Patents

Literature

126results about How to "Rapid cooling down" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Arc extinction slurry for fuse protector

ActiveCN103606497AEffectively extinguishedQuick breakdownEmergency protective devicesSurface mountingOrganosolv

The invention relates to arc extinction slurry for a fuse protector. The arc extinction slurry comprises, by weight, 5-40 parts of gas production materials, 0-10 parts of phenol formaldehyde resin, 20-60 parts of quartz sand, 0.6-10 parts of organic solvents and15-30 parts of deionized water. The gas production materials are mainly urea-formaldehyde resin and other powder materials; the phenol formaldehyde resin can be boron-modified phenol formaldehyde resin and other high-temperature-resistant resin which is soluble in organic solvents, and the main effect of the phenol formaldehyde resin is to improve the heat-resistant performance of urea-formaldehyde resin; the periphery of a melt is covered with the arc extinction slurry in a filling mode or a thick film printing mode or the like, and gas will be produced under the action of an electric arc so as to extinguish the electric arc; fast cooling of the metallic melt is guaranteed by adding the quartz sand, and therefore the arc extinction slurry can be used on the breaking occasion of high voltage and great current of more than 250VAC / 100A. The arc extinction slurry has the predominant advantages of being low in production cost, easy to operate, free of halogen, friendly to environment, high in arc extinction ability and the like, thereby being suitable for being used in a current common tube shell type or thick film printing type surface-mounted miniature fuse protector.

Owner:NANJING SART SCI & TECH DEV

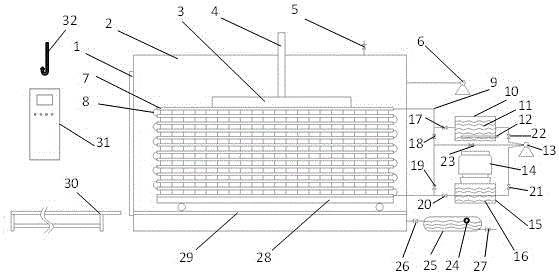

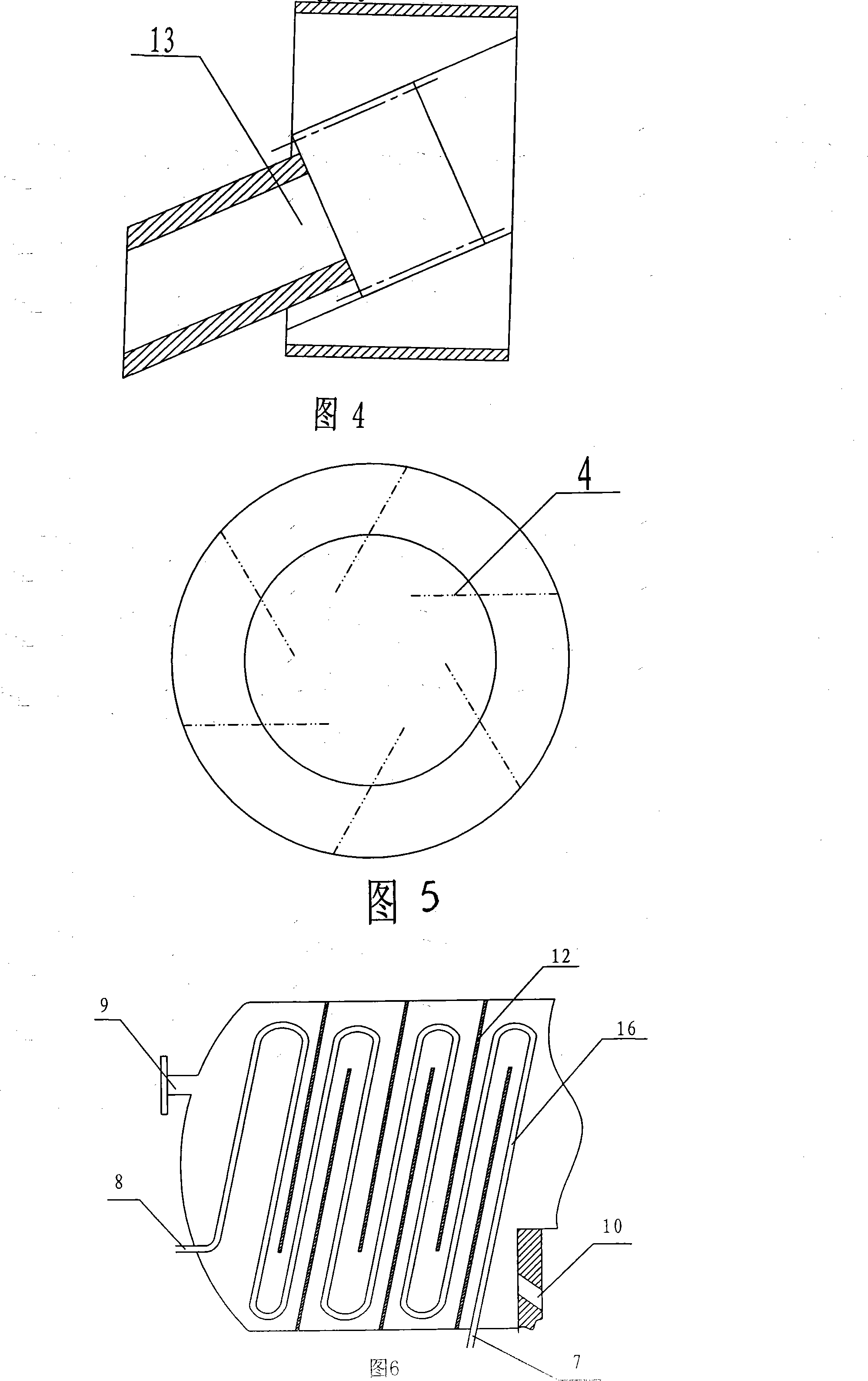

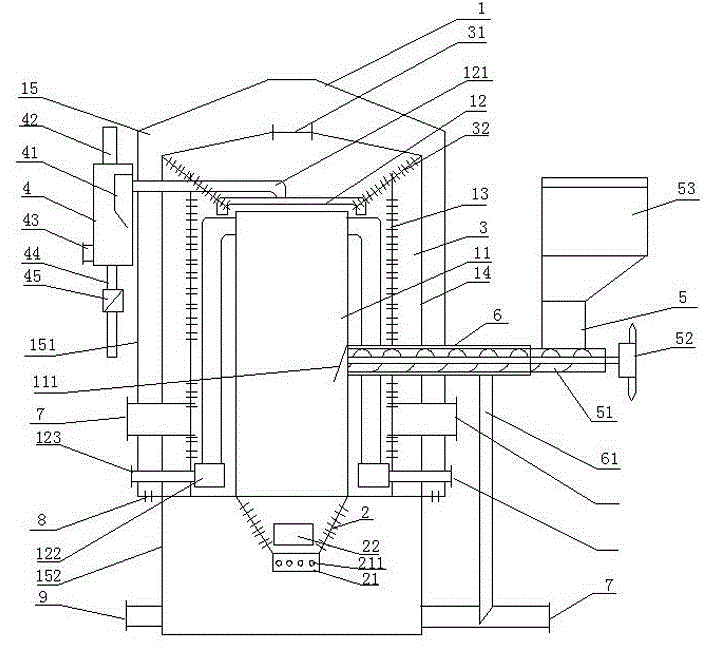

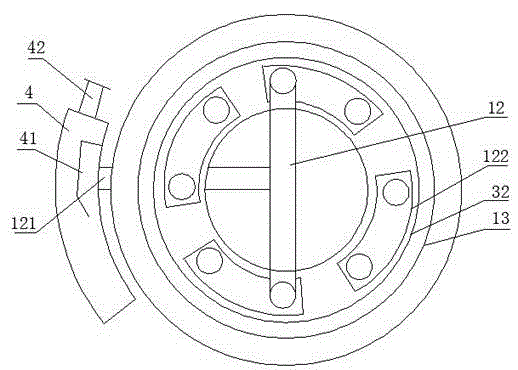

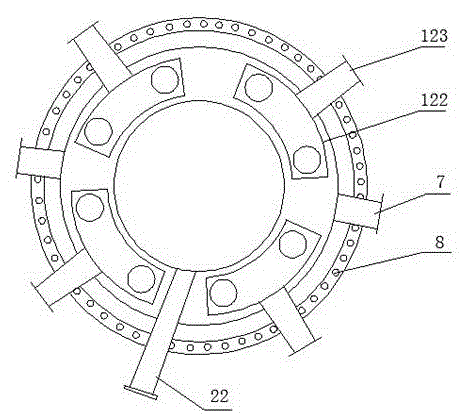

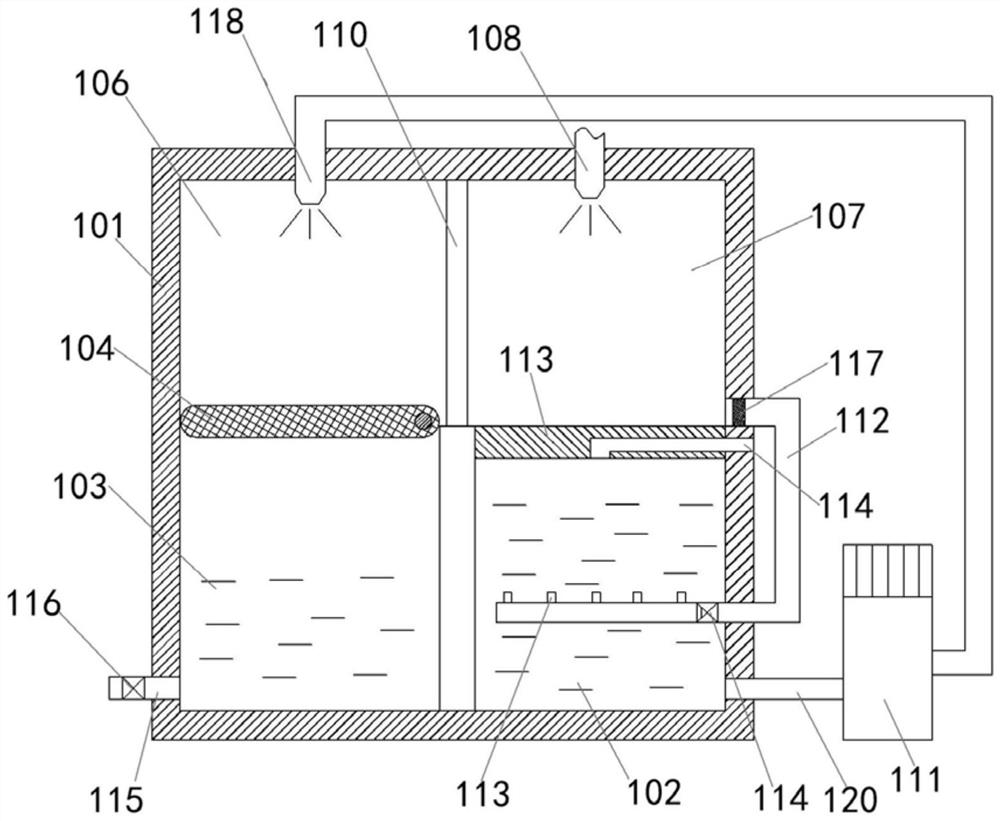

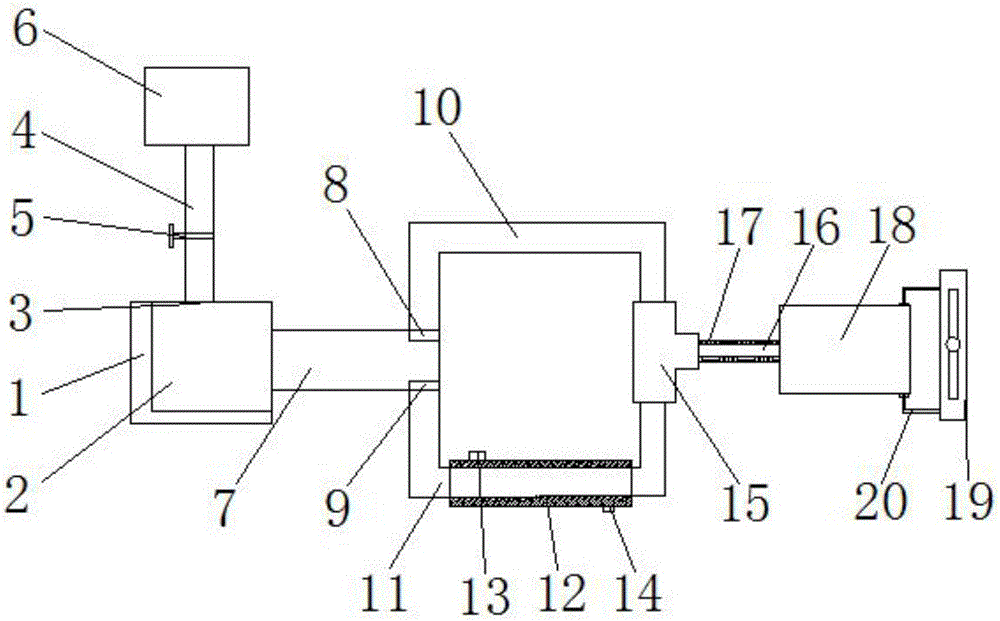

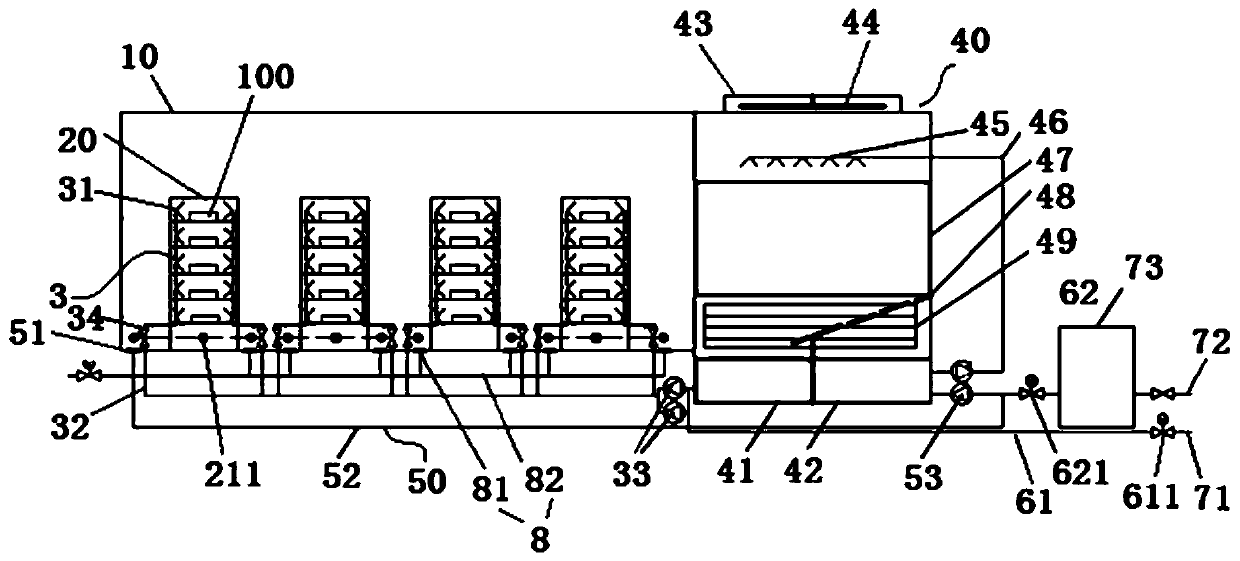

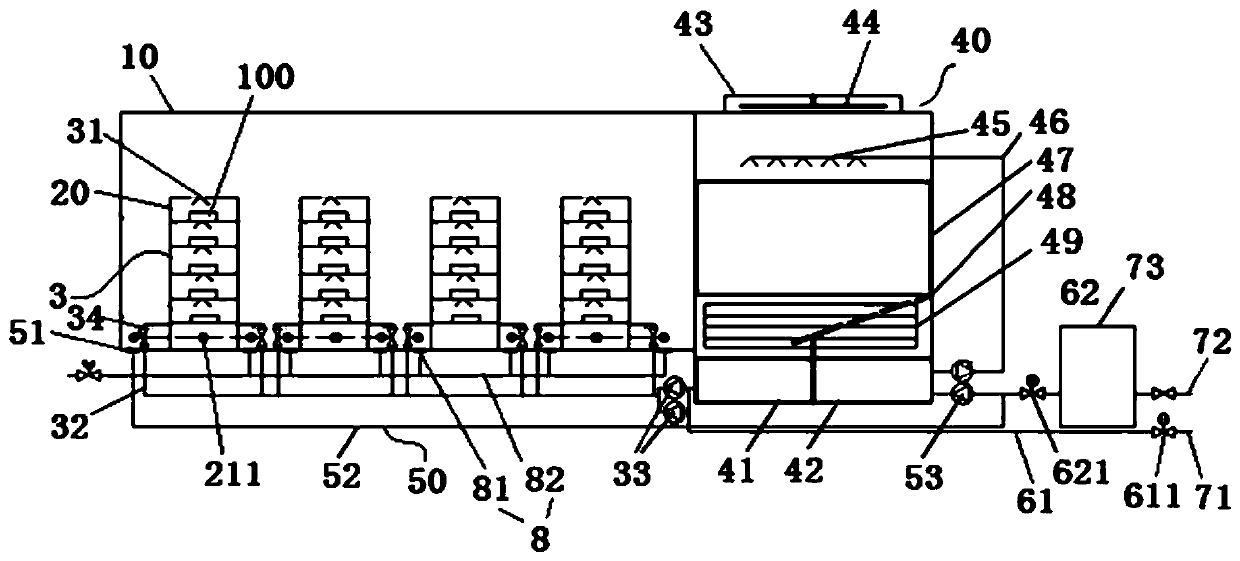

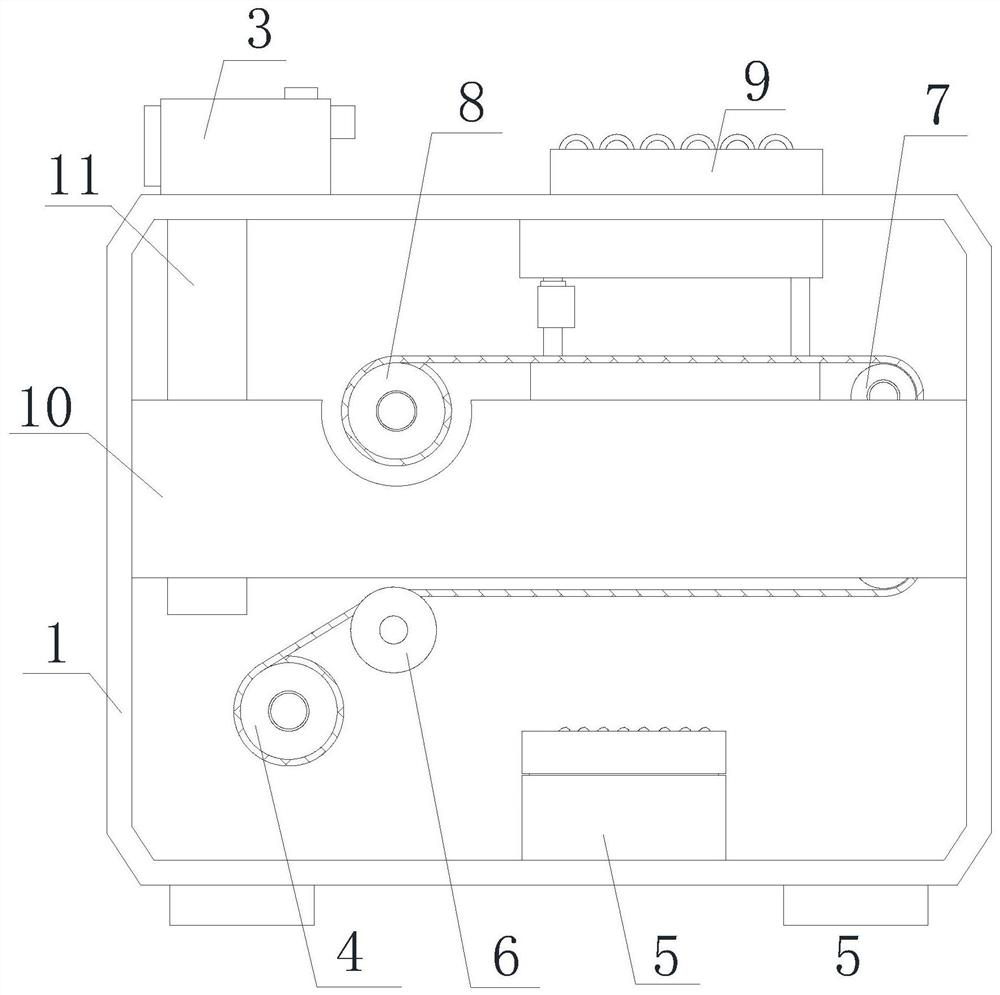

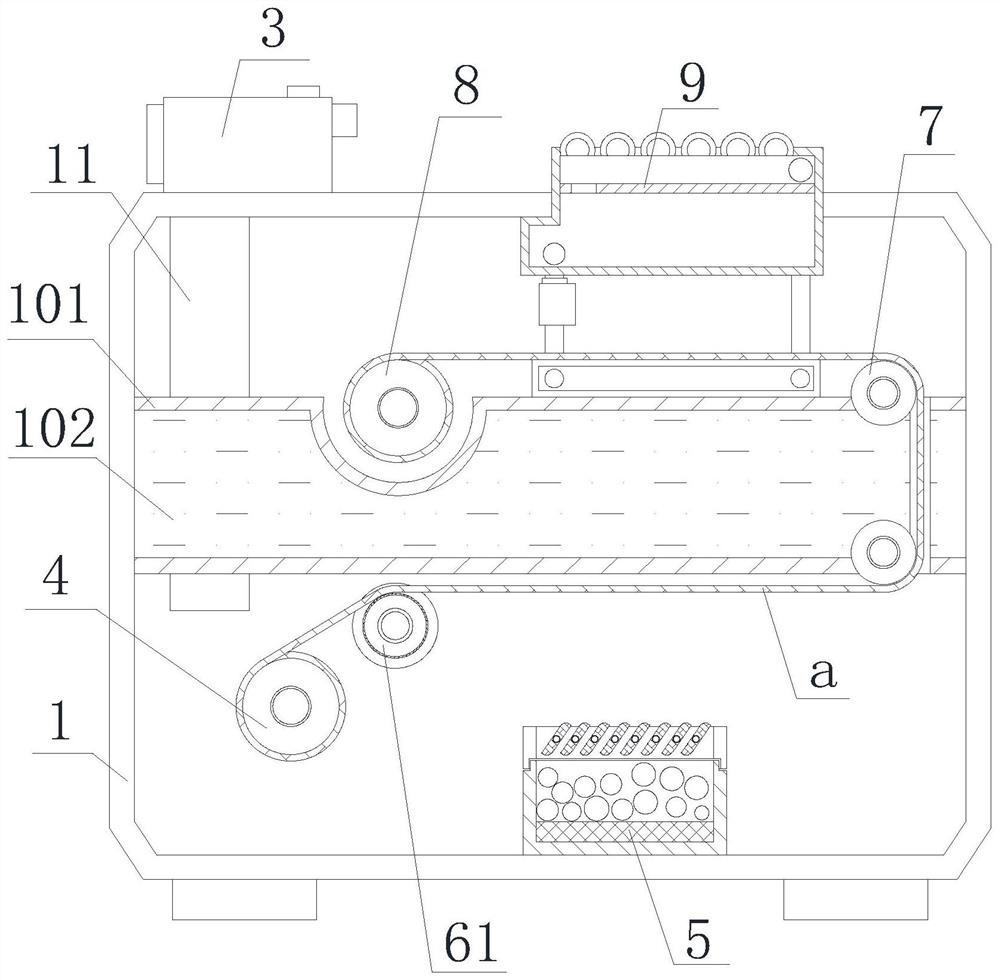

Method and equipment for drying and carbonizing wood integrally on vacuum condition

InactiveCN106426473AShorten carbonization timeImprove processing efficiencyDrying solid materials without heatWood treatment detailsWood dryingHeating cooling

The invention provides equipment for drying and carbonizing wood integrally. The equipment comprises a pressure adjusting system, a heating and cooling system, a material loading, transporting and pressurizing system and a water drainage system; an exo-box heat conduction oil pipe of the heating and cooling system penetrates through a treatment box and is welded to a wall of the treatment box for being sealed; a water inlet valve of the water drainage system is connected to the treatment box and a water drainage box through connection pipelines; and an outer wall of a hydraulic cylinder of the material loading, transporting and pressurizing system is welded to the treatment box in a sealed mode. The equipment has the advantages that the repeated loading, stacking, heating and cooling steps of the drying and heat treating steps of wood are reduced, so that the processing efficiency is improved, and the energy consumption is lowered; a processing method is flexible and multipurpose and the equipment is multifunctional; the whole drying and carbonizing treatment is carried out on the vacuum and negative pressure conditions, the content of air in the treatment box is small, and the oxygen content is low; carbonized wood making contact with a hot plate can be fast cooled; and the wood can be prevented from being deformed, warped and cracked in the vacuum drying and vacuum carbonizing stages.

