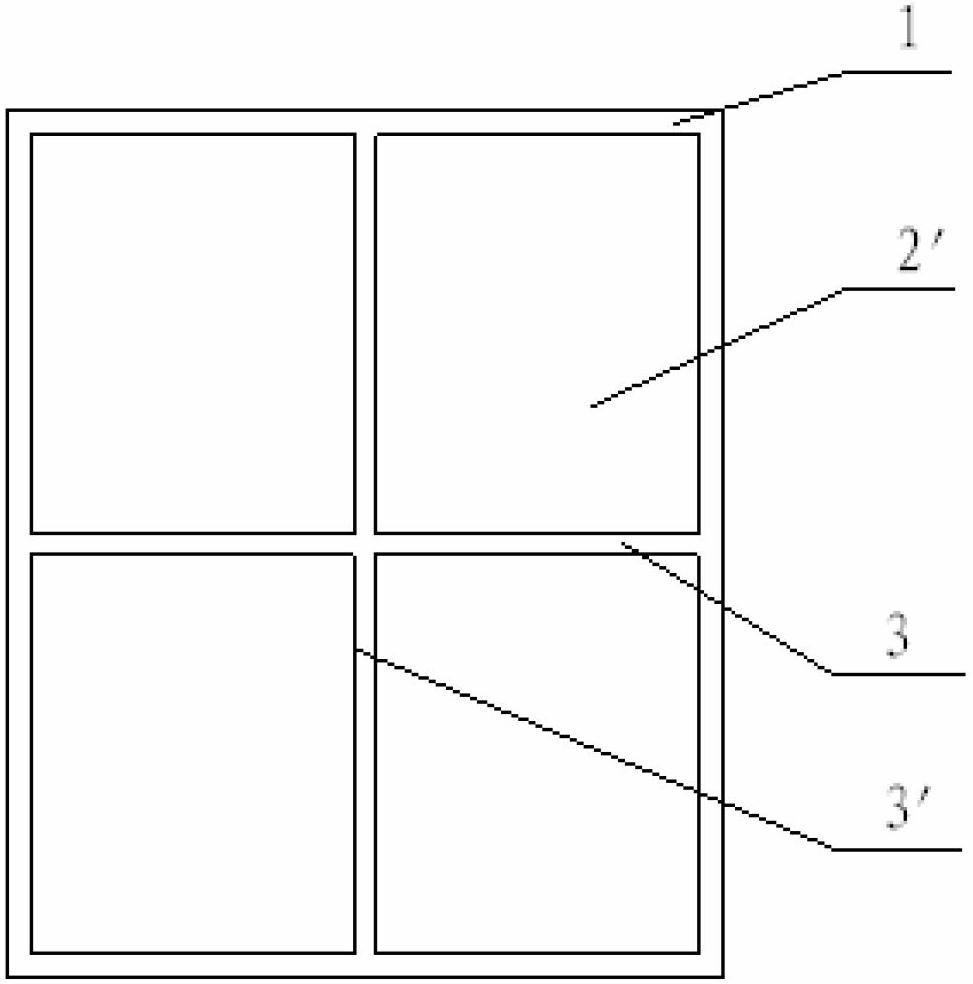

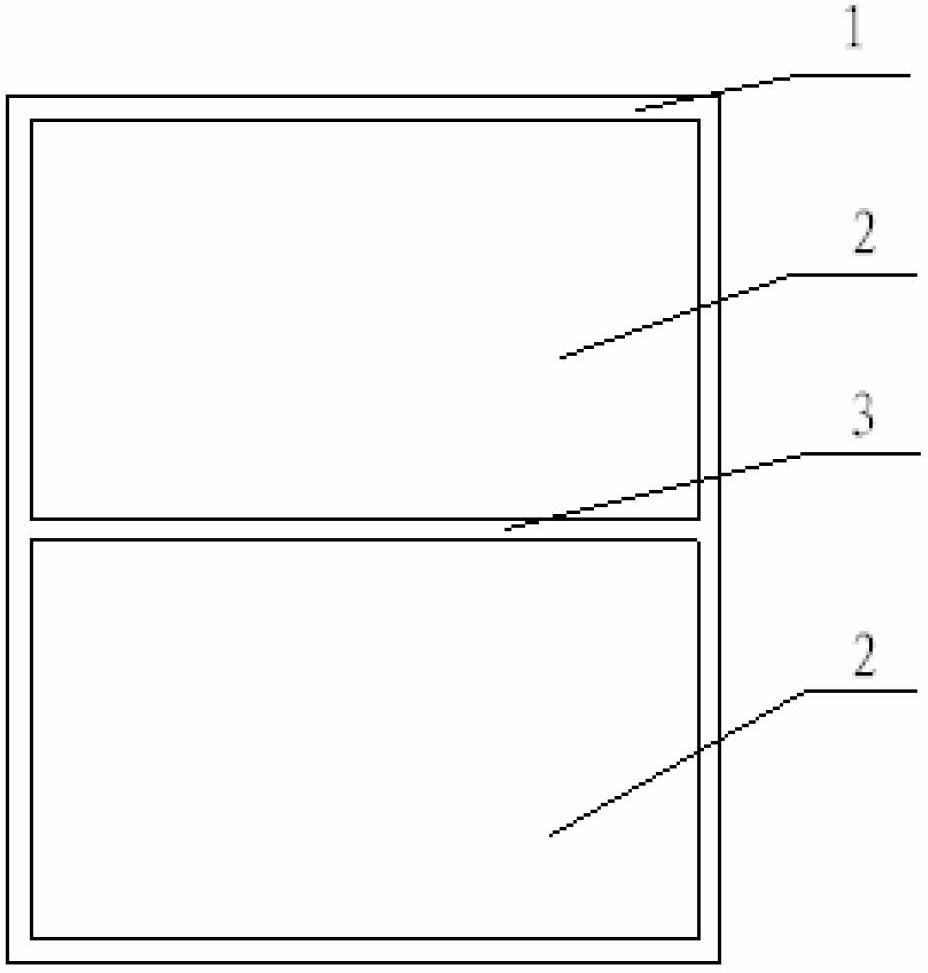

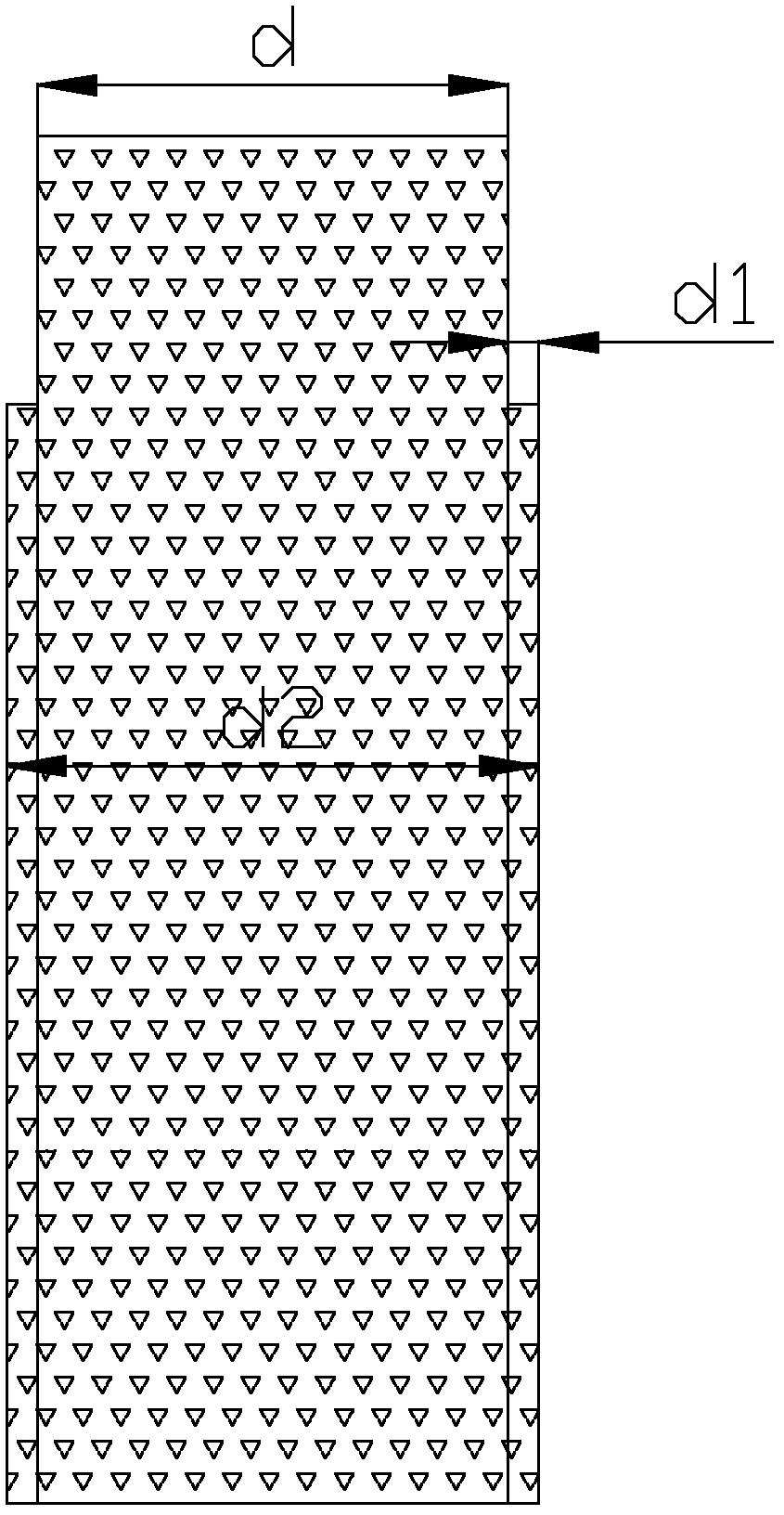

Amorphous alloy transformer core forming template and forming device

InactiveCN104465064AReduce weightIncrease usageInductances/transformers/magnets manufactureProduction scheduleOptoelectronics

The invention discloses an amorphous alloy transformer core forming template and forming device which are used for manufacturing an iron core. The iron core comprises a window. The forming template comprises a substrate and a limiting strip, wherein the transverse length of the substrate is equal to the width of the window, the limiting strip is longitudinally arranged on the substrate, and a gap is formed between the limiting strip and the longitudinal edge of the substrate. By the adoption of the template, the weight of the template can be reduced, the material utilization rate is improved, multiple templates can be used for splicing to form templates of various sizes temporarily, the template purchase cost can be reduced correspondingly, and operation is easy and convenient, so that the size of the template is changed, the template can be used for iron cores of any sizes, the material purchase cost is saved, meanwhile, the production schedule can be accelerated, and production efficiency can be improved.

Owner:SHANGHAI RIGANG ZHIXIN AMORPHOUS METAL

Non-encapsulated-winding stereo wound-core dry-type amorphous alloy transformer

ActiveUS8659382B2Reduce working noiseImprove abilitiesTransformers/inductances casingsTransformers/inductances coils/windings/connectionsVacuum pressureLow voltage

