Patents

Literature

170 results about "Narrow face" patented technology

Efficacy Topic

Property

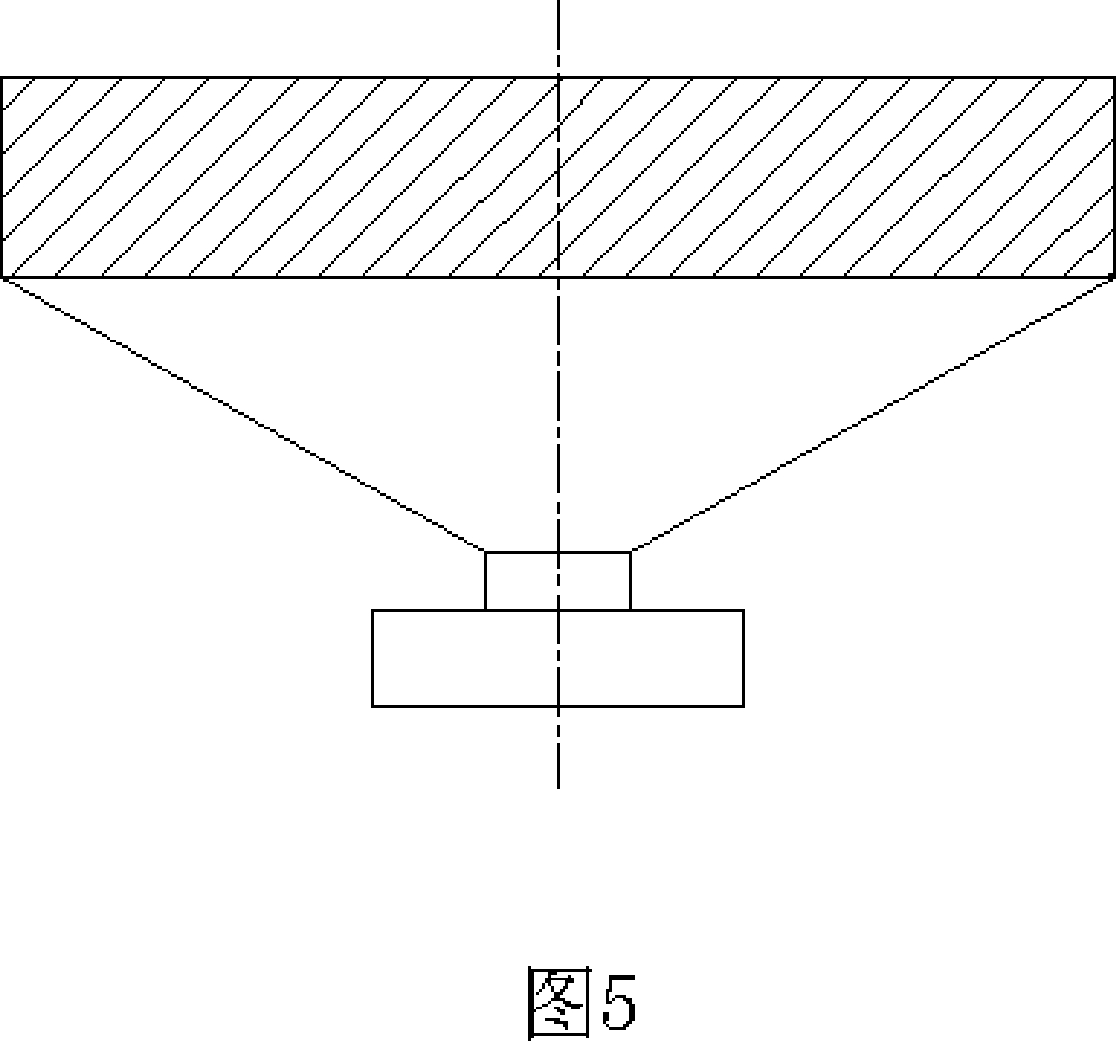

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

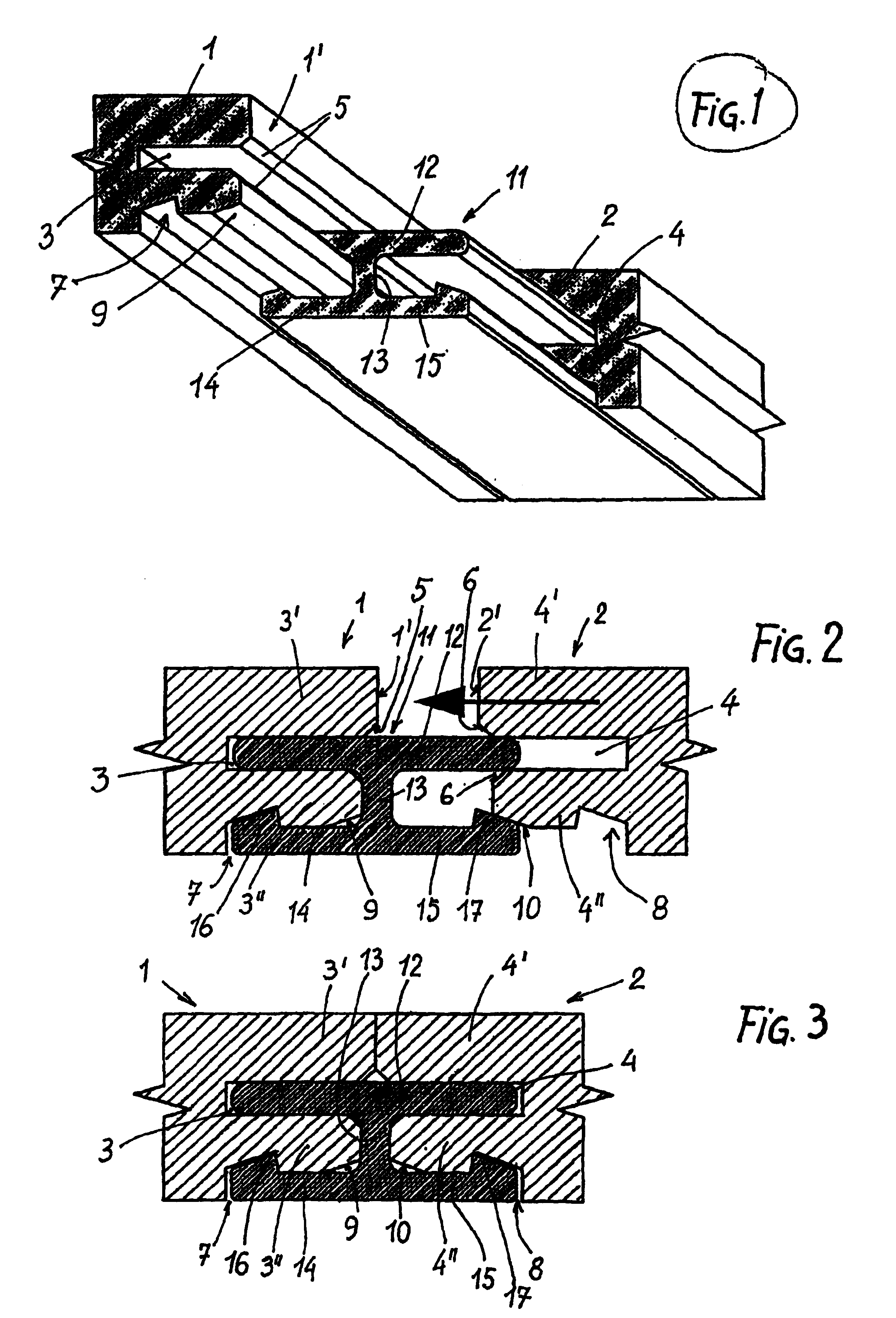

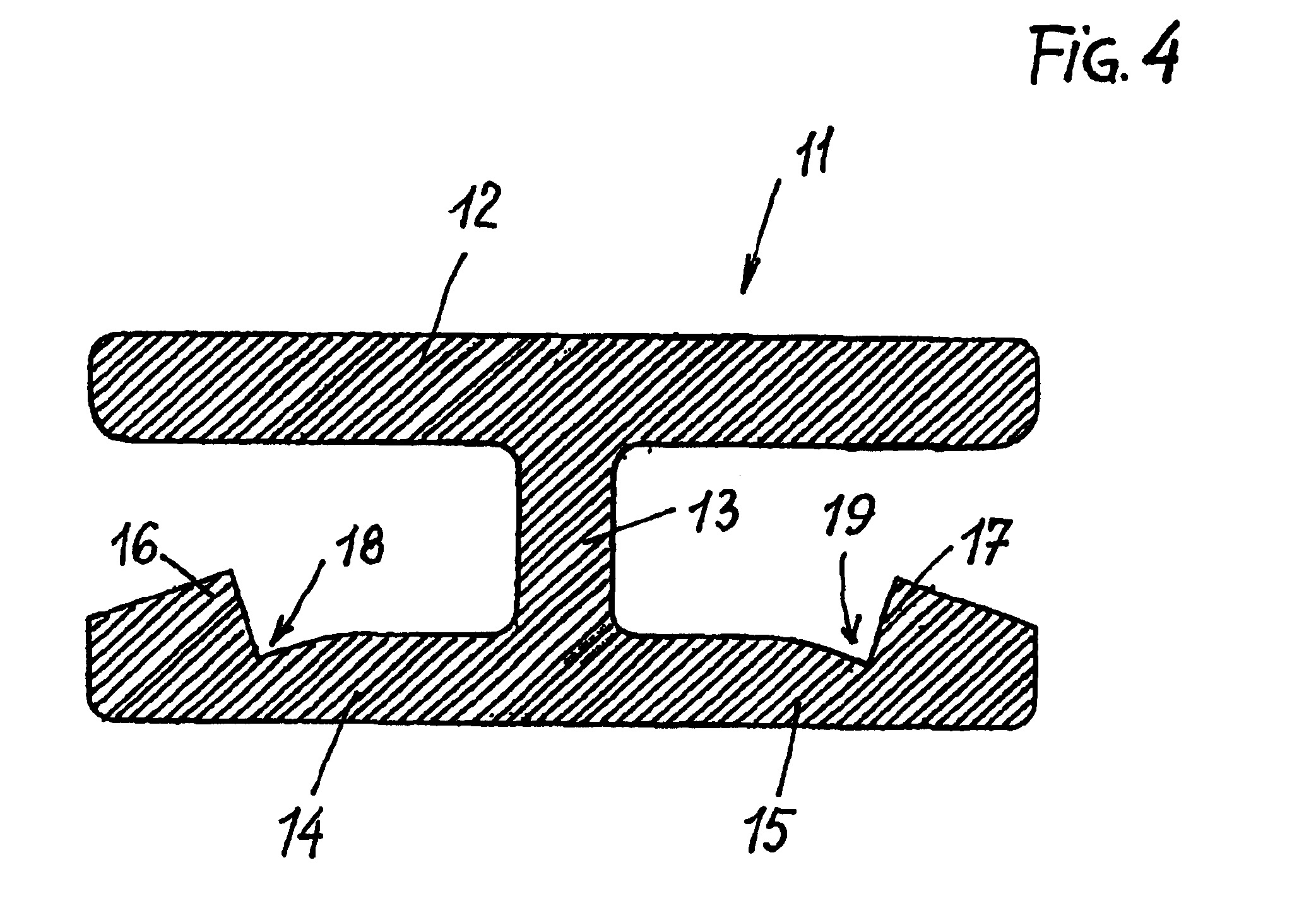

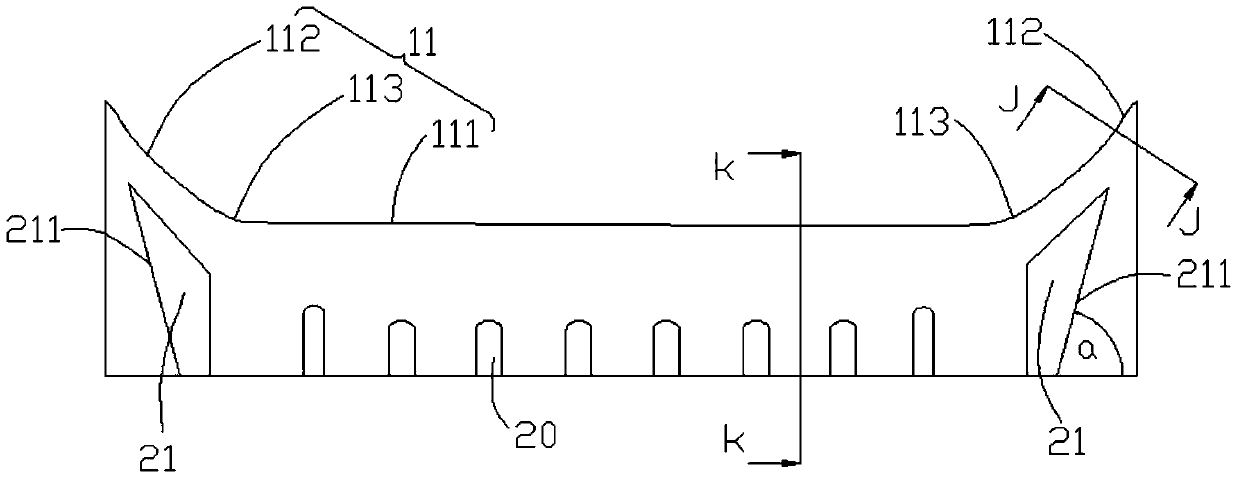

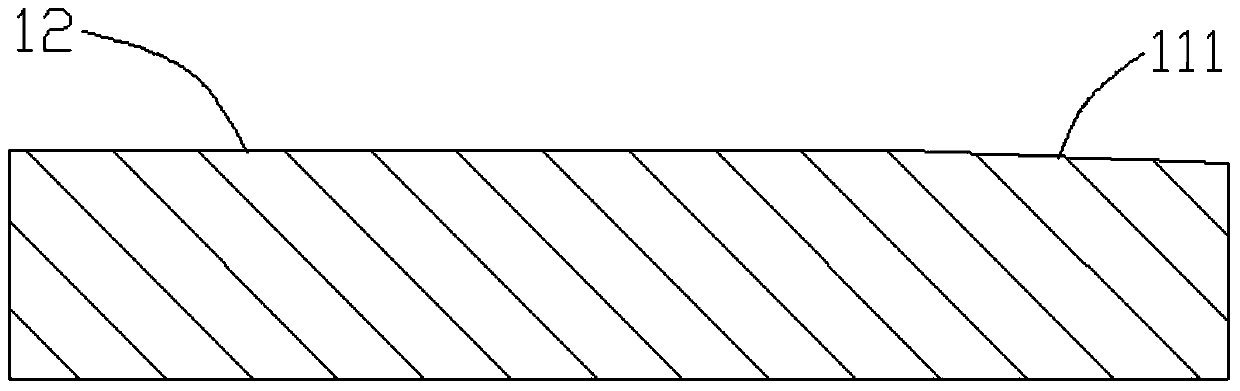

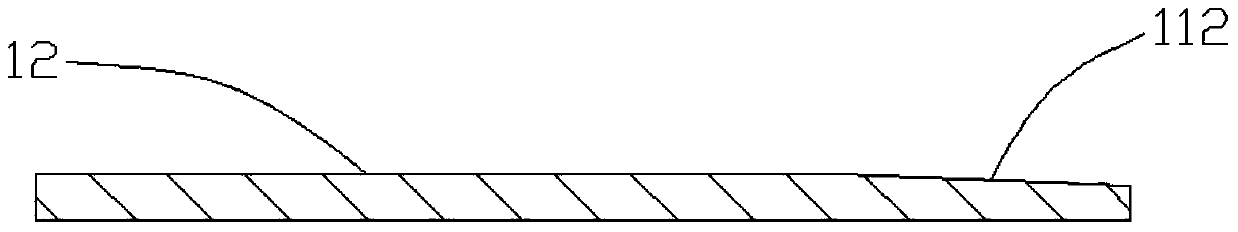

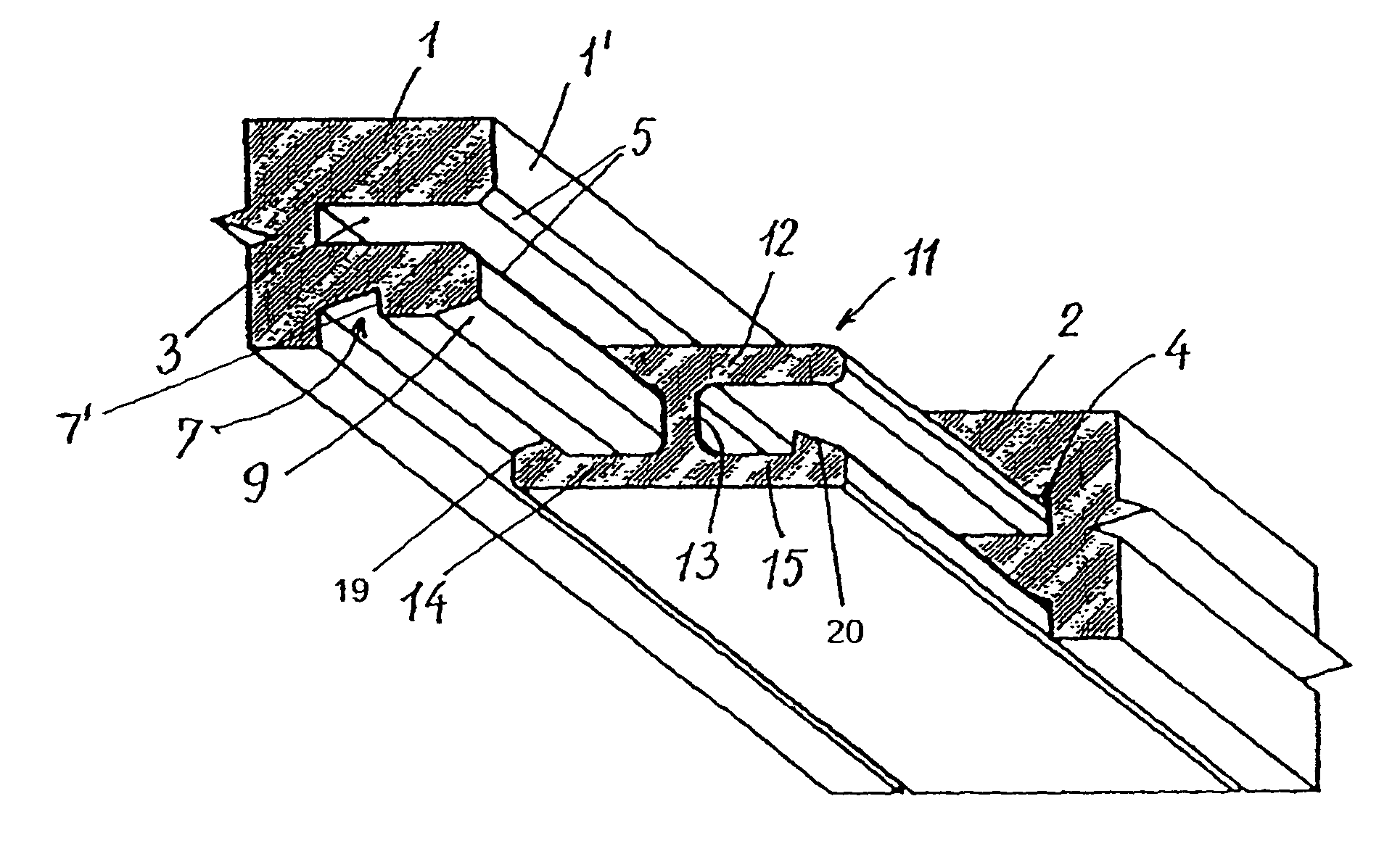

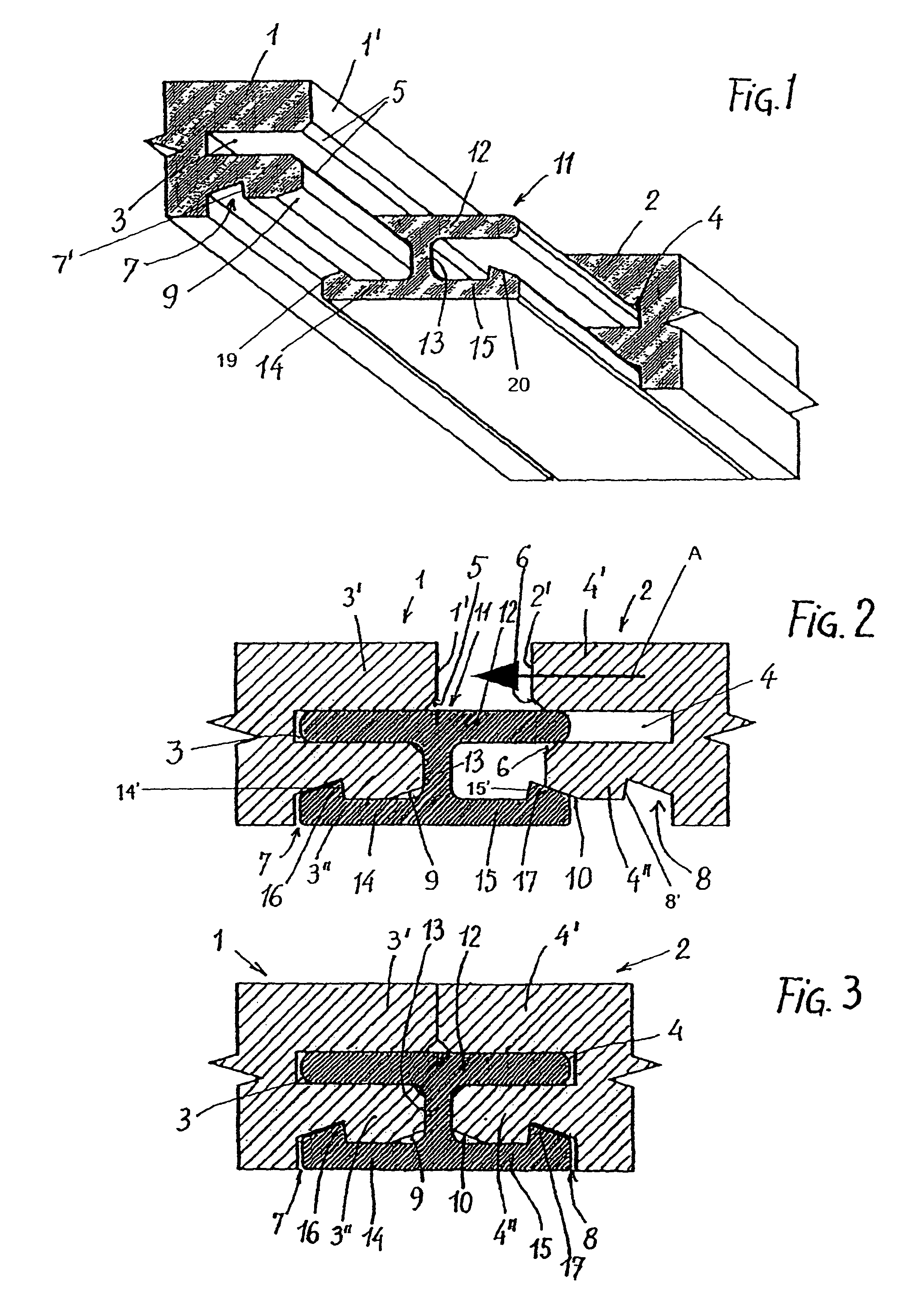

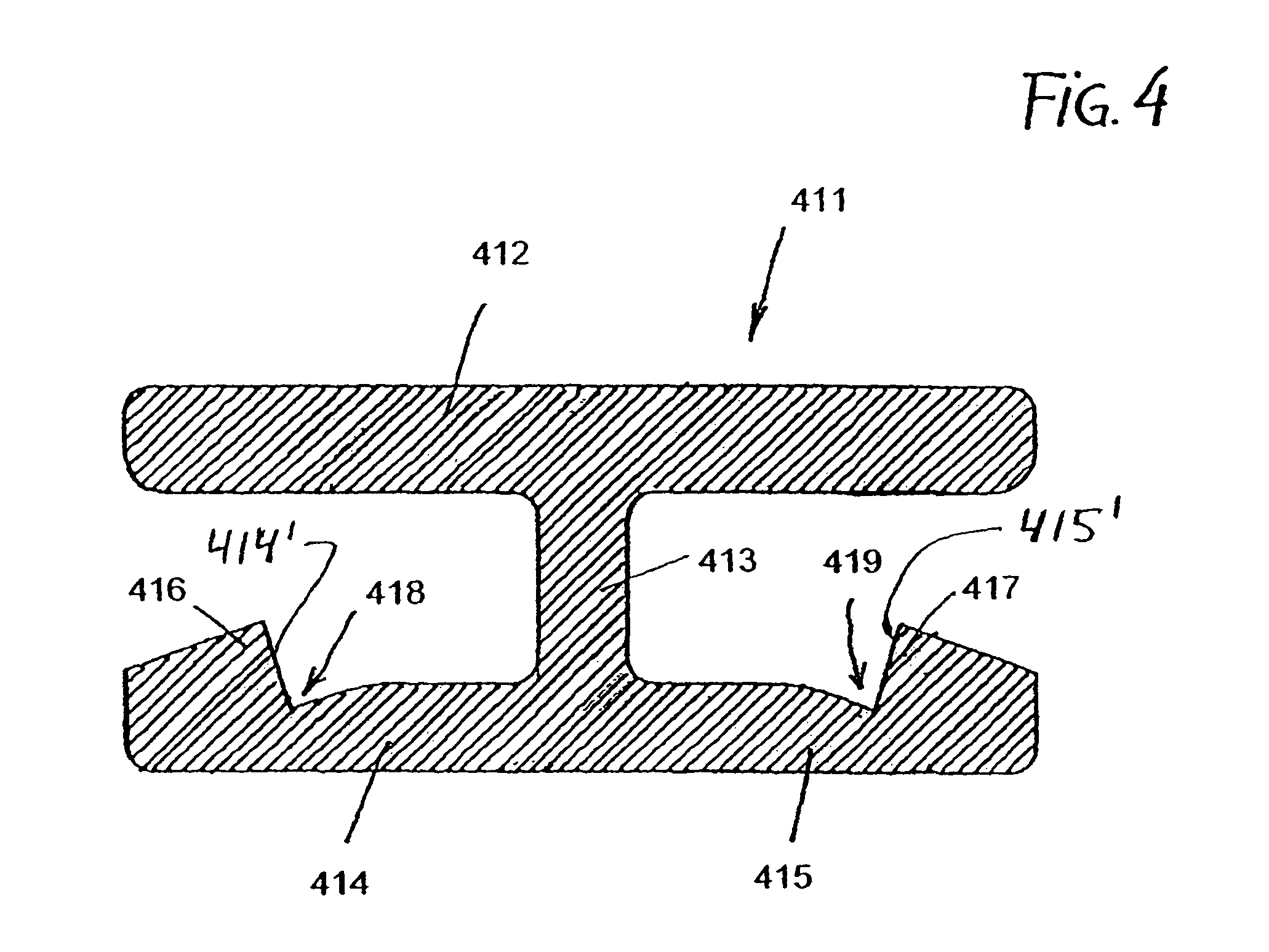

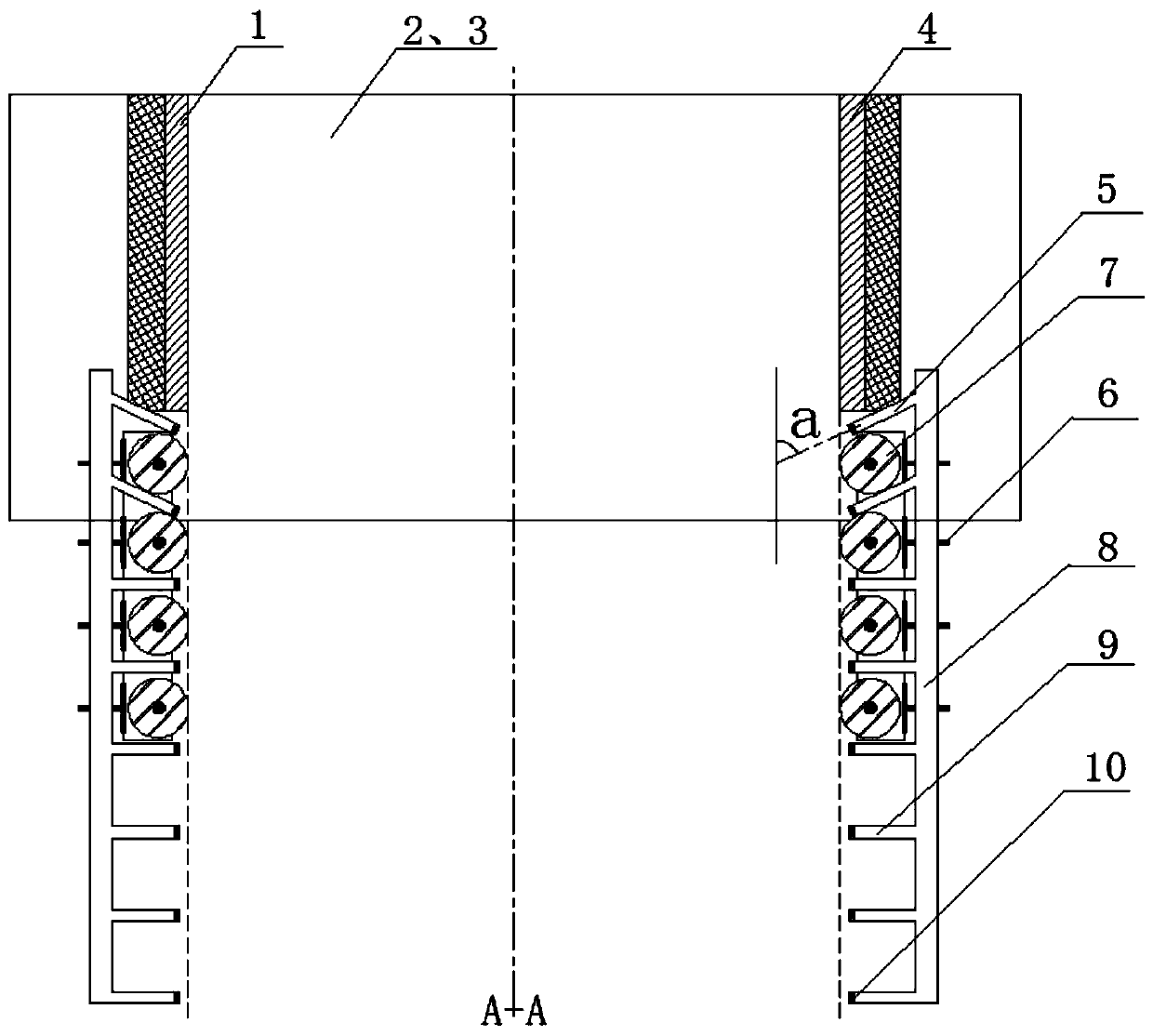

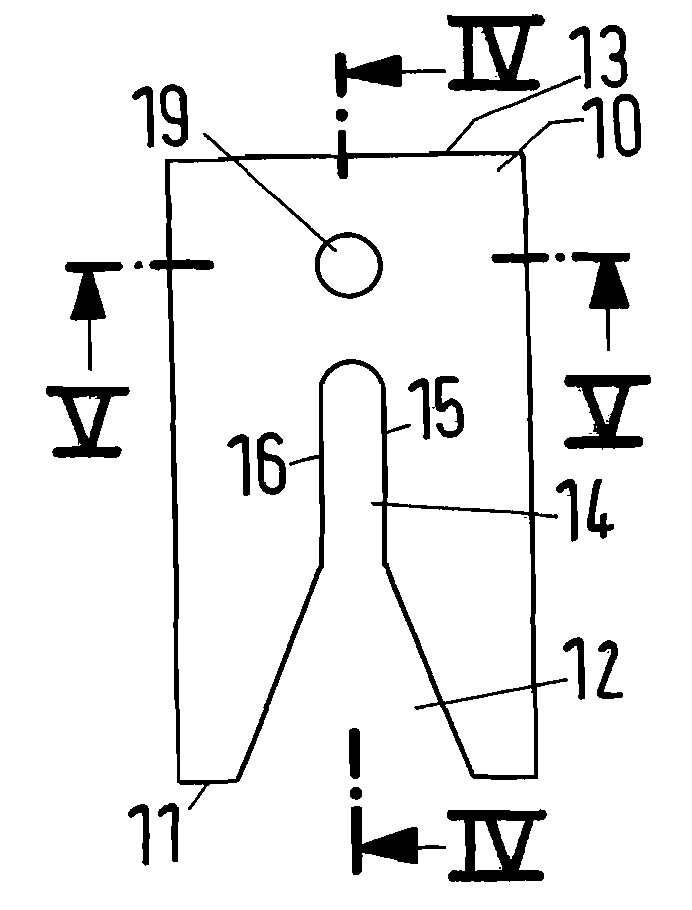

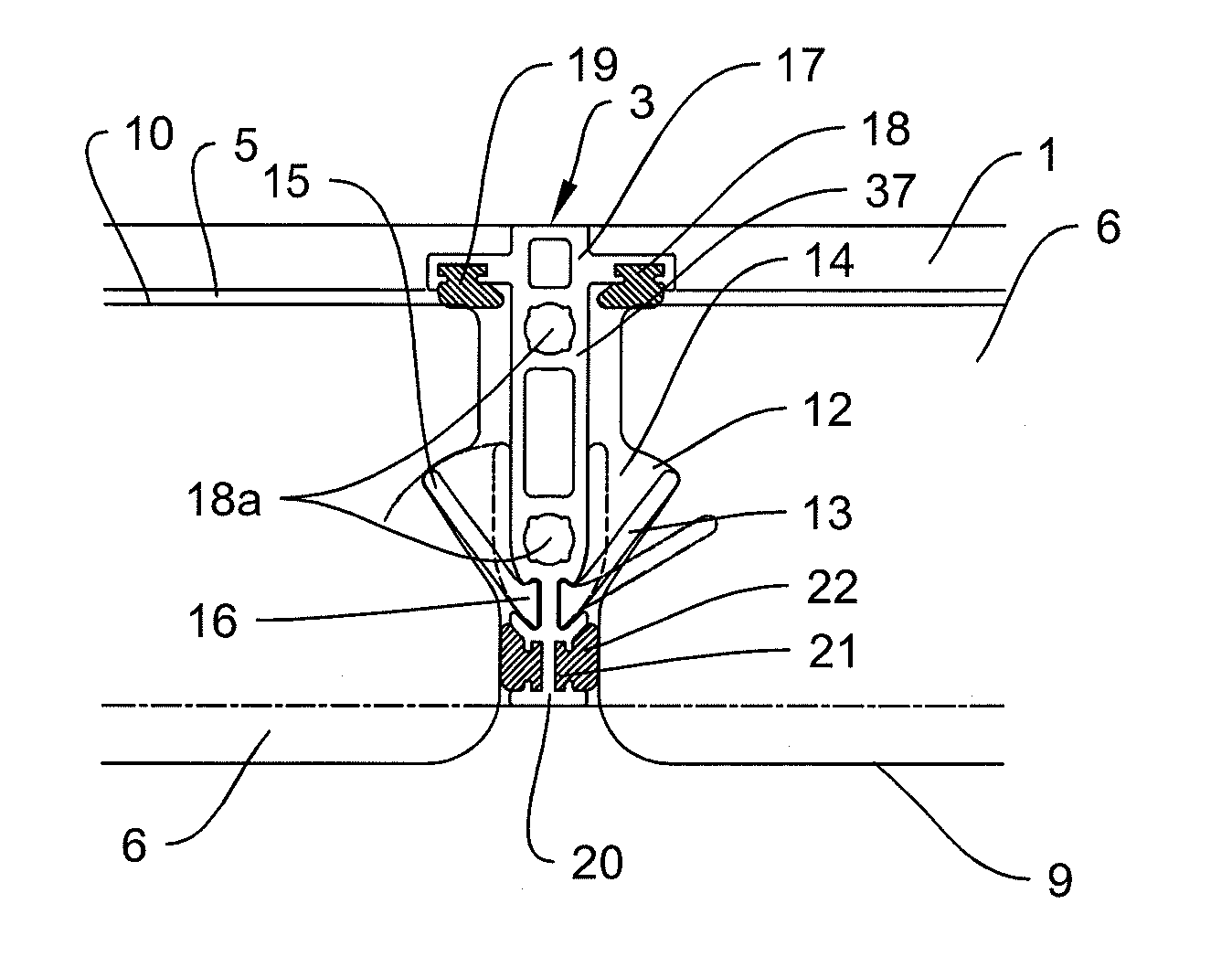

Device for joining flat, thin members that rest against another

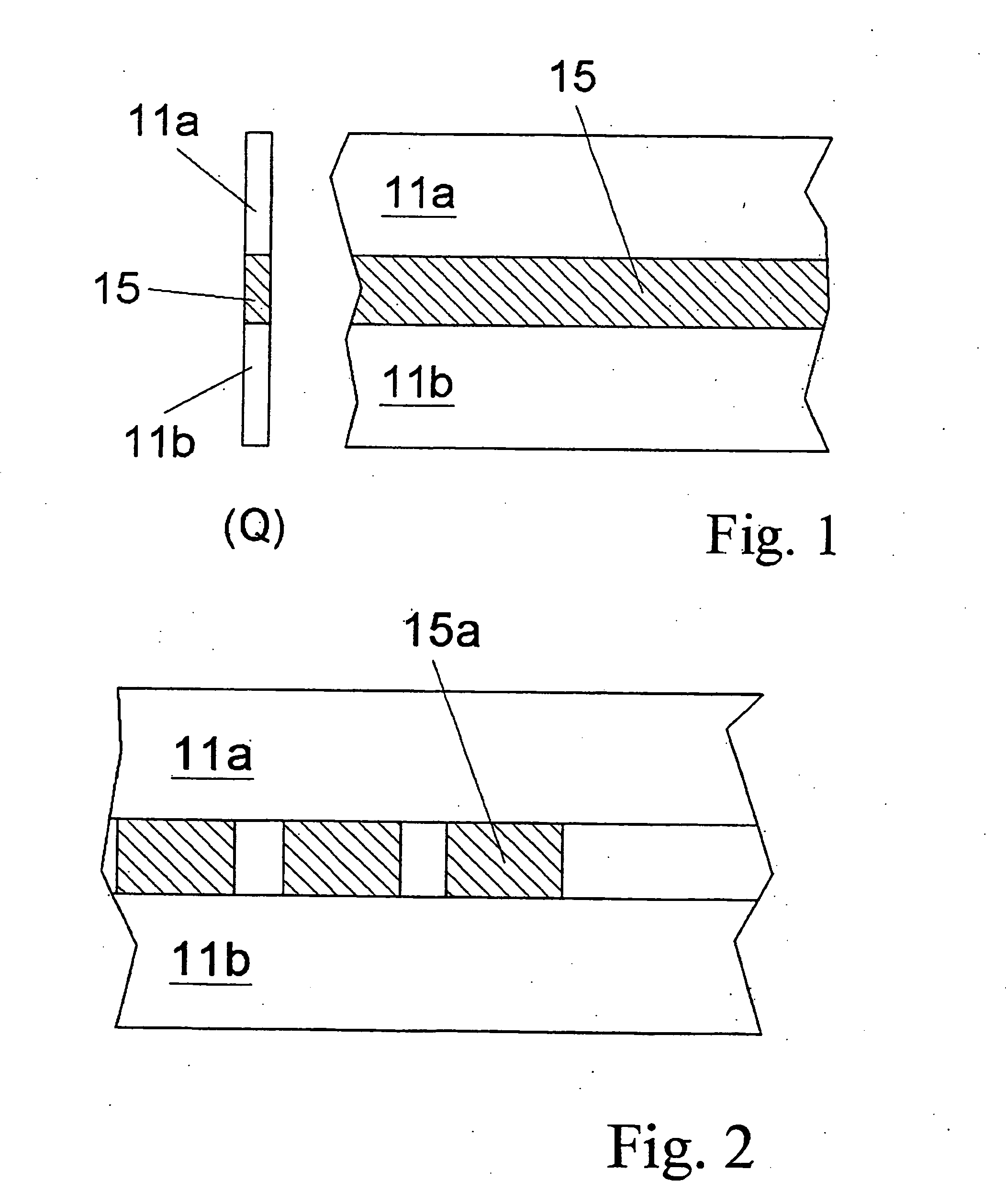

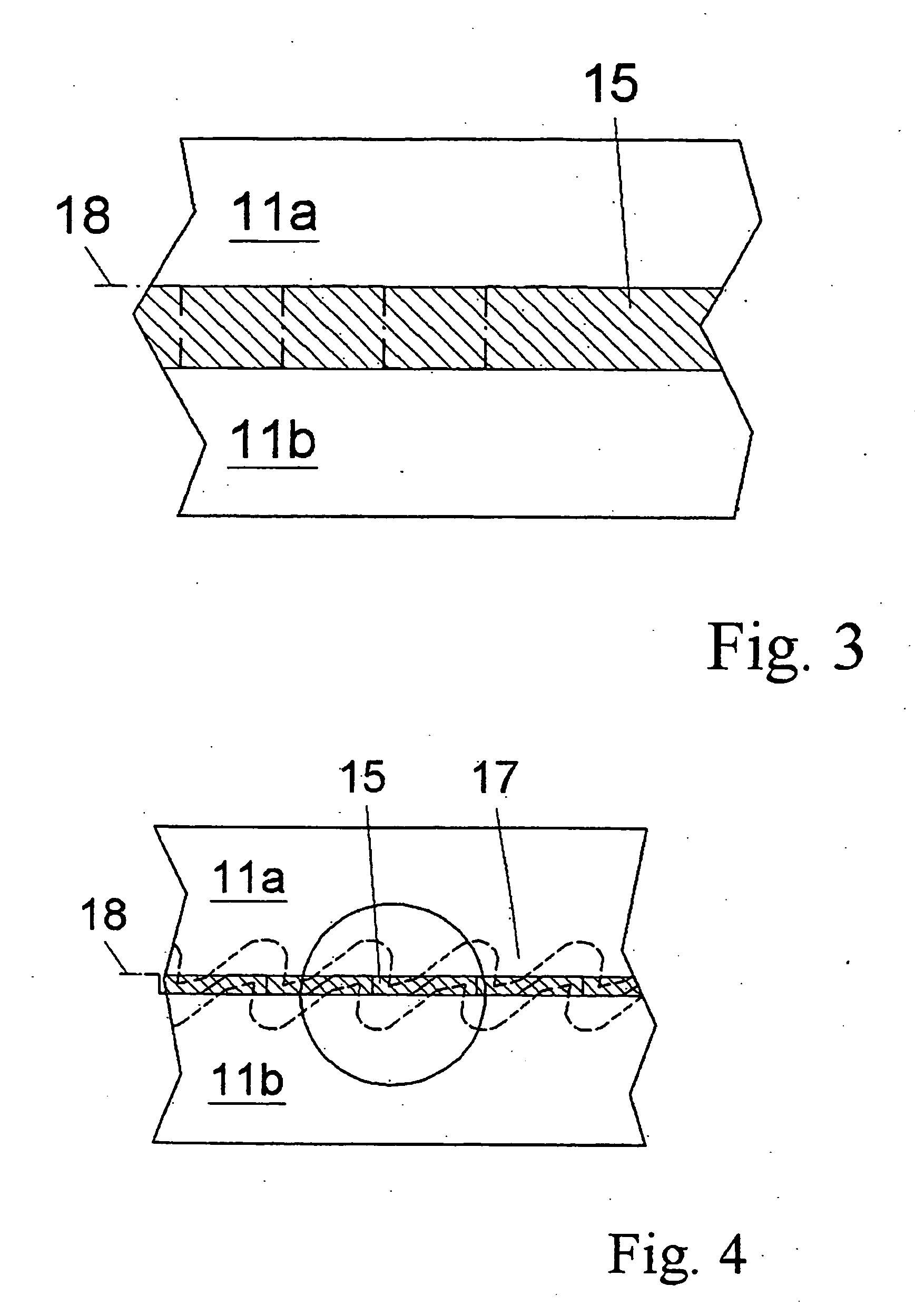

The system relates to a system for joining flat, relatively thin members that adjoin one another along their narrow face, the members having grooves incorporated into the narrow faces that are parallel to the surface and have groove walls that are parallel to each other, and the joining element being inserted into the grooves of two adjacent members and bridging the partition gap between the members in the manner of an external tongue. In this context the joining element (11) has, on its part (12) that can be inserted in the manner of an external tongue in the longitudinal center on its side that faces away from the visible surface of the members, one continuous web or a plurality of aligned webs (13) that preferably protrude at a right angle, from which detent webs (14, 15) protrude on both sides, each of which has a detent projection (16, 17) that projects toward the external-tongue-like part (12), and on the bottom of the member (1, 2), which faces away from its visible surface, detent grooves (7, 8) being provided that run parallel to the adjacent edge at a distance corresponding to the width of the detent webs (14, 15).