Owner:GUANGDONG YIHUA TIMBER IND

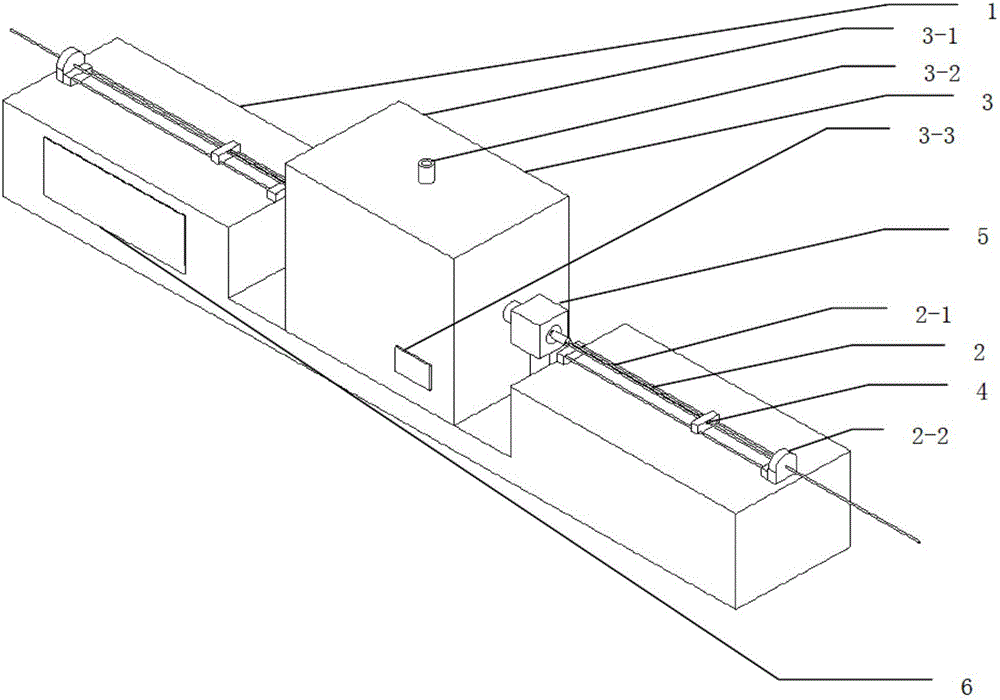

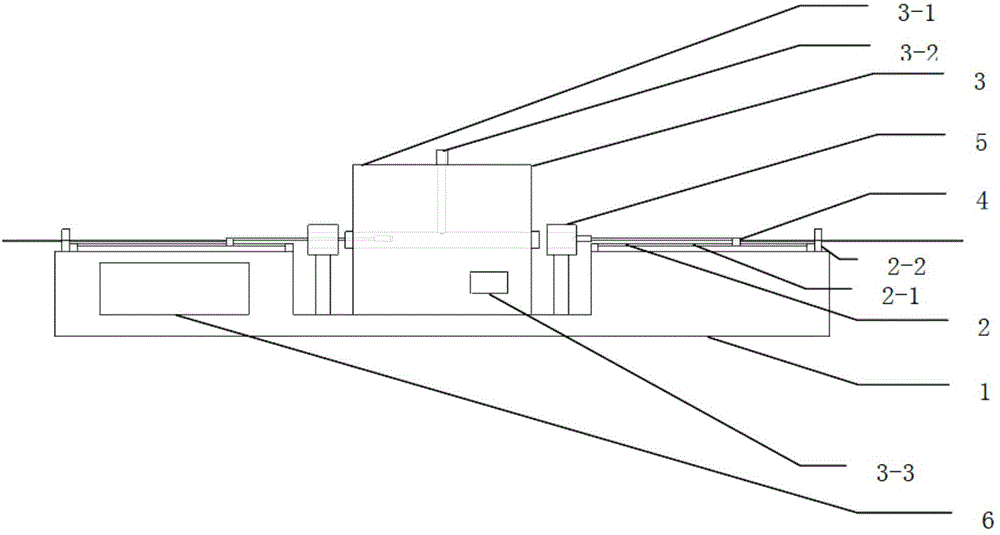

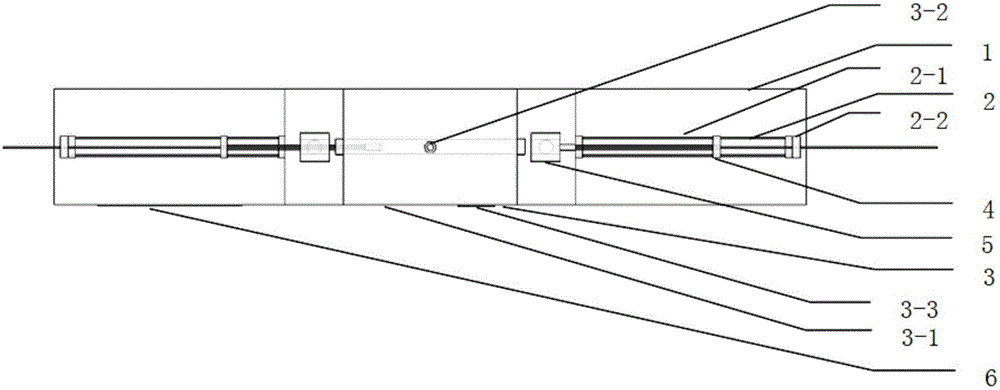

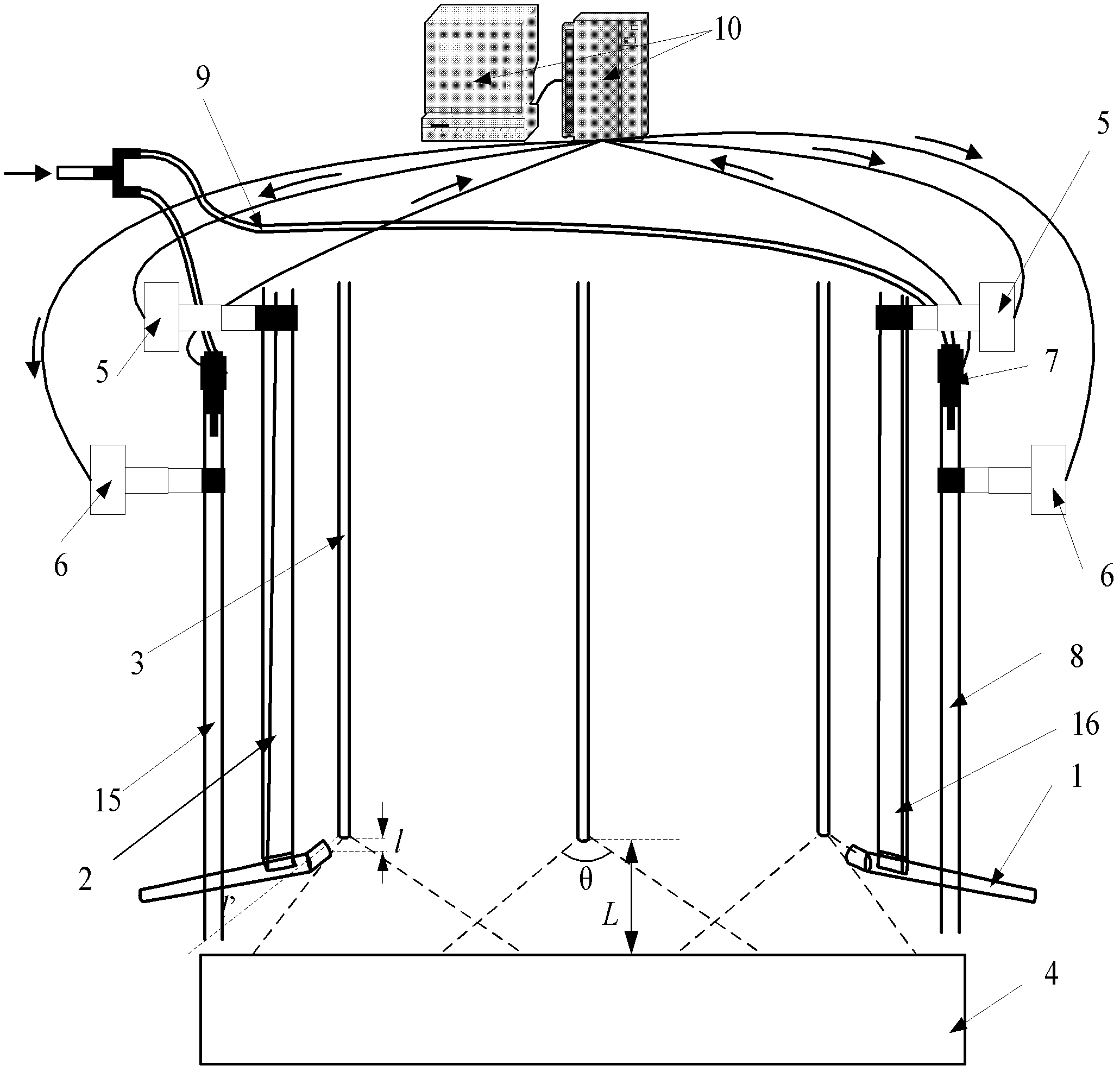

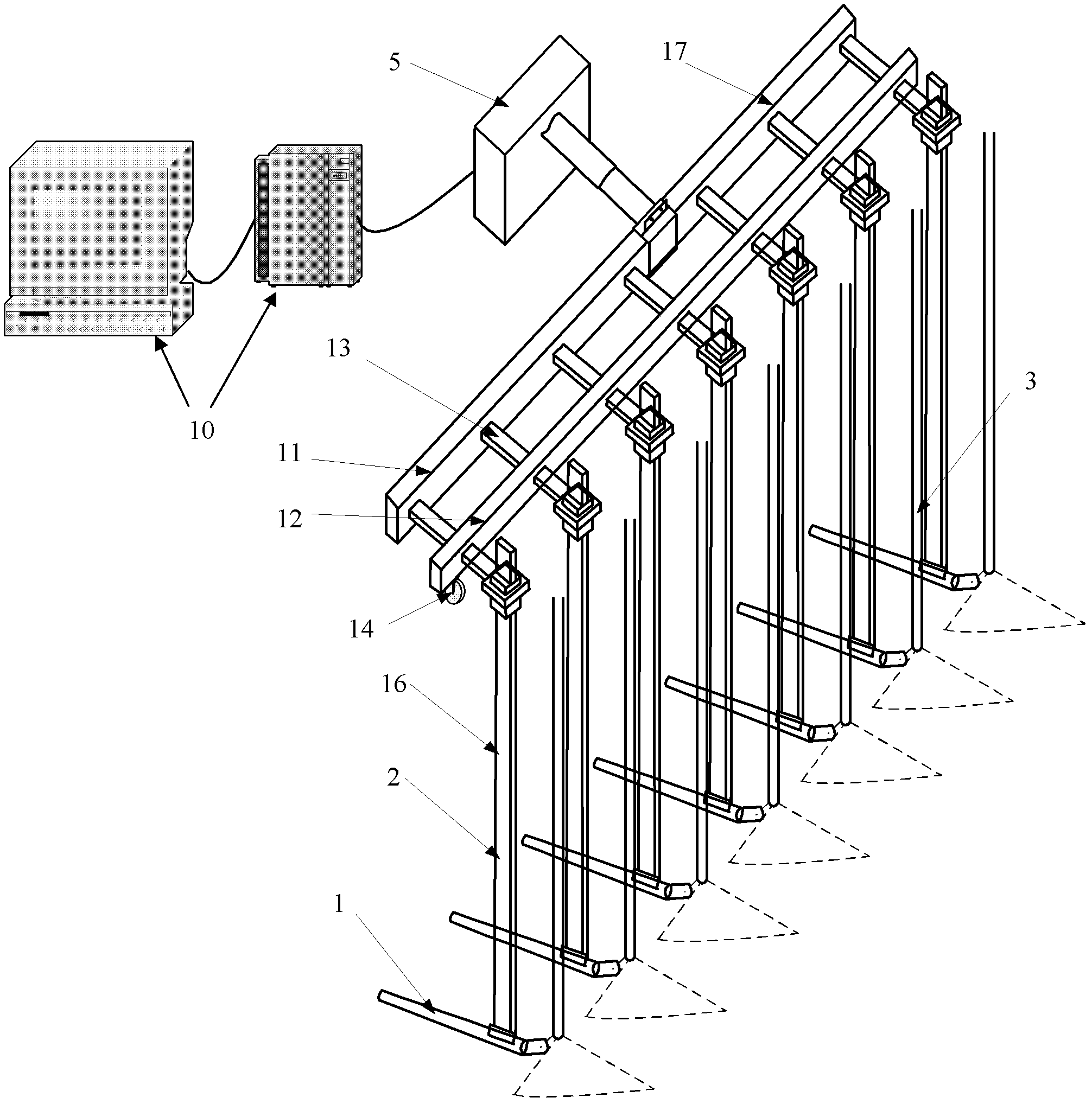

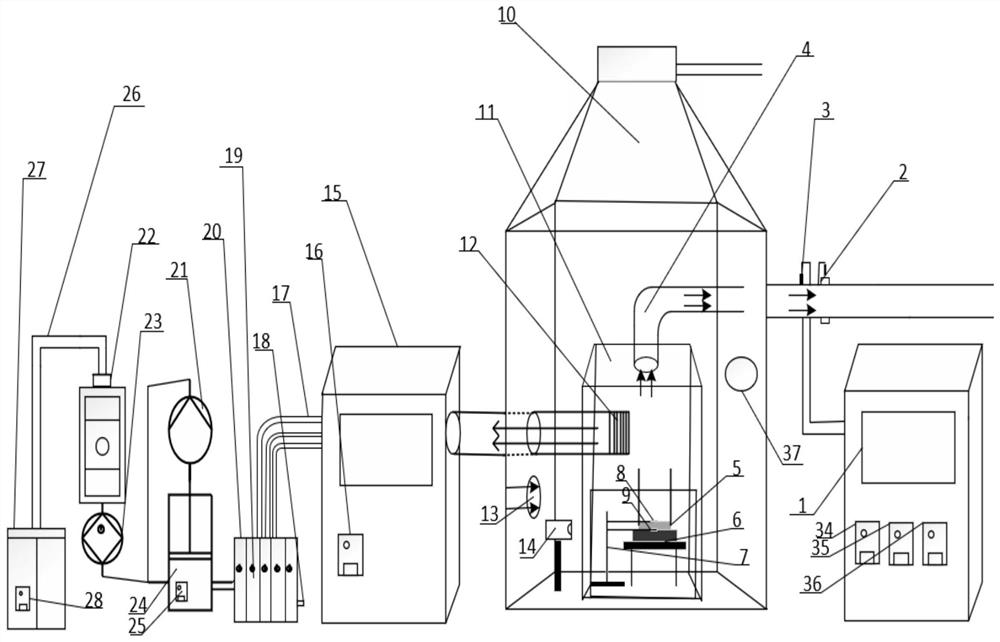

Combined thermal shock testing system and method in lasting gradient temperature field

ActiveCN106092801AAchieving Thermal ShockRapid cooling downStrength propertiesEngineeringPhase change

The invention discloses a combined thermal shock testing system and method in a lasting gradient temperature field. The testing system comprises a frame, a displacement module, a heating module, an internal cooling module, an external cooling module, and a measuring and controlling module, wherein the frame and the displacement module bear a test piece coming in and going out from the heating module and the external cooling module; the heating module provides a lasting high-temperature environment for oxidation-sintering-phase change testing; the internal cooling module and the heating module cooperate with each other to form a gradient temperature field along the thickness direction of the test piece so as to simulate actual service conditions; the external cooling module carries out rapid cooling on the test piece to complete thermal shock; and the measuring and controlling module acquires testing parameters like temperature and flow velocity and regulates and controls cooperative operation of each module. The invention provides the economic, safe and reliable combined thermal shock testing system and method in the lasting gradient temperature field, and parameters can be set to realize experiments including, but not limited to, conventional thermal cycle / shock, gradient temperature field oxidation / sintering, isothermal oxidation / sintering, etc.

Owner:XI AN JIAOTONG UNIV

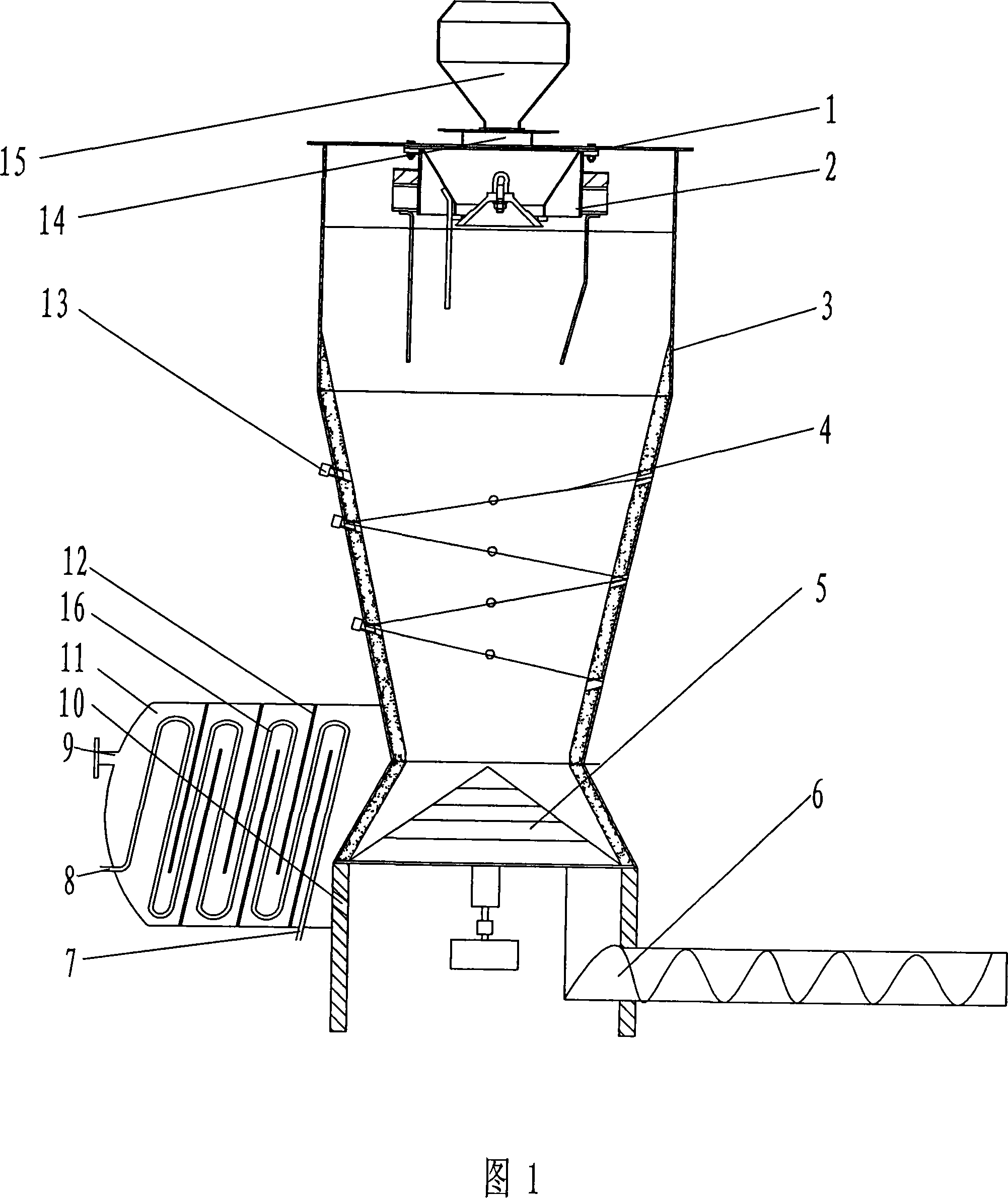

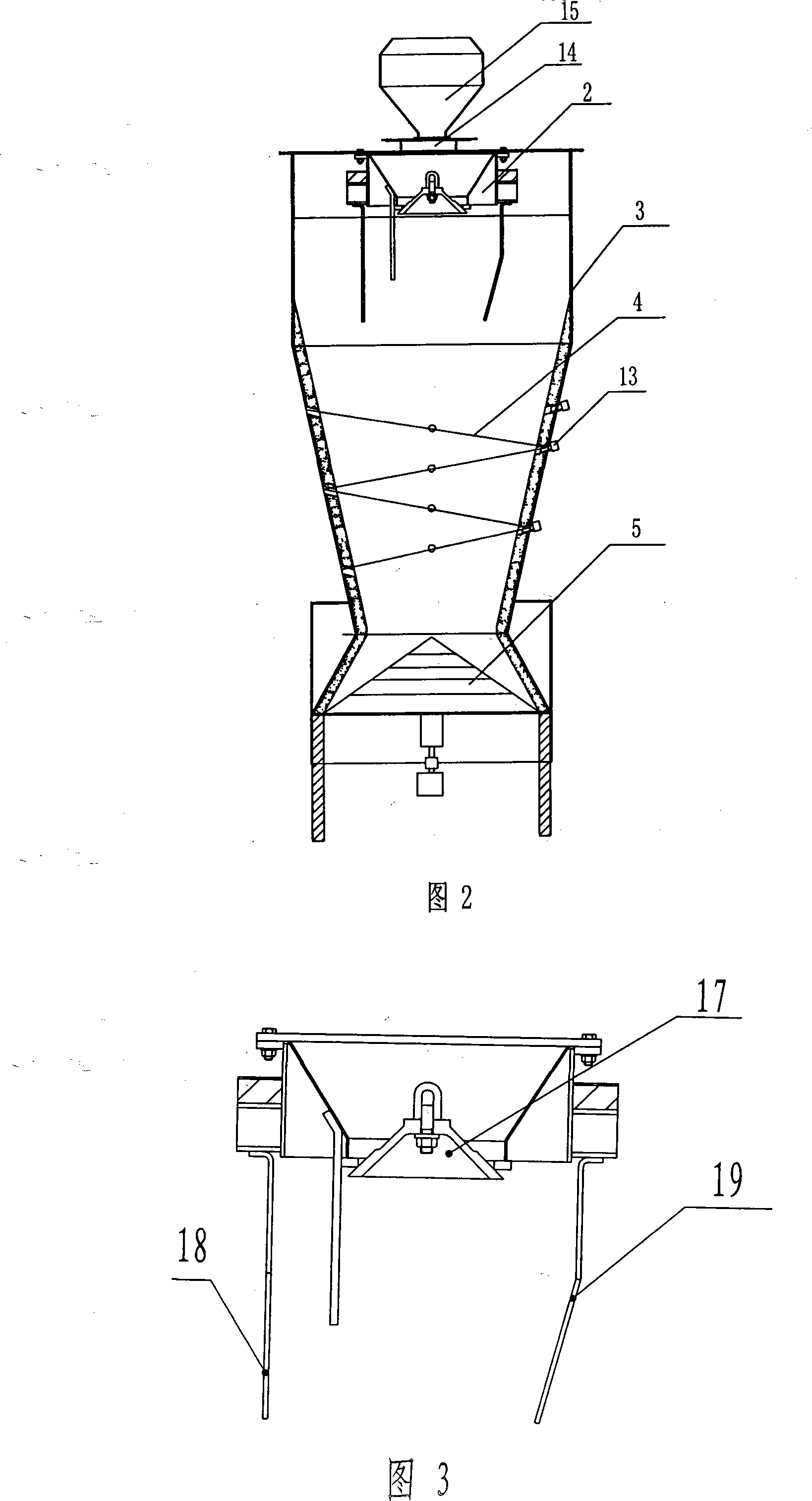

Inflammable refuse gasification gas making device preventing generation of dioxin and technique

InactiveCN101200643AAvoid build conditionsAvoid generatingSpecial form destructive distillationReaction temperatureStop time

The present invention relates to a combustible rubbish gasification gas-making device for preventing dioxin from being produced, comprising a gasifying furnace body, the upper part of which is provided with a feeding bucket; the upper part inside the furnace body is provided with a material distributor; the lower part inside the furnace body is provided with a furnace grate and an ash remover; the lateral wall of the furnace body is provide with a nozzle; the underside outside the furnace body is connected with a fuel gas inlet and a fuel gas outlet; the nozzle is tangent towards and forms an angle of 30 to 60 degrees with the furnace body downwards; the fuel gas outlet is provided with a fuel gas quencher dioxin separator. The present invention also provides a combustible rubbish gasification gas-making technology for preventing the dioxin form being produced. The present invention starts with the structure of the gasifying furnace body, the burning theory and a fuel gas quencher system to completely control the reaction temperature, prolong the fuel gas stopping time at a high temperature area and at the same time realize the rapid quencher and cooling of the fuel gas, which radically destroys the mechanism and the condition for generating the dioxin and avoids the produce of the dioxin.

