Patents

Literature

99results about How to "Reduce the amount of cooling water" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

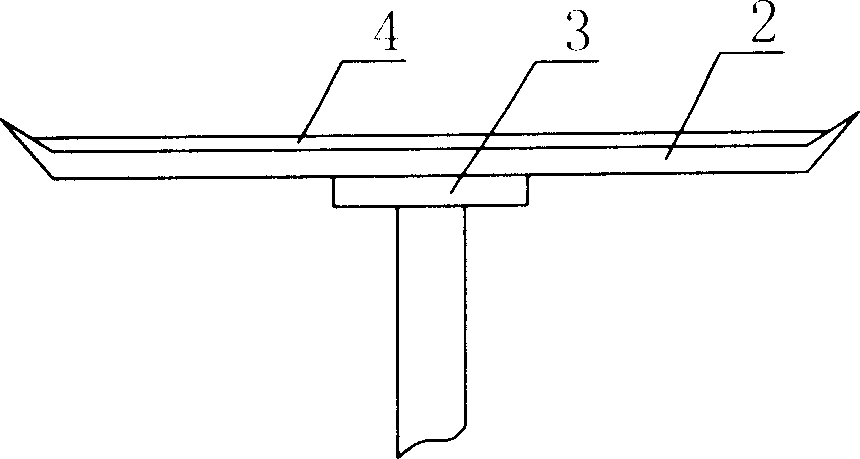

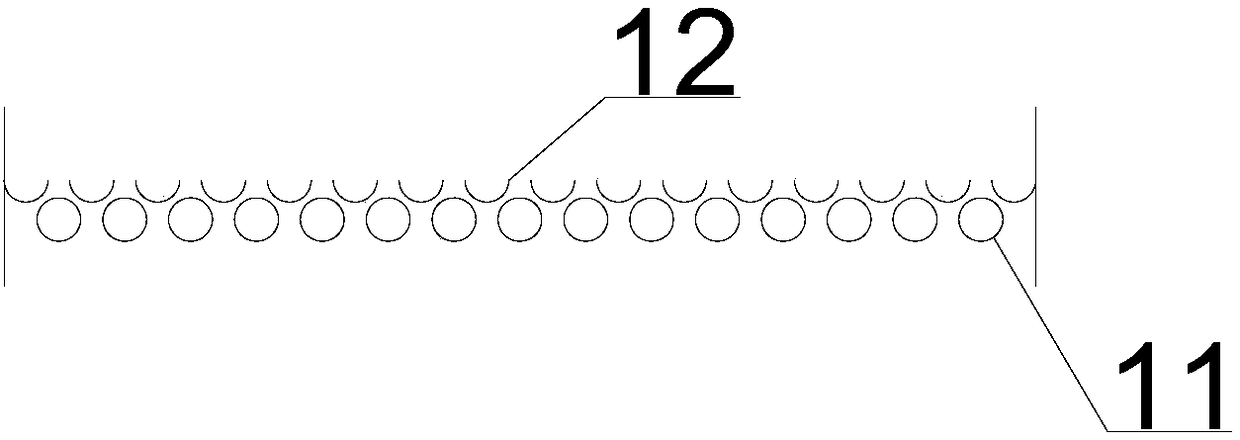

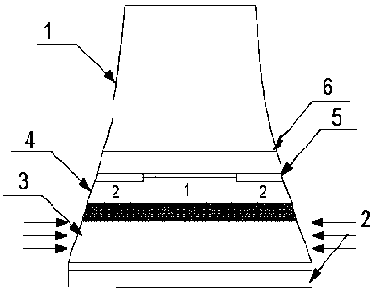

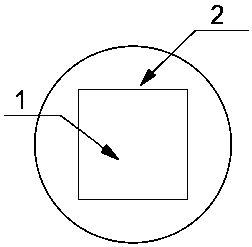

Straight arc casting machine alloy steel sheet billet continuous casting foot roller segment narrow surface cooling method

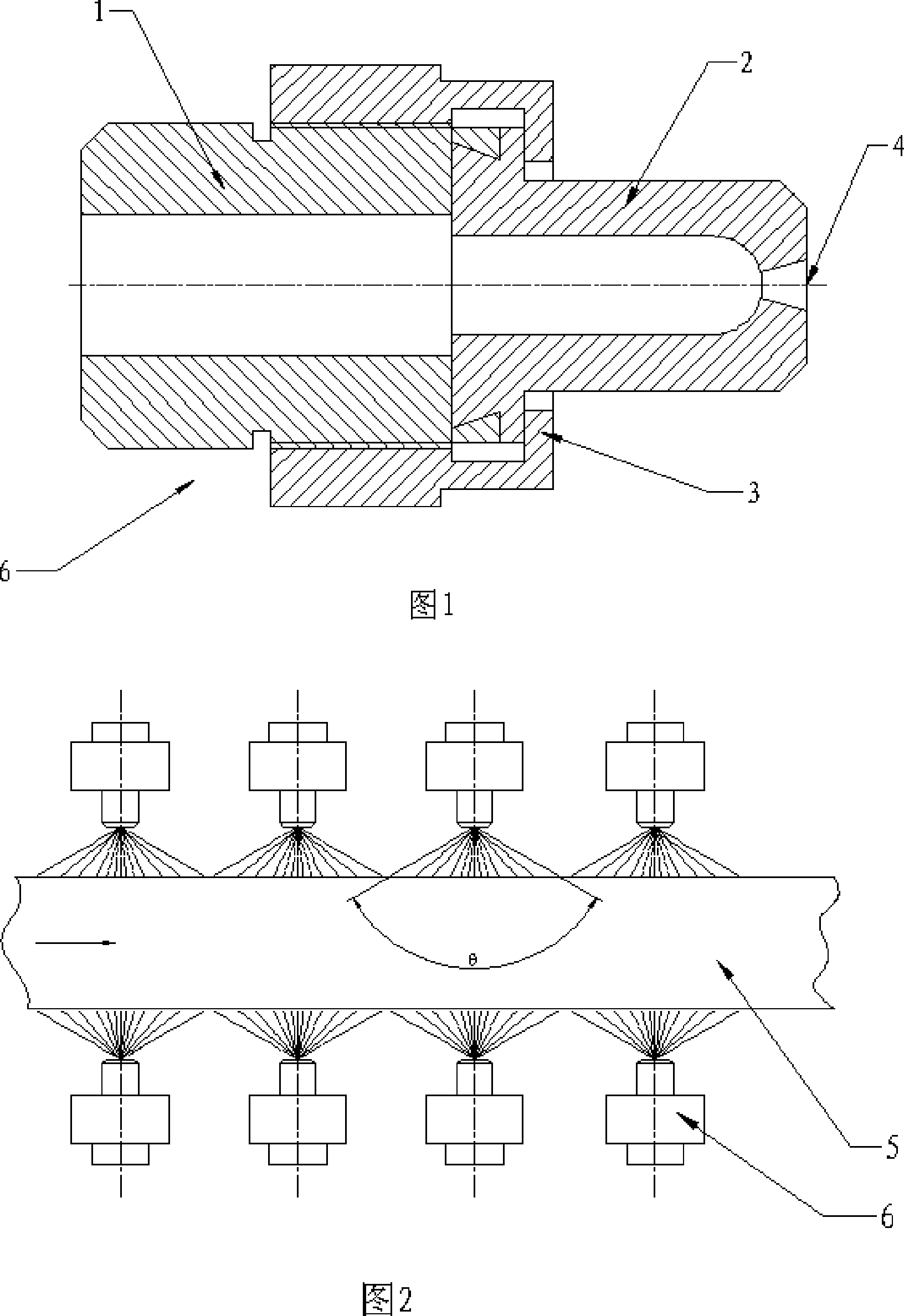

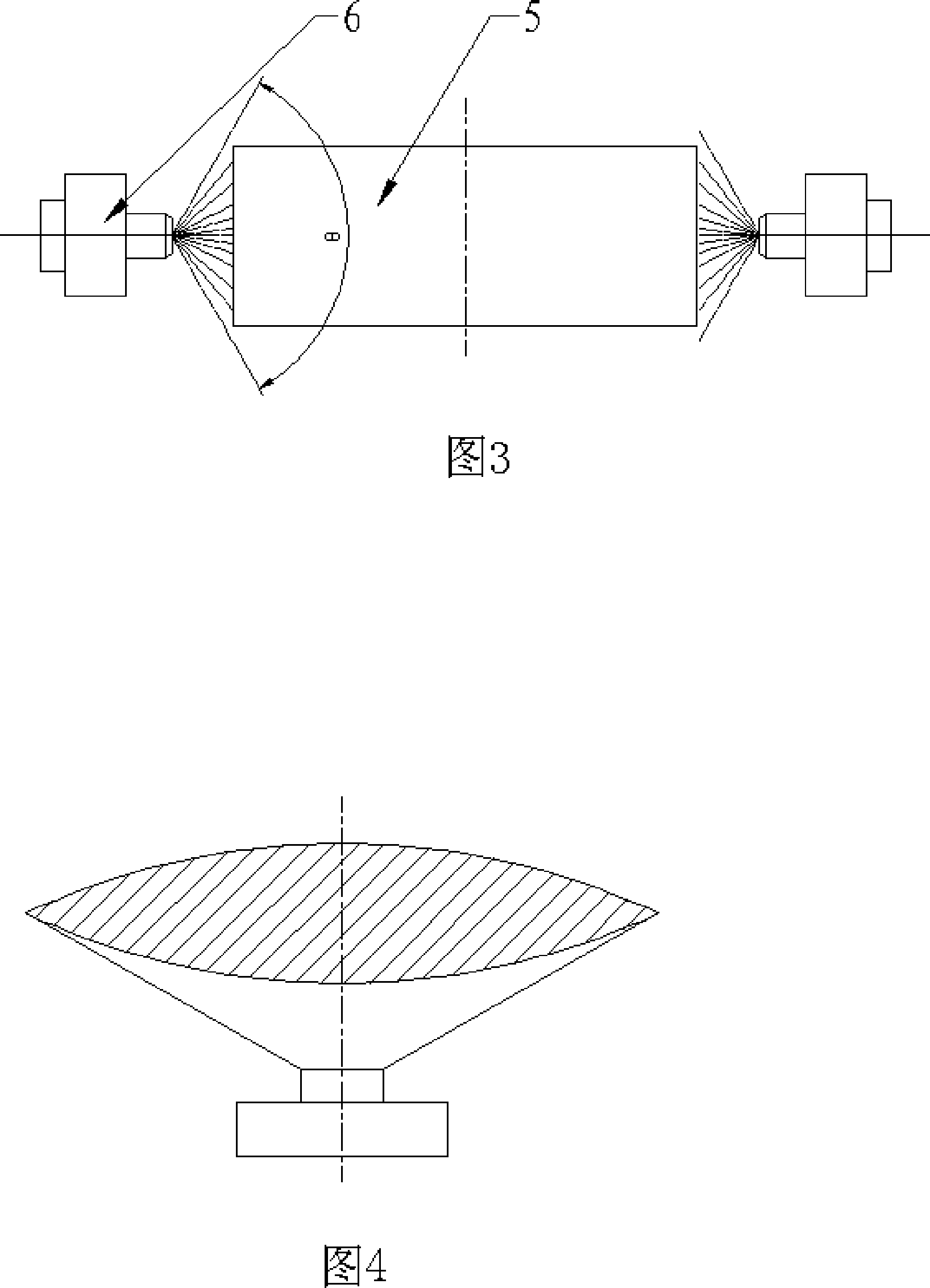

The present invention discloses a straight-curved type casting machine low-alloy steel slab continuous casting full-rolling section narrow face cooling method, and is aimed at solving the problem of that on the casting blank surface corner portion of low-alloy steel the transverse crack can be easily produced. Said invention belongs to the field of metal continuous casting blank cooling and surface quality control technology. Said method is characterized by that in the full-rolling section of continuous casting straight-curved type casting machine slab said invention utilizes the nozzles which are symmetrically mounted at left side and right side of casting blank pouring direction to cool the narrow face of said casting blank, and adopts rectangular nozzles to symmetrically and simultaneously cool the narrow faces of left and right two sides of casting blank. Said invention also discloses a kind of rectangular nozzle for said method, the water outlet hole of its sprayer is a hole with rectangular section. Said invention can reduce casting blank cooling strength of full-rolling section under the crystallizer and can improve casting blank cooling uniformity, so that it can eliminate casting blank surface corner portion transverse crack defect of continuously-cast high-strength low-alloy steel whose steel quality is P510L, P590L, J55 and X52, etc.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

