Body of shell type amorphous alloy transformer

A shell-type transformer, amorphous alloy technology, applied in the direction of transformer/inductor shell, transformer/inductor magnetic core, transformer/inductor coil/winding/connection, etc. Force deformation and other problems, to achieve the effect of reducing electromagnetic force, large capacitance between cakes, reducing oil volume and floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

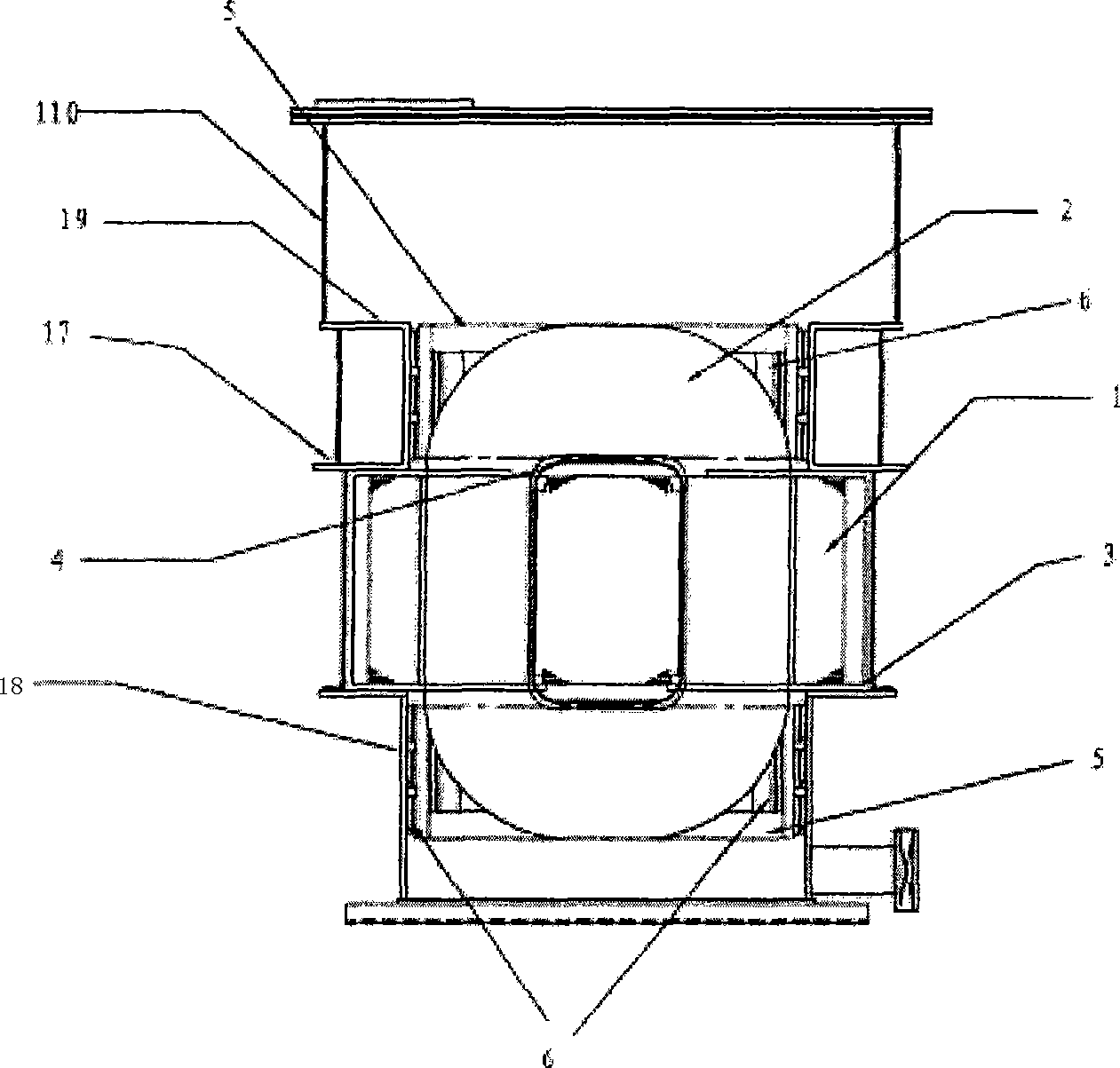

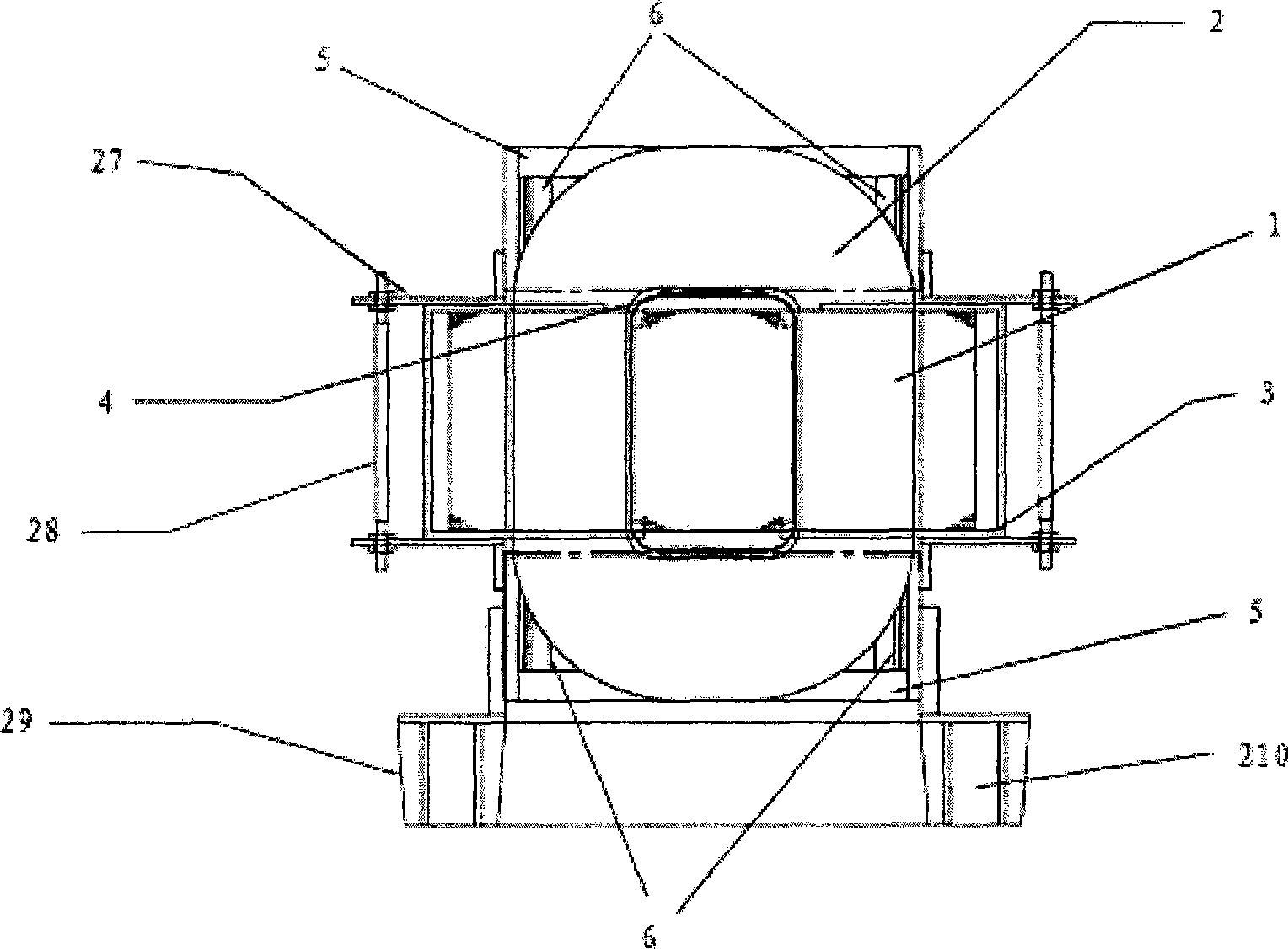

[0031] figure 1 It is the first embodiment of the present invention: a shell-type amorphous alloy transformer with an oil tank or an air tank. Here, the transformer oil tank can be transformer oil or high temperature resistant oil; if gas insulation is used, the gas tank can be sulfur hexafluoride gas, or fluorocarbon gas, or inert gas, or compressed air, or nitrogen, or carbon dioxide gas, etc. .