Owner:SHANDONG UNIV

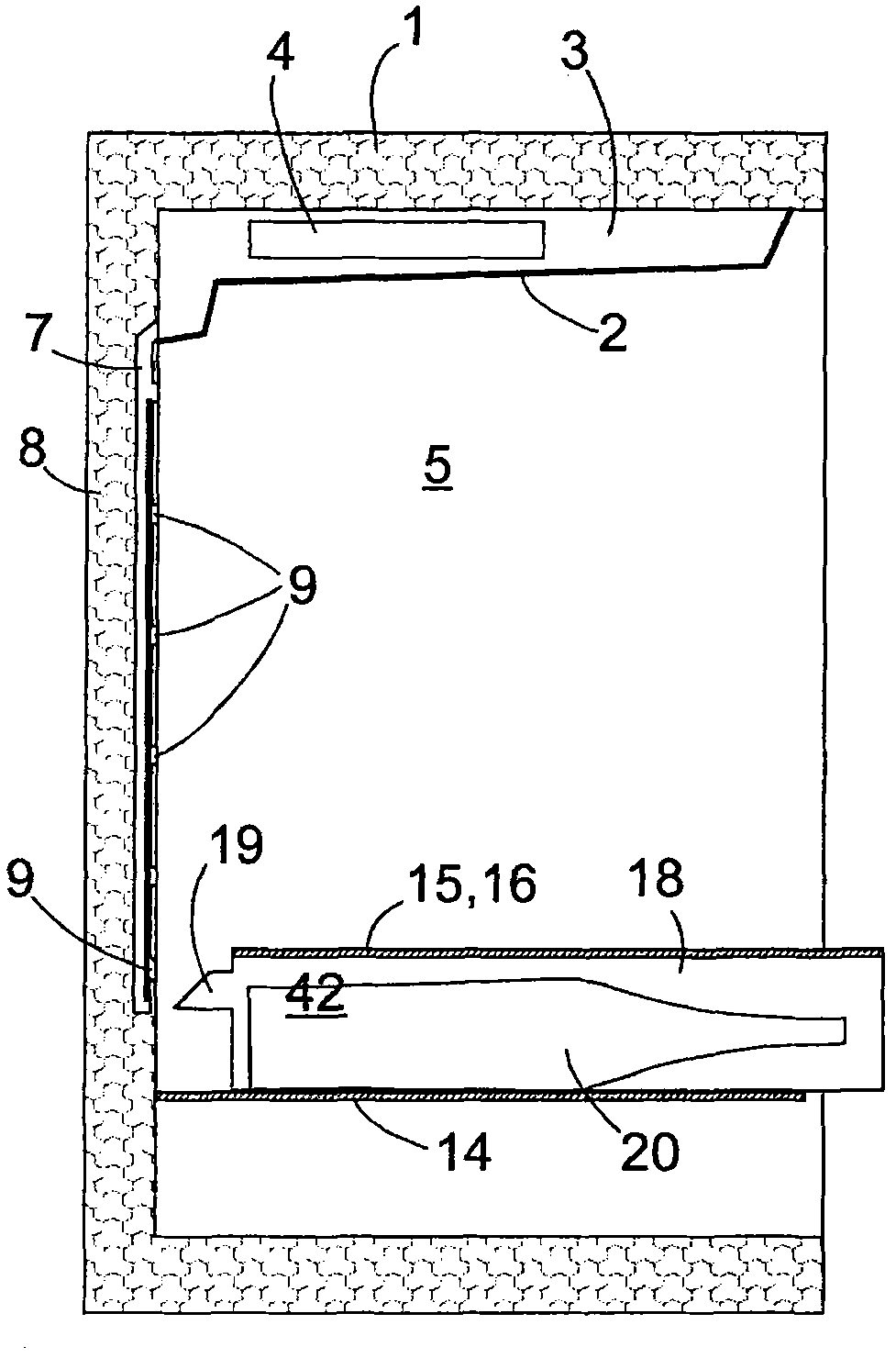

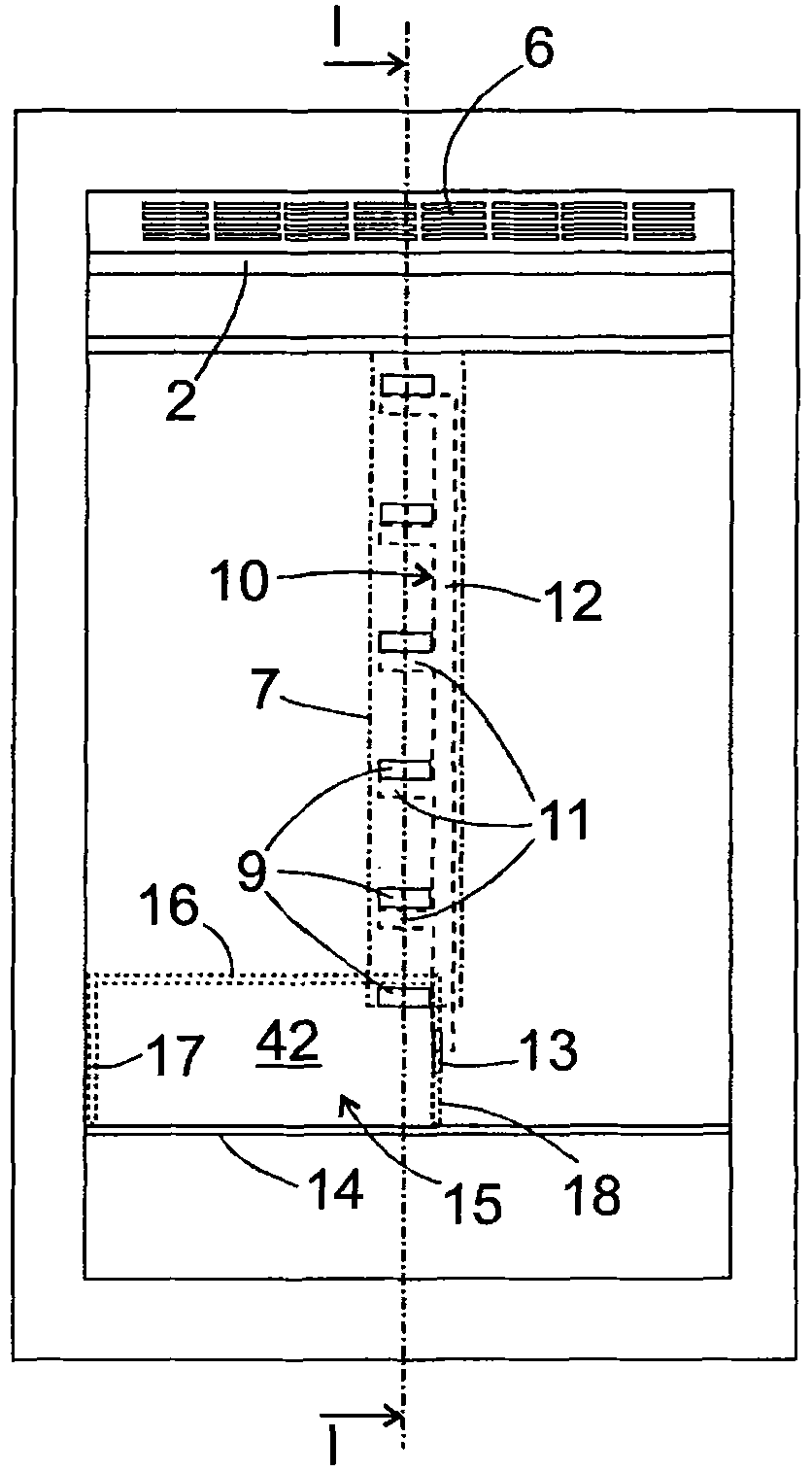

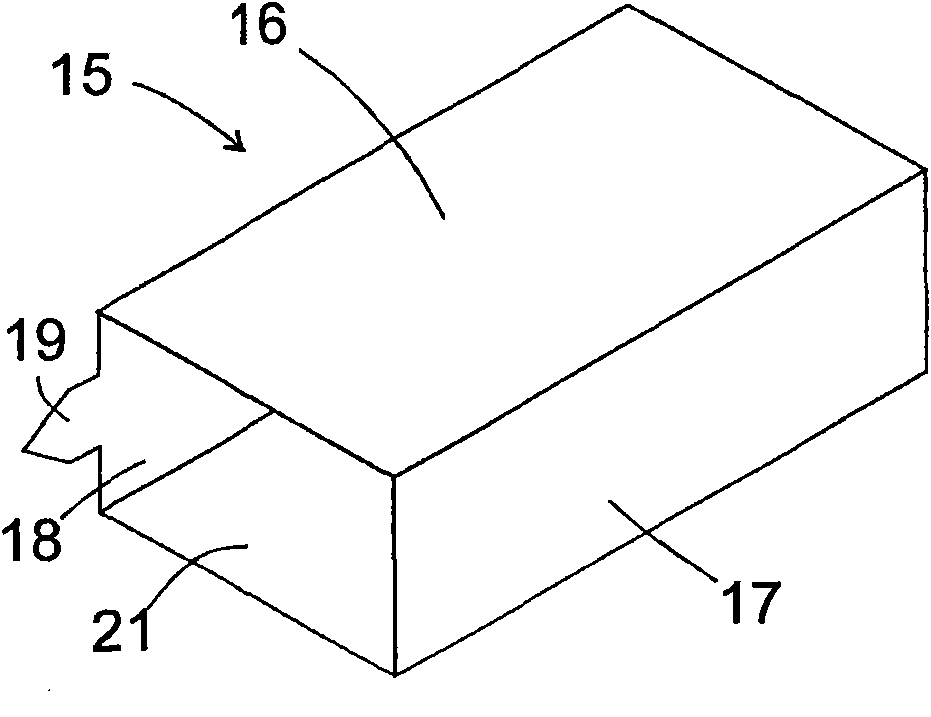

Cooling device with bottle cooling function

InactiveCN101806525AShort average staySpeed up coolingLighting and heating apparatusCooling fluid circulationEngineeringBottle

A cooling device has an evaporator (24) and a storage area (5) cooled by air flowing along an evaporator (4). A flow path of the air runs downstream from the evaporator (24) extends through a compartment (42) partitioned from the storage area (5).

