Patents

Literature

31results about How to "Reduce cleaning losses" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for controlling the cross crack of blank angle of high nitrogen steel casting board containing vanadium

The invention discloses a transverse crack control method of high nitrogen steel continuous casting plate billet angle containing vanadium, the method can not only effectively eliminate transverse crack defect of the continuous casting billet surface and skin inferior angle, but also can eliminate the continuous casting billet surface longitudinal crack and surface transverse crack defect. The method synthetically applies following technique measures: presetting the mold cooling water amount, the wide face cooling water amount is 3000-30500 L / min, the narrow face cooling water amount is set to 360-365 L / min; improving casting pulling rate, the casting pulling rate is stabilized in 0.8-1.5 m / min, the vibration frequency is 140-210 Hz; after spruing the casting pulling rate, quickly putting casting powder into the mold, the alkalinity of the casting powder is 1.0-1.40, the melting point is 1100-1160 DEG C, when at 1300 DEG C, the viscosity is 0.10-0.40 Pa.s; reducing the second cool segment casting billet cooling water amount, and controlling the continuous casting ratio water amount in 0.55-0.60 L / kg by static or dynamic adjusting method.

Owner:PANZHIHUA IRON AND STEEL

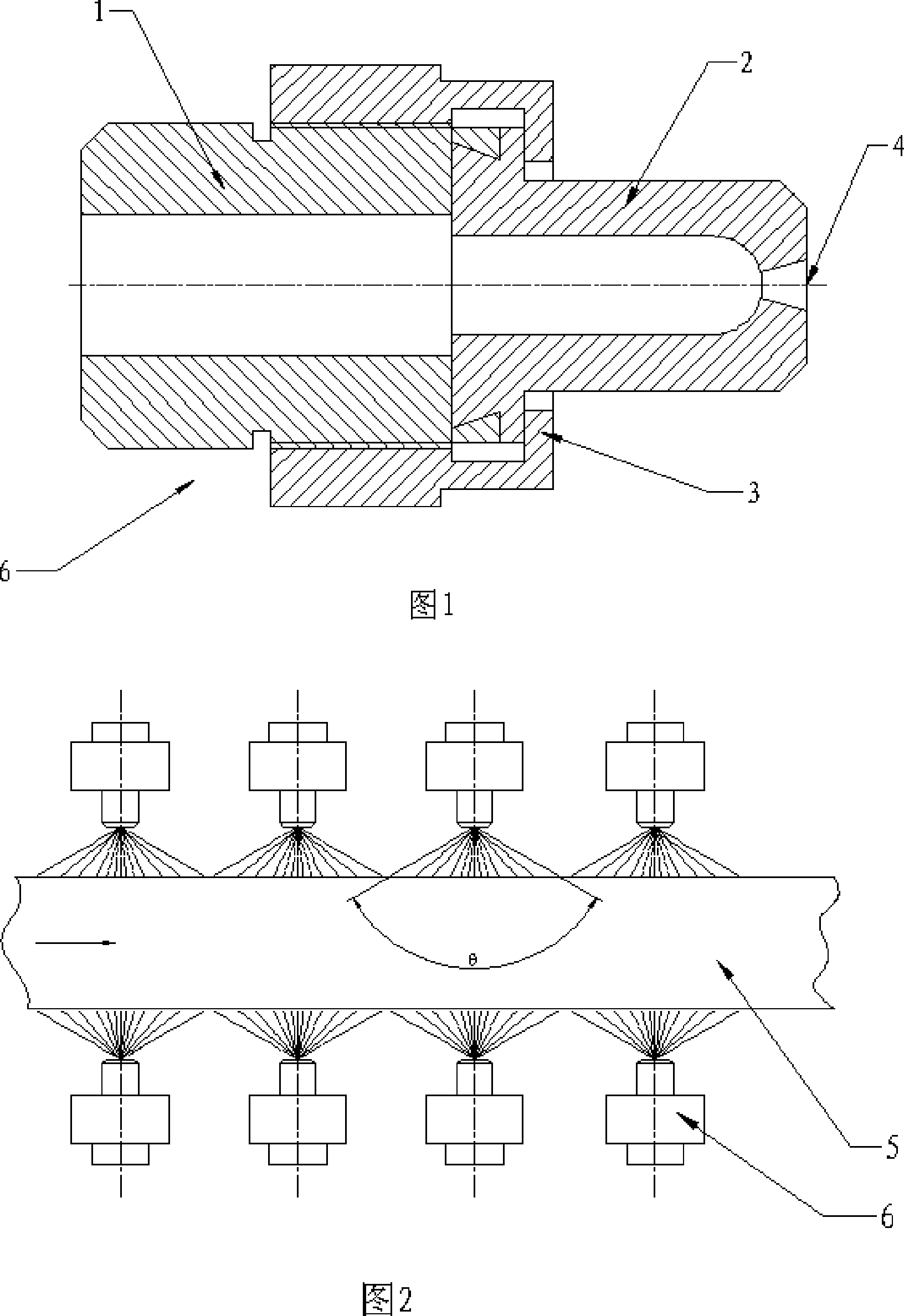

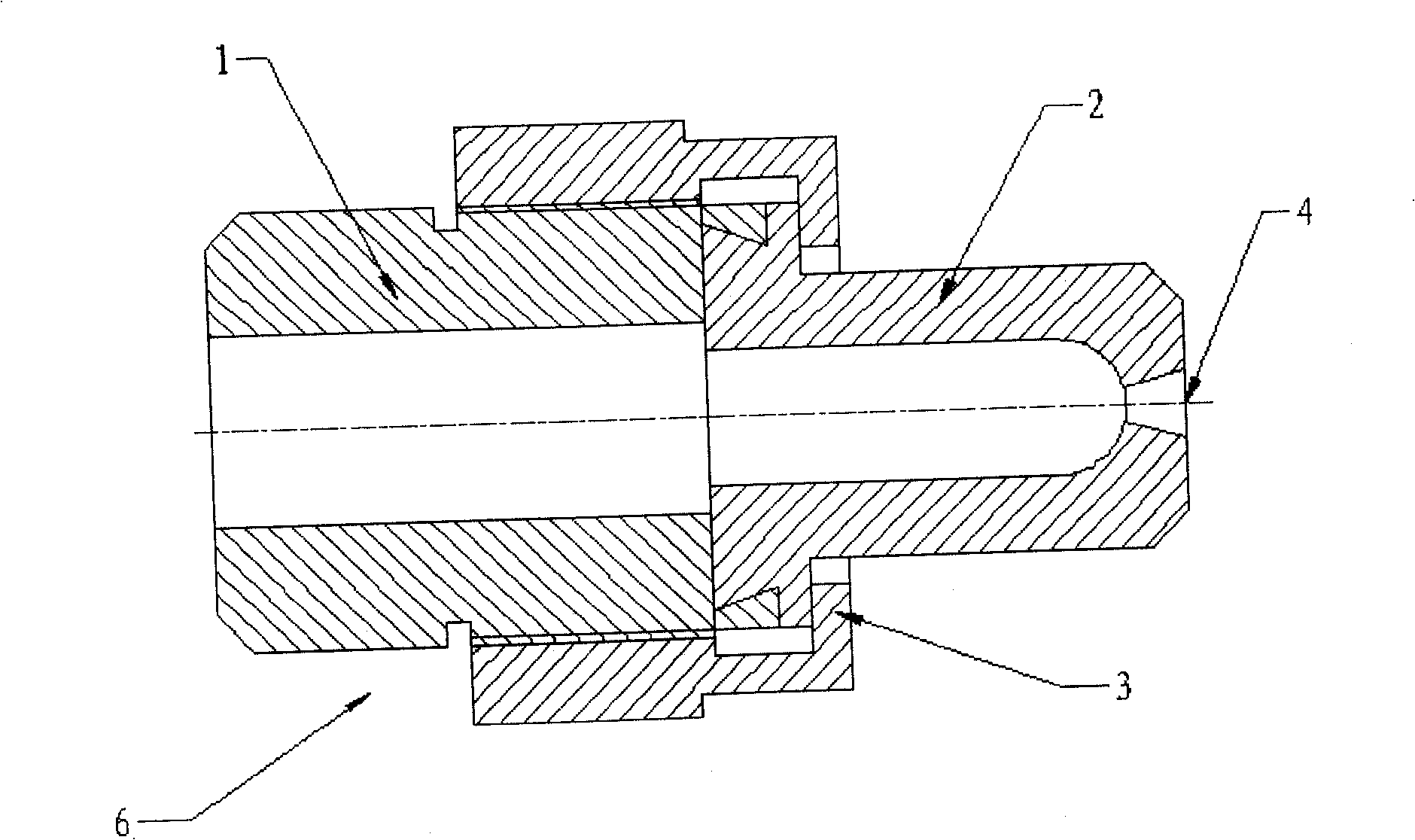

Straight arc casting machine alloy steel sheet billet continuous casting foot roller segment narrow surface cooling method

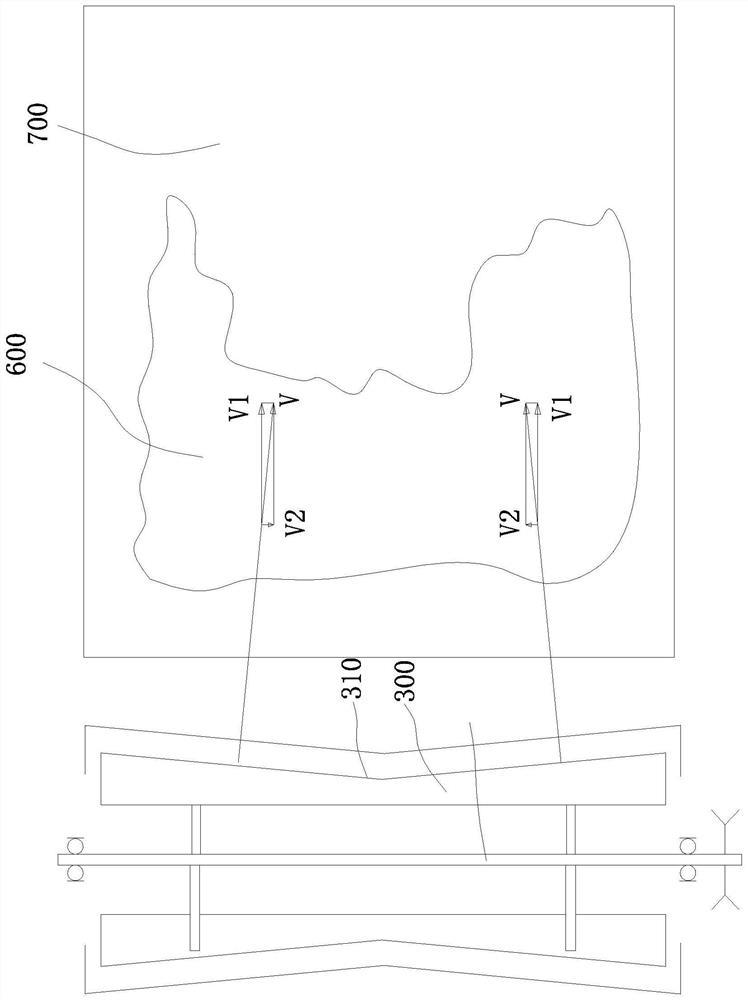

The present invention discloses a straight-curved type casting machine low-alloy steel slab continuous casting full-rolling section narrow face cooling method, and is aimed at solving the problem of that on the casting blank surface corner portion of low-alloy steel the transverse crack can be easily produced. Said invention belongs to the field of metal continuous casting blank cooling and surface quality control technology. Said method is characterized by that in the full-rolling section of continuous casting straight-curved type casting machine slab said invention utilizes the nozzles which are symmetrically mounted at left side and right side of casting blank pouring direction to cool the narrow face of said casting blank, and adopts rectangular nozzles to symmetrically and simultaneously cool the narrow faces of left and right two sides of casting blank. Said invention also discloses a kind of rectangular nozzle for said method, the water outlet hole of its sprayer is a hole with rectangular section. Said invention can reduce casting blank cooling strength of full-rolling section under the crystallizer and can improve casting blank cooling uniformity, so that it can eliminate casting blank surface corner portion transverse crack defect of continuously-cast high-strength low-alloy steel whose steel quality is P510L, P590L, J55 and X52, etc.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

Method of controlling the net crack of high-nitrogen continuous-casting slab of high strength weathering steel containing vanadium

The invention discloses a net-shaped crack control method of high nitrogen and high strength weathering steel continuous casting billet containing vanadium, the method can not only effectively eliminate net-shaped crack of the continuous casting billet, but also can eliminate the continuous casting billet surface longitudinal crack and surface transverse crack defect. The method synthetically applies following technique measures: presetting cooling water amount of the mold wide face to 2485-2515 L / min, the narrow face cooling water amount is set to 304-306 L / min; the casting pulling rate is stabilized in 0.8-1.0 m / min, the billet casing surface temperature of the casting billet out of the mold lower end is increased to 1050-1120 DEG C, the vibration frequency is 110-130 Hz; reducing Cao mixing amount in the casting powder, the alkalinity of the casting powder is 0.95-1.20, the melting point is 1080-1120 DEG C, when at 1300 DEG C, the viscosity is 0.2-0.5 Pa.s; reducing the second cool segment casting billet cooling water amount, and controlling the continuous casting ratio water amount in 0.60-0.65 L / kg by static or dynamic adjusting method.

Owner:PANZHIHUA IRON AND STEEL

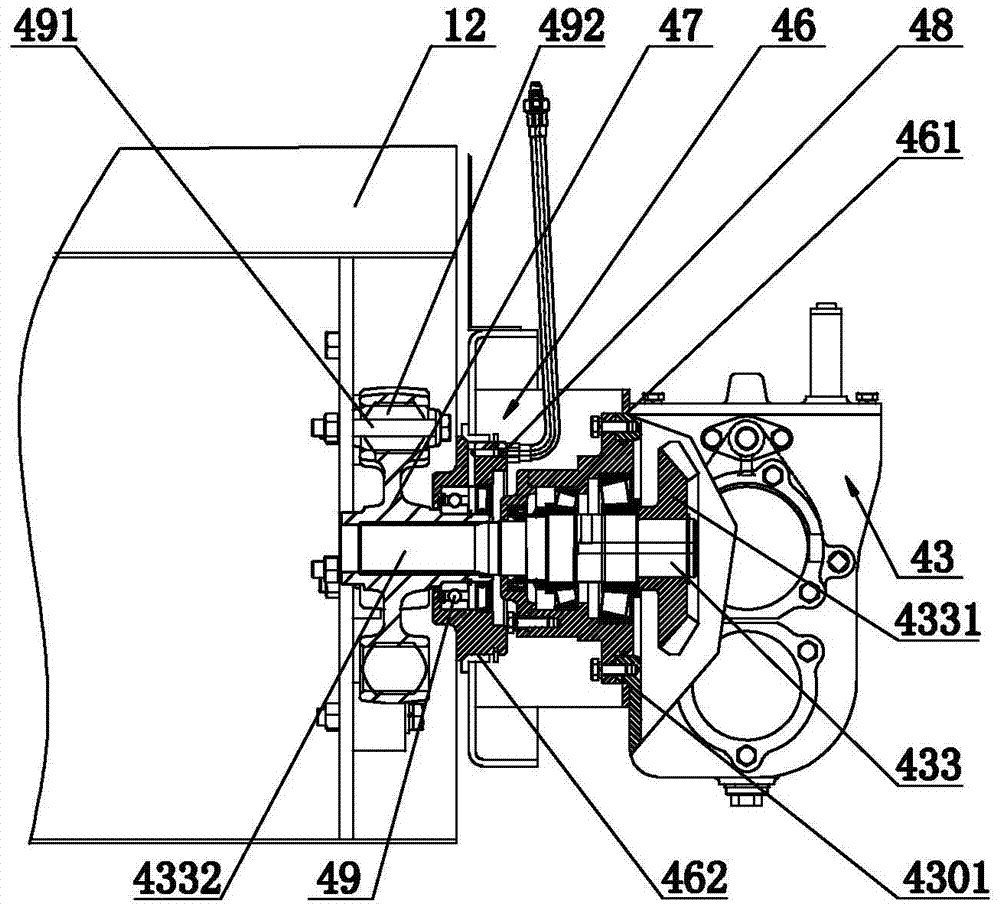

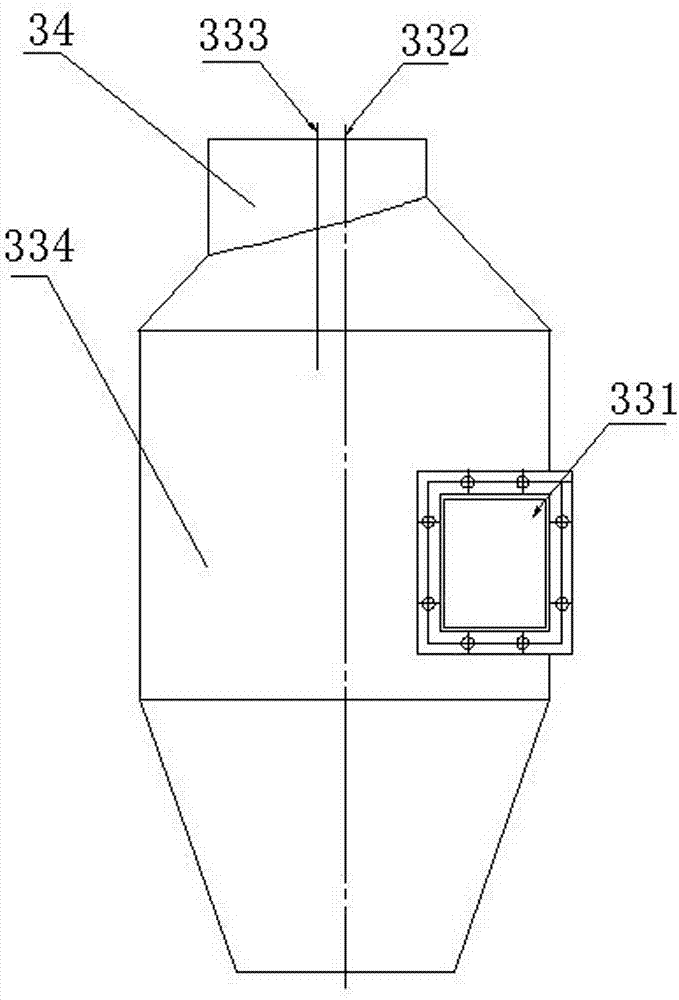

Cleaning system and combined grain harvester adopting same

The invention discloses a cleaning system and a combined grain harvester adopting the cleaning system. A cyclone separation cylinder of the cleaning system comprises a cylinder body; the middle section of the cylinder body is a cylindrical section, and the upper and lower sections are cone sections; the upper end of the cylinder body is communicated with a gettering fan, and the cylindrical section is communicated with a winnower through a separation pipe; the side wall of the separation pipe, which is far from the axis of the cylinder body, is raised from the wall of the cylindrical section of the cylinder body; and ventilation holes are distributed at intervals on the side wall of the lower cone section of the cylinder body. The cleaning system with the structure ensures that the materials to be cleaned is far from the axis of the cylinder body as much as possible when entering the cyclone separation cylinder so that the cleaning loss can be reduced without increasing the diameter of the cylinder body. In addition, the air entering the lower cone section of the cylinder body from the ventilation holes forms an air cushion layer on the inner wall of the lower cone section so that part of the light impurities entered the lower cone section suspends under the action of the air cushion layer, is sucked out by the gattering fan and cannot block the lower cone section hereby.