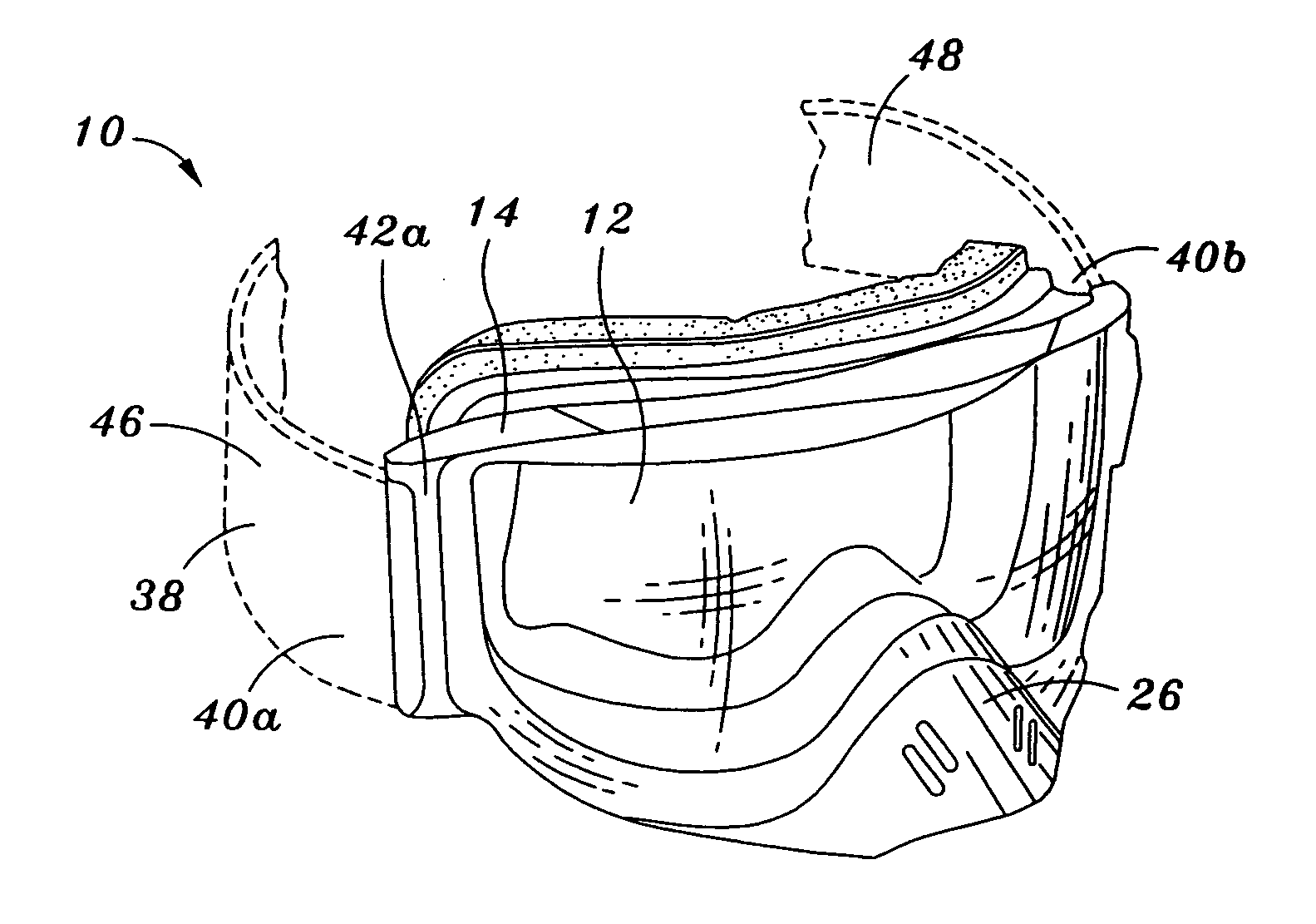

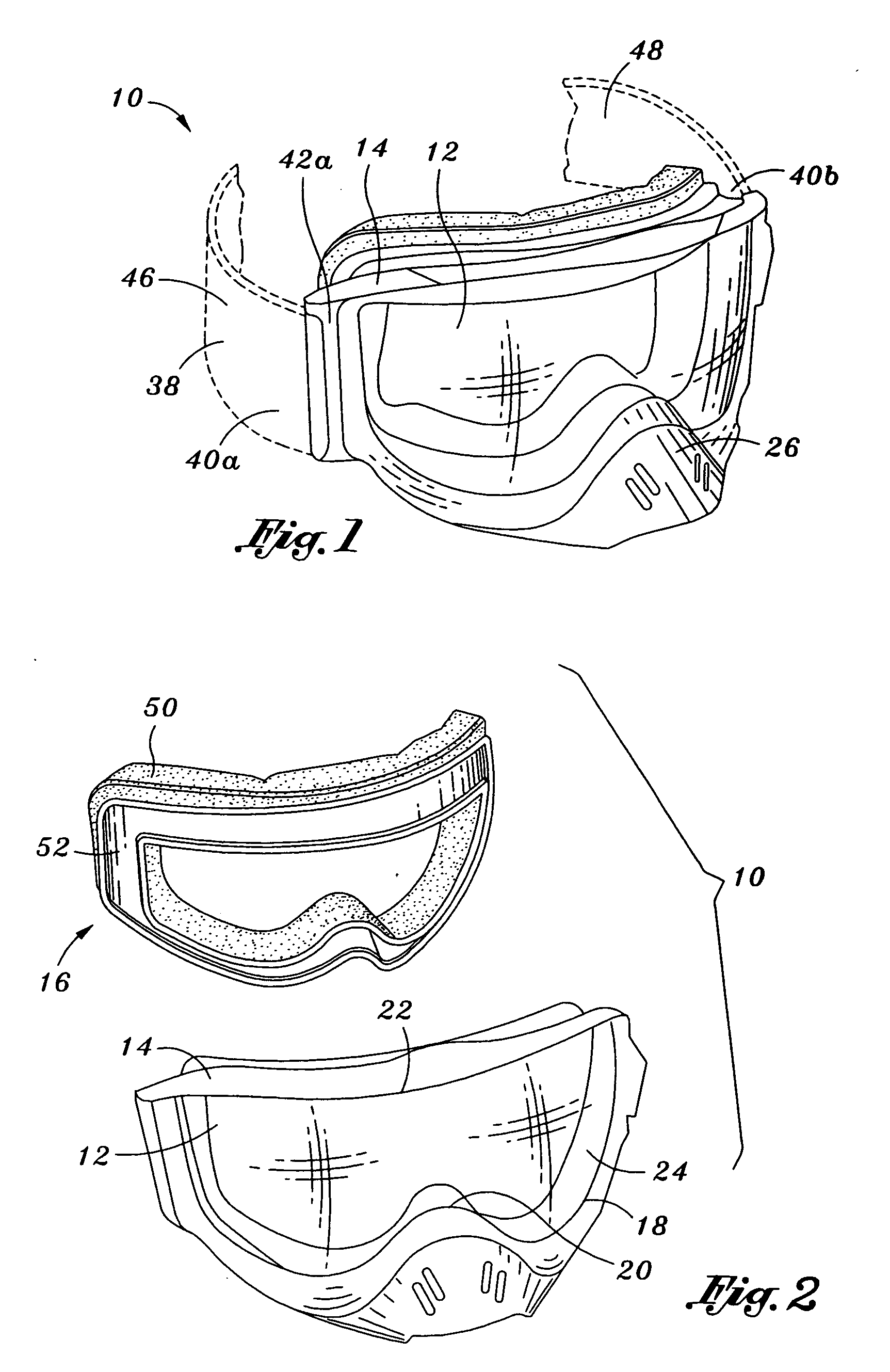

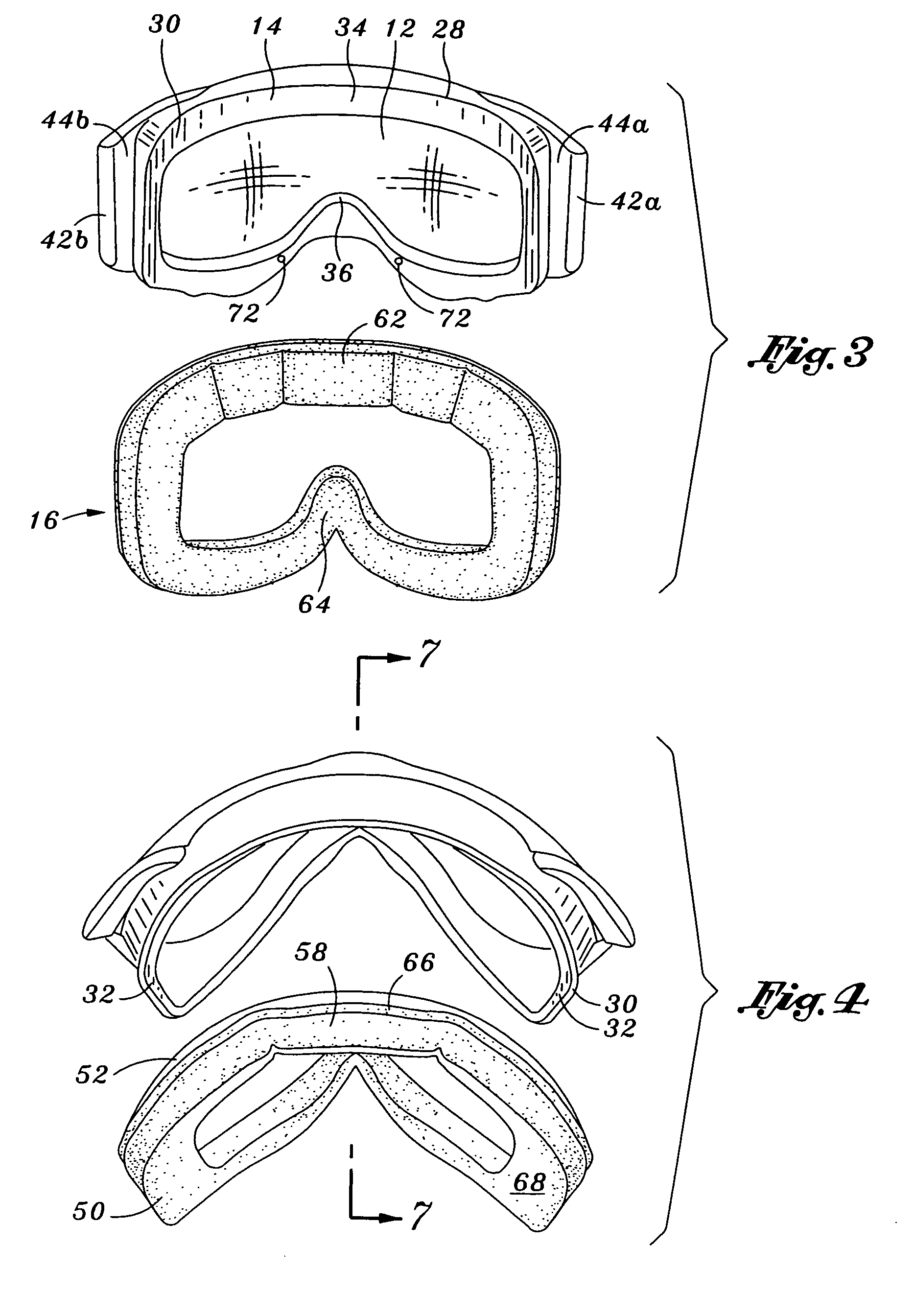

Goggle with removable foam lining

Provided is a goggle comprising a face shield attached to a first subframe and a foam assembly having a foam element and second subframe. The foam assembly is removably attachable to the first subframe such that variously configured foam assemblies are interchangeable with the first subframe and face shield. More particularly, the foam element may define a proximal surface that is sized and configured to fit a wide face, a narrow face, a short face, a long face and / or various combinations thereof. Also, the foam assembly may be sized and configured to be compatible with different helmets. A plurality of these variously configured foam assemblies may be provided with a single first subframe and face shield such that a wearer may select a desired face shield and an appropriate foam assembly in order to accommodate the wearer's uniquely shaped face and / or helmet.

Owner:SPY OPTICS

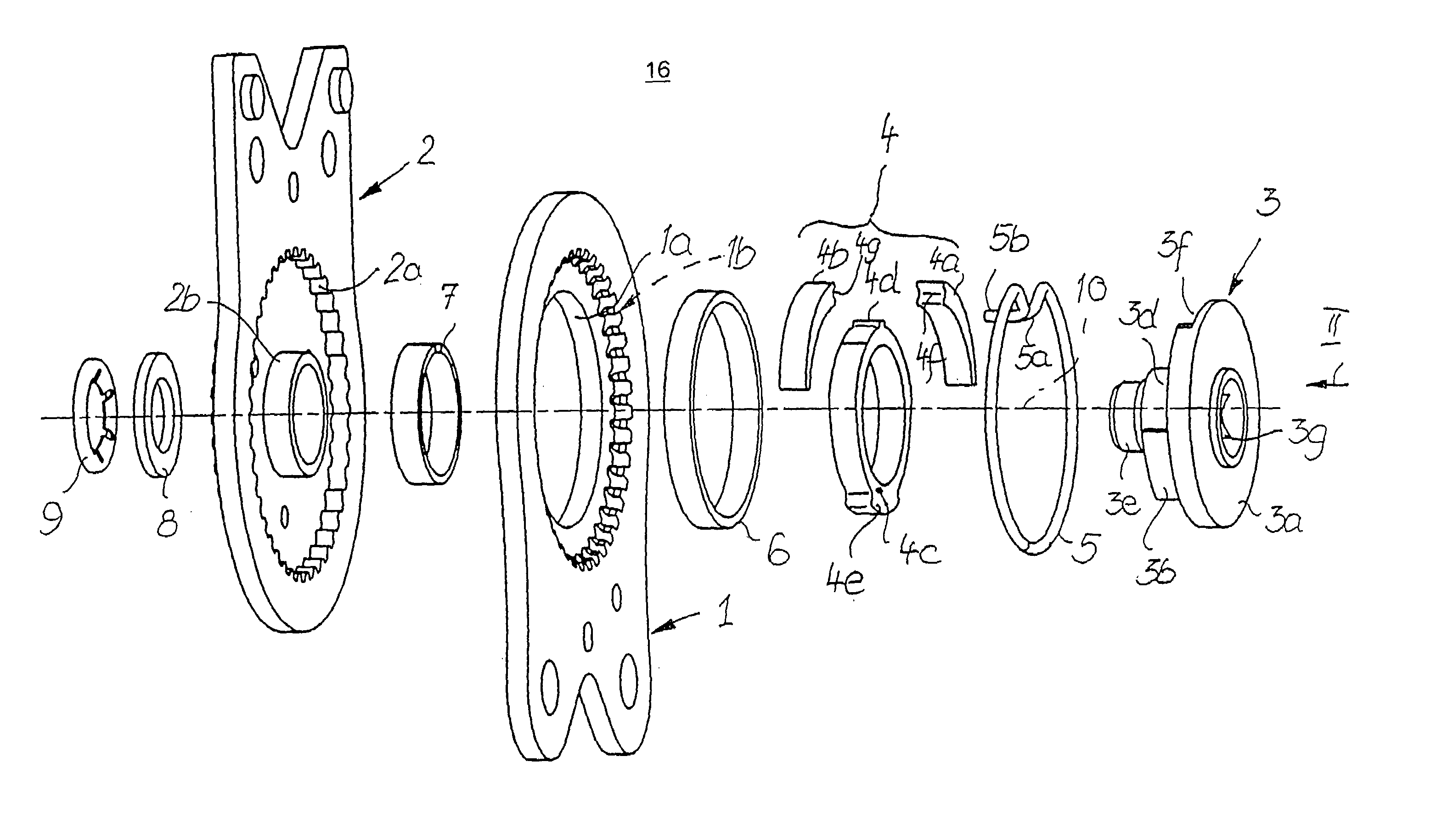

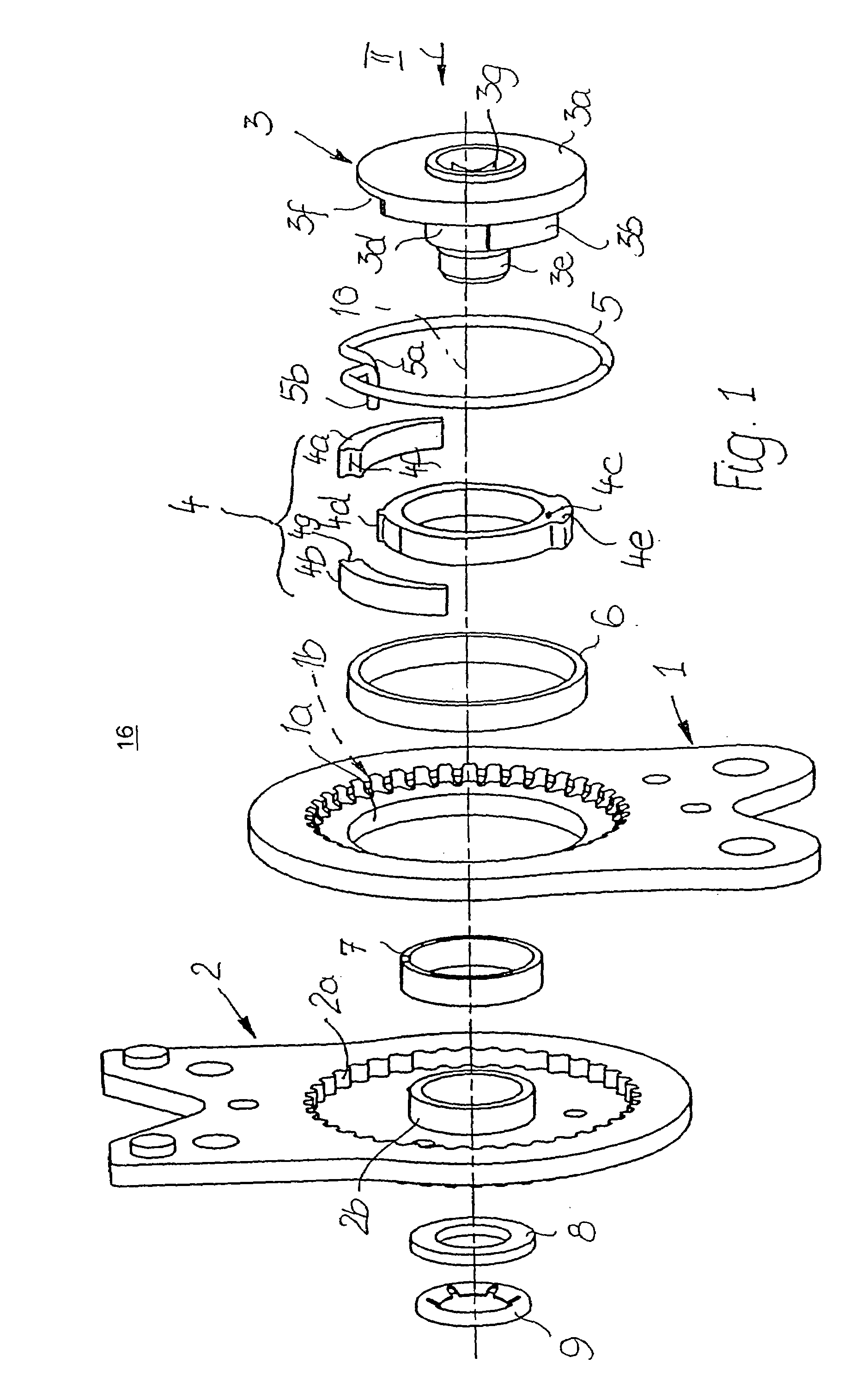

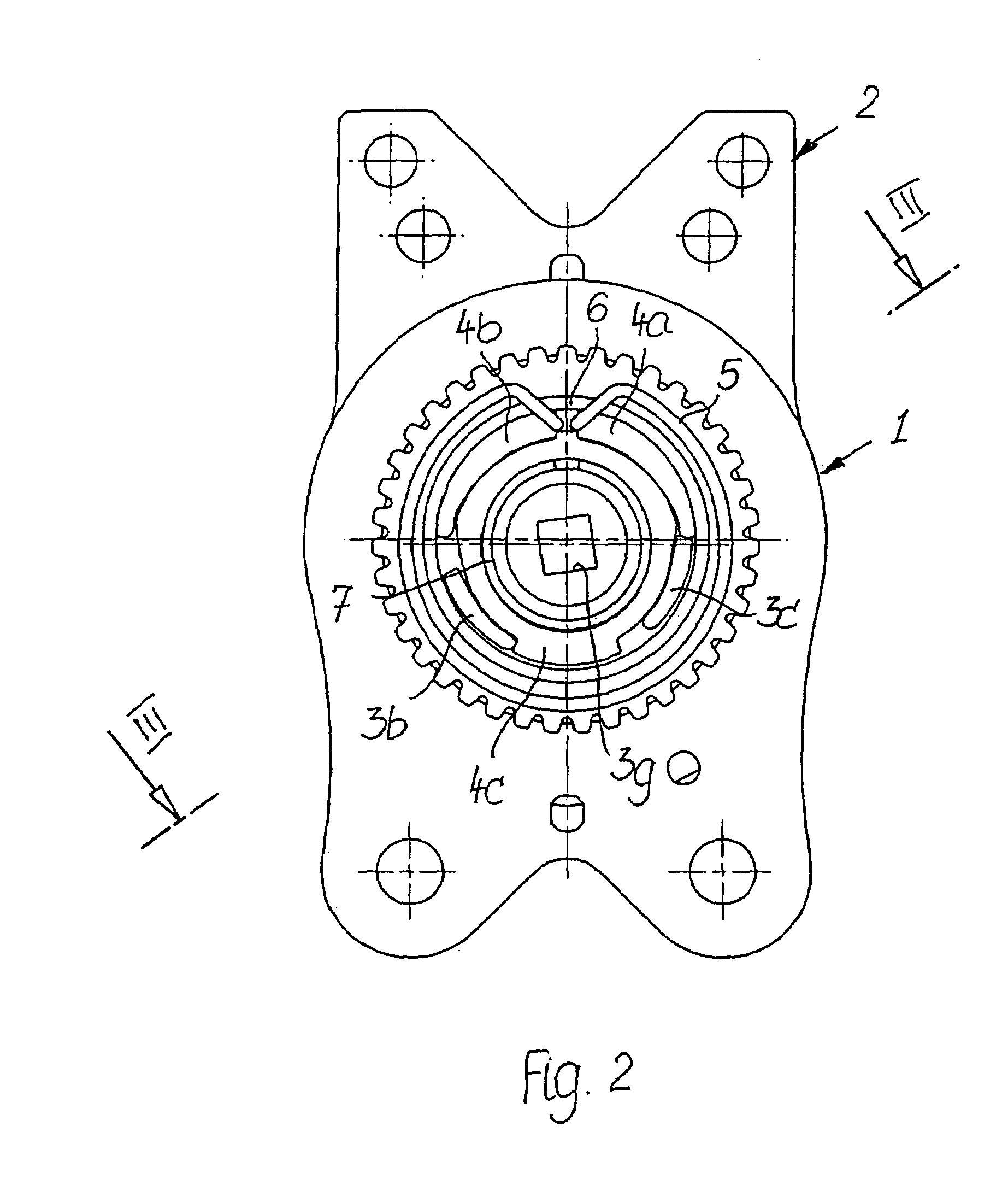

Adjustment fitting for a seat back

InactiveUS7090298B2Smooth rotationMotion continues easily and without chatterTime-division multiplexBearing componentsLocking mechanismNarrow face

An adjustment fitting for a seat such as an automobile seat including a fixed fitting operatively attached to a fixed seat area and a fitting that is operatively attached to a moveable seat area. The adjustment fitting is adjustable via a rotatable fitting. The fixed fitting part and fitting are connected together via a rotating adjusting device. Thus, an adjustment and locking mechanism that determines a position of the fixed fitting part and fitting with respect to each other provides a wobble drive. The rotating adjusting device includes a driven rotating adjusting element and an eccentric element rotatable about a swivel axis. The eccentric element includes crimped wedge segments having wide faces pushed apart by a spring. The eccentric ring is rotatable on a bearing shell with radial play that includes an outer bearing surface of Teflon. The bearing shell grips a collar of the fitting part that supports a collar of the driven rotating adjusting element so that it may rotate. The rotating adjusting element includes fixed followers that rest on the narrow faces of the wedge segments and are displaced with respect to the eccentric ring.

Owner:FAURECIA AUTOSITZE

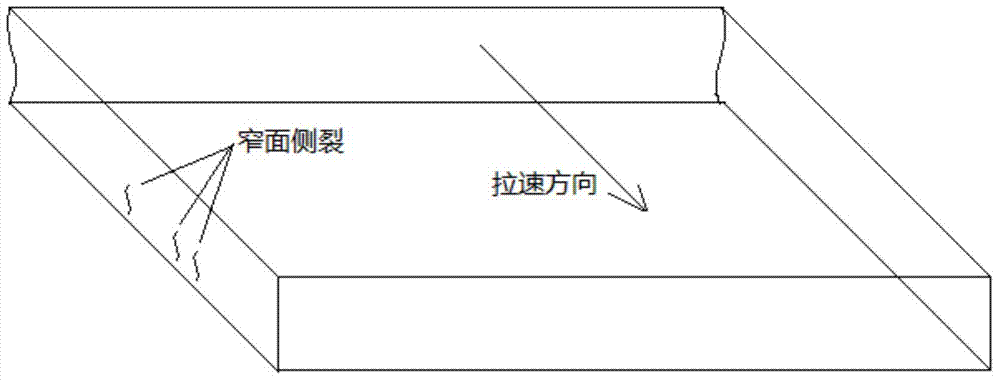

Method for controlling the cross crack of blank angle of high nitrogen steel casting board containing vanadium

The invention discloses a transverse crack control method of high nitrogen steel continuous casting plate billet angle containing vanadium, the method can not only effectively eliminate transverse crack defect of the continuous casting billet surface and skin inferior angle, but also can eliminate the continuous casting billet surface longitudinal crack and surface transverse crack defect. The method synthetically applies following technique measures: presetting the mold cooling water amount, the wide face cooling water amount is 3000-30500 L / min, the narrow face cooling water amount is set to 360-365 L / min; improving casting pulling rate, the casting pulling rate is stabilized in 0.8-1.5 m / min, the vibration frequency is 140-210 Hz; after spruing the casting pulling rate, quickly putting casting powder into the mold, the alkalinity of the casting powder is 1.0-1.40, the melting point is 1100-1160 DEG C, when at 1300 DEG C, the viscosity is 0.10-0.40 Pa.s; reducing the second cool segment casting billet cooling water amount, and controlling the continuous casting ratio water amount in 0.55-0.60 L / kg by static or dynamic adjusting method.

Owner:PANZHIHUA IRON AND STEEL

Fence with adjustable pickets and readily dismantlable

A fence is disclosed where the pickets are mounted on longitudinal pivots so that the pickets may be rotated to present the broad face, narrow face, or any angle between to the zone in front of the fence. Adjustment allows the setting of the opening for light and air passage or changing color or decoration by having different colors or scenes on the opposite sides. The fence is easily dismantled in all or part for repair, painting, or moving to another location. Wind rotated pickets are also described.

Owner:MOHR SYLVIA ANN

Preparation method of ultra-low carbon steel and ultra-low carbon steel plate

InactiveCN101956131AQuality improvementEliminate streak defectsProcess efficiency improvementAlkalinityHeat flux

The invention provides a preparation method of ultra-low carbon steel, comprising the following steps: carrying out pre-deoxidation and alloying, desulfuration, thermoregulation, decarburization and alloy fine adjustment on molten steel; before thermoregulation of the molten steel, adding a slag-adjusting agent containing A1 which accounts for 8-12% of the total weight of the slag-adjusting agent to the surface of ladle slag so that the content of (FeO+MnO) in the ladle slag is not more than 20wt% of the total weight of the ladle slag; after decarburization and alloy fine adjustment, circulating the molten steel under a vacuum condition so that the content of T[O] in the steel is 0.0025-0.004wt% of the total weight of the steel; continuously injecting the obtained molten steel into a crystallizer, and adding casting powder; and continuously drawing out the molten steel with a hard shell from the outlet of the crystallizer to obtain a continuous casting billet. In the method, the viscosity of the casting powder at 1300 DEG C is 0.2-0.3Pa.S, alkalinity is 0.8-1.1, and melting point is 1040-1130 DEG C; the broad-face heat flux density and the narrow-face heat flux density of the cooling crystallizer are 1350-1416kw / sq.m. and 1122-1174kw / sq.m. respectively, and the heat flux ratio of the broad face to the narrow face of the crystallizer is 0.8-0.85; and continuous casting speed is 0.8-1.3m / min.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

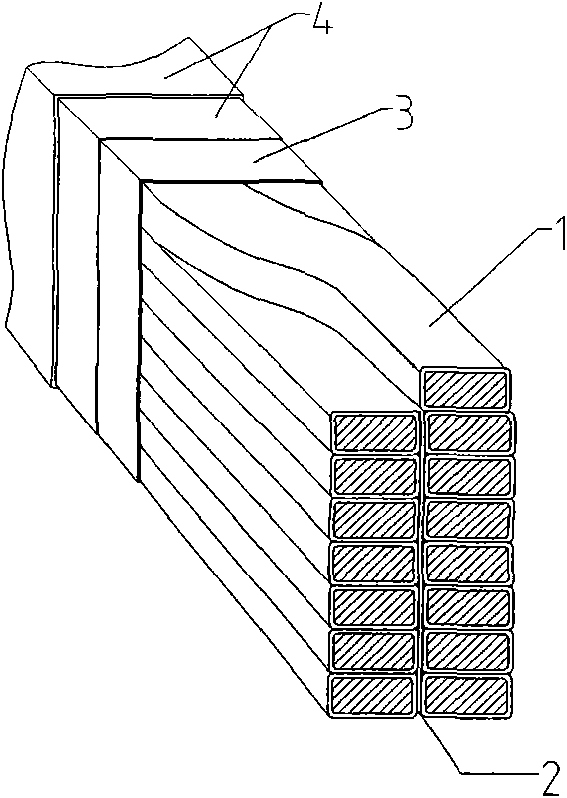

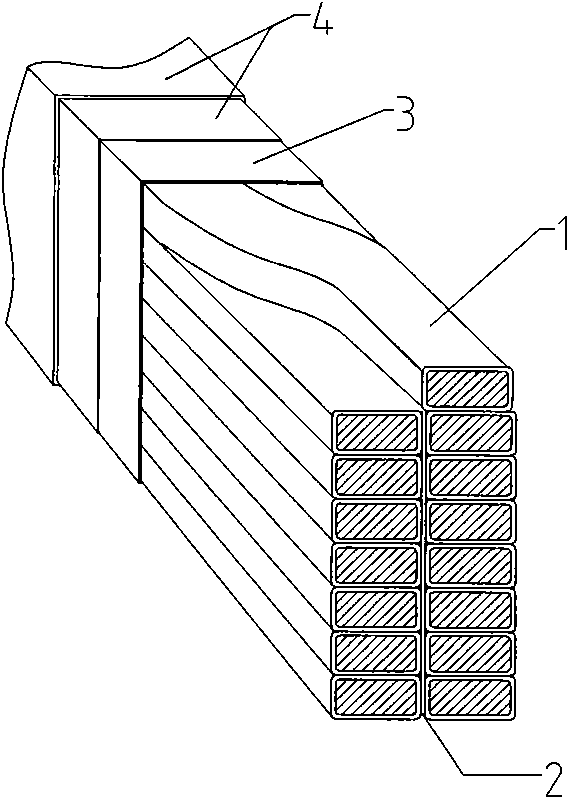

Starting Component For The Production Of Saw Blades Or Bands And Method For The Production Thereof

The present invention relates to a precursor component for the manufacturing of saw blades respectively saw bands, a method for the production of this precursor component, as well as a method for the production of saw blades, respectively saw bands. The above mentioned precursor component comprises at least a pre-manufactured carrier band respectively a pre-manufactured carrier disc, preferably a steel band respectively a steel disc and at least one pre-manufactured segment comprising of a precursor material for a cutting contour of saw blades respectively saw bands, wherein the carrier band respectively the carrier disc as well as the segment comprise a first and second face side, respectively and the first face side is more narrow than the second face side; and wherein the at least one carrier band respectively the at least one carrier disc is connected with the at least one segment via its respective narrow face side, such that by means of a separation of the final precursor component along a separation line which runs through the at least one segment two bi-metal bands respectively bi-metal discs can be generated which comprise one part of the at least one segment, respectively.