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

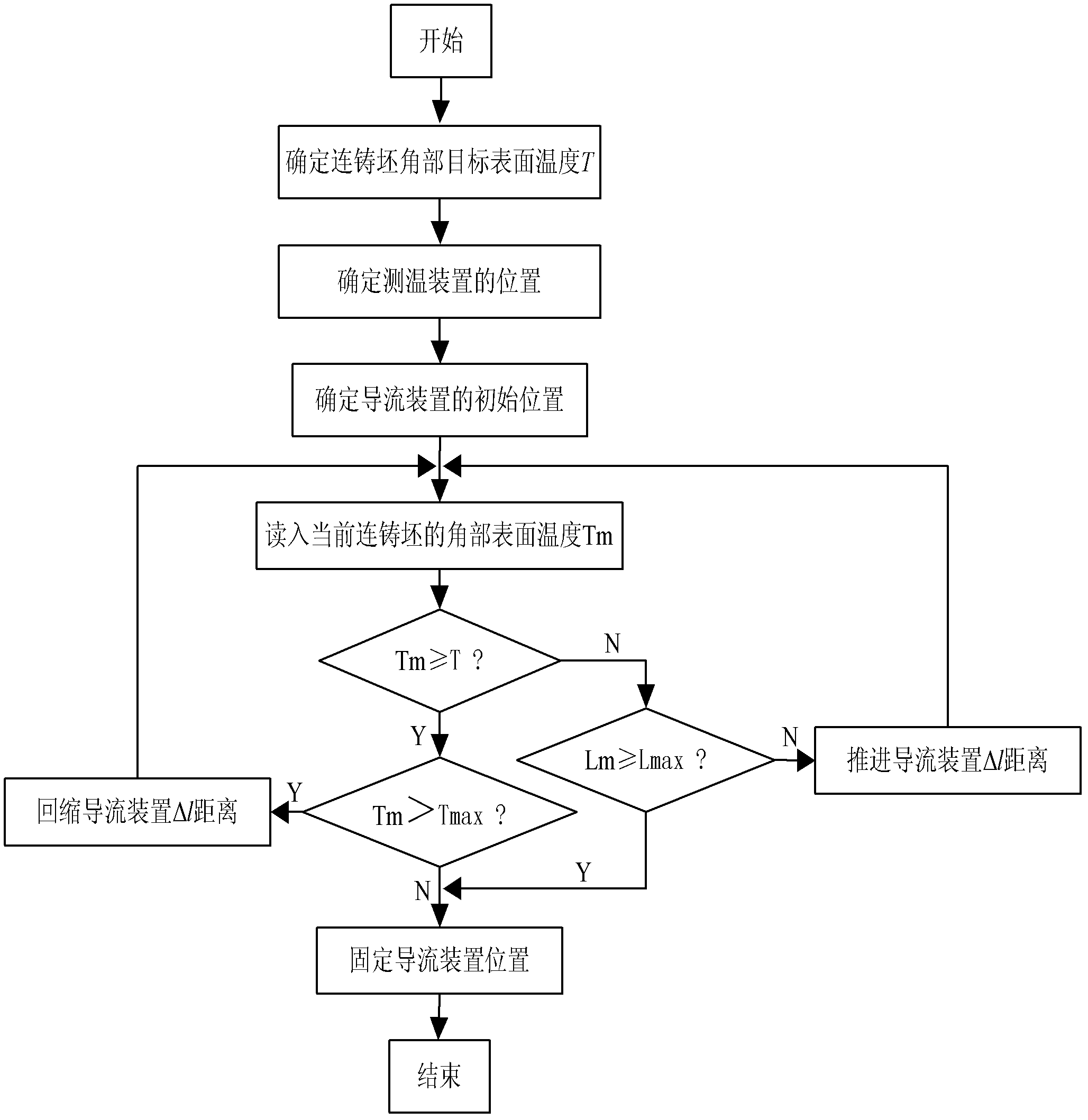

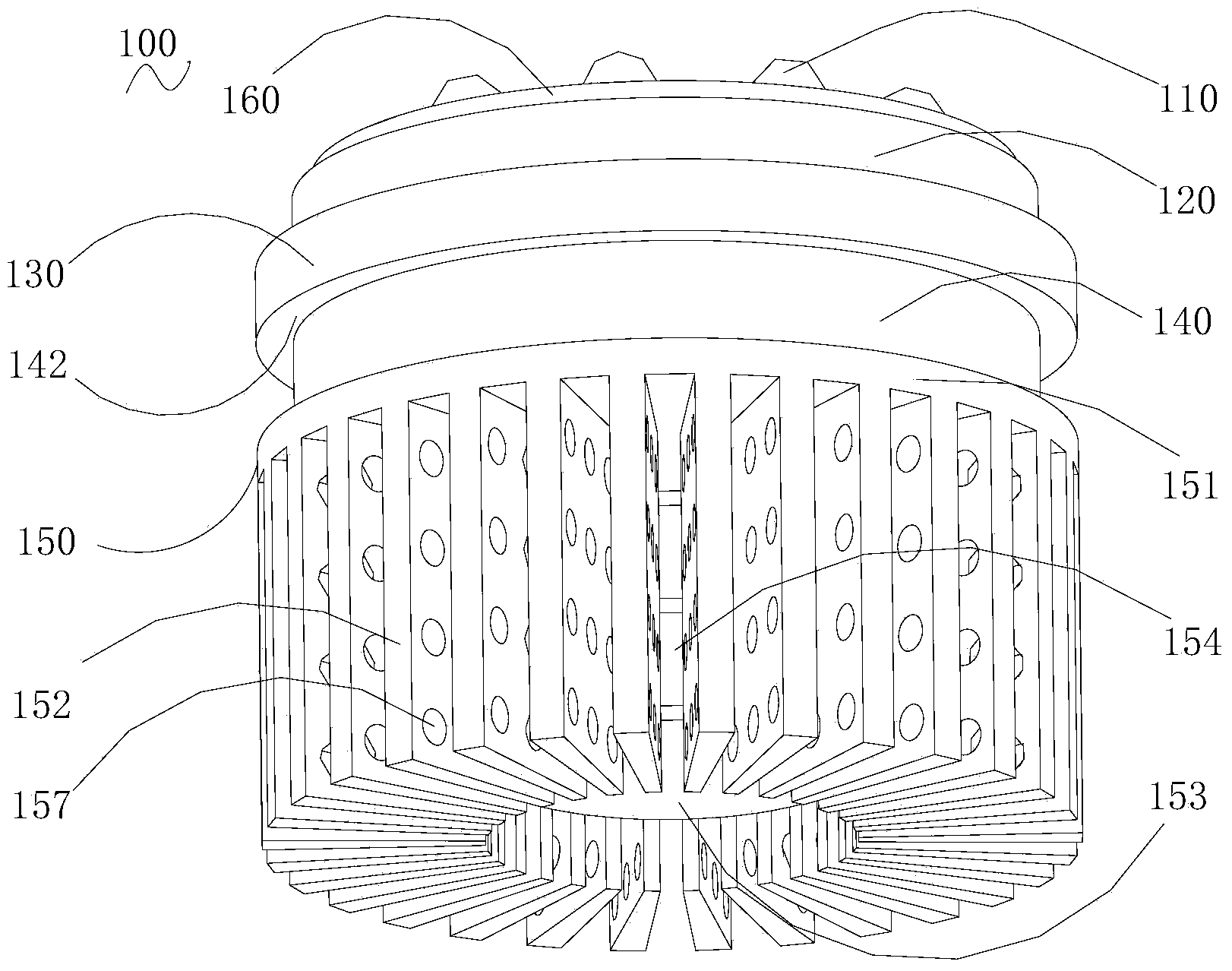

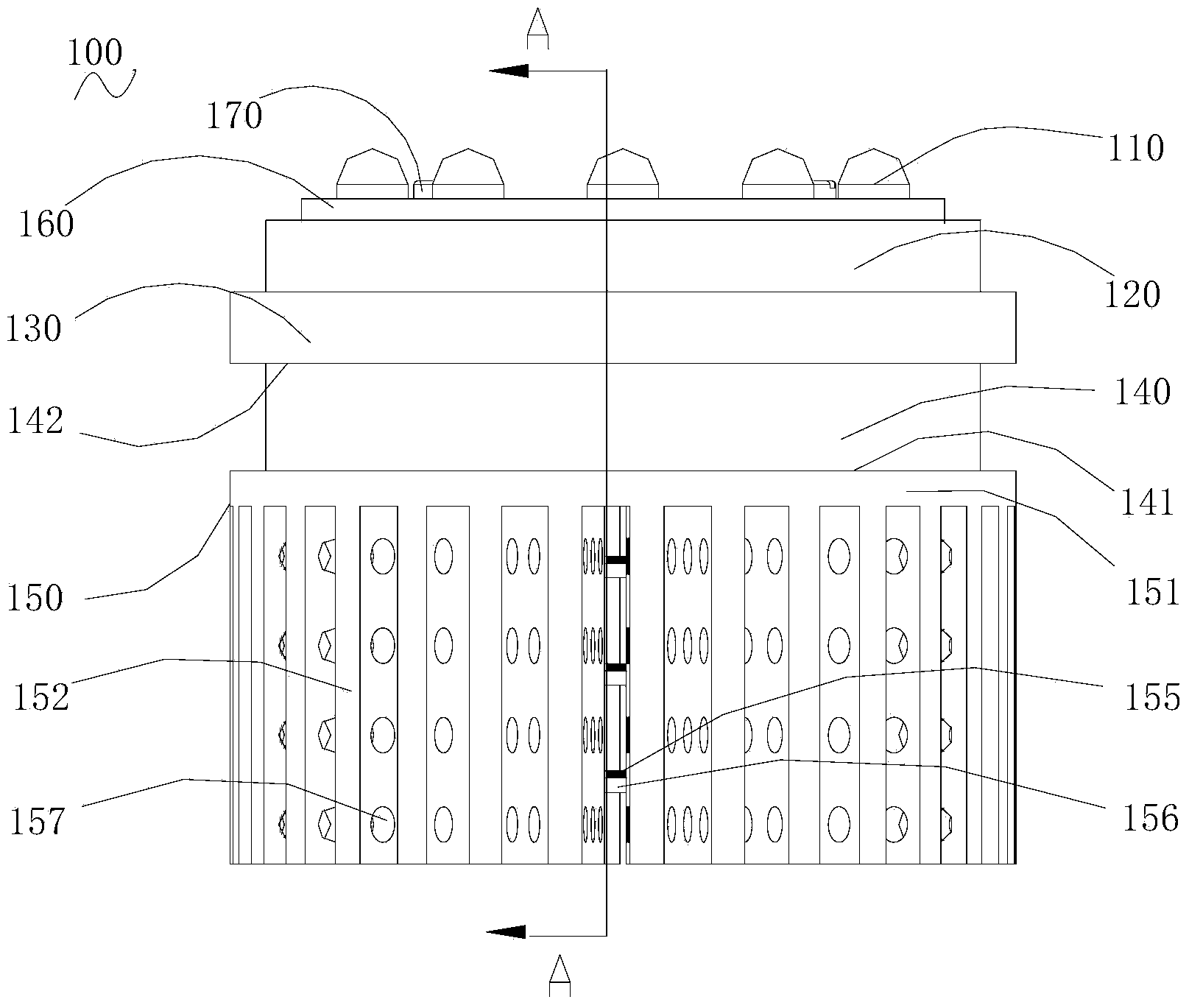

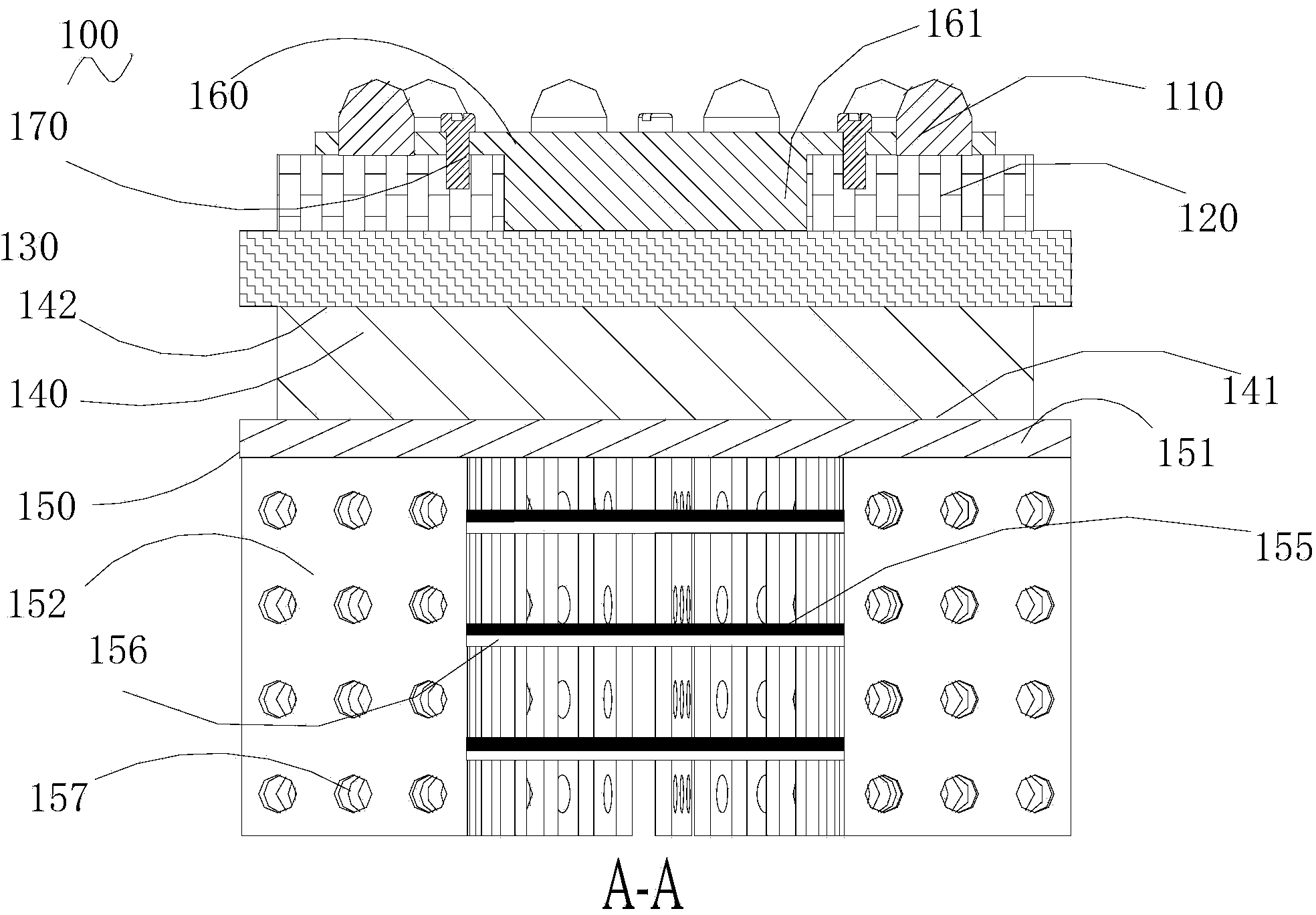

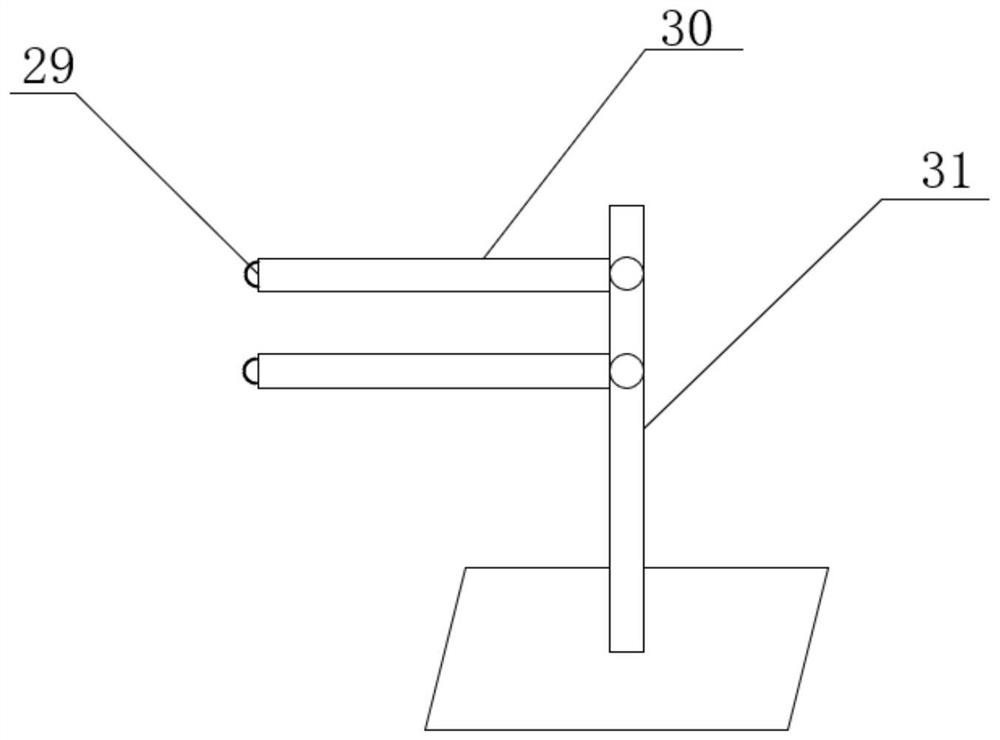

System and method for intelligently controlling temperature of internal arc angle part in straightening region of wide and thick plate blank

The invention discloses a system and a method for intelligently controlling temperature of an internal arc angle part in a straightening region of a wide and thick plate blank, and belongs to the technical field of control over continuously casting secondary cooling temperature of ferrous metallurgy. The system comprises a temperature measurement device, a flow guide device and a control system, wherein the temperature measurement device consists of a temperature measurement pipe and an infrared temperature measurement probe; the infrared temperature measurement probe is arranged at the upperend of the temperature measurement pipe; the upper end of the temperature measurement pipe is communicated with a compressed air pipeline; the top end of a supporting frame connecting rod of the flowguide device is connected with a horizontal supporting frame; the bottom end of the supporting frame connecting rod is connected with a cooling water collection flow guide pipe; the temperature measurement pipe is connected with a temperature measurement device hydraulic pusher; the horizontal supporting frame of the flow guide device is connected with a flow guide device hydraulic pusher; and the hydraulic pushers are connected with the control system. The method comprises the following steps of: taking an actual temperature measurement result on the surface of the internal arc angle part inthe straightening region of a continuously cast blank as a feedback of secondary cooling intensity; and dynamically adjusting a spraying width by adjusting the position of the flow guide device according to a difference between the actual measured temperature and the temperature of the target surface, so that an aim of precisely controlling the temperature of the internal arc angle part of the continuously cast blank entering the straightening region is fulfilled.

Owner:NORTHEASTERN UNIV

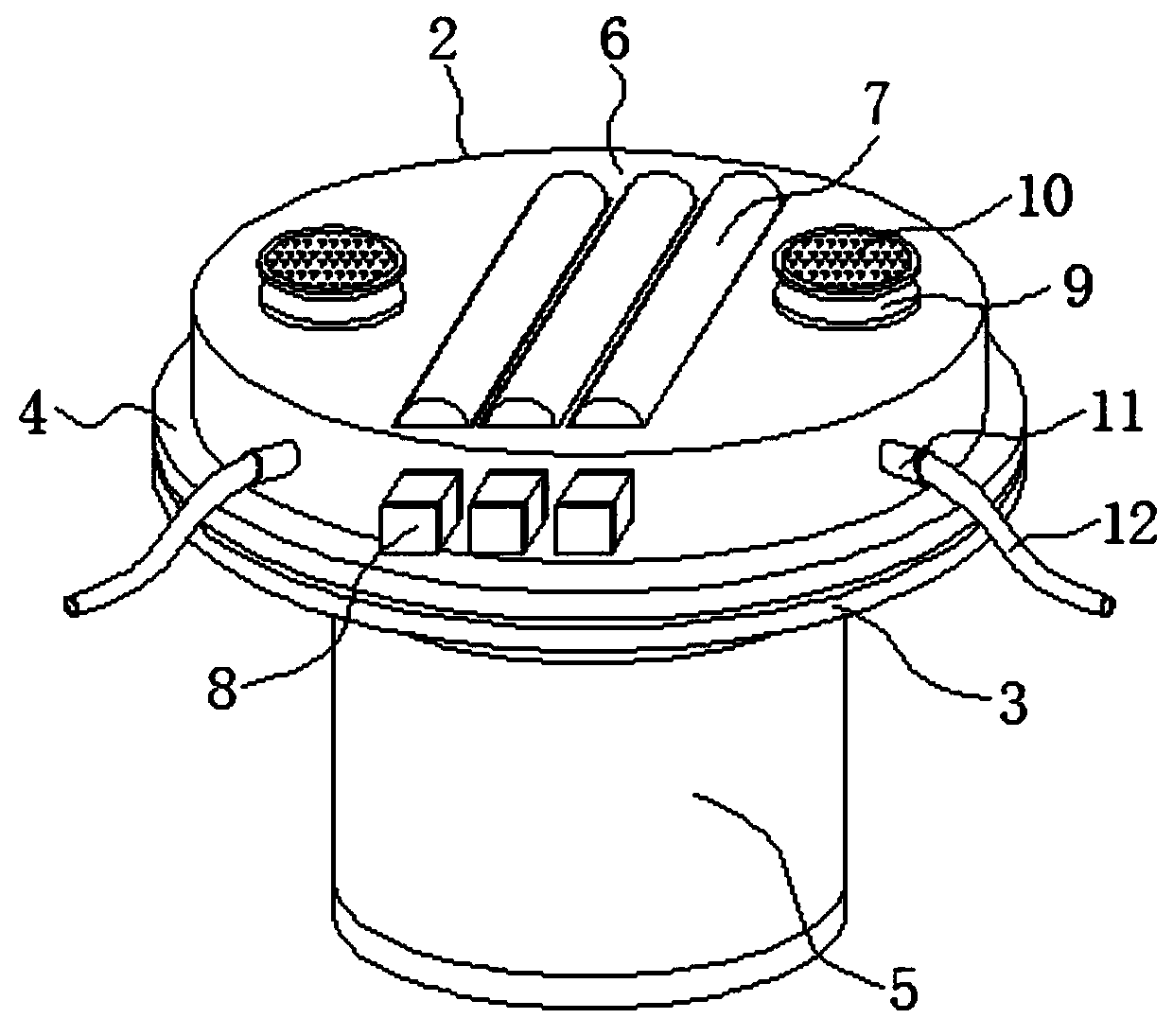

LED lamp

ActiveCN104296100AEasy to collectReduce cooling capacityPlanar light sourcesPoint-like light sourceEngineeringHeat sink

An LED lamp comprises LED luminous units, a circuit board, a heat transfer board, a semiconductor refrigerating plate, a heat sink, a heat transfer plate and a heat transfer post. The LED luminous units, the circuit board, the heat transfer board, the semiconductor refrigerating plate and the heat sink are connected in sequence; the circuit board is used for mounting of the LED luminous units; the heat transfer board is used for transferring heat; the heat transfer plate is closely mounted to one sides of the LED luminous units; the heat transfer post which is protruded is arranged in the middle of the heat transfer plate; the circuit board is provided with a via hole corresponding to the heat transfer post, and the heat transfer post penetrates the via hole to be connected with the heat transfer board. Further, the heat sink comprises a base plate and a plurality of fins mounted on the base plate; the fins on the base plate encircle to form a cavity; a gap is formed between every two adjacent fins; and the cavity is communicated with the gaps. A plurality of piezoelectric oscillator plates are parallelly arranged in the cavity along a direction perpendicular to the fins and are connected with the fins. After power on, the piezoelectric oscillator plates bound in the cavity oscillate to compress air in the cavity to exhaust high-heat air in the cavity rapidly from the gaps, so that heat is dissipated and radiating efficiency of the LED lamp is improved.

Owner:东莞市闻誉实业有限公司

Biomass particle hot-blast furnace

ActiveCN105135672AEasy to recycleIncrease the heat exchange areaAir heatersTemperature controlPlate heat exchanger

The invention relates to a biomass particle hot-blast furnace which comprises a furnace body, wherein the furnace body is sequentially provided with a fire box, a flue connecting pipe, a sieve-plate heat exchange plate, heat-conducting plates and a furnace shell from inside to outside; and the lower part of the fire box is provided with a hearth; the outer wall of the hearth is a sieve-plate structure; the upper part of a furnace chamber formed by the heat-conducting plates is provided with a heat air inlet; an air inlet plate is arranged below the heat air inlet; and an outlet of the flue connecting pipe is connected with a deduster. The biomass particle hot-blast furnace has the advantages of high efficiency, environment friendliness, low carbon, low consumption, time saving, labor saving, low cost, long service life, high temperature control precision and high heat recovery rate (up to 80%), and can save the coal amount by 30% and save the firewood amount by 40%.

