Manufacturing method of amorphous alloy iron cores

A technology of amorphous alloys and manufacturing methods, which is applied in the direction of inductance/transformer/magnet manufacturing, manufacturing tools, transformer/inductor cores, etc., can solve problems such as time-consuming, cost-increased, complex processes and equipment, and achieve operational Convenience, high degree of automation, the effect of alleviating the contradiction of power overload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the technical features of the present invention more obvious and understandable, the present invention will be further described below in conjunction with specific embodiments.

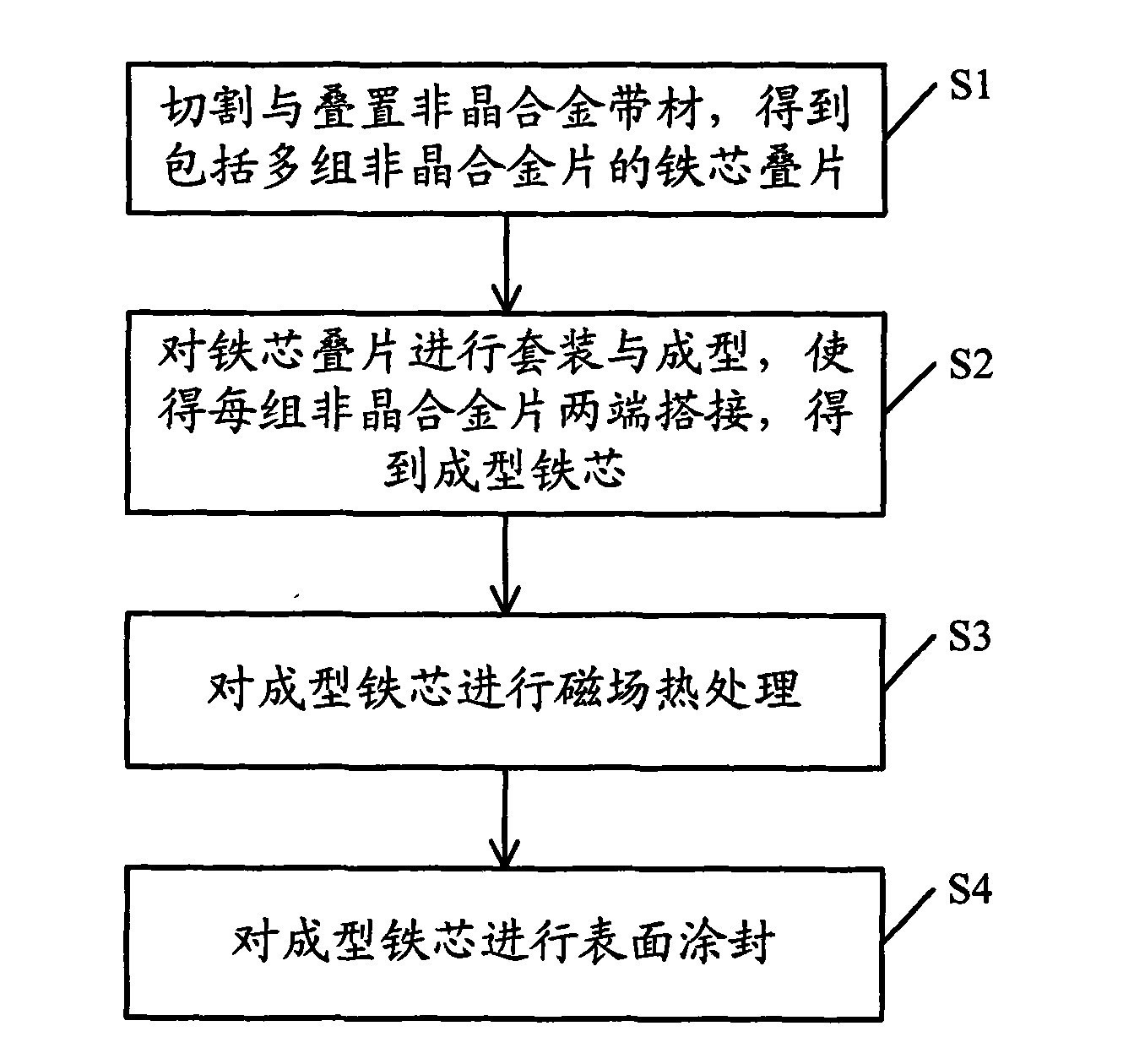

[0043] Please refer to figure 1 , which is a schematic flow chart of a method for manufacturing an amorphous alloy iron core provided by an embodiment of the present invention, as shown in the figure, including the following steps:

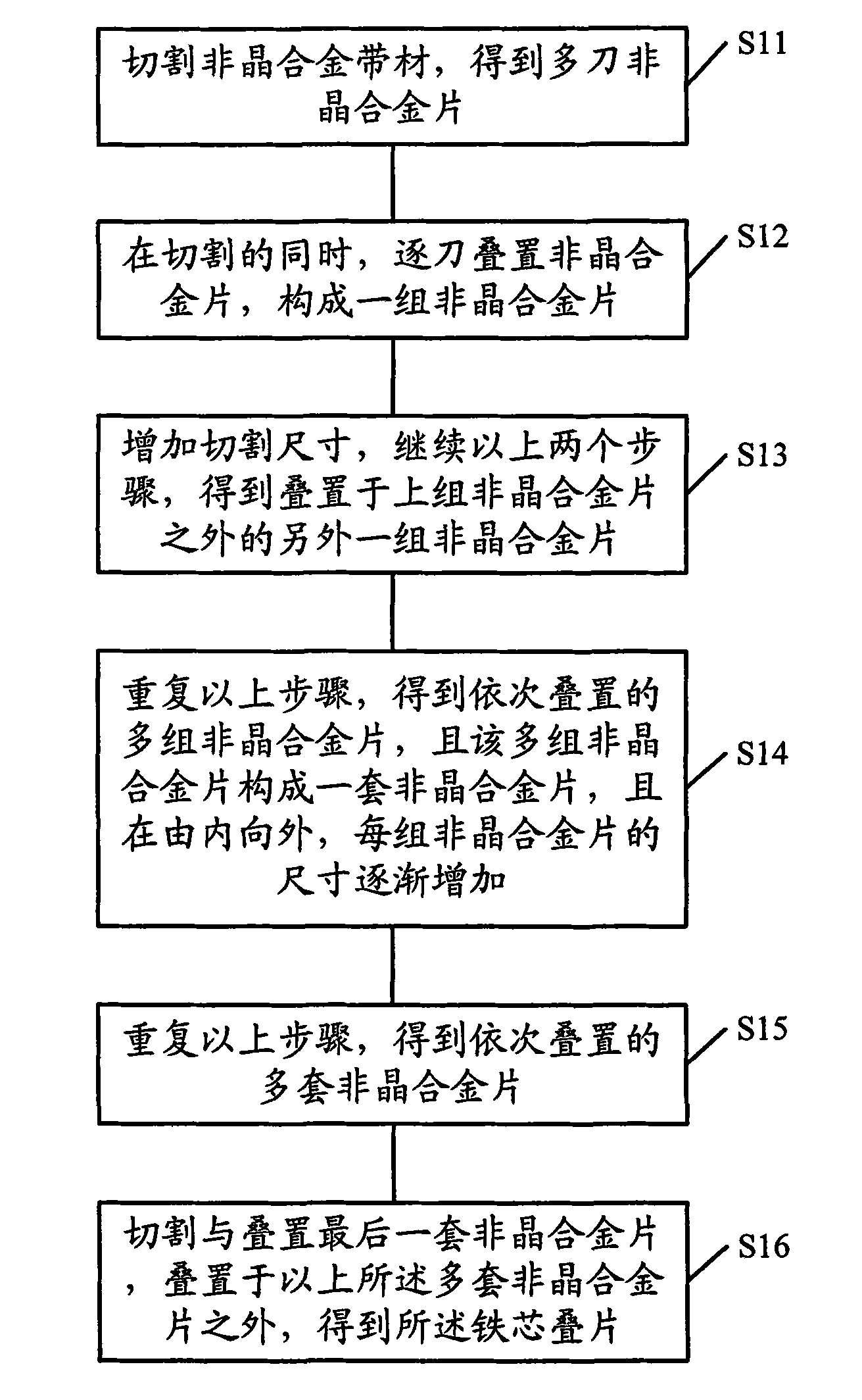

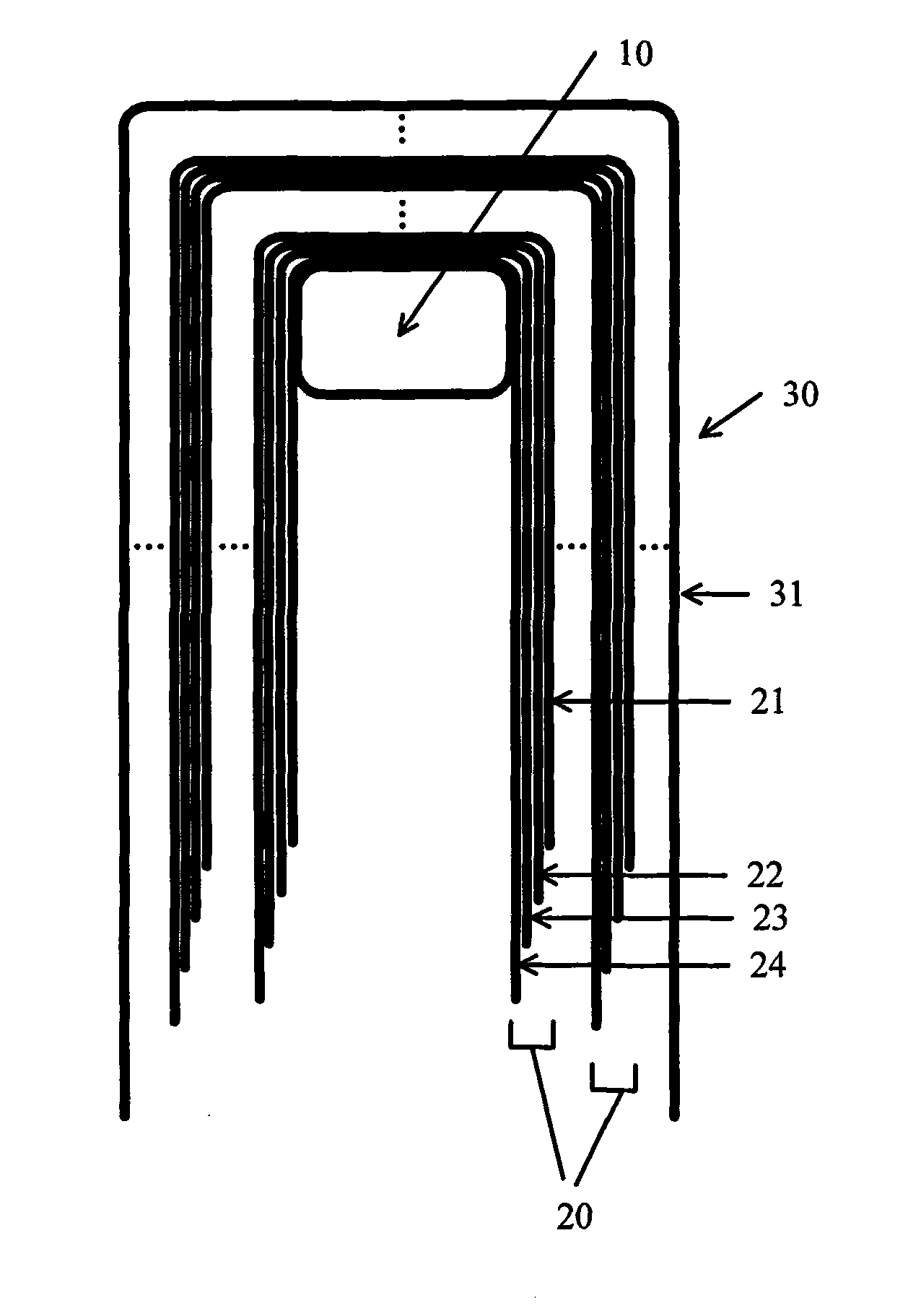

[0044] S1: cutting and stacking amorphous alloy strips to obtain iron core laminations including multiple groups of amorphous alloy sheets;

[0045] S2: Set and form the iron core laminations, so that the two ends of each group of amorphous alloy sheets are overlapped to obtain a formed iron core;

[0046] S3: Perform magnetic field heat treatment on the formed iron core;

[0047] S4: Surface coating and sealing the formed iron core.

[0048] It can be seen that the manufacturing method of this amorphous alloy iron core mainly includes steps suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com