Owner:BOEHLER UDDEHOLM PRECISION STRIP GMBH

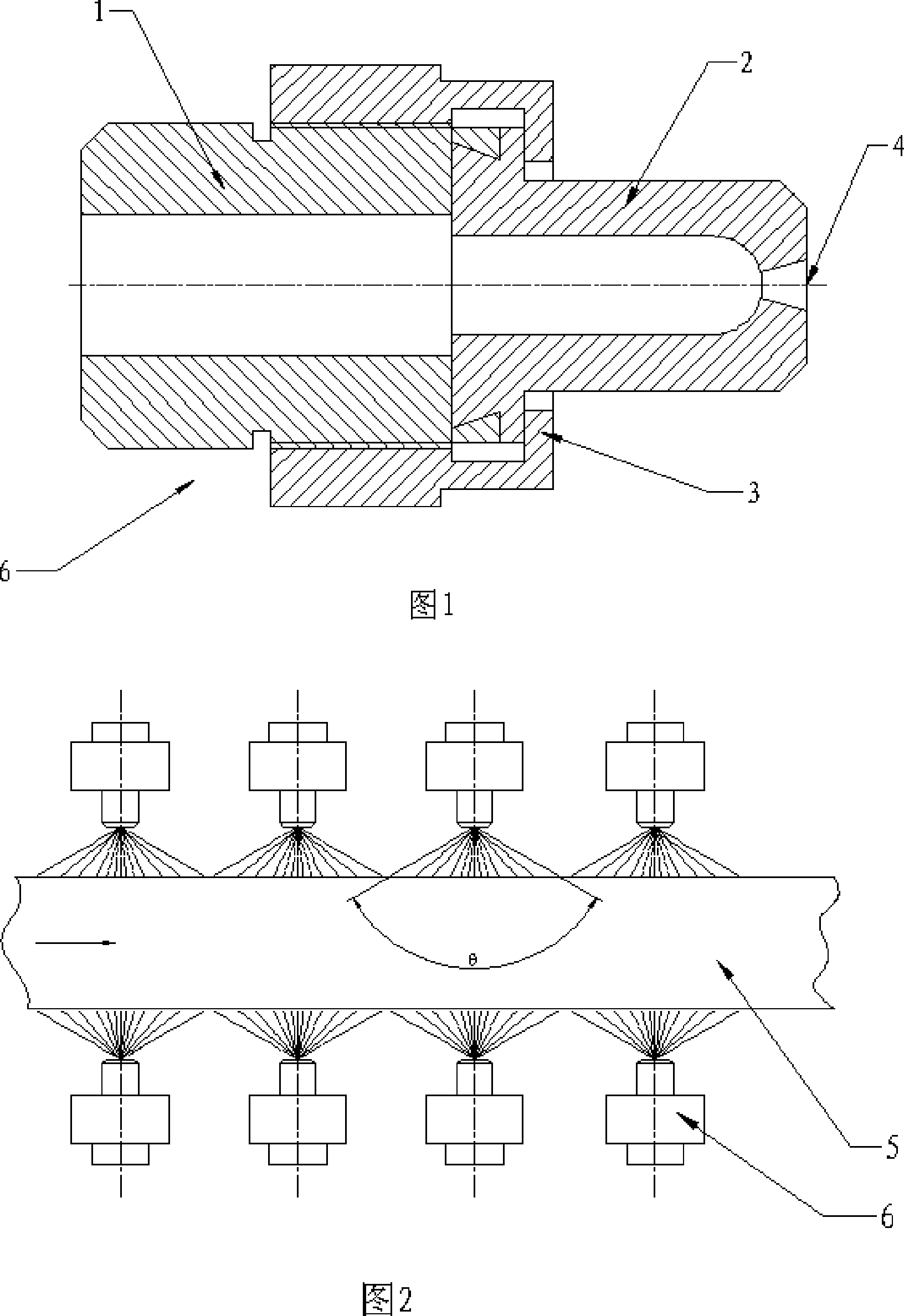

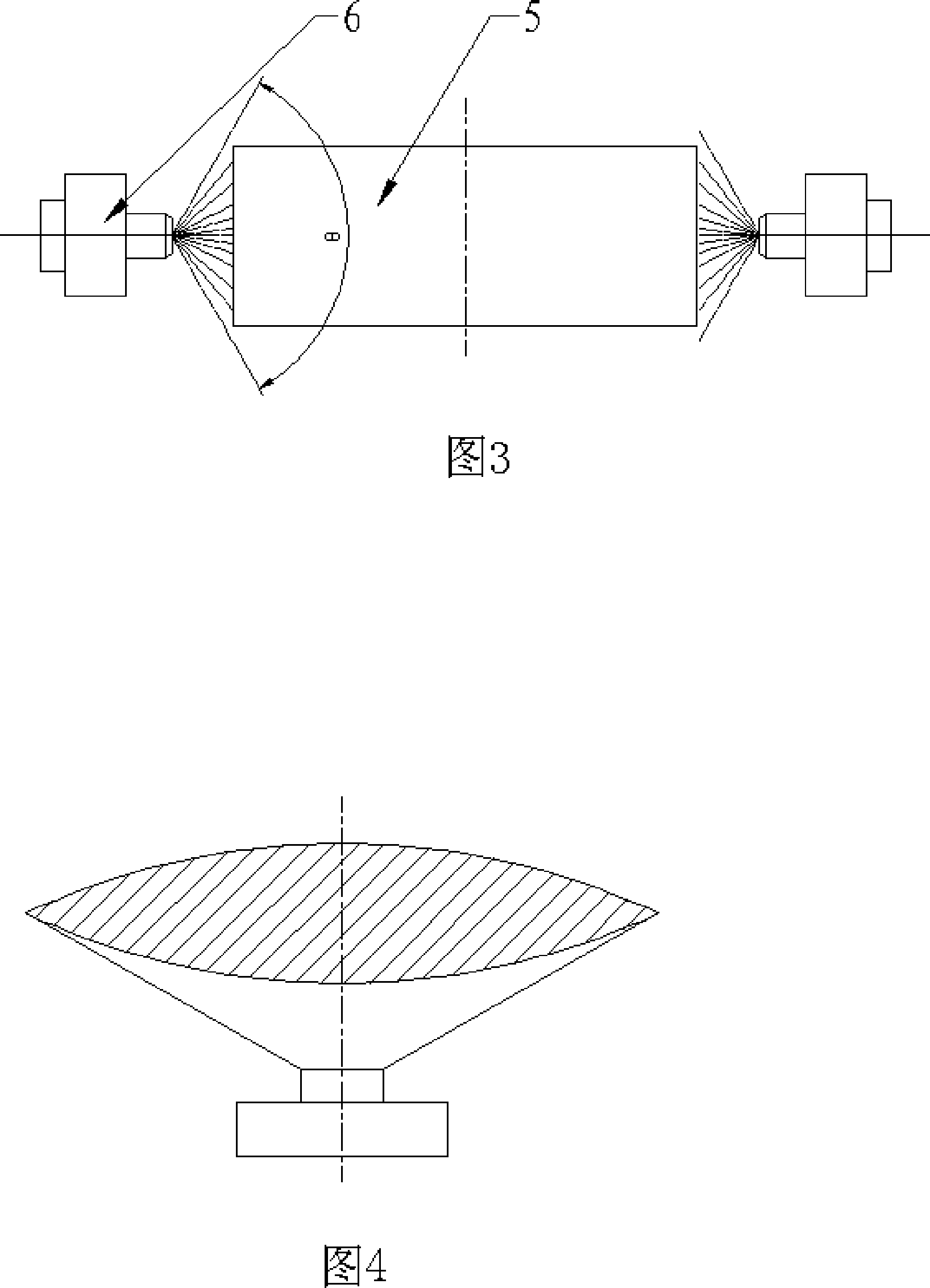

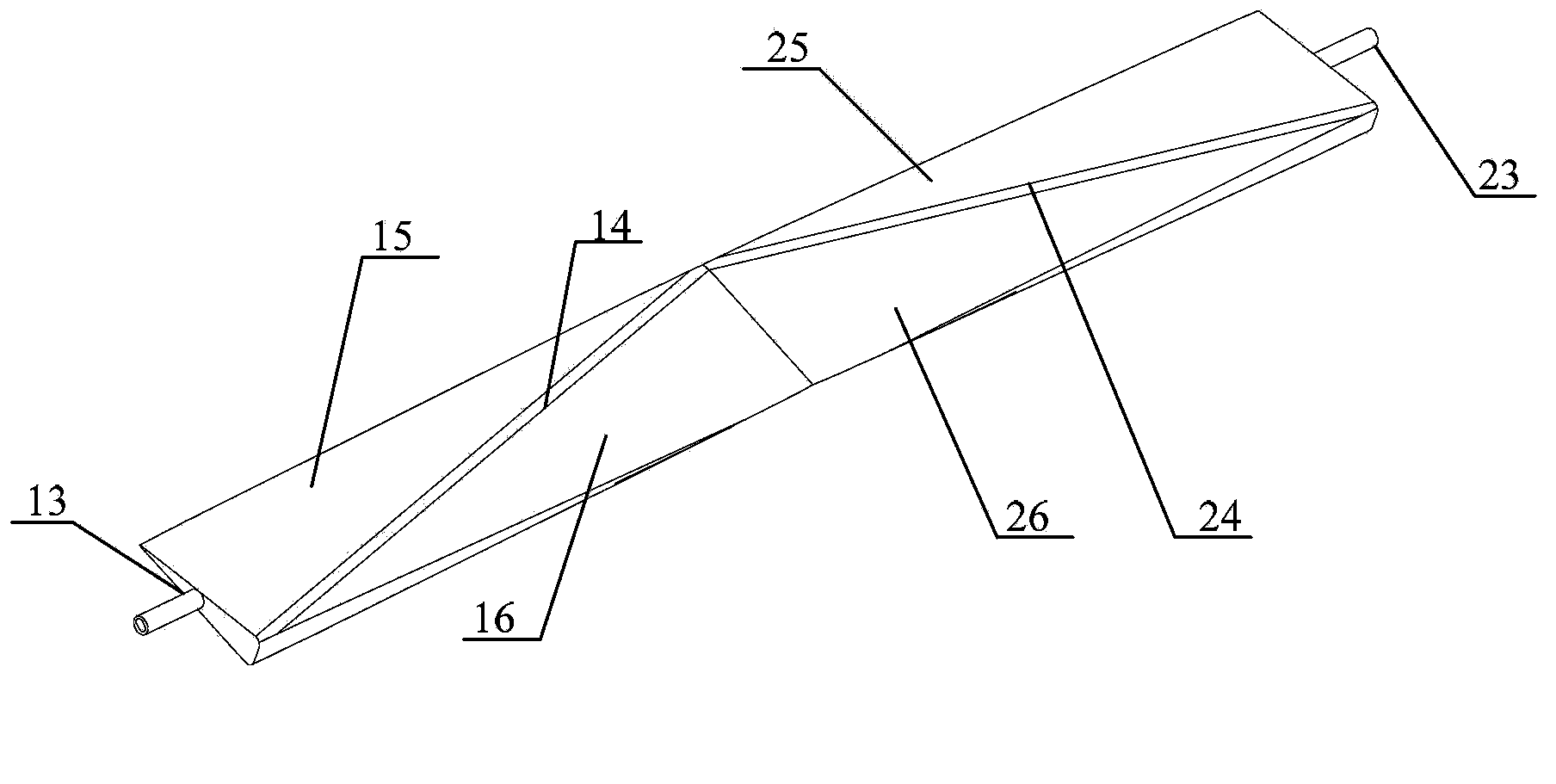

Straight arc casting machine alloy steel sheet billet continuous casting foot roller segment narrow surface cooling method

The present invention discloses a straight-curved type casting machine low-alloy steel slab continuous casting full-rolling section narrow face cooling method, and is aimed at solving the problem of that on the casting blank surface corner portion of low-alloy steel the transverse crack can be easily produced. Said invention belongs to the field of metal continuous casting blank cooling and surface quality control technology. Said method is characterized by that in the full-rolling section of continuous casting straight-curved type casting machine slab said invention utilizes the nozzles which are symmetrically mounted at left side and right side of casting blank pouring direction to cool the narrow face of said casting blank, and adopts rectangular nozzles to symmetrically and simultaneously cool the narrow faces of left and right two sides of casting blank. Said invention also discloses a kind of rectangular nozzle for said method, the water outlet hole of its sprayer is a hole with rectangular section. Said invention can reduce casting blank cooling strength of full-rolling section under the crystallizer and can improve casting blank cooling uniformity, so that it can eliminate casting blank surface corner portion transverse crack defect of continuously-cast high-strength low-alloy steel whose steel quality is P510L, P590L, J55 and X52, etc.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

Method for manufacturing corona resistant transposition winding wires

ActiveCN101964221AReduce temperature riseIncrease resistance to overvoltage shockFlat/ribbon cablesInsulated conductorsInsulation layerTransformer

The invention relates to a method for manufacturing corona resistant transposition winding wires, which comprises the following implementation steps: (1) arranging a wire core into two rows with mutually contacted broad-face by using 5-83 (odd number) enamelled rectangular copper or aluminum wires, transposing the wire core in the same turning direction along a narrow face on and under the two rows of enamelled wires according to the specified pitch so that each enamelled rectangular wire is positioned in one segment with the basically equal length to maintain resistance balance, and setting lining paper in the middle of a paper core; (2) performing single-layer overlapping outside the transposed enamelled rectangular wire core with a corona resistant insulation film; and (3) performing multi-layer continuous lapping on an external layer with electrical insulating paper or a mesh tape insulating material according to the voltage class requirement. In the invention, a polyimide insulation film layer containing a nanoscale inorganic compound is employed in the method, which increases resistance of the insulation layer on local discharge degradation, facilitates charge accumulation diffusion for rapid heat dissipation, plays a role of effectively resisting high-frequency pulse voltage and corona, and lowers temperature rise of a transformer and a reactor.

Owner:天津经纬电力科技有限公司

Method for controlling narrow face bulging of thick continuous casting slab

The invention provides a method for controlling narrow face bulging of all steel grades of thick continuous casting slabs with the thickness above 320mm. The method is characterized in that: a narrow face of the continuous casting slab is subjected to spraying cooling-water in the range of 4-8m below the foot roll part of a continuous casting machine, a used nozzle is in a vapor cooling type, the spraying angle of the nozzle is 80-110 degrees, a distance between the nozzle and the narrow face of the continuous casting slab is 160-350mm, and the water spraying volume is 8-20m<3> / h. Meanwhile, the inverted conicity of a copper plate on the narrow face of a crystallizer is controlled between 1.05 percent and 1.20 percent. By adopting the invention, the effective control both to narrow face bulging of the thick continuous casting slab with the thickness above 320mm and wide face deviation corner depression and longitudinal cracks caused by the narrow face bulging can be realized.

Owner:SHOUGANG CORPORATION

Mold powder capable of effectively controlling peritectic steel thick slab narrow face depression defect

The invention relates to a mold powder capable of effectively controlling peritectic steel thick slab narrow face depression defect. The mold powder comprises the following elements by weight percent: 38.02 to 40.1 percent of Cao, 28.8 to 30.02 percent of SiO2, 9.9 to 10.5 percent of CaF2, 9.06 to 9.5 percent of Na2O, 1.55 to 1.93 percent of MgO, 1.5 to 1.93 percent of AL203, 0.01 to 0.037 percent of Li2O and 0.035 to 0.053 percent of MnO. The mold powder has good lubricating property and spreadability. Because of the high melting speed, the invention can complement the quick consumption of liquid slag in time; because of the high alkalinity, the invention has strong absorbing and mixing capability; and because of the proper viscosity and the reasonable crystallization temperature, the invention plays an important role in uniformity. When the mold powder is applied to the casting of peritectic steel thick slab, the slag entrapment defect caused by crystallizer liquid level fluctuation is reduced greatly, the heat transmission uniformity is improved greatly and the surface quality of casting blank is good.

Owner:SHOUGANG CORPORATION

Method of controlling the net crack of high-nitrogen continuous-casting slab of high strength weathering steel containing vanadium

The invention discloses a net-shaped crack control method of high nitrogen and high strength weathering steel continuous casting billet containing vanadium, the method can not only effectively eliminate net-shaped crack of the continuous casting billet, but also can eliminate the continuous casting billet surface longitudinal crack and surface transverse crack defect. The method synthetically applies following technique measures: presetting cooling water amount of the mold wide face to 2485-2515 L / min, the narrow face cooling water amount is set to 304-306 L / min; the casting pulling rate is stabilized in 0.8-1.0 m / min, the billet casing surface temperature of the casting billet out of the mold lower end is increased to 1050-1120 DEG C, the vibration frequency is 110-130 Hz; reducing Cao mixing amount in the casting powder, the alkalinity of the casting powder is 0.95-1.20, the melting point is 1080-1120 DEG C, when at 1300 DEG C, the viscosity is 0.2-0.5 Pa.s; reducing the second cool segment casting billet cooling water amount, and controlling the continuous casting ratio water amount in 0.60-0.65 L / kg by static or dynamic adjusting method.

Owner:PANZHIHUA IRON AND STEEL

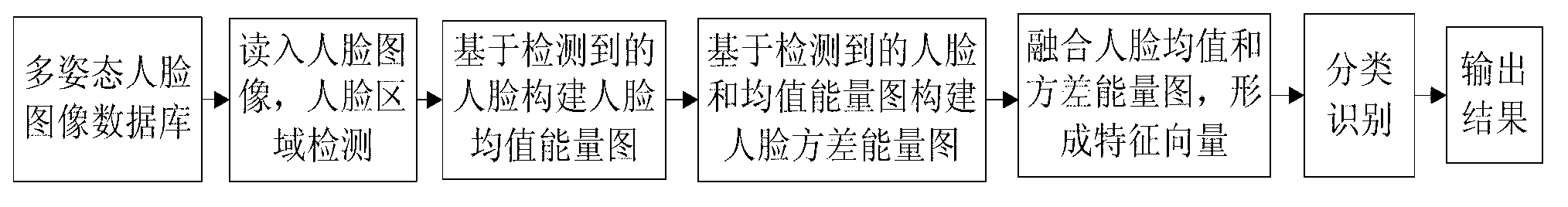

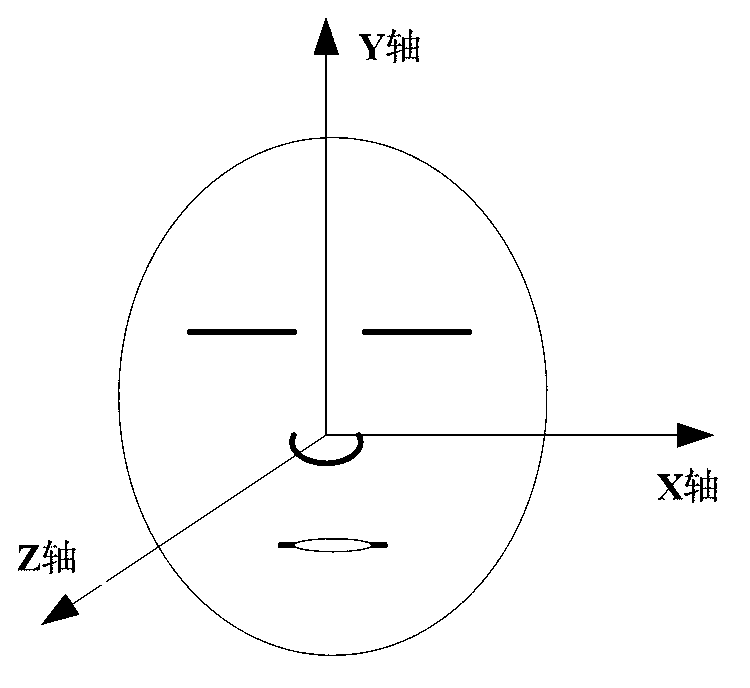

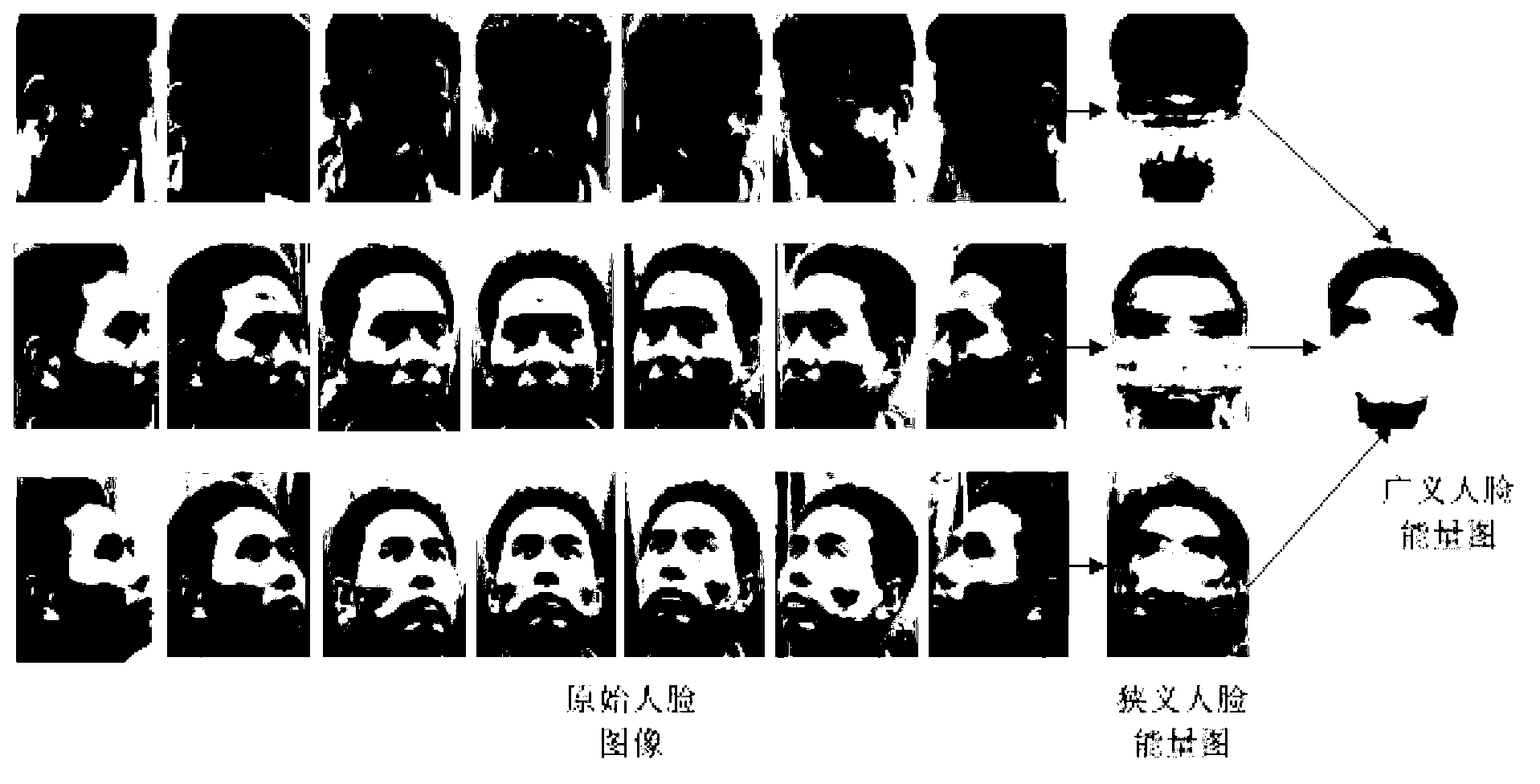

Multi-pose face recognition method based on face mean and variance energy images

InactiveCN103218606AImprove performanceWeaken noise interferenceCharacter and pattern recognitionZero paddingFeature vector

The invention relates to a biological feature identity recognition technique, in particular to a multi-pose face recognition method based on face mean and variance energy images. The method comprises the following steps of detecting face areas to carry out the size normalizing on the images of the face areas; building a narrow face mean energy image and a generalized face mean energy image; building a narrow face variance energy image and a generalized face variance energy image; combining obtained features, so as to obtain a final feature vector; and classifying and recognizing by a nearest neighbor classifier based on Euclidian distance. The method has the advantages that the storage space is well saved, the calculation complexity is reduced, and the noise interference in the single-frame image is weakened; and the face energy images contain face contour information under multiple poses, and have large advantage for recognizing the faces with large-angle pose change, the zero-padding processing is not needed, and the recognition property of the multi-pose face is improved.

Owner:HARBIN ENG UNIV

Control method for corner cracks of boron-containing steel plate slabs

The invention belongs to the technical field of metallurgy, and particularly relates to a control method for corner cracks of boron-containing steel plate slabs. The production procedure of a boron-containing steel plate sequentially comprises molten iron pre-treatment, converter smelting, secondary refining and plate slab continuous casting. In the continuous casting process, the ratio of the water amount of a crystallizer to the product of the casting blank section size and the pulling speed is controlled to be 0.02-0.03; meanwhile, the ratio of the wide face water amount / wide face size of the crystallizer to the narrow face water amount / narrow face size is controlled to be 1-1.5; a full-width coverage spraying manner is adopted as a secondary cooling manner, and the ratio of the total water amount of secondary cooling to the product of the casting blank section size and the pulling speed is controlled to be smaller than or equal to 0.0075; and according to the proportion of the water amount of each segment in the total water amount, the foot roller area accounts for 10%-15%, the zero segment area accounts for 35%-45%, the arc-shaped segment area accounts for 25%-35%, and the straightening area accounts for 5%-10%. According to the control method for the corner cracks of the boron-containing steel plate slabs, the straightening temperature rises, the corner cross cracks are eliminated, and the hot-rolled coiled plate edge portion surface warping defect occurrence rate caused by the corner cross cracks of the plate slabs is reduced to 0.2% or below from 3%.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

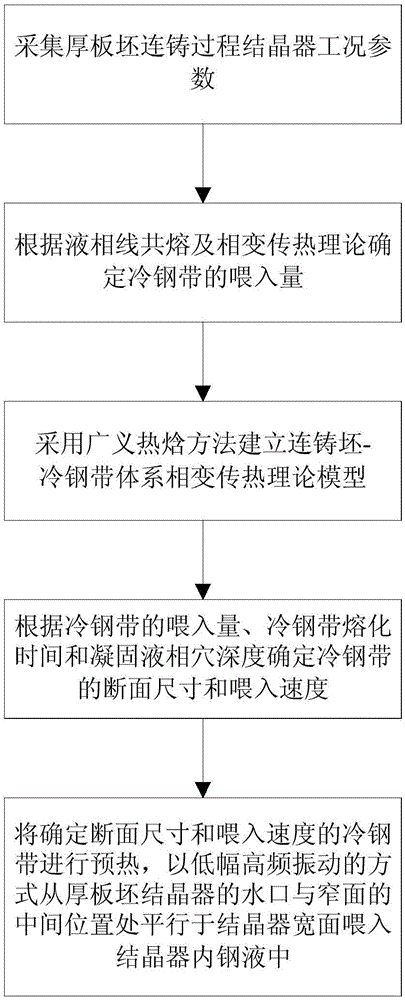

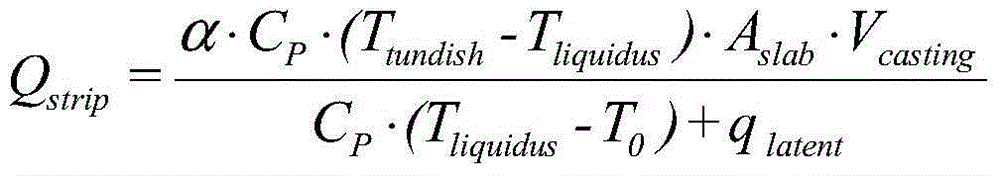

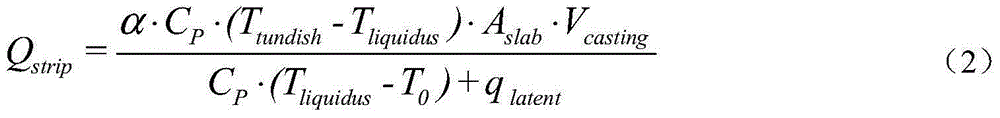

Method for determining steel belt feeding process parameter of crystallizer in thick slab continuous casting process

ActiveCN105033216AReduce macro segregationIncrease equiaxed crystal ratioLiquid coreCongruent melting

The invention relates to a method for determining the steel belt feeding process parameter of a crystallizer in the thick slab continuous casting process. The method comprises the steps the work condition parameter of the crystallizer in the thick slab continuous casting process is collected, and the feeding quantity of a cold steel belt is determined through the work condition parameter of the crystallizer in the thick slab continuous casting process based on the liquidus congruent melting and phase change heat transfer theory; a continuous casting slab-cold steel belt system phase change heat transfer theoretical model is built through a generalized enthalpy method, namely, a relation model among the melting time and feeding thickness of the cold steel belt, the superheat degree of casting molten steel and the initial temperature of the cold steel belt; the section size and feeding speed of the cold steel belt are determined through the continuous casting slab-cold steel belt system phase change heat transfer theoretical model according to the feeding quantity and melting time of the cold steel belt and the depth of a solidified liquid core; and the cold steel belt with the determined section size and feeding speed is preheated and fed into molten steel in the crystallizer through the position between a water opening and a narrow face of the thick slab crystallizer parallel to the wide face of the crystallizer in a low-amplitude high-vibration manner.