Owner:湖南万有能源科技股份有限公司

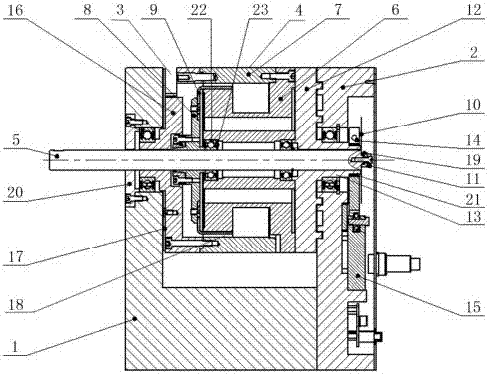

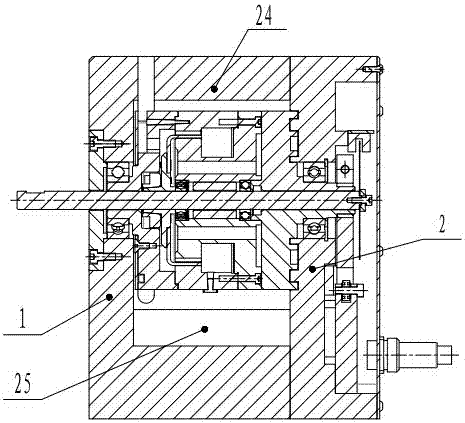

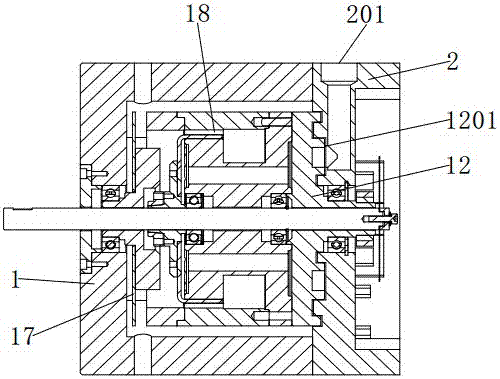

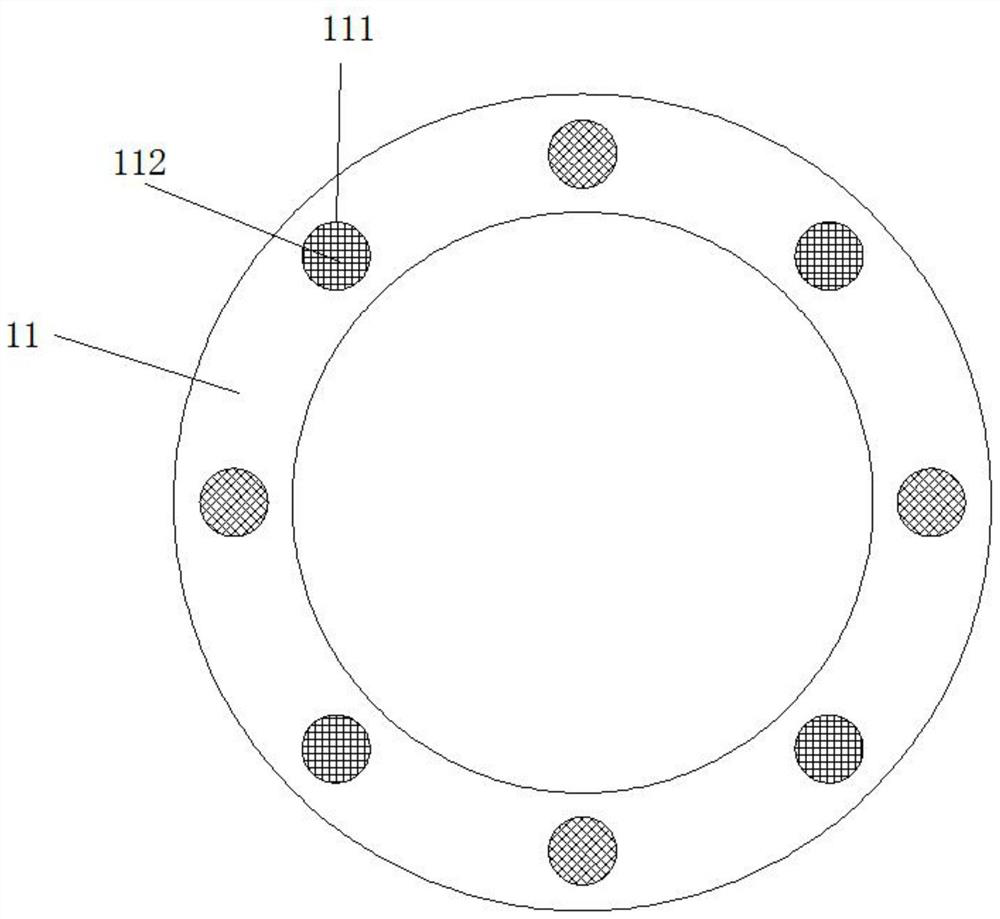

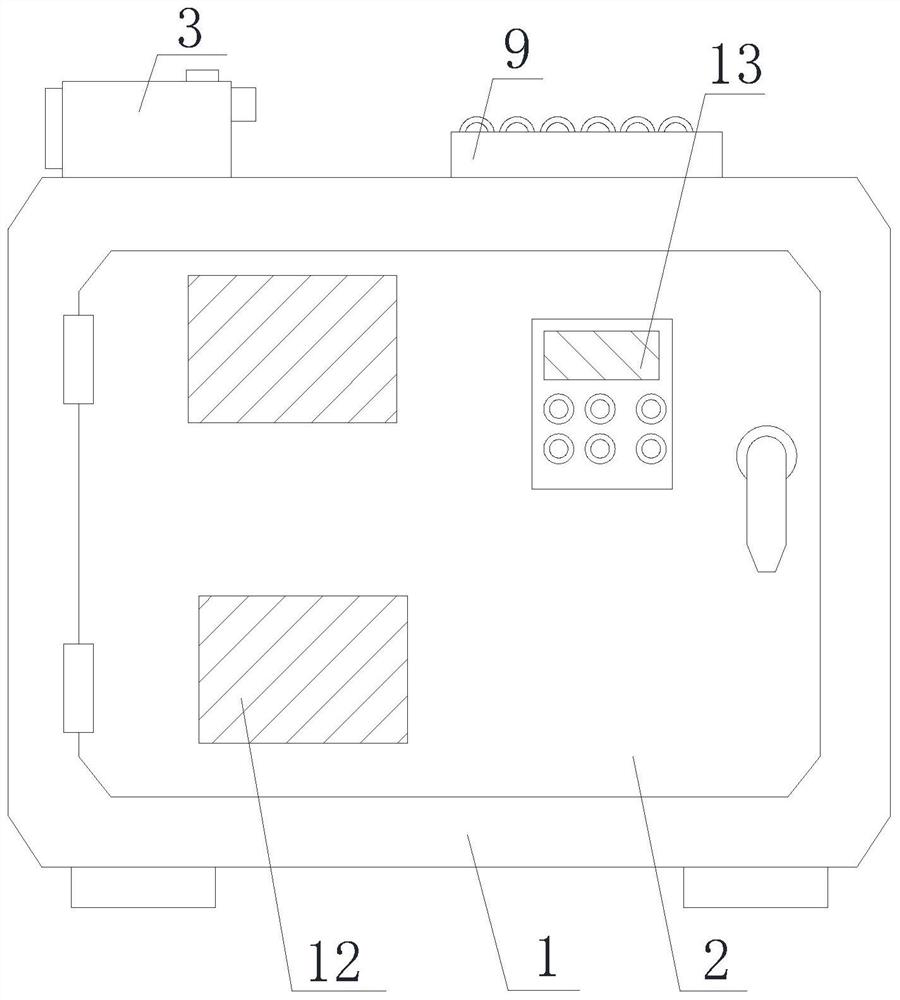

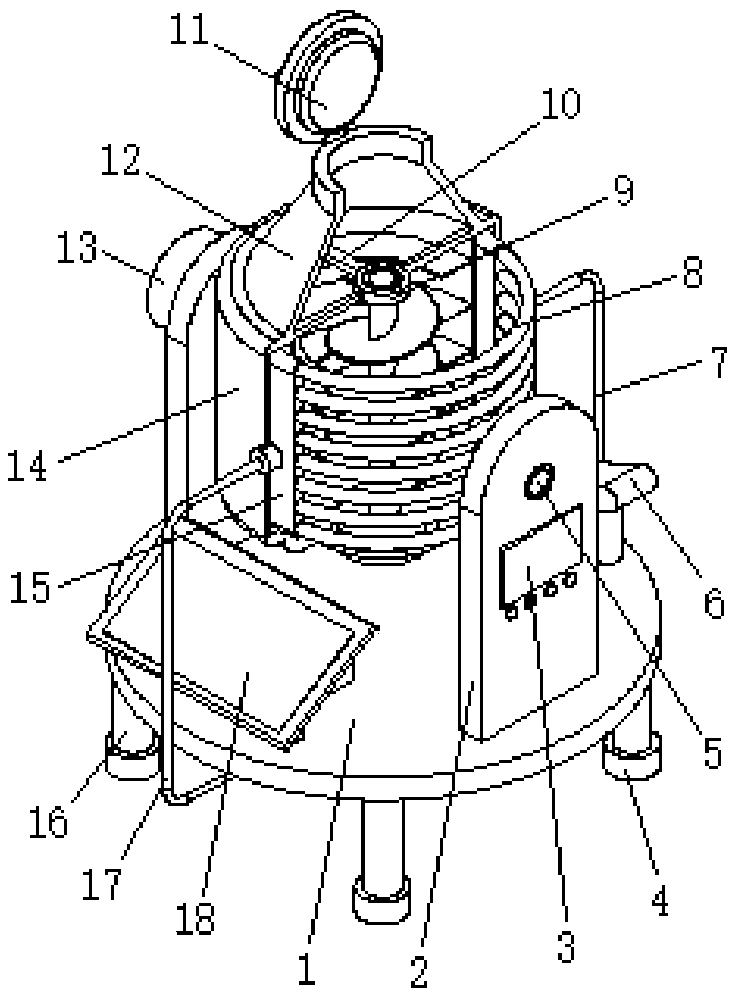

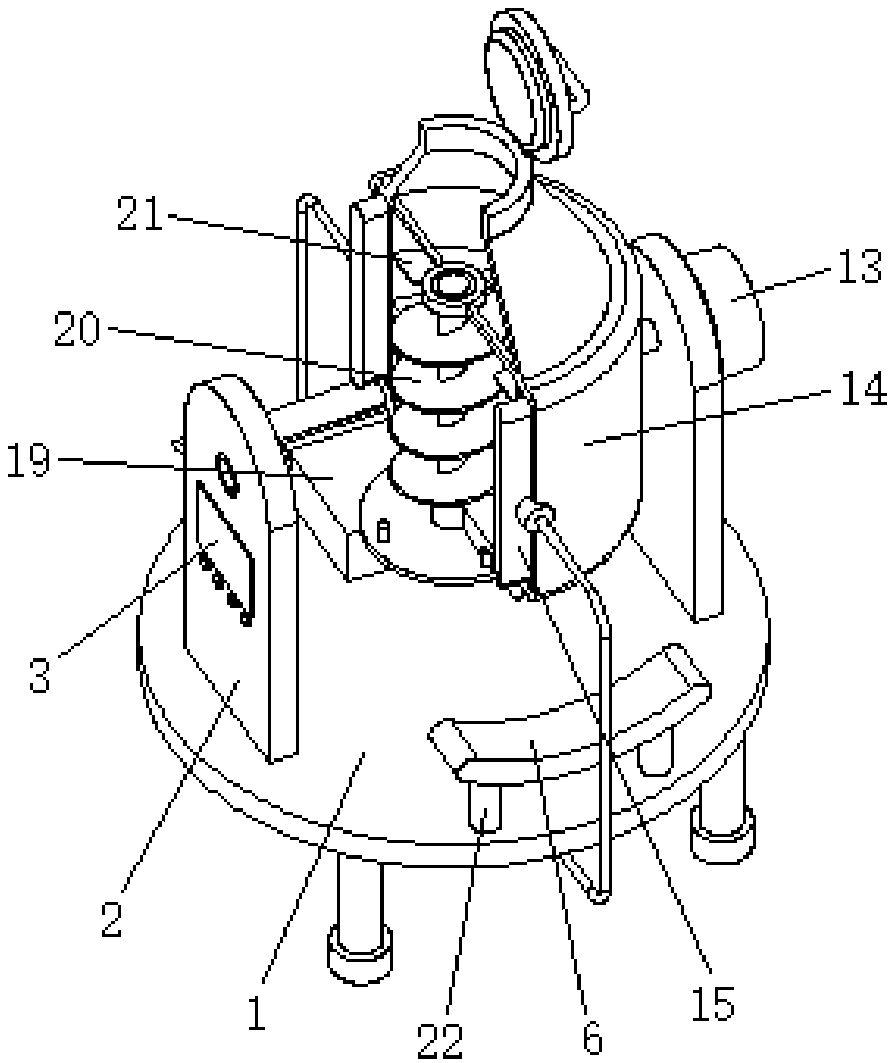

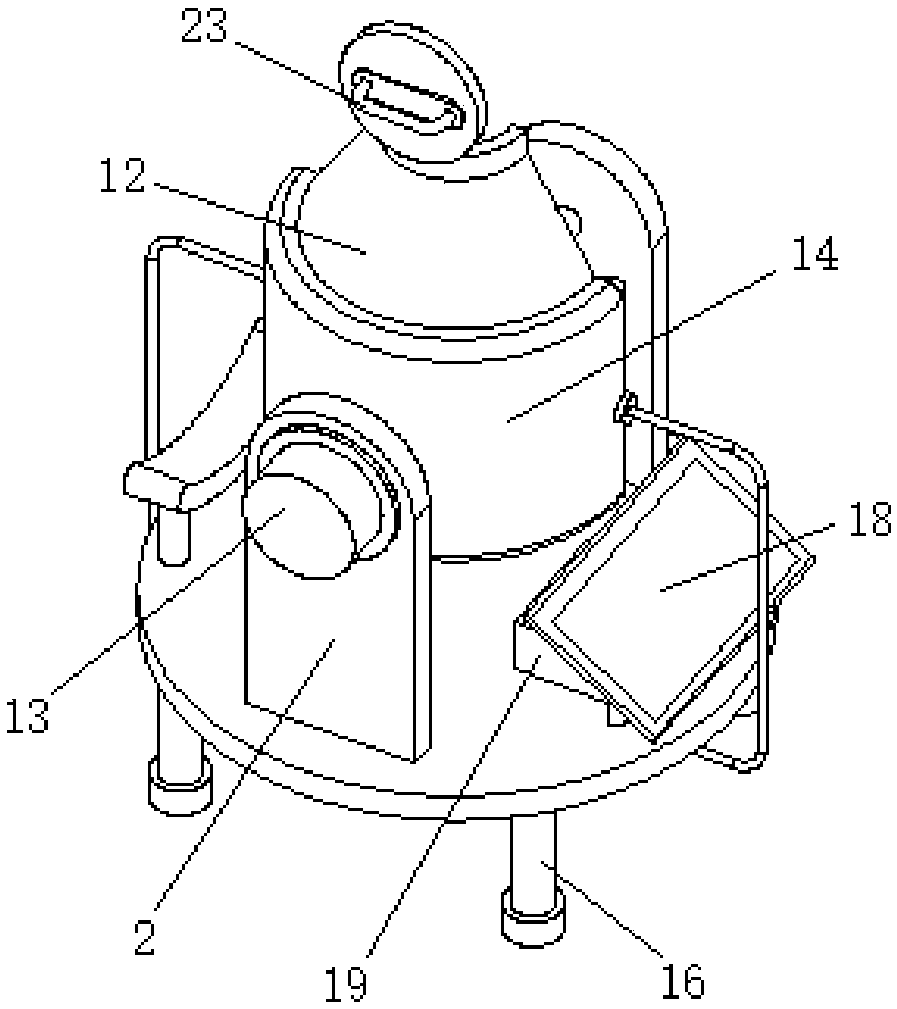

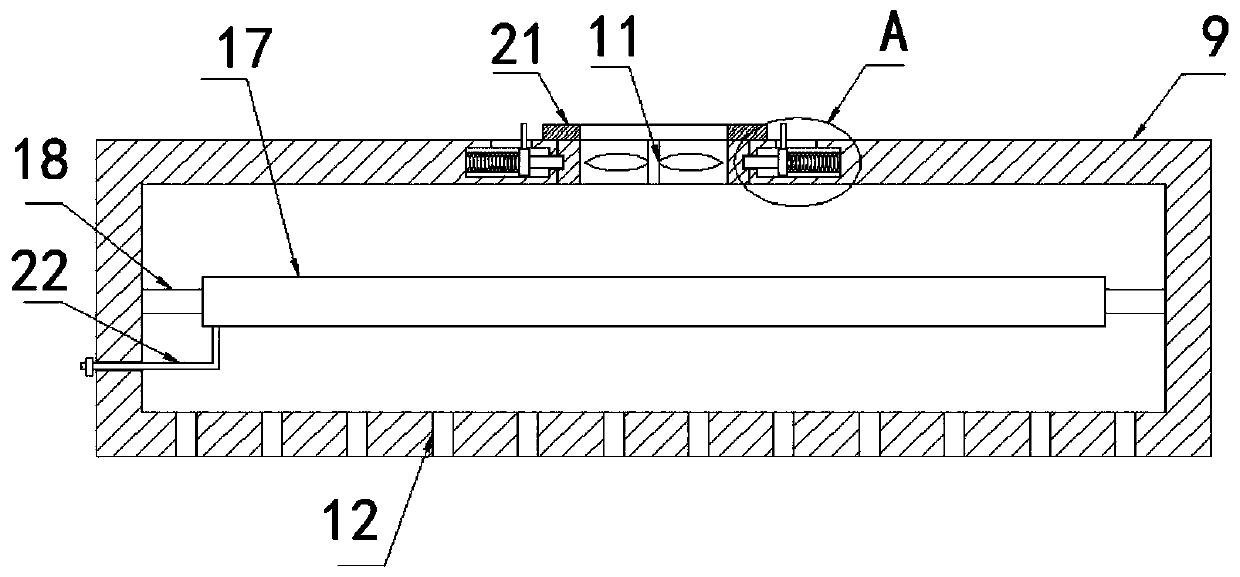

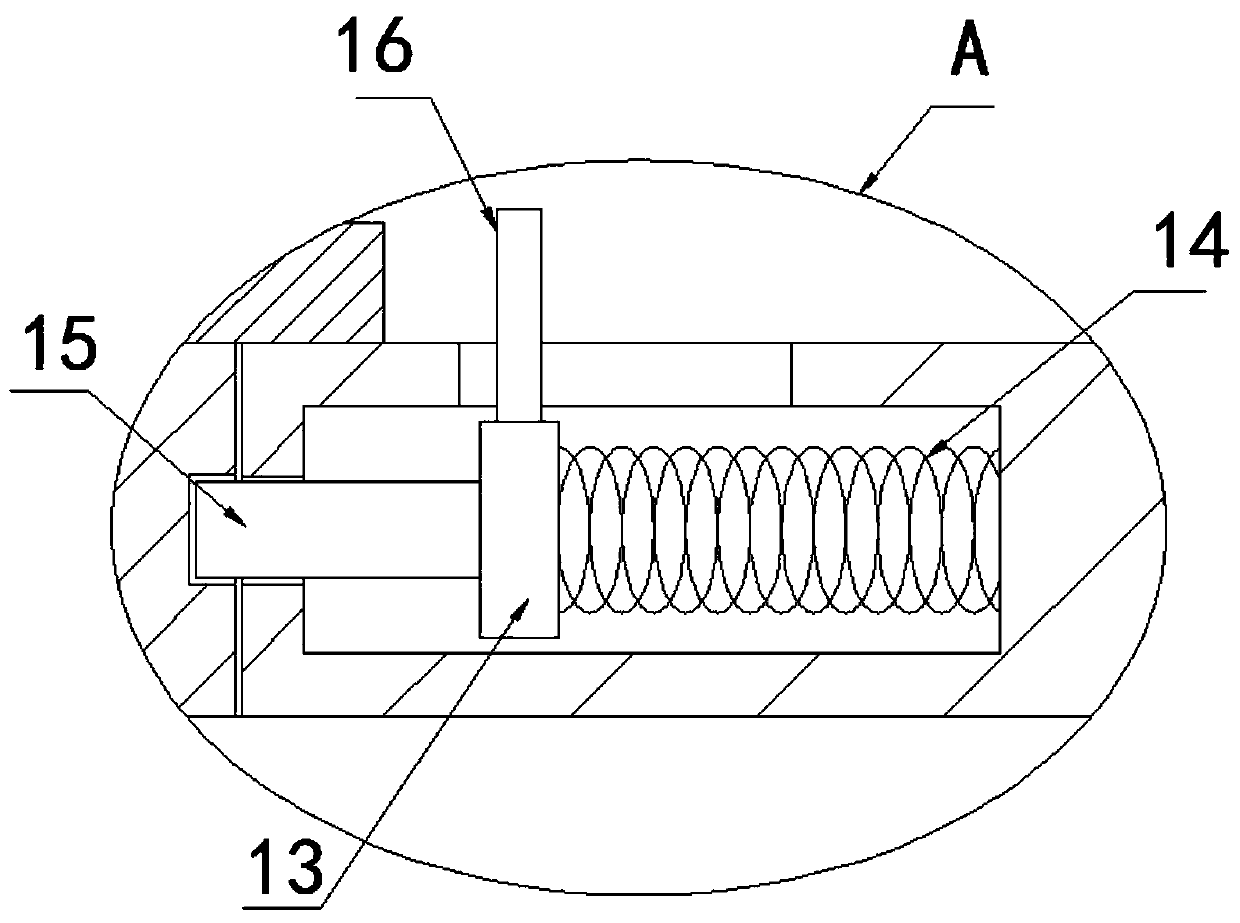

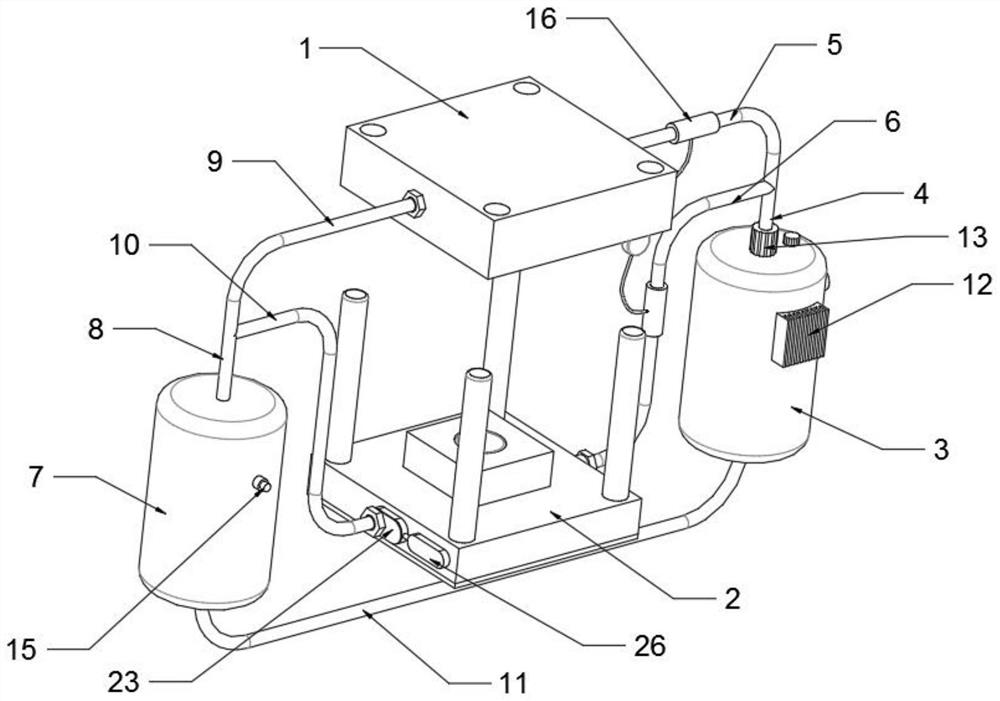

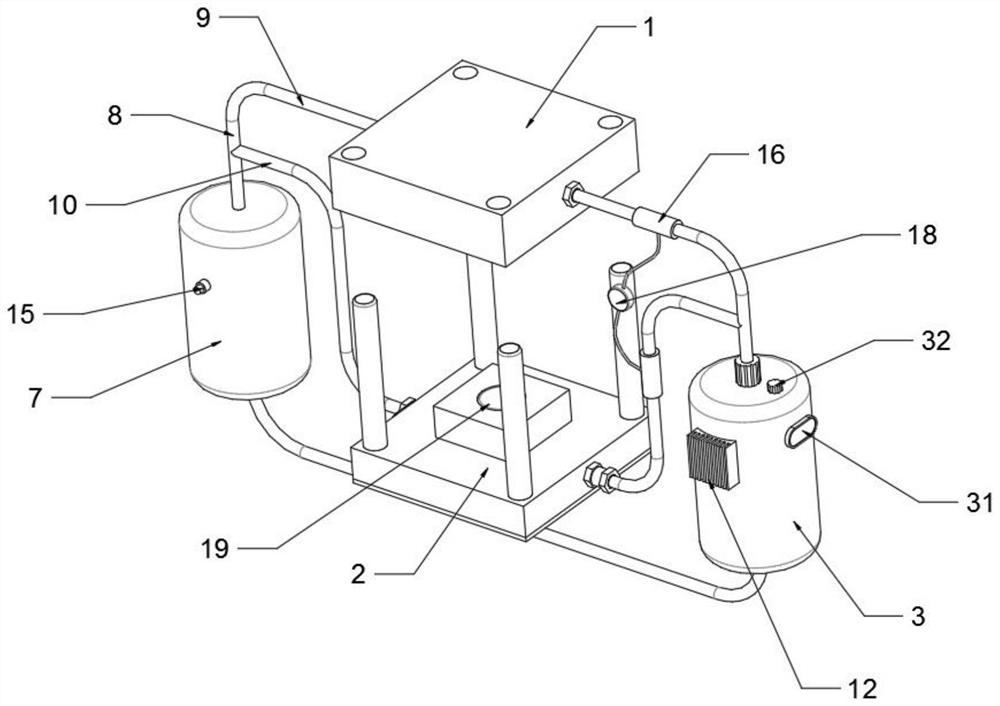

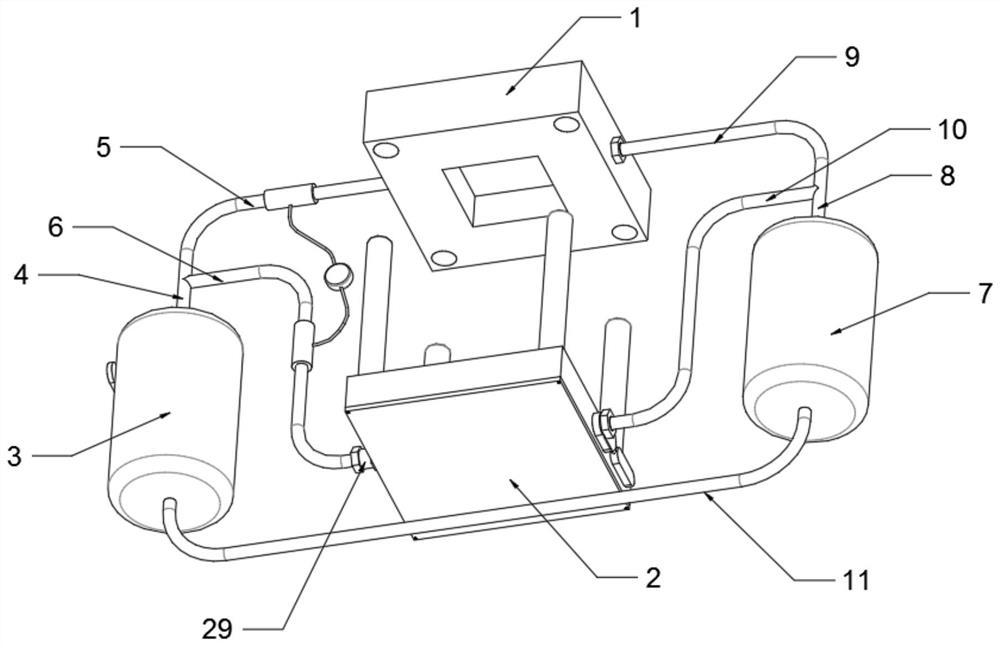

Novel dynamometer

ActiveCN107192483ARapid cooling downEliminate the effects of measurement accuracyWork measurementTorque measurementCooling effectDynamometer

The invention discloses a novel dynamometer. The novel dynamometer comprises a front vertical plate, the rear side of which is provided with a rear vertical plate matched with the front vertical plate. The front vertical plate and the rear vertical plate are localized by positioning pins, and are connected together. An opening is formed between the front vertical plate and the rear vertical plate, and a brake is erected on the opening. The brake is erected between the front vertical plate and the rear vertical plate by a rotating shaft. The brake comprises a rotor disposed on the outer part of the rotating shaft in a sleeved way, and a stator matched with the rotor is disposed on the outer part of the rotor in a sleeved way. The front end of the rotor is fixedly provided with a rotor end cover. The rotor end cover is connected with a rotor cup, and the rotor cup is disposed on the outer part of the rotor. One end of the rotating shaft is extended out of the front vertical plate in a penetrating way, and the other end is disposed in the rear vertical plate. The end of the rotating shaft disposed in the rear vertical plate is connected with a code disc. The novel dynamometer is advantageous in that heat dissipation performance is better, and operation is more stable; during the operation of the dynamometer, hot air is led to the outside the first time, and a rapid cooling effect is achieved, and therefore the stable and normal operation of the dynamometer is guaranteed.

Owner:台州市光中电器制造有限公司

Energy-saving casting system

The invention discloses an energy-saving casting system. The energy-saving casting system comprises a casting material cleaning device and a casting mold, wherein the casting material cleaning devicecomprises a cleaning shell, the lower part of the cleaning shell is divided into a rust removal liquid storage room and a waste liquid storage room by a fixed baffle, a blocking net is arranged abovethe waste liquid storage room, the blocking net is fixedly connected with an output shaft of a turning motor, the turning motor is fixedly connected with the side wall of the cleaning shell, the spaceabove the blocking net is a rust removal room, a rust removal liquid nozzle is fixed at the upper end of the rust removal room, a hot air drying room is arranged at the right side of the rust removalroom, a hot air nozzle is fixed at the upper end of the hot air drying room, the rust removal room is separated from the hot air drying room by a plate of a slide valve, and the slide valve is fixedon the side wall of the cleaning shell; the rust removal liquid nozzle communicates with the outlet of a delivery pump, an inlet pipe of the delivery pump communicates with the bottom of the rust removal liquid storage room, the bottom of the hot air drying room communicates with a plurality of exhaust gas nozzles by a middle pipe, and a check valve is arranged on the middle pipe.

Owner:徐双伟

Environment-friendly casting mold capable of recovering waste heat

InactiveCN111618244AEasy to useImprove cooling effectGas treatmentDispersed particle filtrationThermodynamicsProcess engineering

The invention discloses an environment-friendly casting mold capable of recovering waste heat. The environment-friendly casting mold comprises a lower mold base, wherein connecting plates are symmetrically and fixedly connected to the top end of the lower mold base; an upper mold base is fixedly connected to the top ends of the connecting plates; an injection molding pipe is fixedly connected to the center of the top end of the upper mold base; a heating cylinder is fixedly connected to the top end of the injection molding pipe; cooling and waste heat circulating mechanisms are symmetrically and fixedly connected to the outer end of the heating cylinder; and a waste gas purification and waste heat recovery mechanism is fixedly connected to the top end of the heating cylinder. The environment-friendly casting mold is scientific and reasonable in mechanism and safe and convenient to use; the cooling and waste heat circulating mechanisms are arranged, and water in a water tank is used forexchanging heat with a solution in the mold, so that the heat dissipation effect of the solution is improved, the solution can be rapidly cooled, the material forming efficiency is improved, and theproduction efficiency is improved; and meanwhile, the water subjected to heat exchange is fed into a heating chamber through a water outlet pipe, and materials in the heating cylinder are preheated through the heating chamber.