Owner:HENAN UNIV OF SCI & TECH

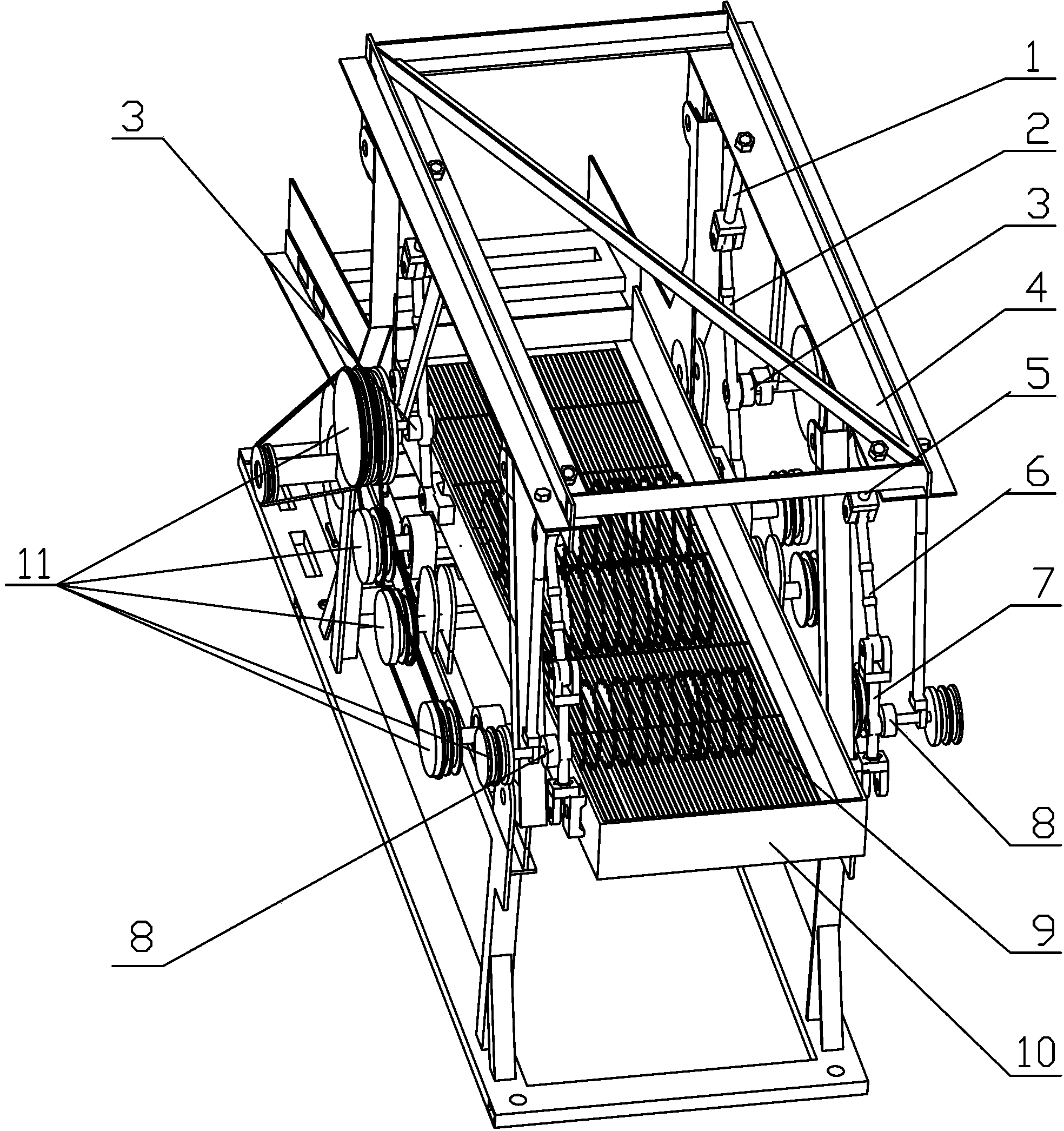

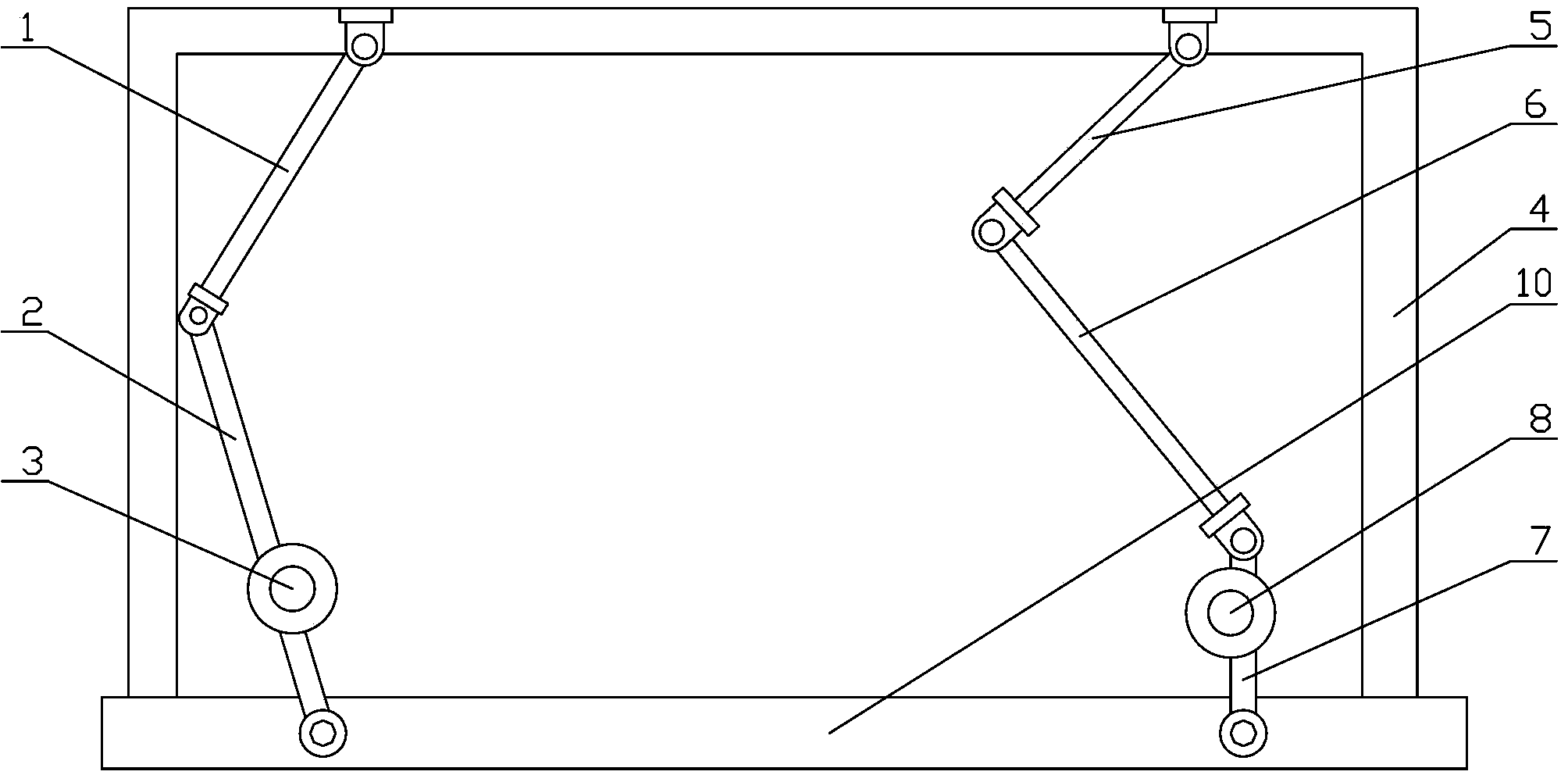

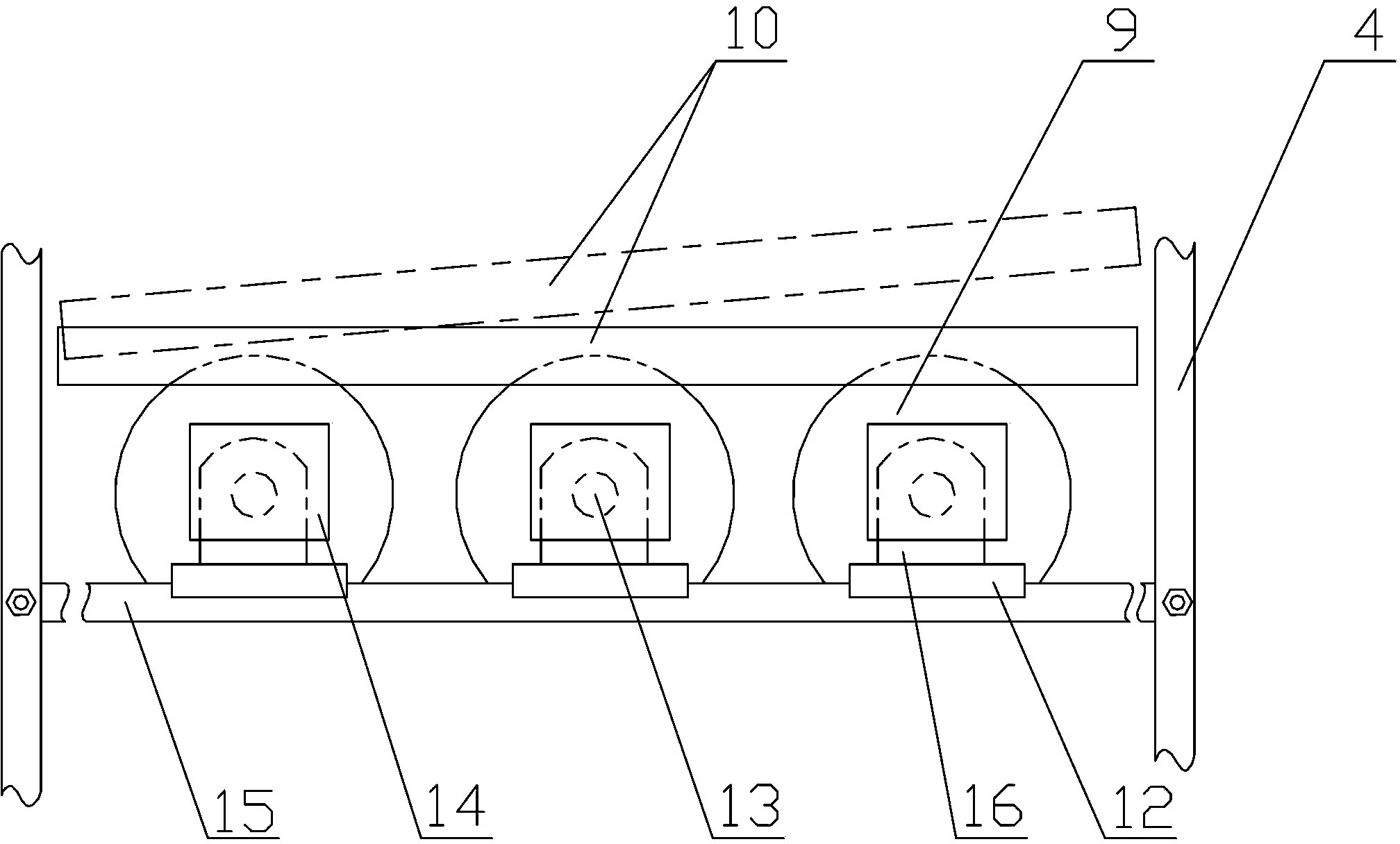

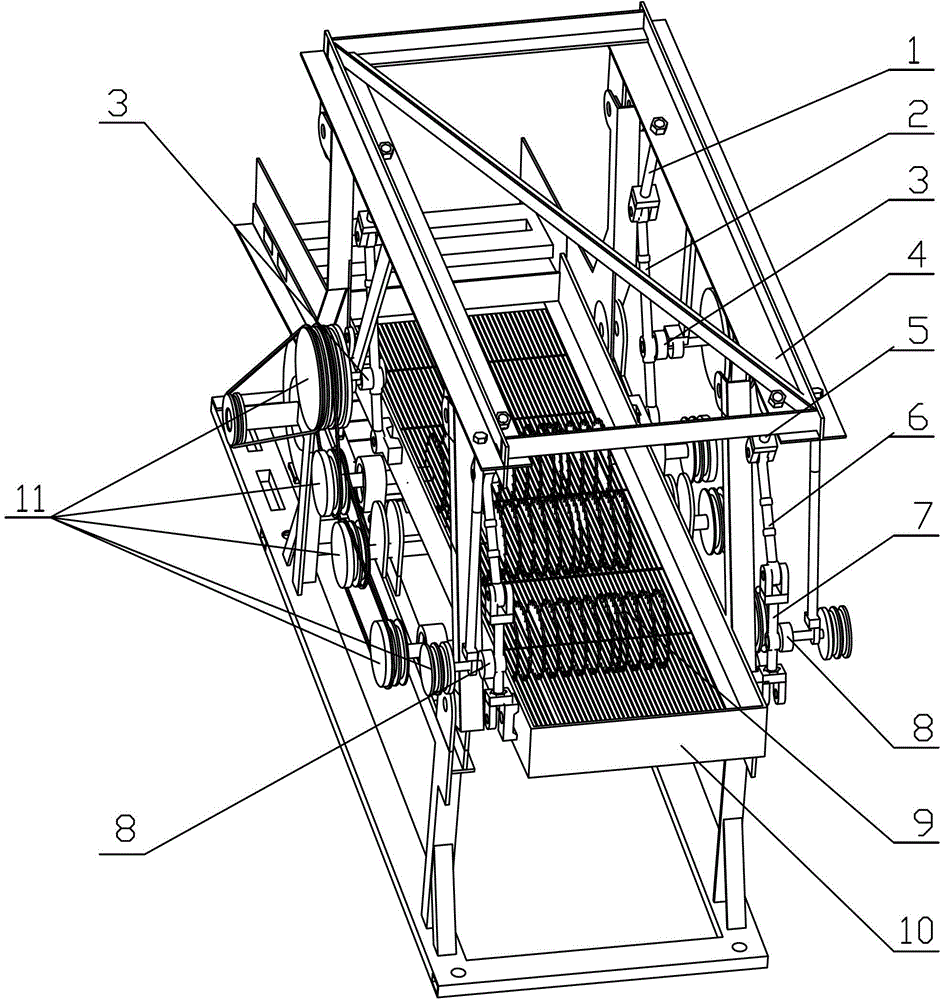

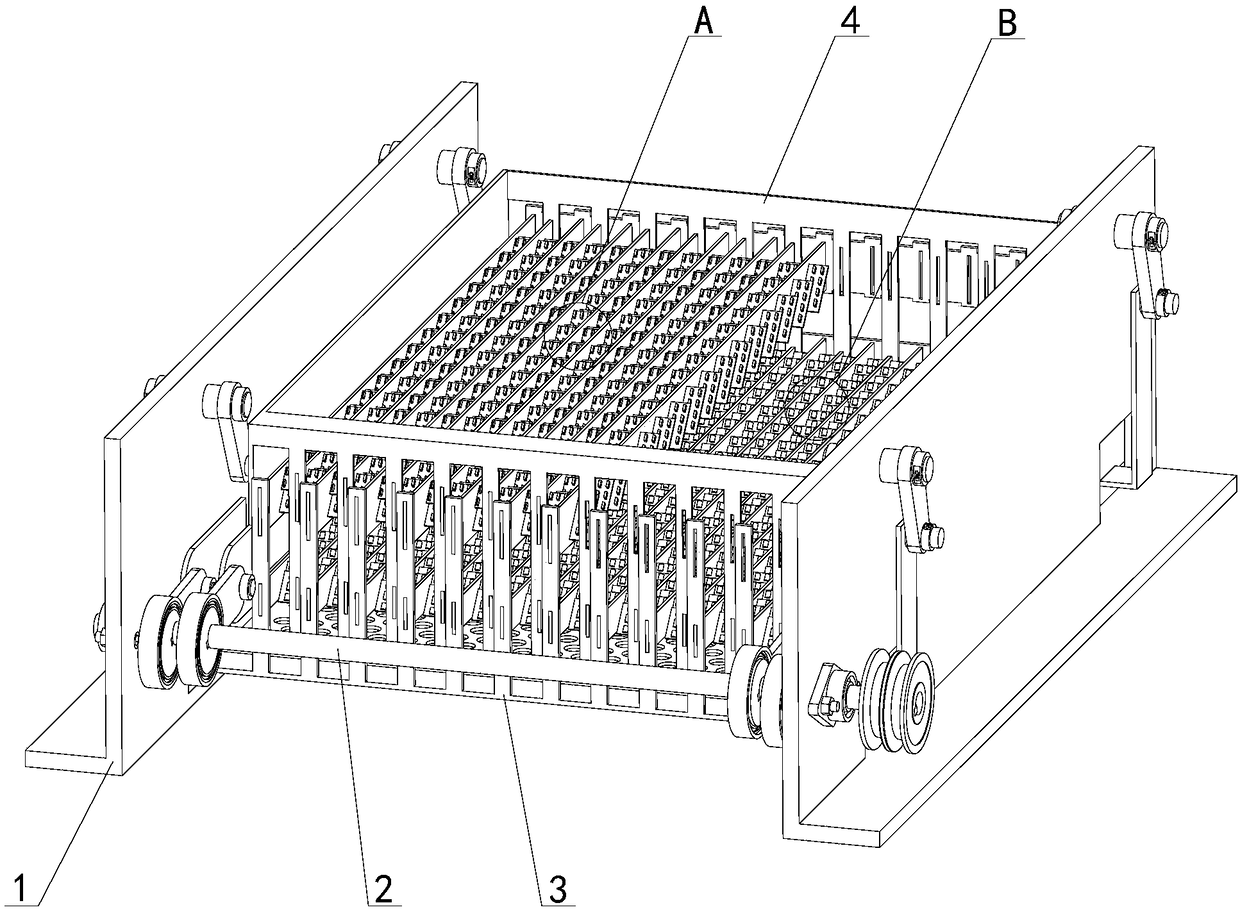

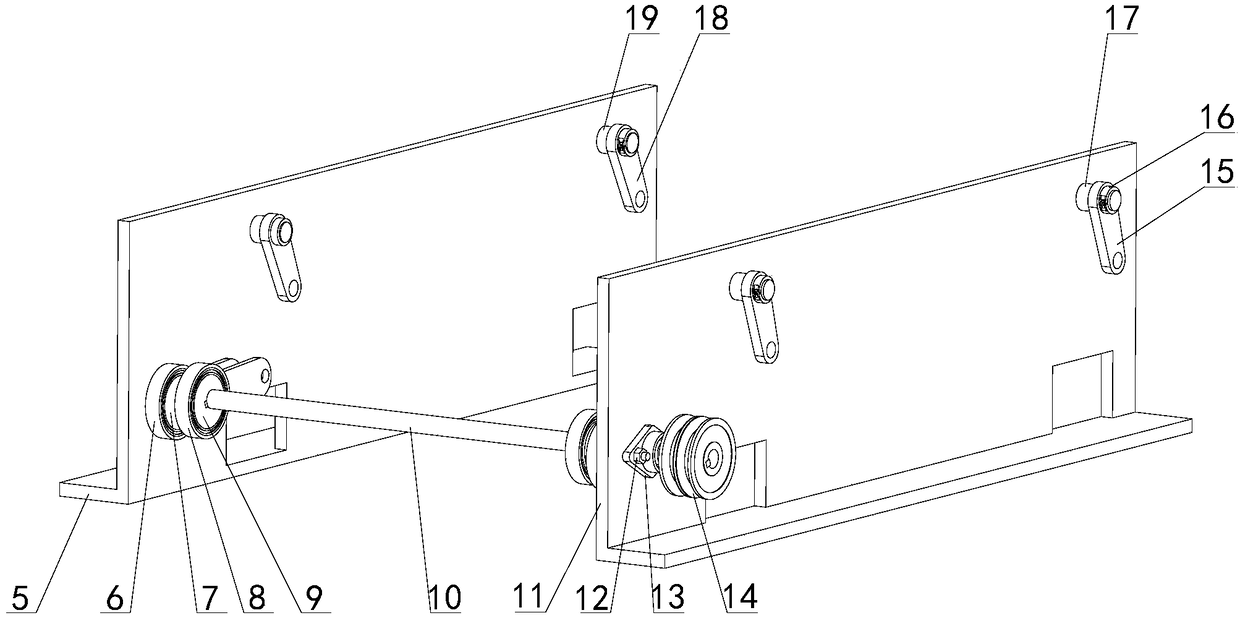

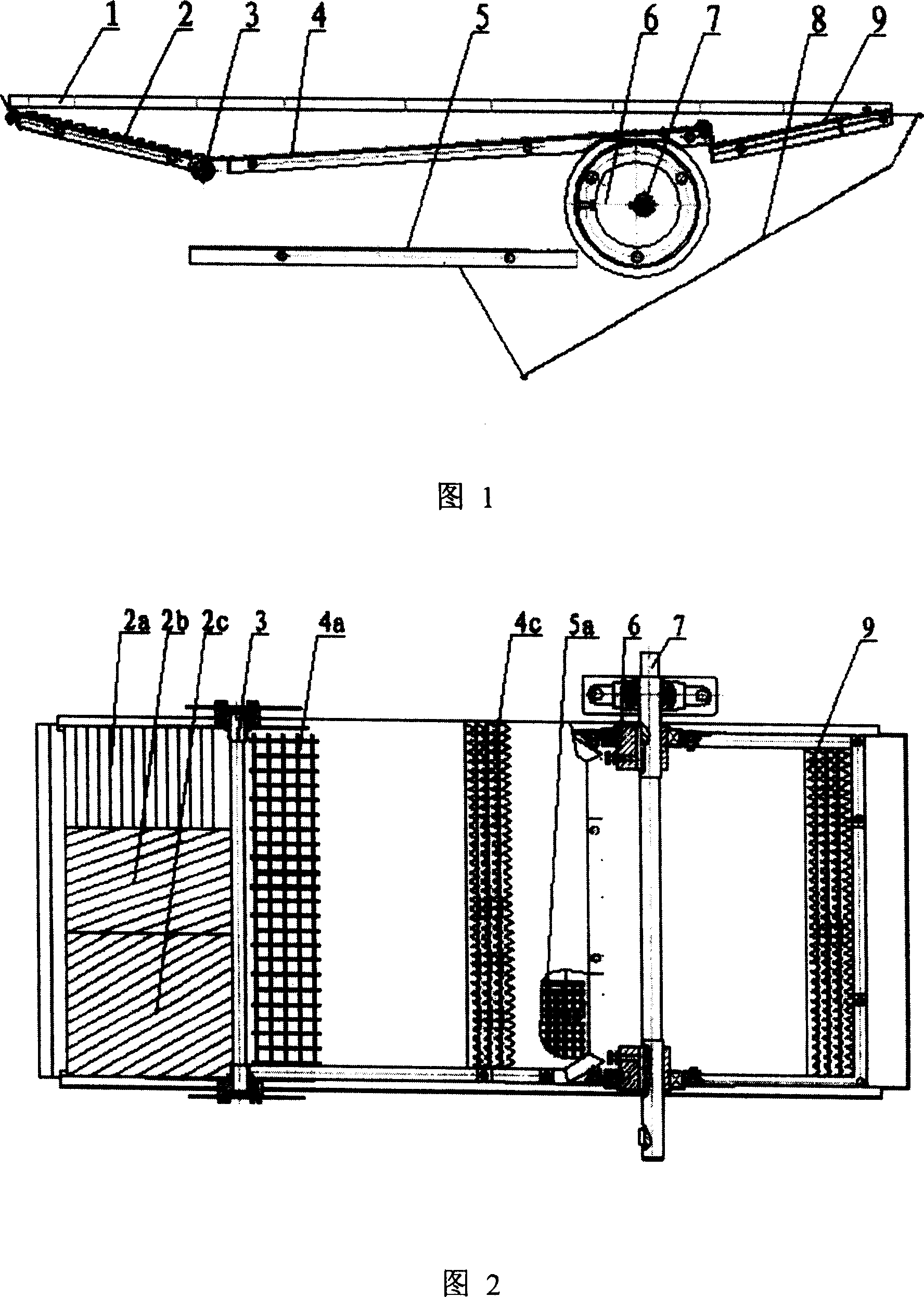

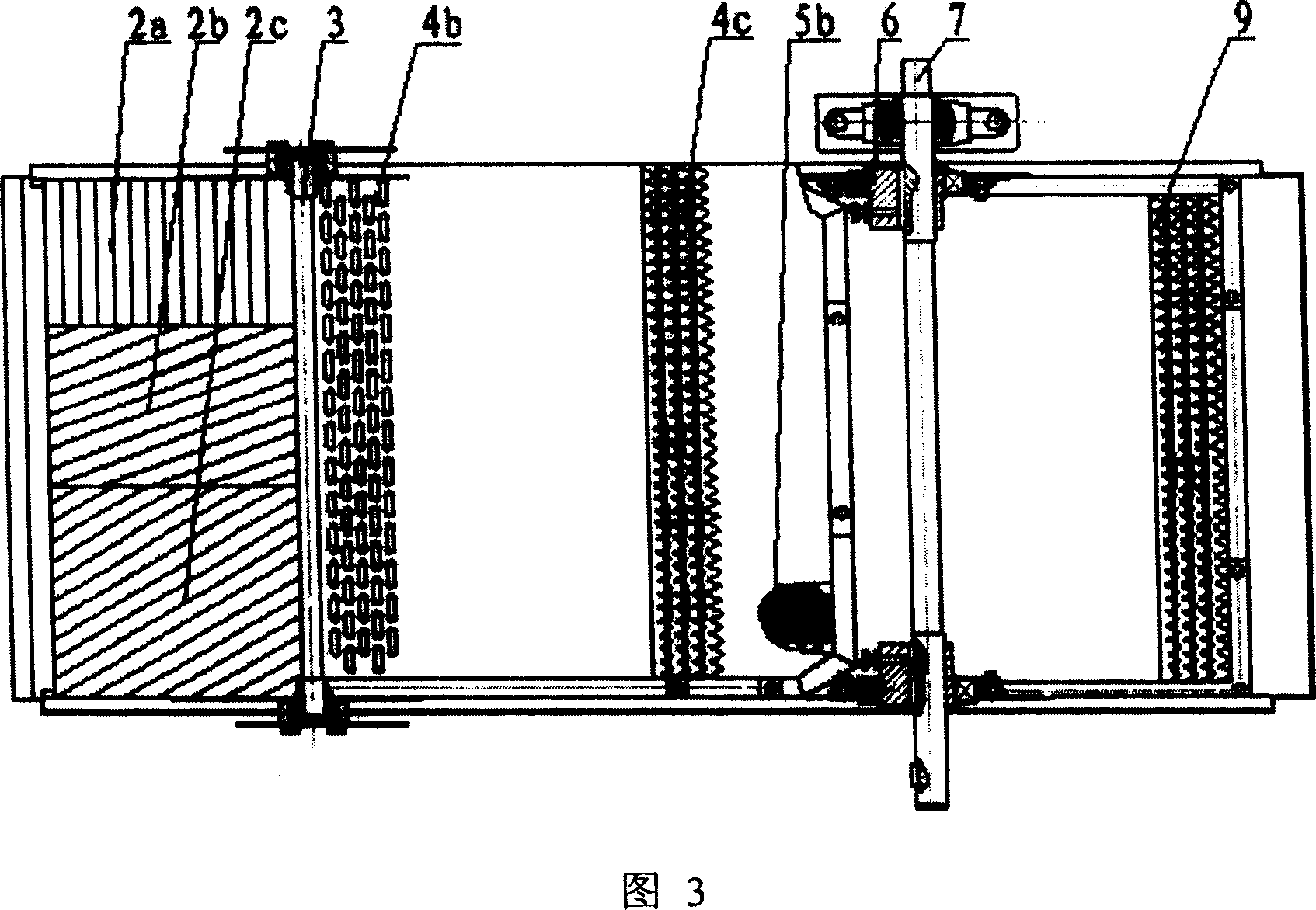

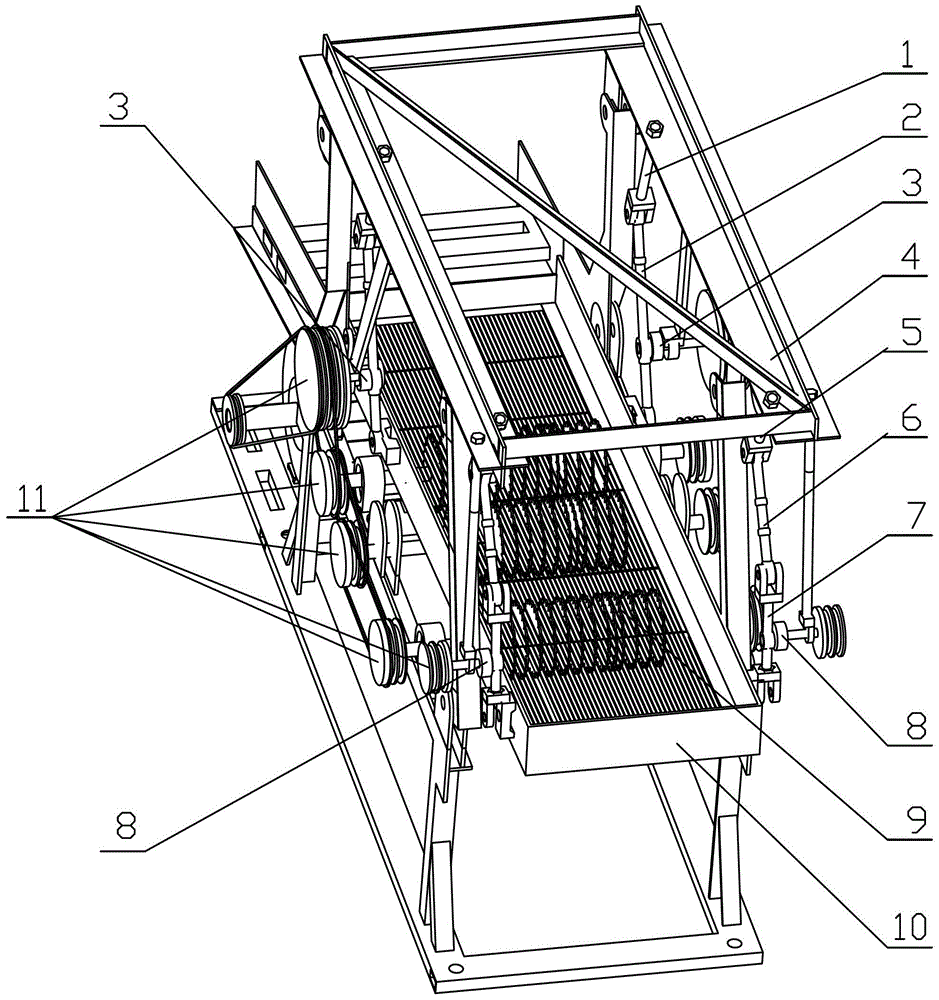

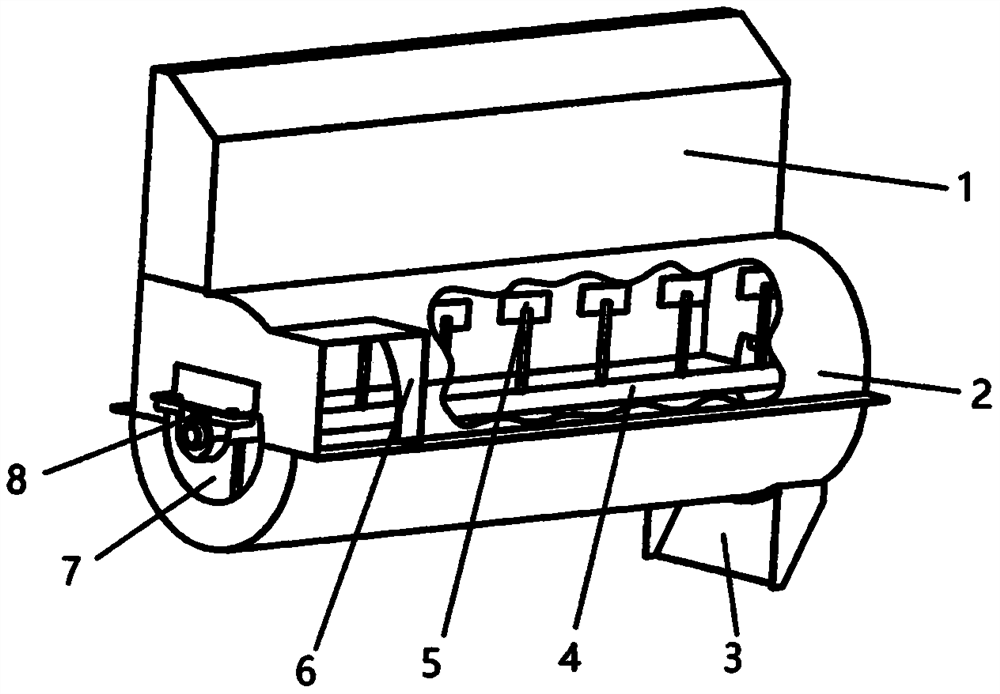

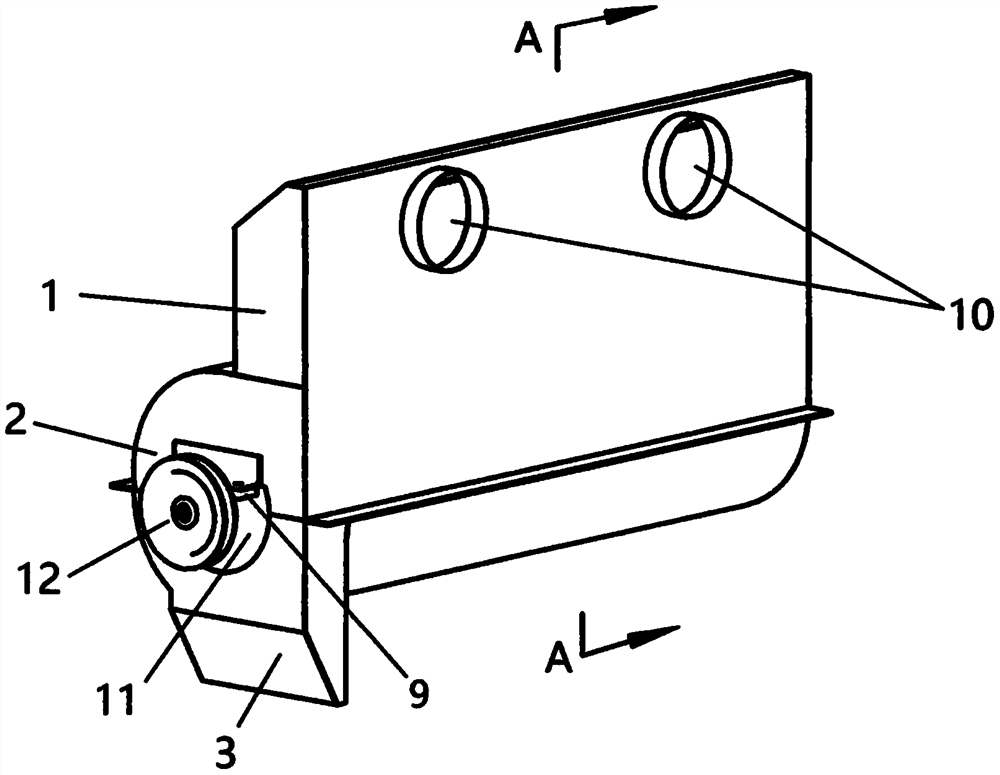

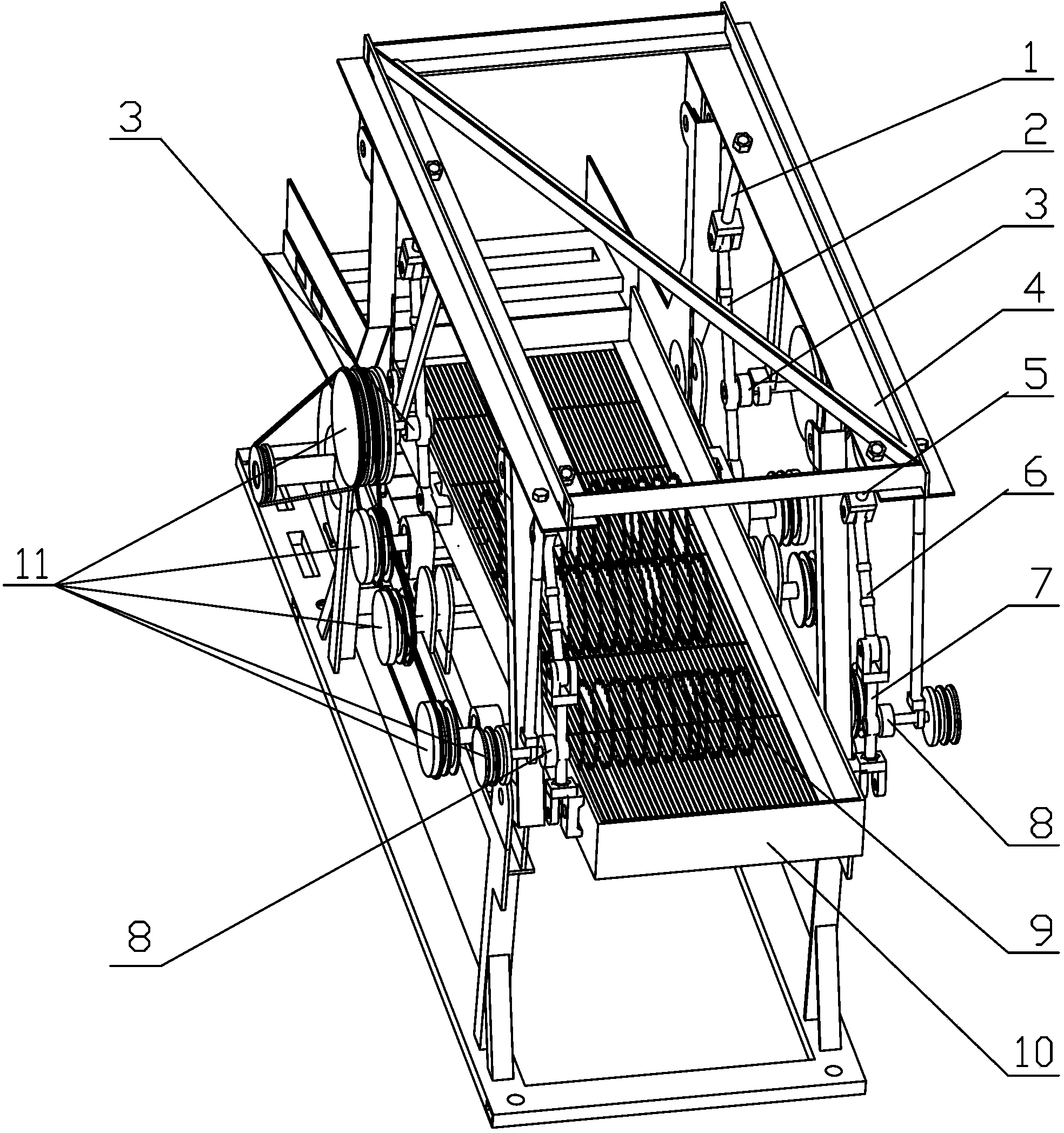

Unequal-amplitude material cleaning sieve

An unequal-amplitude material cleaning sieve comprises a frame, a motor, a vibrating sieve, a feed inlet, a discharge outlet and a vibrating mechanism. The motor and the vibrating mechanism are respectively fixed on the frame, and the front end and the rear end of the vibrating sieve are respectively connected with the vibrating mechanism which is connected with the motor through a transmission mechanism. The vibrating mechanism comprises a pair of front eccentric wheels, a pair of rear eccentric wheels, a pair of front multistage link rods and a pair of rear multistage link rods, the front eccentric wheels and the rear eccentric wheels are driven by the transmission mechanism, the frame is rotationally connected with the front eccentric wheels as well as the rear eccentric wheels, the eccentric distance of each front eccentric wheel is larger than that of each rear eccentric wheel, each front multistage link rod is of a three-stage link rod structure, and each rear multistage link rod is of a two-stage link rod structure. Due to the fact that the vibrating sieve is driven to vibrate by the eccentric wheels and the multistage link rods, and the front link rods and the rear link rods are different in stage number, vibration directions of a sieve surface are diversified and better sieving effect can be achieved.

Owner:QINGDAO AGRI UNIV

Blueberry cleaning device for preparation of blueberry fruit wine