Owner:NORTHEASTERN UNIV

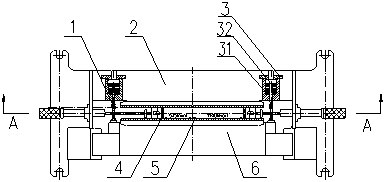

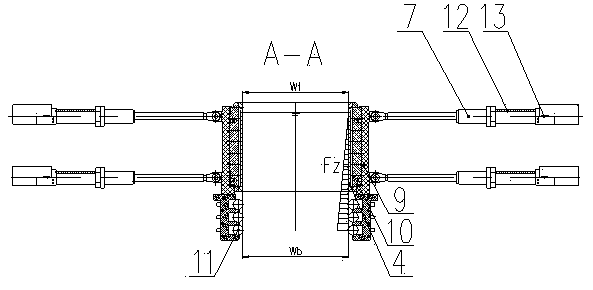

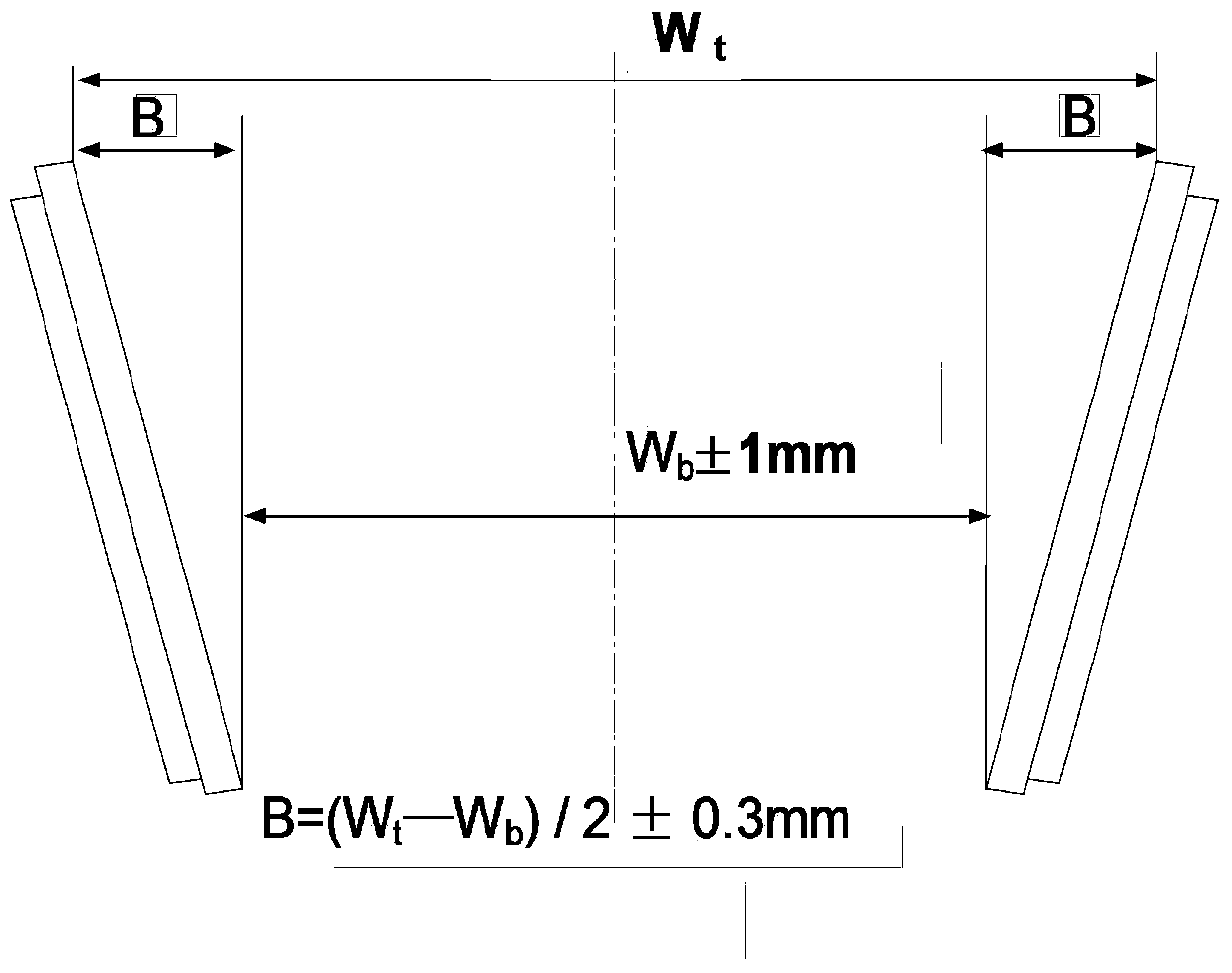

Method and device for dynamically maintaining conicity of narrow face of slab crystallizer on line

The invention belongs to the technical field of continuous casting and particularly relates to a method and device for dynamically maintaining the conicity of a narrow face of a slab crystallizer on line. The method and device for dynamically maintaining the conicity of the narrow face of the slab crystallizer on line can prevent conicity deflection of the narrow edge of the crystallizer in the casting process. According to the method and device for dynamically maintaining the conicity of the narrow face of the slab crystallizer on line, the width changes of an upper port and the width changes of a lower port of the crystallizer are monitored in real time and compensated dynamically in the casting process, it is guaranteed that the conicity of the narrow face is always maintained nearby a target value, the problem of the conicity deflection of the narrow edge of the crystallizer in the slab continuous casting process is solved thoroughly, and therefore the method and device have distinctly important significance to improvement of the quality of casting slabs, reduction of steel leakage accidents, prolonging of the service life of copper plates, improvement of the operation efficiency of a casting machine and the like.

Owner:CONTINUOUS CASTING TECH ENG OF CHINA

Narrow-face copper plate for chamfer crystallizer

The invention discloses a narrow-face copper plate for a chamfer crystallizer. A working face of the narrow-face copper plate for the chamfer crystallizer comprises a first part and a second part; the first part is a sunken curved surface; the first part is a part on the working face in a range of 200mm to 400mm apart from an upper port of the crystallizer. The first part comprises a first curved surface region, two second curved surface regions and two transition curved surface regions, wherein the first curved surface region is a second degree parabola region; the two second curved surface regions are curved surfaces of which the crown heights are 1mm to 3mm; the two transition curved surface regions are curved surfaces with radii of 5mm to 35mm; the two transition curved surface regions are respectively connected with two opposite sides of the first curved surface region and the two second curved surface regions. The second part is connected with the first curved surface region, the two second curved surface regions and the two transition curved surface regions; the second part is a linear conical surface. The narrow-face copper plate for the chamfer crystallizer is also provided with a cooling waterway for cooling the working face; the distance between the cooling waterway and the edge, which is far away from the transition curved surface regions, on each second curved surface region is 20mm to 40mm; the distance between the cooling waterway and each transition curved surface region is 10mm to 30mm.

Owner:SHOUGANG CORPORATION

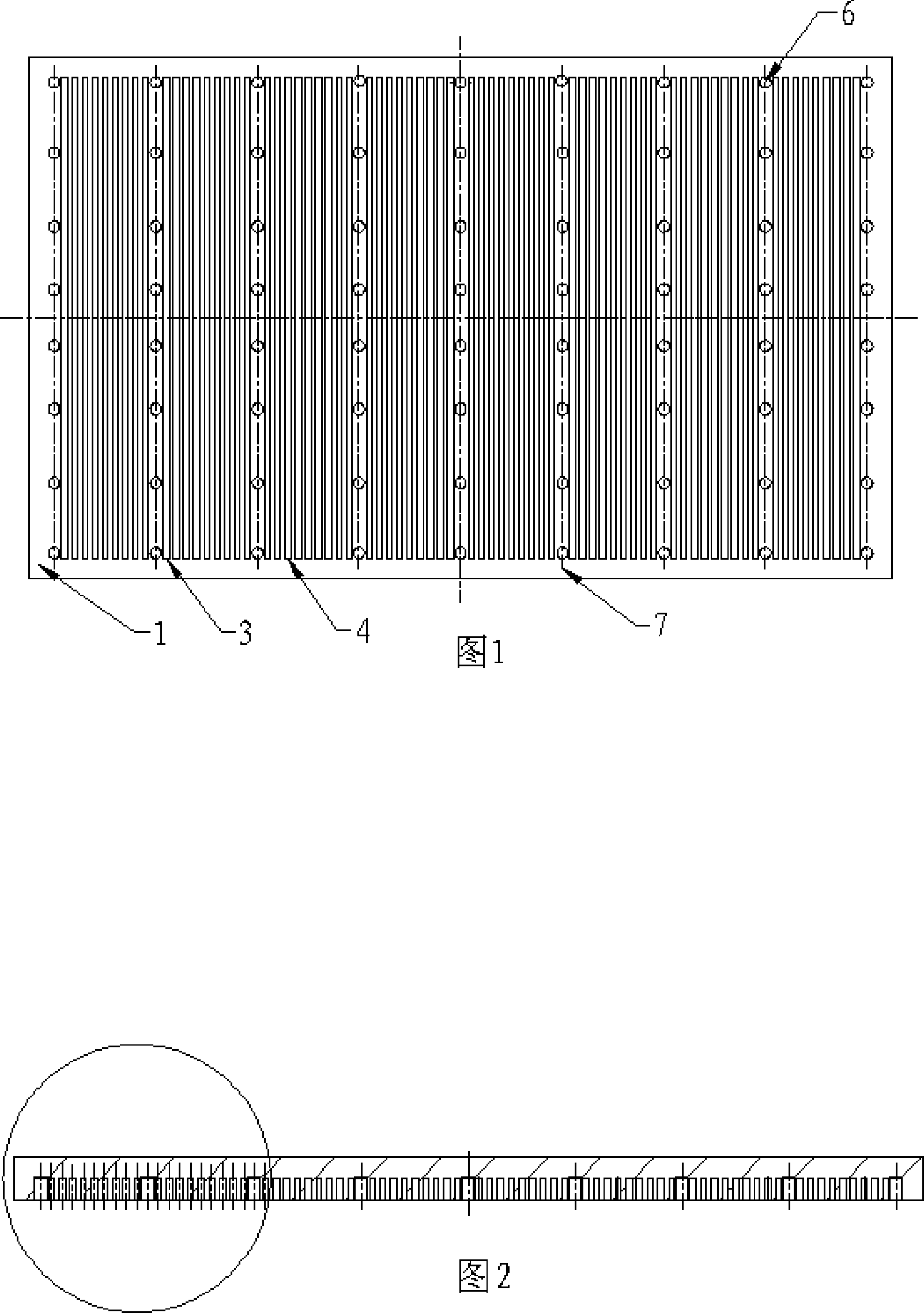

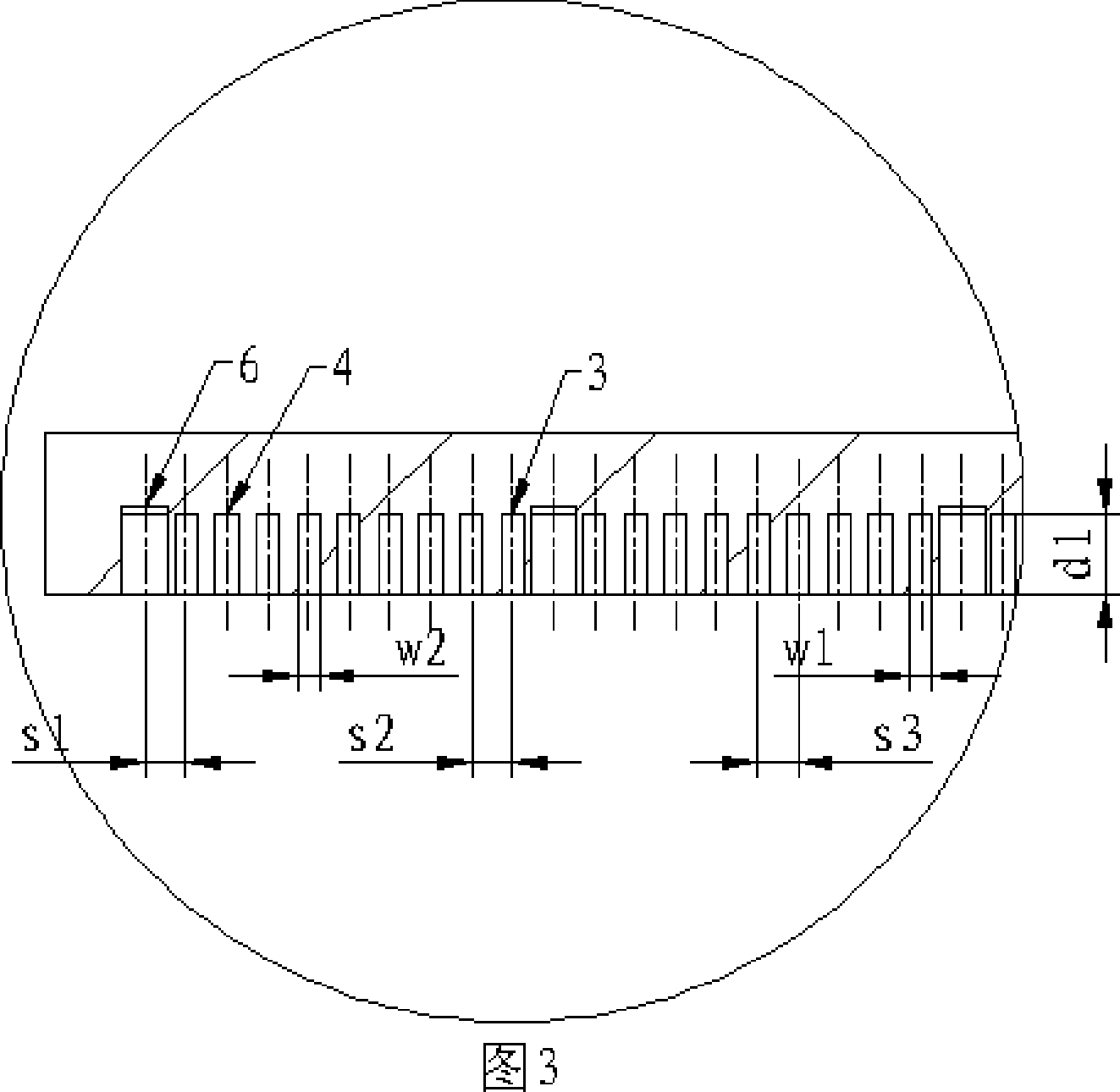

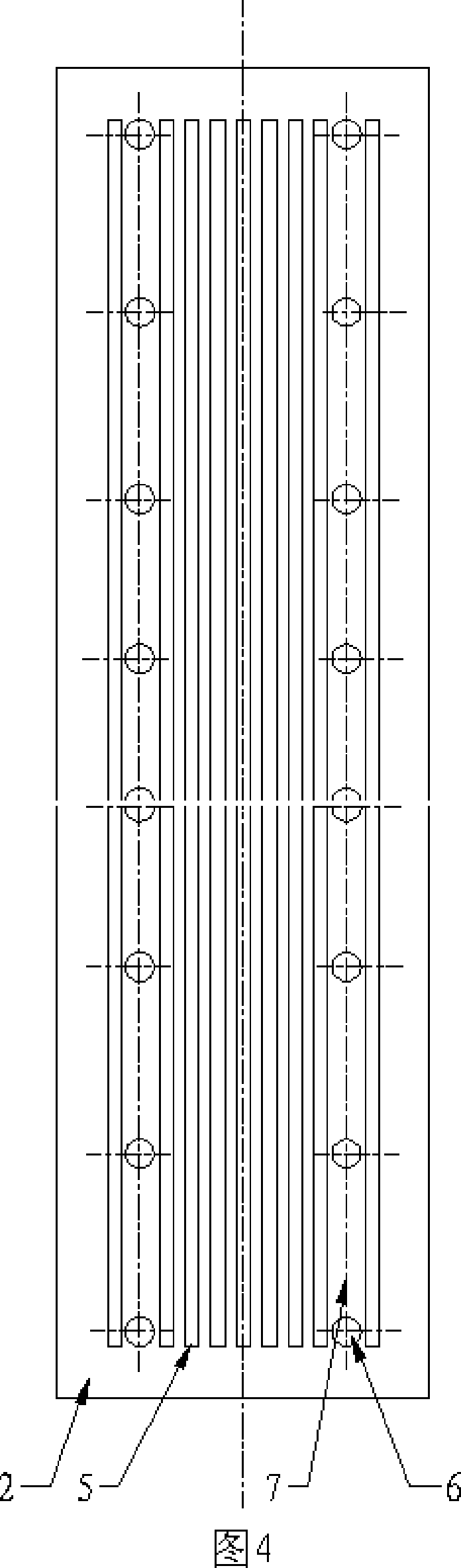

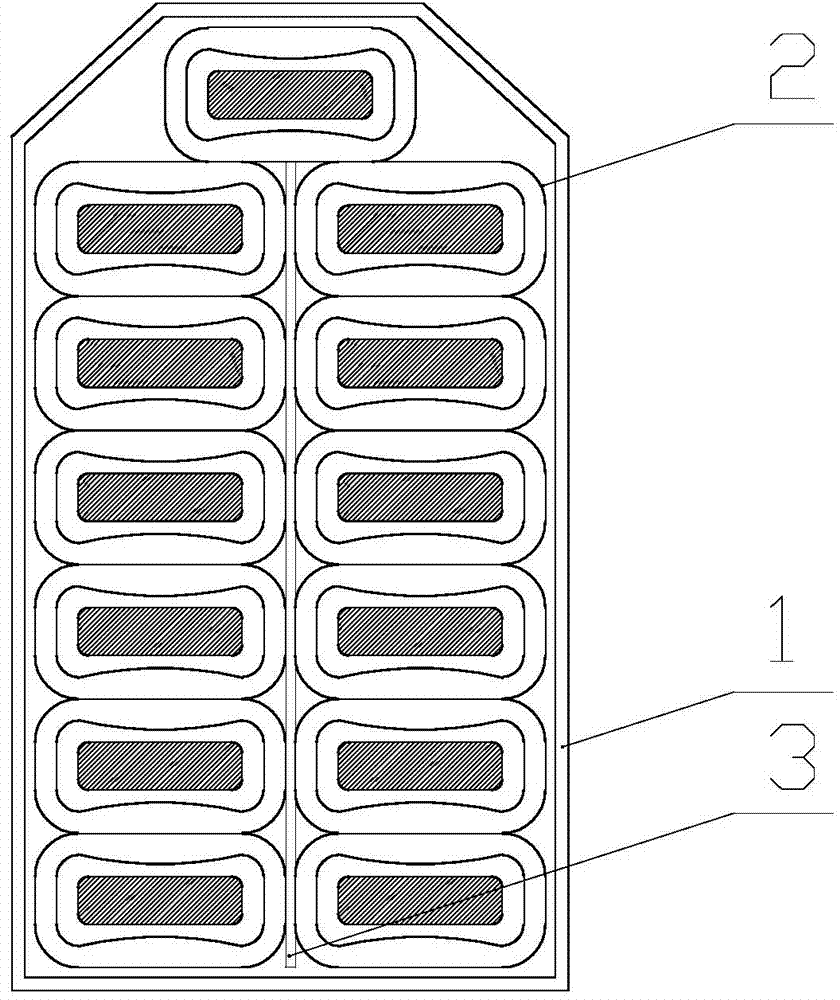

Continuous casting crystallizer for plate billet

The present invention belongs to the field of metal continuous casting auxiliary equipment and continuous casting slab surface quality control technology. In the concrete, it discloses a slab continuous casting crystallizer so as to solve the problem of that the non-uniform cooling of width direction of traditional crystallizer can produce longitudinal corner crack. Said crystallizer includes wide-face copper plate, narrow-face copper plate and connecting screw hole row which is arranged along the slab-drawing direction, on the wide-face copper plate and narrow-face copper plate several rectangular cooling water tanks which are reasonably designed according to the cooling uniformity requirement are respectively and symmetrically distributed.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

