Mobile phone shell and preparation method thereof

A technology for mobile phone shells and plastic shells, which is applied to chemical instruments and methods, sub-office equipment, small shells, etc., and can solve problems such as non-abrasion resistance, drop resistance, corrosion resistance, and weak bonding between metal and plastic parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention simultaneously provides a preparation method for the above-mentioned mobile phone casing, comprising the following steps:

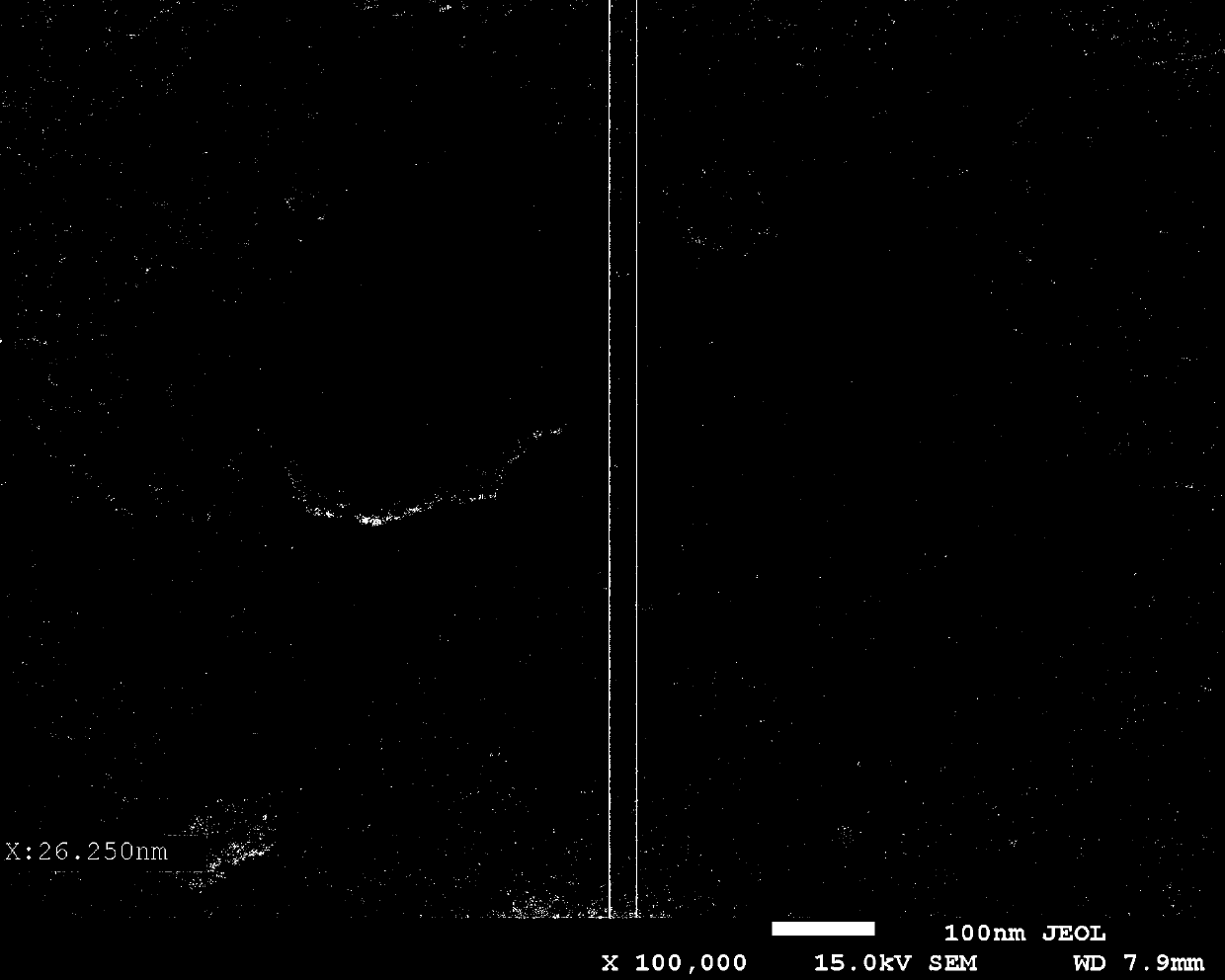

[0032] S1, anodize the surface of the pretreated metal shell body that needs to be combined with plastic parts to obtain a metal shell body with an oxide film layer with a pore size of 10-100 nm nanopores on the surface; anodic oxidation is an anodic well known to those skilled in the art Oxidation technology, the present invention may include putting the pretreated aluminum alloy as an anode into 10wt%-30wt% concentration H 2 SO 4 In the process, the temperature is 10-30°C and the voltage is 10V-100V for 1-40min to obtain an aluminum alloy with a 1-10um thick oxide film layer on the surface. The anodizing equipment adopts known anodizing equipment, such as anodizing tanks.

[0033] Among them, the metal shell body that needs anodized surface treatment can be part of the surface that needs to be combined with plastic parts ac...

Embodiment 1

[0050] 1. Pretreatment: Cut the commercially available 1mm thick 5052 aluminum alloy shell body into a rectangular shell of 15mm*80mm (such as Figure 4 shown), put it into a polishing machine and grind it, and then wash it with absolute ethanol, then immerse the aluminum alloy shell body in 40g / L sodium hydroxide aqueous solution, take it out after 2 minutes and rinse it with deionized water to get Pre-treated aluminum alloy shell body;

[0051] 2. Surface treatment 1: Put the above aluminum alloy shell body as an anode into H2 with a concentration of about 20wt%. 2 SO 4 In the anodizing tank, electrolyze at 20V, 18°C for 10min, and blow dry;

[0052] 3. Surface treatment 2: Prepare 500ml of 10wt% sodium carbonate (pH=12) in a beaker, soak the obtained aluminum alloy shell body in it at 20°C, take it out after 5min, put it in a beaker filled with water and soak for 1min , so that the cycle is 5 times, after the last water soaking, dry the aluminum alloy shell body;

[0...