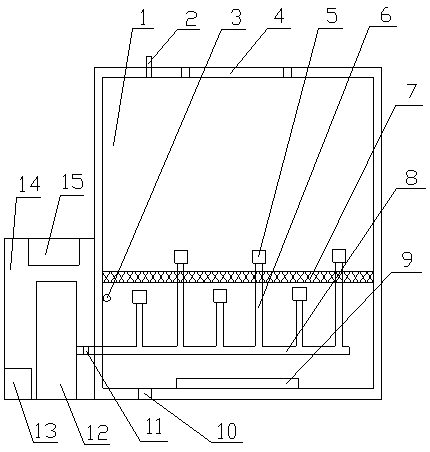

PendingCN108669585AReduce cleaning lossGuarantee product qualityFood treatmentFruit wineExhaust valve

A blueberry cleaning device for preparation of blueberry fruit wine comprises a cleaning tank, an exhaust valve, a temperature sensor, an upper cover, gas spray nozzles, gas spray pipes, a filter screen, a connecting pipe, a heater, a drain port, a solenoid valve, a gas cylinder, a controller, an equipment box and an operation display, wherein the upper cover is arranged right above the cleaning tank; the exhaust valve is arranged at the upper part of the cleaning tank; the filter screen is arranged in the center in the cleaning tank; the equipment box is arranged on the lateral side of the cleaning tank; the gas cylinder is arranged in the equipment box; one end of the connecting pipe is connected with the gas cylinder, and the other end extends into the inner lower part of the cleaning tank; the solenoid valve is arranged in the position, close to the gas cylinder, of the connecting pipe; one end of each gas spray pipe is connected with the connecting pipe, and the corresponding gasspray nozzle is arranged at the other end; the heater is arranged in the bottom of the cleaning tank; the drain port is formed in the lower part of the cleaning tank. The blueberry cleaning device forpreparation of the blueberry fruit wine is simple in structure, collision and breaking in a blueberry cleaning process can be more reduced, cleaning loss of blueberries is reduced, preparation quality of the blueberry fruit wine is ensured, and preparation efficiency of the blueberry fruit wine is improved.

Owner:贵州贵果王实业有限公司

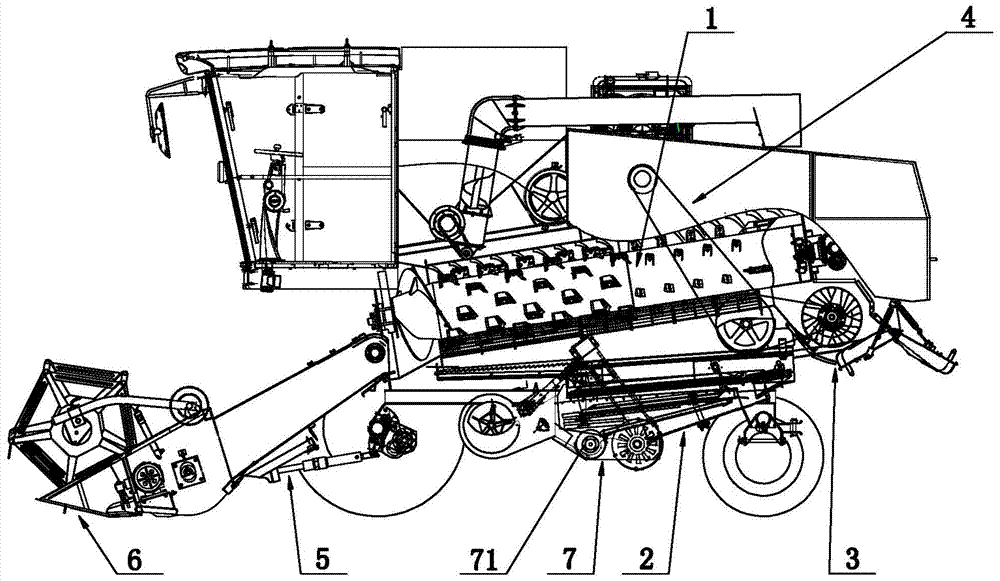

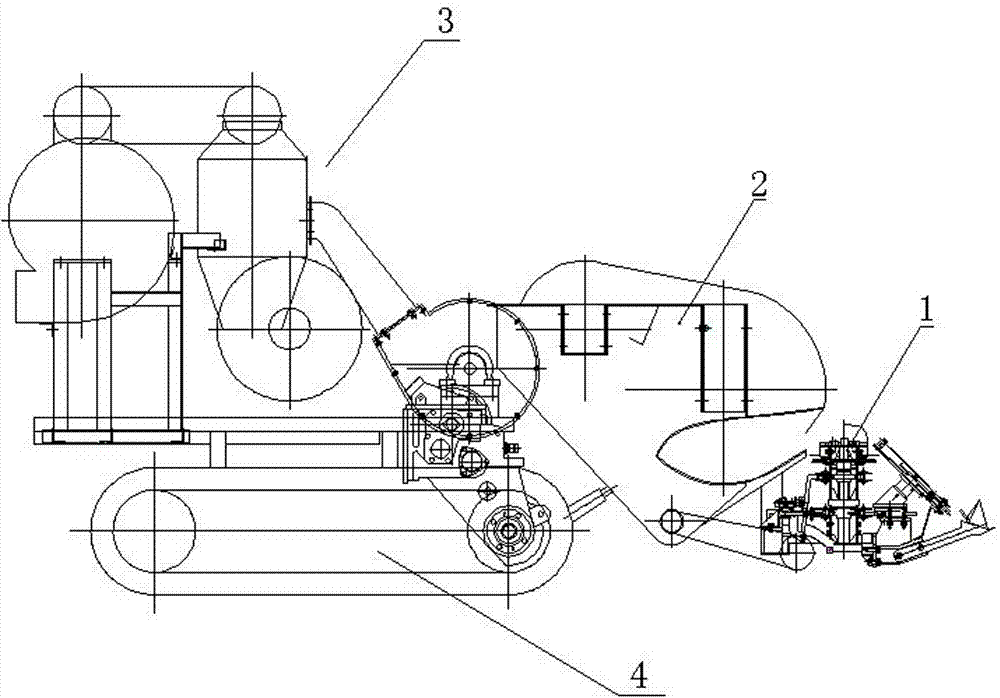

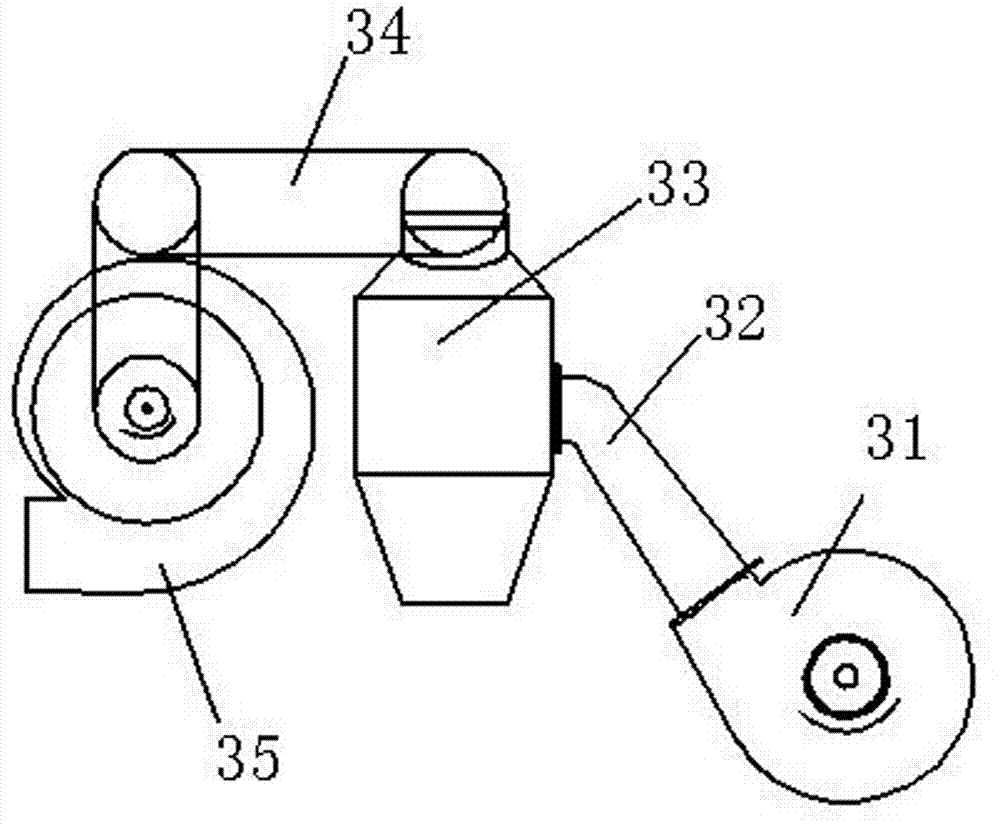

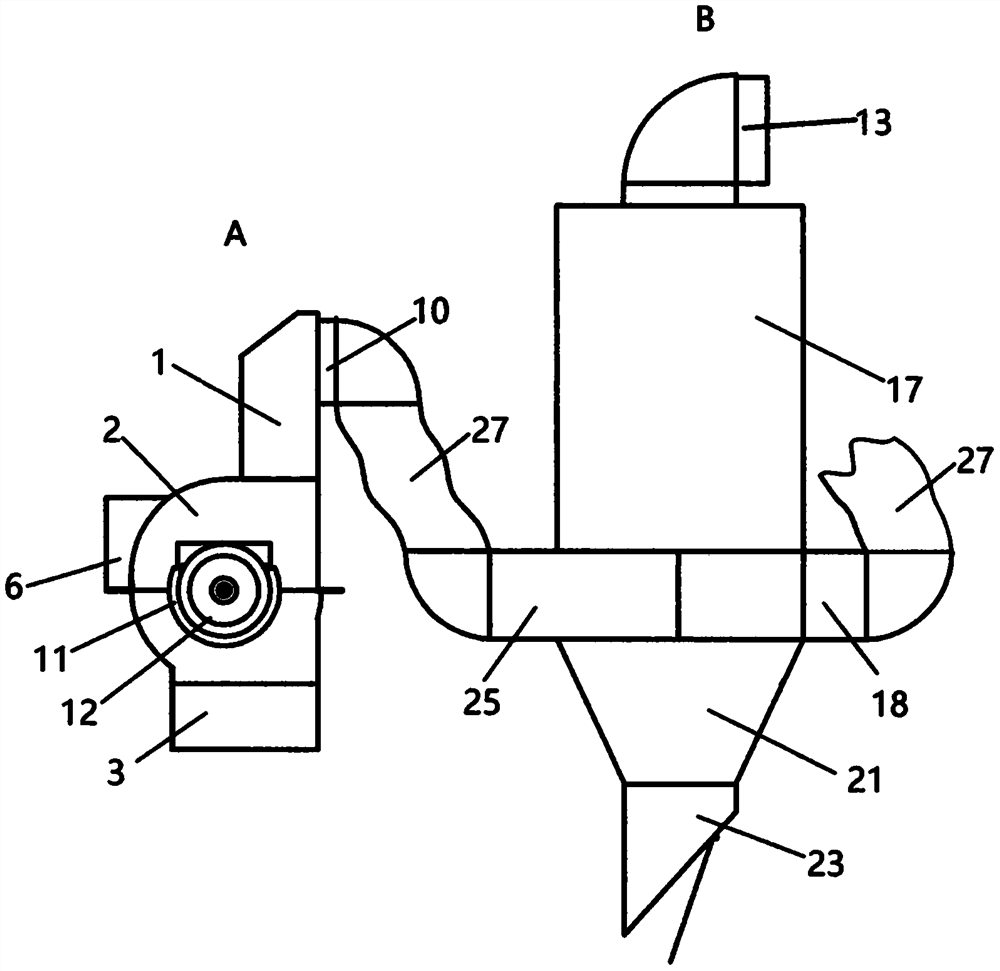

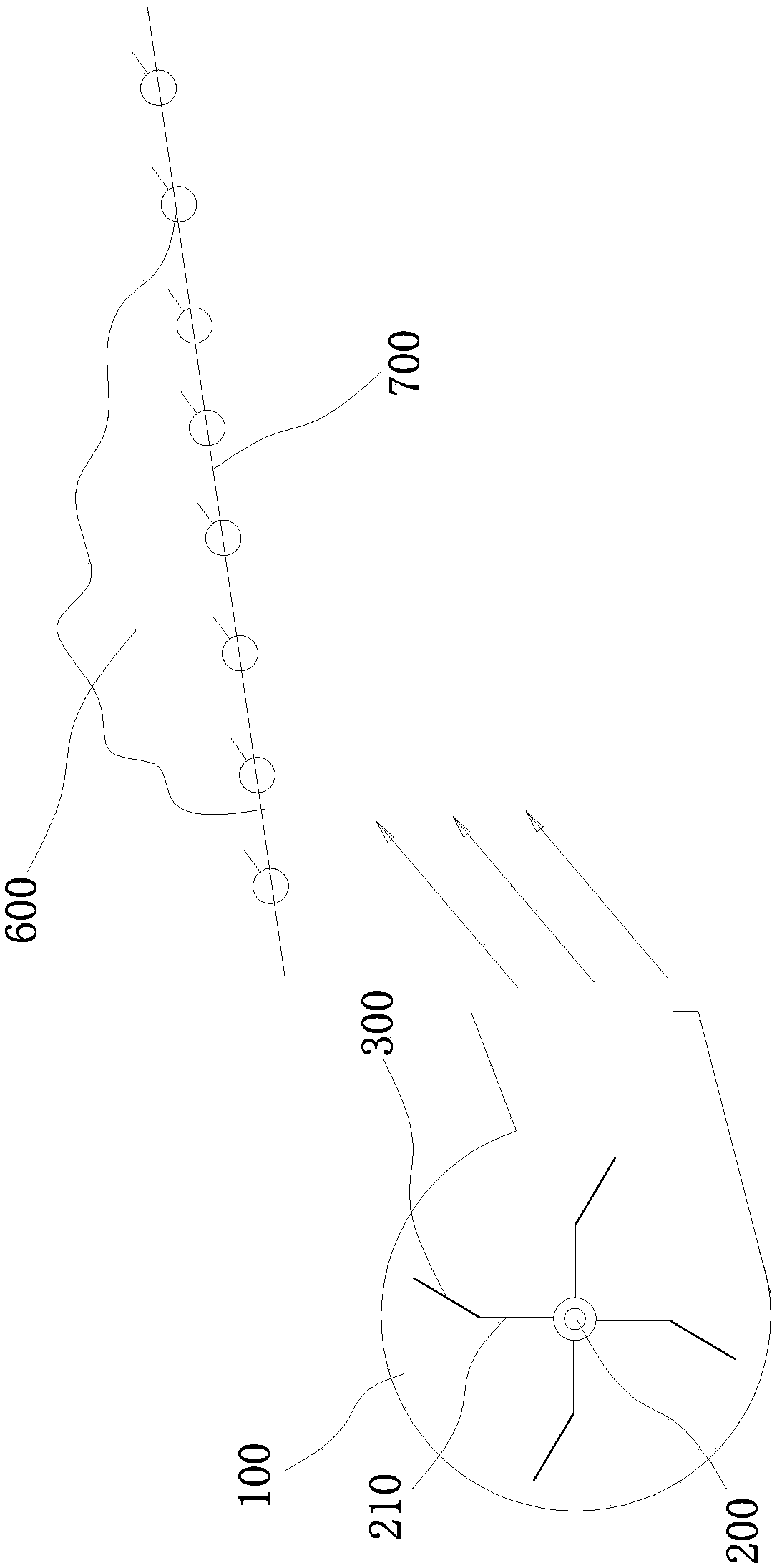

Vertical Axial Flow Combine Harvester

ActiveCN105123094BAchieve bothMeet income requirementsCrop conditionersMowersAgricultural engineeringCombine harvester