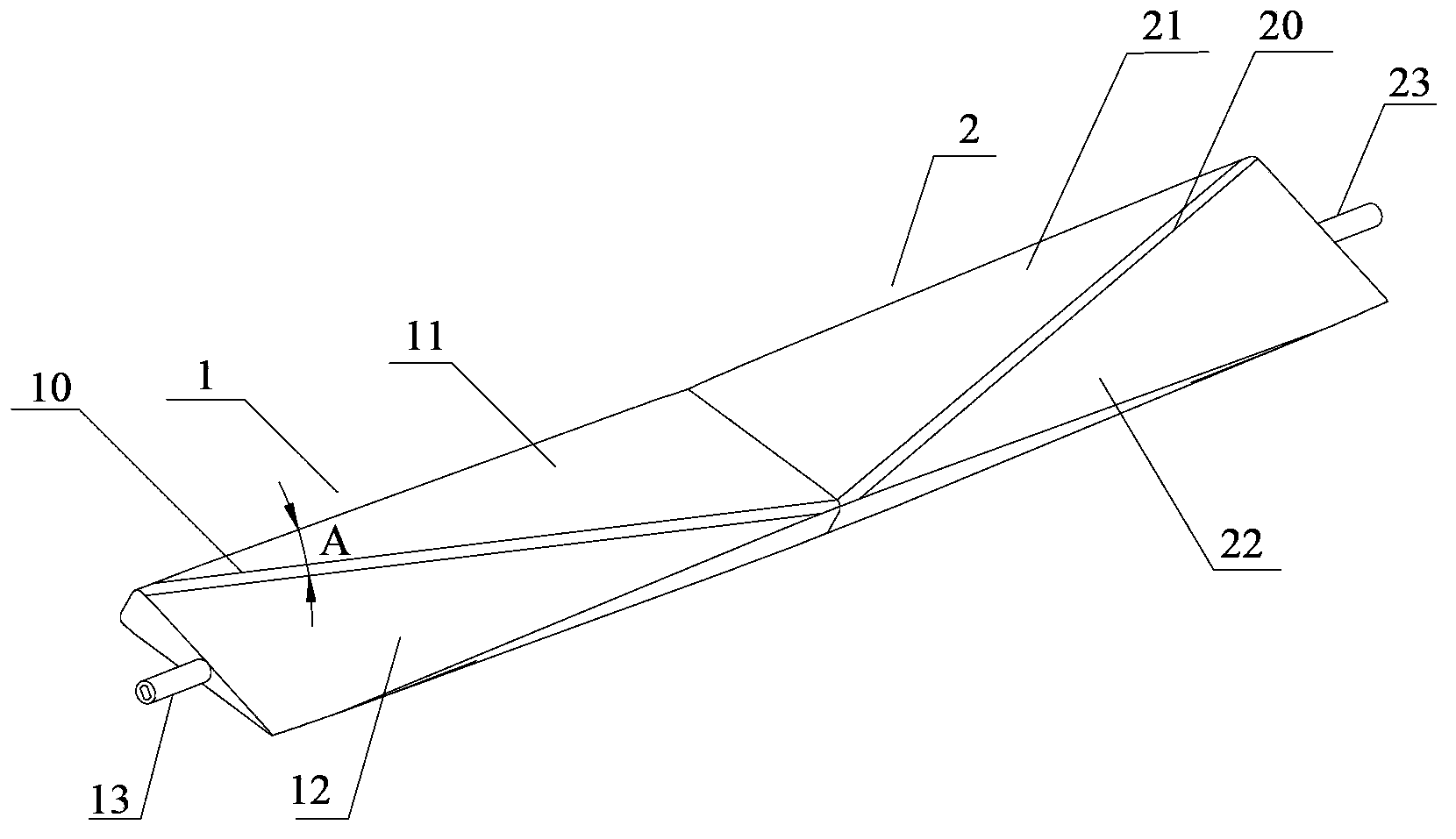

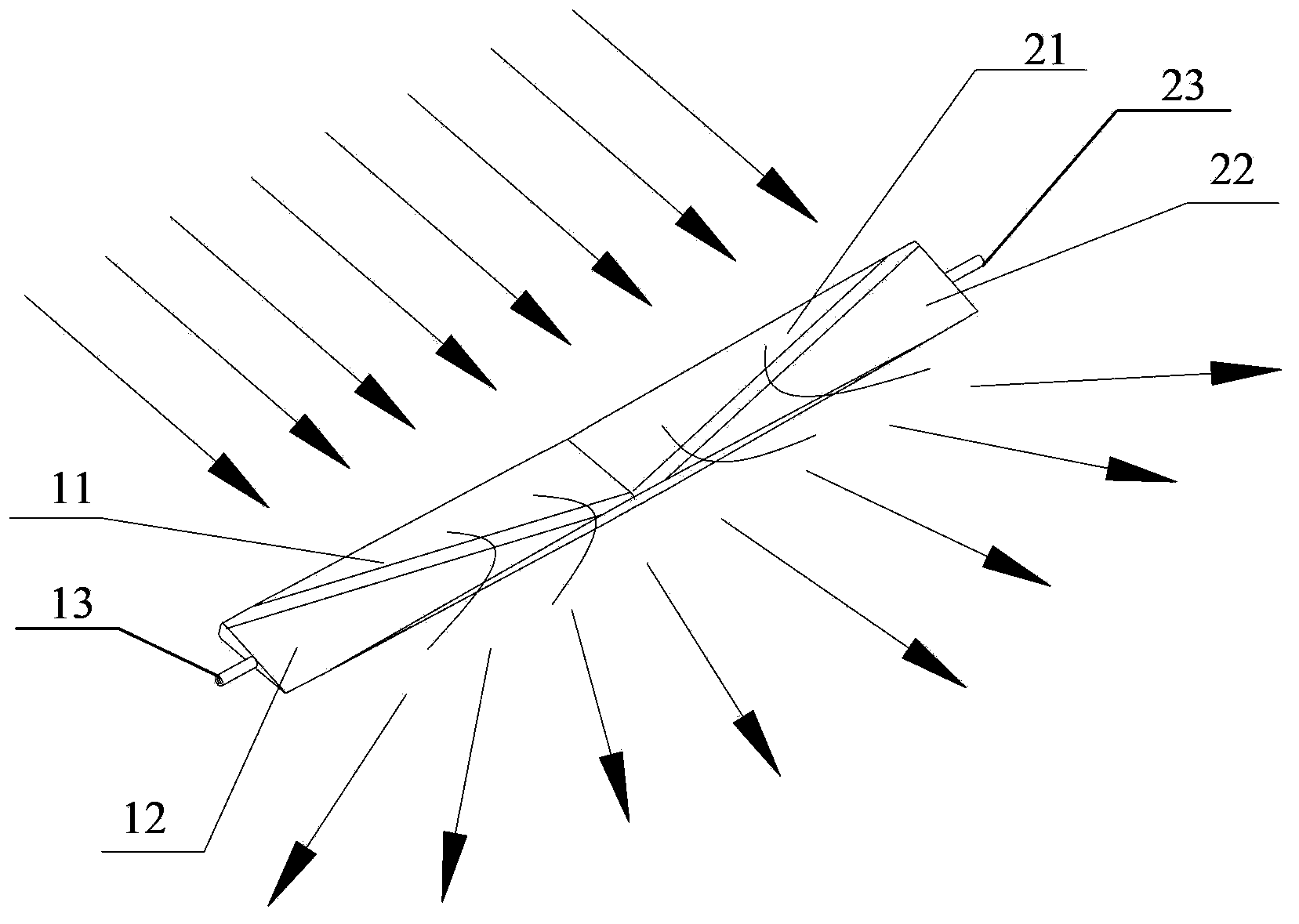

Air vane and air conditioner with same

The invention discloses an air vane for an air conditioner. The air vane in an elongated shape comprises a left air guide portion and a right air guide portion. A guide surface of the left air guide portion comprises a first guide face, a second guide face and a first transition face; the first transition face is a narrow face and forms an included-angle opening, facing the right, with a long edge, close to an air outlet, of the air vane; the first guide face and the second guide face are arranged on two sides of the first transition face; the first guide face is a sloping face at a position, close to an air outlet of an indoor unit, on the inner side of the first transition face; the first guide face guides air from the air outlet of the indoor unit to the position over the left of a user who faces the indoor unit; the second guide face is a sloping face which slopes towards the first guide face and which is arranged on the outer side of the first transition face; the second guide face diffuses the air to the position under the left of the user. The invention further provides the air conditioner with the air vane. The air vane and the air conditioner with the same have the advantages that the air supply range of the air conditioner is adjustable, air supply is tenderer, and comfort is improved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

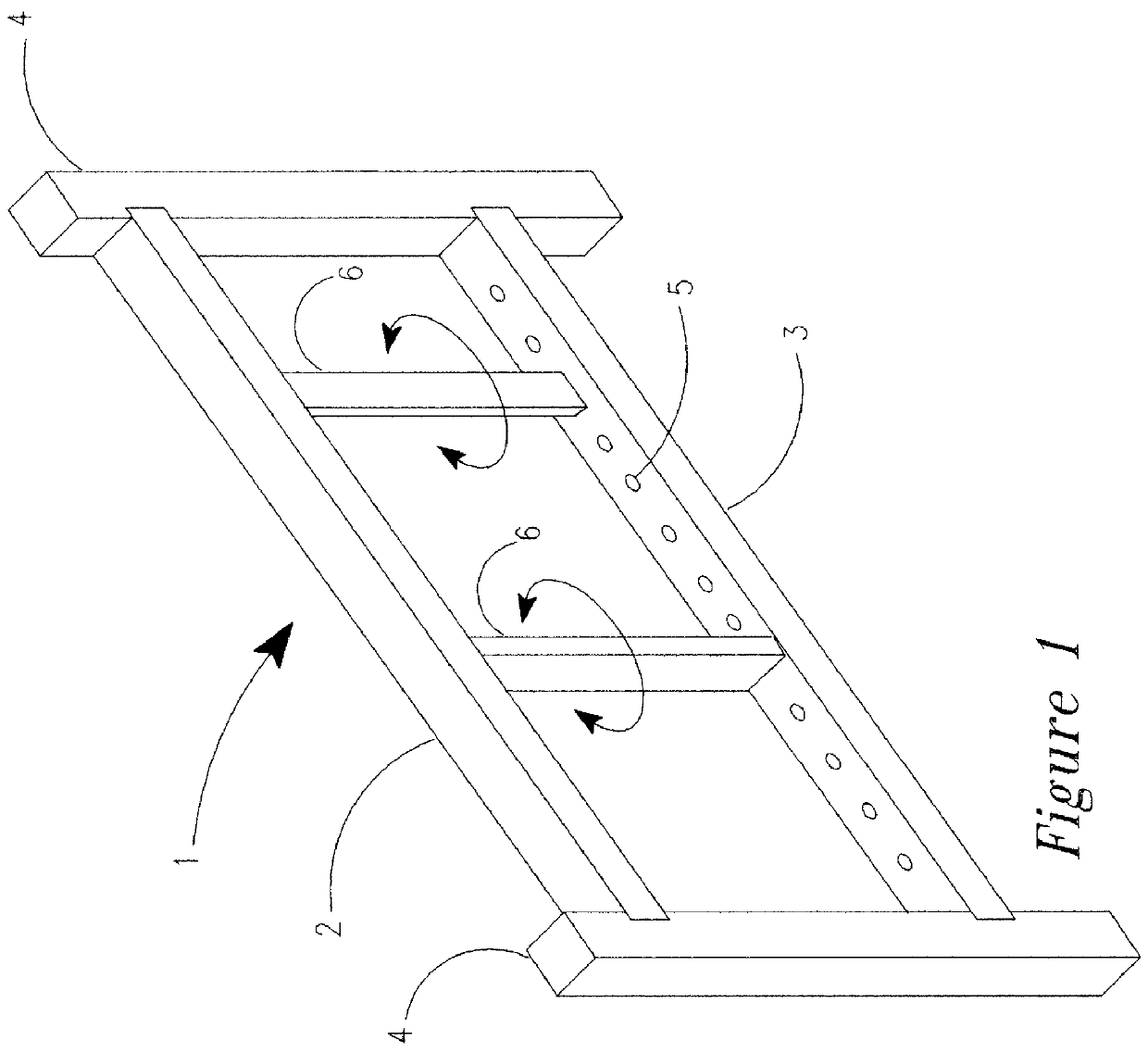

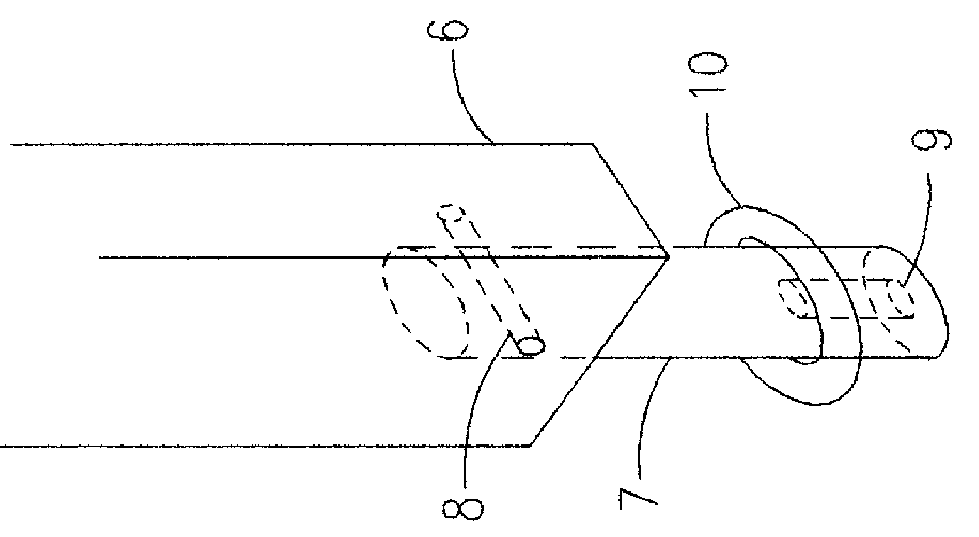

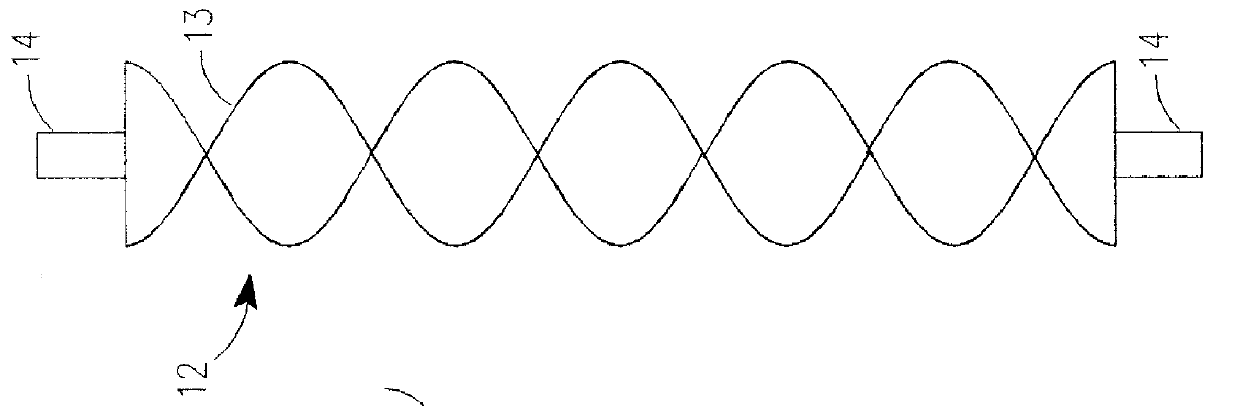

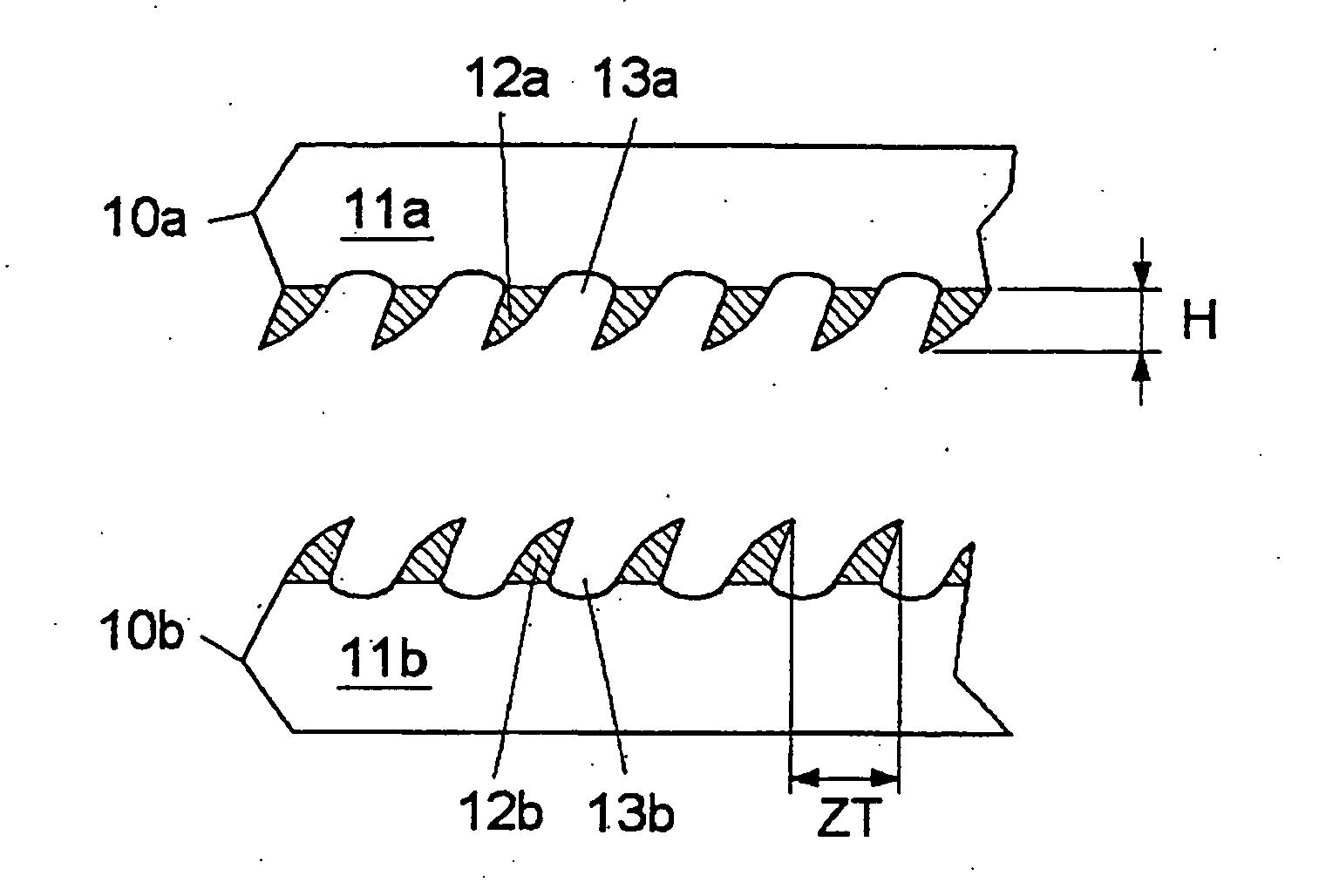

Kit for joining flat, relatively thin members that adjoin each other along their narrow face

The system relates to a system for joining flat, relatively thin members that adjoin one another along their narrow face, the members having grooves incorporated into the narrow faces that are parallel to the surface and have groove walls that are parallel to each other, and the joining element being inserted into the grooves of two adjacent members and bridging the partition gap between the members in the manner of an external tongue. In this context the joining element (11) has, on its part (12) that can be inserted in the manner of an external tongue in the longitudinal center on its side that faces away from the visible surface of the members, one continuous web or a plurality of aligned webs (13) that preferably protrude at a right angle, from which detent webs (14, 15) protrude on both sides, each of which has a detent projection (16, 17) that projects toward the external-tongue-like part (12), and on the bottom of the member (1, 2), which faces away from its visible surface, detent grooves (7, 8) being provided that run parallel to the adjacent edge at a distance corresponding to the width of the detent webs (14, 15).