Owner:徐双伟

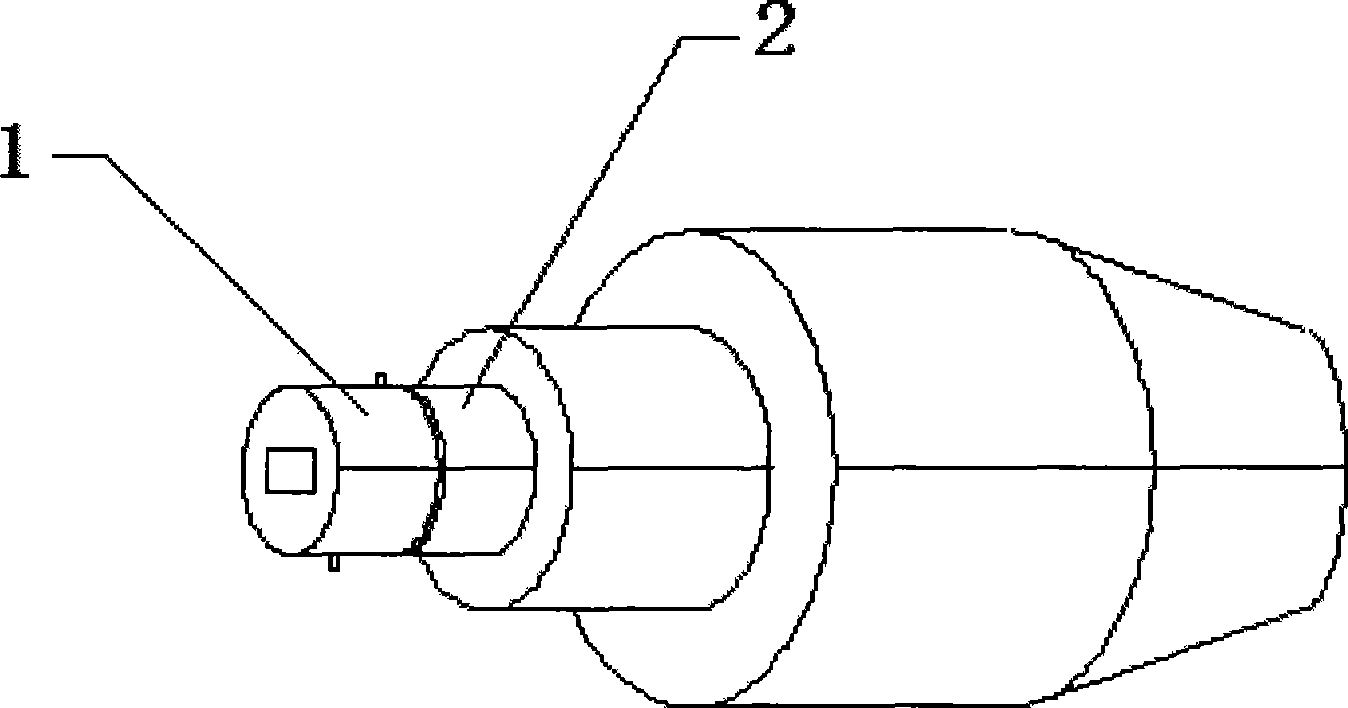

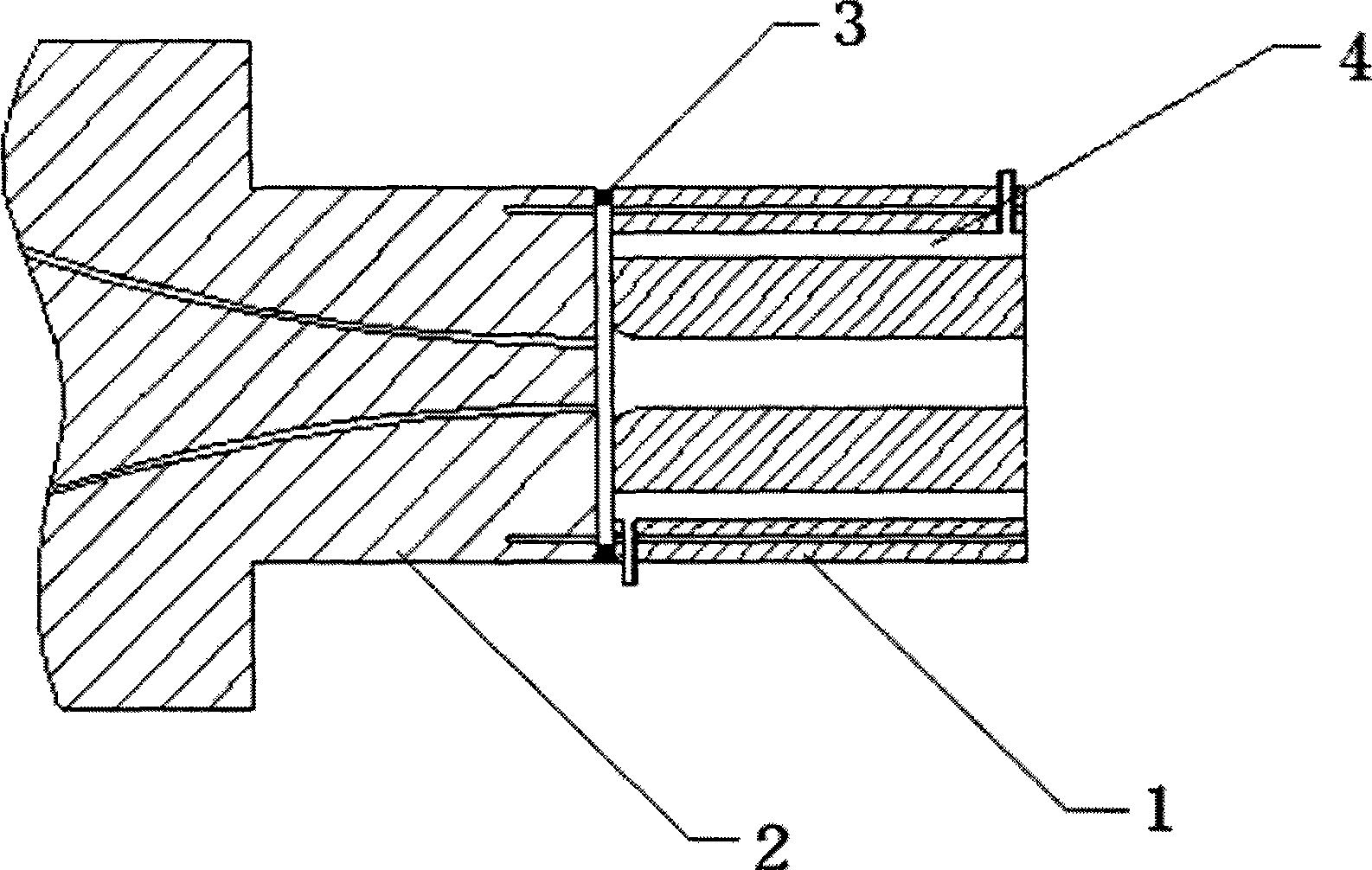

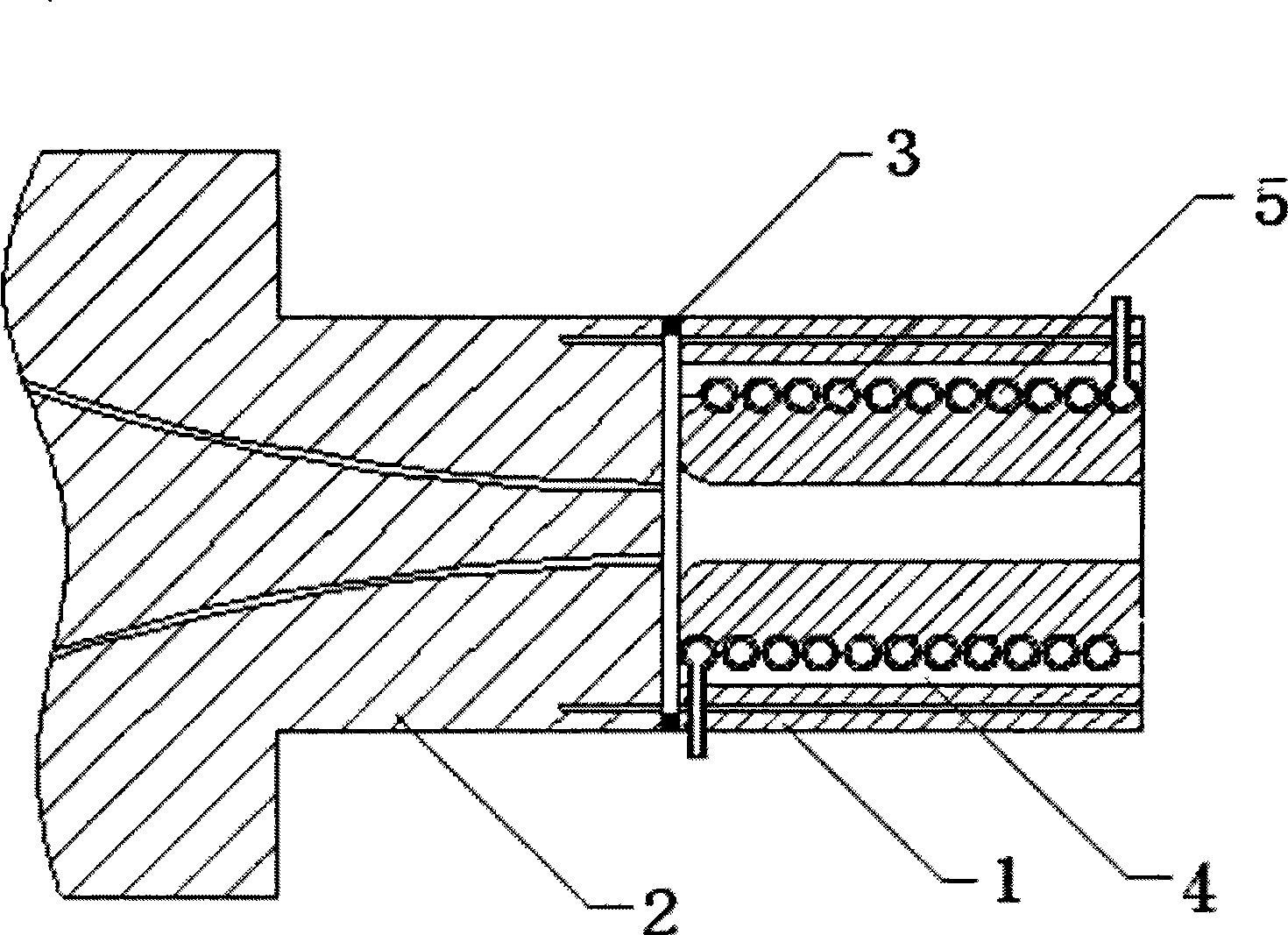

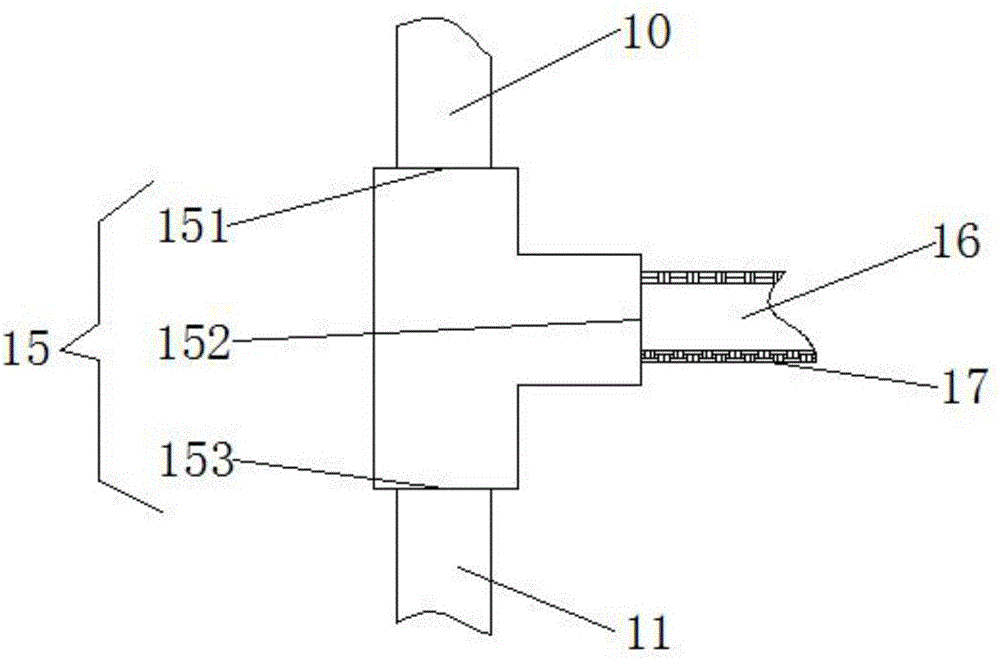

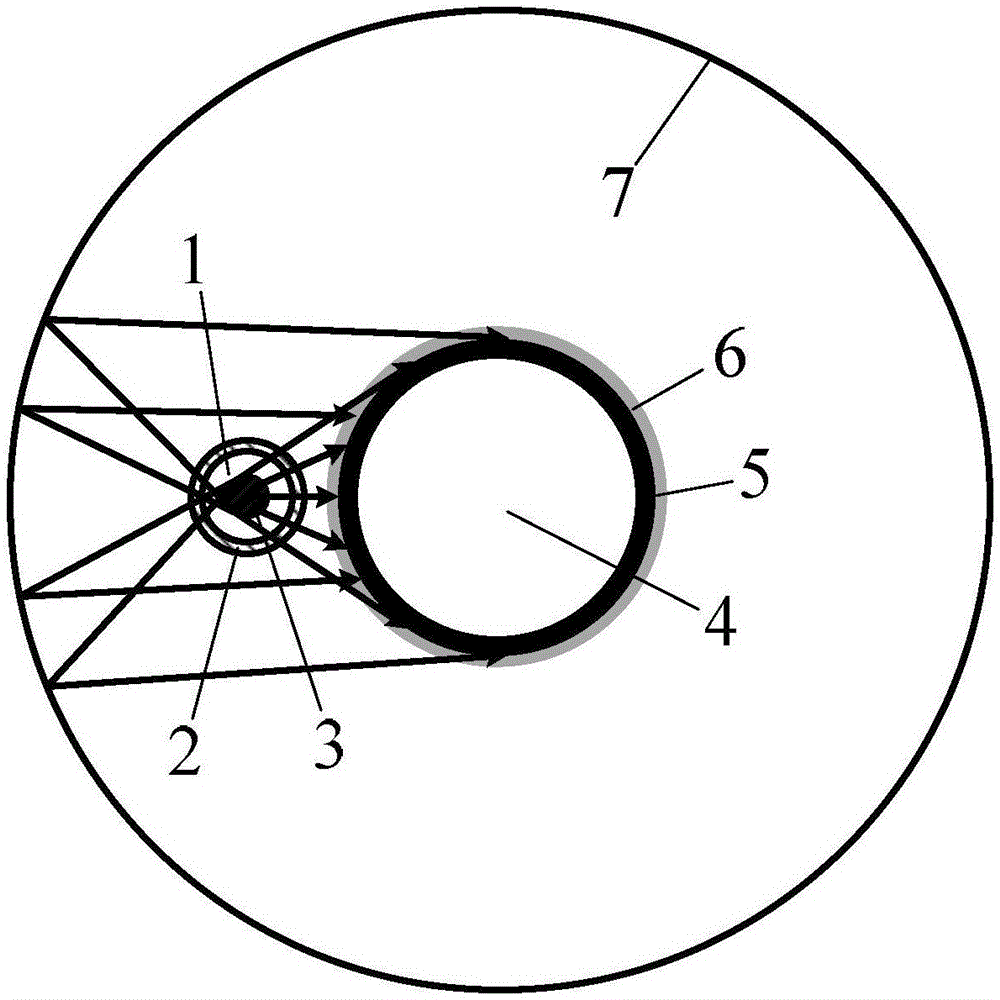

Extrusion cooling method of pipe production line

InactiveCN101444955ARapid cooling downAvoid the problem of many waste and defective products due to molding fluctuationsTubular articlesProduction lineEngineering

The invention discloses an extrusion cooling method of a pipe production line, comprising the following steps: a die of an extrusion die of an extruder is provided with a ring-shaped cooling device; the middle passage of the cooling device is communicated with the extrusion die; the circular wall of the cooling device is provided with a refrigerant passage; the products extruded out of the extrusion die can be quickly cooled by the refrigerant. The extrusion cooling method avoids the problem of lots of waste and defective products due to forming fluctuation of products under the high temperature condition, ensures that the production is carried out stably and continuously without changing the process or affecting the performance of the product, and improves the yield. The appearance and the internal dimension of the cooling device used for the cooling method are consistent with the appearance and the internal dimension of the die; furthermore, the appearance is designed as round, square, or rectangle, and the like, thereby being applicable to dies of various specifications.

Owner:GUANGDONG LIANSU TECH INDAL

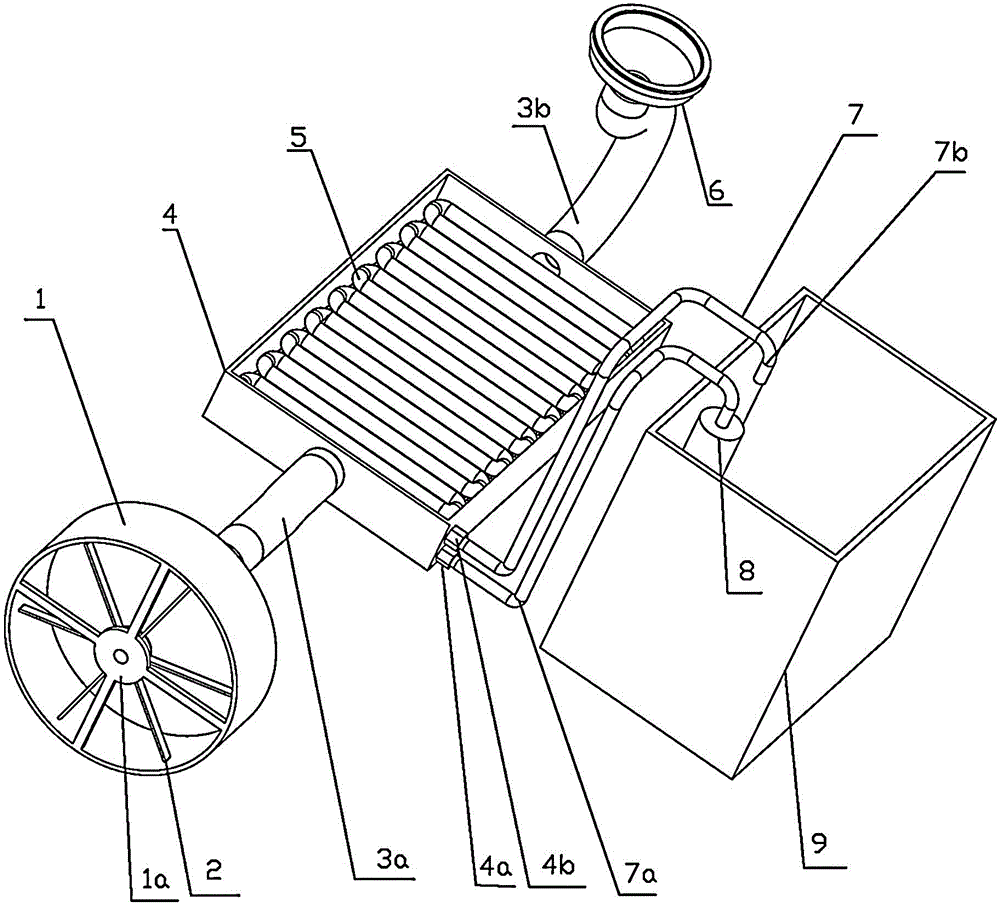

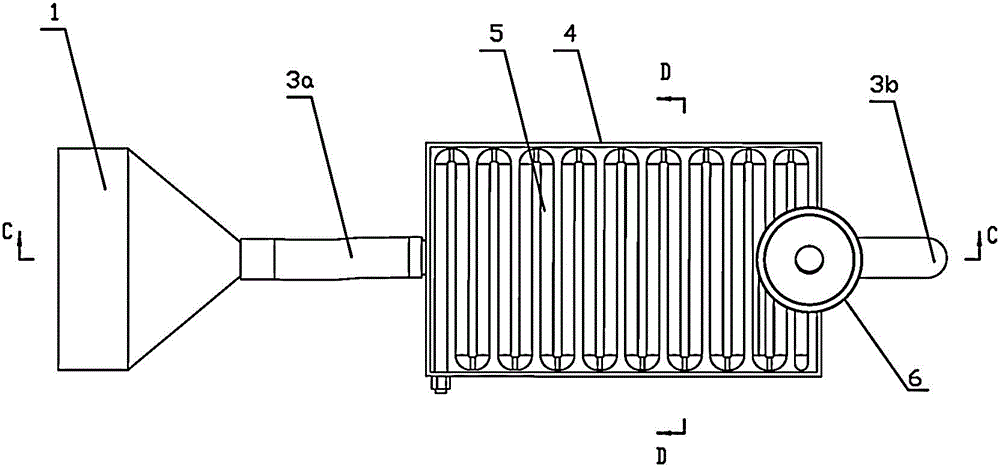

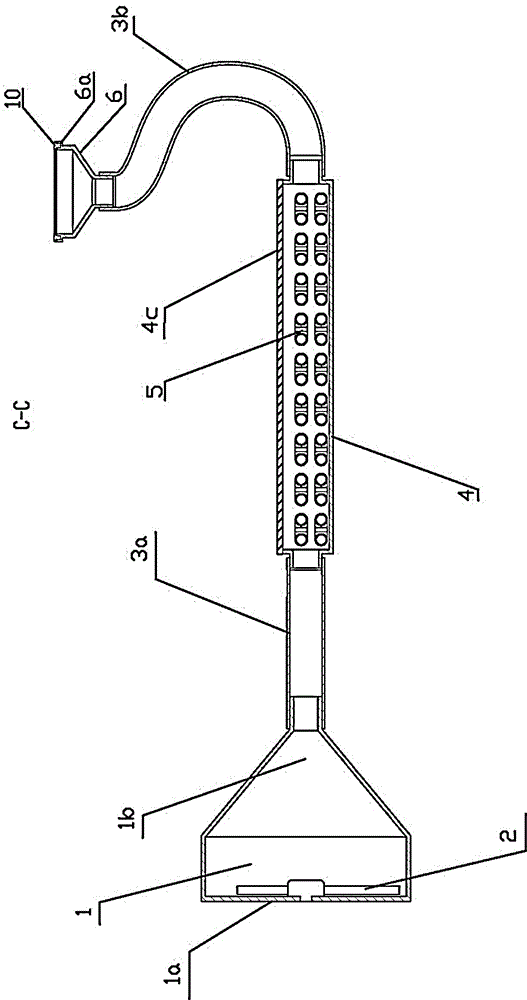

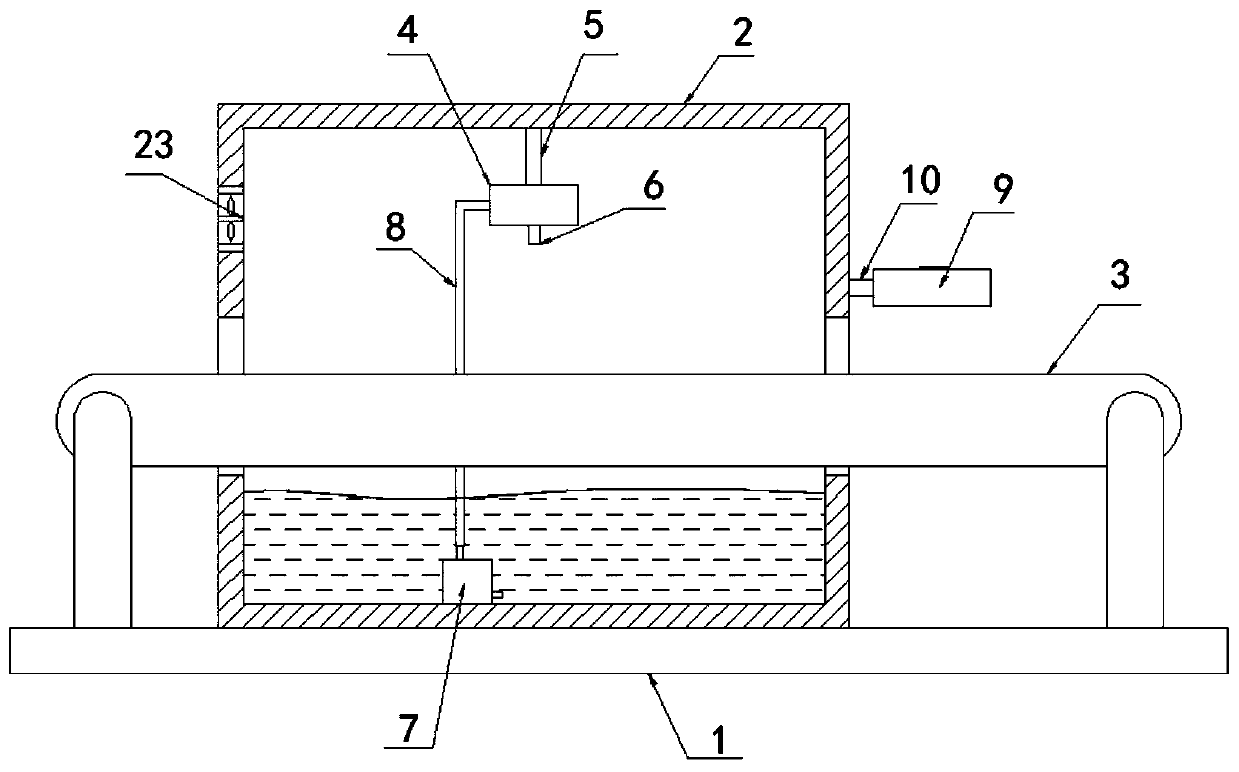

Cooling device in notebook computer radiating base

ActiveCN104898802AReduce the temperatureEasy to get materialsDigital data processing detailsEngineeringTurbofan

The invention relates to a cooling device in a notebook computer radiating base. The cooling device comprises a radiating base which is characterized in that an inhaling cylinder (1) is connected to the notebook computer radiating base, a turbofan (2) is connected at the air inlet of the inhaling cylinder (1), the air outlet of the inhaling cylinder (1) is connected with a cooling air bellow (4) through a hose, and a cooling tube (5) is arranged in the cooling air bellow (4); an air outlet nozzle of the cooling air bellow (4) is connected with an air inlet nozzle in the bottom of an air outlet hopper (6); the water inlet of the cooling tube (5) is connected with the outlet of a liquid pump (8) through a pipeline, and the water inlet of the cooling tube (5) is communicated with a liquid storage box (9) through a pipeline; and the liquid pump (8) is arranged in the liquid storage box (9). With the adoption of the technology, the temperature of a notebook computer is decreased to a great extent, and the scale of drop in temperature in summer can be controlled at about 10 DEG C.

