Continuous casting crystallizer for plate billet

A slab continuous casting and crystallizer technology, which is applied in the field of metal continuous casting auxiliary devices and continuous casting slab surface quality control, can solve the problems of difficult elimination of slab corner cracks, insufficient cooling uniformity, and casting slab corner cracks, etc. problems, to achieve the effect of eliminating longitudinal cracks and surface transverse cracks on the surface of the slab, reducing cleaning losses, and eliminating the defects of the slab

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

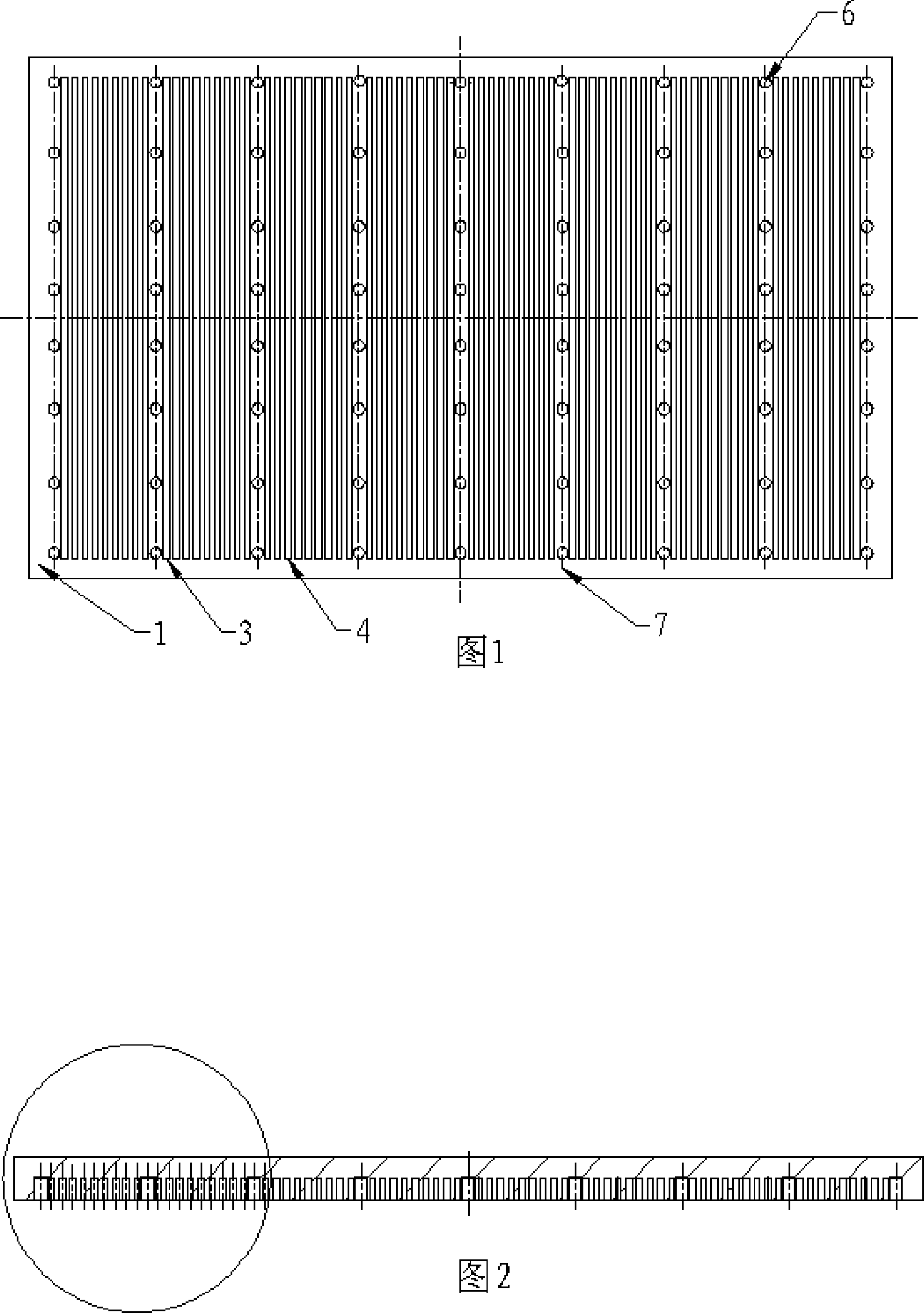

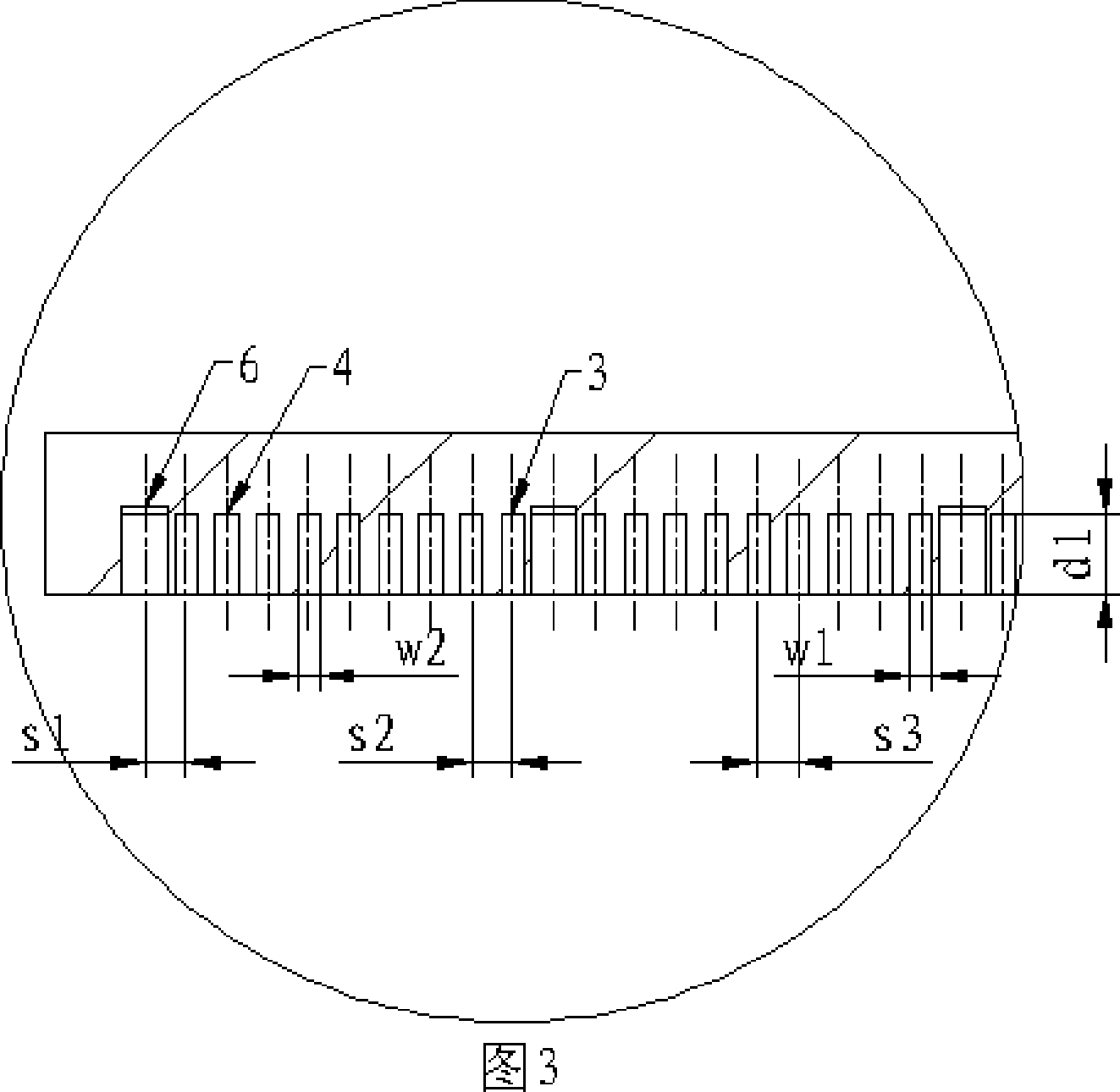

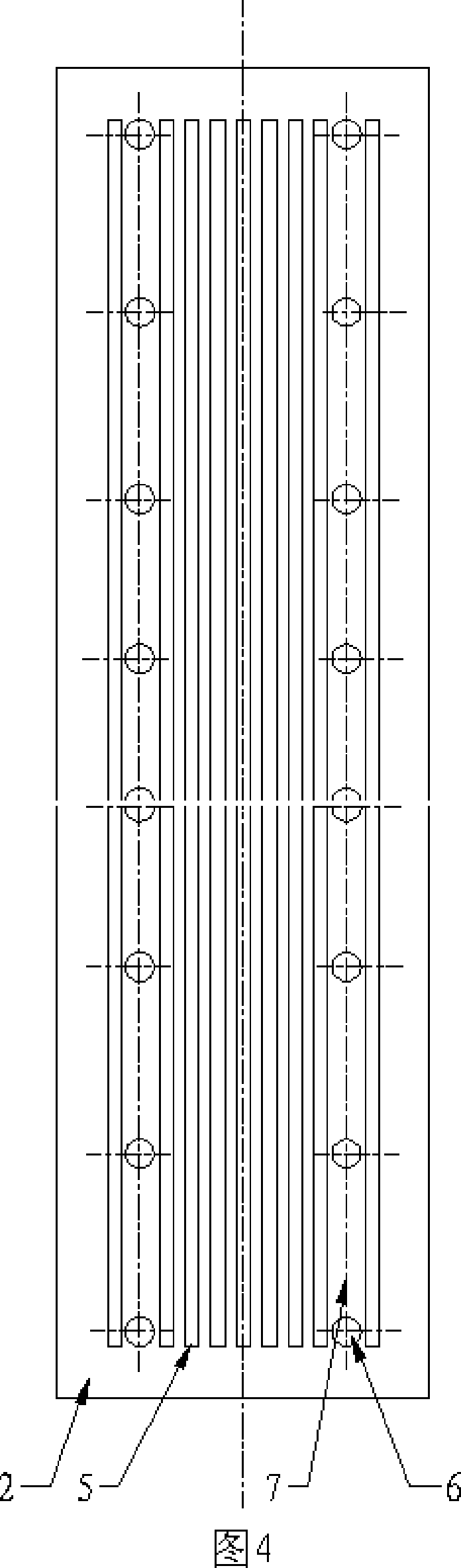

[0033] A converter steelmaking plant adopts the technology of the invention to control the longitudinal crack defect at the corner of the continuous casting billet surface. In continuous casting production, the crystallizer copper plate water tank structure shown in Figure 1, Figure 2, Figure 3, Figure 4, and Figure 5 is used, and the width of the billet is set to 1050mm before casting, and the thickness of the billet is set to 200mm , the crystallizer taper is set to 1.10% / m, and according to the different steel types, select the corresponding billet width, cooling water volume of wide copper plate, cooling water volume of narrow copper plate and casting speed listed in Table 1 below:

[0034] Table 1 Steel type and process parameter table of corresponding billet method

[0035] steel type

Slab width

Wide surface cooling water

Narrow surface cooling water

Throwing speed

IF steel

1050mm

3360l / min

400l / min

1.4m / min

Stb32 lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com