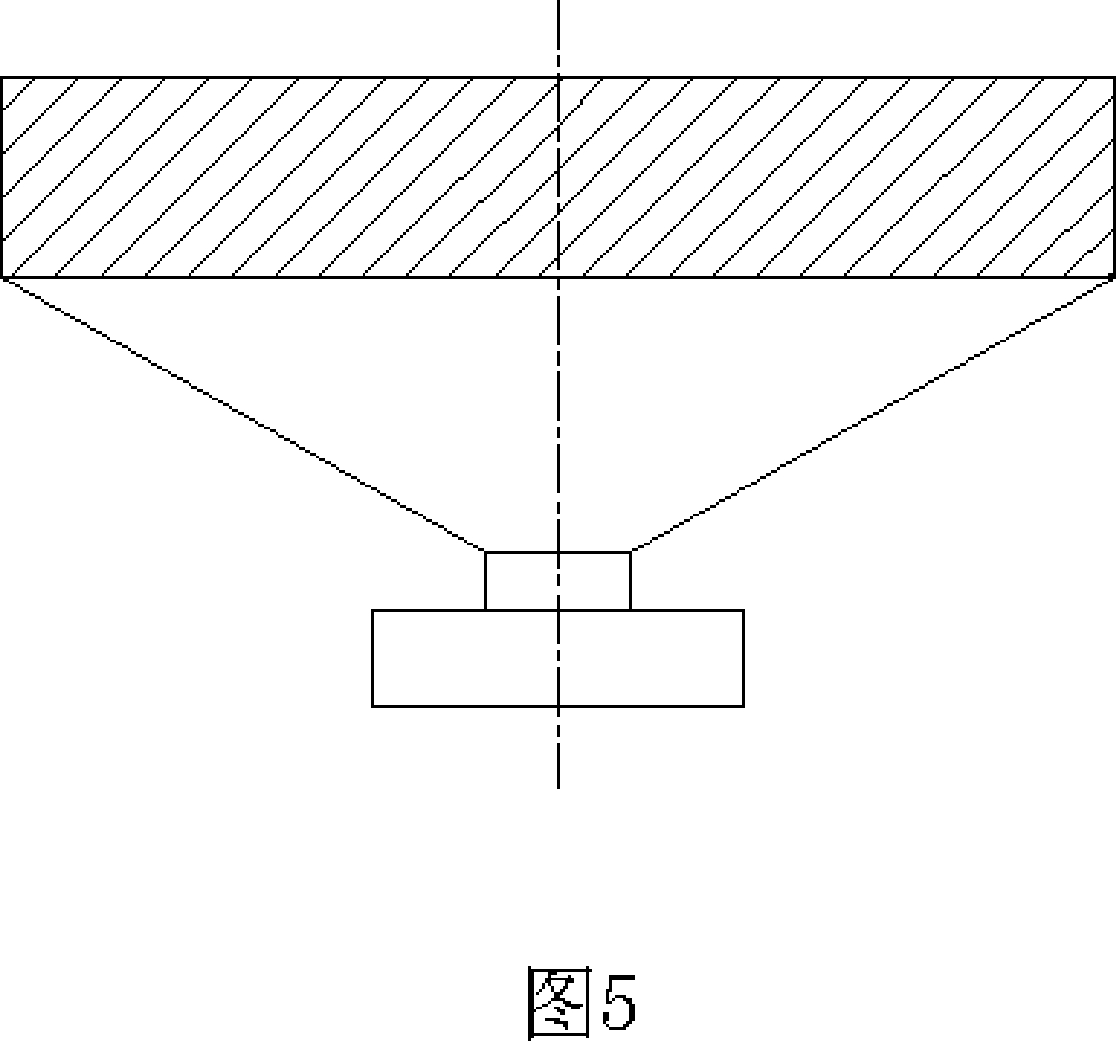

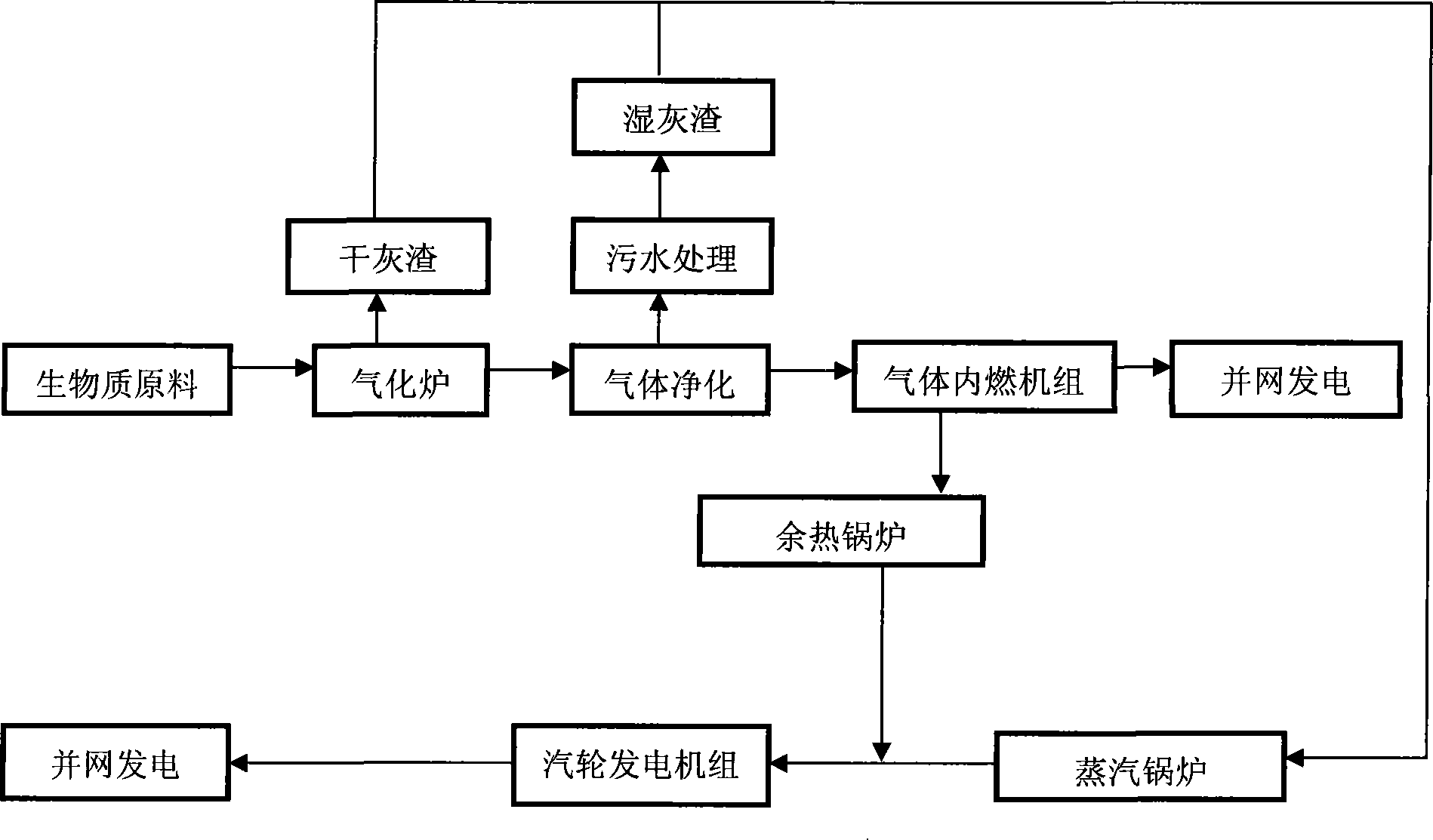

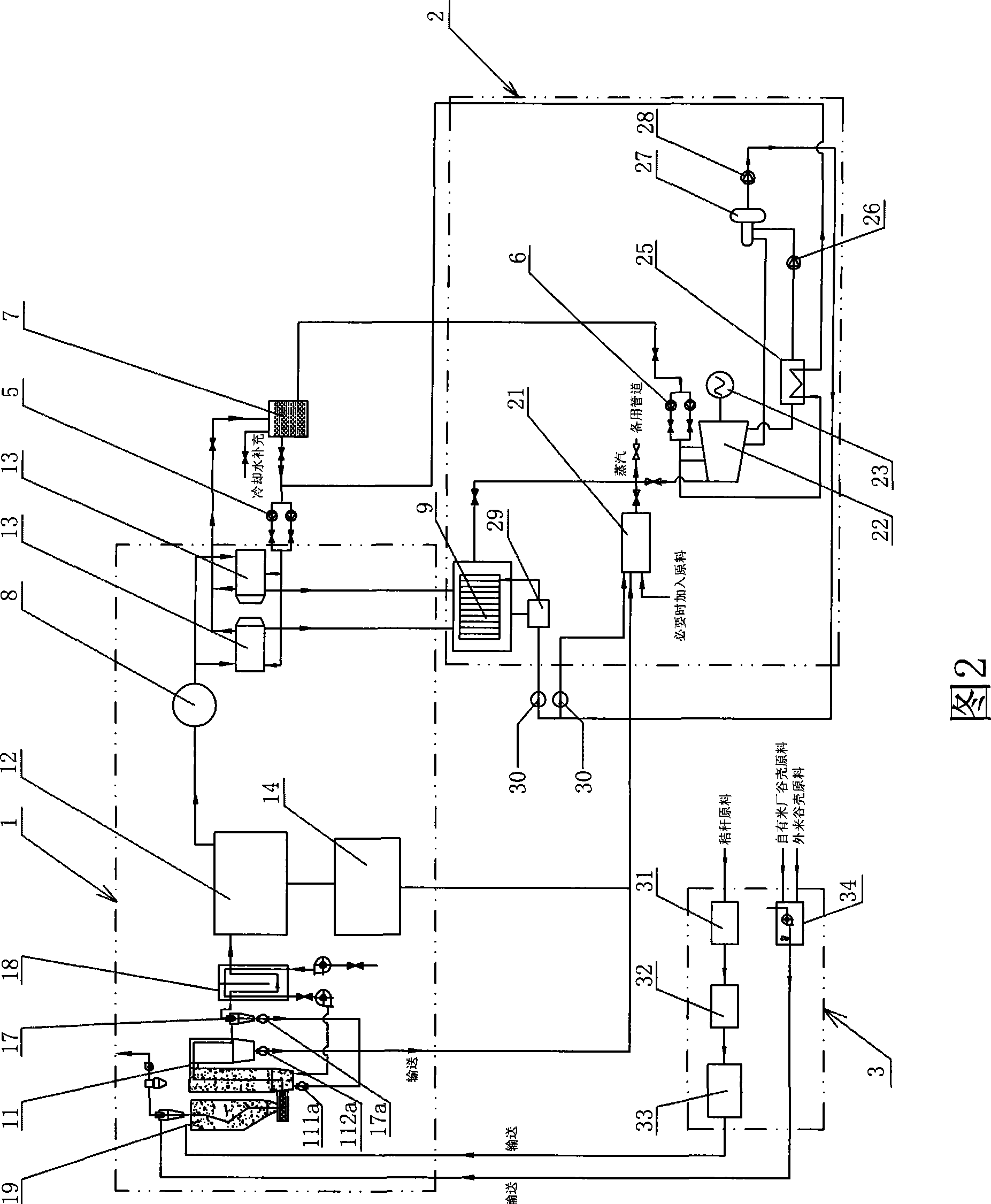

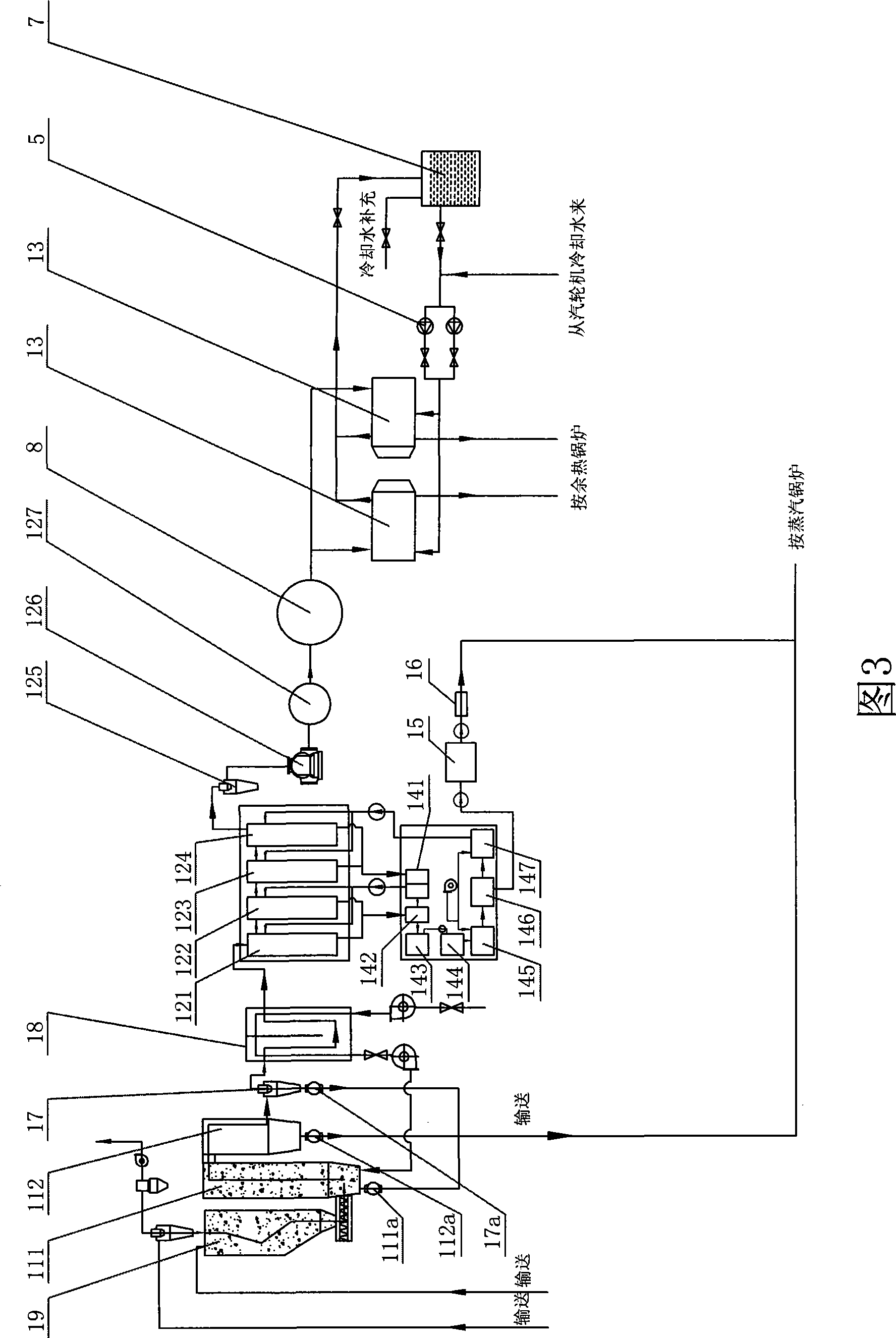

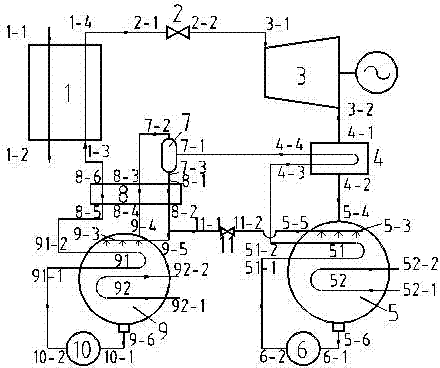

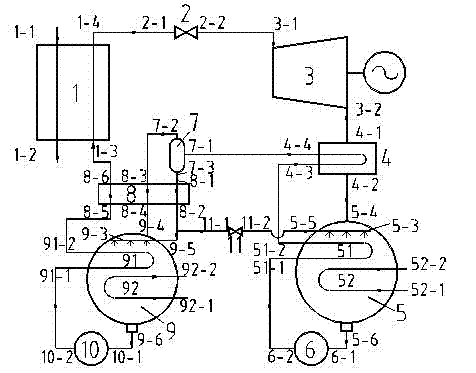

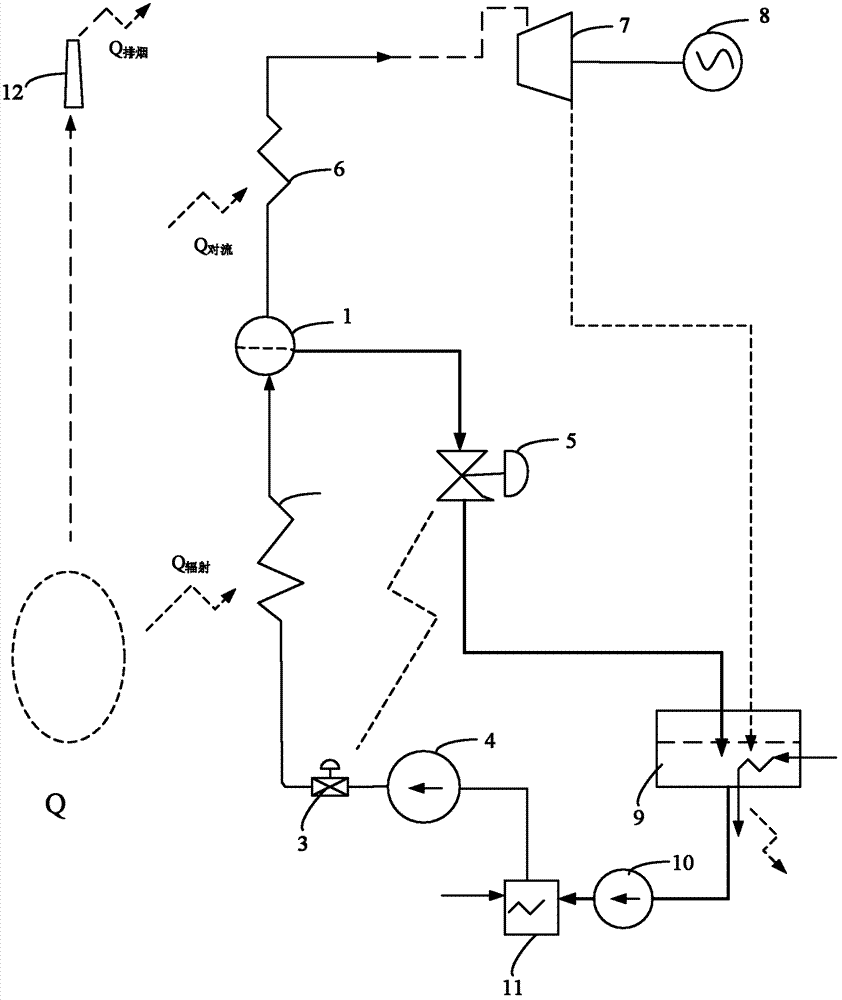

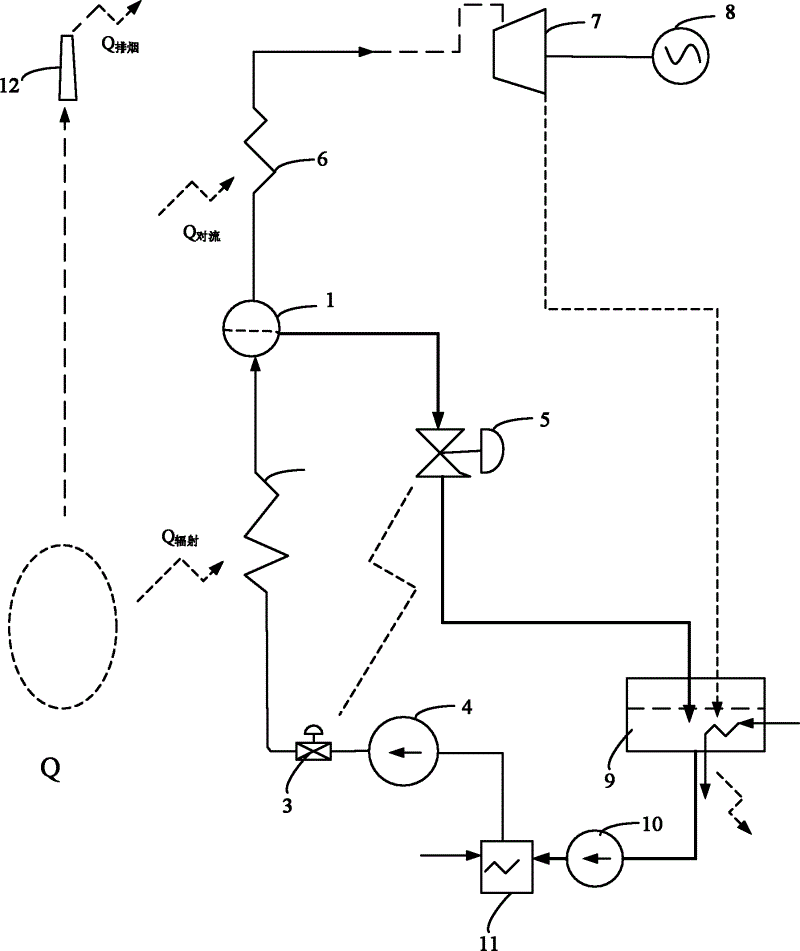

Biomass energy circulation electrification technique as well as generating system thereof

InactiveCN101251045ATake advantage ofImprove power generation efficiencyInternal combustion piston enginesFeed water supplyThermal energyInternal combustion engine

The invention provides a biomass energy IGCC technology which is characterized in that the technology comprises the following steps that: (1) the biomass raw material is gasified to be converted into the combustible gas which is dedusted and decoked as well as purified and is sent to a gas internal-combustion engine to generate electricity; (2) the biomass raw material or the clinker generated in the gasification and power generation process in the step 1 or the mixture of the two is sent to a steam boiler to be burnt in order to generate the superheated steam; the exhaust heat of the gas internal-combustion engine of the step 1 is inlet to an exhaust-heat boiler to generate the superheated steam; (3) the superheated steam generated by the steam boiler and the exhaust-heat boiler of the step 2 is sent to a turbonator set. The biomass energy IGCC technology takes full advantage of the heat energy and the product generated by each processing step in the biomass energy gasification and power generation process and generates electricity circularly, thereby greatly raising the power generation efficiency, taking full advantage of waste materials and lowering the running cost. The invention also discloses a power generation system for realizing the biomass energy IGCC technology.

Owner:黄家笙 +1

High-performance hydrogen sulfide corrosion resistant oil drill rocker and its heat treatment process

InactiveCN101117683AGuaranteed hardenabilityGuaranteed sulfur resistanceDrilling rodsFurnace typesMechanical propertyPetroleum

The present invention relates to a high-performance hydrogen sulfide corrosion resistant petroleum drill pipe with a weight percentage of components as follows: C 0.20-0.32 percent, Si 0.1-0.5 percent, Mn 1.0-1.5 percent, Cr 0.5-1.5 percent, Mo 0.8-1.2 percent, P less than or equal to 0.015 percent, S less than or equal to 0.01 percent and the remainders are Fe and unavoidable impurities. The drill pipe of the present invention has a higher content of Mn, which can guarantee an upset end with a thickness of over 30mms to be fully hardened, thereby guaranteeing the sulfur-resistant performance of the upset end. The drill pipe of the present invention has a higher content of Mo, which can improve the backfire-preventive stability of the material, thereby raising the backfire temperature, reducing the residual stress and guaranteeing the sulfur-resistant performance. Simultaneously, the invention can make the pipe body with a different wall thickness and the upset end have the same cooling speed by controlling the outer water injection of the upset end and pipe body of the steel pipe, reducing the water injection outside the pipe body or increasing the water injection outside the upset end of the drill pipe, to ensure that the pipe body and the upset end have the same quenching structure, and the same mechanical property can be achieved after the backfire.

Owner:BAOSHAN IRON & STEEL CO LTD

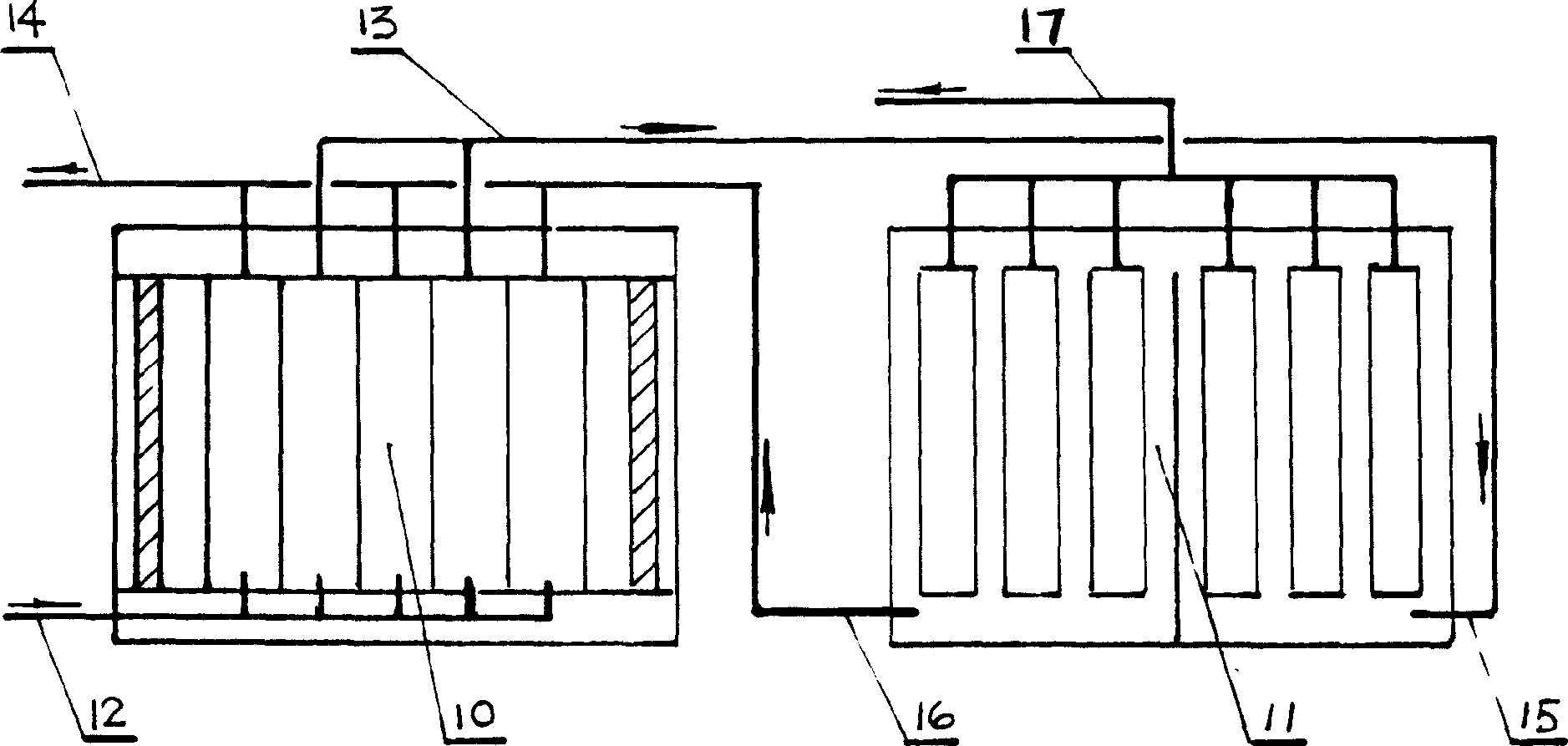

Lithium bromide absorbing refrigerator of membrane separation concentrating solution

InactiveCN1645012AReduce consumptionReduce pollutionSemi-permeable membranesSorption machinesDaily operationReflux

The invention discloses a lithium bromide absorbing refrigerator of a membrane separation concentrating solution, is to realize effects of saving energy, environmental protection, production cost reduction, daily operation expense reduction, easy maintaining and safety. The refrigerator includes an evaporator (1), an absorber (2), an air extractor (3), an evaporator pump (4), an absorbor reflux pump (5), a setting membrane separating and filtering device (6), the membrane separating and filtering device is provided with a liquid inlet, a liquid outlet and a water outlet which are connected with an absorbor dilute solution outlet, an absorbor concentrated solution inlet and an evaporator water inlet respectively. The invention is suitable for central air-condition systems in hotels, emporiums and office buildings.

Owner:宣伯民

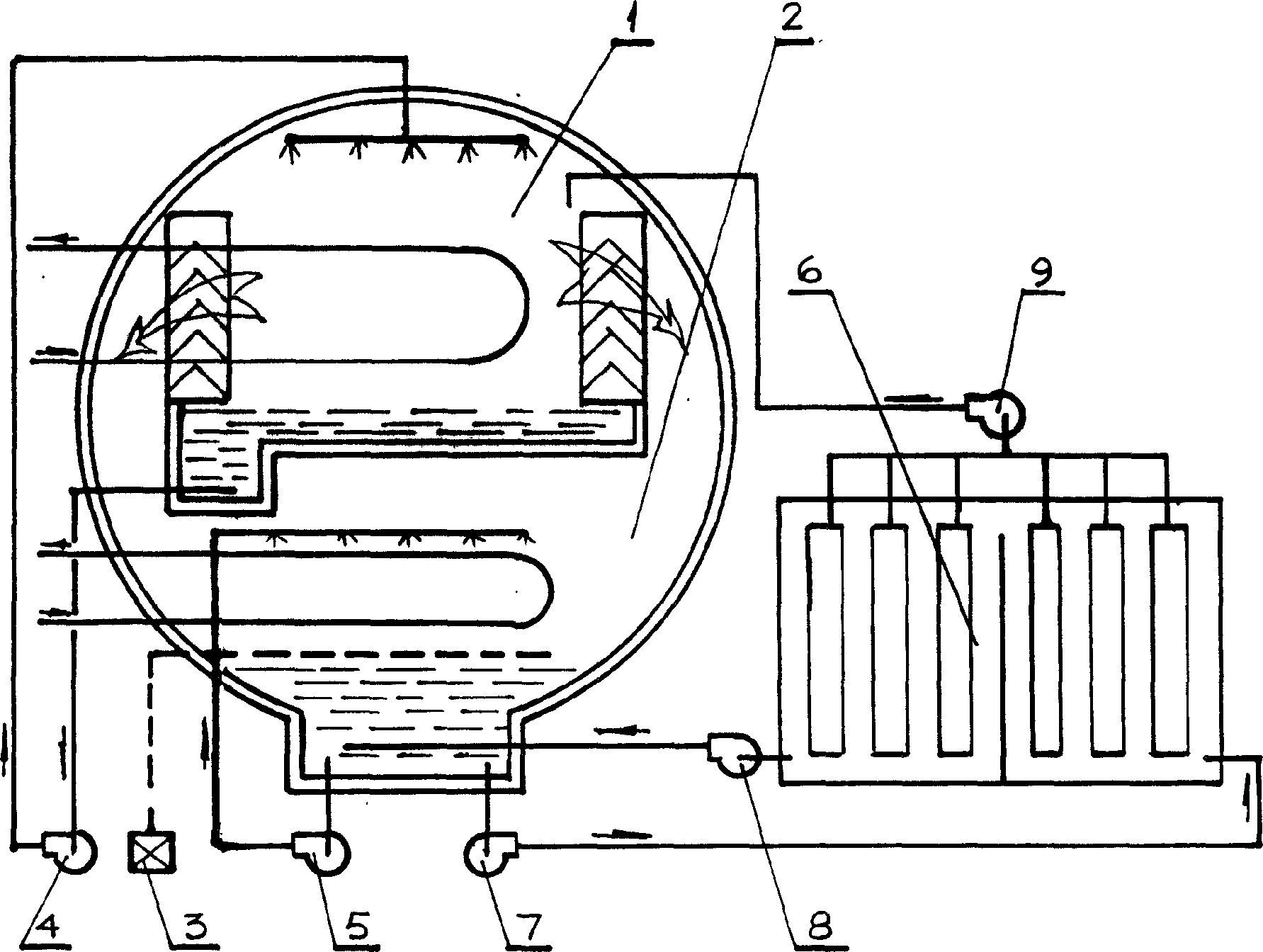

Solution cooling absorption type ammonia water motive power circulation device

InactiveCN102312687AImprove energy conversion efficiencyReduce cooling waterSteam engine plantsHeating efficiencyThermal efficiency

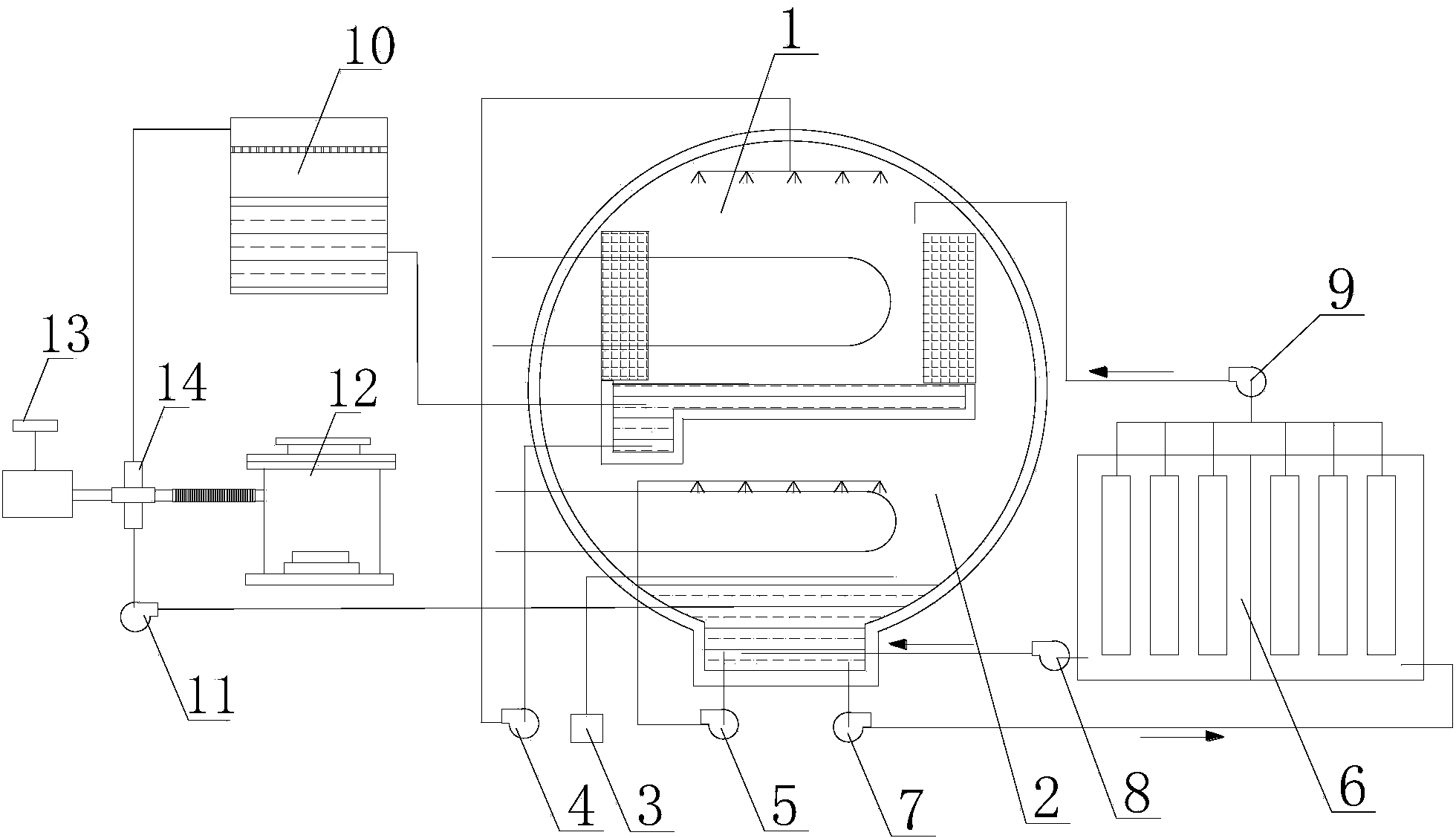

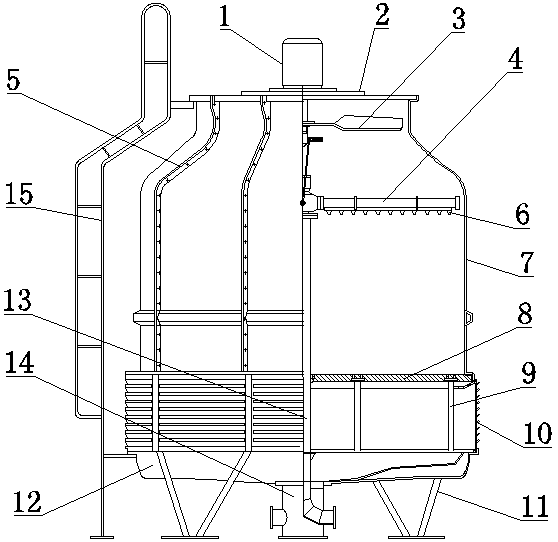

The invention discloses a solution cooling absorption type ammonia water motive power circulation device, which consists of an evaporator 1, a turbine machine set 3, a regenerator 4, a low-pressure absorbing device 5, a low-pressure ammonia pump 6, a gas-liquid separator 7, a pre-heater 8, a high-pressure absorbing device 9, a high-pressure ammonia pump 10, a throttle valve 11 and a connecting pipeline, wherein the low-pressure absorbing device and the high-pressure absorbing device are respectively divided into a solution cooling absorbing section and a cooling water absorbing section, and the solution cooling absorbing section is arranged above the cooling water absorbing section. The solution cooling absorption type ammonia water motive power circulation device has the advantages that the absorbing device outlet solution is used for cooling the front section of the absorbing process, the cooling water quantity can be reduced, the heat discharge and the heat transfer loss on the environment can be reduced, the heat transfer area is favorably reduced, and the circulation heat efficiency is favorably improved. The solution cooling absorption type ammonia water motive power circulation device is provided with the three-flow pre-heater for preheating work solution before entering the evaporator, the dilute solution and rich ammonia gas entering the absorber can be cooled, the absorption driving force can be enhanced, and in addition, the smoke gas low-temperature corrosion resistance of the device is favorably improved.