Owner:来安县颂德信息科技有限公司

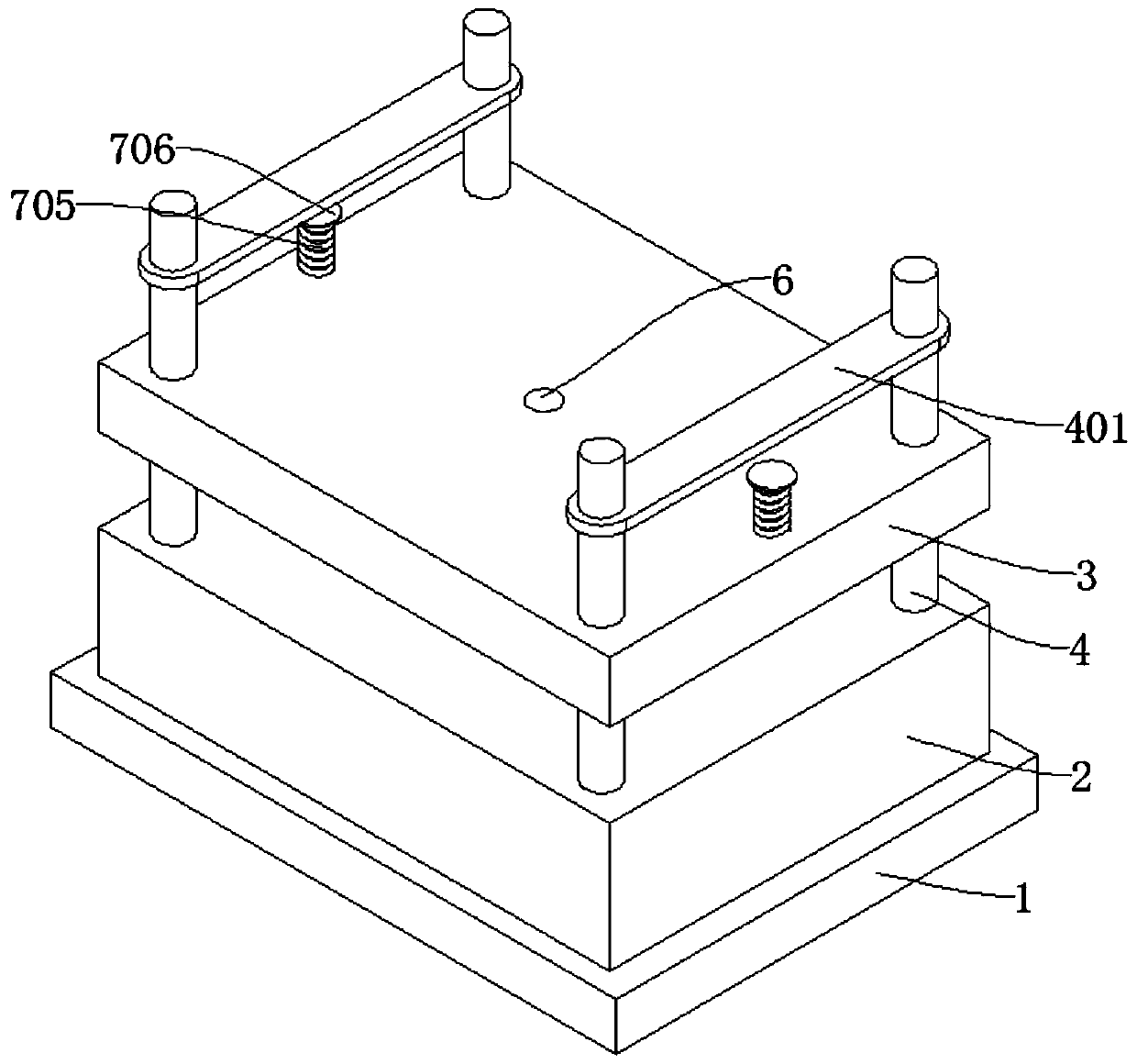

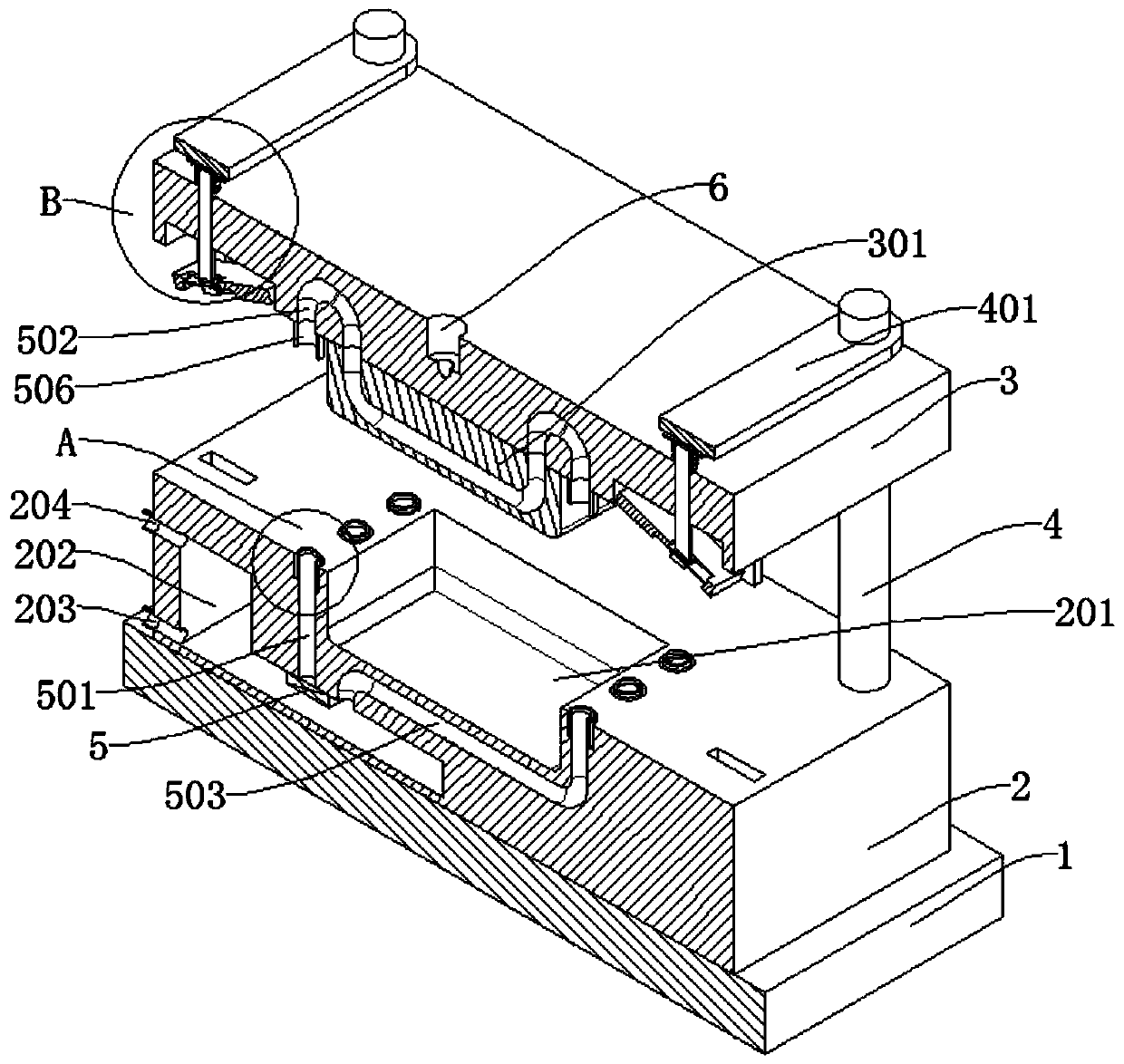

Aluminum alloy die-casting die with rapid cooling function

The invention discloses an aluminum alloy die-casting die with a rapid cooling function, and belongs to the technical field of die-casting dies. The aluminum alloy die-casting die with the rapid cooling function comprises a bottom plate, a lower die plate and an upper die plate, wherein a sliding plate is slidably connected onto a limited rod; the upper die plate is connected to the bottom part ofthe sliding plate; a water channel, a first cooling water channel and a third cooling water channel are dug in the lower die plate; second cooling water channels are dug on the sliding plate and theupper die plate; and two ends of the second cooling water channels penetrate through the sliding plate and are matched with the first cooling water channel and the third cooling water channel. According to the aluminum alloy die-casting die with the rapid cooling function provided by the invention, the die can be comprehensively cooled, so that the cooling speed is accelerated; and then the die can be cooled again through a cooling fan, so that an effect on quickly cooling is achieved, the production efficiency of castings is improved, the quality of the castings is ensured, and the giant economic loss caused to a die use enterprise is avoided.

Owner:JIANGSU XIANGHE ELECTRONICS SCI & TECH

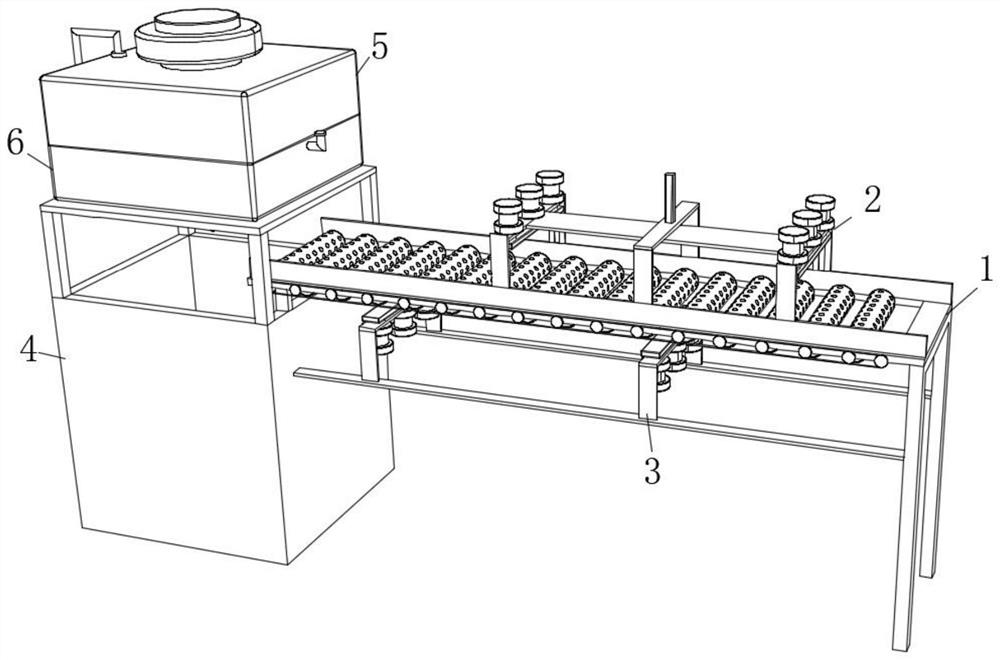

Rapid cooling device for aluminum profiles

InactiveCN111945085ARapid ventilation and heat dissipationFast and even heat dissipationEngineeringSpray cooling

The invention discloses a rapid cooling device for aluminum profiles, and relates to the technical field of aluminum profile production. The rapid cooling device comprises a conveying mechanism, wherein an upper cooling mechanism is arranged at the upper end of the conveying mechanism, a lower cooling mechanism is arranged on the bottom side of the conveying mechanism, a collecting mechanism is arranged at one end of the conveying mechanism, a spraying mechanism is arranged at the upper end of the collecting mechanism, a water return mechanism is arranged at the upper end of the spraying mechanism, and the conveying mechanism comprises a conveying frame and material conveying rollers arranged on the inner side of the conveying frame at intervals. According to the rapid cooling device, thealuminum profiles are conveyed through the material conveying rollers, cooling through holes are annularly distributed in the surfaces of the material conveying rollers at intervals, the contact areaof the aluminum profiles and the material conveying rollers is reduced, rapid ventilation and heat dissipation can be promoted when the aluminum profiles are conveyed, and ventilation and pre-coolingtreatment is conducted on the two faces of the conveyed aluminum profiles correspondingly; and water is sprayed out through a nozzle to conduct spraying cooling treatment on the aluminum profiles in acollecting box, so that the aluminum profiles can be rapidly and evenly cooled, and the treatment efficiency of aluminum profile cooling is improved.

Owner:马鞍山思哲知识产权服务有限公司

TFT cutting and separating device

InactiveCN112551880AEasy to replaceRapid cooling downGlass severing apparatusCutting glassClean environment

The invention discloses a TFT cutting and separating device which comprises a cooling and quenching device, a heating and radiating device and a cutting and separating quality detection module, a glass substrate at the cutting and scribing position is rapidly heated through the heating and radiating device, and the glass substrate at the cutting and scribing position is rapidly cooled through thecooling and quenching device; the cut glass is subjected to stress change from the scribing part and is broken in the scribing direction, the effect that the cut glass can be broken off along the scribing part is achieved, separation is not conducted in a hard breaking mode, and stress change breaking is started from the interior of the glass body in the separation process; therefore, mechanical broken and cracked glass chippings cannot be generated at the moment of separation, equipment pollution and product pollution are well prevented in a clean environment, and the device can be widely applied to glass cutting and thermal separation after lineation of different thicknesses and lengths. High-precision equipment does not need to align to a scribing part, and scribing position changes ofdifferent similar sizes can be conveniently compatible.

Owner:RAINBOW (HEFEI) LIQUID CRYSTAL GLASS CO LTD

Cooling device of motorcycle cylinder

InactiveCN106523172ASimple structureReasonable designCylinder headsCylindersEngineeringControl valves

The invention discloses a cooling device of a motorcycle cylinder. The cooling device comprises a vortex chamber and a compressed air bag; a vortex generator is arranged in the vortex chamber; an air inlet is arranged on the top of the vortex chamber; the air inlet is fixedly connected with the compressed air bag through an air inlet pipe; a control valve is further arranged on the air inlet pipe; a vortex rectifier tube is also fixedly arranged on one side of the vortex chamber; a cool air outlet and a hot air outlet are separately arranged on two sides of the vortex rectifier tube; the cool air outlet and the hot air outlet are separately fixedly connected with an air inlet end of a cool air pipe and an air inlet end of a hot air pipe; and the outer surface of the hot air pipe is wrapped by a cooling clamping bag. The cooling device of the motorcycle cylinder is simple in structure and reasonable in design; the cylinder can be rapidly cooled in a safe and effective manner; service life of parts in the cylinder is prolonged; and working efficiency of the cylinder is effectively improved.

Owner:范广志

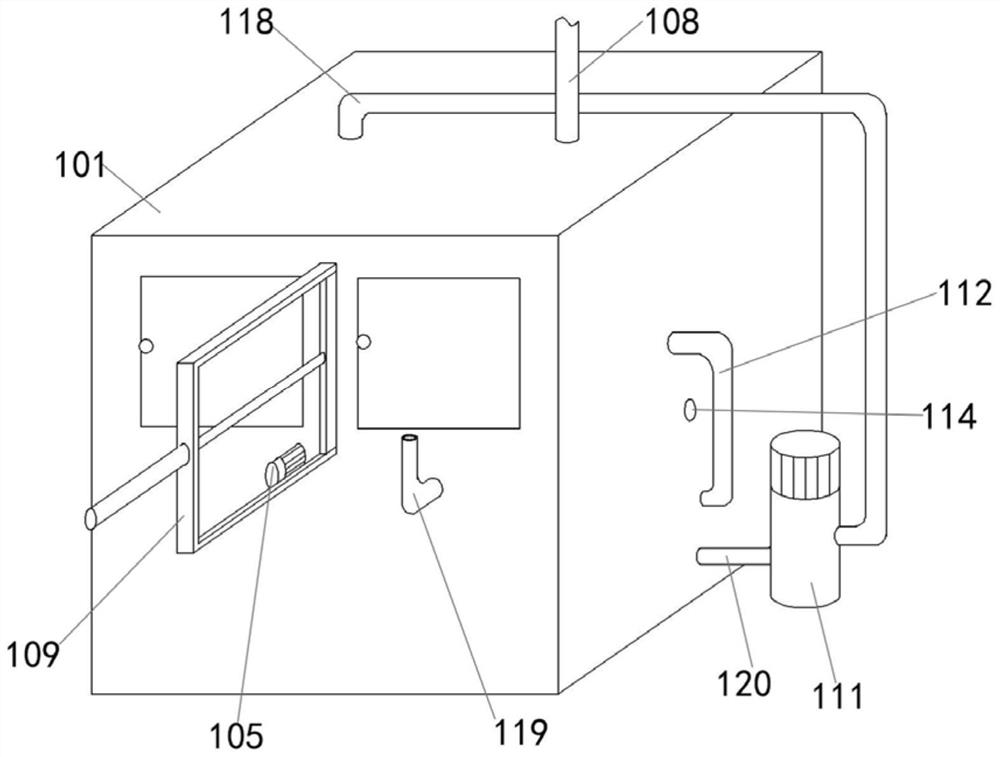

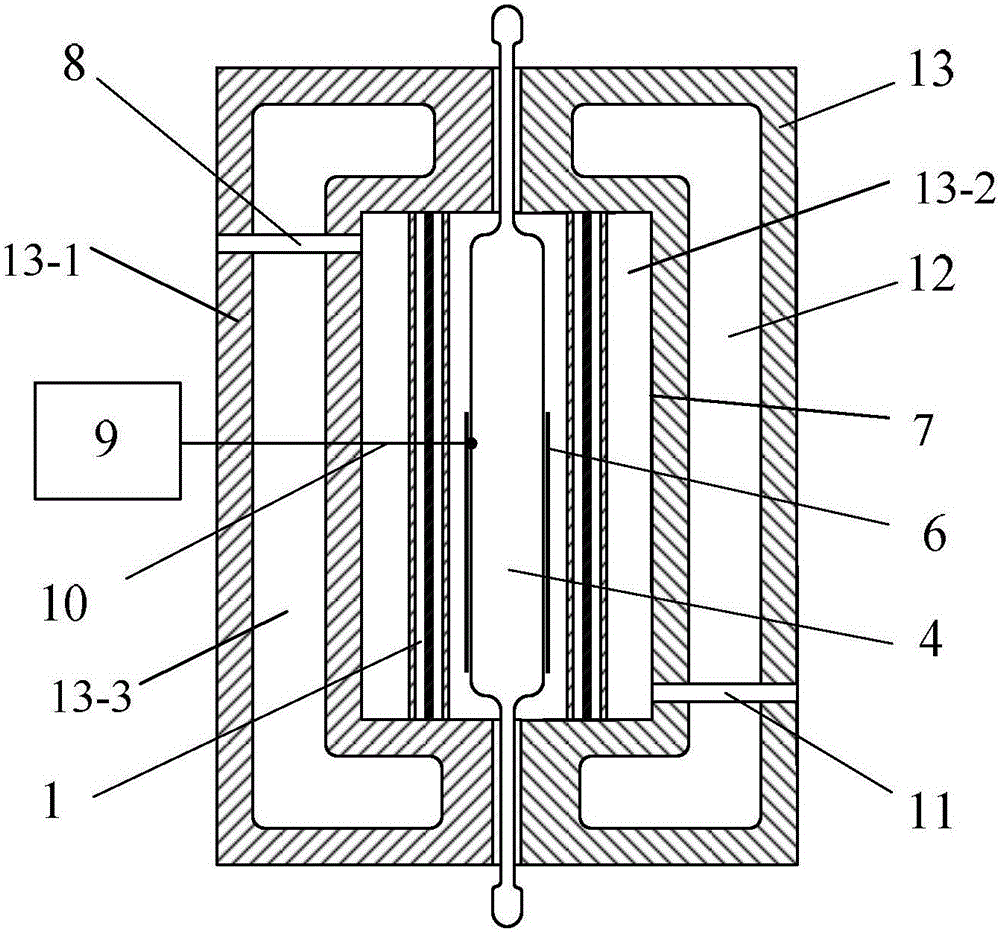

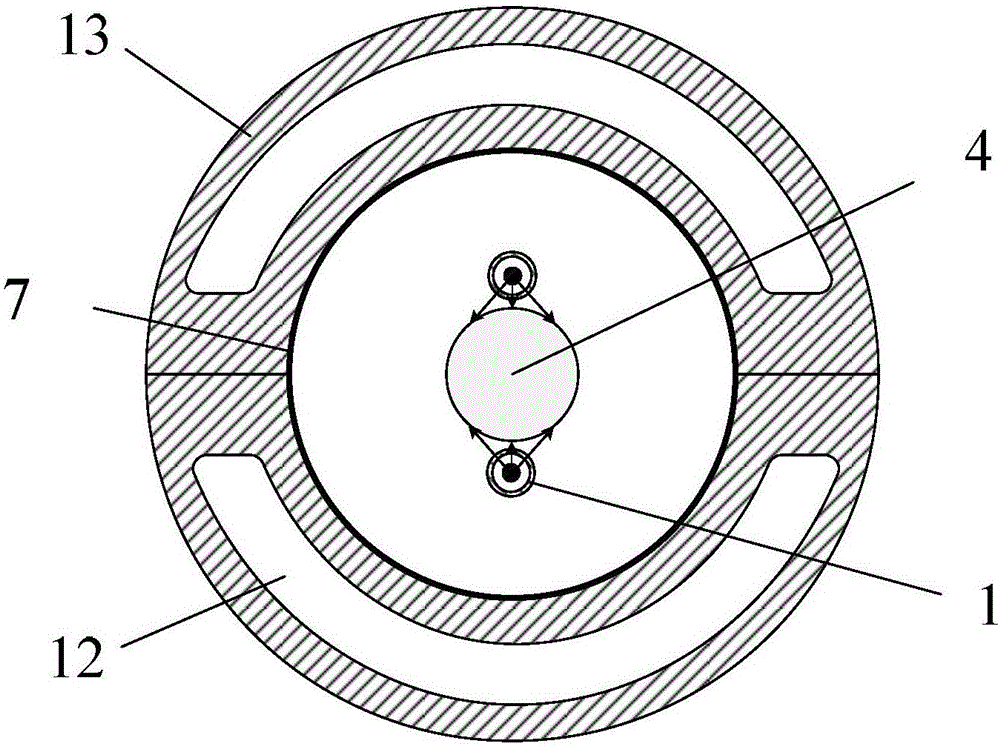

Thermal runaway vacuum cooling device for lithium ion battery in transformation environment

PendingCN113777507AEnabling heat transfer studiesRapid cooling downElectrical measurement instrument detailsElectrical testingPhysicsThermal runaway

The invention discloses a thermal runaway vacuum cooling device for a lithium ion battery in a voltage transformation environment. The thermal runaway vacuum cooling device comprises an experiment cabin control and analysis integrated system, a dynamic temperature voltage transformation experiment cabin, a vacuum cooling system and an experiment internal cabin arranged in the dynamic temperature voltage transformation experiment cabin. According to the device, thermal runaway experiment research of multiple lithium ion batteries can be realized, and large-scale rapid cooling of the multiple batteries can be carried out after thermal runaway; lithium ion battery thermal runaway research under different working conditions (low voltage, low temperature and the like) can be realized; the surface temperature of the lithium ion battery can be measured in real time, the temperature change of the lithium ion battery under different working conditions during thermal runaway of the battery is studied, and meanwhile, the cooling relation of thermal runaway of different battery numbers can be studied; and a more valuable research method is provided for thermal runaway behavior analysis of thermal runaway of the lithium ion battery in a low-voltage environment and accurate and rapid cooling after thermal runaway.