Owner:LOVOL HEAVY IND CO LTD

Unequal-amplitude material cleaning sieve

ActiveCN103447230BAvoid easy cloggingImprove screening effectSievingScreeningThree stageStage number

An unequal-amplitude material cleaning sieve comprises a frame, a motor, a vibrating sieve, a feed inlet, a discharge outlet and a vibrating mechanism. The motor and the vibrating mechanism are respectively fixed on the frame, and the front end and the rear end of the vibrating sieve are respectively connected with the vibrating mechanism which is connected with the motor through a transmission mechanism. The vibrating mechanism comprises a pair of front eccentric wheels, a pair of rear eccentric wheels, a pair of front multistage link rods and a pair of rear multistage link rods, the front eccentric wheels and the rear eccentric wheels are driven by the transmission mechanism, the frame is rotationally connected with the front eccentric wheels as well as the rear eccentric wheels, the eccentric distance of each front eccentric wheel is larger than that of each rear eccentric wheel, each front multistage link rod is of a three-stage link rod structure, and each rear multistage link rod is of a two-stage link rod structure. Due to the fact that the vibrating sieve is driven to vibrate by the eccentric wheels and the multistage link rods, and the front link rods and the rear link rods are different in stage number, vibration directions of a sieve surface are diversified and better sieving effect can be achieved.

Owner:QINGDAO AGRI UNIV

Synchronous different-amplitude embedment kneading type grain repeated husking and impurity removal vibrating screen

The invention discloses a synchronous different-amplitude embedment kneading type grain repeated husking and impurity removal vibrating screen. The synchronous different-amplitude embedment kneading type grain repeated husking and impurity removal vibrating screen comprises a machine frame, a transmission mechanism, a first synchronous vibrating mechanism and a second synchronous vibrating mechanism. The transmission mechanism is installed on the front portion of the machine frame, the first synchronous vibrating mechanism and the second synchronous vibrating mechanism are installed in the middle of the machine frame, and the second synchronous vibrating mechanism is arranged on the top of the first synchronous vibrating mechanism in an embedded mode. A transmission shaft is installed on the machine frame through bearings, and first eccentric wheels and second eccentric wheels are fixedly arranged on the transmission shaft. Outer rockers are hinged to outer lifting lugs, and inner rockers are hinged to inner lifting lugs. A first vibrating frame is hinged to the outer rockers through lifting arms, and a second vibrating frame is hinged to the inner rockers. Third kneading materialguide pieces and first kneading material guide pieces are arranged in a crossed mode, and fourth kneading material guide pieces and second kneading material guide pieces are arranged in a crossed mode. A circular screen face is fixedly arranged at the bottom of the first vibrating frame. The synchronous different-amplitude embedment kneading type grain repeated husking and impurity removal vibrating screen is high in screening efficiency, good in repeated husking effect, high in cleaning rate of separated objects, low in impurity rate, simple in structure and high in reliability.

Owner:JILIN UNIV

A control method for corner cracks of boron-containing steel slabs

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

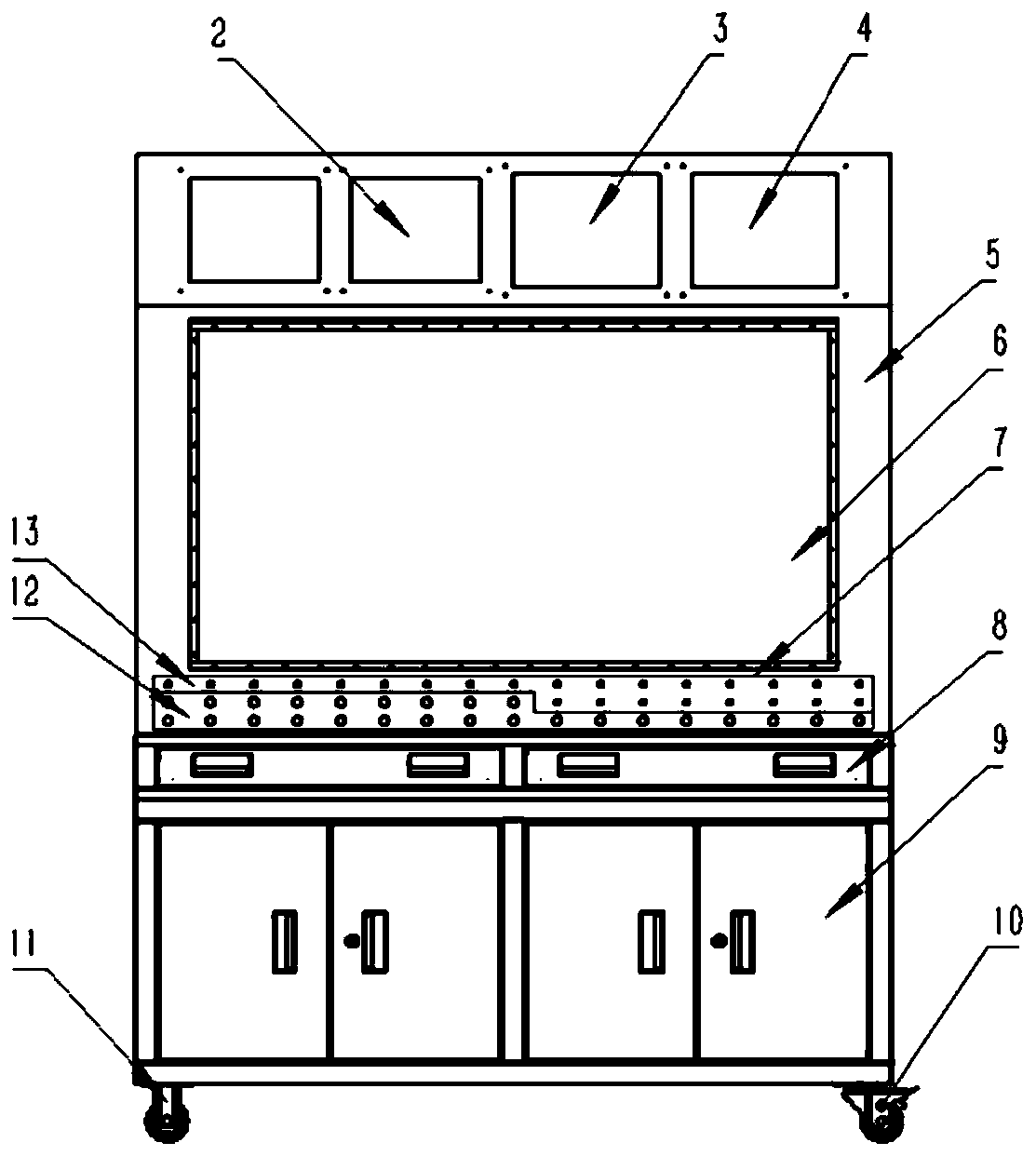

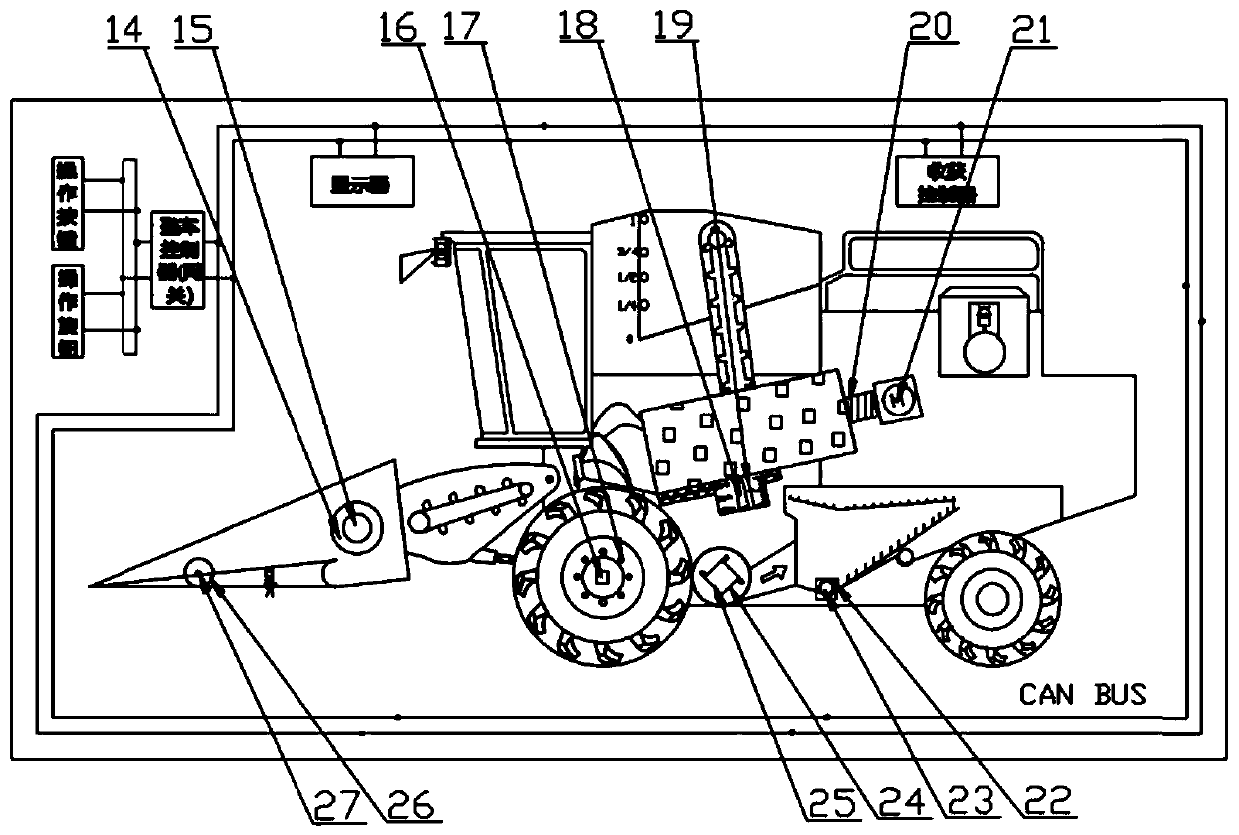

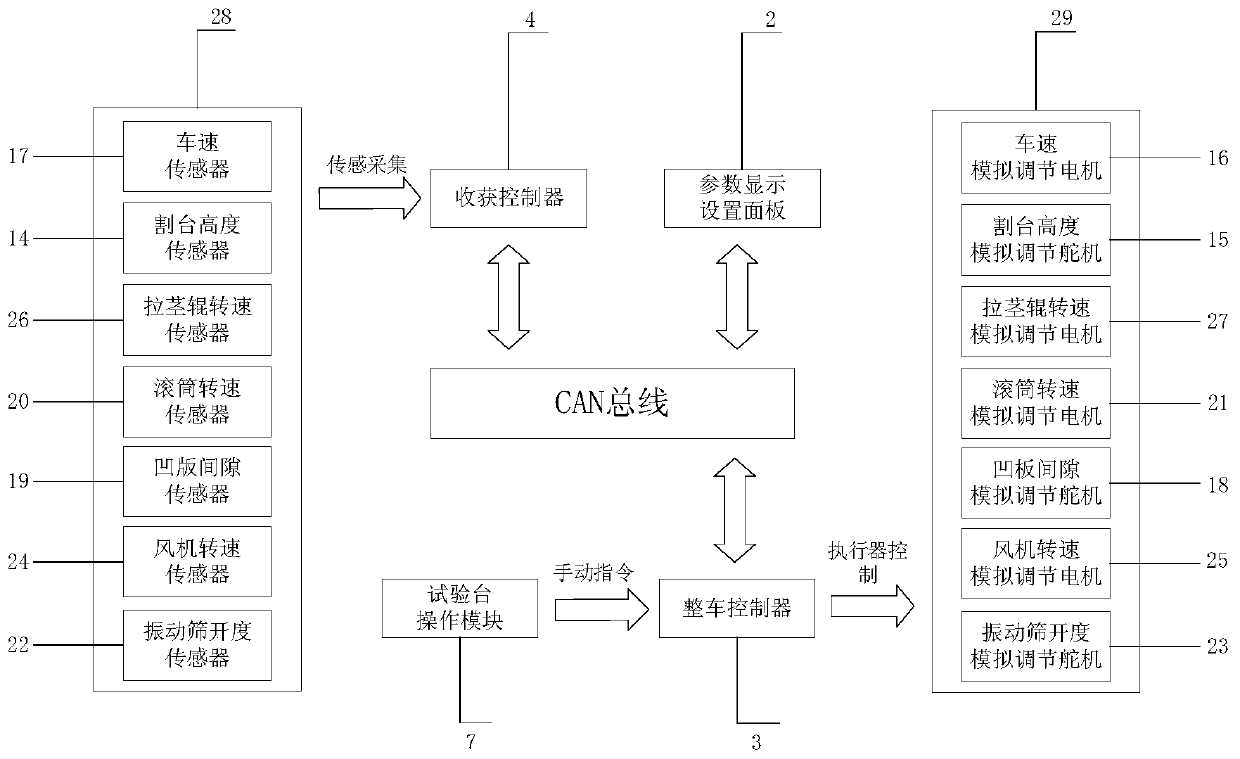

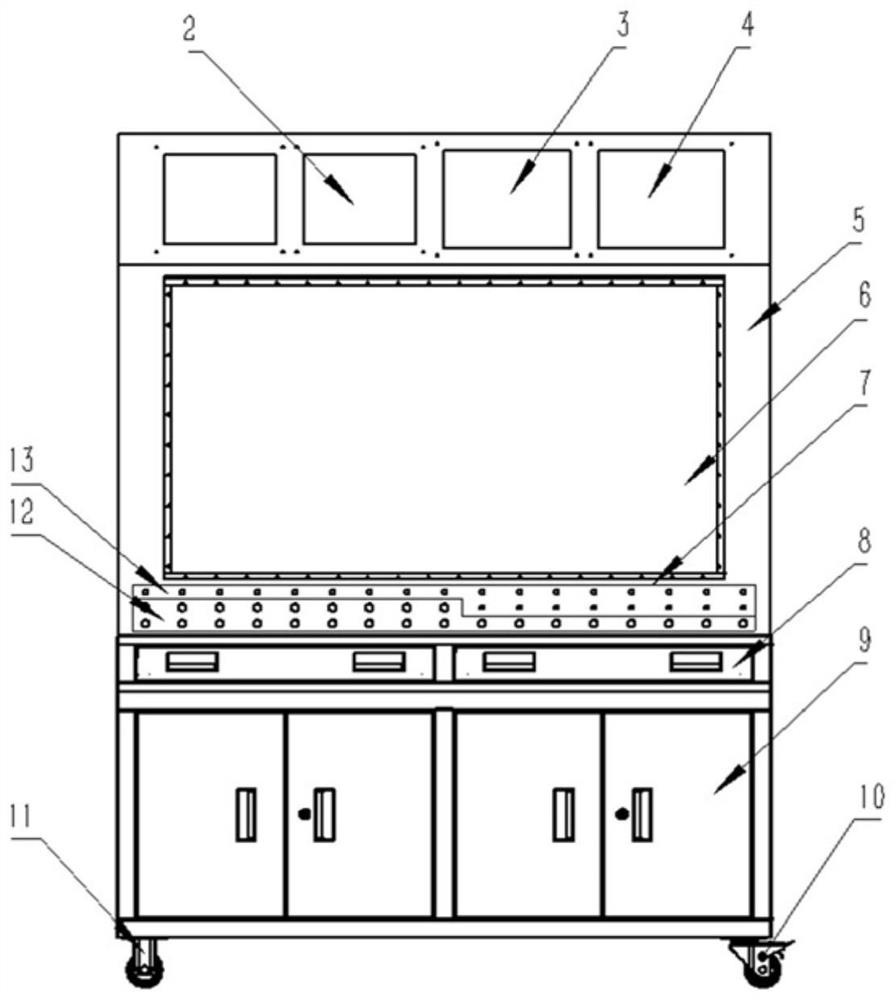

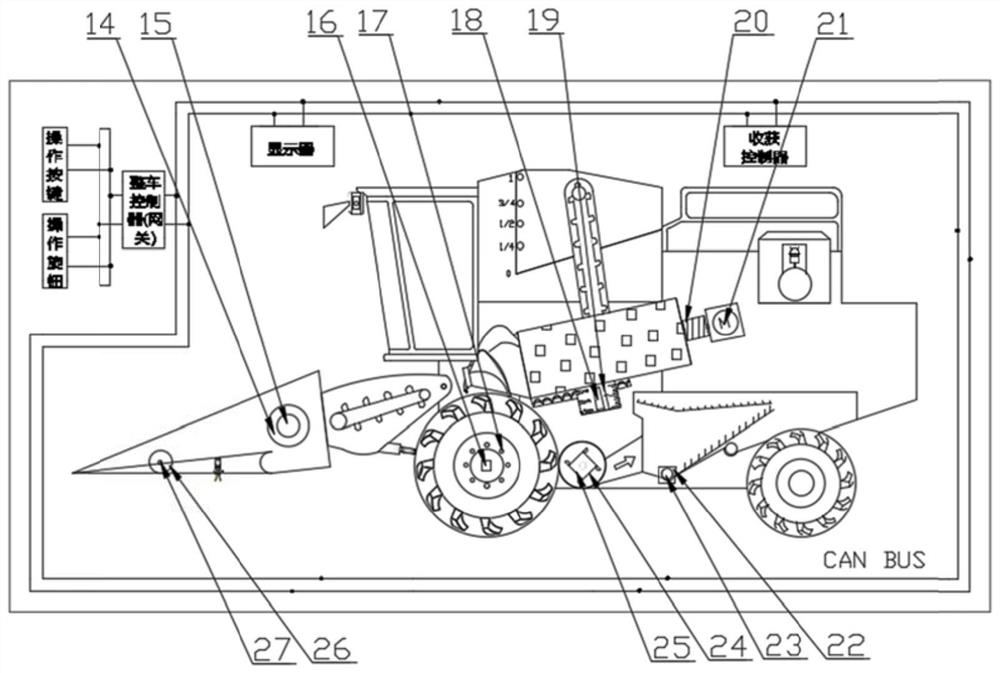

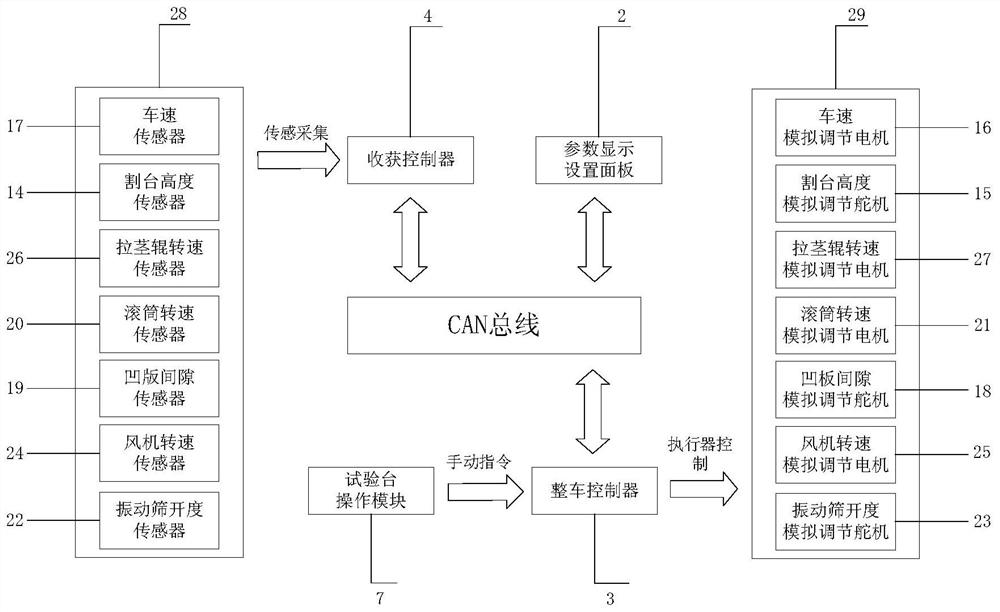

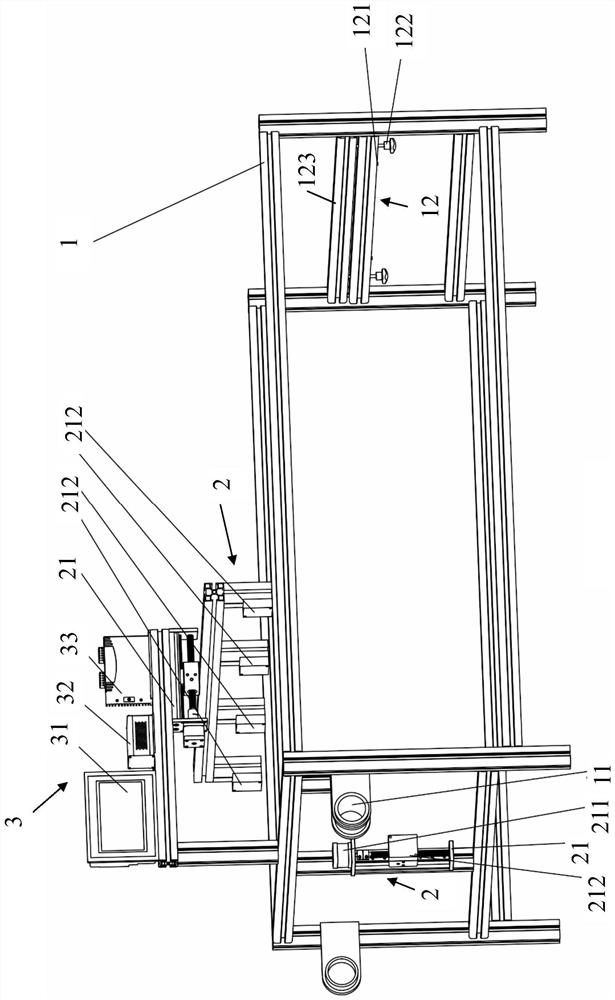

Multi-functional corn harvester intelligent control test platform based on CAN bus

ActiveCN110865631AShorten the development cycleImprove job qualityElectric testing/monitoringControl systemControl engineering

The invention relates to a corn harvester intelligent control test platform based on a CAN bus. The corn harvester intelligent control test platform comprises a test platform main body, and a parameter display setting panel, a vehicle control unit, a harvesting controller, a demonstration panel, a test platform operation module, a simulation execution mechanism and a measurement transmitting device which are arranged on the test platform main body; the parameter display setting panel, the vehicle control unit and the harvesting controller are connected through a CAN bus; and the harvesting controller receives and stores a control module of a corn harvester control system to be simulated and debugged, sends a control instruction to the vehicle control unit according to harvesting parametersset by the parameter display setting panel and the control module, and automatically simulates and adjusts the harvesting process. The test platform operation module is connected with an input port of the vehicle control unit; a corn harvester simulation diagram is drawn on the demonstration panel; the simulation execution mechanism comprises a plurality of simulation execution components which are connected with the output port of the vehicle control unit; and the measurement transmitting device collects data signals of all the simulation execution components.