Owner:SOUTHEAST UNIV

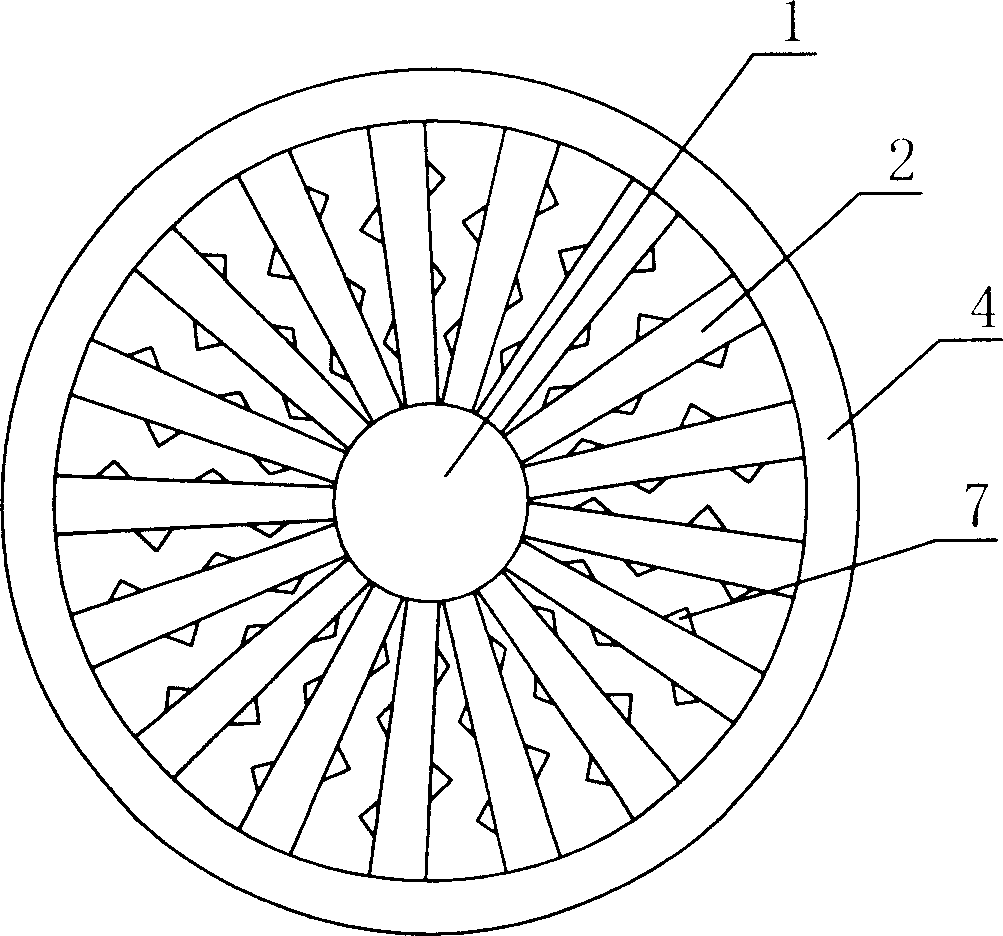

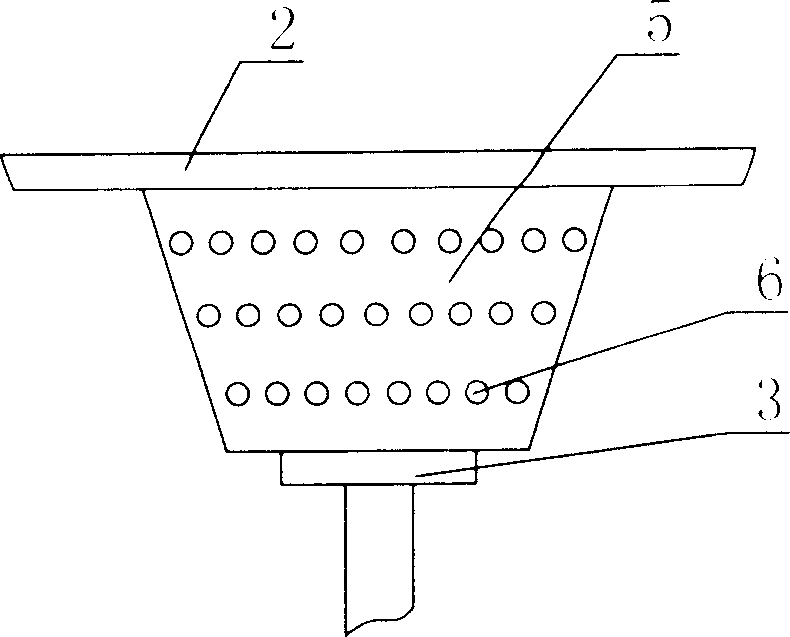

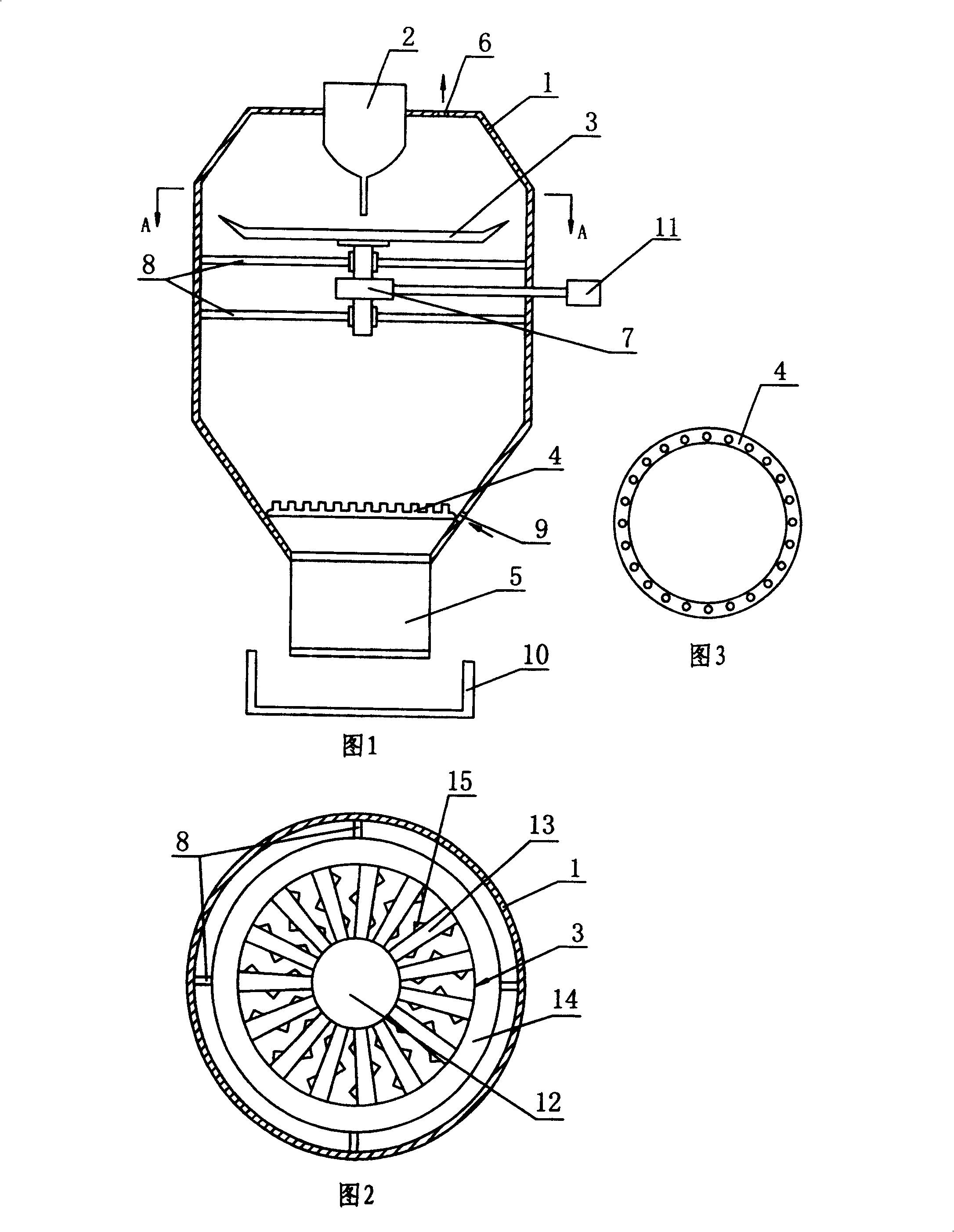

Liquid blast furnace slag pelletizing method and apparatus for heat recovering process

InactiveCN1888081AGuaranteed heat effectHigh activityOther heat production devicesRecycling and recovery technologiesLiquid slagProduct gas

The present invention is liquid blast furnace slag pelletizing method and apparatus for heat recovering process, and features that the liquid slag blast furnace discharges in downward flow is crushed into grains with the pelletizing apparatus in high speed rotation to produce centrifugal force of throwing the liquid slag. Crushing the liquid slag into relatively homogeneous fine grains can ensure the effective heat exchange between slag and gas. The pelletizing apparatus is one wheel spoke type disc or cup structure capable of ensure the effective recovering of heat from the liquid blast furnace slag.

Owner:CHONGQING UNIV

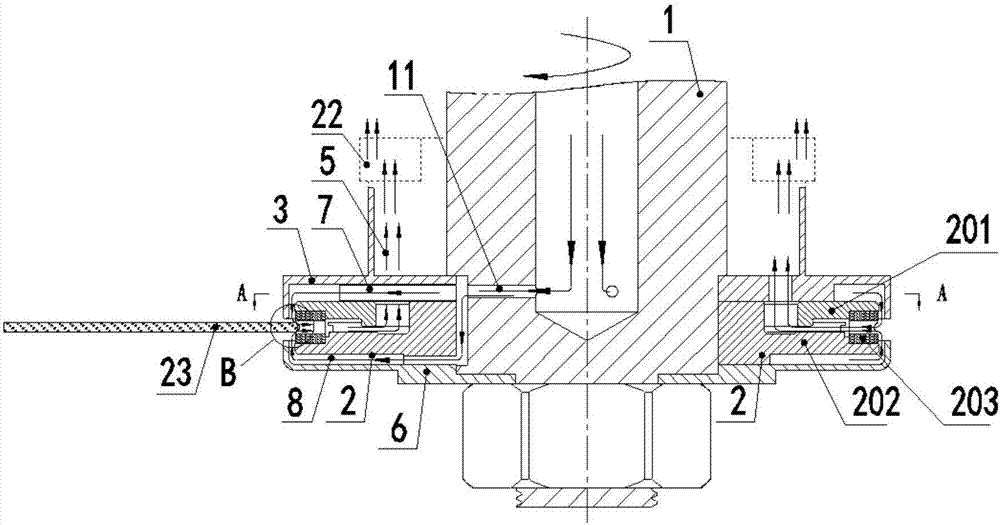

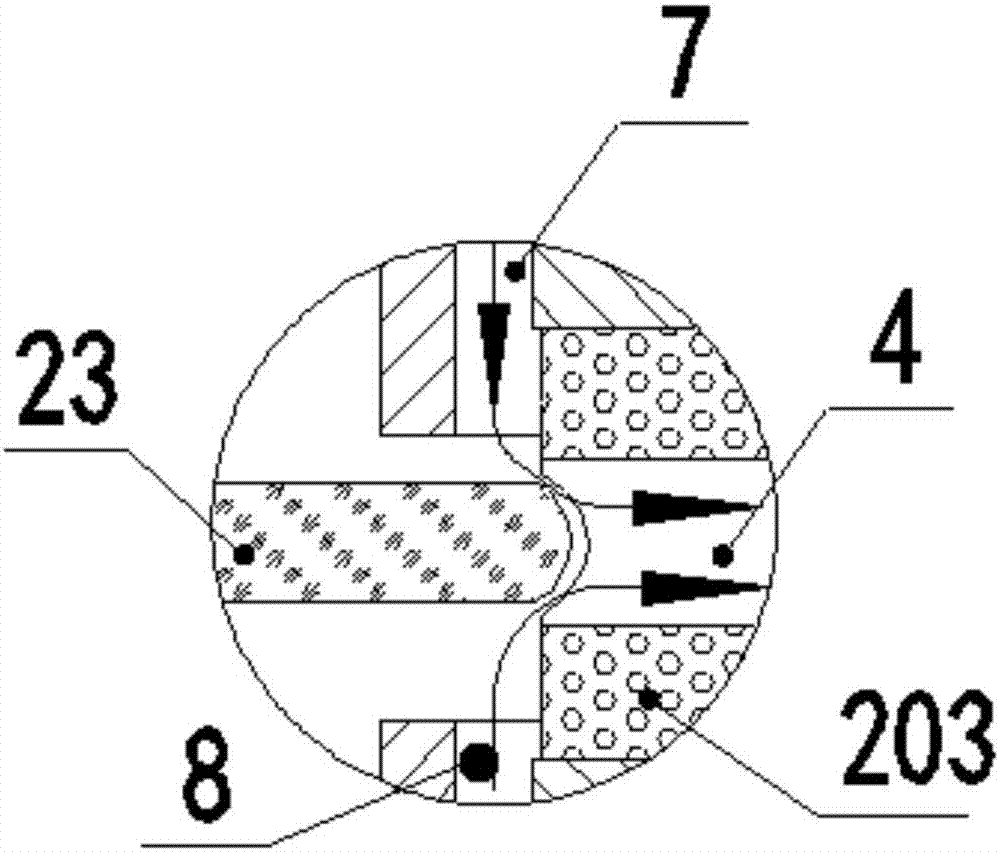

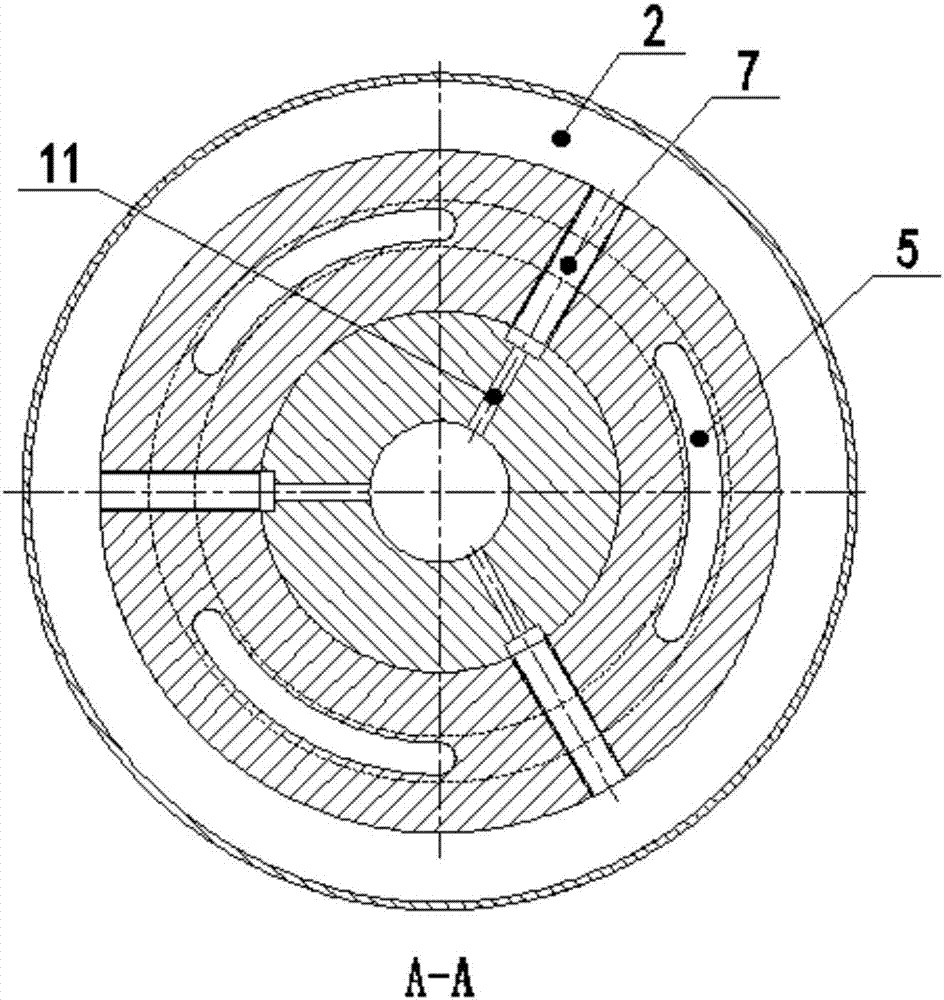

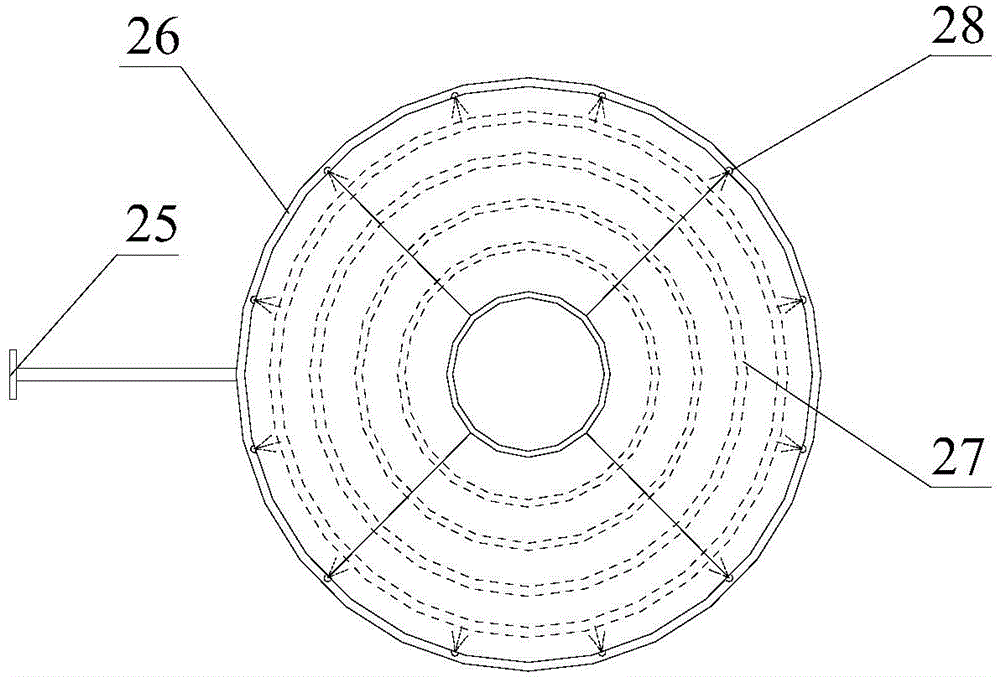

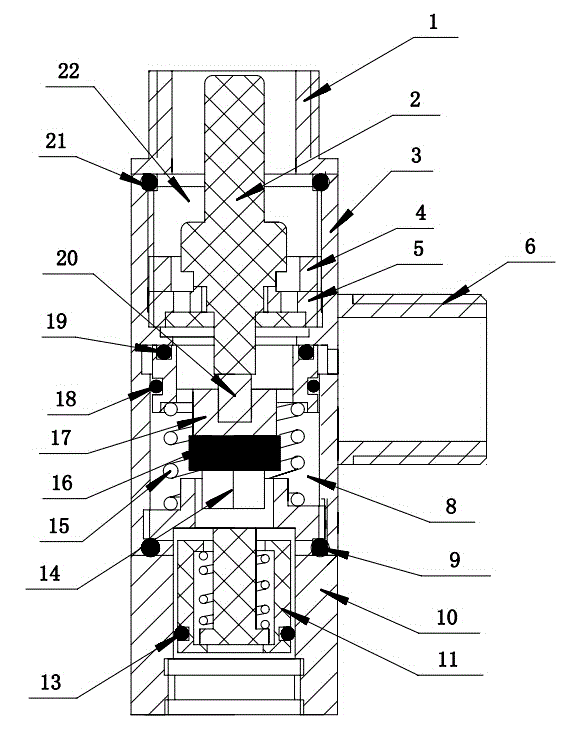

Diamond special-shaped grinding wheel and vertical machining cooling system

ActiveCN106903567AReduce dosageLow costEdge grinding machinesBonded abrasive wheelsMixed flowCooling effect

The invention relates to a diamond special-shaped grinding wheel and a vertical machining cooling system. The diamond special-shaped grinding wheel comprises an upper base body, a lower base body and a grinding ring. The upper base body is arranged at the upper end of the lower base body, and the upper base body and the lower base body are fixedly connected to form a grinding wheel body. The grinding ring is fixed to an outer ring of the grinding wheel body internally provided with one or two annular grooves communicating with the upper end face of the grinding wheel body. A plurality of mixed flow channels sucking in cooling water, powder and air are arranged in the grinding ring. One end of each mixed flow channel extends to an annular grinding opening of the grinding ring. The other end of each mixed flow channel communicates with one annular groove, and the annular grooves communicate with an outside negative pressure air source device. Through the diamond special-shaped grinding wheel and the vertical machining cooling system, the cooling water can form a coating water film on the working face of the diamond special-shaped grinding wheel, the cooling effect is promoted, and the usage quantity of the cooling water is reduced. Frictional heat is reduced, the protrusion height of diamond is also ensured, the grinding ability of the grinding wheel can be improved, and then the grinding wheel adapts to efficient machining.

