Amorphous alloy transformer core forming template and forming device

A technology of transformer iron core and amorphous alloy, applied in the field of transformers, can solve the problems of delayed production progress, time-consuming and labor-intensive, overall weight increase, etc., and achieve the effect of improving material utilization rate, simple and convenient operation, and speeding up production progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

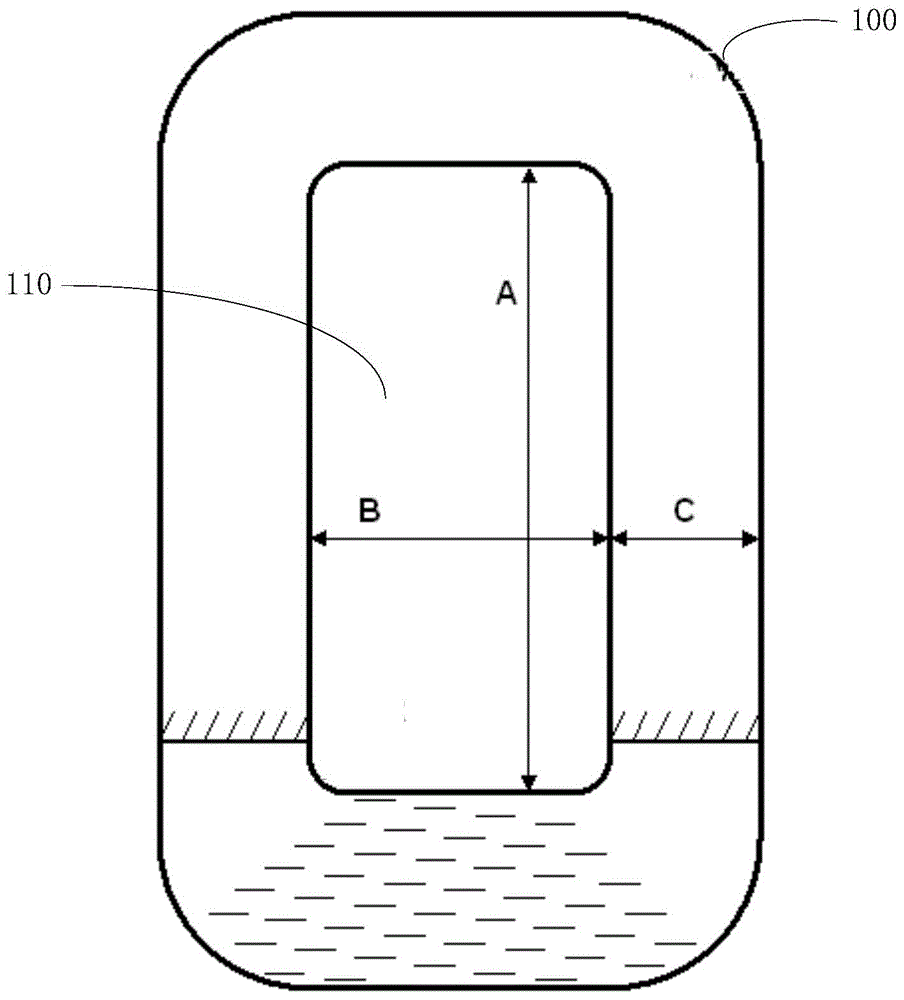

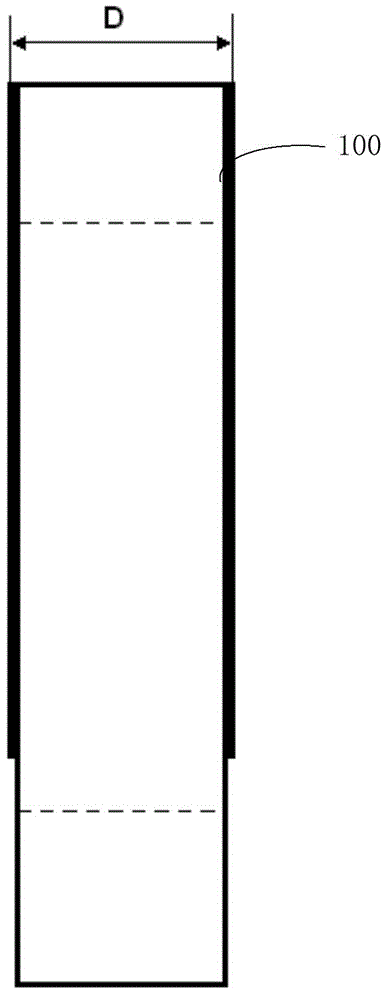

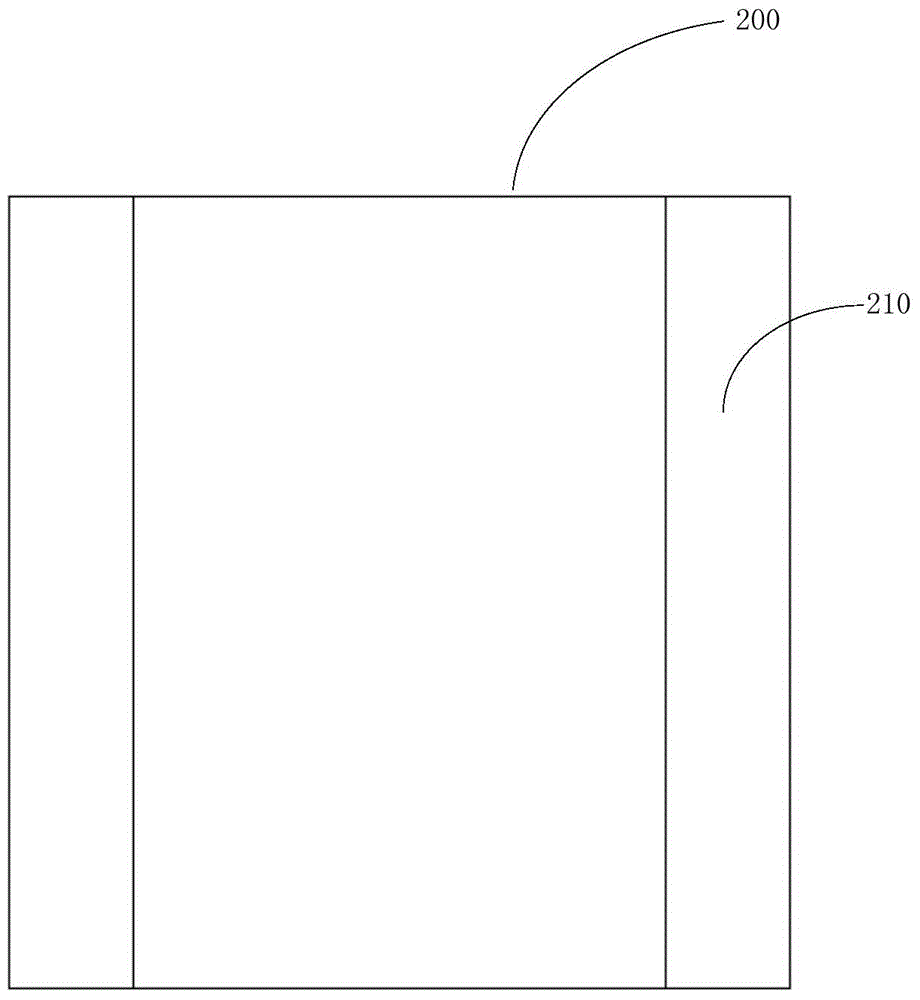

[0030] Considering that the overall weight of the existing molded iron core plus the weight of the formwork increases, it is more difficult to carry the iron core, which is time-consuming and labor-intensive, which affects the production progress of the iron core, and the formwork is made of metal materials. The use of a large amount of material increases the cost of the formwork, and the size is fixed, and the adaptability is poor. Different size formworks are required to produce iron cores of different sizes. Therefore, the present invention adopts a thin design on the formwork, and uses a limiting columnar bar instead The groove structure on the edge of the formwork saves the use of metal materials, greatly reduces the weight of the formwork, and facilitates handling. In addition, multiple formworks can be spliced to meet the needs of different iron cores, saving costs and improving production efficiency. .

[0031] In order to more clearly illustrate the embodiments of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com