Owner:M KAINDL

Taper measuring apparatus for slab crystallizer

Owner:INNER MONGOLIA UNIV OF SCI & TECH

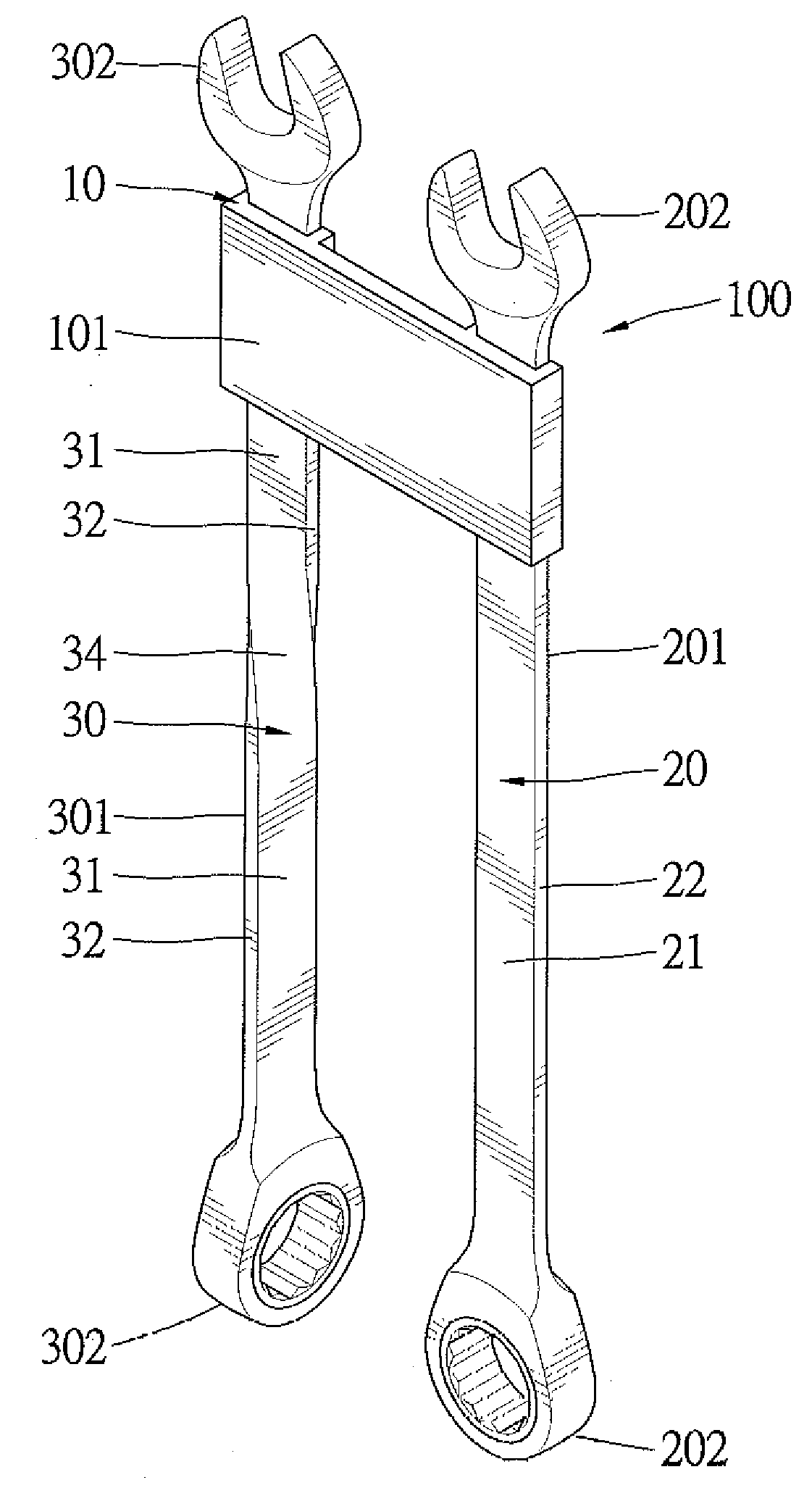

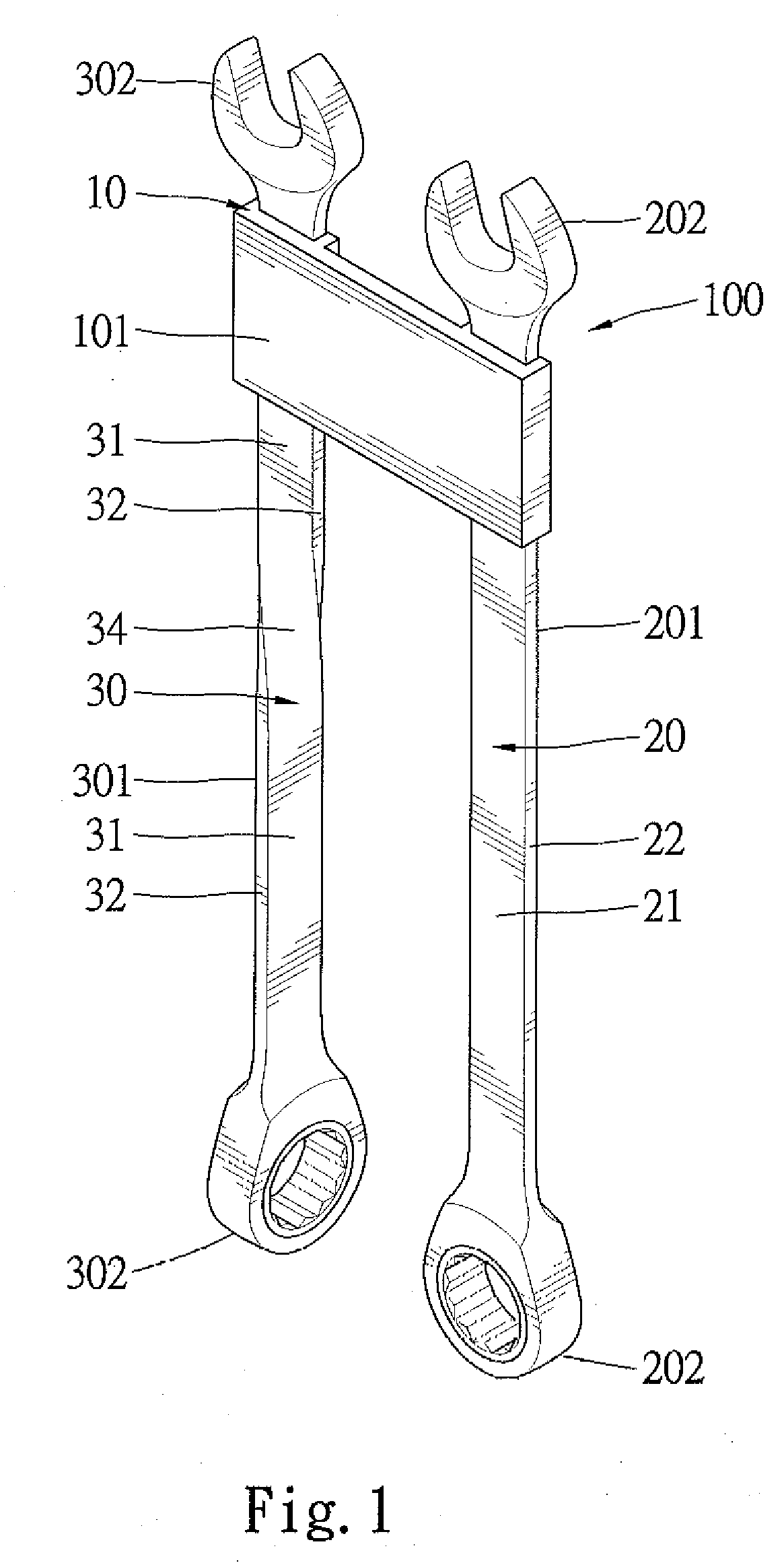

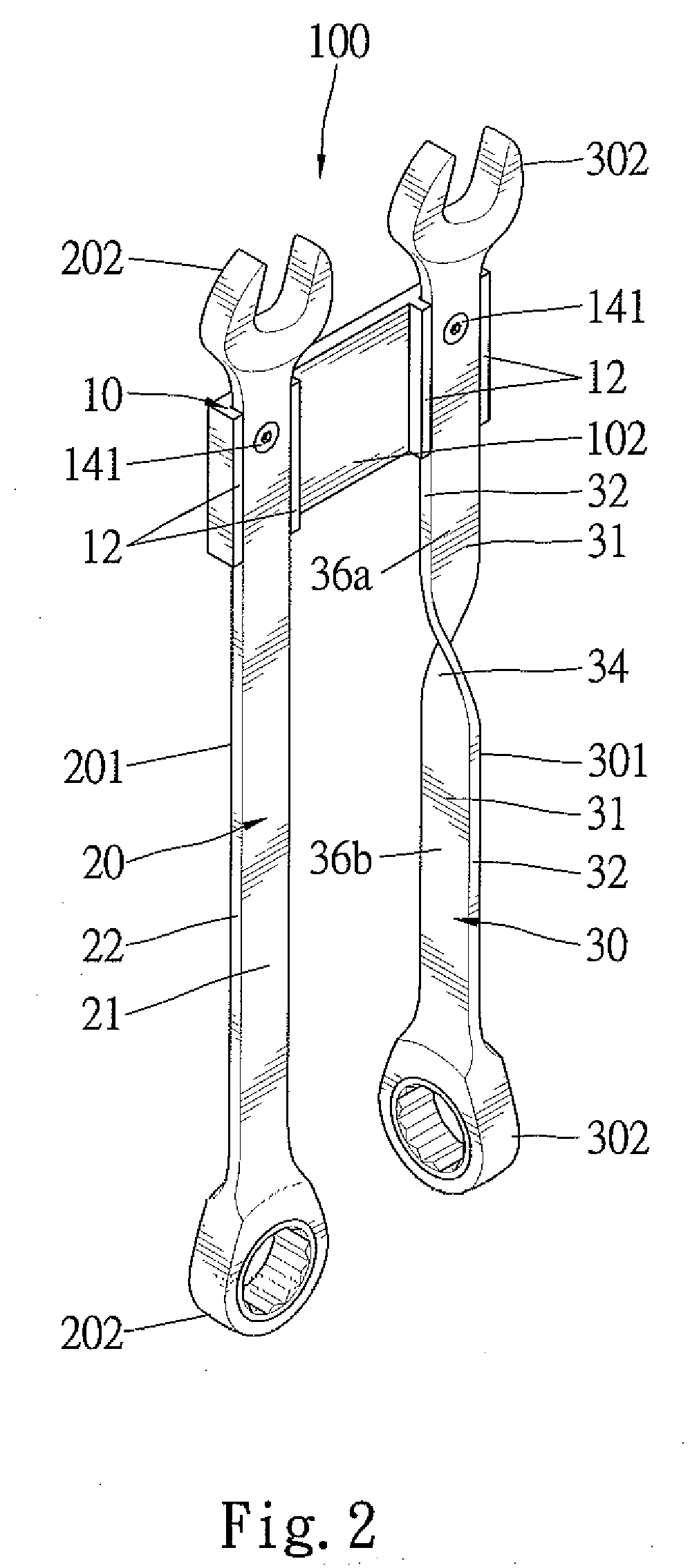

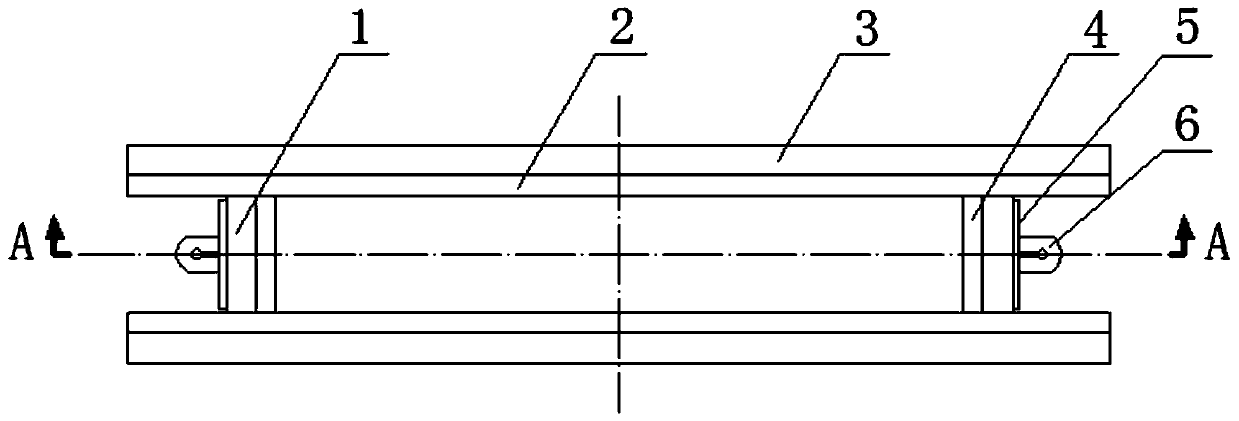

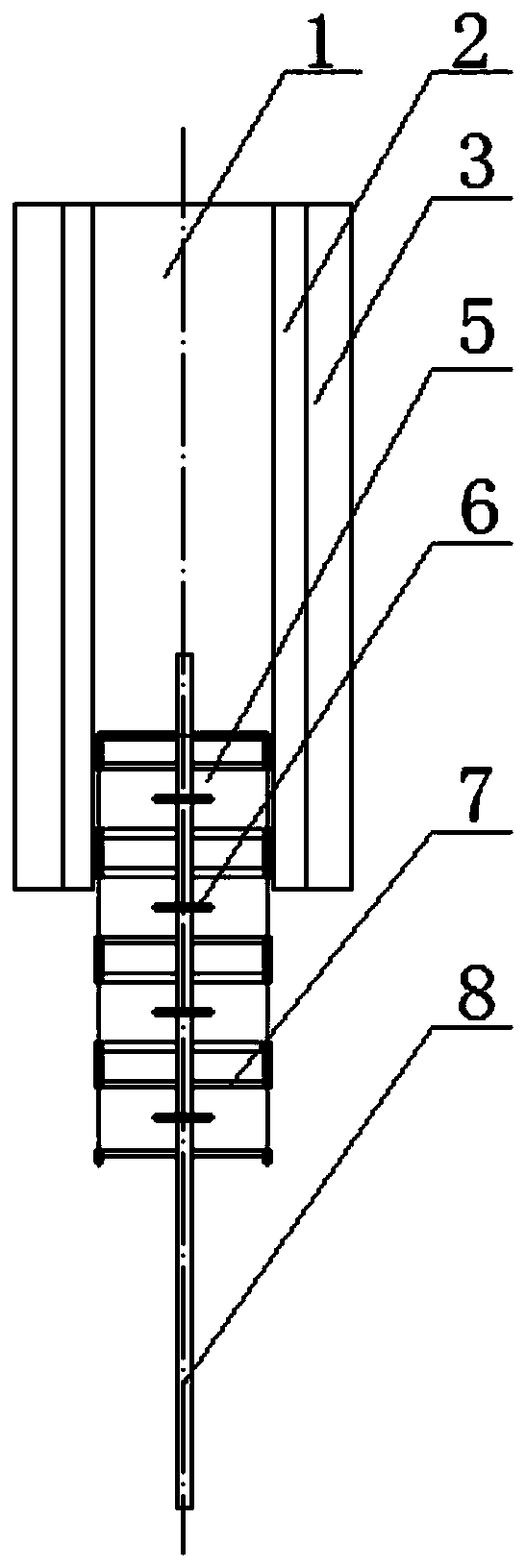

Display Rack Assembly for Wrenches with Different Handles

A display rack assembly includes a rack having two coupling sections for releasably and fixedly coupling with a first wrench with a first handle and a second wrench with a second handle. The second handle includes a handle section having two opposite wider faces perpendicular to two opposite wider faces of the first handle. The handle section further includes two opposite narrower faces perpendicular to two opposite narrower faces of the first handle. A customer may hold one of the narrower faces of the first handle and one of the wider faces of the handle section of the second handle and apply a rotational force to try the wrenches.

Owner:HU BOBBY

Method and device for inhibiting size of austenite grains at corners of continuous casting slab

InactiveCN110860662AImprove Narrow Face QualityPromoting disperse distribution precipitationAustenite grainNarrow face

The invention discloses a method and device for inhibiting size of austenite grains at corners of a continuous casting slab, and belongs to the technical field of metallurgical continuous casting. Thedevice comprises a wide-face copper plate fixed to a wide-face supporting plate and a narrow-face copper plate fixed to a narrow-face supporting plate, wherein the upper end face of the narrow-face copper plate is flush with the upper end face of the wide-face copper plate; the lower end face of the narrow-face copper plate is 100-300mm shorter than the lower end face of the wide-face copper plate; foot roller supports are symmetrically fixed to the lower end face of the narrow-face supporting plate; foot rollers are symmetrically arranged on the foot roller supports; the inner roller face formed by the foot rollers positioned on one side and the inner wall of the narrow-face copper plate are positioned on the same plane; a spraying rod is fixed to the foot roller supports through spraying rod supports; and one end of a spraying branch pipe is fixed to the spraying rod and communicates with an inner cavity of the spraying rod, and a nozzle is mounted at the other end of the spraying branch pipe. The heat transfer condition is improved, the cooling rate is increased, surface grain refinement and dispersion distribution and precipitation of precipitates in crystals are effectively promoted, and the quality of the narrow face of the casting slab is improved.

Owner:MAANSHAN IRON & STEEL CO LTD

Arc splitter arrangement for an electrical switch

InactiveUS20090255904A1Increase currentImprove featuresHigh-tension/heavy-dress switchesAir-break switchesNarrow faceElectrical and Electronics engineering

An arc splitter arrangement for an electrical switch comprises at least two arc splitters composed of a ferromagnetic material disposed parallel to one another, wherein each of the at least two arc splitters has a V-shaped cutout on a narrow face edge forming an inlet area for an arc, and an insulating material at least partially coating at least one side of the arc splitter, wherein the at least one side includes an area located behind the inlet area in an arc running direction, the area being free of, and surrounded by, the insulating material. A service switching device comprises at least one arc splitter arrangement.

Owner:ABB (SCHWEIZ) AG

Heat-resistant self-sticking transposed conductor for transformers and manufacturing method thereof

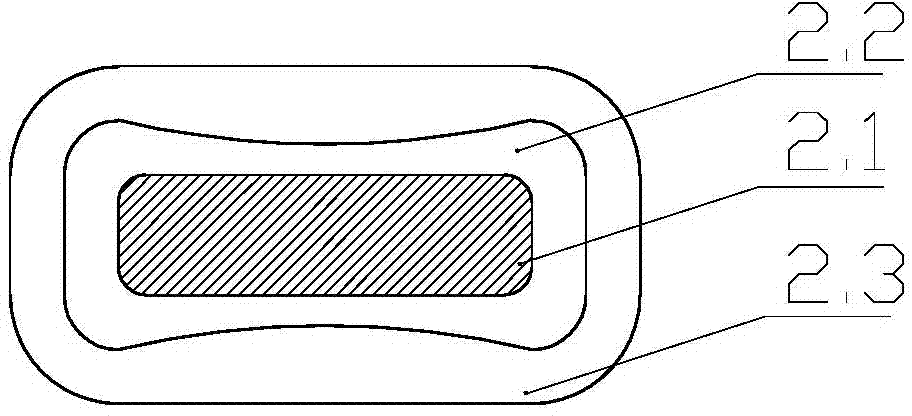

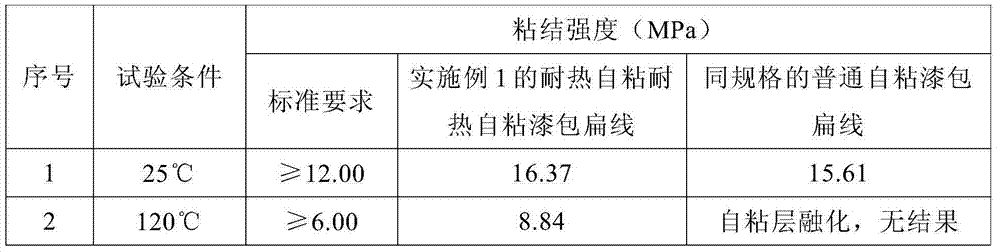

ActiveCN104240804AHigh single line bond strengthIncreased single-line bond strengthTransformers/inductances coils/windings/connectionsInsulated cablesElectrical conductorNarrow face

The invention discloses a heat-resistant self-sticking transposed wire for transformers and a manufacturing method thereof. Two rows of heat-resistant self-sticking enameled flat wires, having mutually contacted wide faces, are arranged within an outer insulating layer. Middle lining paper is arranged between the two rows of heat-resistant self-sticking enameled flat wires in such a manner that the middle lining paper is transposed in a same direction above and below the two rows of heat-resistant self-sticking enameled flat wires along their narrow faces. Each heat-resistant self-sticking enameled flat wire comprises a rectangular conductor, the cross section of the rectangular conductor is rounded, the outside of the rectangular conductor is coated with a primer film, and the outside of the primer film is coated with a finish film. From view of the cross section of the heat-resistant self-sticking enameled flat wires, the wide side of each primer film is concavely arced, and the outline of each finish film is a rectangle rounded. The heat-resistant self-sticking transposed wire has the advantages that mechanical strength of the transformer windings under high temperature can be effectively improved, short circuit resistance of the transformer windings is improved, and the service lives of the transformer windings are prolonged.

Owner:WUXI TOLY ELECTRIC WORKS

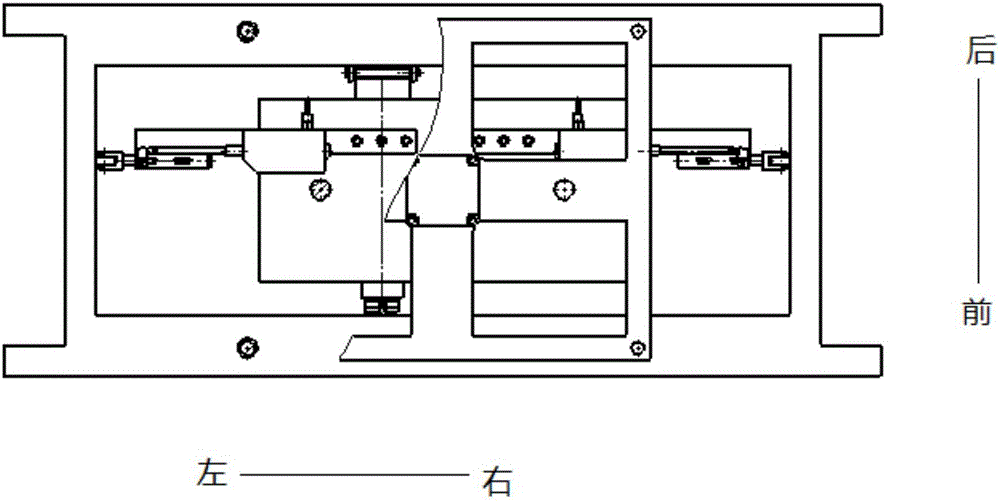

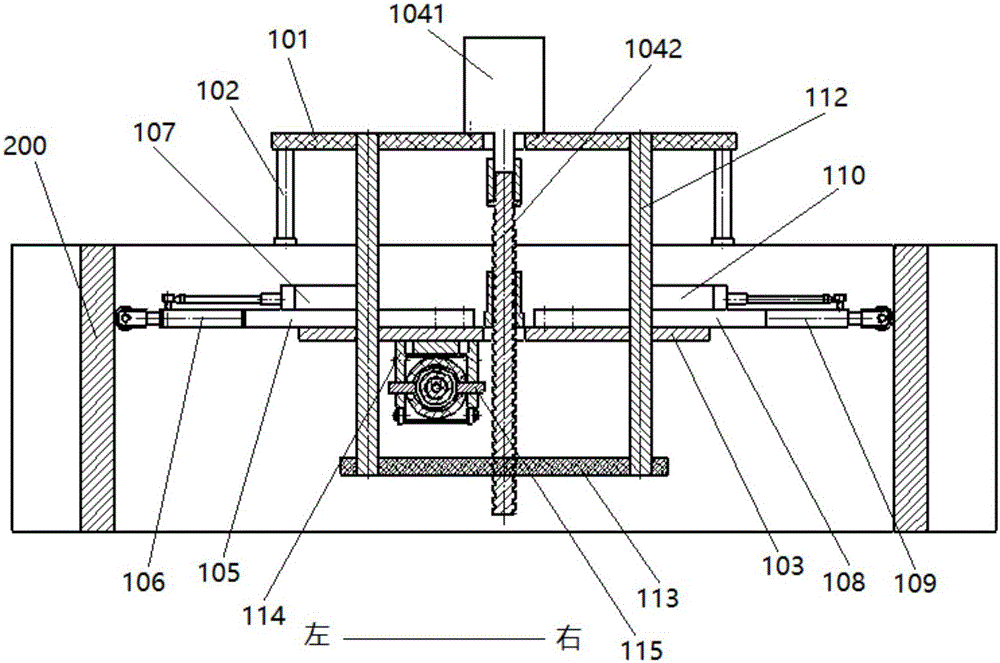

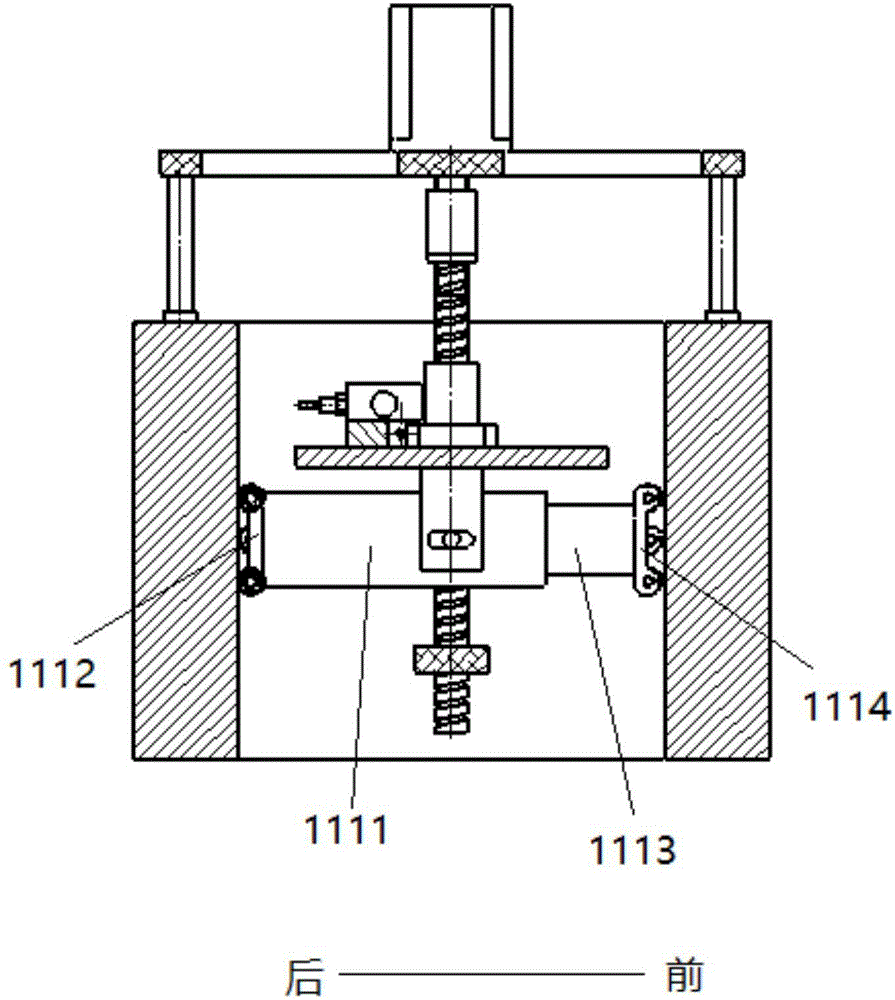

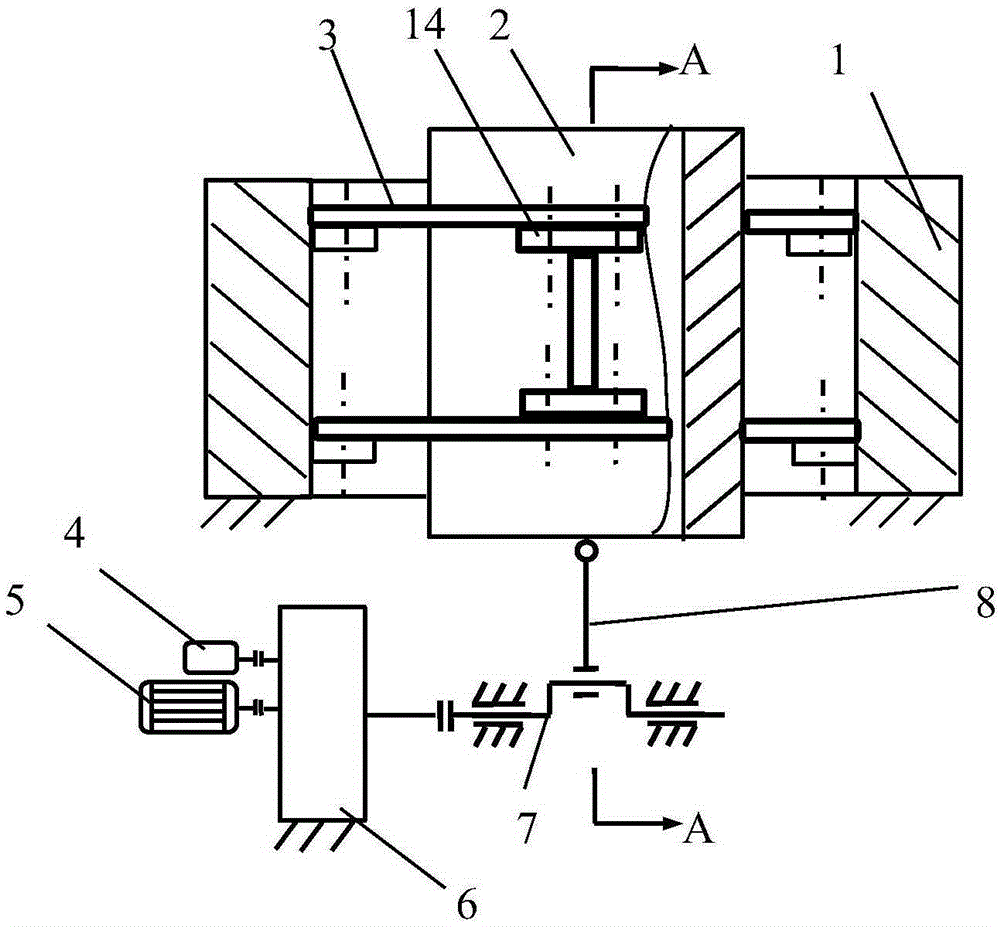

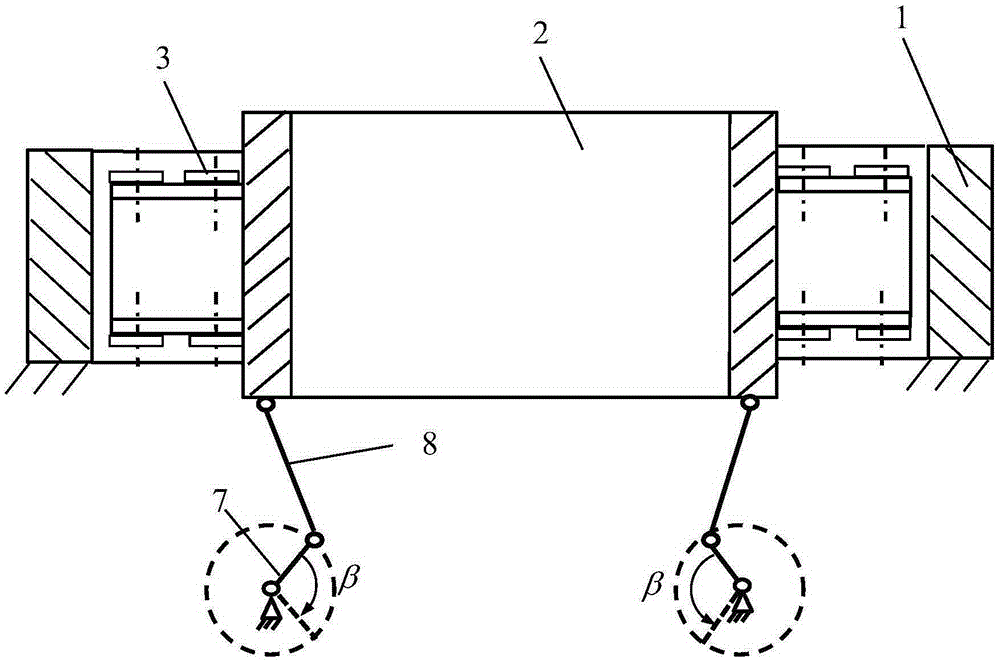

Swing type bilateral non-sine drive device of continuous casting crystallizer

The invention discloses a swing type bilateral non-sine drive device of a continuous casting crystallizer. The swing type bilateral non-sine drive device mainly comprises two identical waveform generators and a crystallizer vibration table. A vibration frame is arranged in a fixed frame. At least two guide plate springs are arranged on each side of two narrow faces of the vibration frame. The two ends of each plate spring are connected with the fixed frame, and the center lines of all the plate springs are parallel and perpendicular to the vibration direction of the crystallizer. A normal-speed motor and a servo motor of each waveform generator are meshed with two driving components of a differential gear train transmission mechanism respectively, and driven components of the differential gear train transmission mechanisms are connected with shock wave shafts. The shock wave shafts of the two waveform generators are symmetrically arranged below the two narrow faces of the vibration frame; one or two eccentric wheels are arranged on each shock wave shaft; the eccentric wheels are connected with the vibration frame through connecting rods; and the two ends of the connecting rods are hinged to the eccentric wheels and the vibration frame respectively. The swing type bilateral non-sine drive device is easy to control, high in running precision and good in impact resistance, prime mover one-way rotation is achieved, and all the amplitude, the waveform and the frequency can be adjusted online.