Owner:GUILIN CHAMPION UNION DIAMOND CO LTD

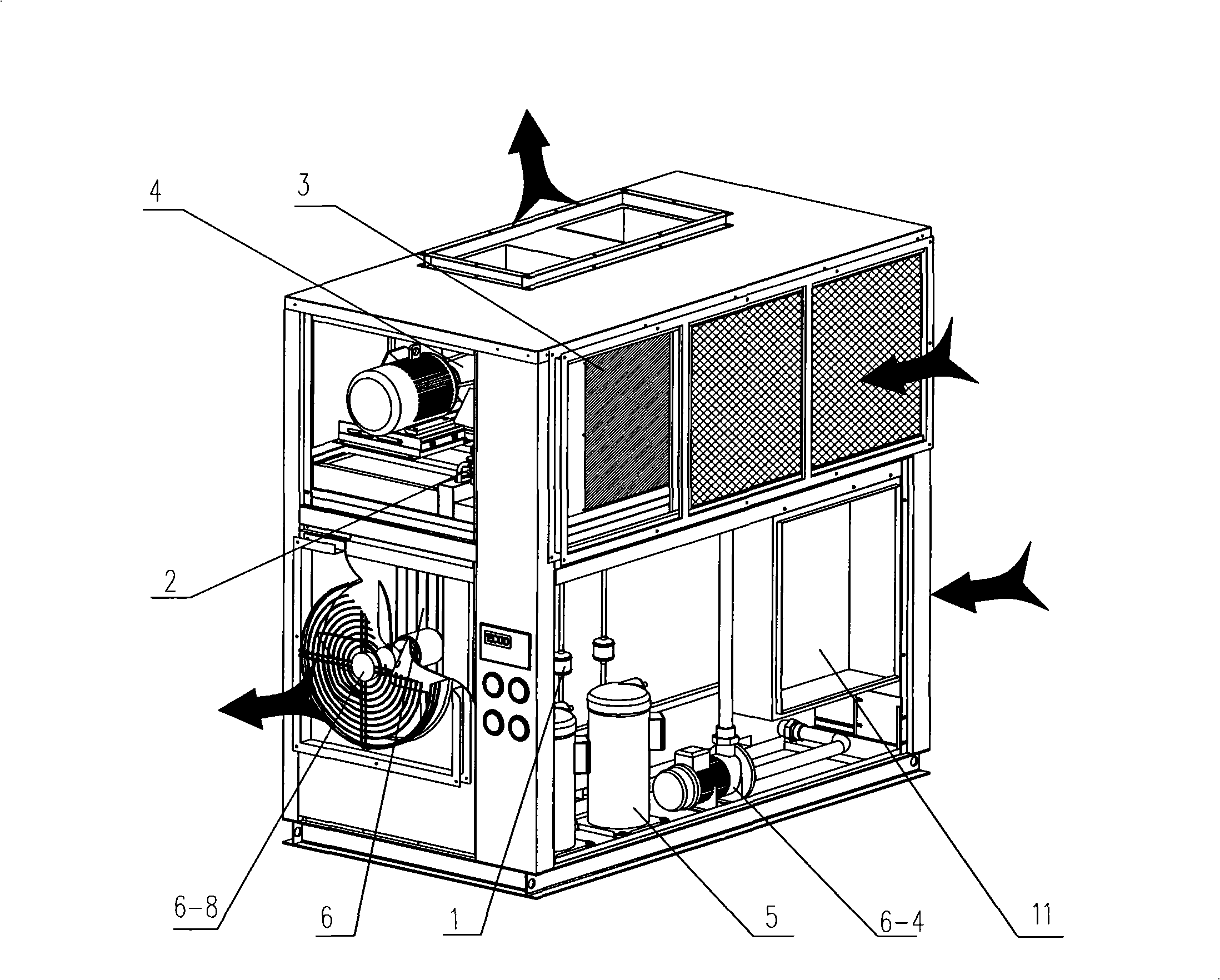

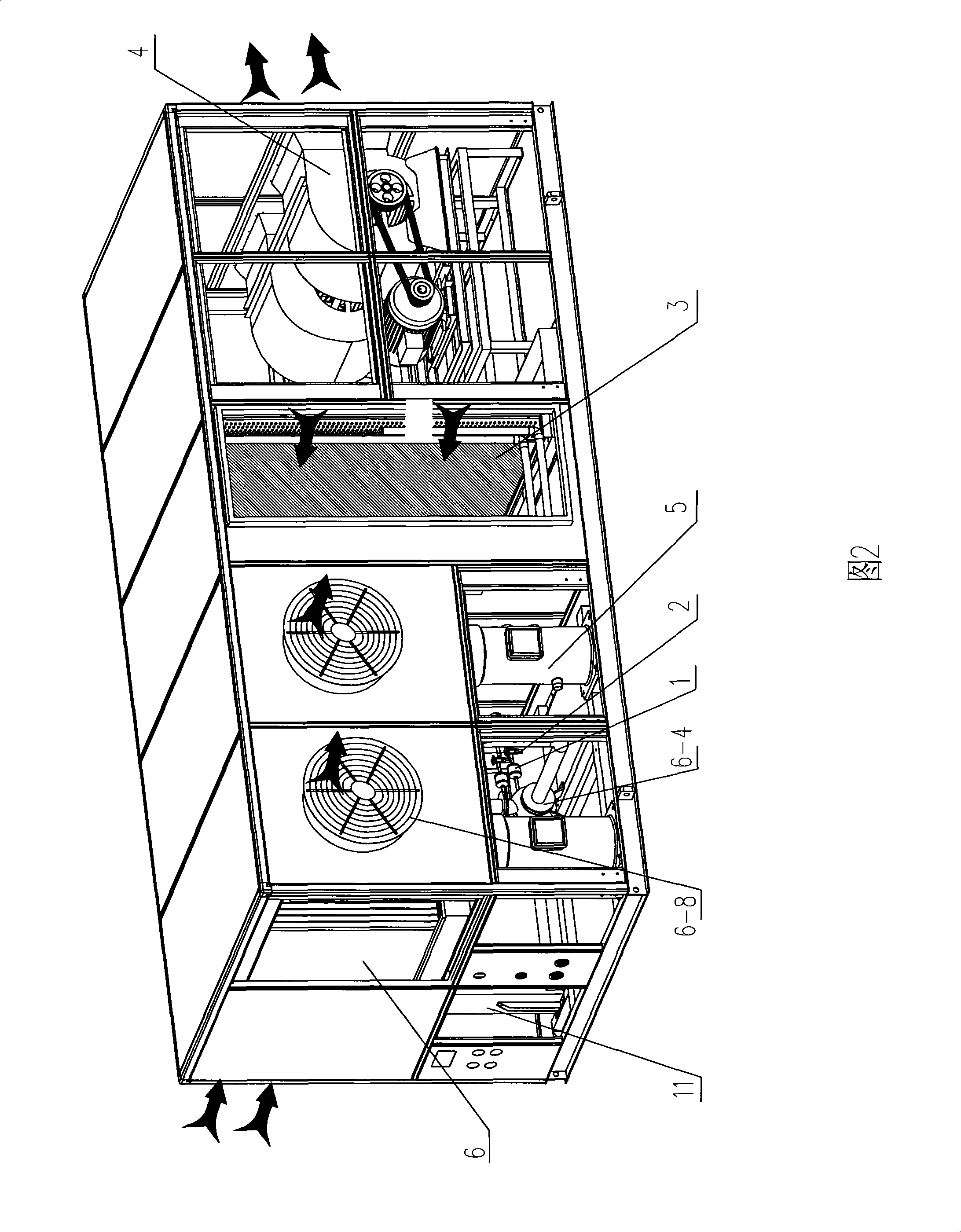

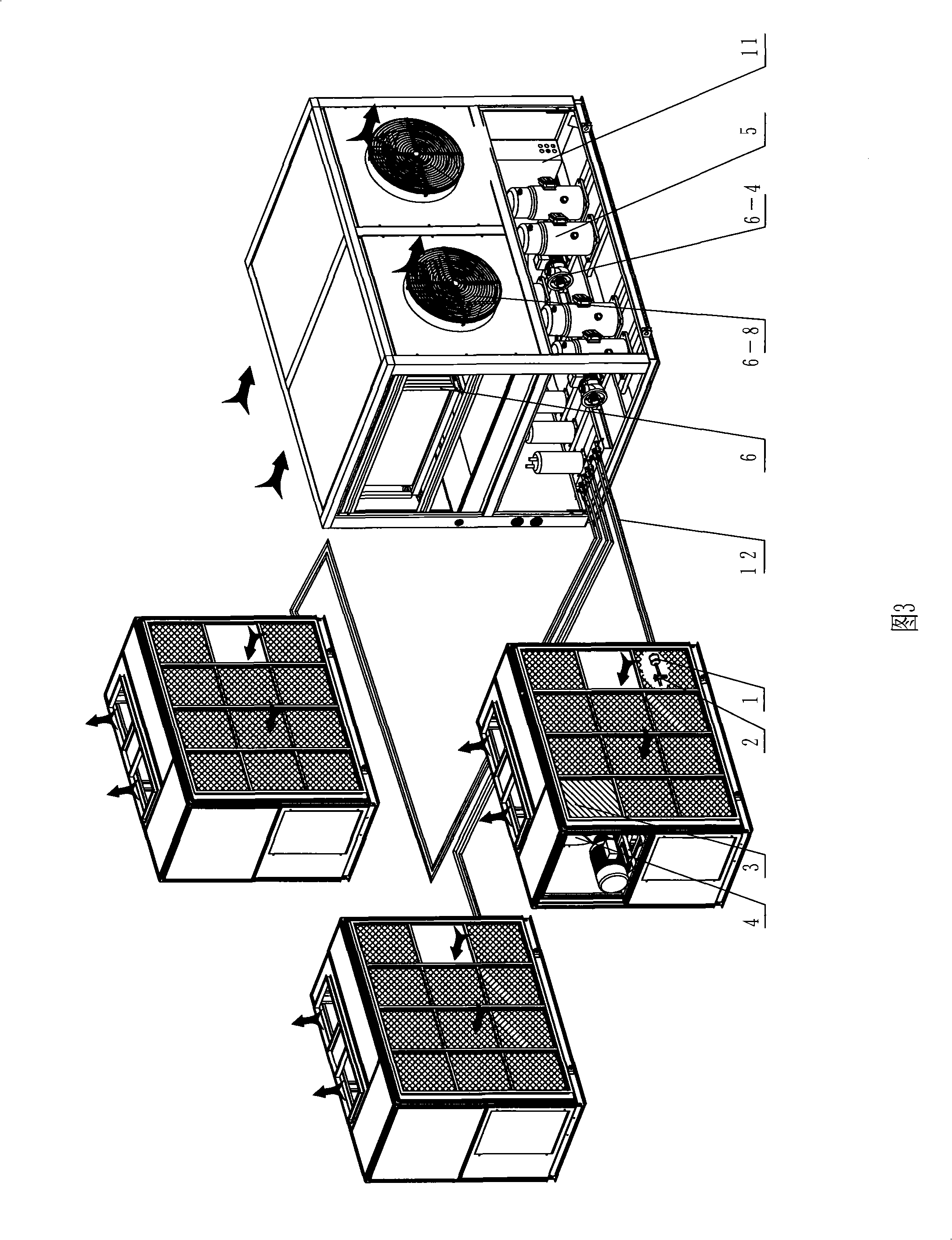

Tube-plate evaporative condensing air-conditioning unit with packing

ActiveCN101514829ARealize heat exchangeAchieve heat transfer performanceEnergy recovery in ventilation and heatingSpace heating and ventilation safety systemsFresh airEvaporation

The invention provides a tube-plate evaporative condensing air-conditioning unit with packing. The unit comprises an evaporation and air supply unit and a compression and condensing unit. The evaporation and air supply unit consists of a drying and filtering device, an expansion valve, an evaporator and a centrifugal fan which are sequentially connected, and the compression and condensing unit is formed by connecting a compressor and a condenser; the condenser is connected with the drying and filtering device, and the compressor is connected with the evaporator; the air-conditioning unit is provided with a condensate recovery system which is formed by connecting a condensate recovering collector of the evaporator with the condenser by a tube or a water pump; and an indoor air supply system of the evaporation and air supply unit consists of an outdoor fresh air inlet of the evaporator, a unit air supply outlet and the centrifugal fan, or consists of the outdoor fresh air inlet of the evaporator, a unit return air inlet, the unit air supply outlet and the centrifugal fan. The tube-plate evaporative condensing air-conditioning unit has high heat exchange efficiency, and can realize maximal energy recovery and reduction of energy consumption and water consumption, effectively solves increased energy consumption resulting from increased fresh air volume of an air-conditioning system and realizes double performance of saving energy and water and health care.

Owner:GUANGZHOU WIDE IND

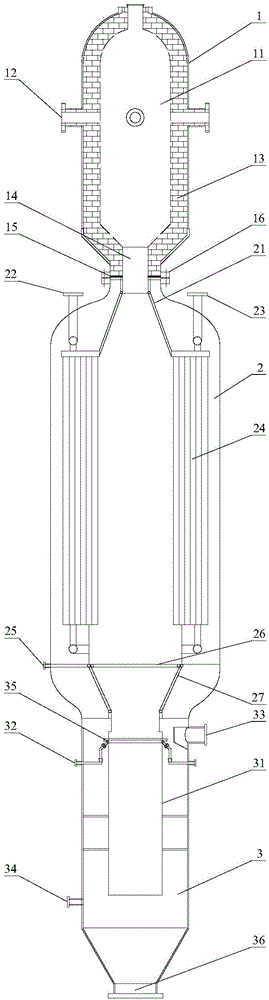

Chilling process gasifier with high-temperature heat recovery unit

InactiveCN104629807AMeet the requirements of the transformationApplicableEnergy inputCombined combustion mitigationCombustion chamberCooling chamber

The invention discloses a chilling process gasifier with a high-temperature heat recovery unit, which comprises an upper gasification / combustion chamber, a middle radiation waste pot with high-temperature heat recovery function and a bottom washing and cooling chamber, wherein the top of the gasification / combustion chamber furnace body or a certain plane on the periphery of the furnace body or a plurality of planes is / are provided with one or a plurality of nozzles; the radiation waste pot is composed of a flange connected with the gasification / combustion chamber, an interface water cooling coil pipe, a single-channel water cooling wall, a water cooling coil pipe connected with the washing and cooling chamber, and the like; the washing and cooling chamber is mainly composed of a chilling water ring and a down pipe; and the upper part of the side surface of the washing and cooling chamber is provided with a synthetic gas outlet. The chilling process gasifier can enhance the adaptability to coal types, effectively recovers the high-position sensible heat of the gasification product, and is suitable for a process unit for preparing synthetic gas and an integral coal gasification combined cycle generation system. Compared with the traditional waste-pot process gasifier, the chilling process gasifier is simpler in structure and convenient for manufacturing and maintenance, and has higher popularization and application values.

Owner:EAST CHINA UNIV OF SCI & TECH

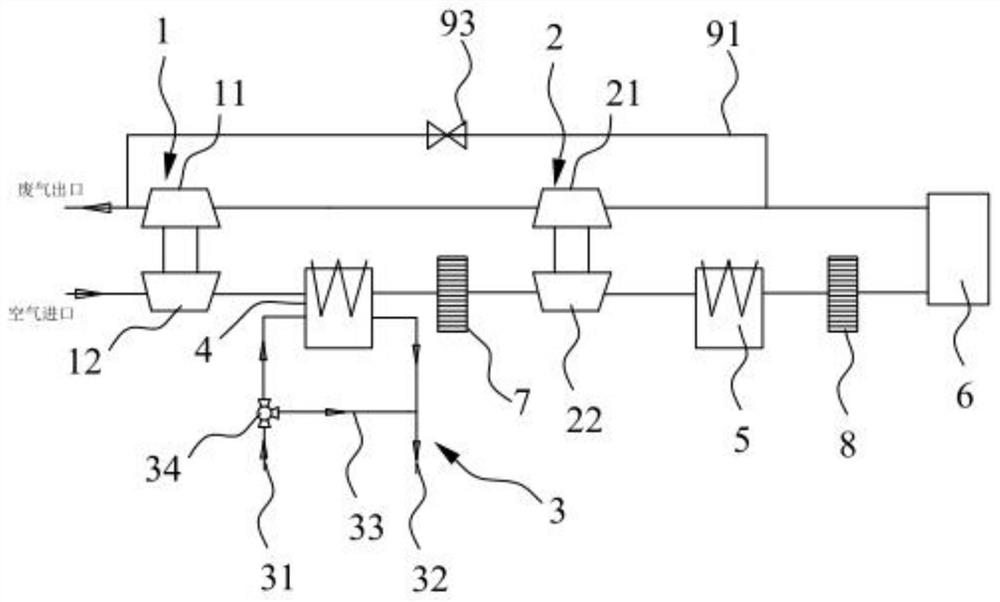

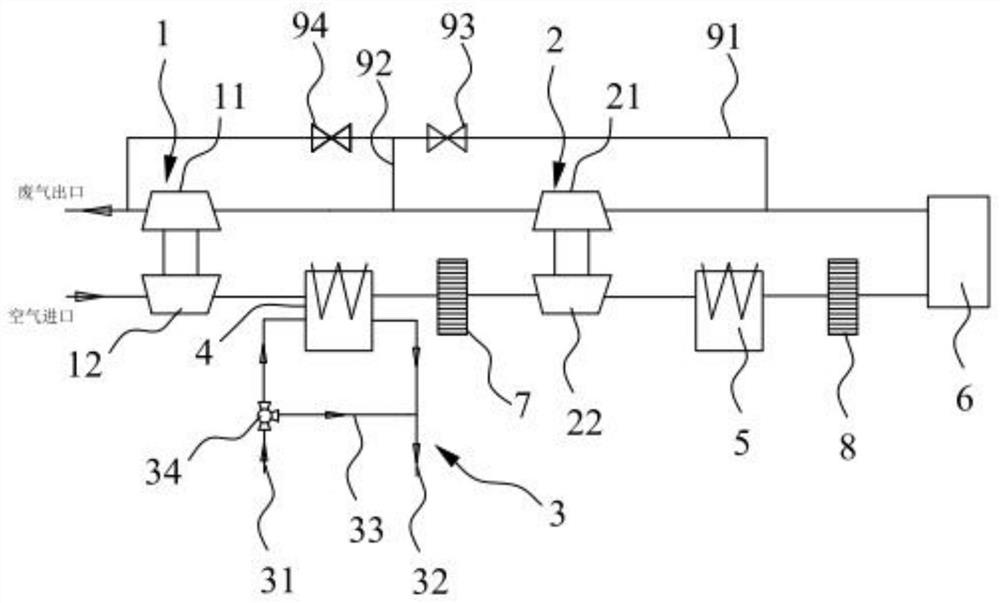

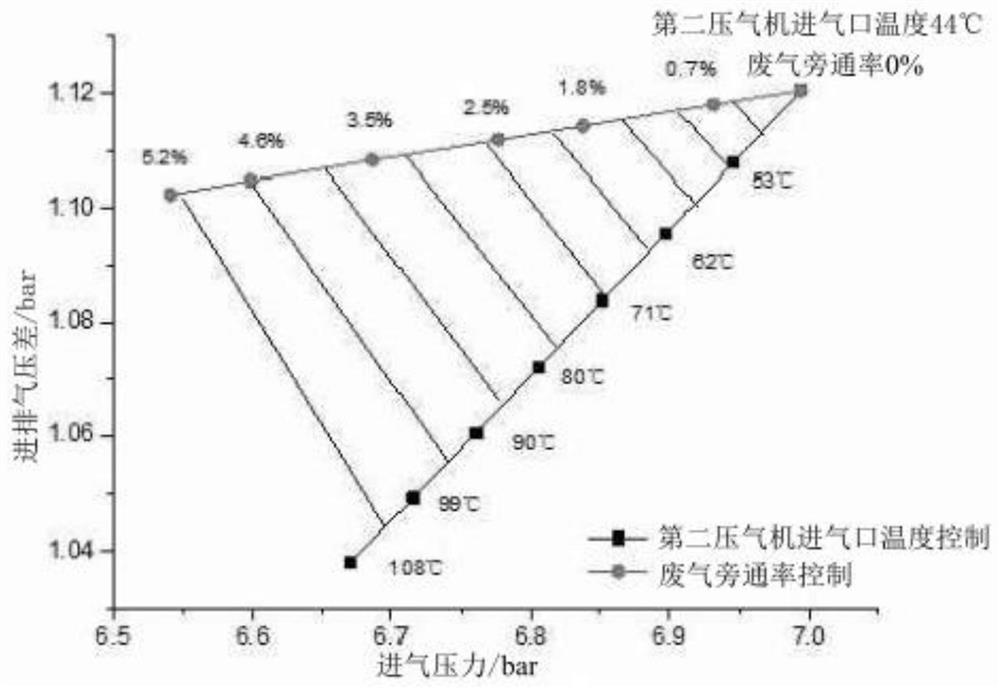

Two-stage supercharging system, engine and engine intake and exhaust pressure difference control method

PendingCN112832901AStay flammableReduce bypass openingInternal combustion piston enginesEngine componentsTurbochargerAir compressor

The invention relates to the technical field of engines, and particularly discloses a two-stage supercharging system, an engine and an engine intake and exhaust pressure difference control method. The two-stage supercharging system comprises a first turbocharger, a second turbocharger and an exhaust bypass device, wherein the first turbocharger comprises a first air compressor; the second turbocharger comprises a second air compressor; the first air compressor and the second air compressor are sequentially arranged between an air inlet and the engine at intervals; a first air cooler is arranged between the first air compressor and the second air compressor and provided with a temperature adjusting assembly; the exhaust bypass device is used for adjusting the amount of waste gas passing through the first turbocharger and / or the second turbocharger; a first pressure sensor and a second pressure sensor are used for detecting the intake pressure and the exhaust pressure of the engine correspondingly; and a controller controls the temperature adjusting assembly through data of the first pressure sensor and the second pressure sensor. By means of the arrangement, the intake pressure and the intake and exhaust pressure difference of the engine can be effectively, independently and accurately adjusted.