Owner:CHINA AGRI UNIV

Method of controlling the net crack of high-nitrogen continuous-casting slab of high strength weathering steel containing vanadium

Owner:PANZHIHUA IRON AND STEEL

Method for controlling the cross crack of blank angle of high nitrogen steel casting board containing vanadium

Owner:PANZHIHUA IRON AND STEEL

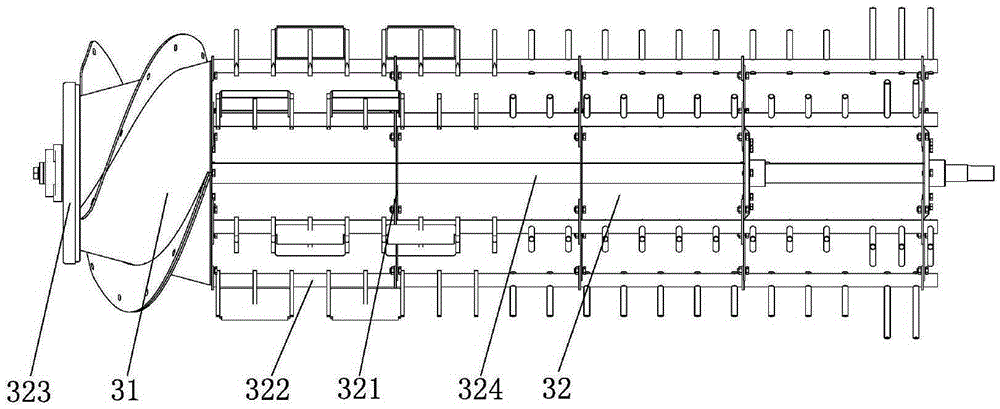

a threshing device

Owner:XINGGUANG AGRI MACHINERY

Vibration sorting screen

InactiveCN100364374CSolve the problem of horizontal distribution uniformityImprove cleanlinessSievingScreeningSlide plateEngineering

Owner:JIANGSU UNIV

A cleaning sieve fish scale sieve detection device and method

ActiveCN112414313BImprove detection efficiencyHigh dimensional consistencyUsing optical meansClassical mechanicsDisplay device

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI

Cleaning system and combined grain harvester adopting same

The invention discloses a cleaning system and a combined grain harvester adopting the cleaning system. A cyclone separation cylinder of the cleaning system comprises a cylinder body; the middle section of the cylinder body is a cylindrical section, and the upper and lower sections are cone sections; the upper end of the cylinder body is communicated with a gettering fan, and the cylindrical section is communicated with a winnower through a separation pipe; the side wall of the separation pipe, which is far from the axis of the cylinder body, is raised from the wall of the cylindrical section of the cylinder body; and ventilation holes are distributed at intervals on the side wall of the lower cone section of the cylinder body. The cleaning system with the structure ensures that the materials to be cleaned is far from the axis of the cylinder body as much as possible when entering the cyclone separation cylinder so that the cleaning loss can be reduced without increasing the diameter of the cylinder body. In addition, the air entering the lower cone section of the cylinder body from the ventilation holes forms an air cushion layer on the inner wall of the lower cone section so that part of the light impurities entered the lower cone section suspends under the action of the air cushion layer, is sucked out by the gattering fan and cannot block the lower cone section hereby.

Owner:HENAN UNIV OF SCI & TECH

All-wheel-drive non-amplitude vibrating screen mechanism

ActiveCN103447232BMultiple directions of vibrationImprove screening effectSievingScreeningEngineeringAll-wheel drive

Owner:QINGDAO AGRI UNIV

Straight arc casting machine alloy steel sheet billet continuous casting foot roller segment narrow surface cooling method

The present invention discloses a straight-curved type casting machine low-alloy steel slab continuous casting full-rolling section narrow face cooling method, and is aimed at solving the problem of that on the casting blank surface corner portion of low-alloy steel the transverse crack can be easily produced. Said invention belongs to the field of metal continuous casting blank cooling and surface quality control technology. Said method is characterized by that in the full-rolling section of continuous casting straight-curved type casting machine slab said invention utilizes the nozzles which are symmetrically mounted at left side and right side of casting blank pouring direction to cool the narrow face of said casting blank, and adopts rectangular nozzles to symmetrically and simultaneously cool the narrow faces of left and right two sides of casting blank. Said invention also discloses a kind of rectangular nozzle for said method, the water outlet hole of its sprayer is a hole with rectangular section. Said invention can reduce casting blank cooling strength of full-rolling section under the crystallizer and can improve casting blank cooling uniformity, so that it can eliminate casting blank surface corner portion transverse crack defect of continuously-cast high-strength low-alloy steel whose steel quality is P510L, P590L, J55 and X52, etc.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

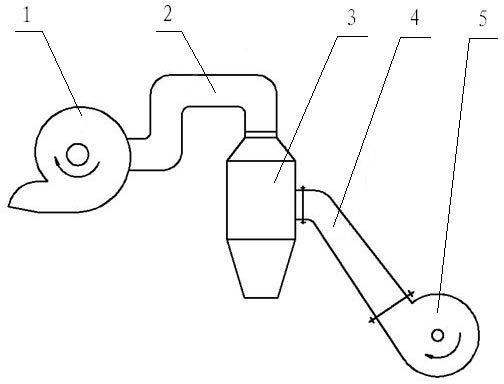

Teff combined type cleaning system and teff threshing and cleaning machine

The invention discloses a teff combined type cleaning system and a teff threshing and cleaning machine. The teff combined type cleaning system comprises a rack, a vibrating screen assembly and an airflow cleaning device, wherein the vibrating screen assembly and the airflow cleaning device are arranged on the rack; the vibrating screen assembly is used for screening away long straw and weeds whichare obtained after teff threshing; a seed discharge port of the vibrating screen assembly is connected with the airflow cleaning device; after being adsorbed by the airflow cleaning device, seeds aredischarged from the seed discharging port of the vibrating screen assembly, and shells in the seeds and the fine straw are discharged from an impurity removal port of the airflow cleaning device. Thecombined type cleaning system is provided with the teff threshing and cleaning machine and comprises a feeding device, a threshing device, a combined type cleaning system body, an engine device and awalking land wheel. The teff threshing and cleaning machine is reasonable in structure matching, convenient to operate, simple in test process and reliable to apply, and a solution is provided for obtaining the clean teff seeds.

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI

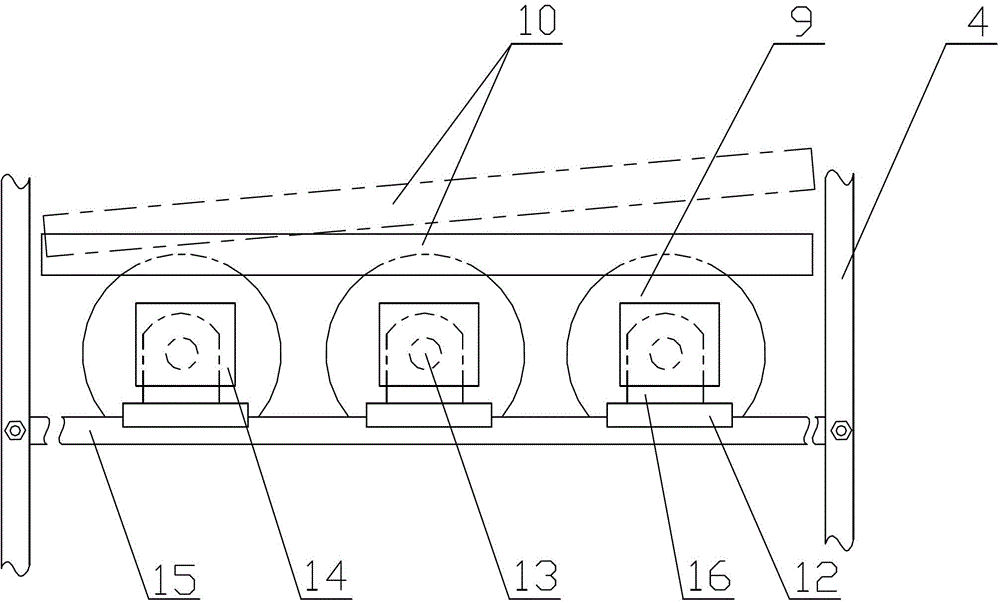

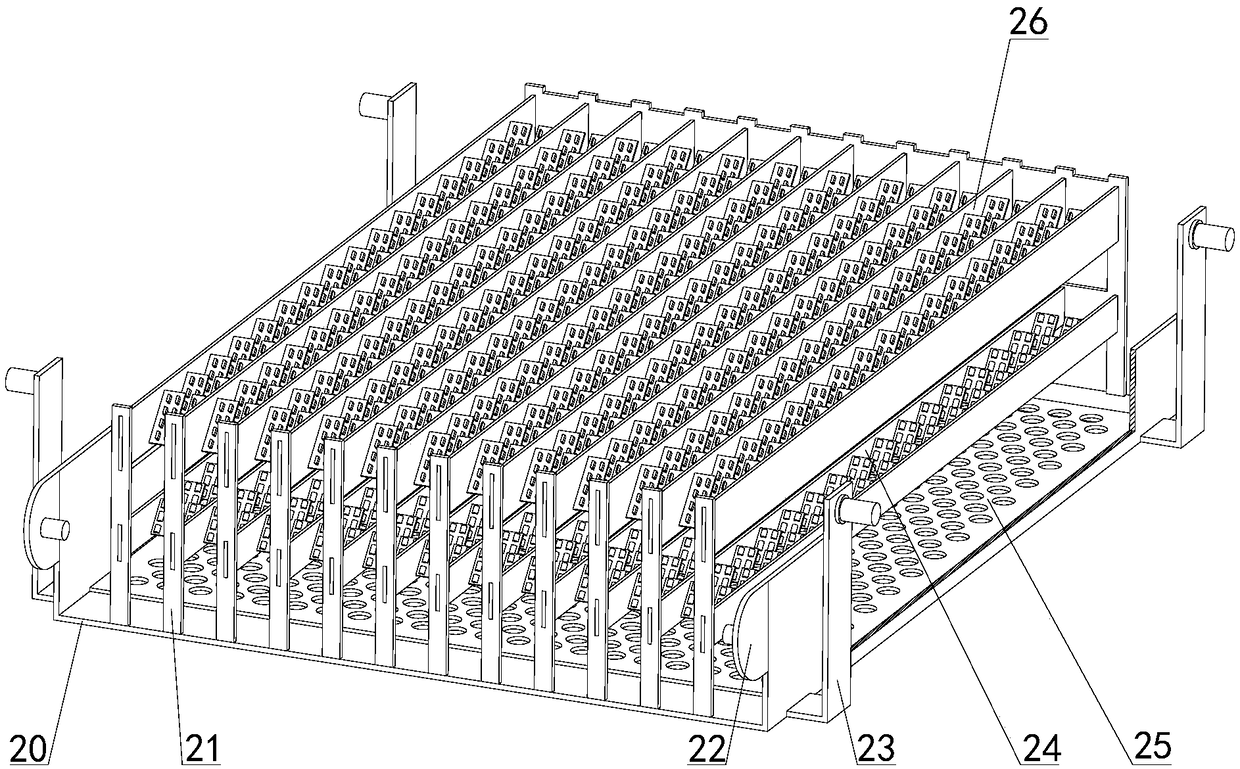

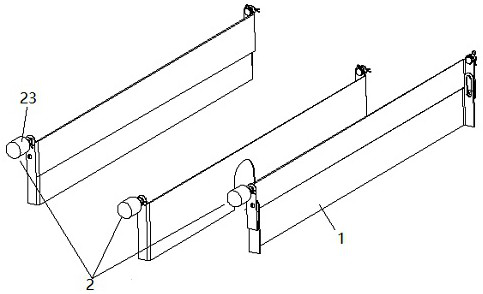

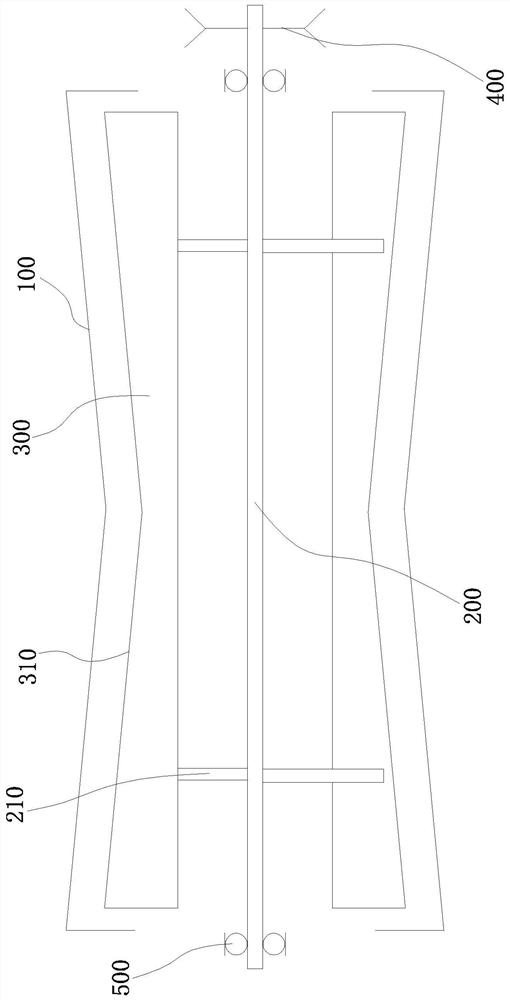

Adjustable cleaning system of soybean harvester

ActiveCN114731851AImprove efficiencyQuality improvementMowersClimate change adaptationAgricultural engineeringMechanical engineering

The invention relates to an adjustable cleaning system of a soybean harvester, and belongs to the technical field of agricultural machinery. A main shaft of a uniform flow fan of the system is provided with a reducing belt wheel and is in transmission connection with a driving belt wheel through a transmission belt with a tension adjusting mechanism; a front grid screen and a rear grid screen in a vibrating screen of the system respectively comprise screen pieces which are arranged in a frame and distributed at intervals; hinge holes and receding holes which are uniformly distributed at intervals are formed in side plates of the rear grid screen; the upper ends of screen pieces of the rear grid screens are hinged to the corresponding hinge holes, and the lower ends of the screen pieces of the rear grid screens stretch out of the corresponding receding holes and then are hinged to the corresponding holes of the outer connecting rods, so that a parallel four-connecting-rod mechanism is formed. And one of the screen pieces of the rear grid screen is fixedly connected and movably connected with the upper end and the lower end of the rear adjusting handle respectively. After the soybean harvester is adopted, the rotating speed of the fan and the rear grating screen can be adjusted as required, so that the soybean harvester is suitable for harvesting and cleaning soybeans of different varieties, planting modes and working conditions, the cleaning efficiency and quality of soybean harvesting can be remarkably improved, and the cleaning loss is reduced.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

