Adjustable type amorphous alloy transformer winding die and manufacturing and use method

An amorphous alloy, winding die technology, applied in the direction of inductance/transformer/magnet manufacturing, coil manufacturing, electrical components, etc. problem, to achieve the effect of low cost, reduce inventory and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

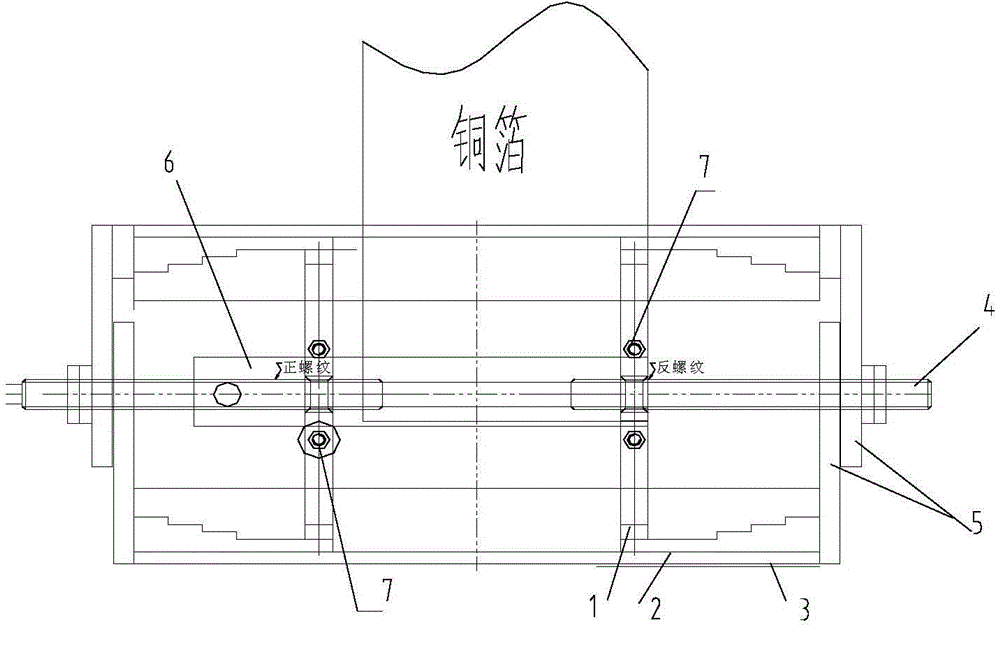

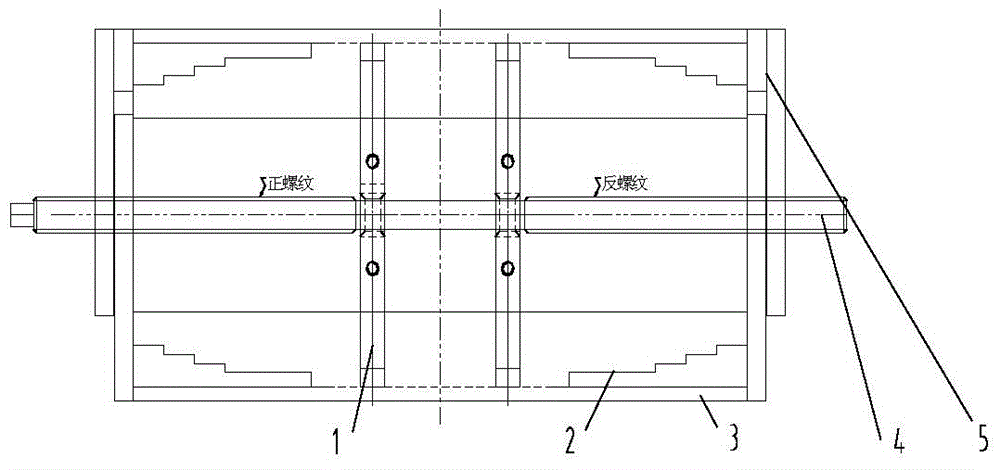

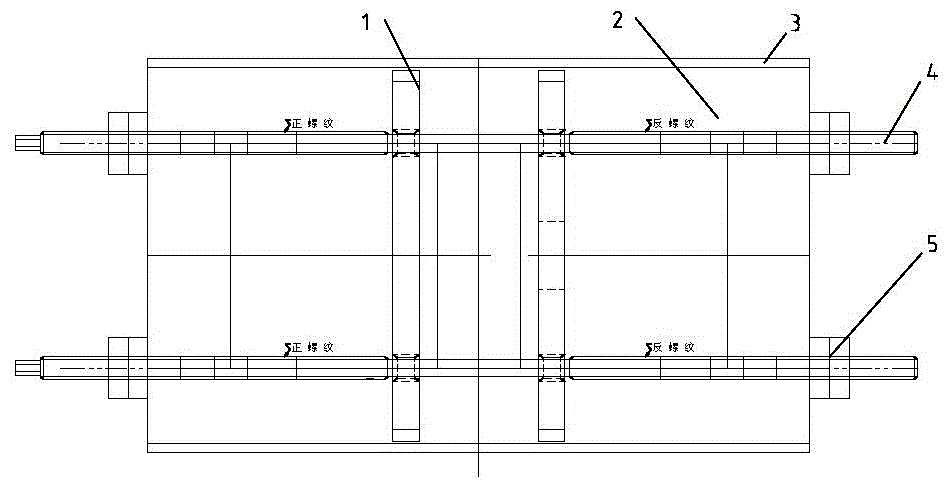

[0017] An adjustable amorphous alloy transformer coil winding die of the present invention includes an adjustable low-voltage winding die, a high-voltage support die and a wooden block for shaping, and the adjustable low-voltage winding die has two sets of positive and negative threaded lead screws 4, Support plate 1, panel 3, 8 pads 2, fixed plate 5, characterized in that the structure of the adjustable low-voltage winding die: panel 3, pad 2 and fixed plate 5 are components, see Figure 4a ~b, two parallel support plates 1 passed through by 2 forward and reverse screw screws 4 are perpendicular to the middle of the wide side of the panel 3, and the two forward and reverse screw screws 4 are perpendicular to the panel 3 of the lower assembly Place the wide end, fasten the two components up and down, adjust the support plate 1 to the step of the spacer 2 with the required size of the coil through the positive and negative threaded screw 4, and tighten it with a nut, see Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com