Winding mould used in transformer coil

A technology for transformer coils and molds, applied in coil manufacturing, inductance/transformer/magnet manufacturing, electrical components, etc., can solve the problems of fixed mold size, difficult mold processing, and many mold opening materials, so as to reduce mold opening materials. , the structure is simple, the effect of reducing the cost of the mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

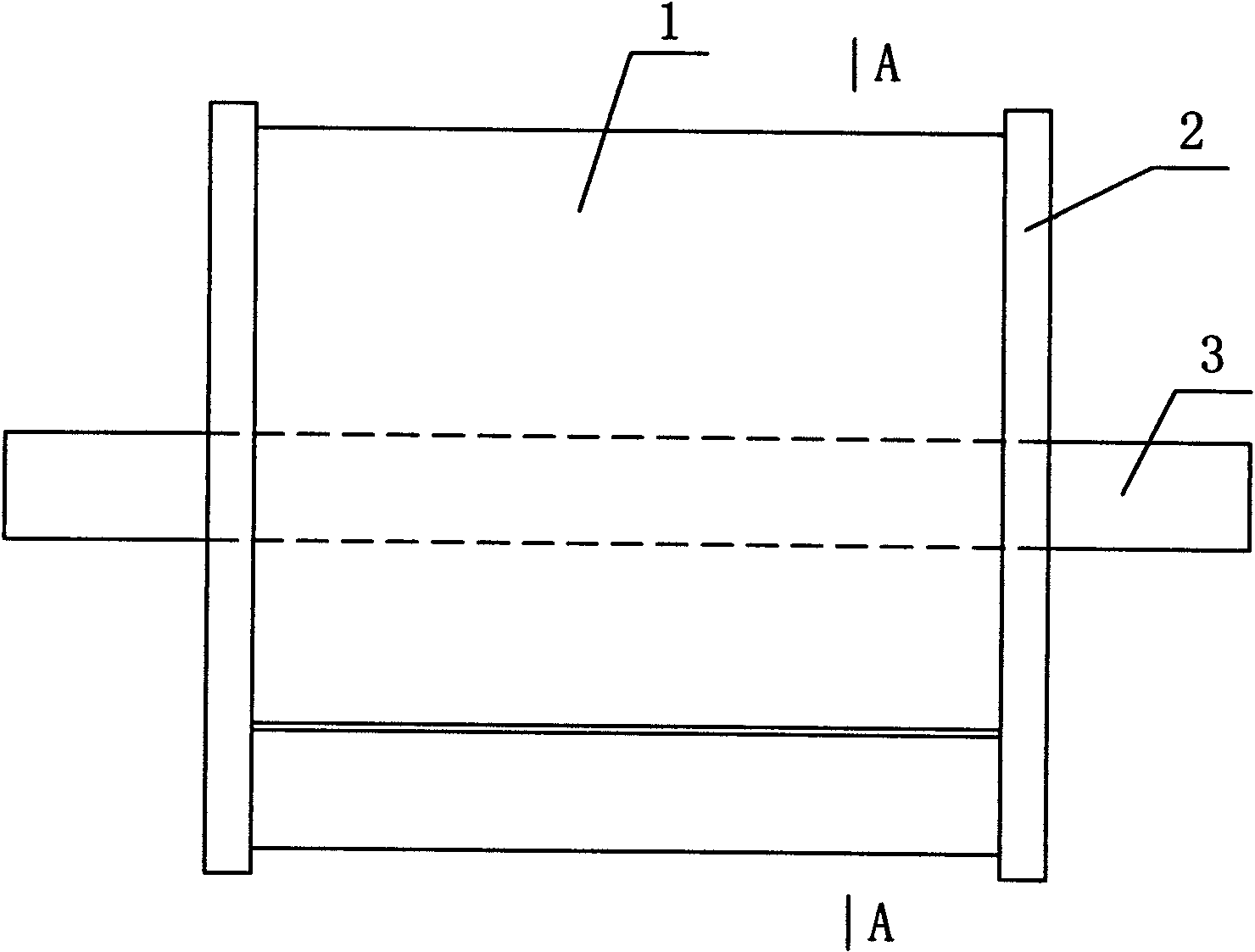

[0011] like figure 1 As shown, the present invention includes a rectangular inner mold 1, an end support plate 2 arranged at two ends of the rectangular inner mold 1, and a bobbin 3 arranged in the middle of the rectangular inner mold 1.

