Low-noise amorphous metal transformer

A technology of amorphous alloys and transformers, applied in the field of low-noise amorphous alloy transformers, can solve the problems of low no-load loss, high noise, and affecting the living environment of residents, and achieve the effects of significant noise reduction, noise reduction, and unit loss reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

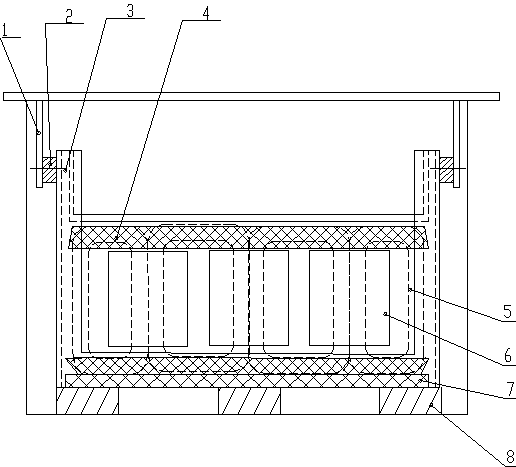

[0009] Accompanying drawing is a kind of specific embodiment of the present invention.

[0010] The low-noise amorphous alloy transformer of the present invention comprises a plurality of iron cores 5 connected together, and coils 6 are sheathed on the iron cores. The frame of the transformer body is formed by clips 3 and the iron cores. Plate 1, the transformer body is placed in the oil tank; the iron core is made of the latest amorphous alloy 2605 HB1M material with high magnetic flux saturation density; after the iron core lap is completed, an 8mm thick rubber pad 7 is placed on the bottom to reduce the Noise generated by hysteresis shrinkage; wrap a layer of 1mm thick nitrile rubber skin 4 on the outside of the iron core 5 to hinder the propagation path of noise and reduce noise; place a 20mm thick shock-absorbing rubber pad 8 on the bottom of the fuel tank, and place a 20mm thick shock absorbing rubber pad 8 on the body hanging plate 1. A 10mm rubber pad 2 is placed at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com