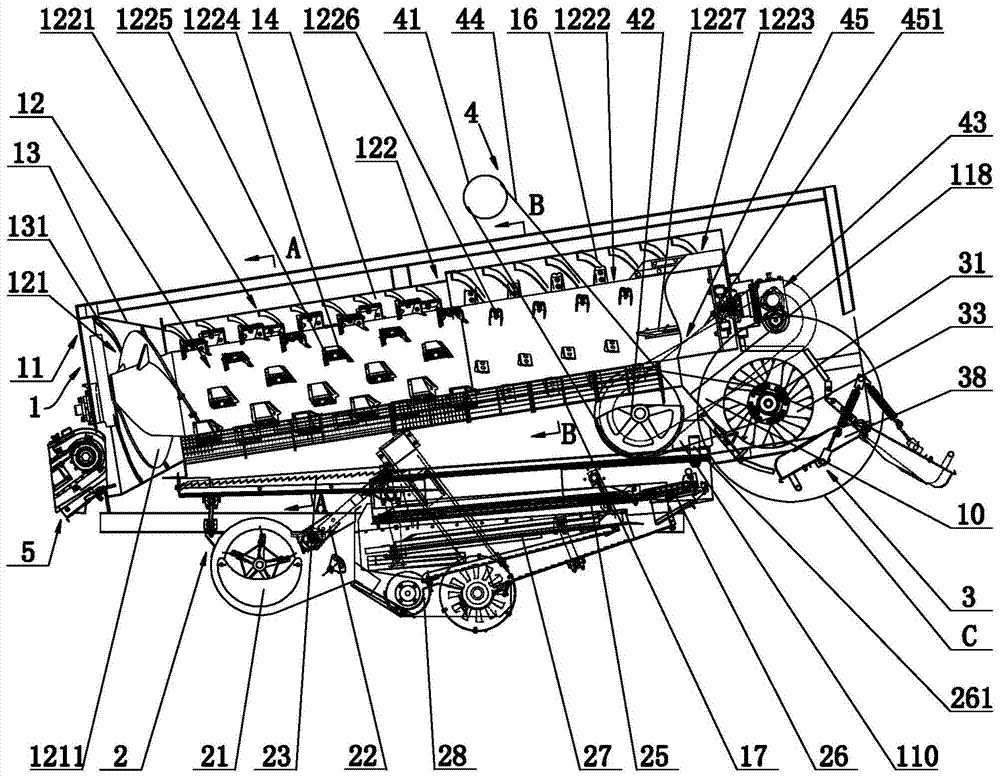

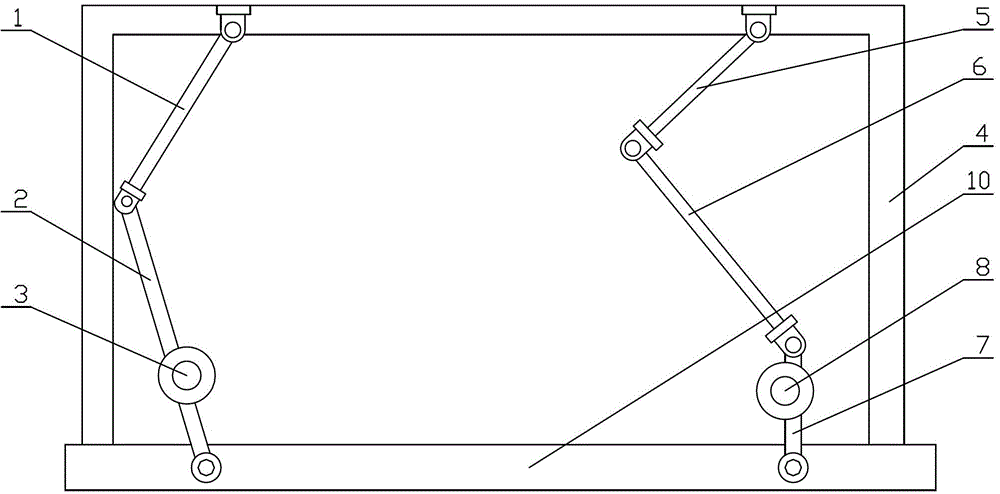

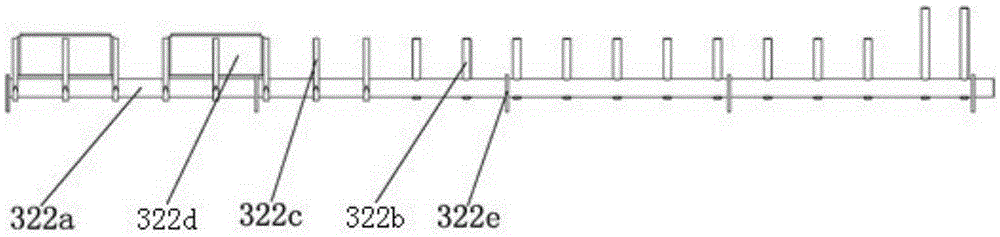

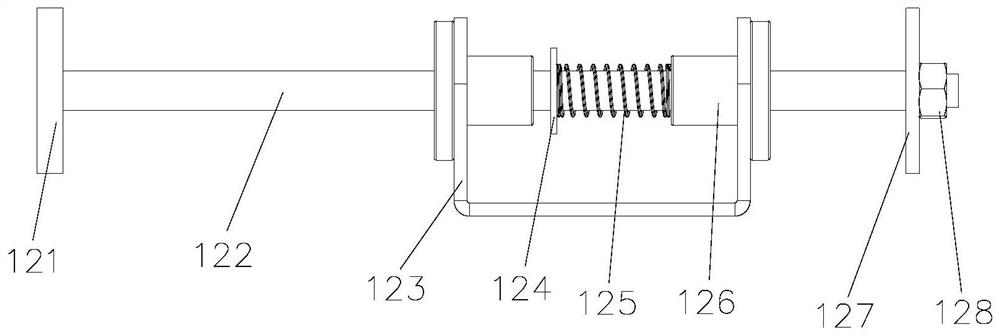

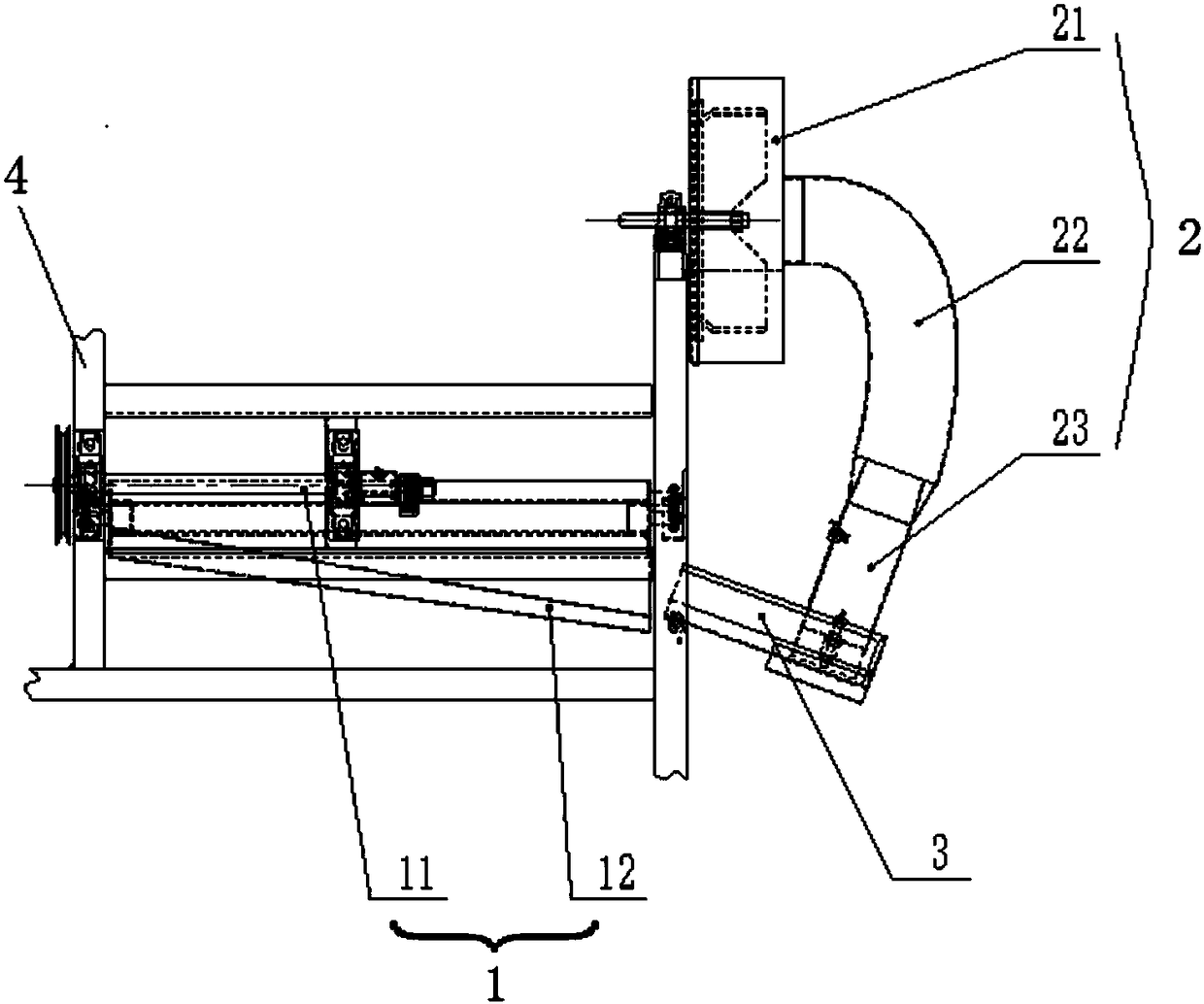

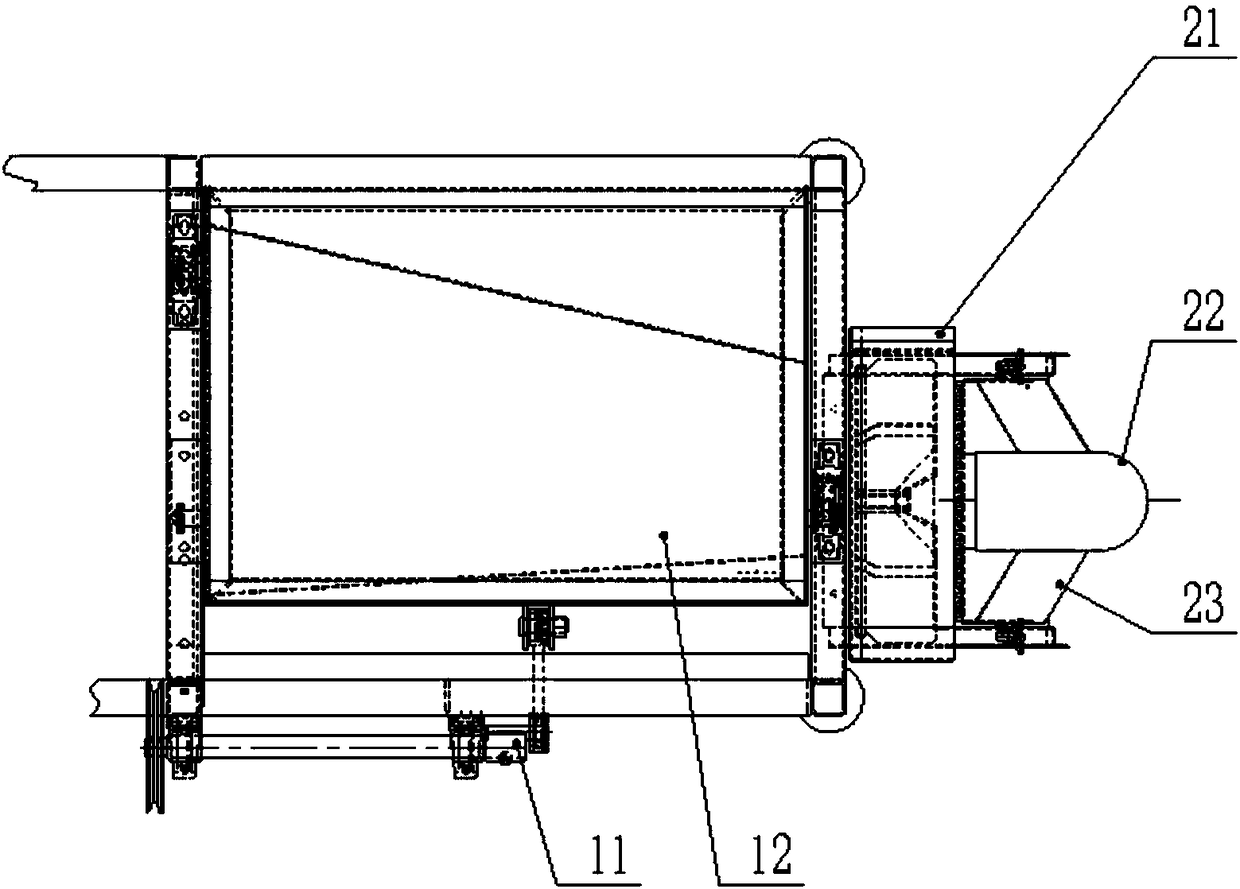

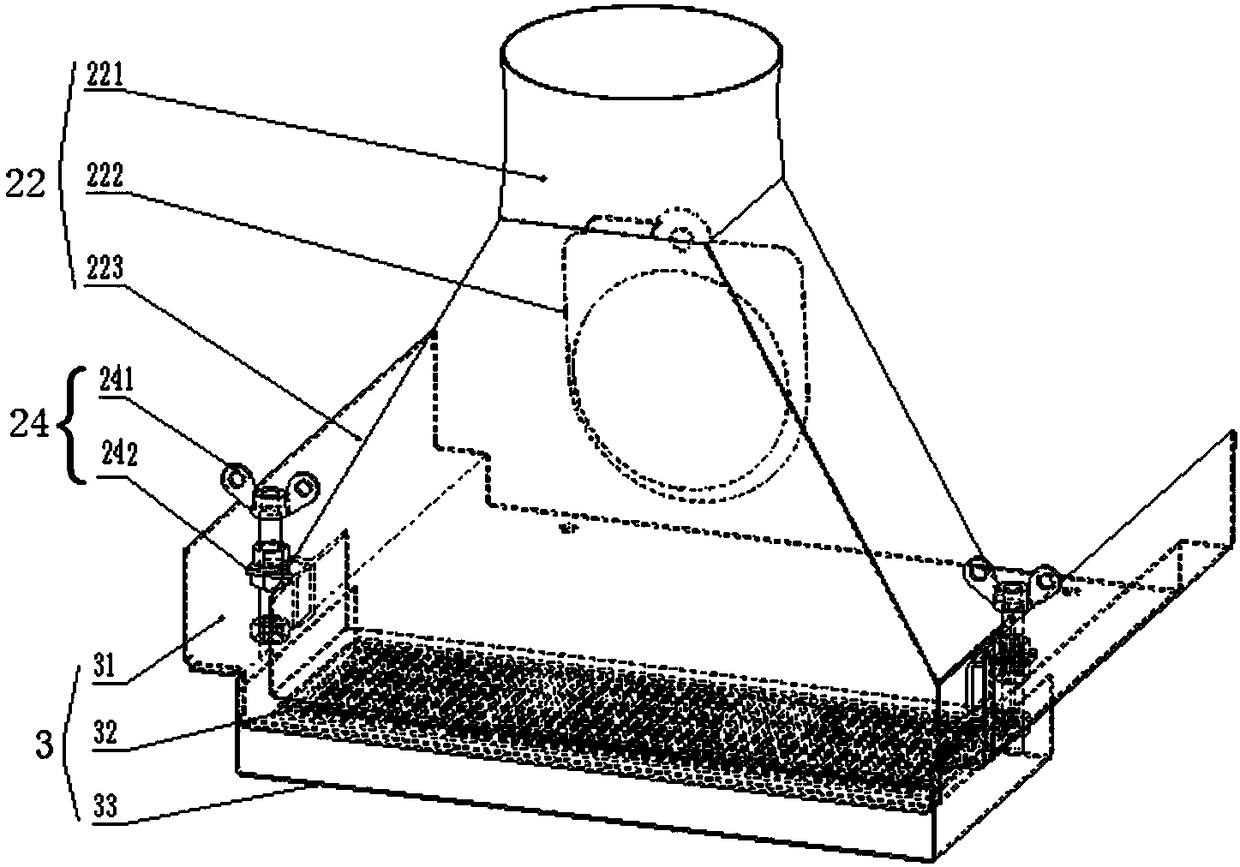

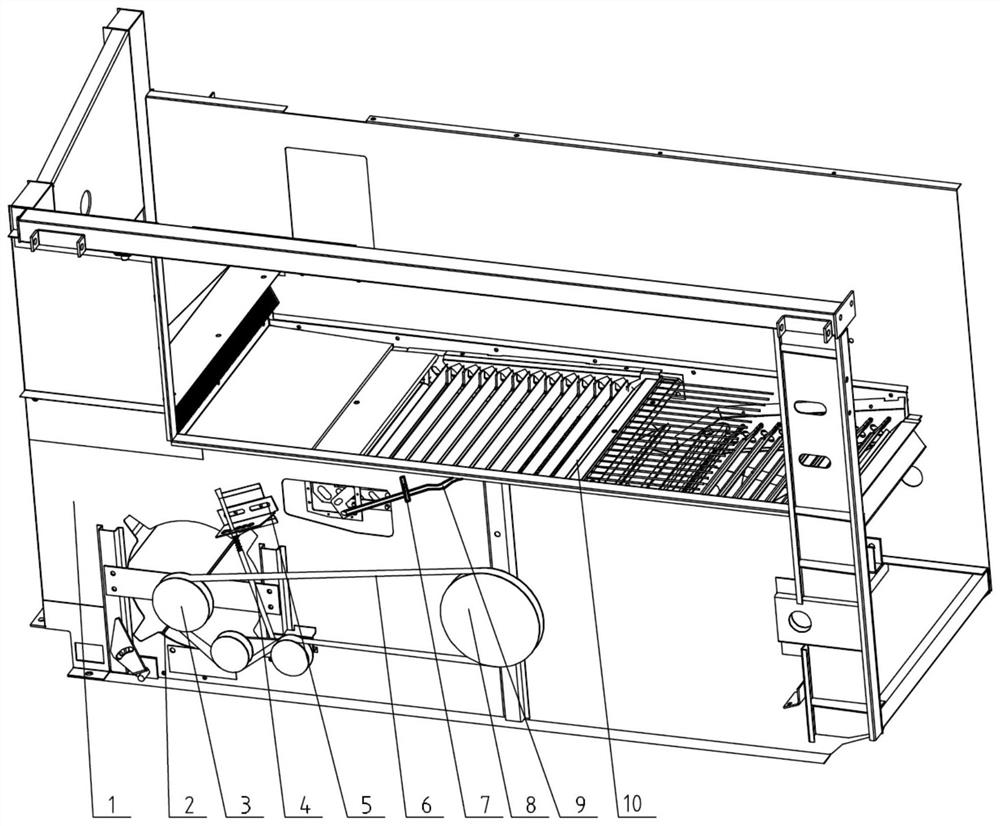

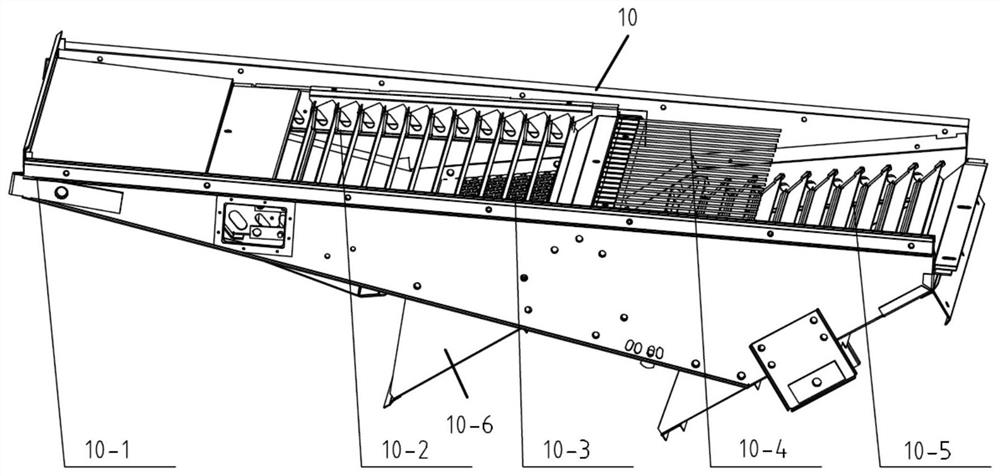

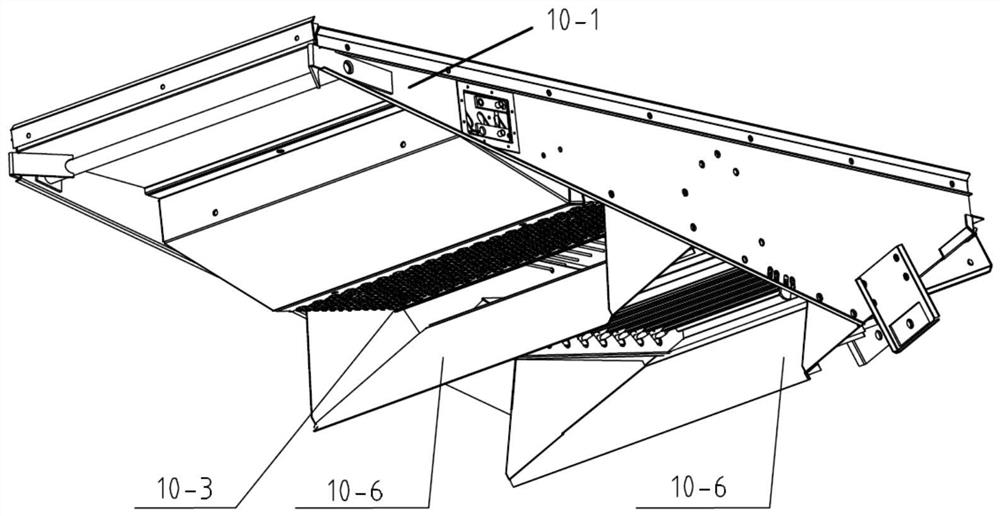

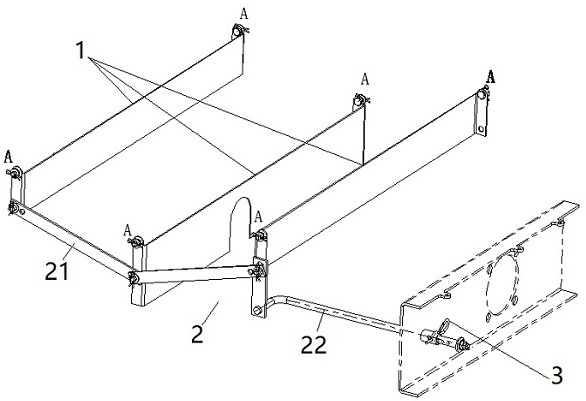

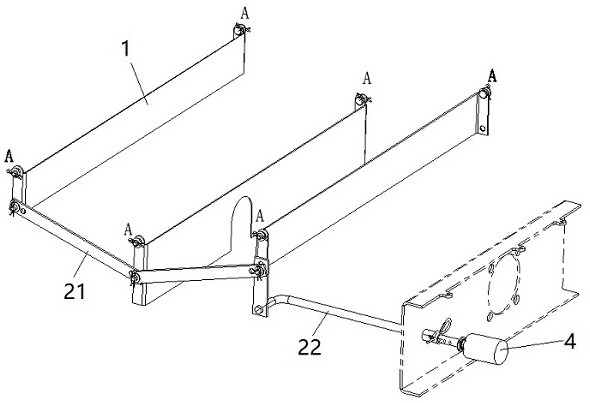

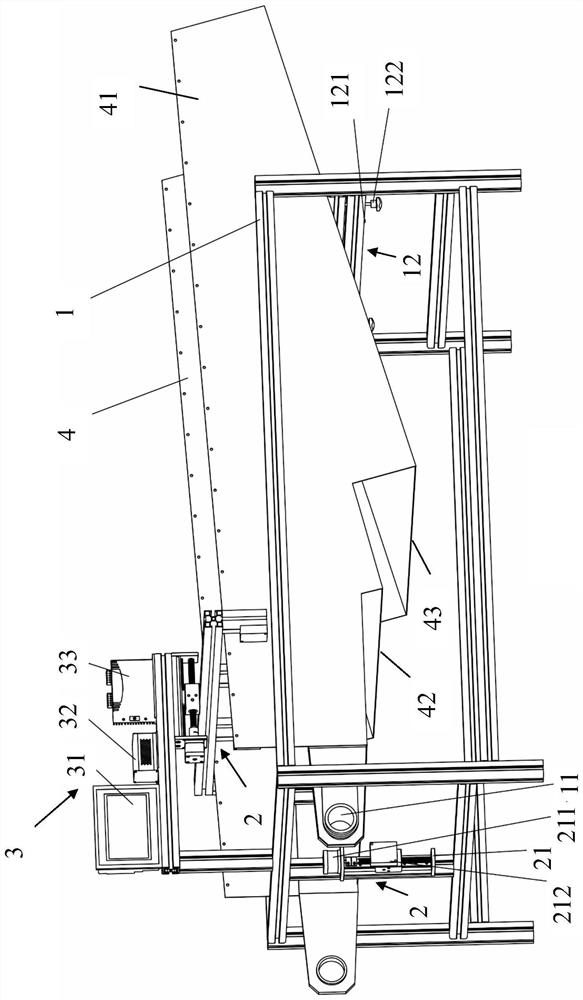

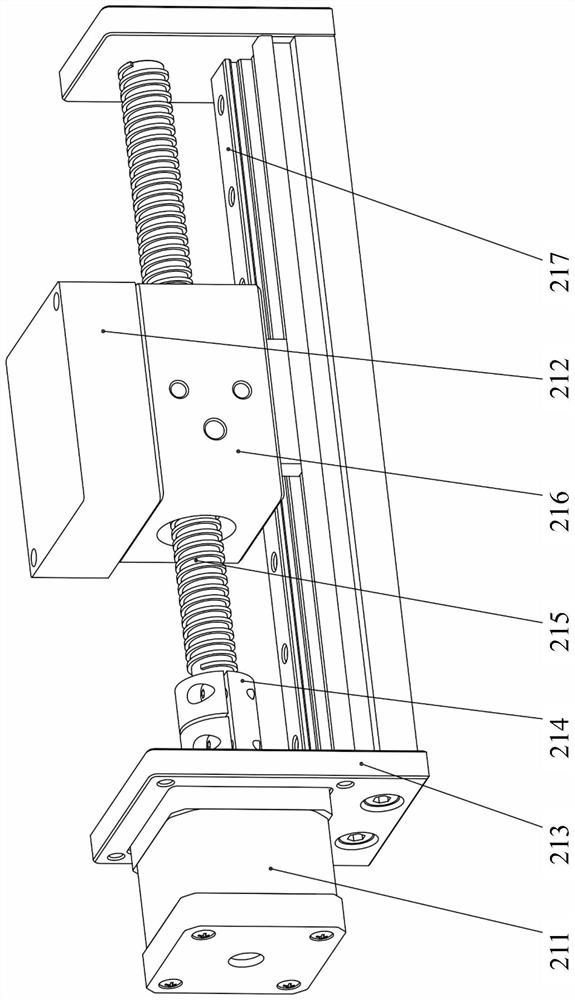

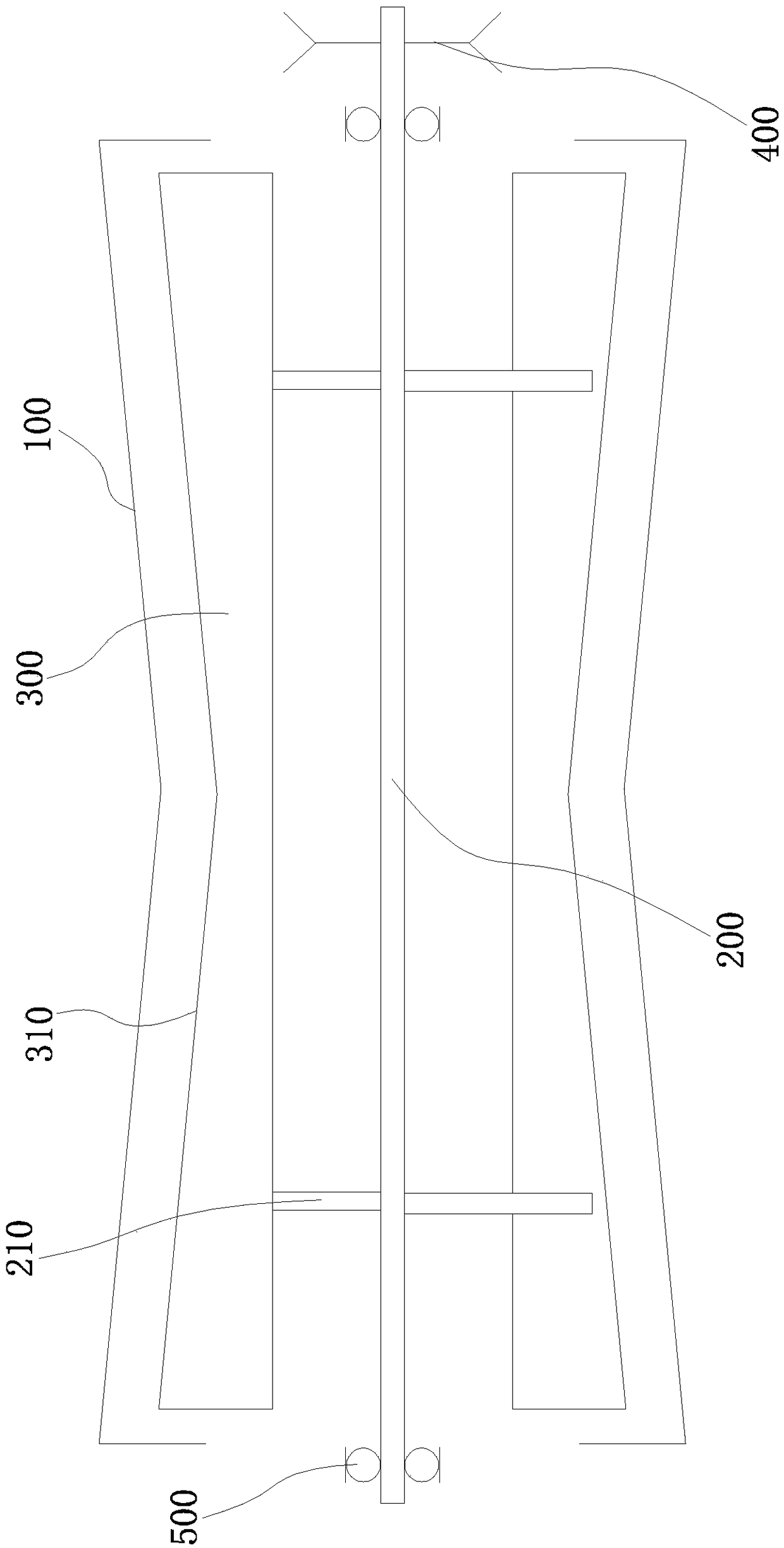

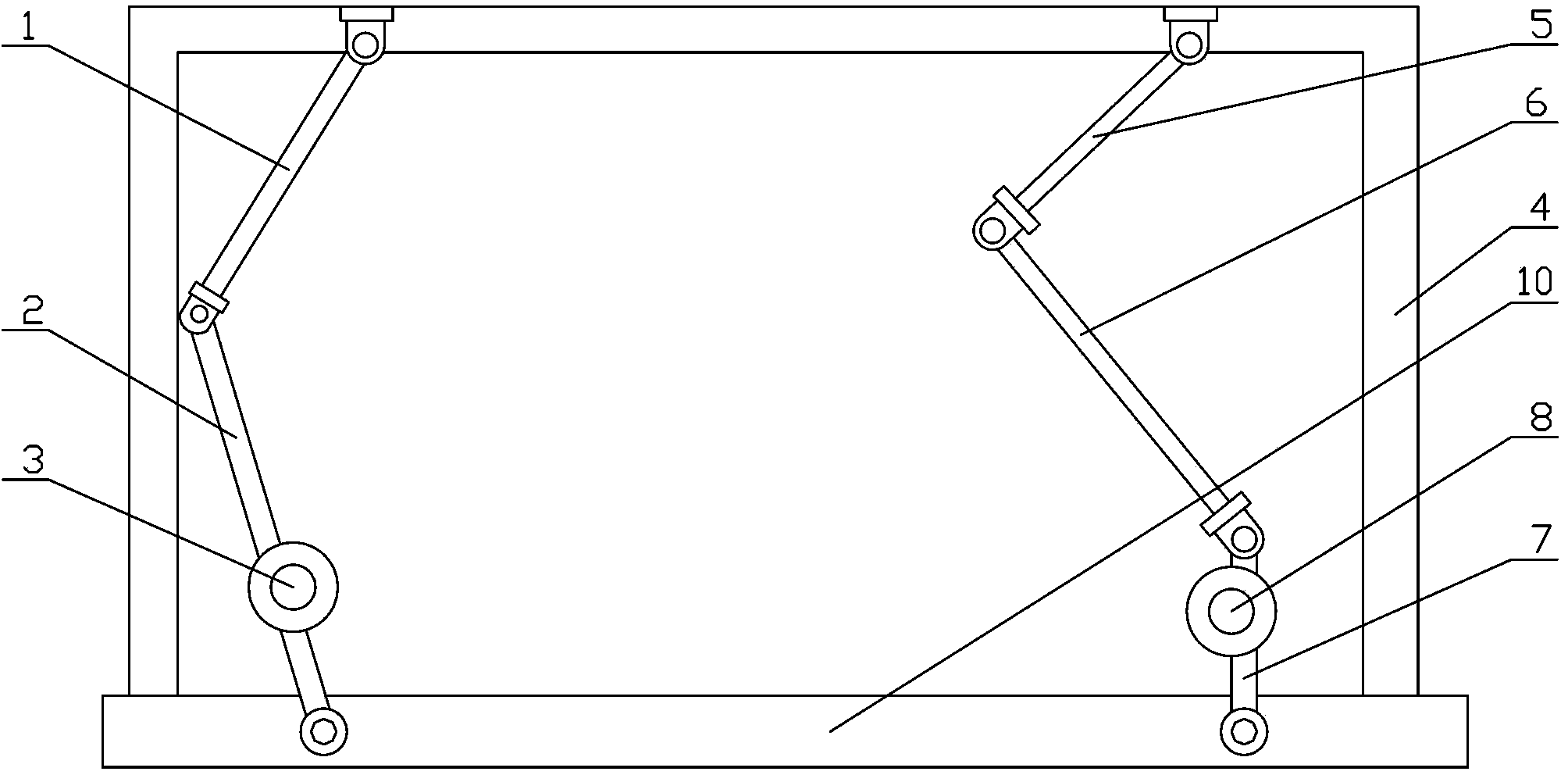

A Harvester Material Distribution Adjustment Mechanism

ActiveCN111386867BEasy to adjustImprove work efficiencyMowersThreshersAgricultural engineeringStructural engineering

The invention belongs to the technical field of agricultural mechanical equipment, and particularly relates to a material distribution adjusting mechanism of a harvester. The material distribution adjusting mechanism is arranged between an arc-shaped concave plate of the harvester and an upper screen mesh at a lower part, comprises a plurality of adjusting plates and an angle adjusting mechanism,wherein the adjusting plates are arranged along an axial direction of the arc-shaped concave plate, the adjusting plates are used for driving each adjusting plate to swing towards two ends of the arc-shaped concave plate around hanging points of the adjusting plates and the arc-shaped concave plate. The material distribution adjusting mechanism has simple and reasonable structure design, simple and convenient operation, can effectively and conveniently adjust material on a surface of a cleaning screen, reduces cleaning loss, and improves working efficiency of the harvester.