Owner:CSSC POWER INST CO LTD

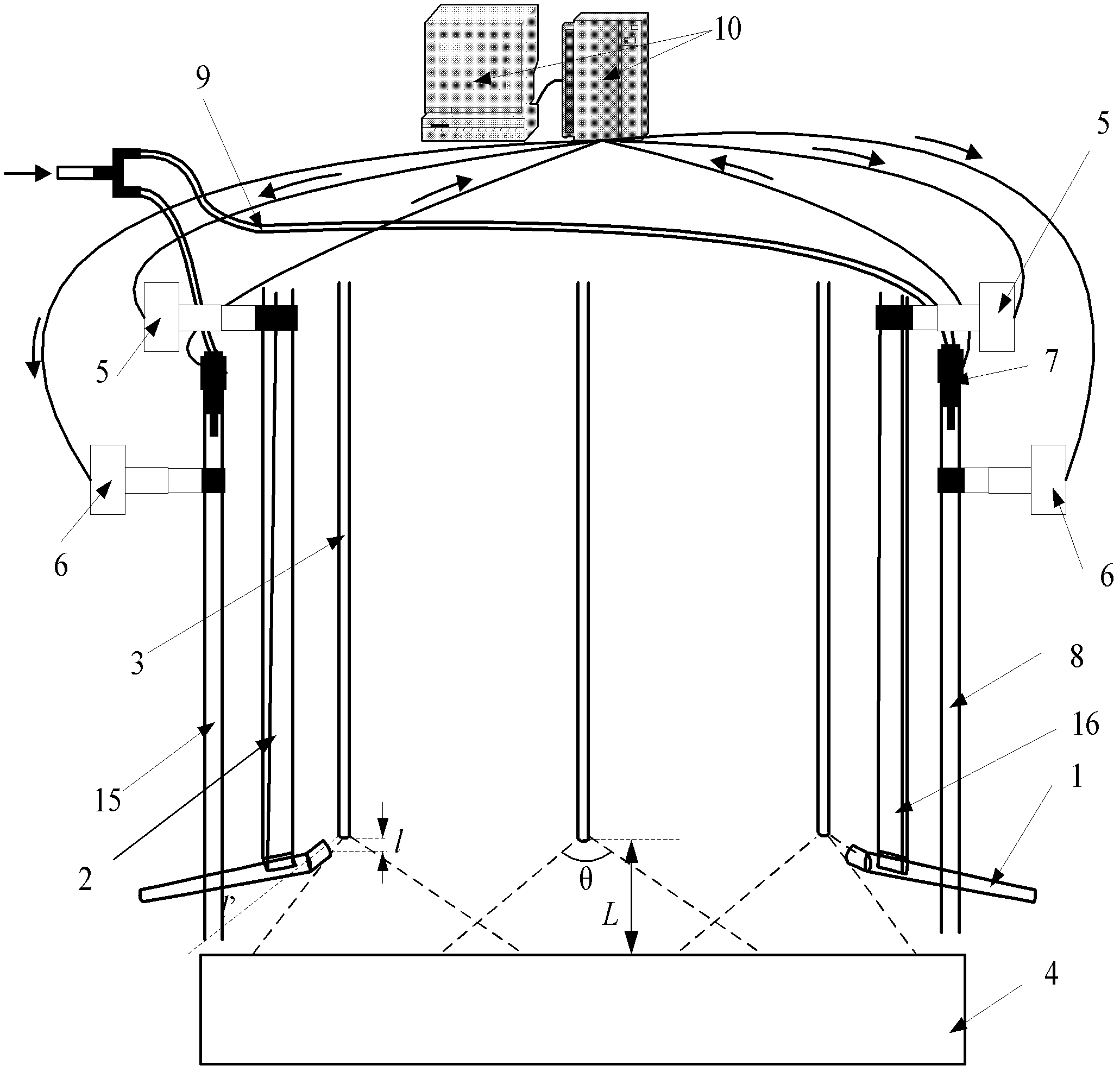

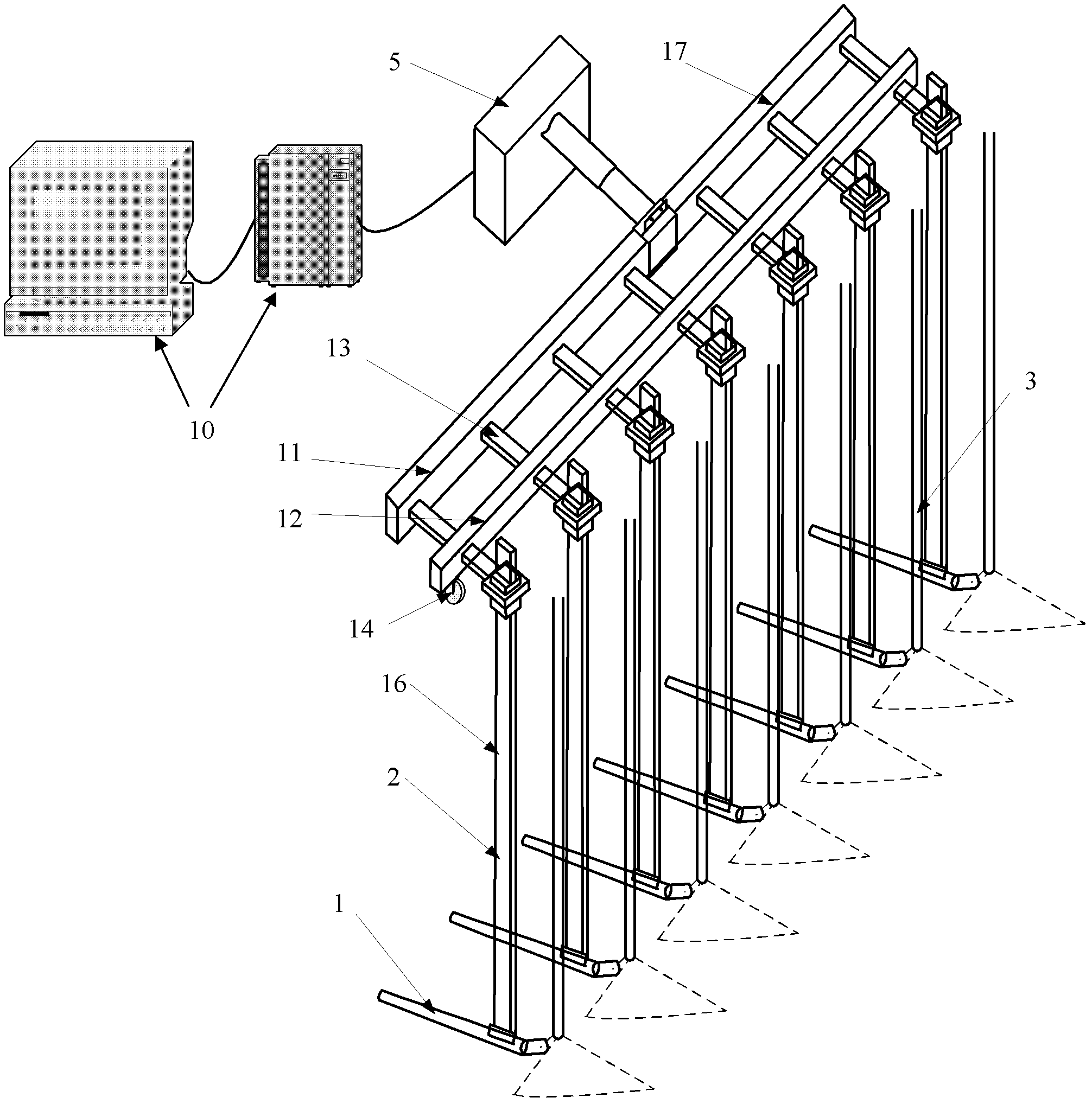

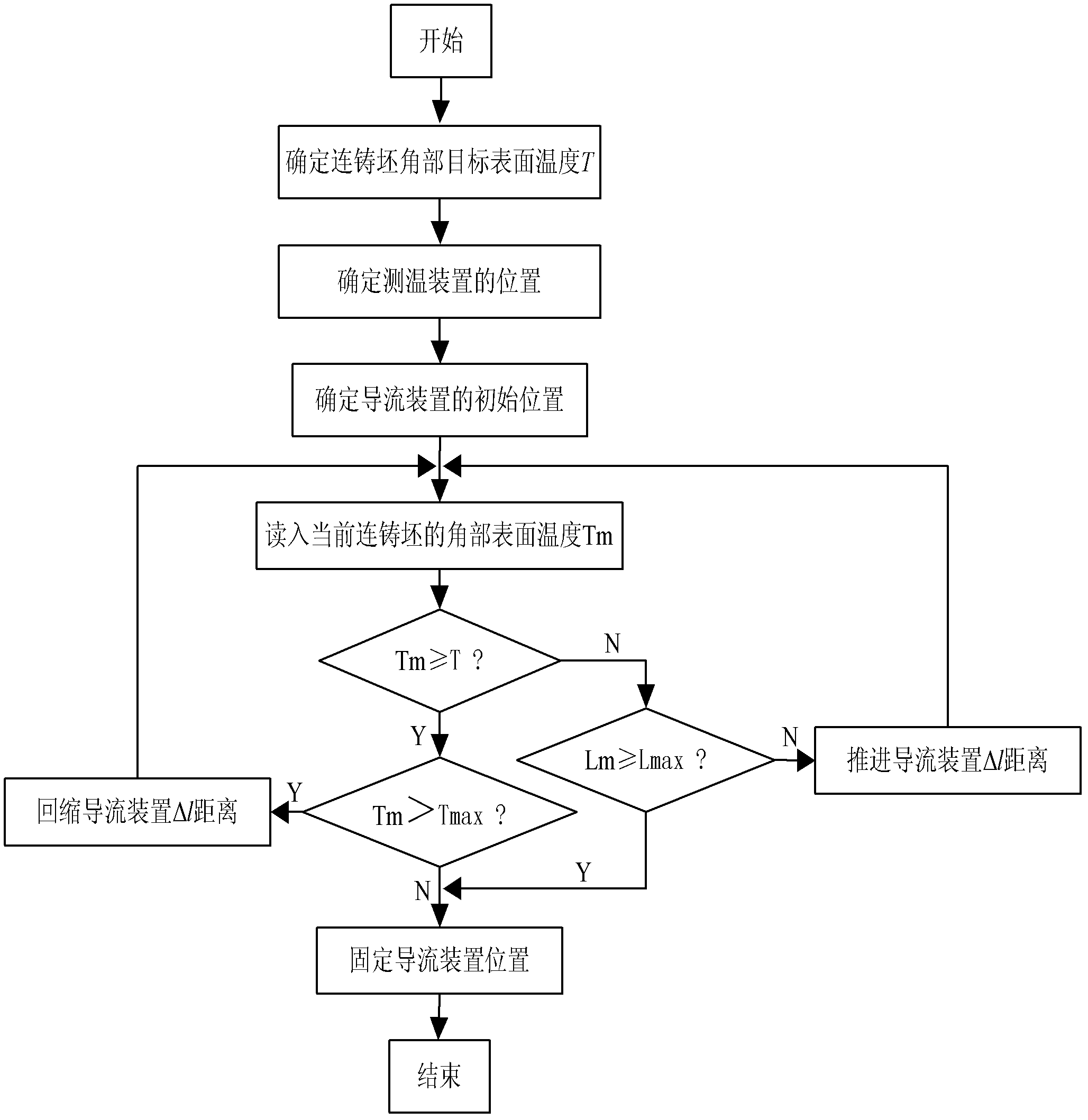

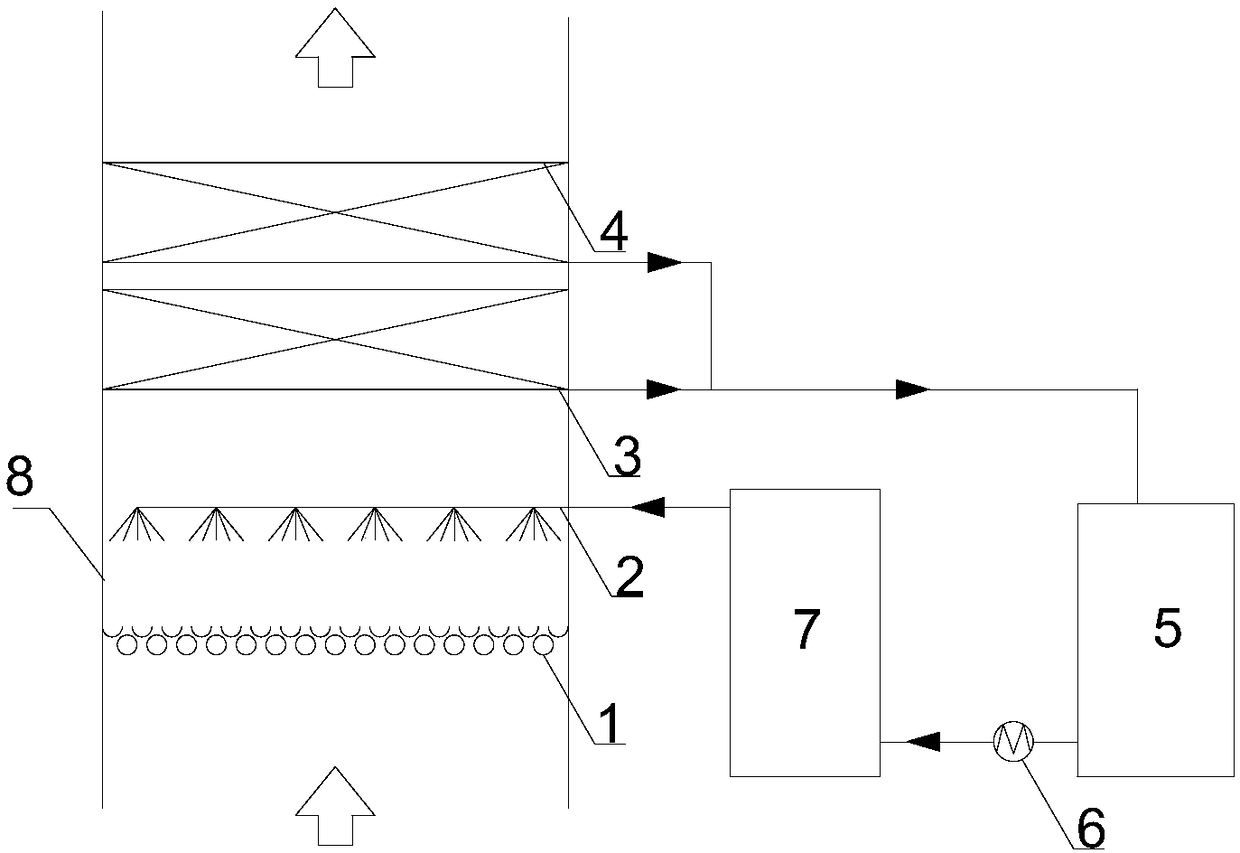

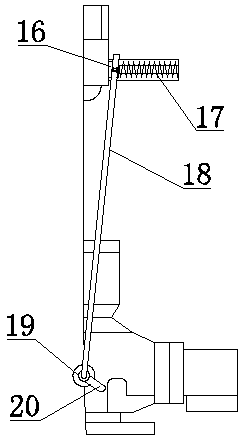

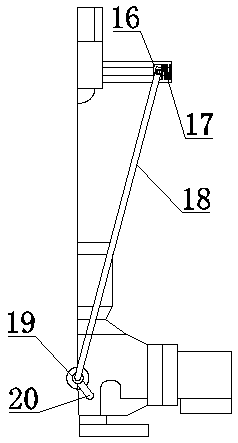

System and method for intelligently controlling temperature of internal arc angle part in straightening region of wide and thick plate blank

The invention discloses a system and a method for intelligently controlling temperature of an internal arc angle part in a straightening region of a wide and thick plate blank, and belongs to the technical field of control over continuously casting secondary cooling temperature of ferrous metallurgy. The system comprises a temperature measurement device, a flow guide device and a control system, wherein the temperature measurement device consists of a temperature measurement pipe and an infrared temperature measurement probe; the infrared temperature measurement probe is arranged at the upperend of the temperature measurement pipe; the upper end of the temperature measurement pipe is communicated with a compressed air pipeline; the top end of a supporting frame connecting rod of the flowguide device is connected with a horizontal supporting frame; the bottom end of the supporting frame connecting rod is connected with a cooling water collection flow guide pipe; the temperature measurement pipe is connected with a temperature measurement device hydraulic pusher; the horizontal supporting frame of the flow guide device is connected with a flow guide device hydraulic pusher; and the hydraulic pushers are connected with the control system. The method comprises the following steps of: taking an actual temperature measurement result on the surface of the internal arc angle part inthe straightening region of a continuously cast blank as a feedback of secondary cooling intensity; and dynamically adjusting a spraying width by adjusting the position of the flow guide device according to a difference between the actual measured temperature and the temperature of the target surface, so that an aim of precisely controlling the temperature of the internal arc angle part of the continuously cast blank entering the straightening region is fulfilled.

Owner:NORTHEASTERN UNIV

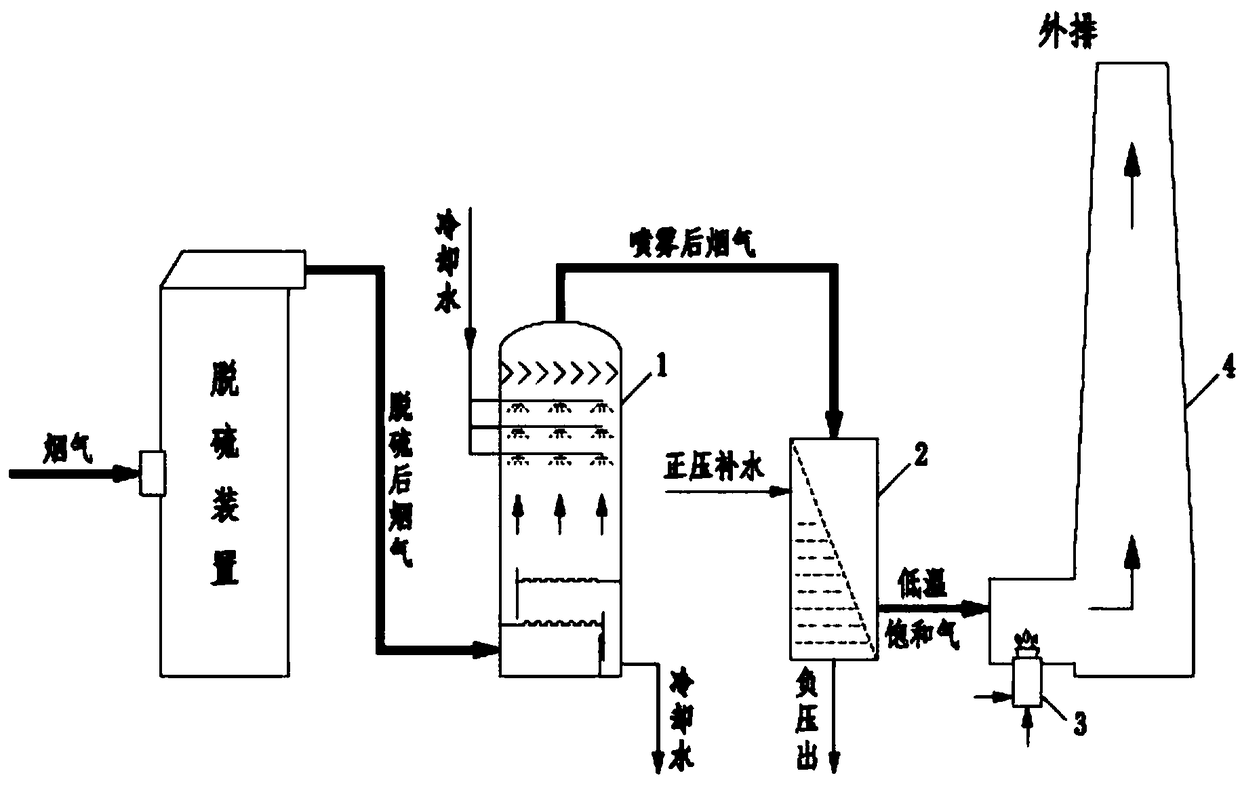

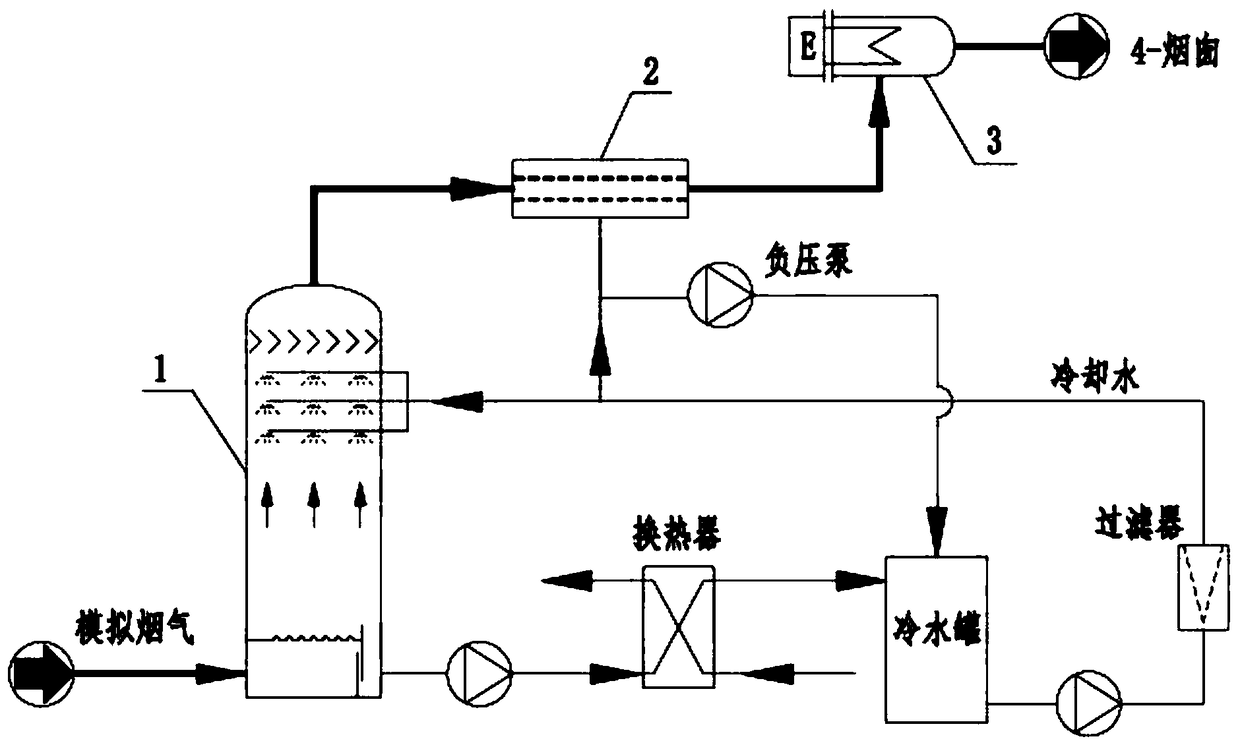

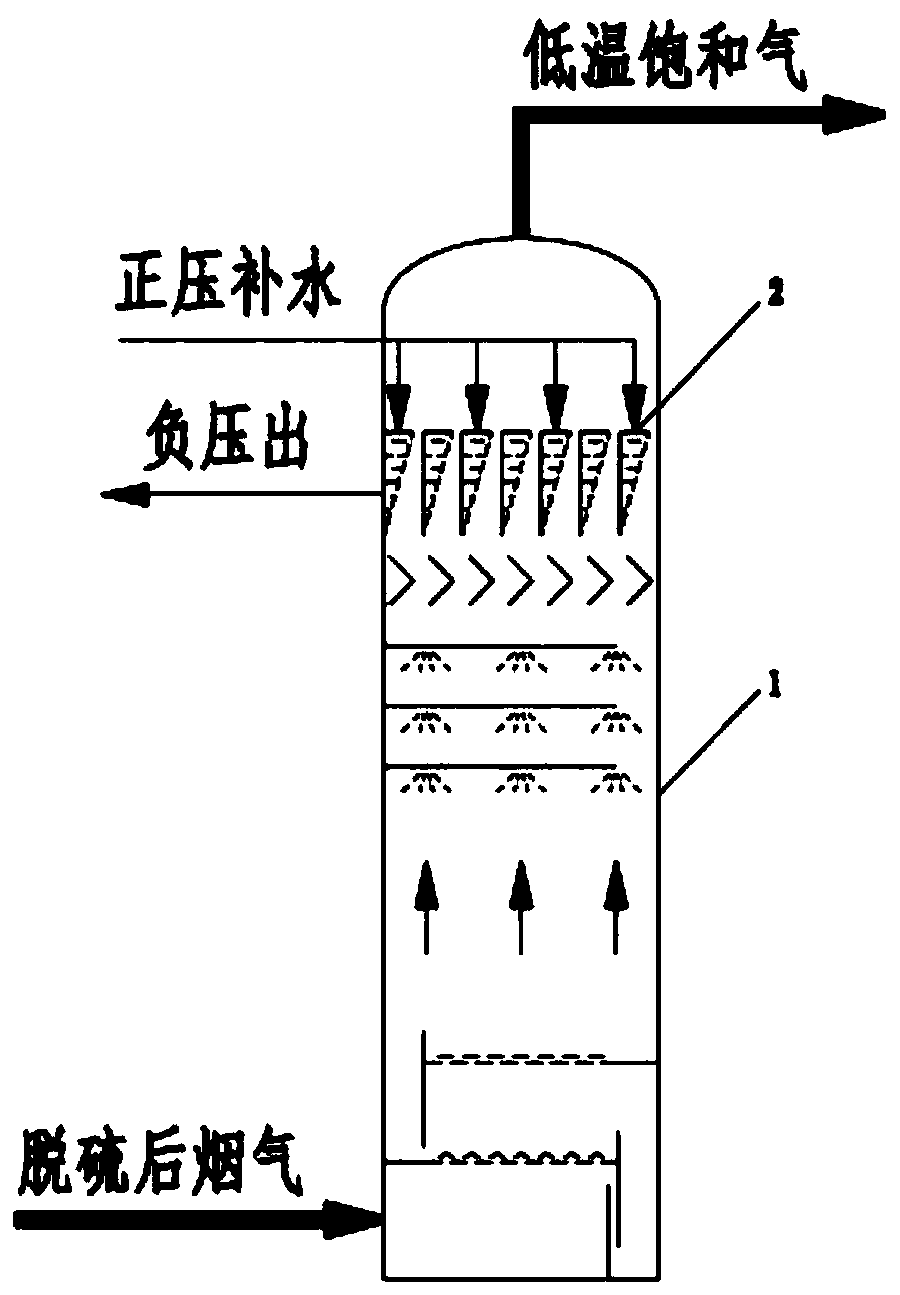

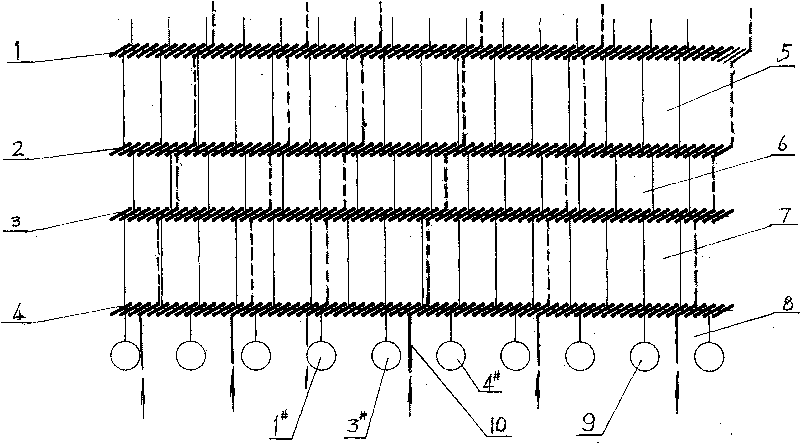

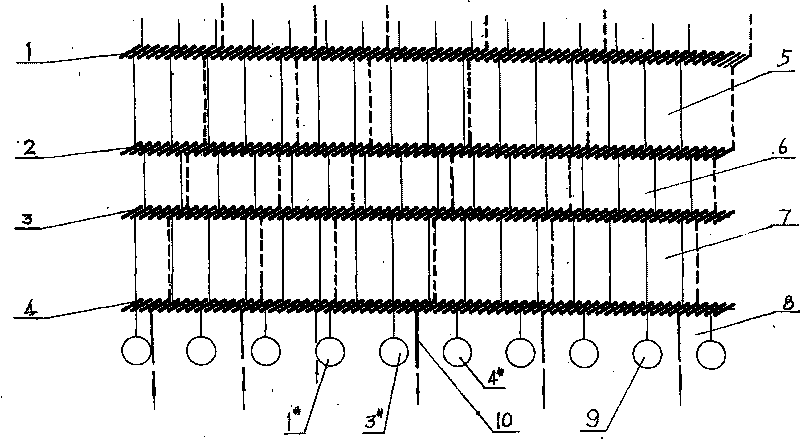

White desulfurization tail smoke eliminating technology and device

InactiveCN108310929ADroplet bigReduce difficulty of captureGas treatmentDispersed particle separationCooling towerAtmospheric air

