SBH15-M sealed amorphous alloy power transformer

A technology of power transformers and amorphous alloys, which is applied in the field of power transformers, can solve the problems of amorphous alloy transformers working at high temperatures, the difficulty of normal heat dissipation of amorphous alloy transformers, and affecting the normal service life of amorphous alloy transformers, etc., to increase the fixed effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

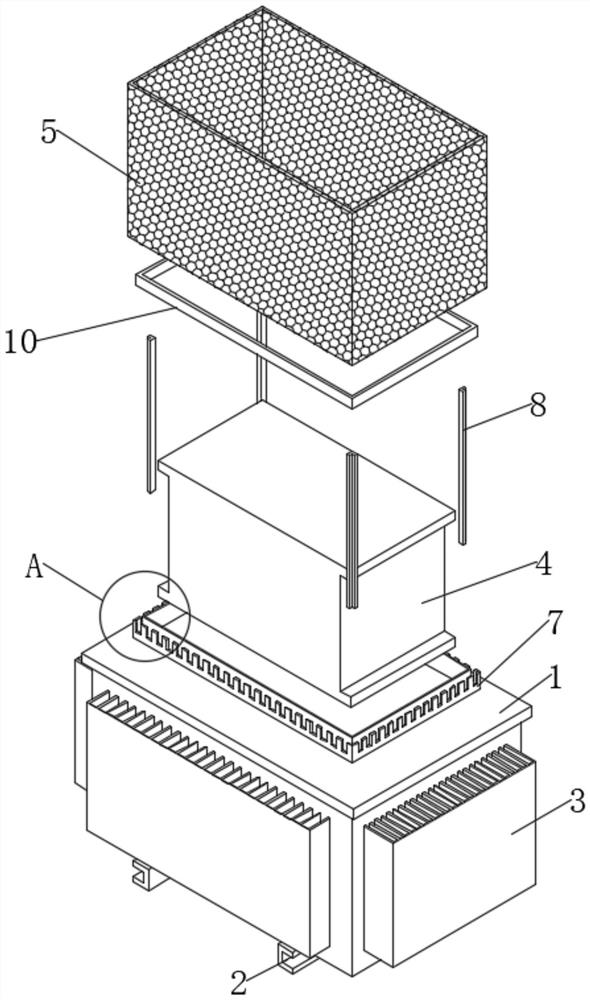

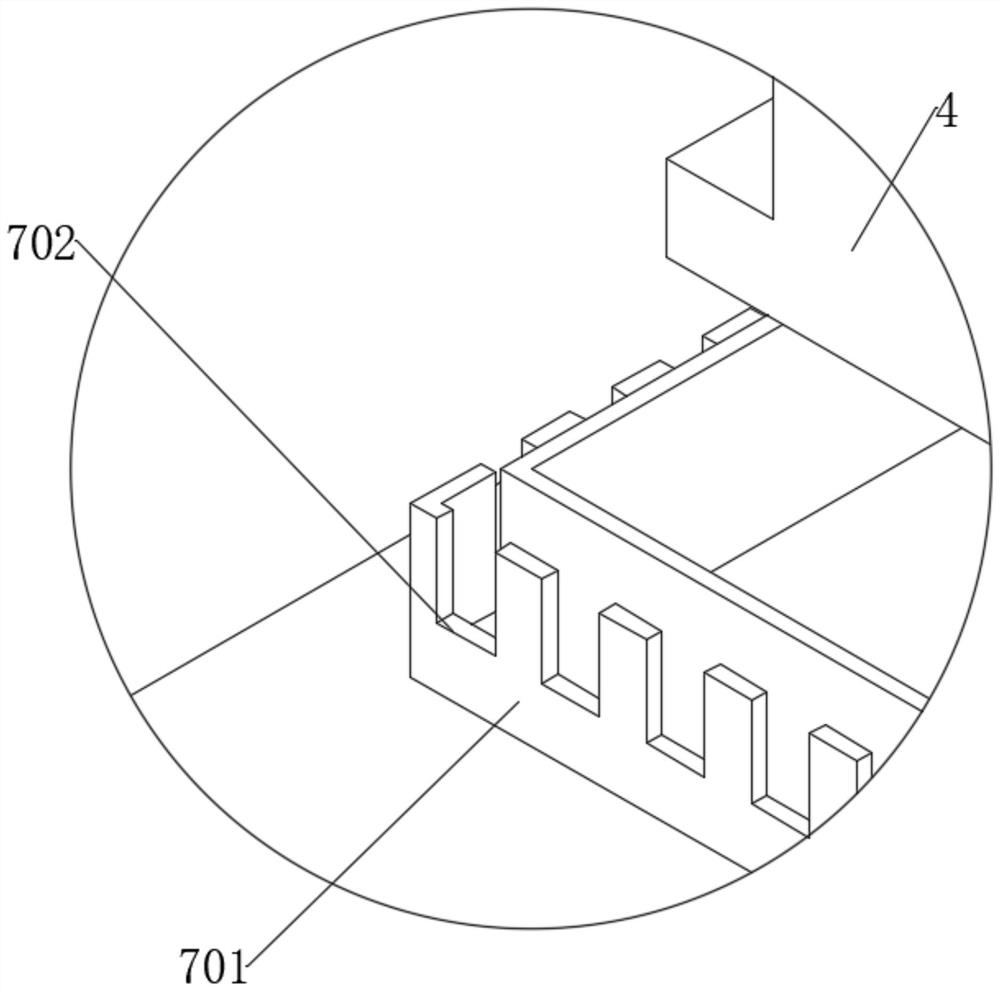

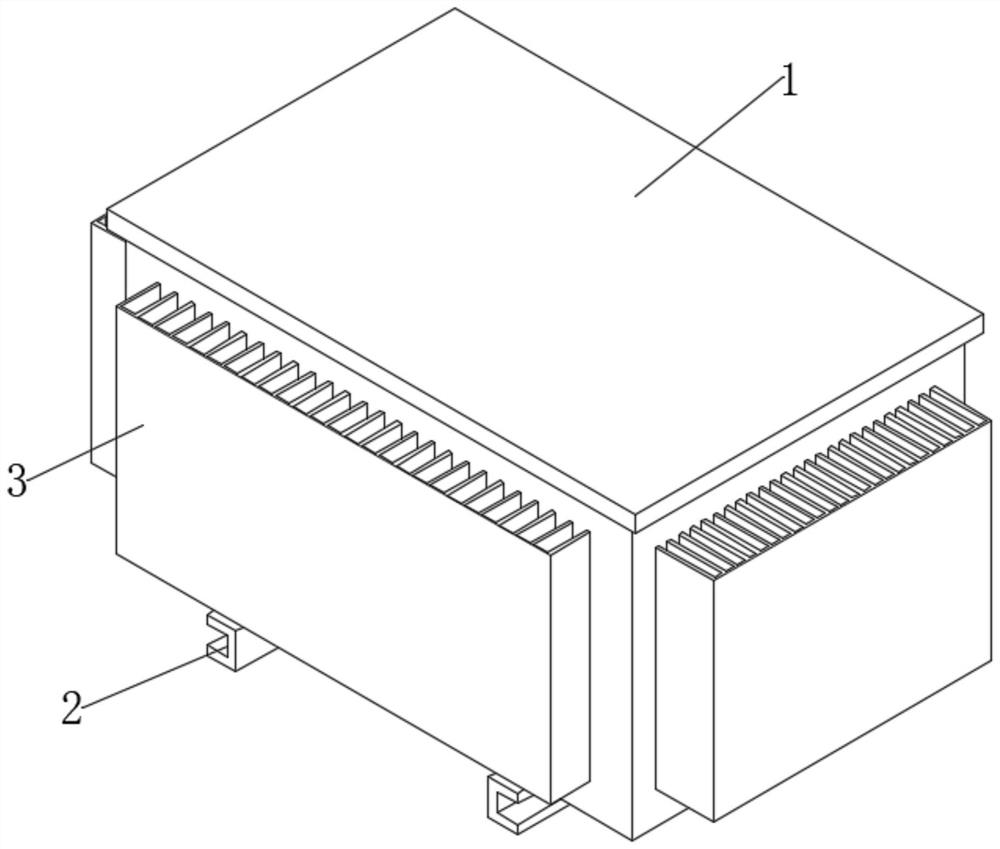

[0036] see figure 1 and Figure 3-7 , a SBH15-M sealed amorphous alloy power transformer, including a transformer shell 1, a transformer inner core 4 that matches itself is fixedly connected inside the transformer shell 1, a pair of mounting bases 2 are fixedly connected to the lower end of the transformer shell 1, and the transformer The housing 1 is connected with a cooling fin group 3, the cooling fin group 3 includes external fins 301, the external fins 301 are located outside the transformer housing 1, and the end of the external fins 301 close to the transformer housing 1 runs through the side wall of the transformer housing 1 And extend into the transformer shell 1, the external fins 301 are fixedly connected with the inner heat conduction plate 302 that matches the transformer shell 1 first, and the inner heat conduction plate 302 is located in the transformer shell 1;

[0037] The anti-skid net 5 is fixedly connected inside the transformer shell 1, and the anti-skid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com