Owner:LOVOL HEAVY IND CO LTD

Cyclone separating barrel and cleaning system and combine harvester using cyclone separating barrel

InactiveCN103460912BSmall diameterRequirements for reduced gettering capacityThreshersCycloneCyclonic separation

The invention relates to a cyclone separating barrel and a cleaning system and a combine harvester using the cyclone separating barrel. The combine harvester comprises a frame and the cleaning system arranged on the frame, wherein the cleaning system comprises a gettering fan, a cyclone separating barrel and a gettering pipeline; the gettering separating barrel comprises a barrel body of which the central axis extends along a longitudinal direction and is open at the two ends; an opening in the upper end of the barrel is a gettering hole; the circumferential wall of the barrel is provided with a material inlet; the material inlet is formed on one side of the central axis of the barrel body; the gettering hole vertical line extending upwards and downwards through the center of the gettering hole is deviated away from the central axis of the barrel body; the gettering hole central vertical line and the material inlet are formed on two opposite sides of the central axis of the barrel body along the radial direction of the barrel body. On the premise of ensuring the cleaning capability, the diameter of the cyclone separating barrel can be reduced, so that the size and rotating speed of the gettering fan are reduced, the vibration of the entire combine harvester is reduced, and the application reliability of the entire combine harvester is improved.

Owner:HENAN UNIV OF SCI & TECH

Negative pressure type grain secondary winnowing device

InactiveCN113457974AImprove cleanlinessReduce pollutionGas current separationStructural engineeringFan blade

The invention relates to a negative pressure type grain secondary winnowing device. A first winnowing part A comprises a winnowing shell, a winnowing shaft and a plurality of winnowing sheets, an air duct is arranged on the upper part of the winnowing shell, the interior of the air duct communicates with the interior of the winnowing shell, an air suction opening A is formed in the upper part of the air duct, a left air inlet A and a discharging opening are formed in the left end of the winnowing shell, a right air inlet A and a feeding opening are formed in the right end of the winnowing shell, the multiple winnowing sheets are fixed to the winnowing shaft, and the two ends of a shaft head are correspondingly arranged on a left bearing seat and a right bearing seat. A second winnowing part B comprises an upper bearing frame, a lower bearing frame and a spiral shaft, the upper bearing frame is fixed to the upper part of the inner wall of a outer barrel, the lower bearing frame is fixed to the upper part of the inner wall of a cone, a short shaft is fixed to the top of an inner barrel and provided with an upper bearing, the upper bearing is installed on the upper bearing frame, a plurality of fan blades are fixed to the outer wall of the lower part of the inner barrel, the spiral shaft is fixed at the bottom of the inner barrel, a lower bearing is installed on the spiral shaft, and the lower bearing is arranged on the lower bearing frame.

Owner:高平市宏大机械制造有限公司

Intelligent control test platform for multifunctional corn harvester based on CAN bus

ActiveCN110865631BShorten the development cycleImprove job qualityElectric testing/monitoringControl systemControl engineering

The invention relates to an intelligent control test platform for a corn harvester based on a CAN bus, comprising a test bed main body, a parameter display setting panel, a vehicle controller, a harvesting controller, a demonstration panel and a test bed operation panel arranged on the test bed main body. Module, analog actuator and measurement and transmission device; parameter display and setting panel, vehicle controller and harvest controller are connected through CAN bus; harvest controller receives and stores the control module of the corn harvester control system to be simulated and debugged, according to the parameters The harvesting parameters set by the display setting panel and the control module send control commands to the vehicle controller to automatically simulate and adjust the harvesting process; the test bench operation module is connected to the input port of the vehicle controller; the demo panel is drawn with a corn harvester Simulation diagram; the simulation execution mechanism includes a plurality of simulation execution parts respectively connected with the output ports of the vehicle controller; the measurement and transmission device collects the data signals of the simulation execution parts.

Owner:CHINA AGRI UNIV

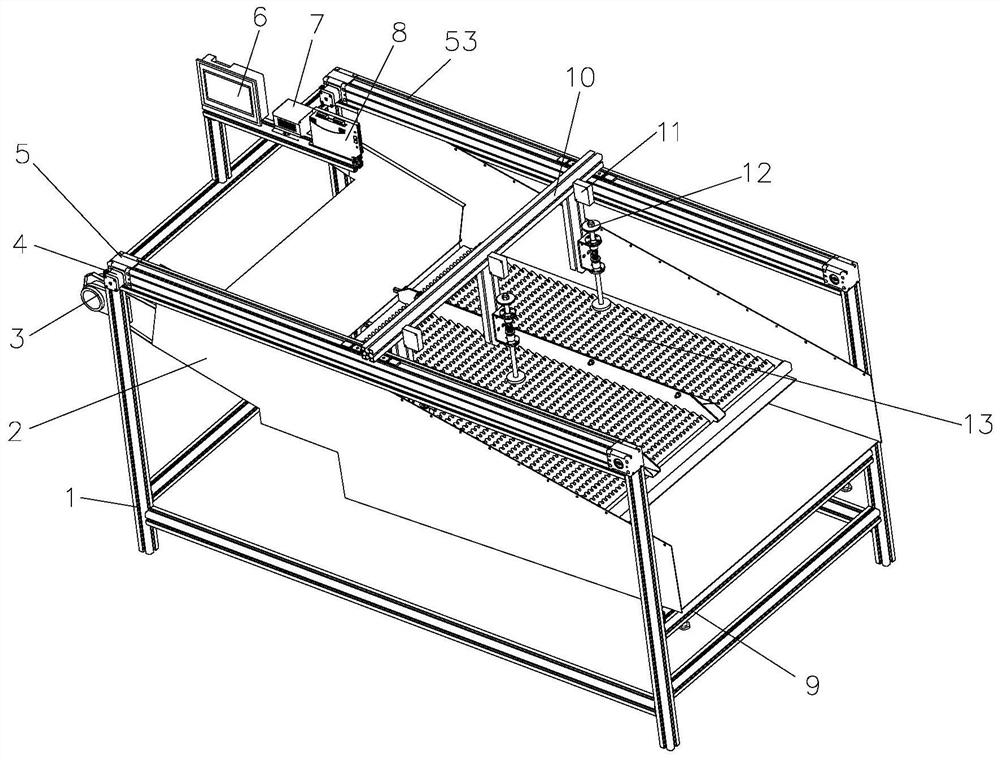

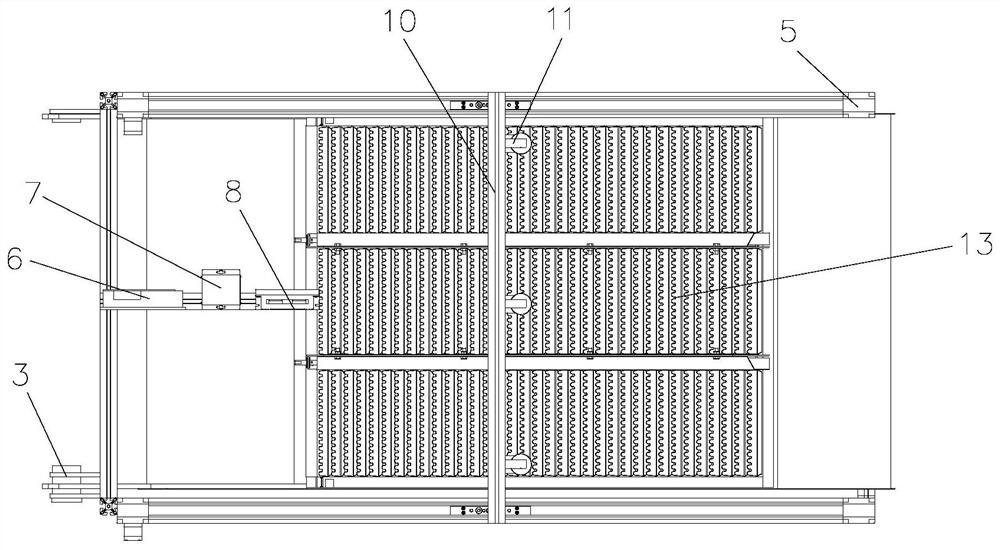

Device and method for detecting welded body of grain cleaning sieve box

ActiveCN111025311BImprove detection efficiencyHigh dimensional consistencyElectromagnetic wave reradiationLaser rangingDisplay device

The invention discloses a grain cleaning sieve box welded body detection device and method, which are used for detecting a grain cleaning sieve box welded body. The grain cleaning sieve box welded body detection device includes: a frame, the frame It includes a positioning device and a leveling device; a detection component, which includes two slide rail assemblies, each of which includes a stepping motor and at least one laser ranging sensor; and a control display component, The control and display component includes a display device and a controller, and the controller is signal-connected with the detection component and the display device. The invention can detect the size of the welded body of the grain cleaning sieve box quickly and with high precision.