The invention discloses a white desulfurization tail smoke eliminating technology and a white desulfurization tail smoke eliminating device. The white desulfurization tail smoke eliminating device comprises a tower body, wherein gas enters from the bottom of the tower body and is discharged from the top of the tower body; a uniformly-distribution cooling device, an ultrafine atomizing sprinkling device, a cyclone defogger and an ultrafine liquid droplet trapping packing layer are sequentially arranged inside the tower body in the flow direction of flue gas; bottom water collecting pipes of thecyclone defogger and the ultrafine liquid droplet trapping packing layer are externally connected with a condensed water storage tank; the outlet water of the condensed water storage tank is connected to an air cooling tower; the outlet water of the air cooling tower is connected into the ultrafine atomizing sprinkling device. Desulfurization tail smoke enters the tower body from the bottom of the tower body, more than 60% of water vapor in the flue gas is condensed after two interactions with cold water droplets, and finally the dried flue gas is discharged into the atmosphere; hot water collected by the cyclone defogger and the ultrafine liquid droplet trapping packing layer is sent into the condensed water storage tank and stored, and a part of the stored water is sent into the air cooling tower, cooled by the air cooling tower and then sprinkled into the tower body by the ultrafine atomizing sprinkling device, so that the water vapor content of the flue gas is reduced and the purpose of eliminating white smoke is achieved.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

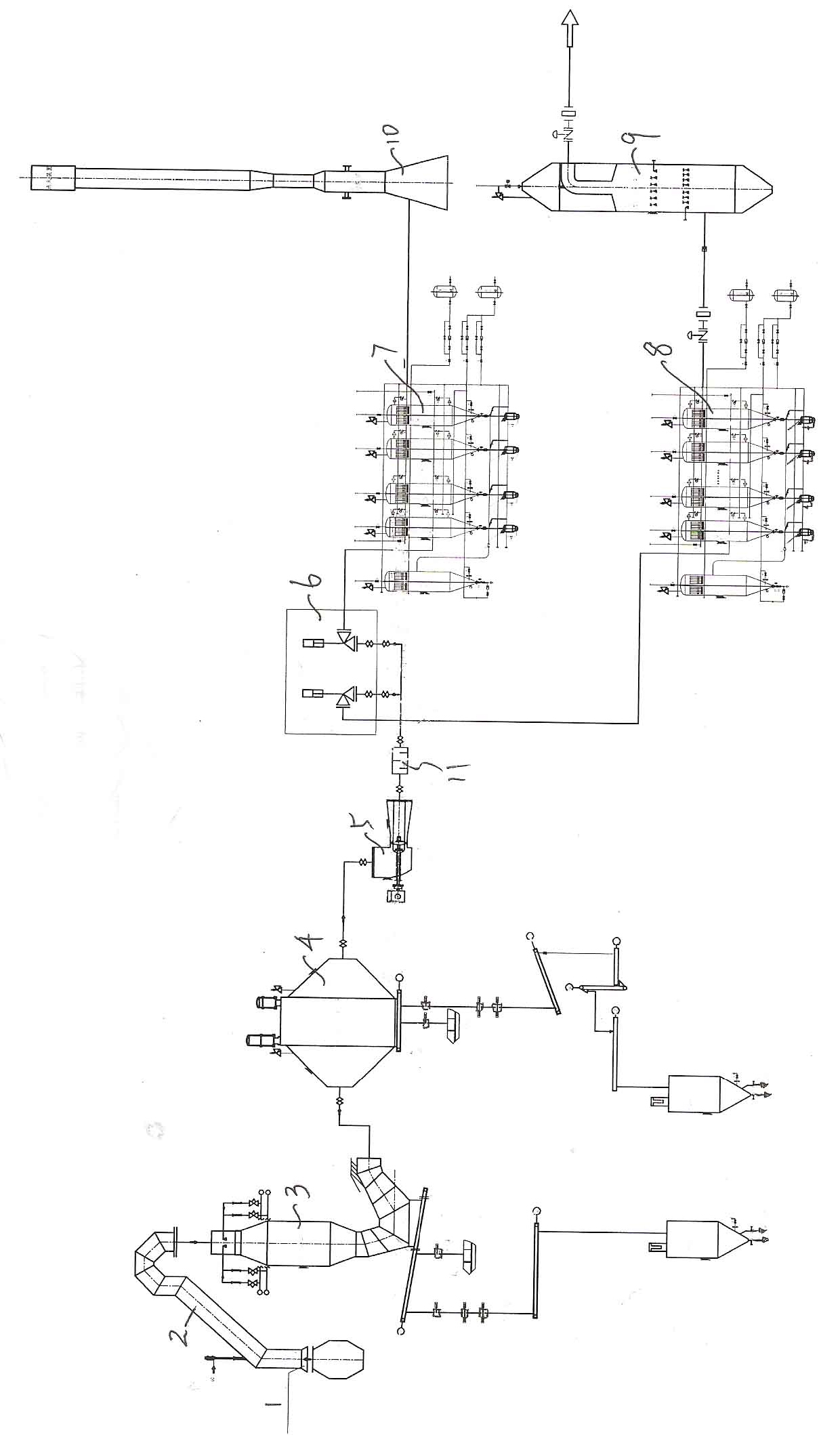

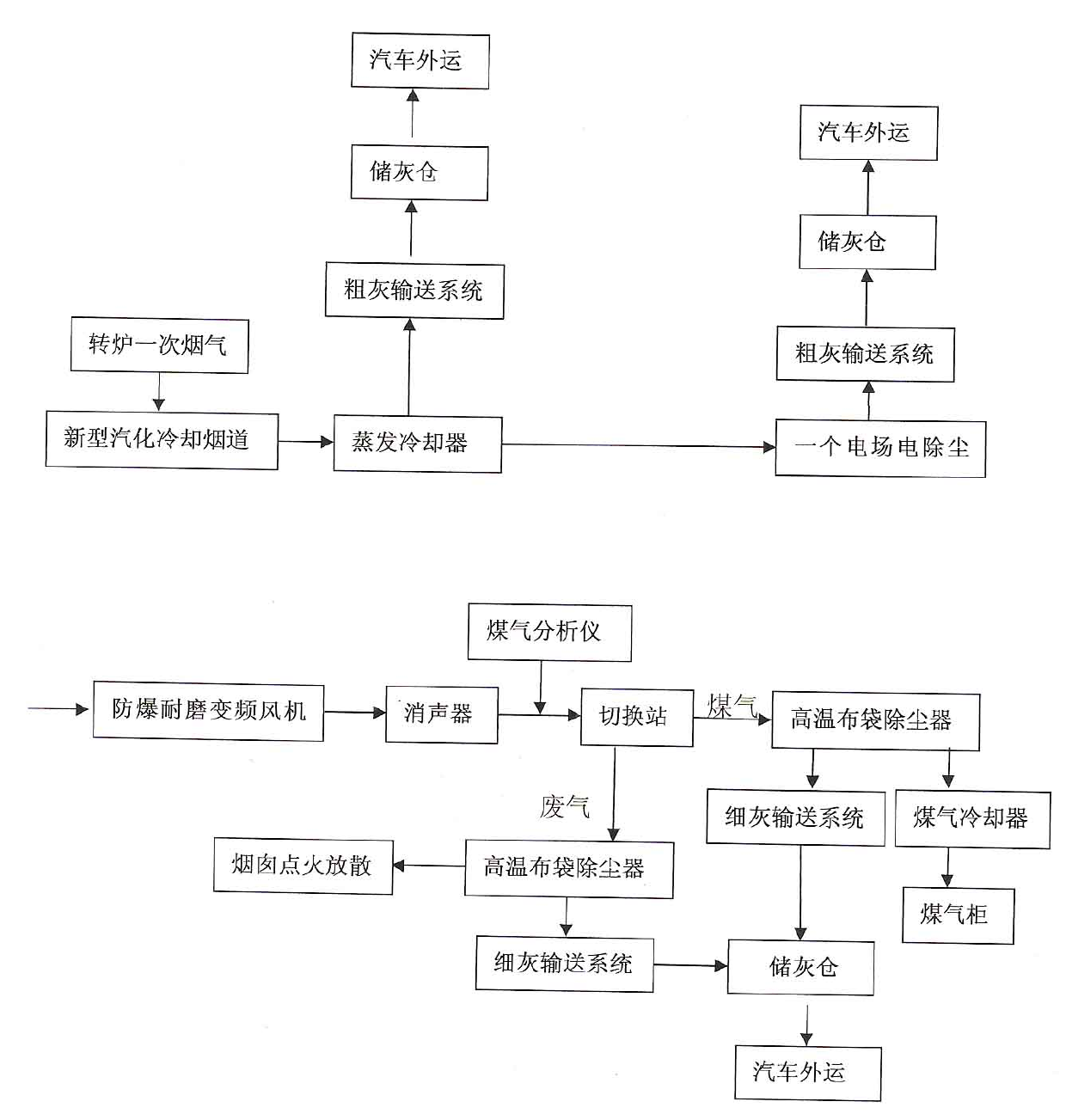

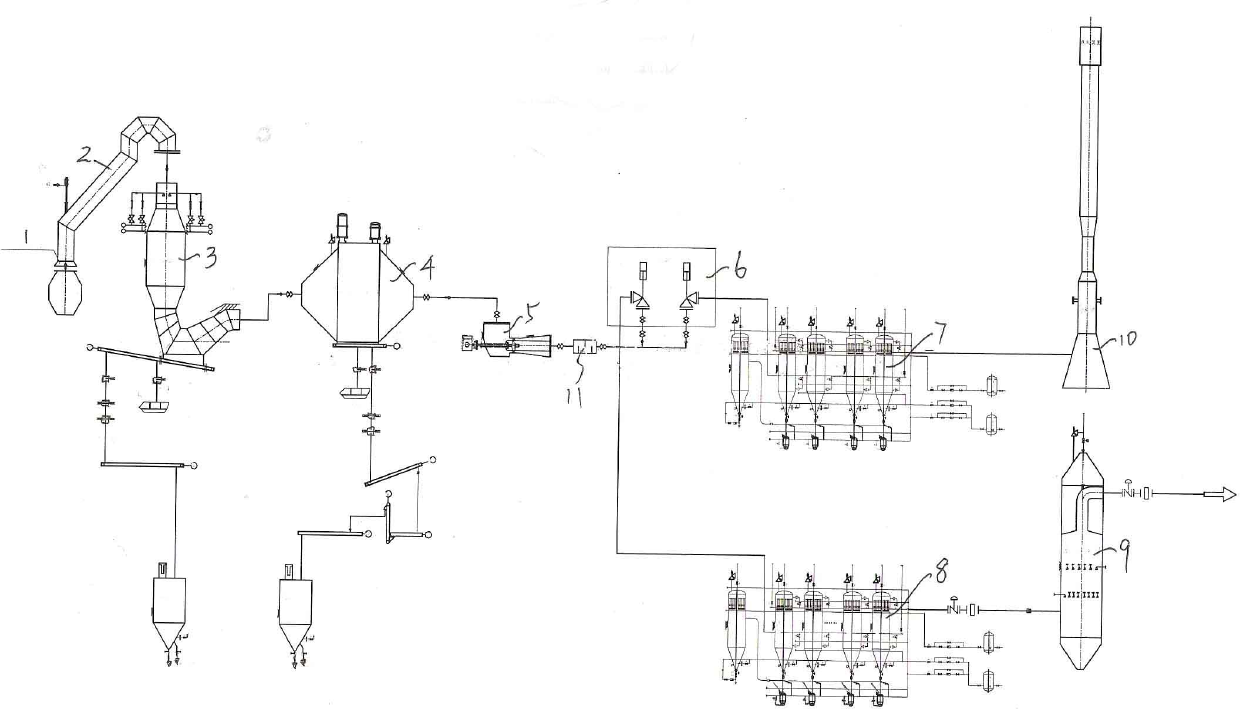

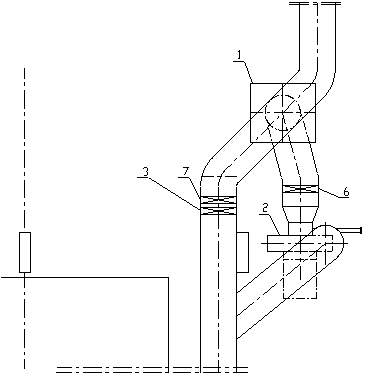

Electric-bag combined converter gas dry cleaning and recovering system

InactiveCN102653806AReduce cooling loadReduce the amount of cooling waterManufacturing convertersCooling towerCombustor

The invention discloses an electric-bag combined converter gas dry cleaning and recovering system. The system is characterized in that a gas hood is connected with an evaporation cooling stack; an evaporative cooling tower is arranged behind the evaporation cooling stack; a single-cell drum-type electrostatic dust collector is arranged behind the evaporative cooling tower; a fan is arranged behind the electrostatic dust collector; a switching station of a bag type waste gas dust collecting device and a bag type gas dust collecting device is arranged behind the fan; the bag type waste gas dust collecting device and the bag type gas dust collecting device are arranged behind the switching station; a gas cooler is arranged behind the bag type gas dust collecting device; and a waste gas burner is arranged behind the bag type waste gas dust collecting device. The system has reasonable structure and good working performances.

Owner:JIANGSU RUIFAN ENVIRONMENTAL PROTECTION EQUIPCO

Lithium bromide flashing absorption type refrigerating machine

InactiveCN103512264AReduce consumptionReduce pollutionClimate change adaptationEnergy efficient heating/coolingDaily operationStrong solutions

The invention discloses a lithium bromide flashing absorption type refrigerating machine which comprises an evaporator (1), an absorber (2), a compressor (3), an evaporator pump (4) and an absorber reflux pump (5). A membrane separation filter (6) is arranged outside the absorber (2), the membrane separation filter is provided with a liquid inlet, a liquid outlet and a water outlet, and the liquid inlet, the liquid outlet and the water outlet are connected with a dilute solution outlet of the absorber (2), a strong solution inlet of the absorber (2) and a water inlet of the evaporator (1) respectively. The lithium bromide flashing absorption type refrigerating machine further comprises a flash evaporator (10), a liquid inlet pipe of the flash evaporator (10) stretches into the position below the liquid level of the evaporator (1), and a gas outlet pipe of the flash evaporator (10) is connected to the position below the liquid level of the absorber (2) through a four-way part (14). One of the two remaining ports of the four-way part (14) is communicated with an interface active agent generator (12), and the other port is communicated with a negative pressure pump (13). According to the lithium bromide flashing absorption type refrigerating machine, daily operation cost is reduced, the cooling water amount is reduced, and electric energy consumed by the pump is lowered.

Owner:昆山市周市溴化锂溶液厂

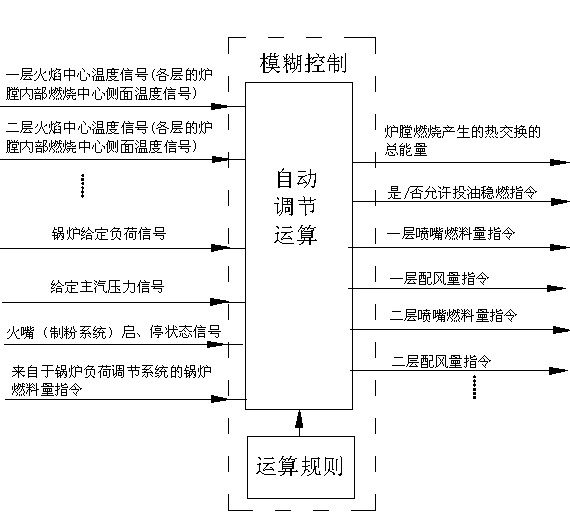

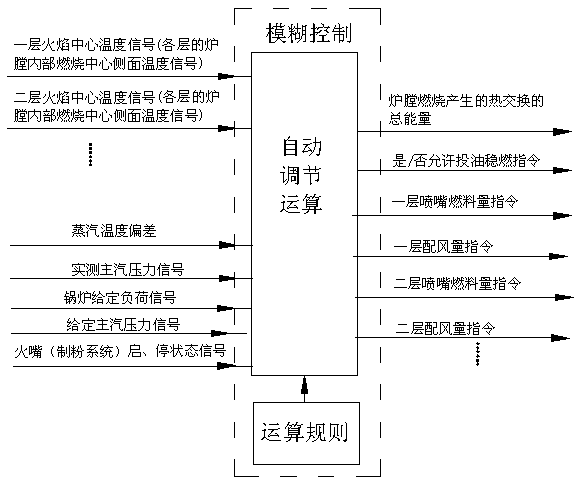

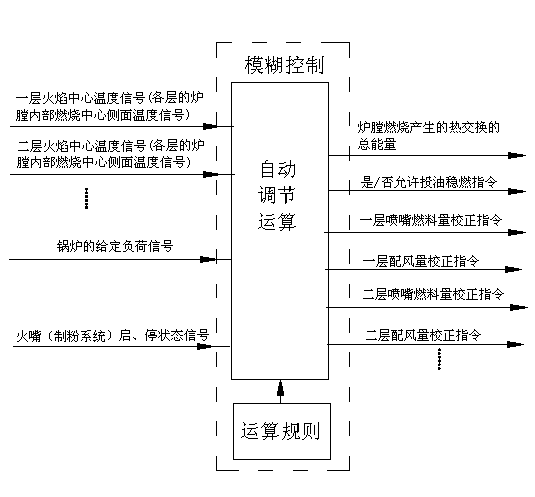

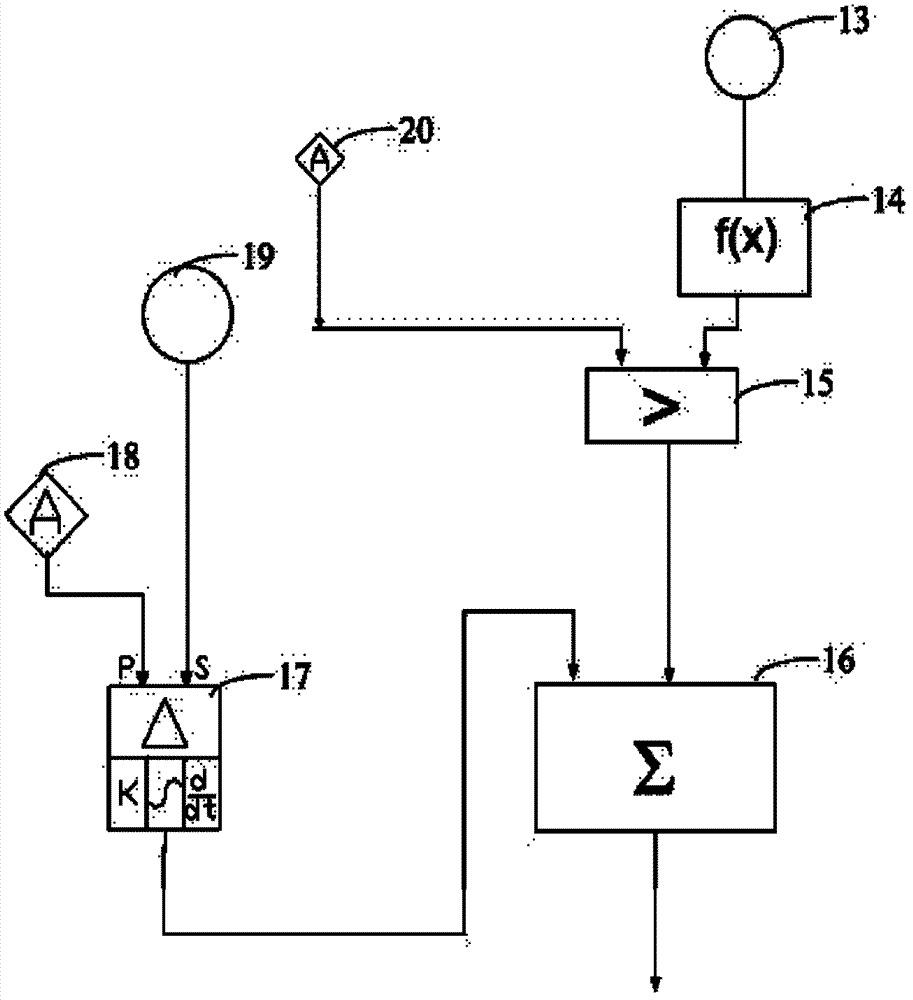

Automatic control method for preventing extinguishment and realizing ideal combustion for hearth

ActiveCN103047678AAutomatically adjust coal consumptionPrevent deflagrationCombustion regulationAutomatic controlCombustion

The invention discloses an automatic control method for preventing extinguishment and realizing ideal combustion for a hearth. The automatic control method is implemented by the aid of a full hearth control unit, signals inputted into the full hearth control unit at least include center temperature signals of various flame layers, given load signals of a boiler and starting and stopping state signals of various nozzles or pulverizing systems, automatic control operation is carried out inside the full hearth control unit, and signals outputted after automatic control operation at least include one type of fuel quantity instructions or fuel quantity correcting instructions of the various layers, air distribution quantity instructions or air distribution quantity correcting instructions of the various layers, oil feed combustion stabilizing instructions and total heat exchange energy signals generated during combustion of the hearth. The automatic control method has the advantages that the fuel coal quantity of the boiler and air quantities of the combustion nozzles can be adjusted automatically, excessively high temperature of the inside of the hearth is prevented, the boiler keeps in a stable combustion state, the extinguishment condition is stopped, the automatic control method is safe and convenient, and accordingly purposes of preventing extinguishment and realizing ideal low-nitrogen combustion are achieved for the hearth.

Owner:刘建松

Water-saving environment-friendly cooling tower

PendingCN108917421AReduce cooling waterEasy to adjustHeat exchange apparatusTrickle coolersWater savingNozzle

The invention discloses a water-saving environment-friendly cooling tower which comprises an upper tower body and a lower tower body. An opening is formed in the upper end of the upper tower body, a fan support is installed at the position of the opening in the upper end and provided with a motor reducing gear, the lower end of the motor reducing gear is provided with symmetrically-distributed fanblades, a spraying system is installed in the middle inside the upper tower body, the spraying system comprises a water inlet pipe, a spraying pipe connected with the water inlet pipe and a nozzle installed on the spraying pipe, an adjusting device for controlling the spraying water amount is arranged between a rotating shaft at the lower end of the motor reducing gear and the water inlet pipe, the adjusting device comprises a movable sliding block installed at the lower end of the rotating shaft of the motor reducing gear, the movable sliding block is movably installed on one side of the rotating shaft of the motor reducing gear through a cylindrical guide rail, and a spring is arranged between the movable sliding block and the guide rail. According to the cooling tower, the spraying water amount can be controlled without labor only by setting the adjusting device according to experience in practical work and controlling the rotating speed of a fan.