Embodiment 2

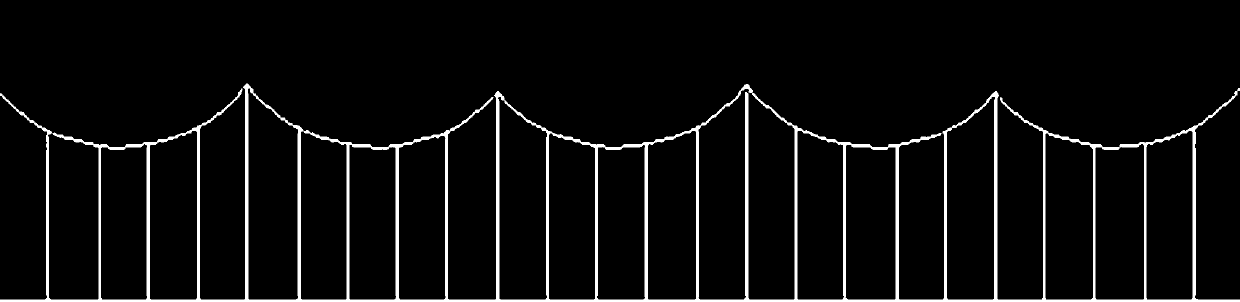

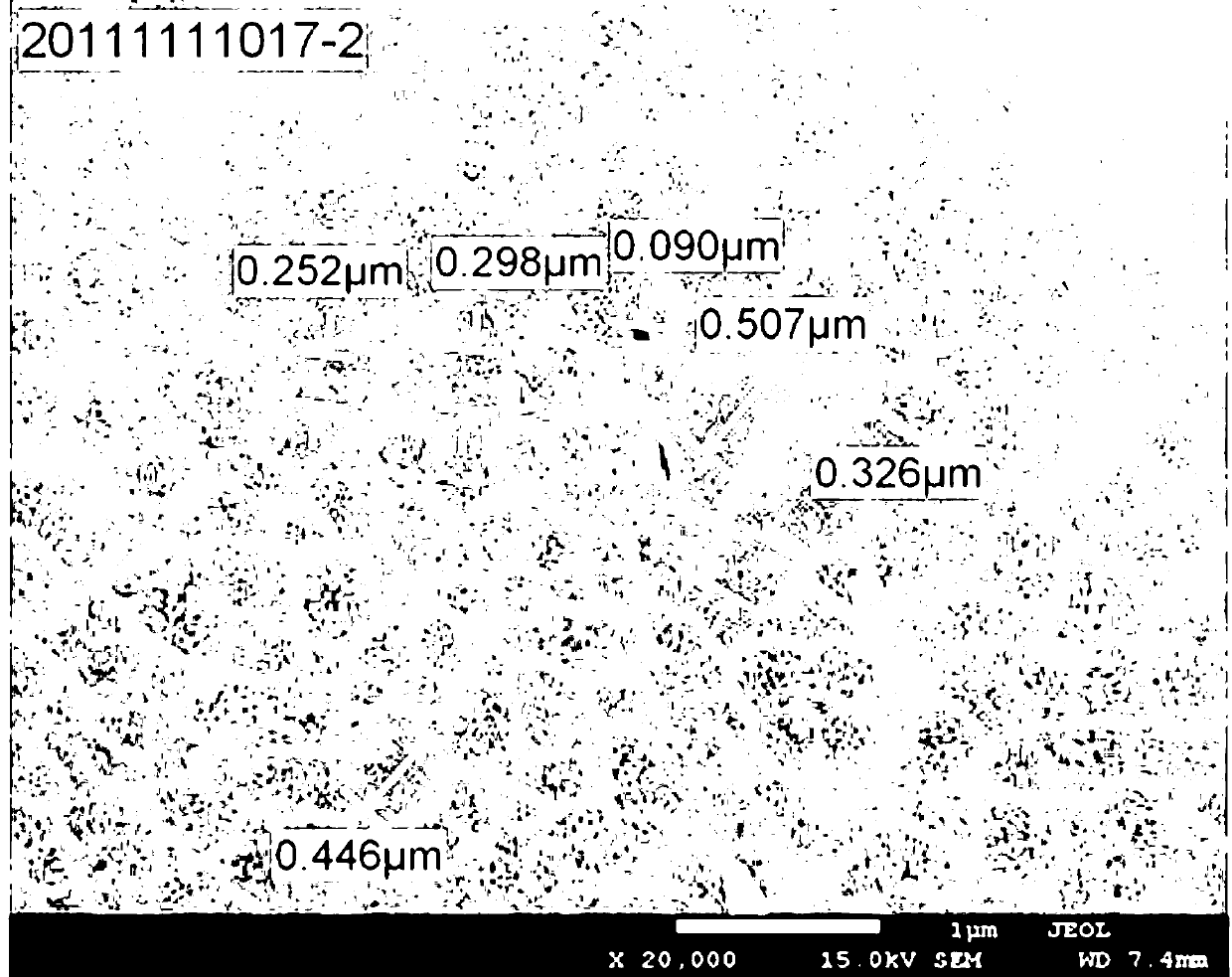

[0059] The same method as in Example 1 was used to prepare the mobile phone casing, except that the surface treatment 1 was to put the above-mentioned aluminum alloy casing body as an anode into H 2 SO 4 In the anodizing tank, electrolyze at 15V and 18°C for 10min, and blow dry. Adopt the same method as claim 1 to measure the surface of the aluminum alloy shell body after electrolysis to make a 5um thick aluminum oxide film layer, which contains nano-micropores with a pore size of 20-40nm, and the pore depth of the nano-micropores It is 1um. It is measured that there are corrosion holes with a diameter of 300-1000nm on the surface of the main body of the aluminum alloy shell after soaking, and the depth of the corrosion holes is 4um. It can be observed that there are such as figure 1 The structure shown is similar to the double-layer three-dimensional hollow structure, and there are interconnected structures in the nanopores and corrosion pores.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com