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI

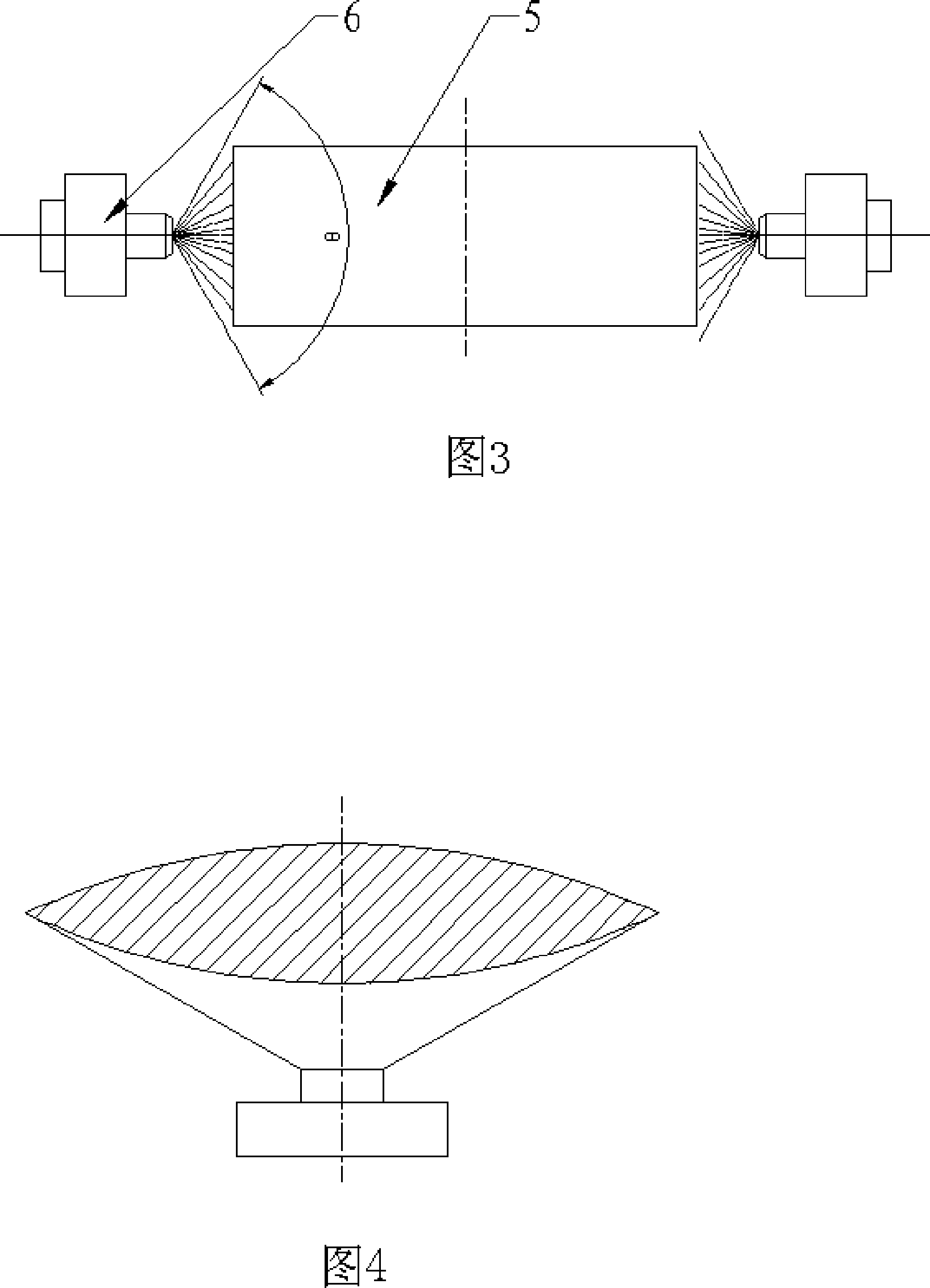

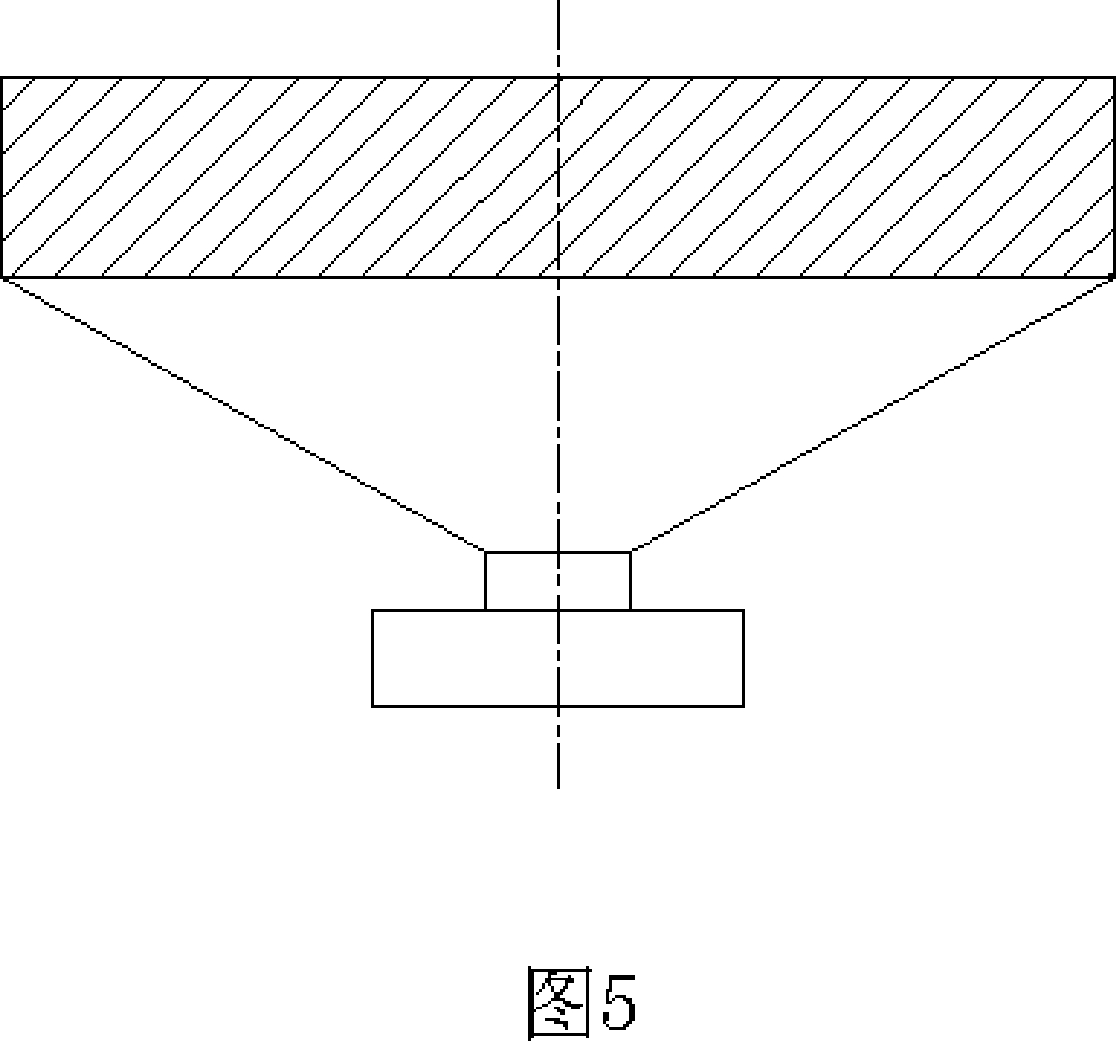

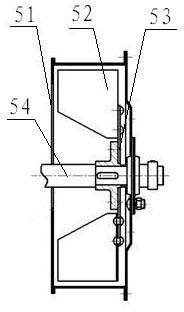

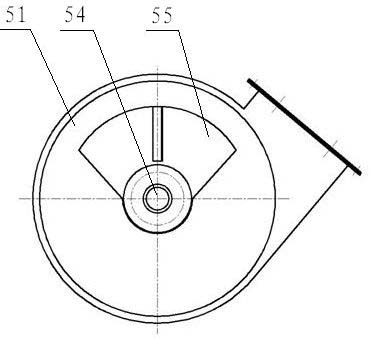

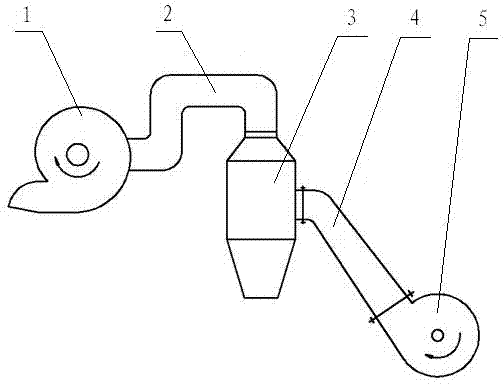

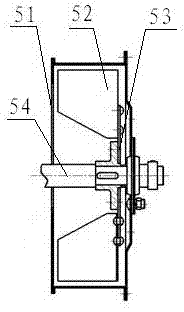

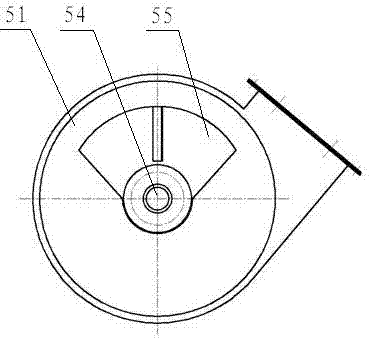

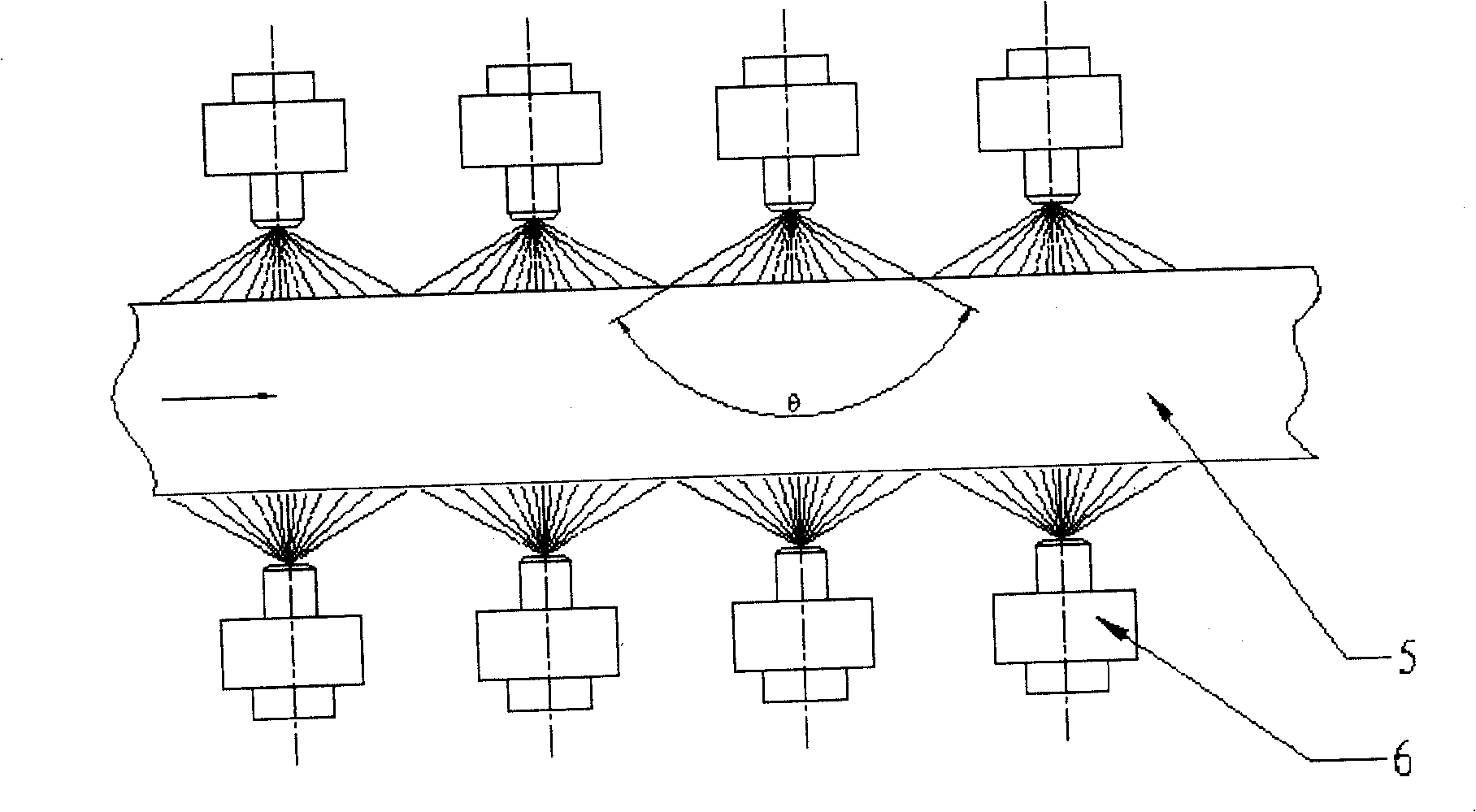

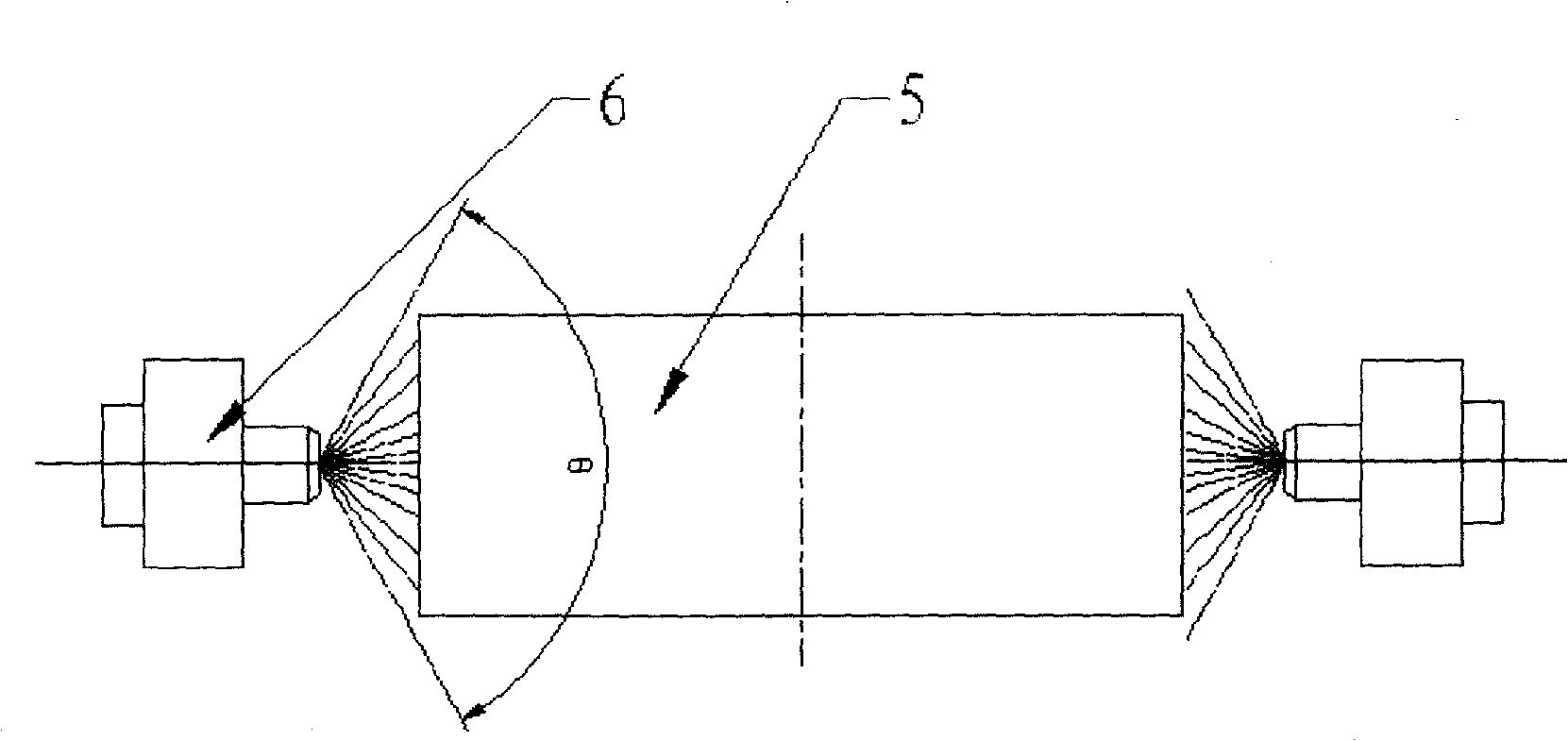

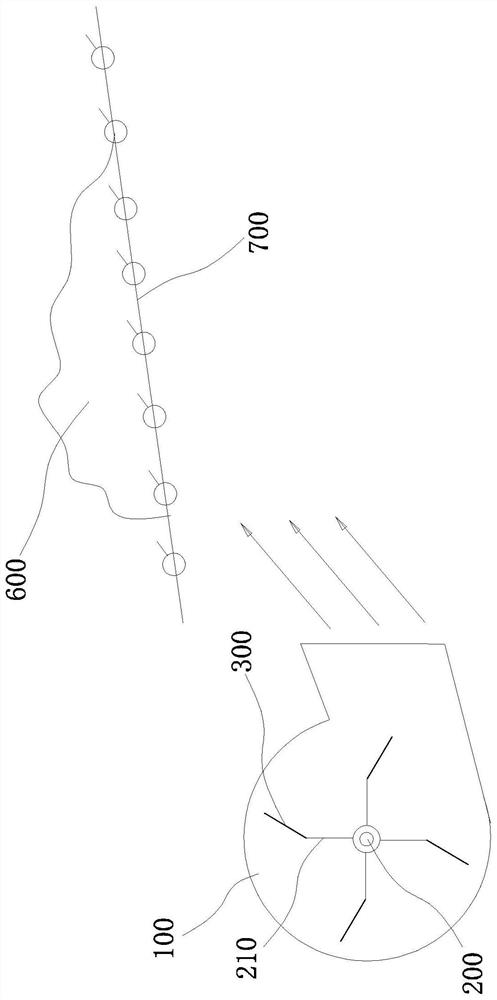

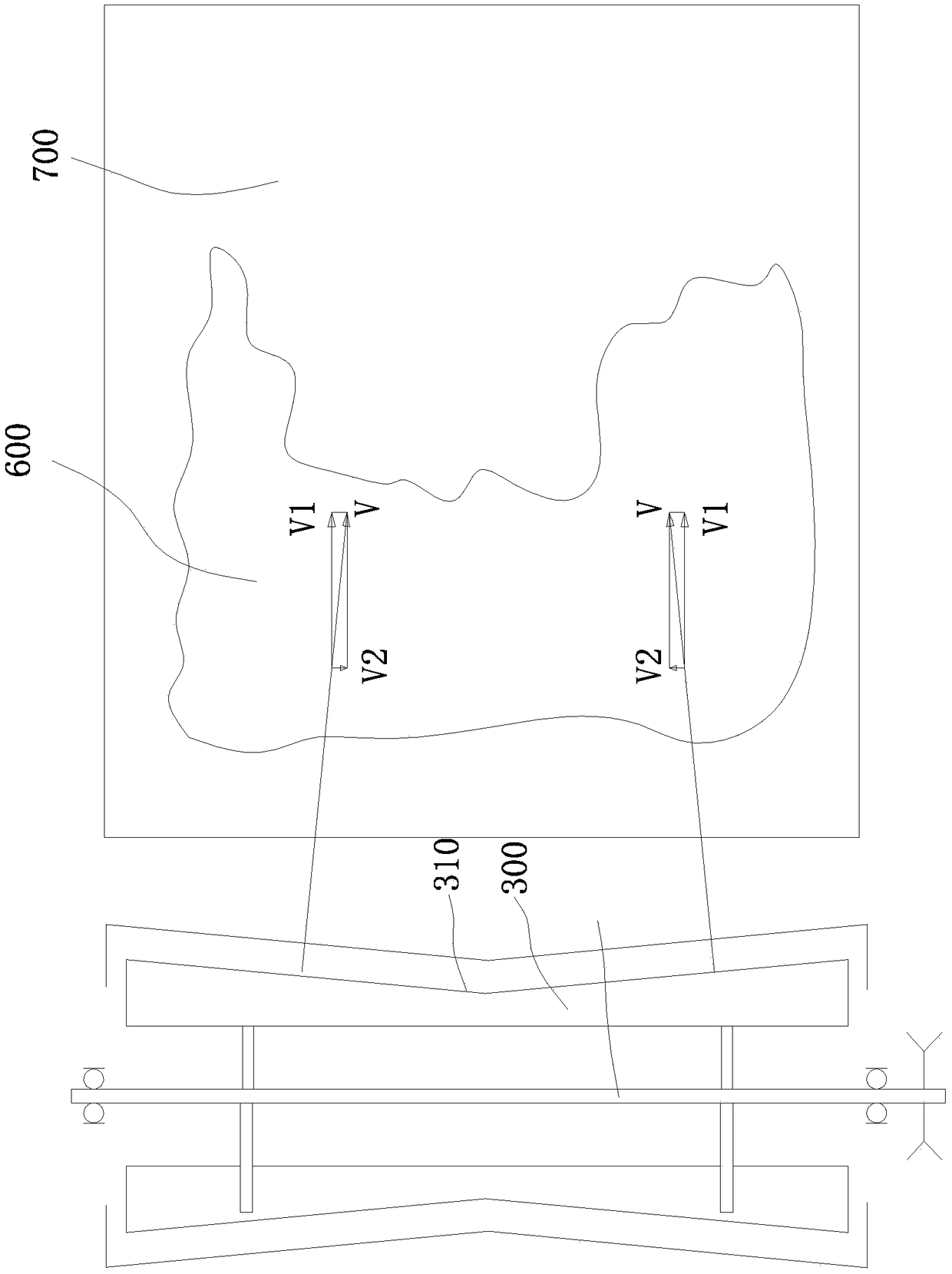

A cleaning method of a double-cone centrifugal cleaning fan

The invention provides a double-cone centrifugal cleaning fan. The double-cone centrifugal cleaning fan comprises a fan housing, a fan shaft arranged in the fan housing, and fan blades connected to the fan shaft; each fan blade has a V-shaped outer side edge with the two ends wide and the middle narrow, and when the fan shaft rotates, the tracks formed by the outer side edges of the fan blades aredouble cones. The double-cone centrifugal cleaning fan has the advantages of being simple in structure, reliable in work and capable of uniformly distributing load on the surface of a vibrating screen, improving the cleaning quality and reasonably utilizing the airflow to reduce the cleaning loss.

Owner:JINHUA VOCATIONAL TECH COLLEGE

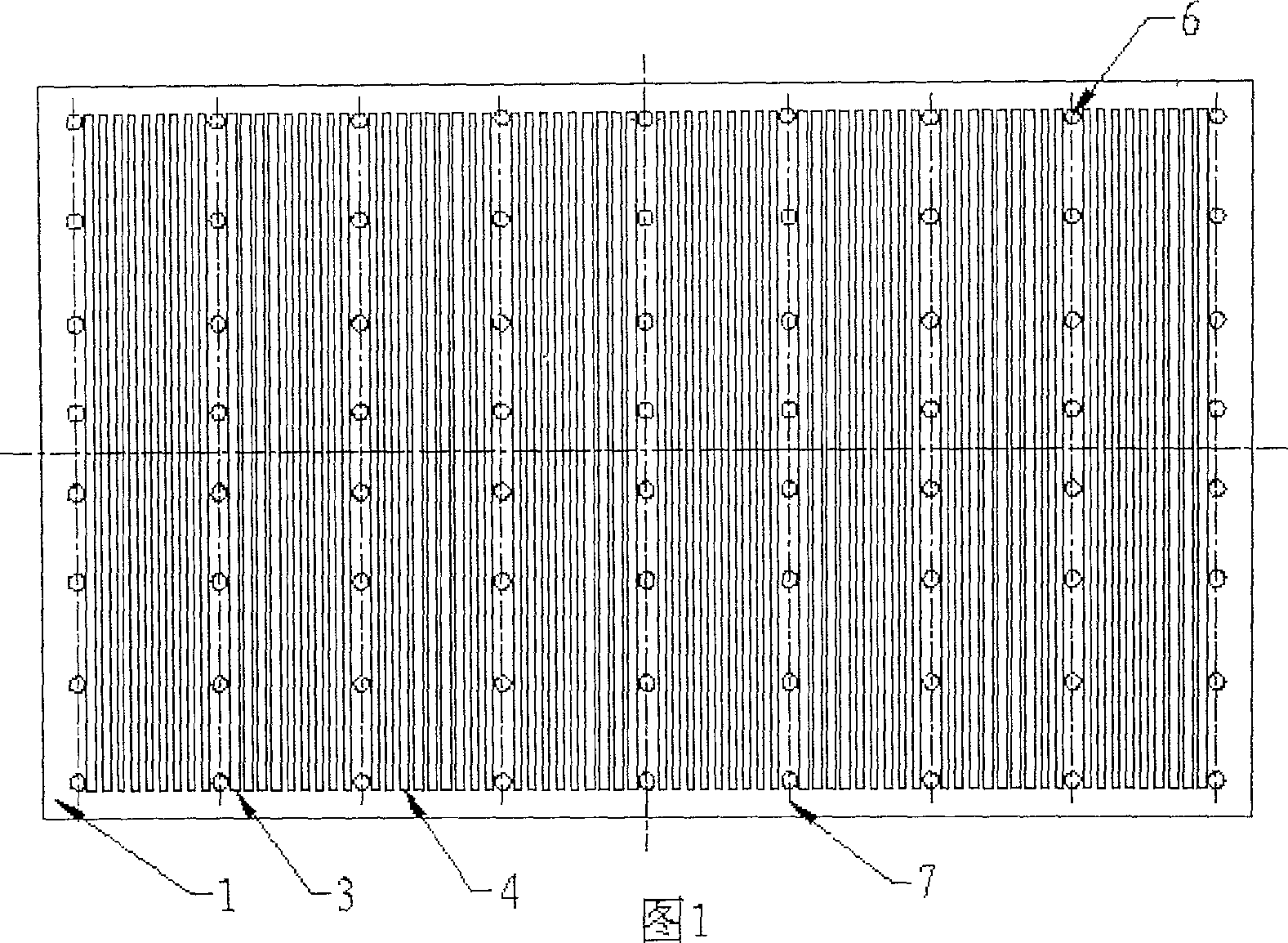

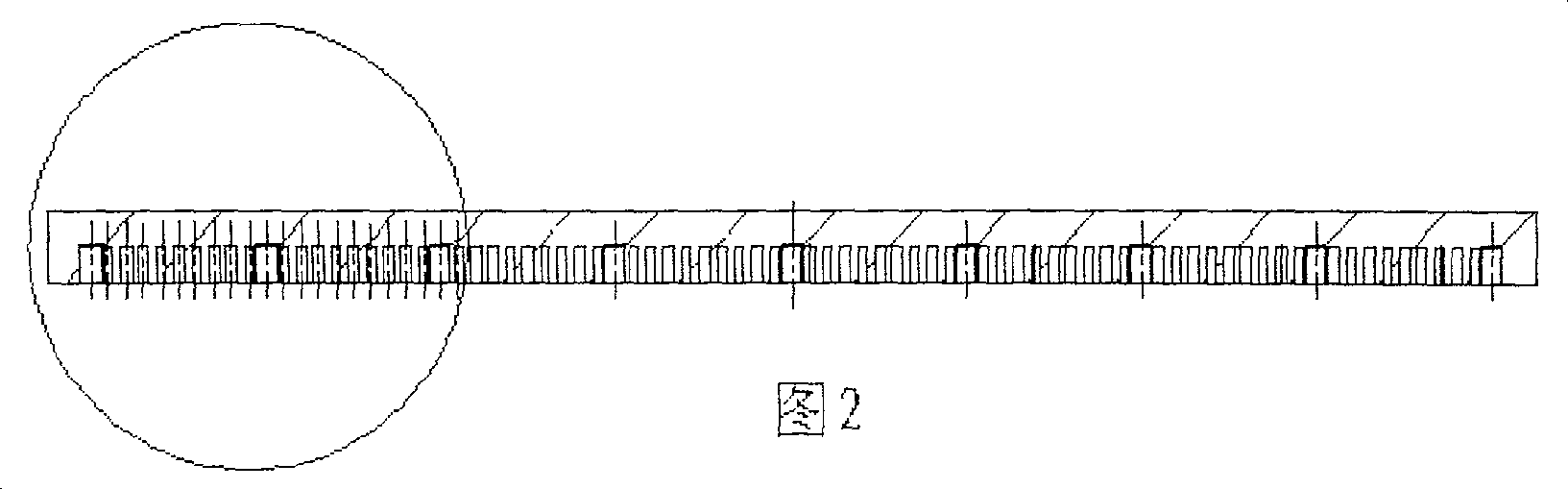

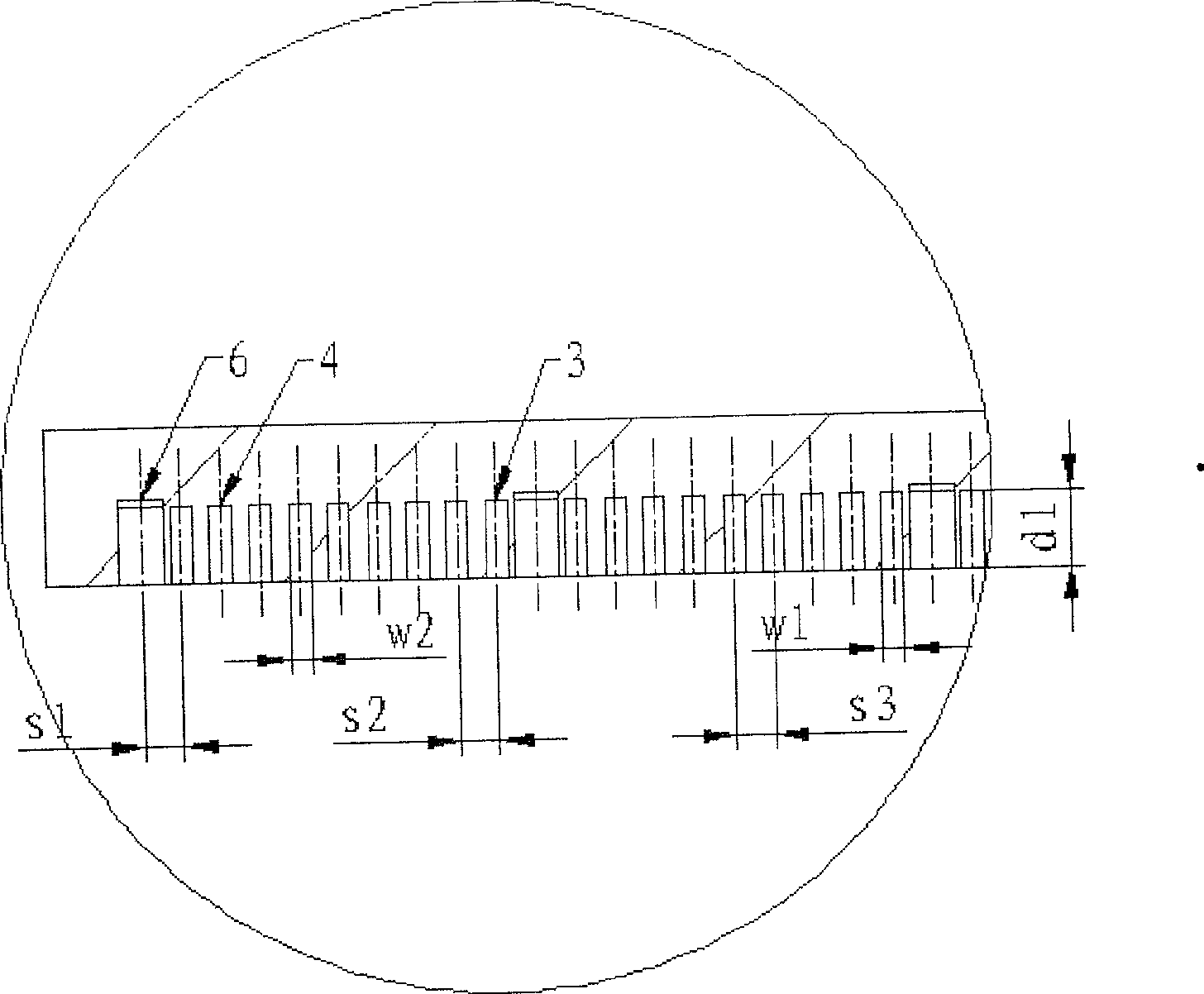

Continuous casting crystallizer for plate billet

The present invention belongs to the field of metal continuous casting auxiliary equipment and continuous casting slab surface quality control technology. In the concrete, it discloses a slab continuous casting crystallizer so as to solve the problem of that the non-uniform cooling of width direction of traditional crystallizer can produce longitudinal corner crack. Said crystallizer includes wide-face copper plate, narrow-face copper plate and connecting screw hole row which is arranged along the slab-drawing direction, on the wide-face copper plate and narrow-face copper plate several rectangular cooling water tanks which are reasonably designed according to the cooling uniformity requirement are respectively and symmetrically distributed.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

Double-cone centrifugal cleaning fan

The invention provides a double-cone centrifugal cleaning fan. The double-cone centrifugal cleaning fan comprises a fan housing, a fan shaft arranged in the fan housing, and fan blades connected to the fan shaft; each fan blade has a V-shaped outer side edge with the two ends wide and the middle narrow, and when the fan shaft rotates, the tracks formed by the outer side edges of the fan blades aredouble cones. The double-cone centrifugal cleaning fan has the advantages of being simple in structure, reliable in work and capable of uniformly distributing load on the surface of a vibrating screen, improving the cleaning quality and reasonably utilizing the airflow to reduce the cleaning loss.

Owner:JINHUA VOCATIONAL TECH COLLEGE

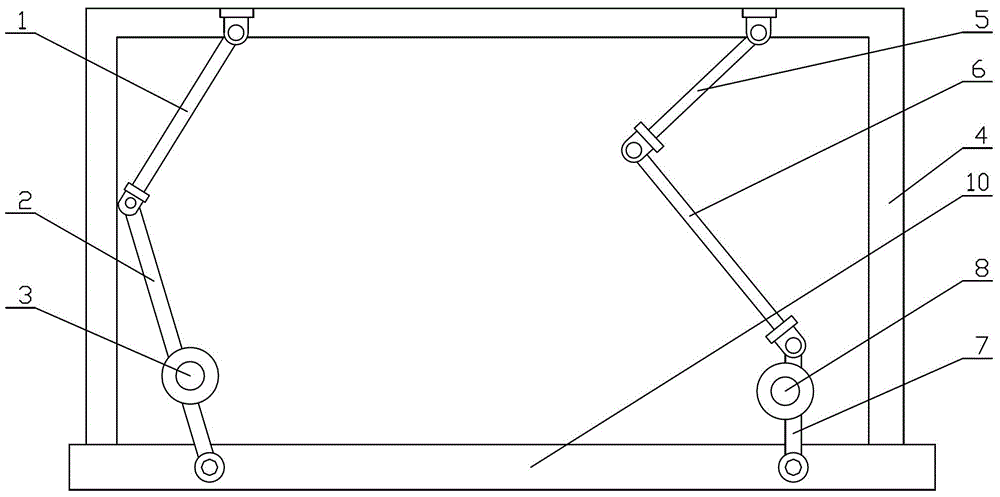

All-wheel-drive non-amplitude vibrating screen mechanism

ActiveCN103447232AMultiple directions of vibrationImprove screening effectSievingScreeningEngineeringAll-wheel drive

An all-wheel-drive non-amplitude vibrating screen mechanism comprises a vibrating screen and a vibrating system. The vibrating system comprises a pair of front eccentric wheels, a pair of rear eccentric wheels, a pair of front multi-stage connecting rods and a pair of rear multi-stage connecting rods. The front eccentric wheels and the rear eccentric wheels are driven by a transmission mechanism, and are connected with a frame rotatably; the eccentric distance of the front eccentric wheels is large than that of the rear eccentric wheels. The front multi-stage connecting rods are in three-segment connecting rod structure, and the rear multi-stage connecting rods are in two-segment connecting rod structure. According to the all-wheel-drive non-amplitude vibrating screen mechanism, since the front multi-stage connecting rods adopts the three-segment connecting rod structure, the rear multi-stage connecting rods adopts the two-segment connecting rod structure, by means of driving by the eccentric wheels and interactive effect of structures of the vibrating screen and the like, so that the moving track of the front end of the vibrating screen is in a shape of a transverse 8, the moving track of the rear end of the vibrating screen is elliptical, vibrating directions of the entire screen surface are increased, and better screening effect is achieved.

Owner:QINGDAO AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com