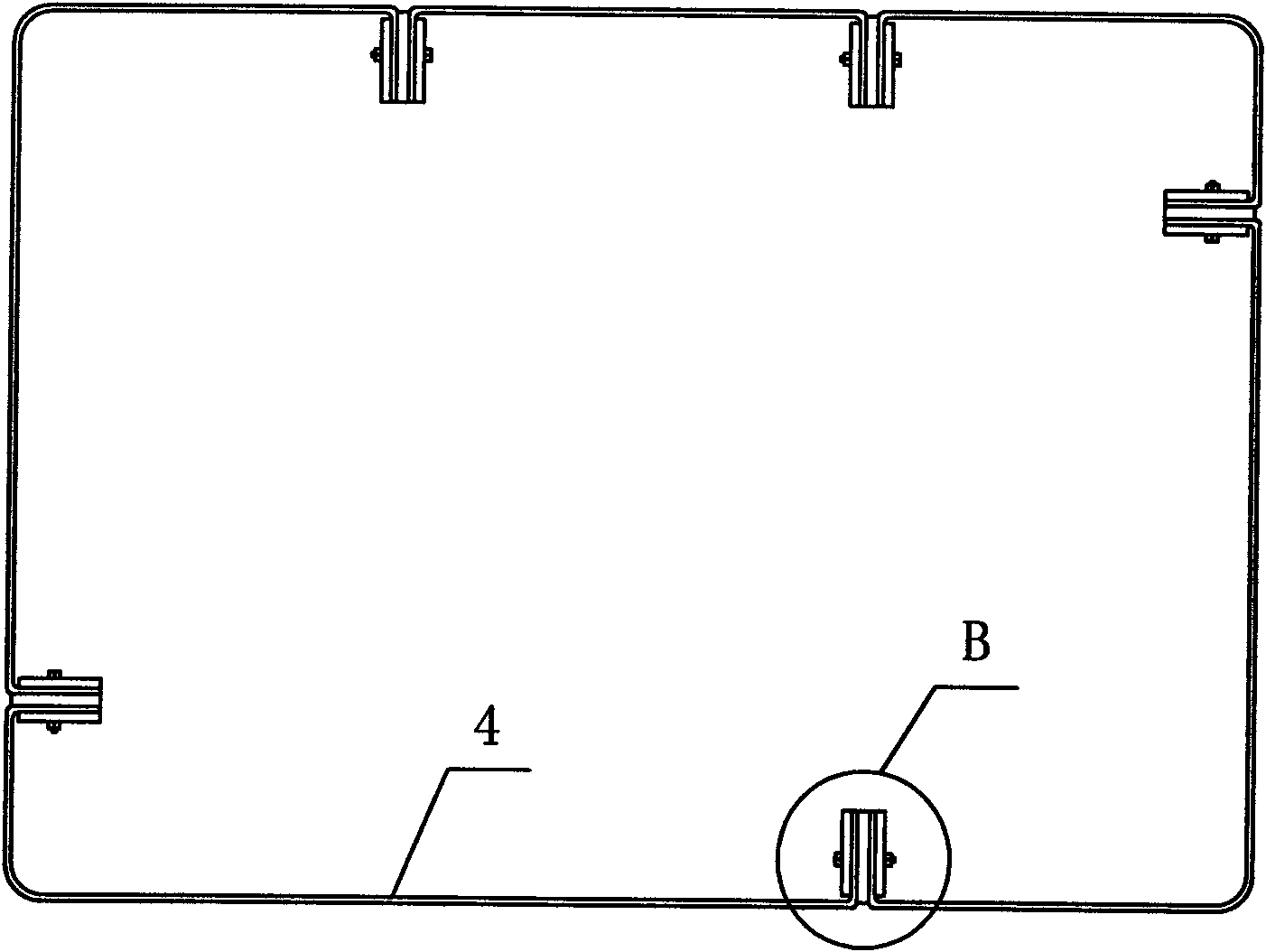

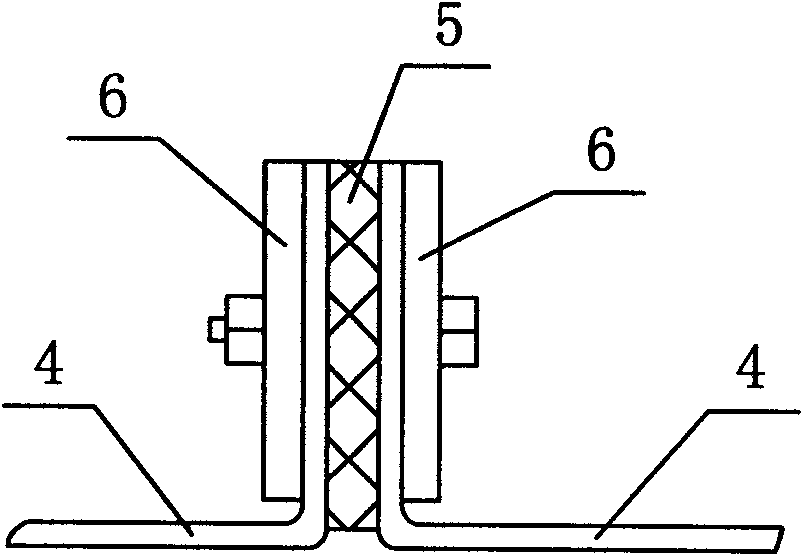

[0012] like Figure 2~3 As shown, the rectangular inner mold 1 of the present invention is composed of five steel plates 4 connected end to end. A silicone rubber plate 5 is clamped, and reinforcing plates 6 are respectively arranged outside the two bent ends, and the two reinforcing plates 6, the two bent ends and the silicone rubber plate 5 are fastened by bolts.

[0013] During installation, connect the bent ends of the five steel plates 4 at right angles end to end, install a silicon rubber plate 5 between the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com