Owner:YANSHAN UNIV

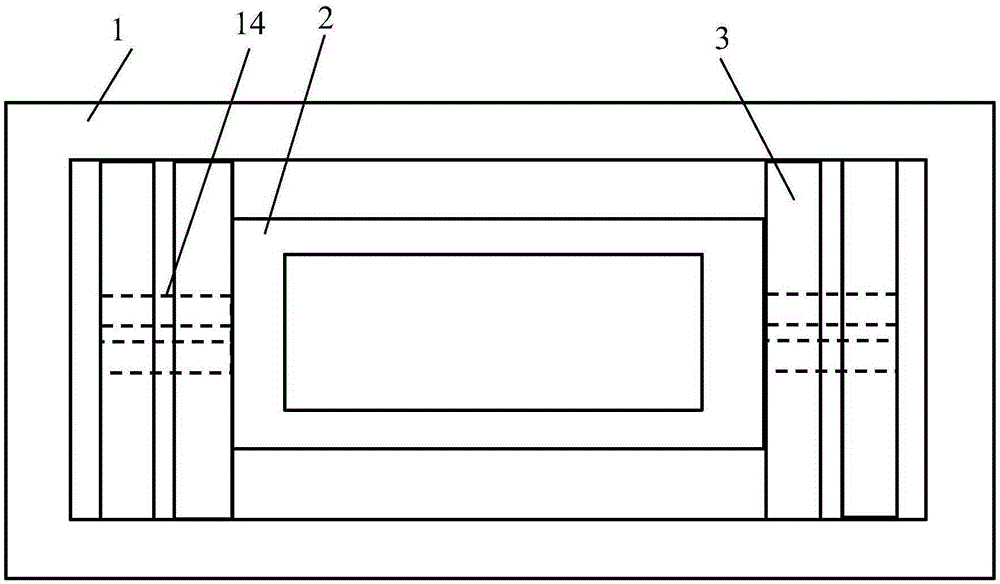

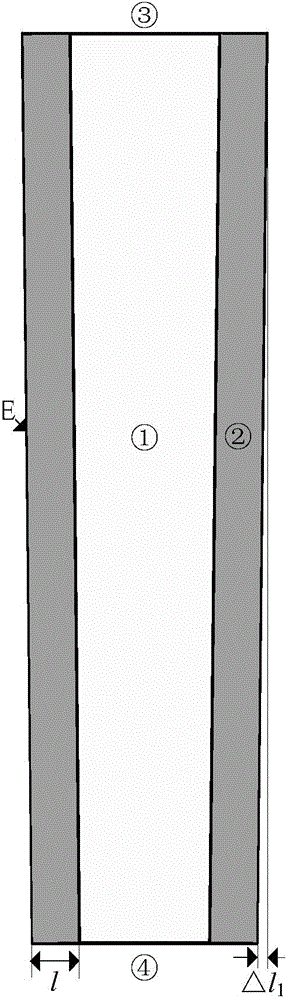

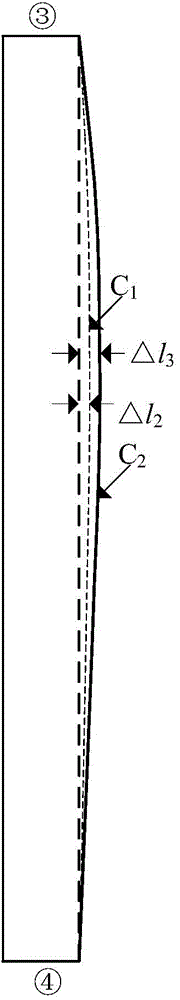

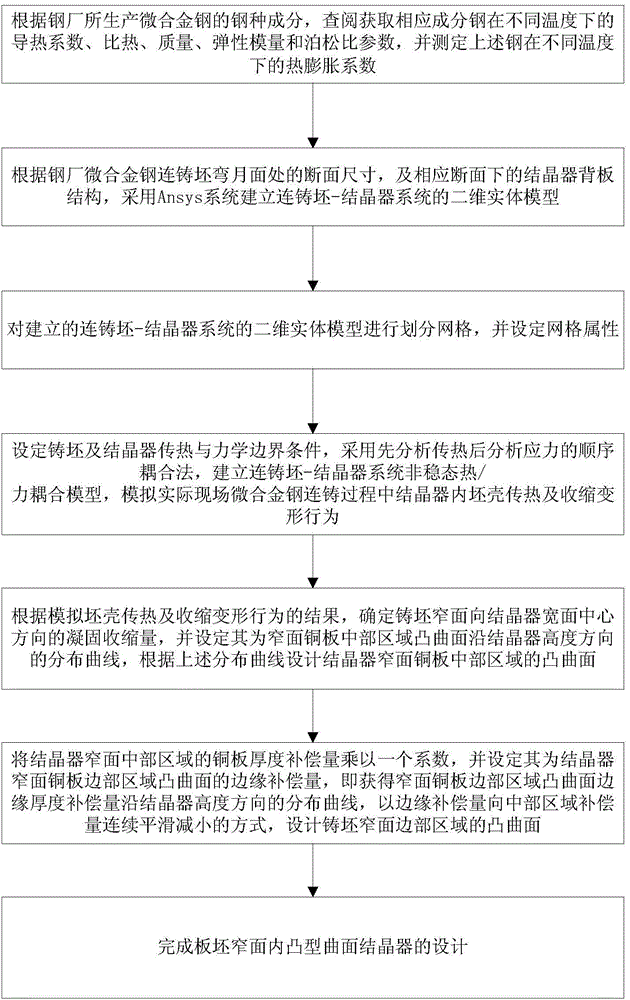

Slab narrow-face inwards-convex curved-surface crystallizer and design method thereof

The invention provides a slab narrow-face inwards-convex curved-surface crystallizer and a design method thereof and belongs to the field of continuous steel casting. The narrow-face copper plate of the crystallizer is of a structure wide in upper opening and narrow in lower opening, and the upper-opening copper plate and the lower-opening copper plate are equal in thickness. The inner surface of the narrow-face copper plate is of an inwards-convex curved-surface structure and is composed of a middle regional convex curved surface and an edge regional convex curved surface. The slab narrow-face inwards-convex curved-surface crystallizer can fully compensate shrinkage of a slab shell in the crystallizer, effectively inhabit distribution of casting slag films and air gaps in the areas nearby corners of the slab shell, accordingly achieve quick cooling of corners of the cast slab, refine initially-set structure crystal grains of the corners of the cast slab, disperse carbonitride precipitated in the grains and grain boundaries and fundamentally inhibit production of cracks at the corners of the micro-alloyed steel continuously-cast slab. By using the slab narrow-face inwards-convex curved-surface crystallizer, 'hot spots' in the areas nearby the corners of the wide face and the narrow face of the slab shell can be effectively eliminated, and even growth of the slab shell in the crystallizer is achieved.

Owner:NORTHEASTERN UNIV

Comprehensive control method of medium-carbon niobium-containing steel narrow face lateral fissure of thick plate blank

ActiveCN103611907AIncrease surface temperatureIncreased high temperature thermoplasticityThick plateNiobium

The invention provides a comprehensive control method of medium-carbon niobium-containing steel narrow face lateral fissure of thick plate blank, and belongs to the technical field of steelmaking-continuous casting. The method includes the steps that special medium-carbon niobium-containing steel casting powder suitable for casting components within a peritectic range is designed; different immersion depth change technologies are designed for submersed nozzles according to continuous casting furnace times and specific steel types; the taper value of a crystallizer is 0.95%-1.05%; the narrow face foot roller water yield is set as 145L / min-160L / min. The method has the advantages that the method is relatively simple and is high in generalization performance, the thickness of the continuous casting plate blank which the method is applicable to ranges from 300-420mm, and the width ranges from 1600 to 3000mm. After the method is used, the medium-carbon niobium-containing steel narrow face lateral fissure of the thick plate blank is well controlled.

Owner:SHOUGANG CORPORATION

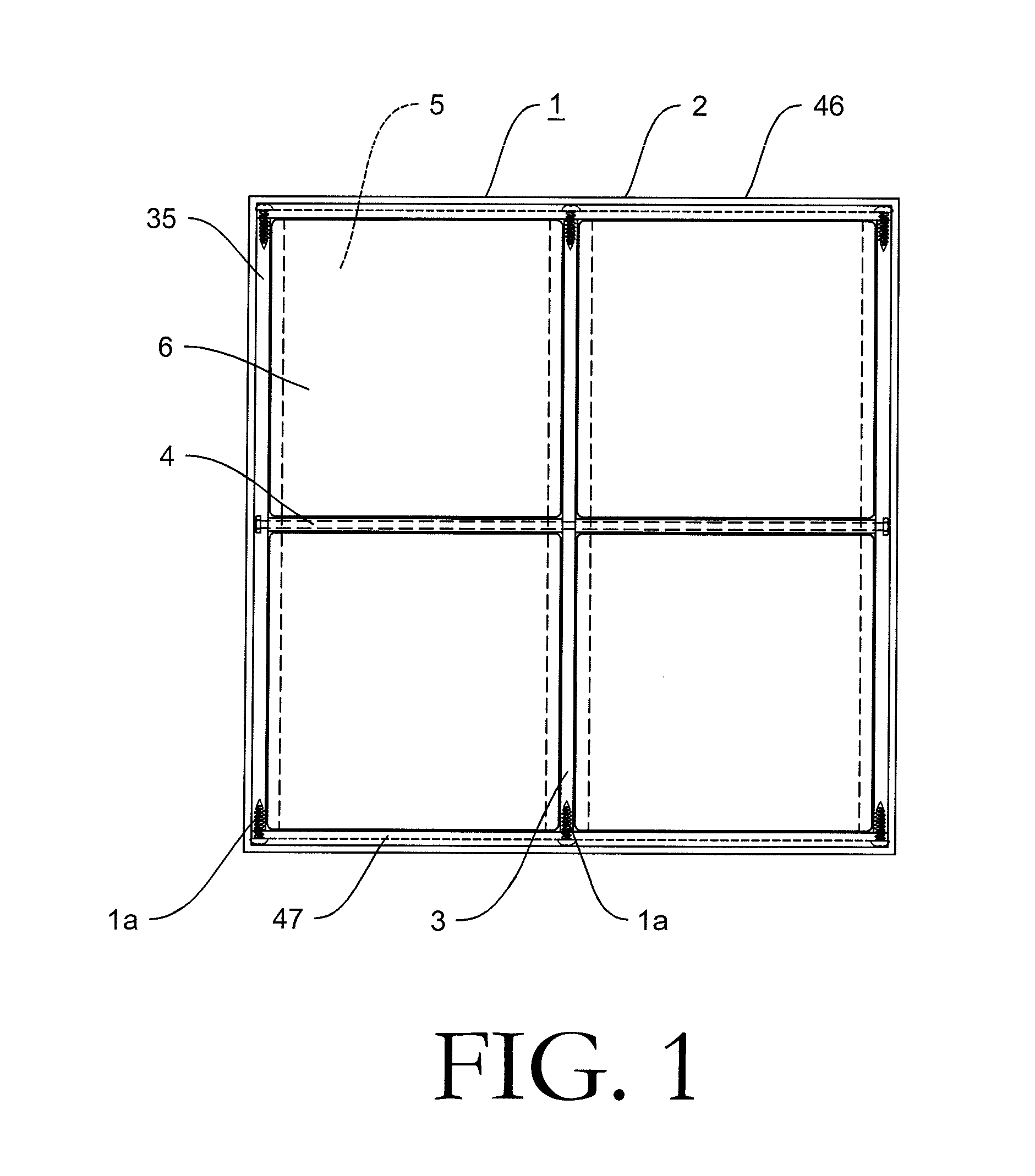

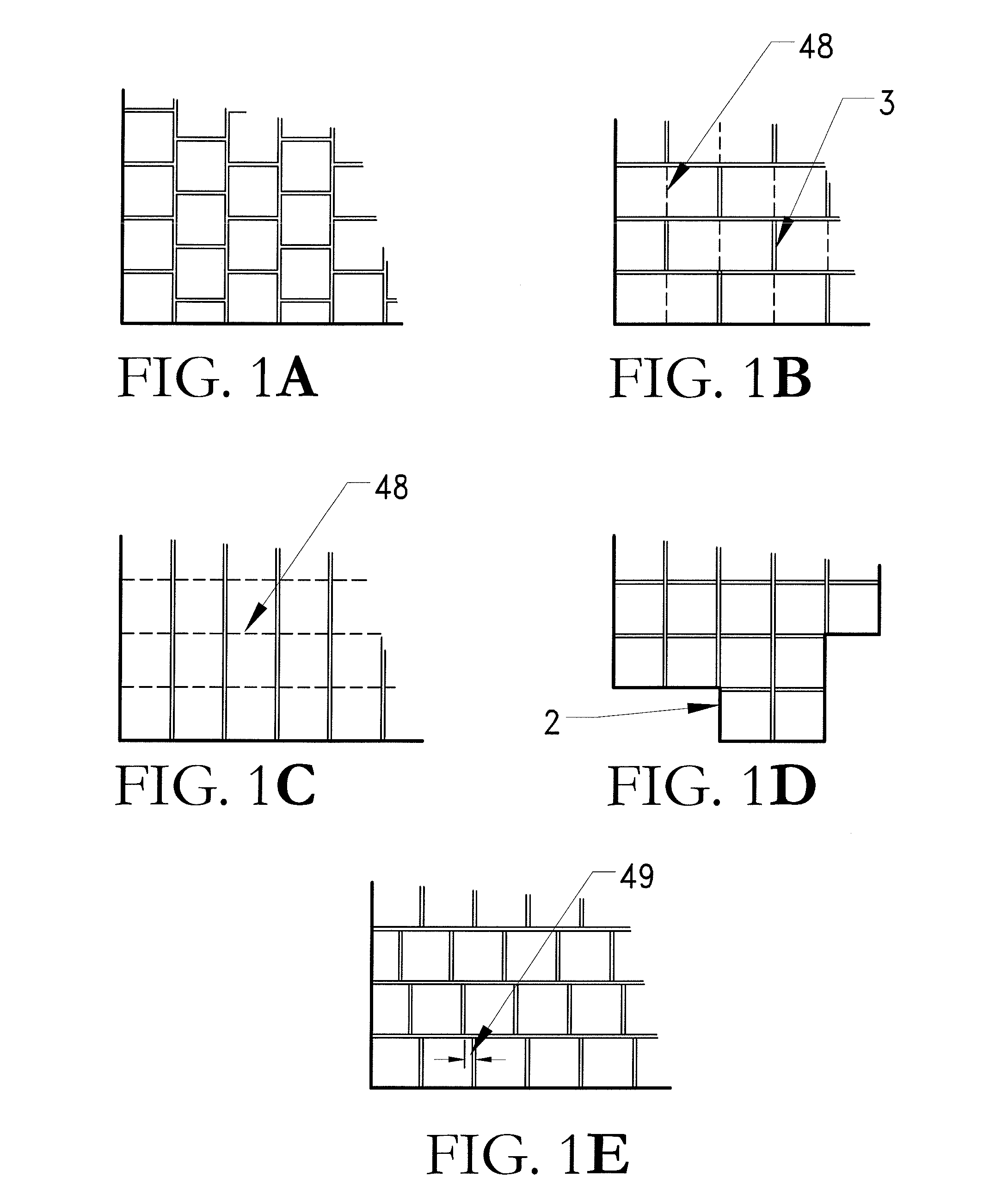

Snap-in glass block system

InactiveUS8683764B2Easy to replaceAddressing slow performanceConstruction materialStrutsNarrow faceEngineering

A block wall system comprising a framework having a perimeter, an intermediate vertical mullion, and an intermediate horizontal mullion with the blocks retained therein using flexible flanges. The intermediate vertical mullion and the intermediate horizontal mullion define one or more cavities within the framework. A block has a top, a bottom, a front face, a back face, and a pair of narrow faces. One or more detents are defined within each narrow face. Next, a flange is anchored within the intermediate vertical mullion, wherein the flange flexes and thereafter retracts to embed itself into the detent of the block when the block is inserted into the cavity such that the block is retained within the framework, thereby eliminating the need to use a fastener directly into or against the block to secure the block within the framework.

Owner:EXTECH EXTERIOR TECH

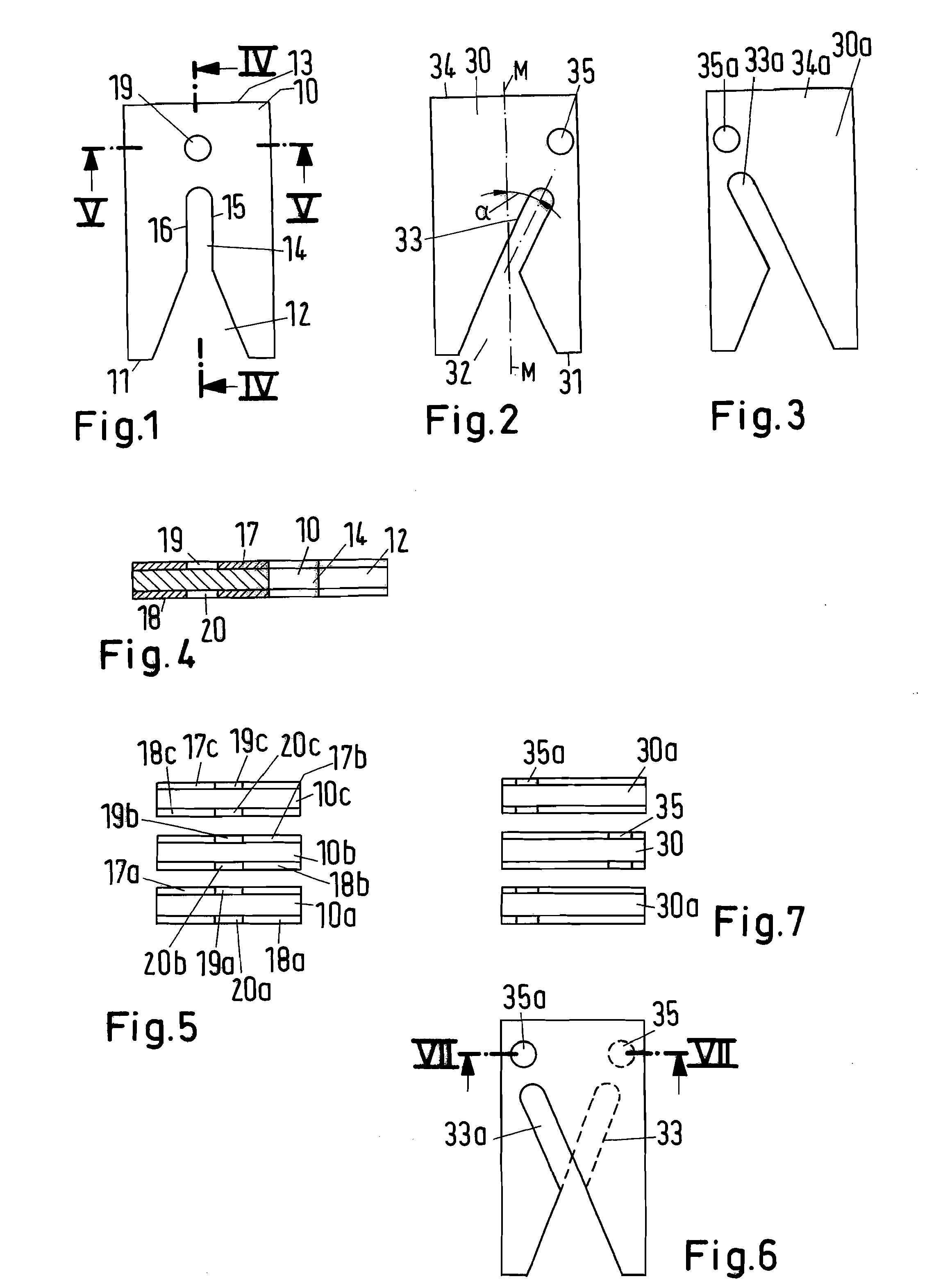

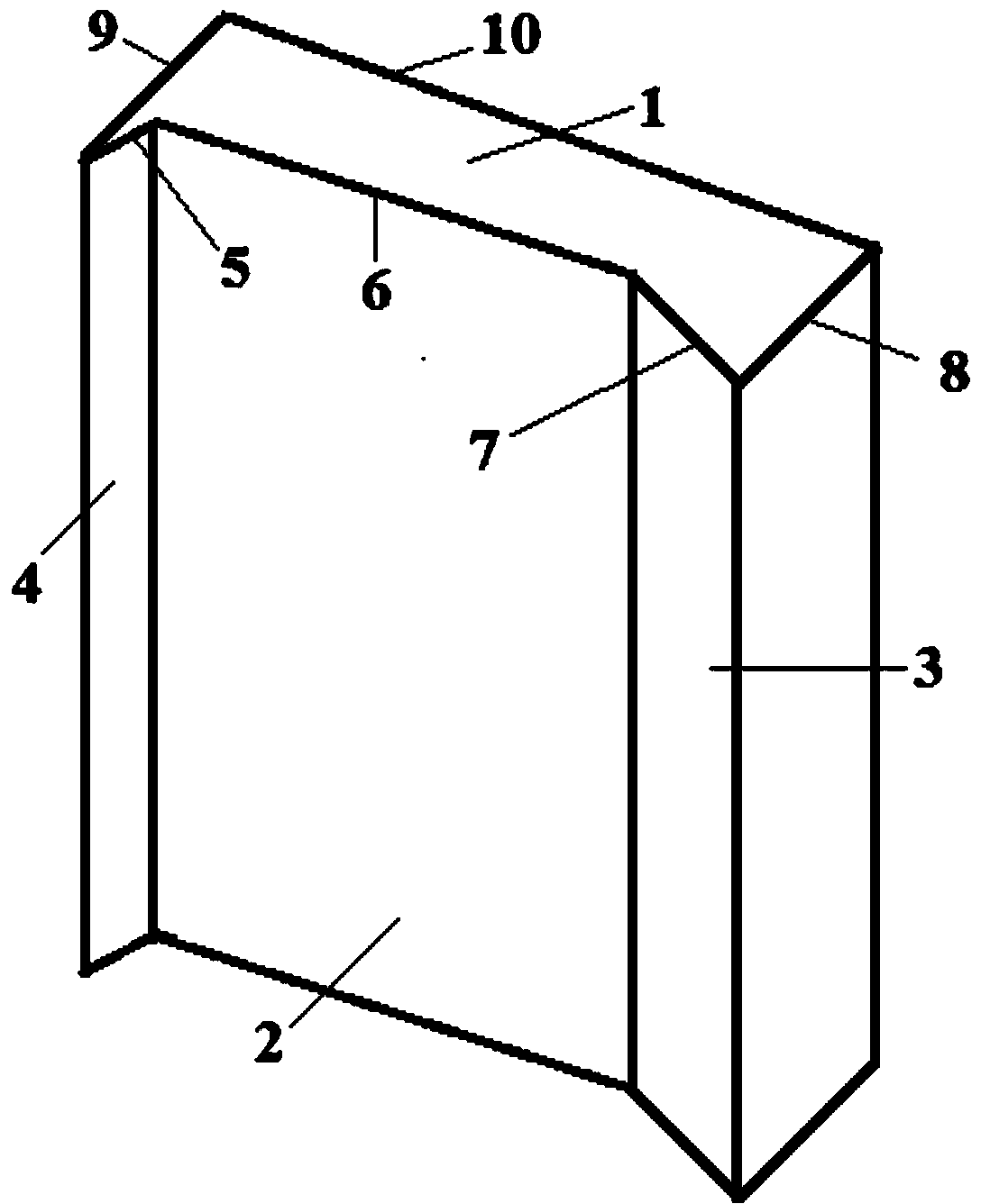

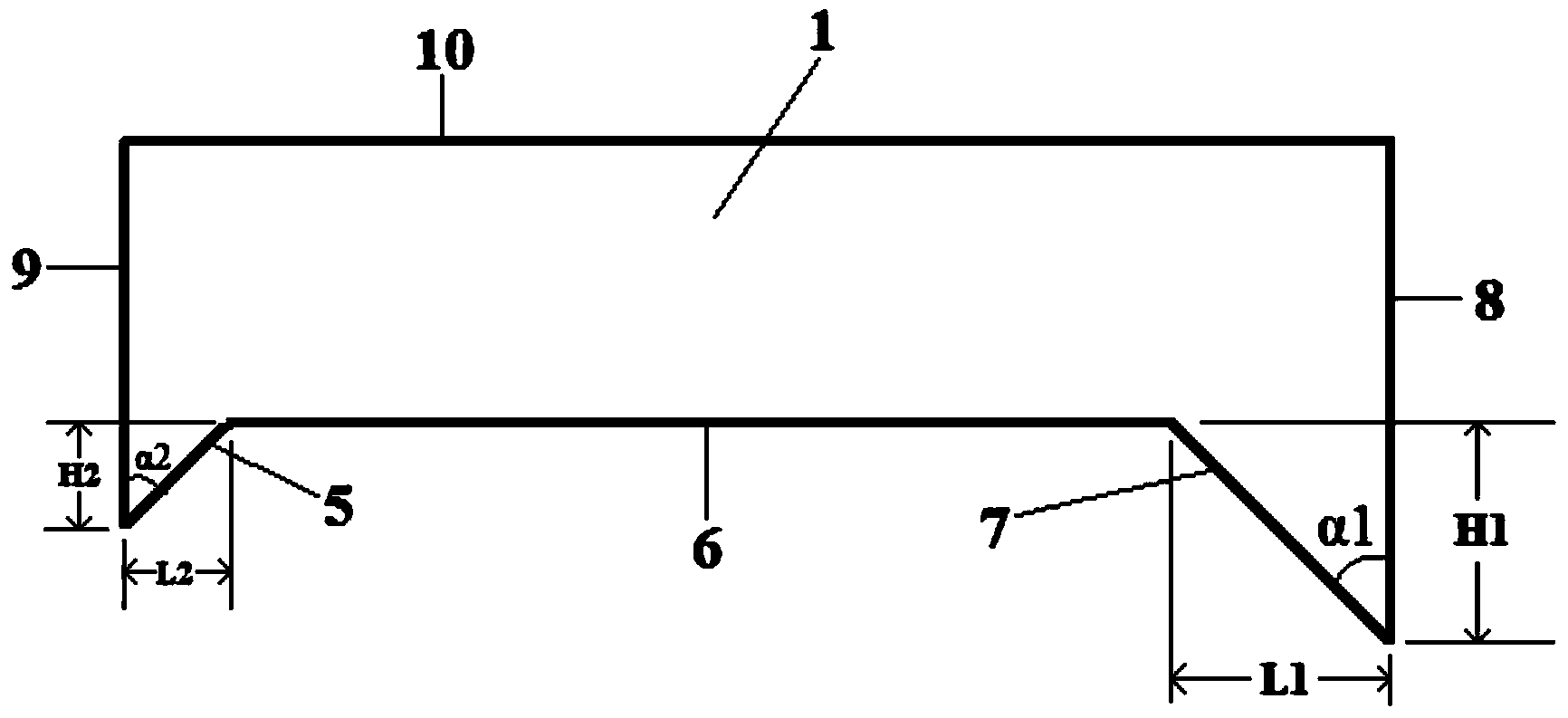

Narrow-face copper plate for asymmetric slab continuous casting chamfering crystallizer

The invention provides a narrow-face copper plate for an asymmetric slab continuous casting chamfering crystallizer and belongs to the technical field of steelmaking-continuous casting. A working face of the narrow-face copper plate consists of a middle working face (2), a large-size inner-arc chamfer (3) and a small-size outer-arc chamfer (4). An upper opening of the narrow-face copper plate is defined by a small-size outer-arc chamfering upper edge (5), a middle working face upper edge (6), a large-size inner-arc chamfering upper edge (7), an inner-arc copper plate upper edge (8), an outer-arc copper plate upper edge (9) and a copper plate back side upper edge (10). Two-dimensional heat transfer of corner portions is changed by changing corner portions of a medium-thickness slab, the slab corner portion temperature is improved, meanwhile differential treatment is performed by considering inner-outer-arc difference, accordingly the problem that corner transverse crack defects easily occurred in the continuous casting slab can be solved. In addition, the temperature difference between the outer arc and the inner arc is also considered, and the safety of the slab on a heating furnace roller way is ensured while the outer-arc corner transverse crack defects are overcome.

Owner:SHOUGANG CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com