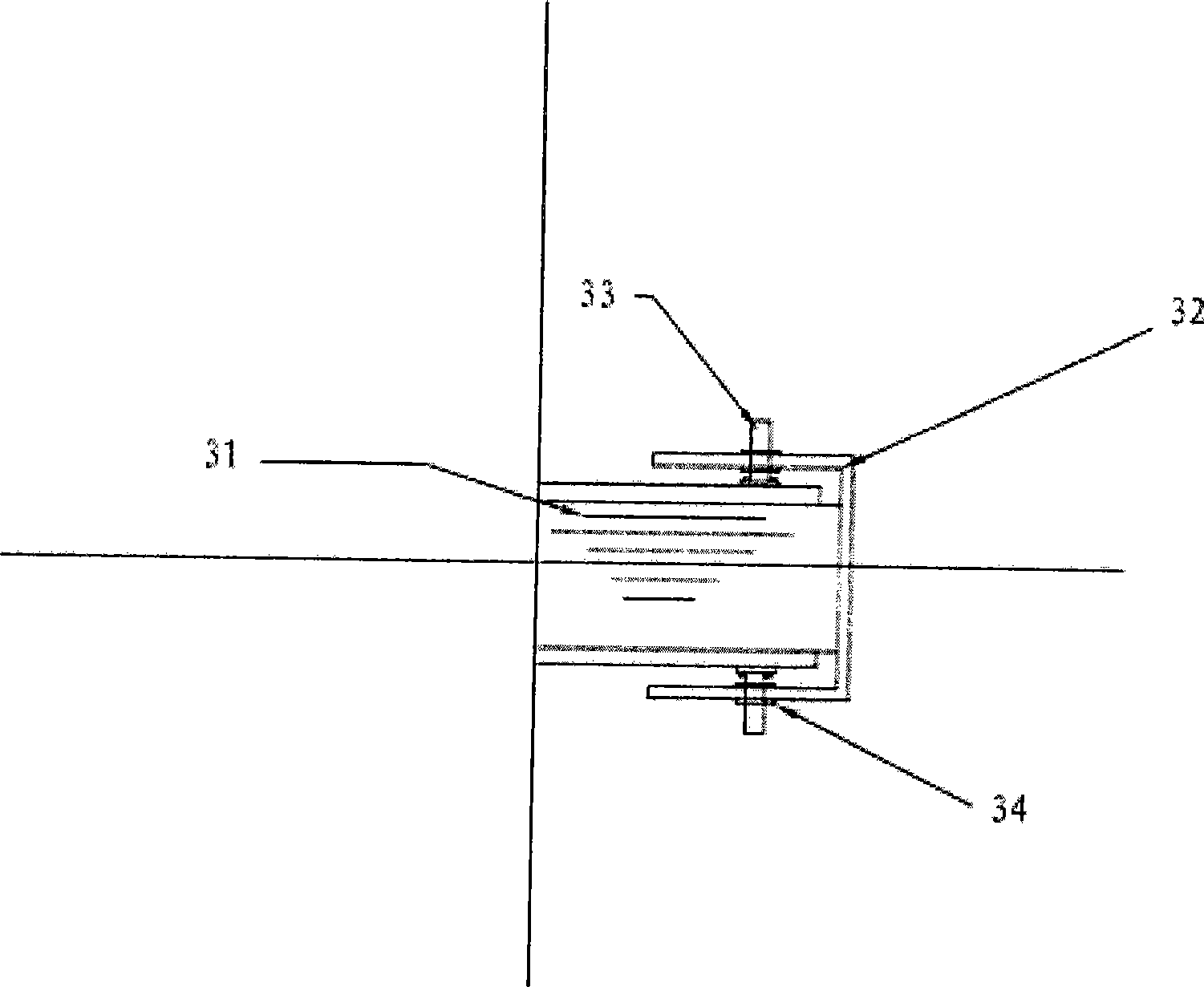

[0032] Such as figure 1 As shown, the amorphous alloy shell core 1 of this embodiment is formed by winding an amorphous alloy strip, and has a rectangular cross section. The structure of the amorphous alloy shell core 1 can be Figure 4 The common three-phase shell-type iron core structure shown, that is, the iron core columns are connected in series in the three-phase windings, and the iron yoke between the phase windings has only one magnetic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com