Owner:HAIHONG ELECTRIC CO LTD

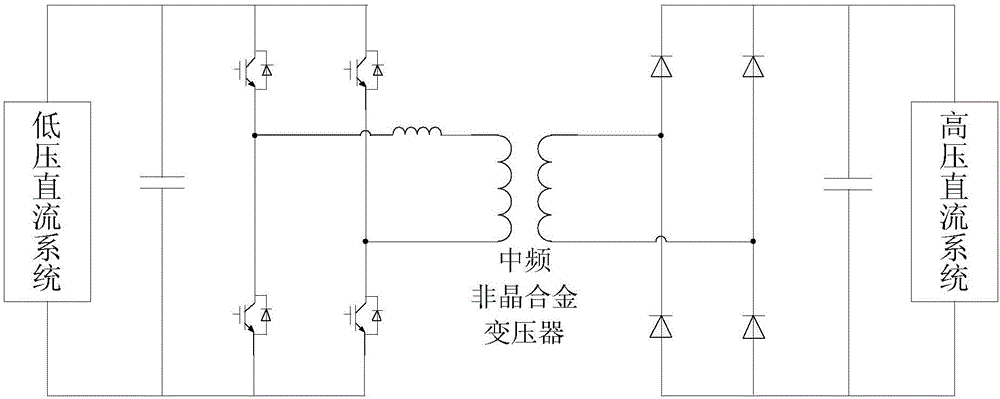

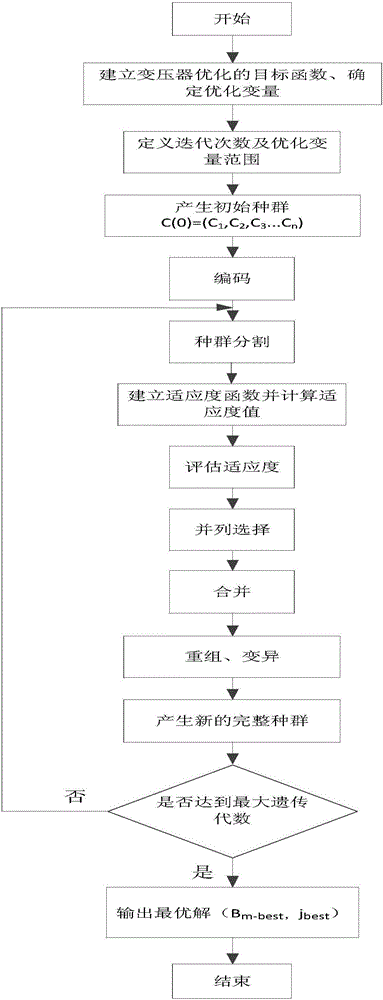

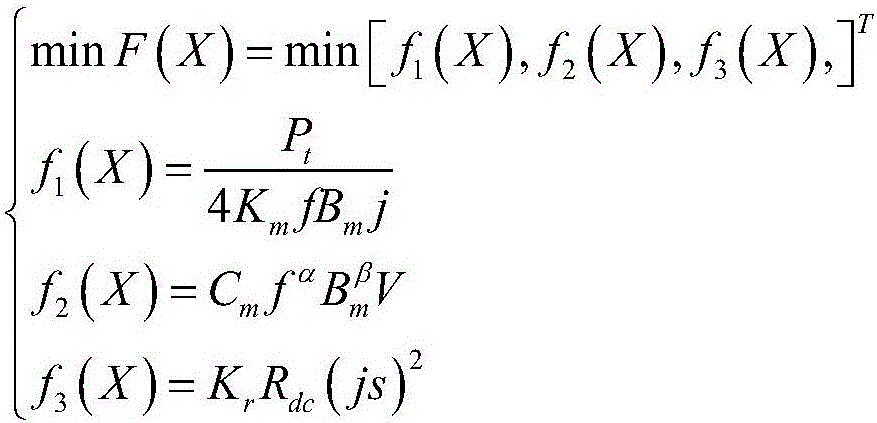

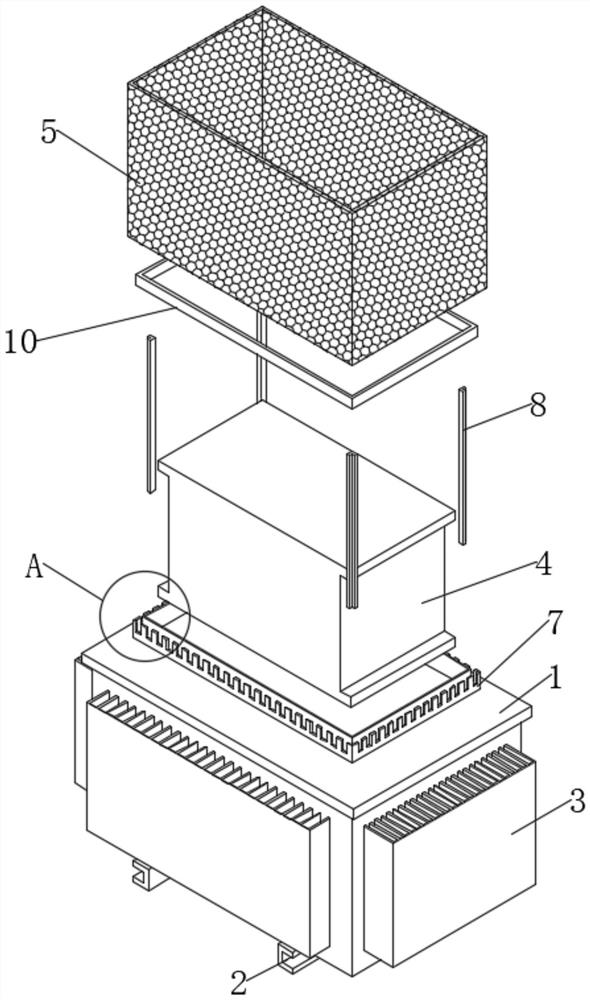

Multi-target genetic algorithm based medium-frequency amorphous alloy transformer optimization method

ActiveCN106257477ALoss minimizationMaximize efficiencyArtificial lifeSpecial data processing applicationsSub populationsMedium frequency