Owner:德州贝泰制冷设备有限公司

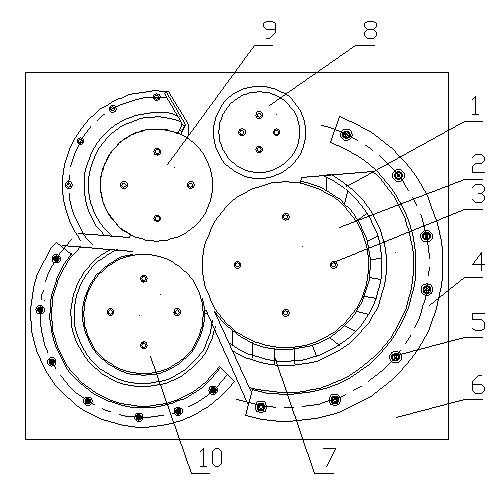

Four-roller centrifugal machine for rock cotton fiber forming system

ActiveCN103265168AAdvanced technologyReasonable and reliable designGlass making apparatusSlagEngineering

The invention relates to a four-roller centrifugal machine for a rock cotton fiber forming system. The four-roller centrifugal machine for the rock cotton fiber forming system comprises a rack, as well as a No.1 centrifugal roller with the diameter of 160-190mm, a No.2 centrifugal roller with the diameter of 223-250mm, a No.3 centrifugal roller with the diameter of 300-325mm and a No.4 centrifugal roller with the diameter of 310-340mm which are arranged on the rack; the line of centers of the No.1 centrifugal roller and the No.4 centrifugal roller and a horizontal line form an angle of 50-63 degrees, and the line of centers of the No.2 centrifugal roller and the No.3 centrifugal roller and a horizontal line form an angle of 87-95 degrees; the four-roller centrifugal machine also comprises three air rings arranged outside the No.2 centrifugal roller, the No.3 centrifugal roller and the No.4 centrifugal roller; each of the three air rings is externally provided with an atomizer; and each atomizer is provided with more than one adhesive jetting port. The centrifugal machine provided by the invention improves the fiber forming quality of fibers greatly, increases the adhesive applying uniformity, reduces the slag ball content effectively, also is energy-saving and environment-friendly, is simple in structure, and is convenient to operate.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

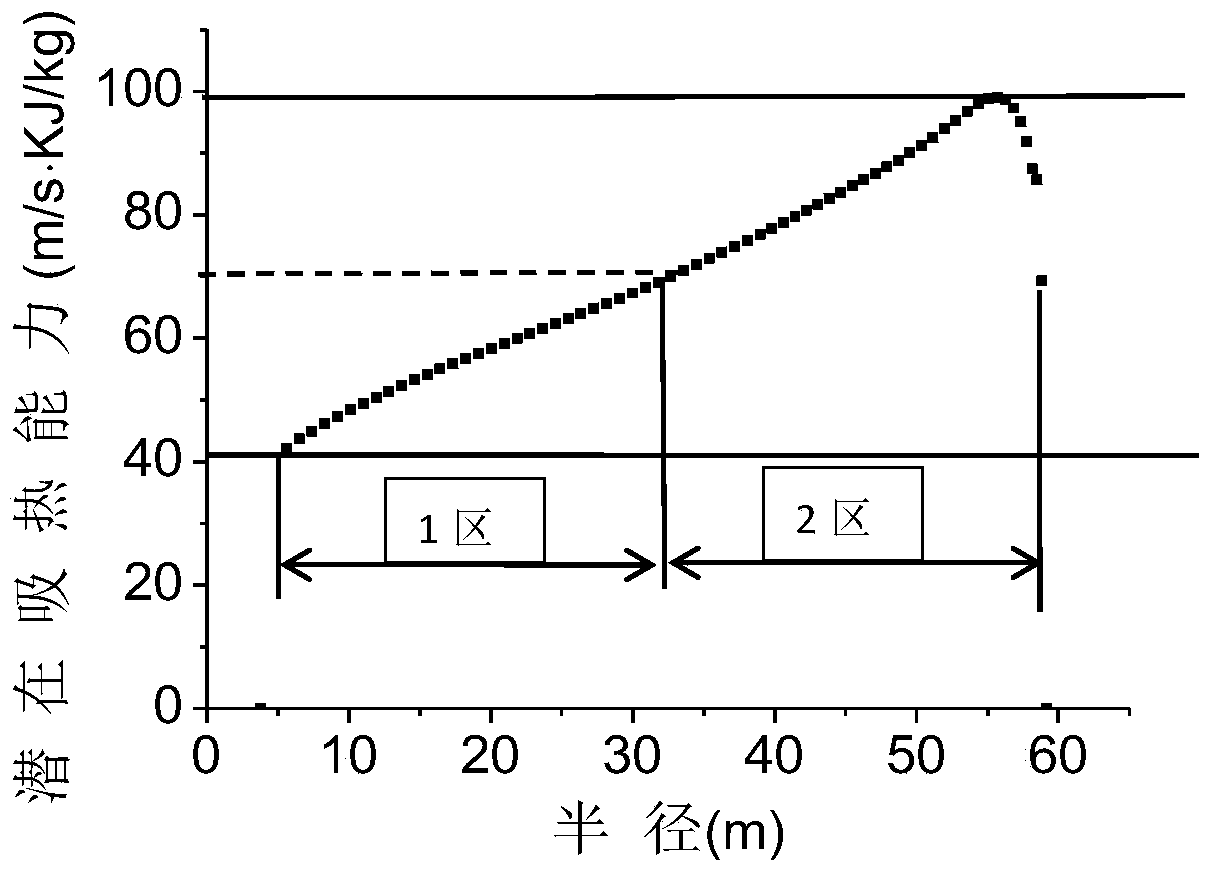

Cooling tower water distribution optimization method based on cooling potential force

ActiveCN110686527AImprove cooling efficiencyIncrease cooling waterTrickle coolersCooling towerDistribution system

The invention discloses a cooling tower water distribution optimization method based on cooling potential force and belongs to the technical field of cooling towers, in particular to a water distribution optimization method in the technical field of cooling towers. In the method, unequal water distribution and uneven area arrangement of a water distribution system are achieved in a cooling tower water distribution area based on the distribution characteristic of the cooling potential force. By means of the method, the heat transfer and mass transfer performance at all positions in a tower canbetter become uniform, and the cooling efficiency of the cooling tower is further improved.

Owner:济南蓝辰能源技术有限公司 +1

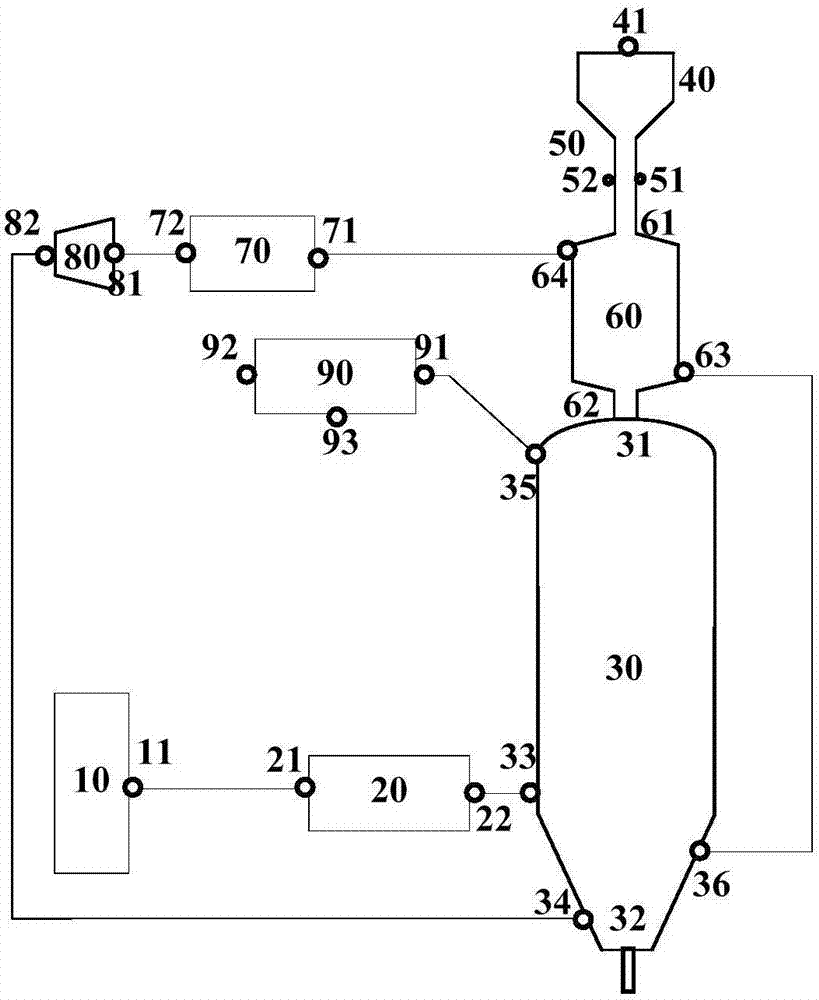

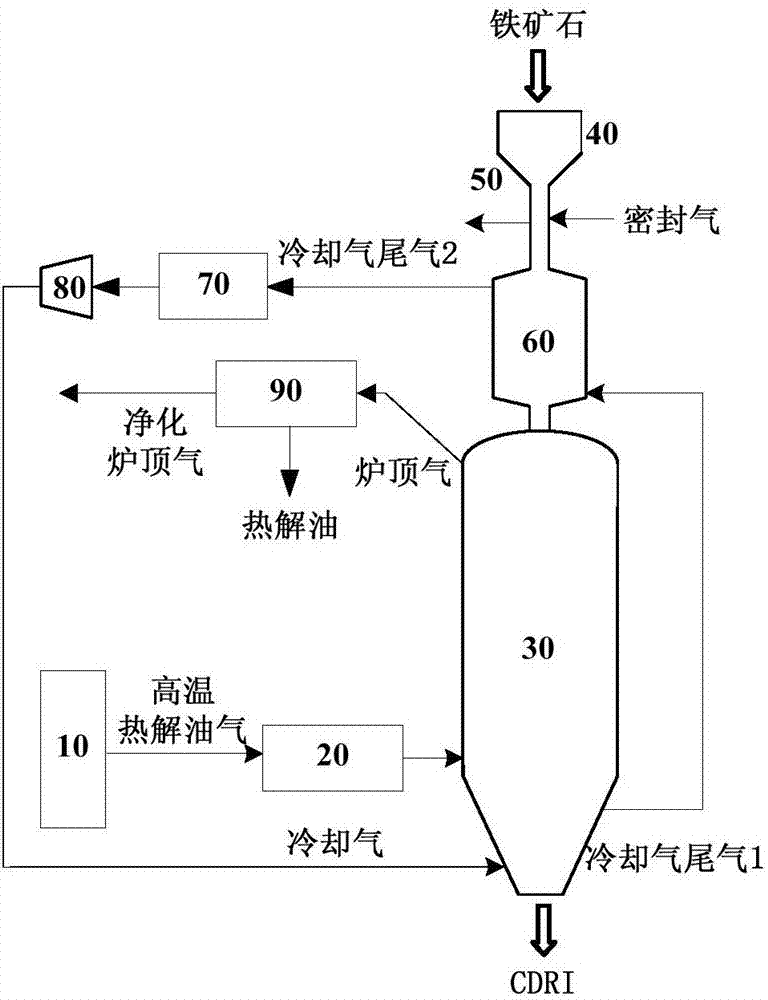

System and method for smelting direct reduced iron through pyrolytic oil gas

PendingCN107400747AReduce maintenance costsReduce product costShaft furnaceGas emission reductionProcess engineeringCoal

The invention relates to a system and method for smelting direct reduced iron through pyrolytic oil gas. The system comprises a pyrolyzing furnace, a heating device and a gas-based shaft furnace which are connected in sequence. The method is implemented through the system. Through the system and the method, sensible heat of the high-temperature pyrolytic oil gas is sufficiently and efficiently utilized, and the energy source utilization efficiency is high; low-cost low-rank coal serves as a raw material to produce reducing gas instead of using a large amount of natural gas, so that gas-based shaft furnace production lines are built in areas scarce in natural gas, high-quality direct reduced iron is produced, and the product cost is obviously reduced; and a lot of expensive reforming catalysts do not need to be used, the maintenance cost is low, and the content of sulphur in the reducing gas of the gas-based shaft furnace does not need to be strictly limited.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

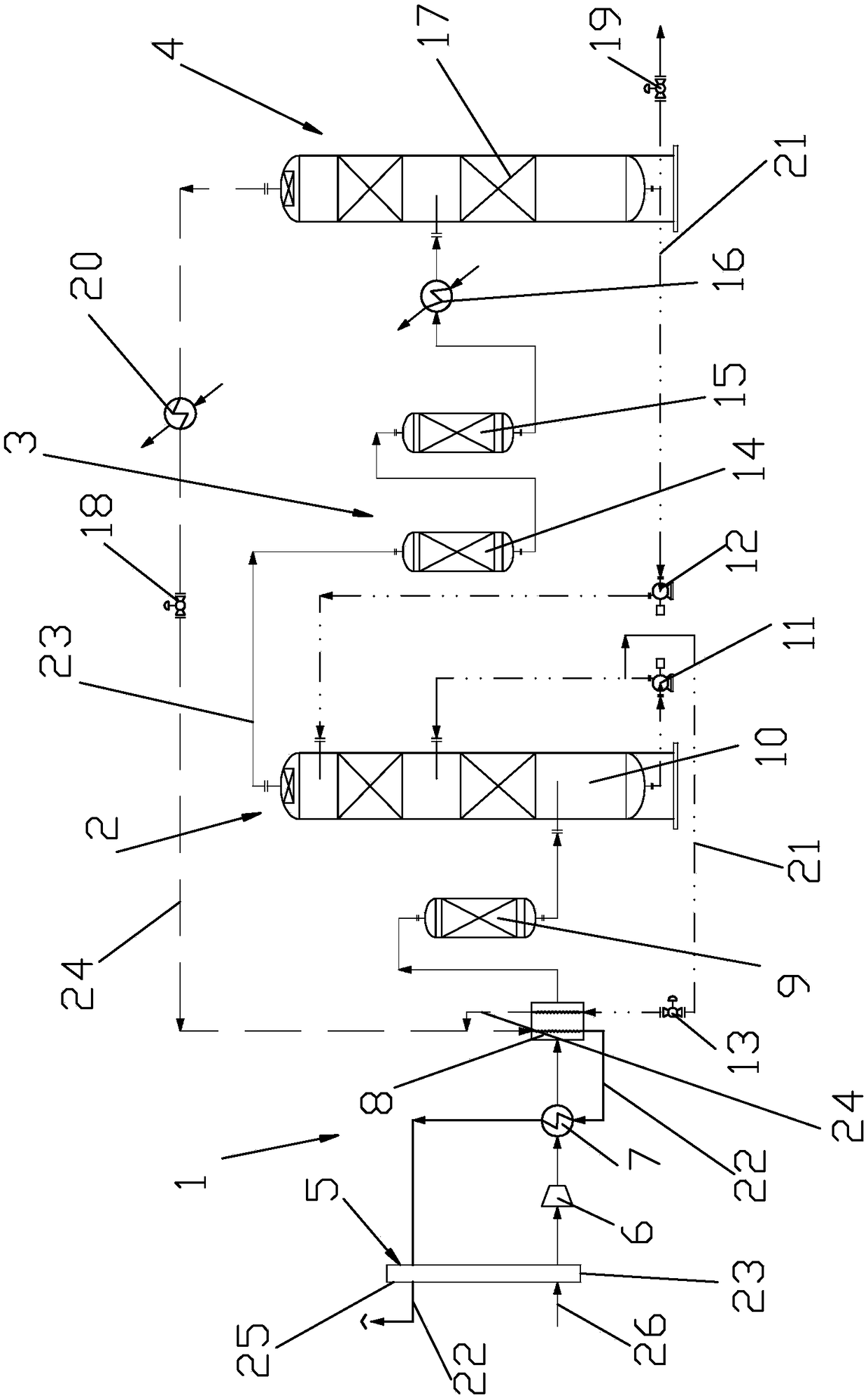

Preparation device and technology for producing high-quality liquid carbon dioxide

ActiveCN108821288AReduce dehydration energy consumptionReduce the temperatureCarbon compoundsProcess equipmentProcess engineering

The invention discloses a preparation device for producing high-quality liquid carbon dioxide. The preparation device comprises a drying system, a heavy component removing system, an impurity removingsystem and a light component removing system; a rotating wheel dehumidifying machine comprises a dehumidifying region and a regeneration region; a smoke cooler, a heater and the regeneration region are communicated through a regenerated gas pipeline; the dehumidifying region is communicated with a compressor through a raw gas pipeline; the compressor is communicated with the heater through the raw gas pipeline; the heavy component removing system comprises a heavy component removing tower, a heavy component removing circulating pump and a CO2 washing pump; a preparation technology comprises the following steps: (1) drying and dehydrating; (2) washing and removing a heavy component; (3) carrying out low-temperature deep impurity removal; (4) carrying out liquefaction and rectification. Thepreparation device and the preparation technology, disclosed by the invention, have the advantages of simple technology, low operation energy consumption and convenience for operation; under the condition that a few of sets of equipment need to be increased based on previous process equipment, and the liquid carbon dioxide with the content more than 99.995 percent can be stably produced; the generation of solid wastes is reduced and the investment cost is reduced.

Owner:杭州快凯高效节能新技术有限公司

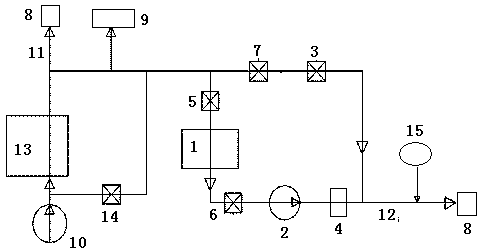

Method and device for eliminating white smoke of wet-containing flue gas

PendingCN109126363AReduce the amount of cooling waterReduce unit consumptionGas treatmentUsing liquid separation agentGas heaterFlue gas

The invention discloses a method and a device for eliminating white smoke of a wet-containing flue gas and belongs to the technical field of gas or steam separation. The method comprises the followingsteps: carrying out cooling spraying on a flue gas after desulfuration, mixing a wet-containing flue gas with cooling mist in a countercurrent manner till the wet-containing flue gas is cooled to a cooling water temperature approximately; carrying out imbibitions demisting on the wet-containing flue gas after cooling spraying, and enabling the flue gas to sufficiently contact the surface of a hydrophilic porous membrane in a membrane demister so as to obtain a low-temperature saturated gas; further heating the low-temperature saturated gas in the step II by using a flue gas heater, and discharging an unsaturated flue gas through a chimney, thereby eliminating white smoke. By adopting the method, the flue gas after desulfuration is fed into a spraying tower, a cooling spraying device is arranged at the upper part inside the spraying tower, and a tower disc is arranged at the lower part of the spraying tower; the cooling spraying device is connected with the membrane demister, the membrane demister is connected with the chimney, and a secondary glue gas heater is arranged between the outlet of the membrane demister and the inlet of the chimney. By adopting the method, a 'white smoke' phenomenon caused when flue gases are discharged can be effectively eliminated, and pollutants such as dust and aerogel can be deeply removed.

Owner:南京圣卡孚科技有限公司

Cooling water pipe connected net for cooling walls of soft water blast furnace

The invention discloses a cooling water pipe connected net for cooling walls of a soft water blast furnace. A tuyere zone cooling wall, a furnace bosh cooling wall, a furnace waist cooling wall and a furnace body cooling wall are installed on the wall of the soft water blast furnace, and at least two external cooling water pipes are connected to each cooling wall; a first external cooling water pipe, a second external cooling water pipe, a third external cooling water pipe and a fourth external cooling water pipe are connected to the outside of a furnace shell between two adjacent cooling wall layers, and the first external cooling water pipe, the second external cooling water pipe, the third external cooling water pipe and the fourth external cooling water pipe all incline or deviate towards the same direction; and internal cooling water pipes with the trend from the lower part of the soft water blast furnace to the upper part of the furnace body ascend to the uppermost layer of the cooling wall of the soft water blast furnace along the furnace shell of the soft water blast furnace in a winding stair type structure mode. The cooling water pipe connected net for the cooling walls can restrain damage of cooling equipment caused by local airflow development, is beneficial to keeping the stability of the shape of the blast furnace and reducing the running expense and the energy consumption of the cooling system of the blast furnace, and can be generalized to cooling devices of various large and medium metallurgy blast furnaces.

Owner:湖南华菱涟源钢铁有限公司

Device for reducing cold air doping rate of hot primary air

ActiveCN103836636AImprove efficiencyAdjust Penetration DepthLump/pulverulent fuel preparationAir preheaterCold air

The invention relates to a device for reducing the cold air doping rate of hot primary air. The device comprises a blower, an air preheating device and a combustor, wherein the blower, the air preheating device and the combustor are sequentially connected in the air inlet direction. The air preheating device is connected with the combustor through a primary air pipe. The device for reducing the cold air doping rate of the hot primary air is characterized in that a bypass air channel is arranged, the initial end and the tail end of the bypass air channel are connected to different positions of the primary air pipe, the flow direction of the inner air of the bypass air channel is identical with the flow direction of the inner air of the primary air pipe and an inlet closing baffle, a hot primary air cooler, an outlet closing baffle, a pressurizing fan and an air channel compensator are sequentially arranged on the bypass air channel in the air inlet direction. A regulating baffle and a first closing baffle are sequentially arranged on the part, located between the initial end and the tail end of the bypass air channel, of the primary air pipe in the air inlet direction. A pulverized coal feeding machine is arranged behind the tail end, located on the bypass air channel, on the primary air pipe in a connected mode. The device for reducing the cold air doping rate of the hot primary air has the advantages of being simple in structure, convenient to use, low in cost of coal in generating electricity and capable of improving the efficiency of a boiler and saving the operation cost.

Owner:山东英电环保科技有限公司

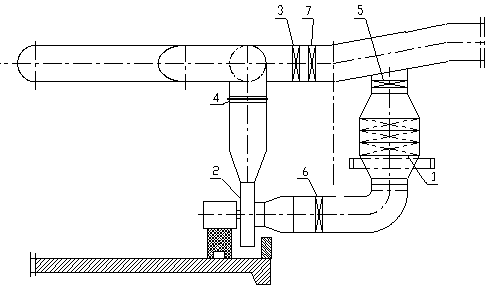

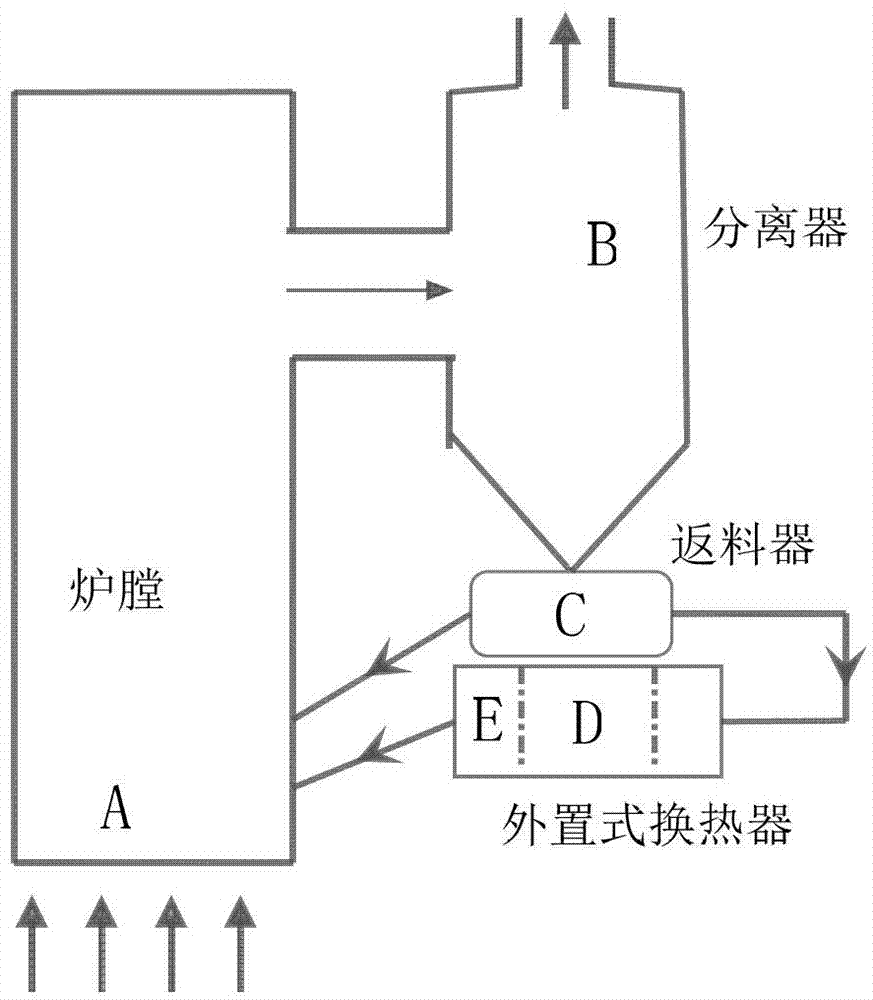

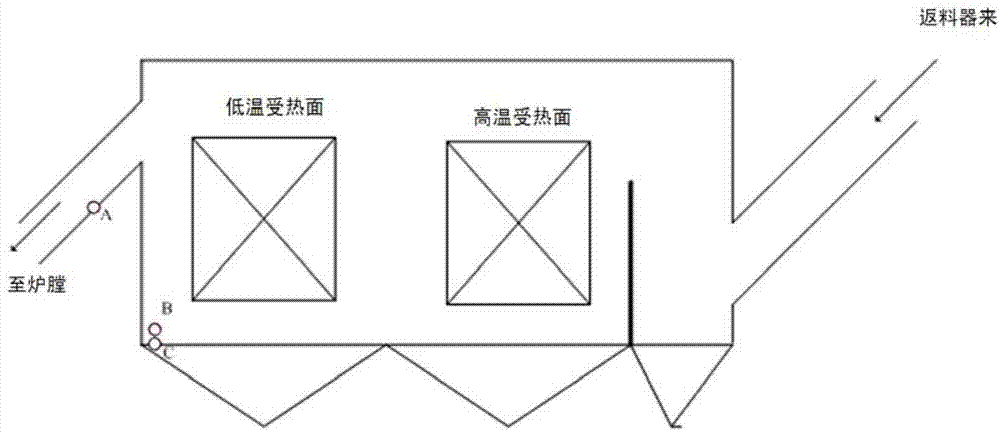

Method for discharging slags from circulating fluidized bed boiler based on external heat exchanger

InactiveCN102809150AEffective recovery of physical sensible heatLower average slag temperatureFluidized bed combustionApparatus for fluidised bed combustionSlagCooling effect

The invention discloses a method for discharging slags from a circulating fluidized bed boiler based on an external heat exchanger. A slag discharge port is formed at a circulating ash outlet in a low-temperature heated surface of the external heat exchanger, and low-temperature circulating ash is discharged through the port, so that the average slag temperature at the inlet of a slag cooler is lowered effectively, a slag cooling effect is ensured, and physical sensible heat of ash is recovered effectively. The method has the beneficial effects of simple design, no increase in the slag discharge cost, average recovery of heat, reduction in cooling water amount and reduction in slag discharge temperature.