The invention discloses a multi-target genetic algorithm based medium-frequency amorphous alloy transformer optimization method. The method comprises the following steps that 1, optimization variables are selected from parameters of a medium-frequency amorphous alloy transformer to establish a target function optimized by the transformer, and the ranges of iteration times and optimization variables are defined to produce an initial population; 2, the initial population is segmented into a plurality of sub-populations, sub-target functions are distributed for the sub-populations, a fitness function is established, and a fitness value is calculated; parallel selecting operation is performed in each sub-population, and individuals in the sub-populations having higher fitness are selected out to form new sub-populations; 3, the new sub-populations are merged into a complete new sub-population, and nest generation of new complete population is generated through recombination and variated operation; 4, constant iteration is performed, and the steps 2 and 3 are repeatedly and sequentially performed to calculate an optimal solution of the optimization variables. The maximum efficiency and minimum loss of the transformer can be ensured, the transformer can operate more stably, and the service life is longer.

Owner:NANJING INST OF TECH

SBH15-M sealed amorphous alloy power transformer

ActiveCN111739708AAffect normal heat conductionNot easy to affect normal heat conductionTransformers/inductances coolingTransformers/inductances casingsFiberAlloy

The invention discloses an SBH15-M sealed amorphous alloy power transformer, and belongs to the field of a power transformer. According to the SBH15-M sealed amorphous alloy power transformer, flocculent impurities in the cooling oil are primarily captured by utilizing a heat dissipation fiber cluster, and normal heat conduction of the cooling oil is not easily influenced; after the oil temperature in the transformer housing rises, the elbow part is straightened from a bent shape under the action of nitrogen filled in the elbow part; at the moment, a cleaning frame is used for arranging the heat dissipation fiber cluster under the action of an electromagnetic guide rail and an electromagnetic sliding block, and the flocculent impurities released by the heat dissipation fiber cluster are recycled in a unified manner; and finally, under the action of a pressing frame, the flocculent impurities are pressed into a capture fiber cluster to be fixed, so that the flocculent impurities are noteasy to escape from the cleaning frame, the flocculent impurities can be conveniently recycled in a unified manner during maintenance of the amorphous alloy transformer, the flocculent impurities incooling oil in the amorphous alloy transformer can be reduced, and the normal heat dissipation of the amorphous alloy transformer is not easy to influence.

Owner:易仁通电气集团股份有限公司

Manufacturing method of transformer body of oil immersion type amorphous alloy transformer

ActiveCN104465058AReduce lossGood effectTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresLap jointAlloy

The invention discloses a manufacturing method of a transformer body of an oil immersion type amorphous alloy transformer. The manufacturing method includes the following steps: (1) annealing treatment is carried out on iron cores; (2) the iron cores are pushed to the testing position for testing according to the furnace exiting sequence; (3) coils for forming the transformer body of the transformer draw close; (4) iron core jackets are drawn off after the iron cores are pushed into the testing position; (5) packing is carried out; (6) binding is carried out, wherein the binding belt tension ranges from 1500 N to 2500 N according to different weights of the transformer body; (7) after an amorphous sheet layer on the outmost face is closed, a shock pad is placed on the outer face of the amorphous sheet layer, a silicon steel sheet hasp on the outer layer is tightened, the hasp part is firmly glued through adhesive tape, and the adhesive tape is used for firm gluing if the hasp is damaged; (8) the coils are cleaned; (9) the lap joint position is coated with glass cement; (10) upper clamp insulation is arranged, and an upper clamp is installed in place. By means of the manufacturing method, stable-performance annealing parameters can be guaranteed, the fixing effect is improved through an elastic insulation binding belt, and the sound insulation effect and the sound absorption effect can be improved.

Owner:宁波奥克斯智能科技股份有限公司

Low-noise amorphous metal transformer

InactiveCN103871718ADrop unit lossReduce noiseTransformers/inductances noise dampingTransformers/inductances magnetic coresLow noiseNitrile rubber

The invention discloses a low-noise amorphous metal transformer. An iron core is made of an amorphous metal 2605HB1M material with high saturation flux density; after the iron core is lapped, the bottom of the iron core is provided with a rubber pad which is 8mm in thickness to reduce noise generated by magnetic-lag contraction; the outer side of the iron core is coated with a layer of nitrile rubber which is 1mm in thickness to hinder a travel path of the noise and reduce the noise; a shock-reducing rubber pad which is 20mm in thickness is arranged at the bottom of an oil tank, a joint of a transformer body hanger plate and a clamp is provided with a rubber pad which is 10mm in thickness, and the noise generated by vibration of the iron core is reduced. The noise is reduced by changing the material of the iron core and arranging the rubber pads to hinder the travel path of the noise and reduce vibration frequency, so that the noise of the amorphous metal transformer can be controlled to be lower than 45dB and the noise is obviously reduced. The iron core is made of the new amorphous metal 2605HB1M material, the noise is reduced and the energy-saving effect is better.