Owner:YUN NAN ELECTRIC TEST & RES INST GRP CO LTD ELECTRIC INST +1

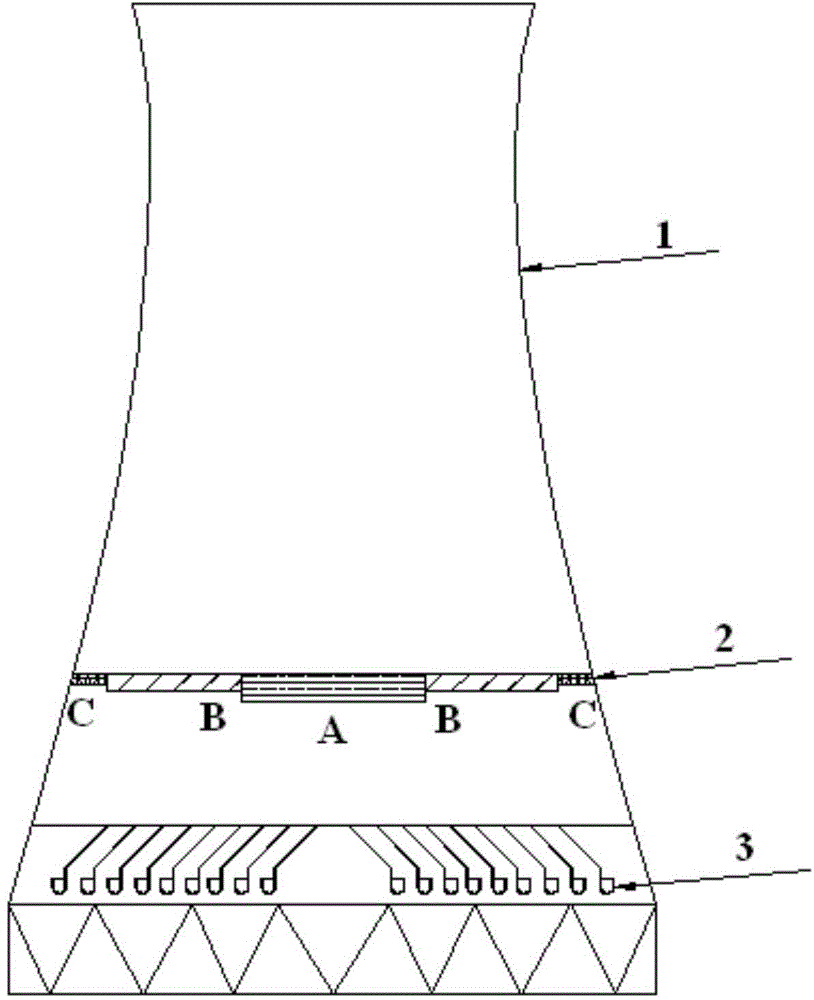

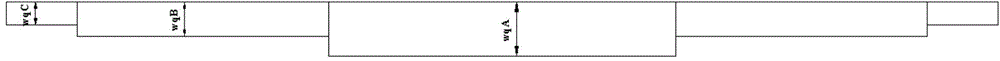

Non-uniform water distribution system for high-position water collecting cooling tower

The invention discloses a non-uniform water distribution system for a high-position water collecting cooling tower. The non-uniform water distribution system comprises a water distribution area located in the cooling tower, the water distribution of the water distribution area is in non-uniform arrangement and zoning arrangement; that is to say, a non-uniform arrangement mode is adopted from inside to outside in the diameter direction of the high-position water collecting cooling tower. The zoning mode of the water distribution area is that with the vertical axis of the cooling tower as the center, the water distribution area is sequentially divided into three annular areas of different radiuses outwards, and the three annular areas are an area A, an area B and an area C. The non-uniform water distribution system reduces the influence on air uniformity in the tower caused by water spraying density, the cooling capability in the tower is fully utilized, and the cooling efficiency of the high-position water collecting cooling tower is improved.

Owner:SHANDONG UNIV

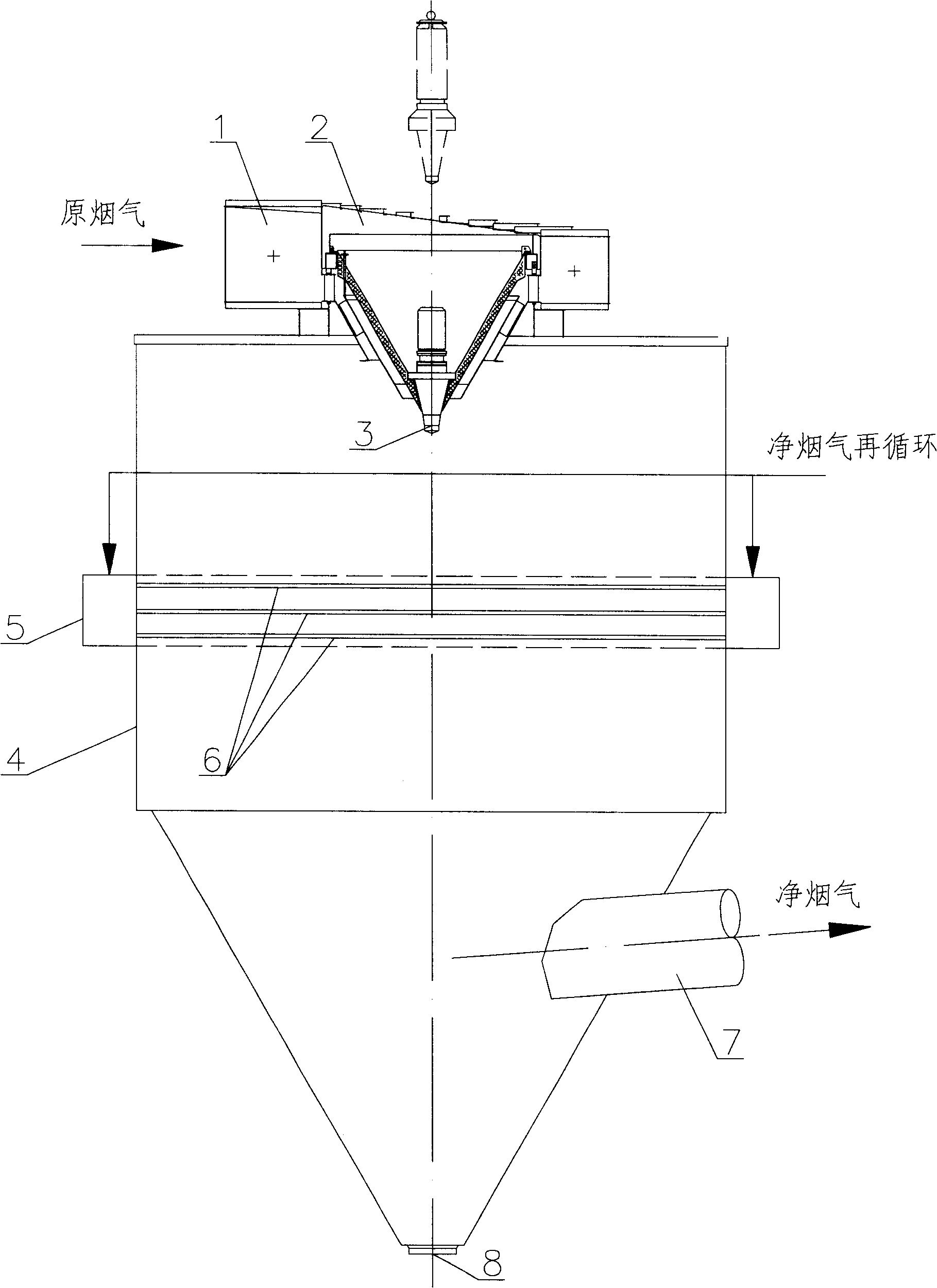

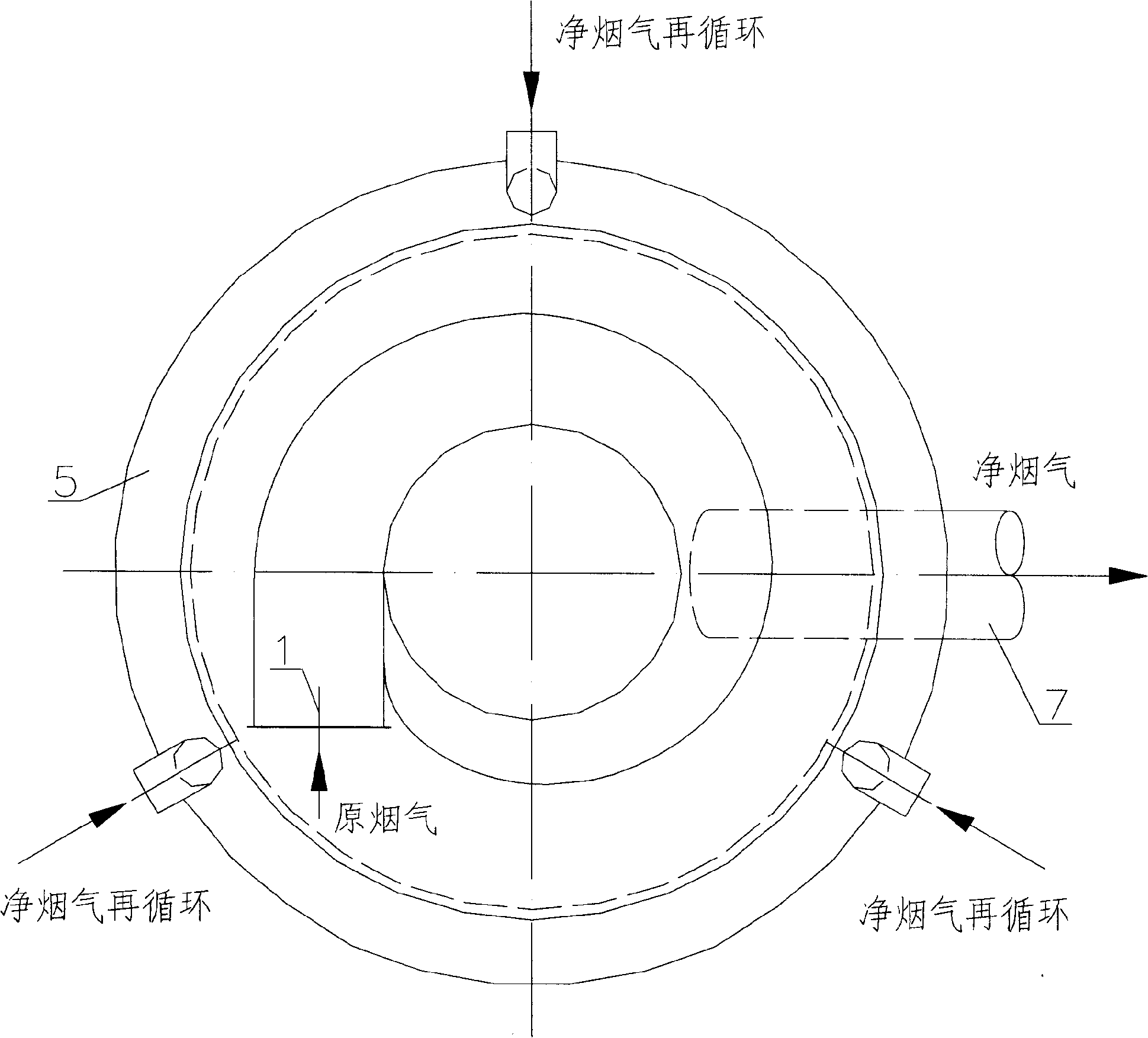

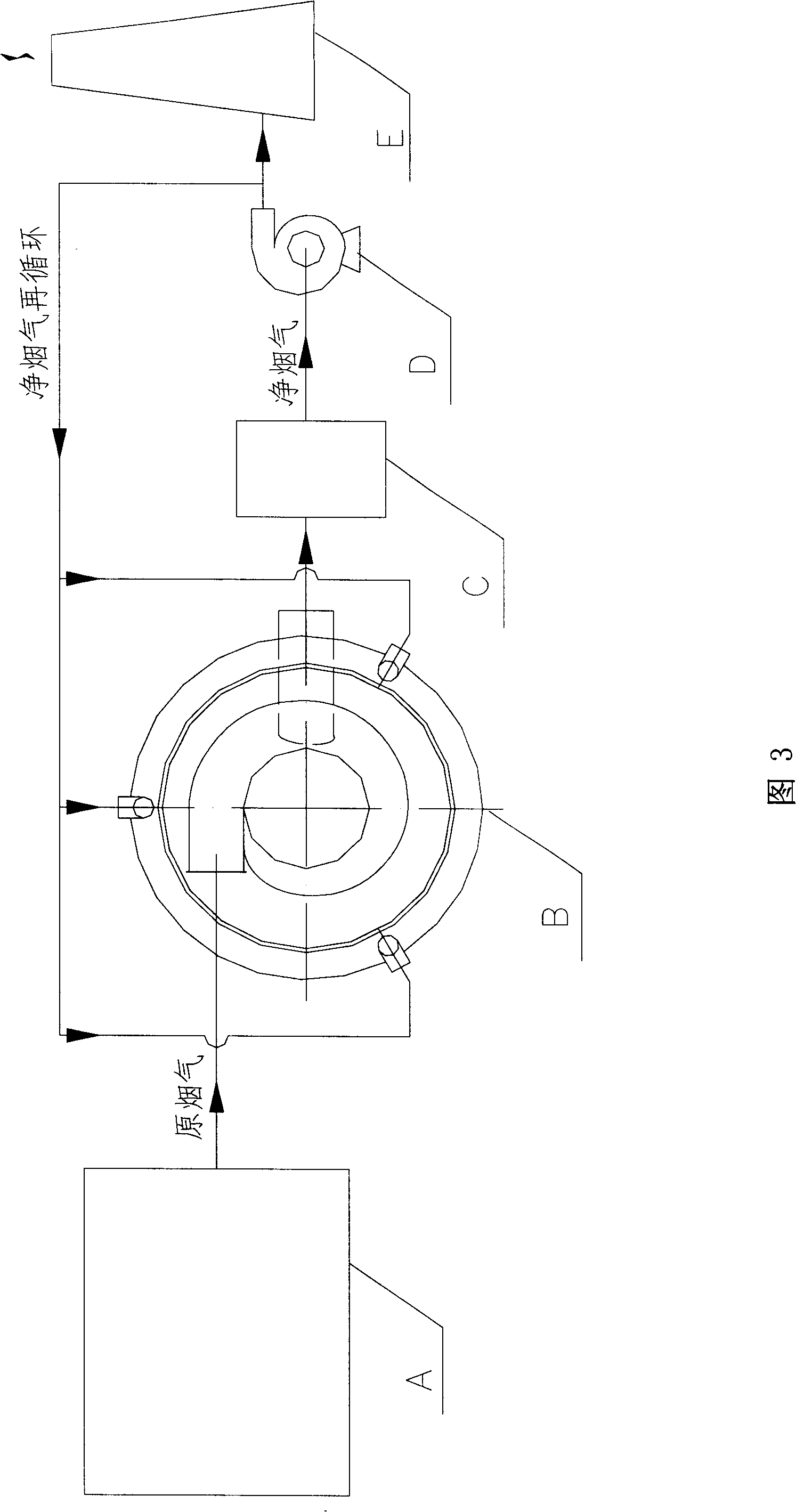

Recirculation type semidry process reaction tower for purifying flue gas and technique thereof

InactiveCN101322909AAvoid the disadvantages of sewage treatmentAdequate mass and heat transferDispersed particle separationFlue gasSprayer

The invention discloses a clean flue gas recycling semi-dry reaction tower which includes a raw flue gas inlet, a raw flue gas rectifying and guide plate, a rotary sprayer, a reaction tower body, a clean flue gas outlet and an ash exhaust opening. The reaction tower also includes a recycling clean flue gas collecting container and a clean flue gas spout; the wall surface of the reaction tower body is provided with a circle or a plurality of circles of annular clean flue gas spouts; a recycling clean flue gas collecting container is arranged outside the location of the annular clean flue gas spout. Besides, the invention also discloses a clean flue gas recycling semi-dry technique which is additionally provided with a clean flue gas recycling step. The invention can effectively overcome the boundary escape of the prior art, stop the wall surface of the reactor tower to be hardened, improve the reaction efficiency and can be applied to purify the acidic gases (HCl, SOx) and heavy metal ions in the flue gas at the outlet of a boiler for burning garbage.

Owner:上海融新能源环境科技有限公司 +5

Constant temperature water economizer

ActiveCN104896151AReduce the amount of cooling waterConserve waterOperating means/releasing devices for valvesMultiple way valvesWaxWarm water

The invention discloses a constant temperature water economizer. The constant temperature water economizer comprises a water economizer body, a hot water inlet connection accessory, a cold water inlet connection accessory, a warm water output connection accessory, a wax type temperature sensing bag, a thermoregulation seat, a locking nut, a constant temperature piston, a reset spring, a hex head screw, a hot water stop plug and a check valve, wherein a mixing water cavity and a warm water cavity are formed in a cylinder of the water economizer body, the mixing water cavity and the warm water cavity are separated through inner platforms, the centers of the inner platform are communicated through a via hole, the warm water cavity is of an internal thread structure, and the wax type temperature sensing bag is screwed on the thermoregulation seat and overall installed in the warm water cavity. The constant temperature water economizer is an automatic mixing device which uses a thermal sensitive element to keep water outlet temperature constant, automatically closes a cold water channel when temperature of mixed water is less than 35 degree centigrade, only drains cold water accumulated in a hot water channel when a faucet is opened, only opens the cold water channel when the water outlet temperature reaches a set value, and then greatly reduces the cold water drainage amount when a user waits for hot water, and thereby achieves the purpose of saving water.

Owner:KAIPING MAGNA SANITARY WARE CO LTD

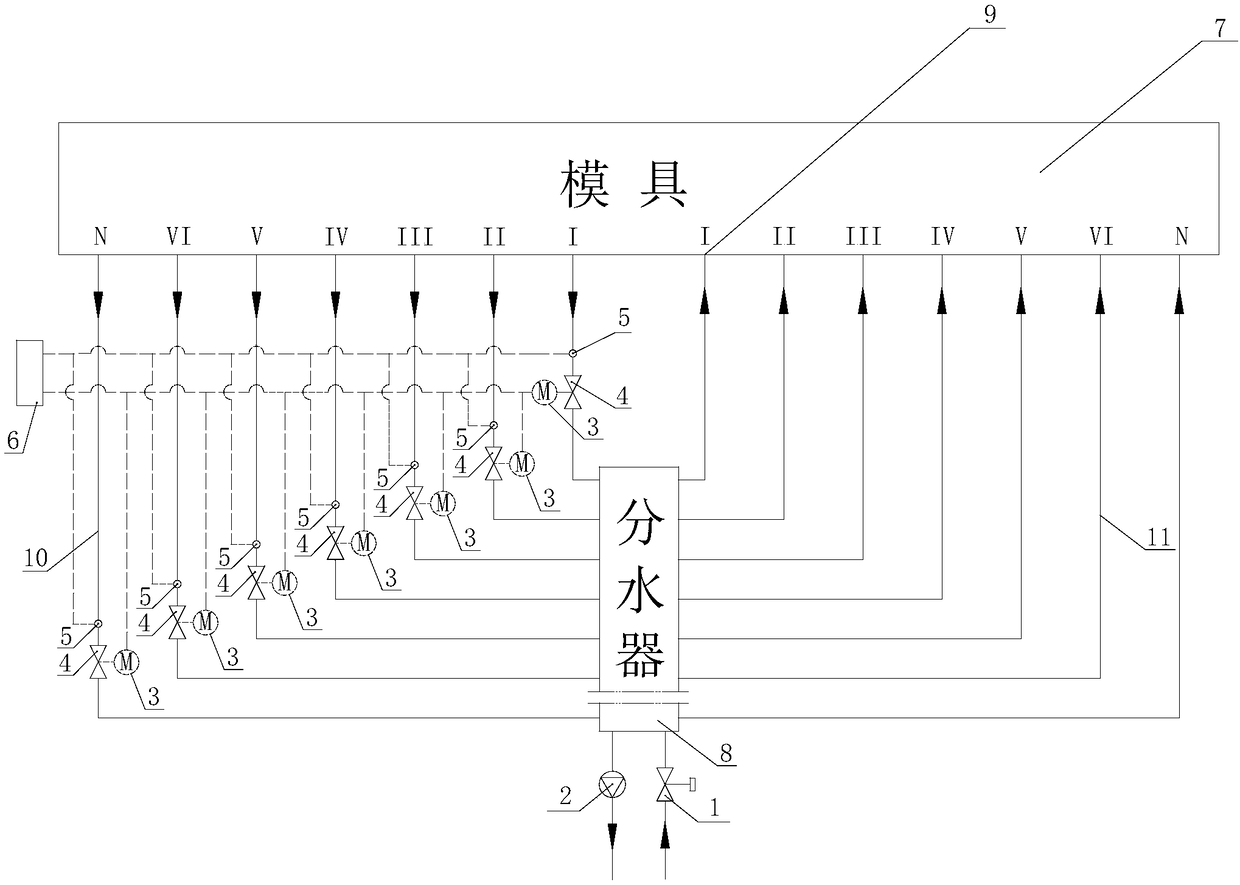

Mold cooling system and mold cooling control method

The invention discloses a mold cooling system and a mold cooling control method. The mold cooling system includes a mold and a water segregator, two or more circulating flow paths are formed between the mold and the water segregator, and cooling media are disposed in the circulating flow paths. Electrical control throttle valves and temperature sensors are disposed on the circulating flow paths, and the temperature sensors are used for monitoring the temperature of the cooling media and sending the collected real-time temperature information to a microcomputer. The microcomputer is connected with stepping motors, and the stepping motors are connected with the electrical control throttle valves; and the microcomputer is used for realizing an opening size of the electrical control throttle valves by controlling the number of revolutions of the stepping motors. According to the mold cooling system and the mold cooling control method, the whole system collects data through the microcomputer and controls the cooling water volume of the corresponding circulating flow paths through the stepping motors, and the cooling balance of the mold is ensured.

Owner:GUANGDONG WEIDA INTELLIGENT EQUIP CO LTD

Feed water control method for supercritical concurrent boiler without boiler-water circulating pump

A feed water control method for a supercritical concurrent boiler without a boiler-water circulating pump includes providing a supercritical concurrent boiler system without the boiler-water circulating pump. The supercritical concurrent boiler system without the boiler-water circulating pump comprises a feed water flow control valve and a steam separator regulating valve. The feed water flow for load of concurrent operation of the concurrent boiler from starting to drying state is preset. Actual feed water flow during concurrent operation process of the concurrent boiler from starting to drying state is obtained by dynamically regulating opening degree of the steam separator regulating valve to regulate preset feed water flow. The feed water flow entering the boiler is adjusted by regulating the opening degree of the steam separator regulating valve. The feed water control method for the supercritical concurrent boiler without the boiler-water circulating pump is easy to realize by common control equipment.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

Liquid blast furnace slag heat recovering apparatus and method

InactiveCN100424187CSmall granularityEfficient recyclingOther heat production devicesRecycling and recovery technologiesRecovery methodLiquid slag

The liquid blast furnace slag heat recovering apparatus includes one sealed cylindrical container with top gas outlet, one liquid slag gate on the top of the container, one pelletizing unit comprising motor and its driving system inside the container, and one cooling-gas injecting unit. The heat recovering method includes leading liquid blast furnace slag through the gate into the container, pelletizing the liquid slag with the pelletizing unit, heat exchange between the falling blast furnace slag grains and the cooling gas, and exhausting the cooling gas, which is compressed air or nitrogen, after heat exchange through the gas outlet for reuse. The present invention has effective heat exchange.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com