Owner:SHANDONG HUACHI TRANSFORMER

Low-noise amorphous alloy transformer iron core

InactiveCN102938297AIsolation of noise transmission pathsReduced sound insulationTransformers/inductances noise dampingTransformers/inductances magnetic coresLow noiseAlloy

The invention discloses a low-noise amorphous alloy transformer iron core which comprises an inner side wrapping sheet, an outer side wrapping sheet, an amorphous alloy core and deadening felts. The amorphous alloy core is arranged between the inner side wrapping sheet and the outer side wrapping sheet, and the deadening felts are arranged on non-touch surfaces of the inner side wrapping sheet, the outer side wrapping sheet and the amorphous alloy core. The deadening felts are arranged on the inner side surface and the outer side surface of the amorphous alloy transformer iron core, so that noise transmission routes of the amorphous alloy iron core can be effectively isolated, and the low-noise amorphous alloy transformer iron core is simple in process, convenient to operate, low in cost and remarkable in noise reduction effect.

Owner:SHANGHAI RIGANG ZHIXIN AMORPHOUS METAL

Amorphous alloy transformer body structure having short-circuit resistant capability

PendingCN107910167ANo destructive deformationImprove short circuit resistanceTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresDistribution transformerLow voltage

The invention relates to an amorphous alloy transformer body structure having short-circuit resistant capability. The amorphous alloy transformer body structure is a three-phase four-frame iron core structure and comprises an upper-layer amorphous alloy iron core, a lower-layer amorphous alloy iron core and three phase windings A, B and C and also comprises C-shaped insulation plates, hard insulation cylinders, a left-side press plate, a right-side press plate, a left clamp, a right clamp, an upper press plate, a lower press plate, an upper clamp and a lower clamp, wherein the C-shaped insulation plates are arranged between the A-phase winding and the B-phase winding, between the B-phase winding and the C-phase winding and between the A-phase winding and the C-phase winding, the left-sidepress plate and the right-side press plate and the left clamp and the right clamp are arranged at a left side and a right side of the body structure, the upper press plate and the lower press plate and the upper clamp and the lower clamp are arranged at an upper side and a lower side of the body structure, and the two layers of amorphous alloy iron cores are partitioned by a first reinforcement plate and a second reinforcement plate. By arranging the upper clamp, the lower clamp, the left-side clamp, the right-side clamp, the hard insulation cylinders, the first reinforcement plate and the second reinforcement plate, the windings can bear abrupt short-circuit, destructive deformation cannot be generated, reactance does not exceed standard, the amorphous alloy iron cores cannot be pressed to be broken and affect performance by the winding deformation, and the short-circuit resistant capability of the amorphous alloy power distribution transformer is reliably improved.

Owner:SHANDONG ELECTRICAL ENG& EQUIP GRP INTELLIGENT ELECTRIC CO LTD

Amorphous alloy strip and preparation method thereof

The invention discloses an amorphous alloy strip and a preparation method thereof. The amorphous alloy strip comprises the following components by mass percent: 10-15% of Si, 4-6% of B, 3-5% of C, 2-4% of Nb and the balance Fe. The preparation method of the amorphous alloy strip comprises the following steps: (1) Si, B, C, Nb and Fe at the corresponding mass percent are put into a crucible: (2) an inert gas is input to the crucible from the bottom of the crucible, passes through the interior of the crucible, then reaches the top of the crucible and is output, the internal vacuum degree of the crucible is kept constant, and slow heating is carried out till a mother alloy in the crucible is in a molten state; and (3) under a vacuum condition, the amorphous alloy strip is prepared by adopting a singlestick process. The amorphous alloy strip is mainly applied to an amorphous alloy transformer, the occurring probability of heterogeneous nucleation can be reduced, and a yield of the amorphous alloy strip is raised.

Owner:SICHUAN FUXI ELECTRIC POWER EQUIP MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com