Owner:CIVIL AVIATION FLIGHT UNIV OF CHINA

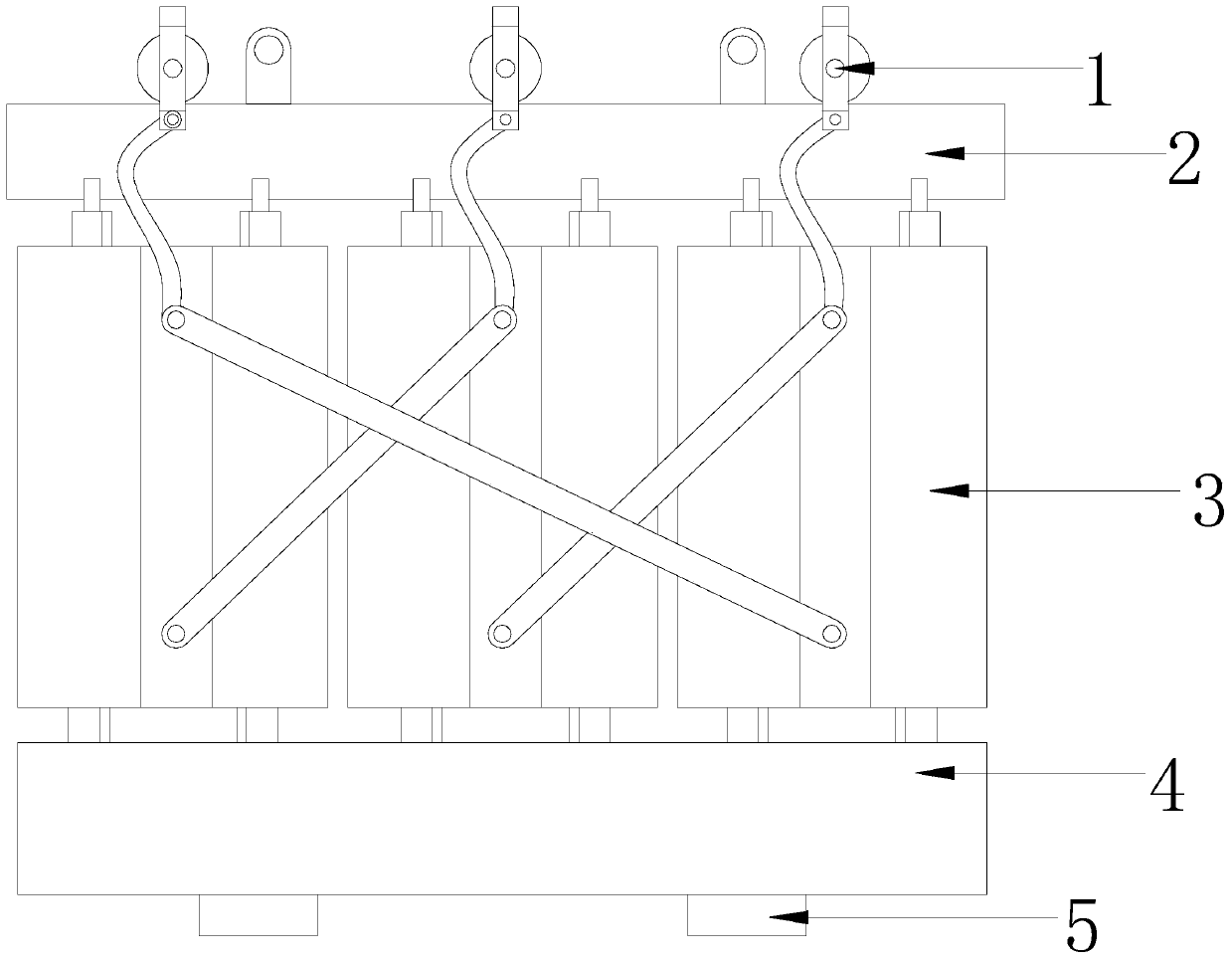

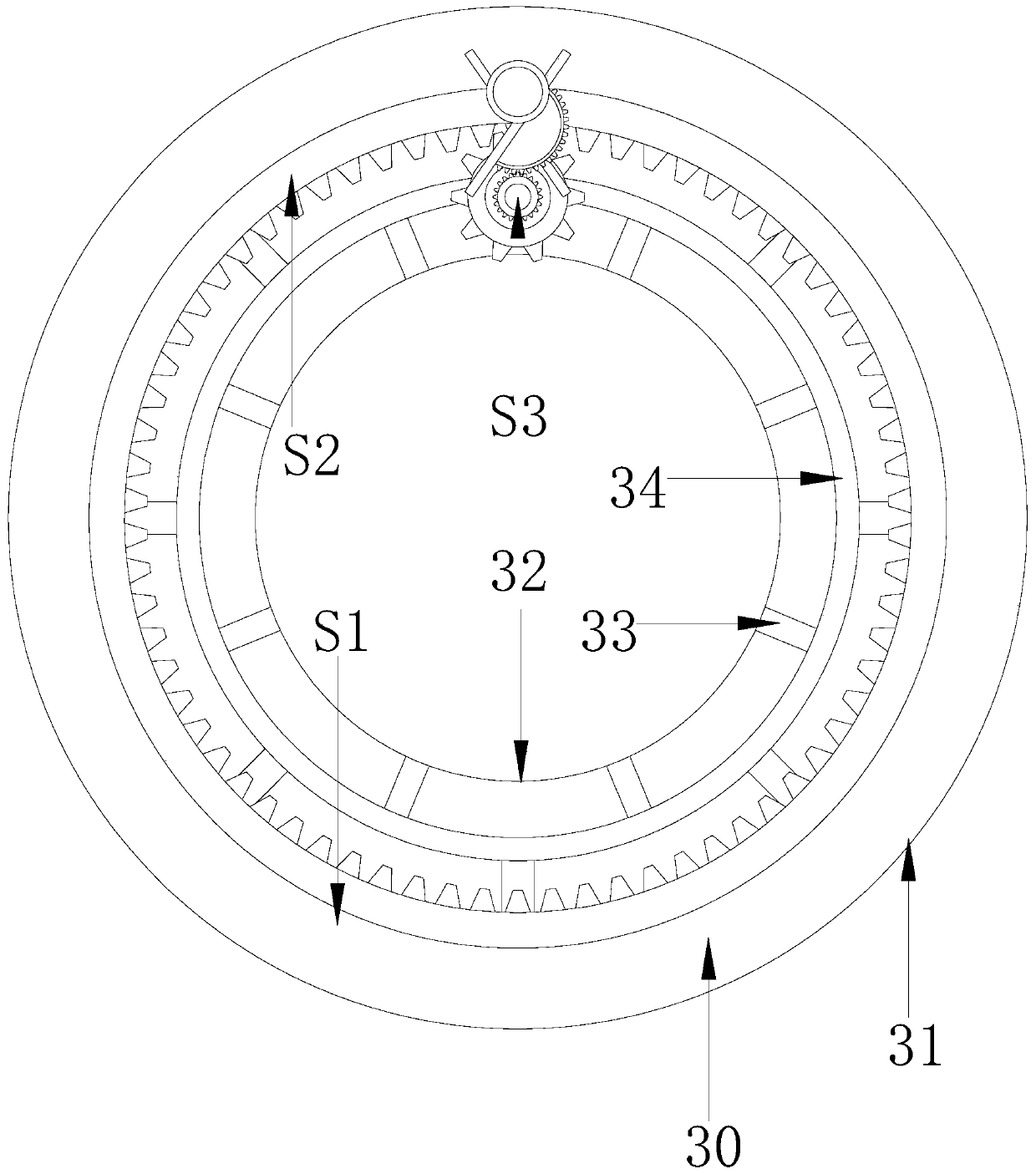

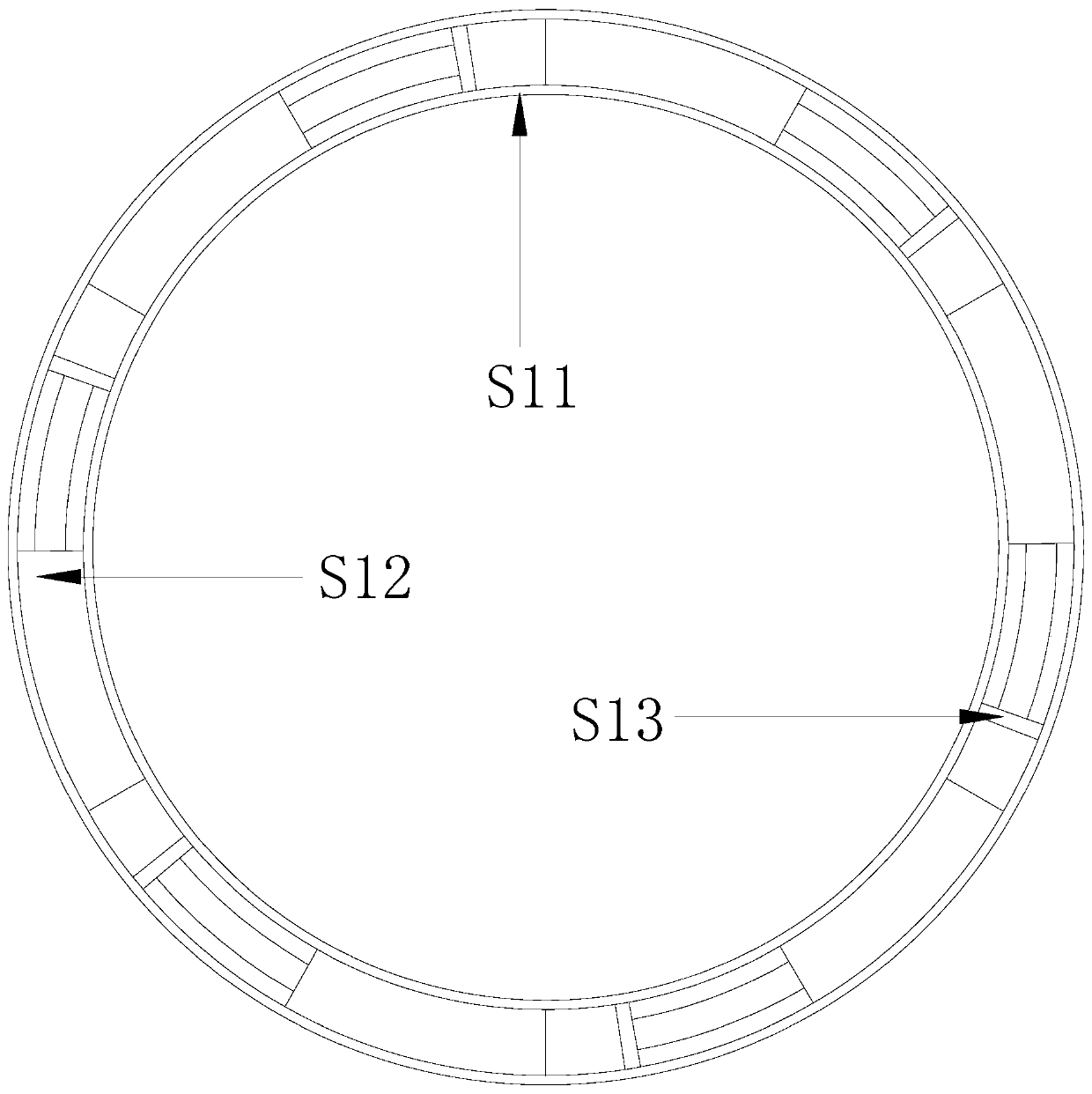

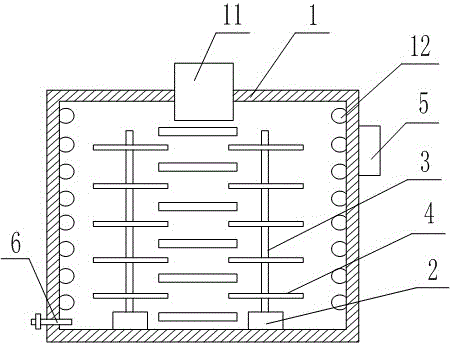

Double-cooling epoxy resin pouring dry-type transformer

ActiveCN110428957AAvoid thermal damageExtended service lifeTransformers/inductances coolingTransformers/inductances coils/windings/connectionsEpoxyTransformer

The invention discloses a double-cooling epoxy resin pouring dry type transformer. The transformer structurally comprises a high-voltage terminal, clamping pieces, coil windings, a cooling box and a base; three coil windings are arranged in parallel, each top of which is connected with the clamping piece through a cushion block, and the bottoms are connected to the cooling box through cushion blocks; the cooling box is mounted on the base; compared with the prior art, the beneficial effects of the invention are that a cooling pipe which is coiled into a circle in a snake shape, a flow equalizing pipe with a gas dispersing cover, a X-shaped power set, a reciprocating rotating translation assembly, an arc-shaped gas guide cylinder and other components are arranged in a combined mode; a modeof directly adopting a fan is abandoned, a circulating water cooling mode is mainly adopted, and air cooling is used as an auxiliary mode, so that each surface of the transformer can be cooled, cooling and heat dissipation are more balanced, the phenomenon of thermal damage of the transformer is prevented, the internal winding is prevented from being damaged, and the service life of the transformer is prolonged.

Owner:江苏普拓电气科技有限公司

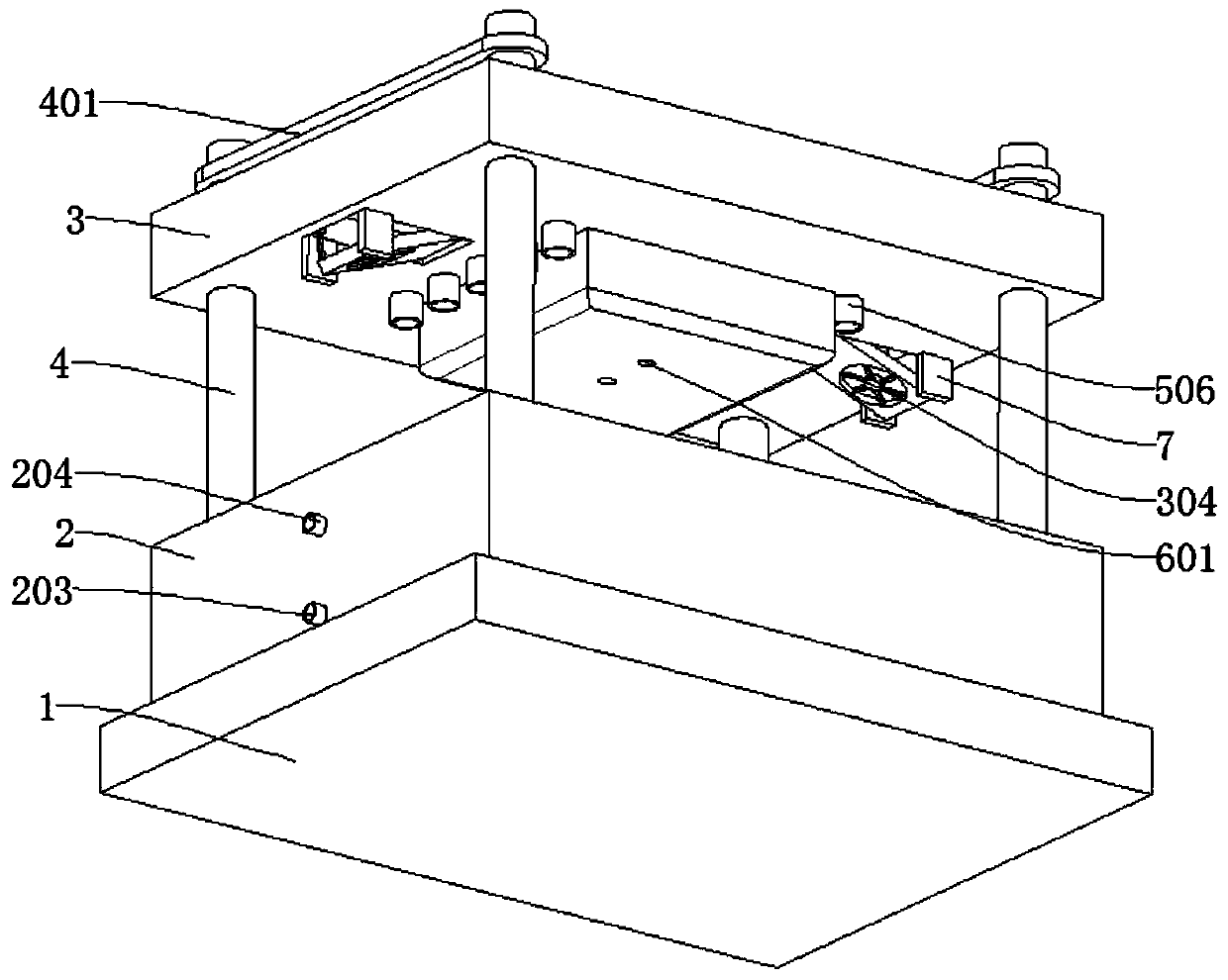

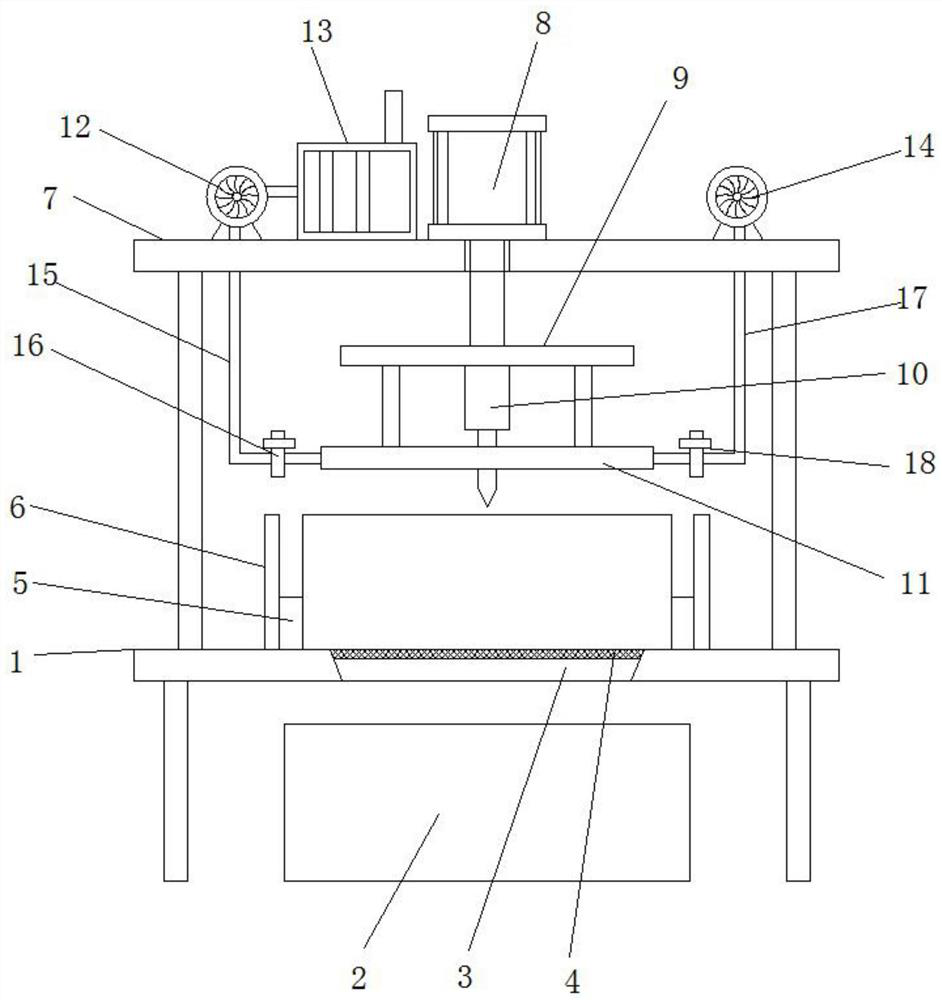

Front wall vertical plate assembly welding tool

InactiveCN112264730AAvoid burnsReduce body damageCombination devicesDispersed particle filtrationSlag (welding)Hydraulic cylinder

The invention discloses a front wall vertical plate assembly welding tool, and belongs to the field of front wall vertical plate machining. The tool comprises a welding table and a collecting box, wherein a discharging hole is formed in the welding table, a grid plate is arranged in the discharging hole, positioning blocks are symmetrically arranged on the upper surface of the welding table, a protection device is fixed to the upper surface of the welding table, a top plate is fixed to the top wall of the welding table through a supporting rod, a hydraulic cylinder is installed on the upper surface of the top plate, a piston rod of the hydraulic cylinder is connected with an installation plate, a welding gun is installed in the middle of the lower surface of the installation plate, a smokesuction pipe is fixed to the lower surface of the installation plate through an installation rod, an air suction fan, an adsorption box and a blower are arranged on the upper surface of the top plate, and an air outlet of the air suction fan is communicated with the adsorption box. The tool is novel in design, ingenious in structure, capable of absorbing and purifying generated smoke during welding, capable of reducing damage of the smoke to the body of a worker, capable of rapidly dissipating heat of a product and cleaning up welding slag after welding is completed, convenient for follow-upmachining, simple, practical and worthy of popularization.

Owner:十堰澳士力工贸有限公司

Outdoor power distribution cabinet with high protection performance

InactiveCN112271565ATimely self-controlImprove the protective effectSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsElectric power equipmentStructural engineering

The invention discloses an outdoor power distribution cabinet with high protection performance, which belongs to the technical field of power equipment and comprises a cabinet body, ventilation squareholes are symmetrically formed in the left side wall and the right side wall of the cabinet body, and first cavities are formed in the left side wall and the right side wall of the cabinet body and located on the upper sides of the ventilation square holes. A fireproof sealing plate is arranged in the first cavity, the size of the fireproof sealing plate is matched with that of the ventilation square hole, a sealing cover plate is fixed to the top end of the fireproof sealing plate, a hanging rope is connected to the top end of the sealing cover plate, the top end of the hanging rope is hungat the inner top end of the first cavity, and a hanging rope cutting-off structure is arranged at the inner top of the first cavity; and the ventilation square holes can be automatically blocked whenopen fire is generated in the power distribution cabinet, so that the interior of the cabinet body is sealed, the effect of isolating oxygen is achieved, the situation that the fire behavior is increased due to continuous circulation of air is avoided, timely self-control of the power distribution cabinet when open fire occurs is achieved, and the protection performance and the safety of the powerdistribution cabinet are effectively improved.

Owner:潘玉霞

Multi-station automatic welding machine tool for non-standard parts

ActiveCN111545969AFlexible and self-correctingAvoid crush injuryWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMachine tool

The invention discloses a multi-station automatic welding machine tool for non-standard parts, and relates to the technical field of a welding machine tool. The multi-station automatic welding machinetool concretely comprises a base, steering mechanisms, heat dissipation baffle plates, height adjustment mechanisms, shifting mechanisms and welding mechanisms, wherein a mounting seat is arranged inthe upper surface of the base, and the steering mechanisms are arranged at the upper part of the mounting seat equidistantly; the heat dissipation baffle plates are vertically and fixedly arranged on the front side and the rear side of the upper part of the base; mounting stand columns are vertically welded on the four corners of the upper surface of the base, and the height adjustment mechanisms are arranged on the inner sides of the mounting stand columns; the side parts of the height adjustment mechanisms are connected with the shifting mechanisms; and the welding mechanisms are glidinglyarranged on the shifting mechanisms. The multi-station automatic welding machine tool for the non-standard parts controls the steering and shift positions of various non-standard parts through the steering mechanisms, so that the positions of various non-standard parts can be flexibly and automatically corrected. Thus, the operation is convenient, the welding efficiency is improved, the manpoweris greatly saved, and the multi-station automatic welding machine tool is conducive to safe production.

Owner:HUNAN UNIV OF ARTS & SCI

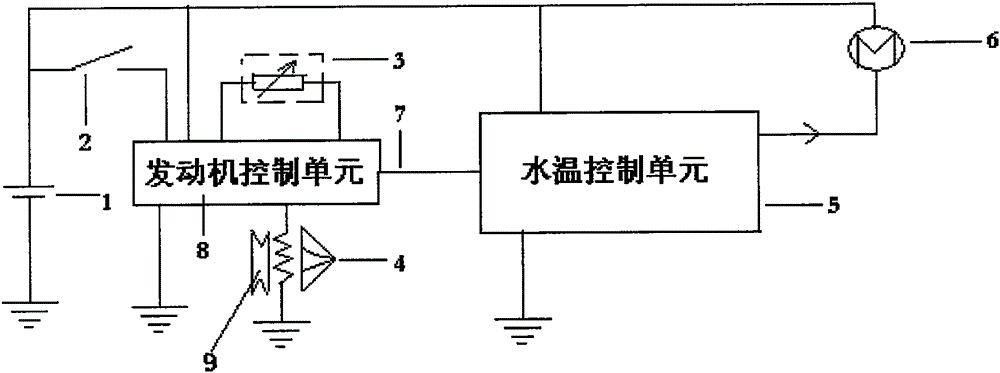

Vehicle engine cooling system

InactiveCN104989511ATroubleshootingReduce failureCoolant flow controlMachines/enginesElectromagnetic clutchWorking temperature

The invention discloses a vehicle engine cooling system. The vehicle engine cooling system comprises an engine control unit, wherein a signal input end thereof is connected with a water temperature sensor, a first signal output end thereof is connected with a circulating water pump having an electromagnetic clutch, and a second signal output end thereof is connected with a water temperature control unit; and a control output end of the water temperature control unit is connected with an electric cooling fan. The vehicle engine cooling system further comprises an accumulator; a power supply output end thereof is respectively connected with the engine control unit, the water temperature control unit and the electric cooling fan; and an ignition switch is arranged between the accumulator and the engine control unit. As a thermostat is cancelled, the cooling system eliminates faults caused by the thermostat, the fault generation probability is reduced, and the engine working temperature can be guaranteed to be always kept in a normal working temperature range.

Owner:WUXI INST OF COMMERCE

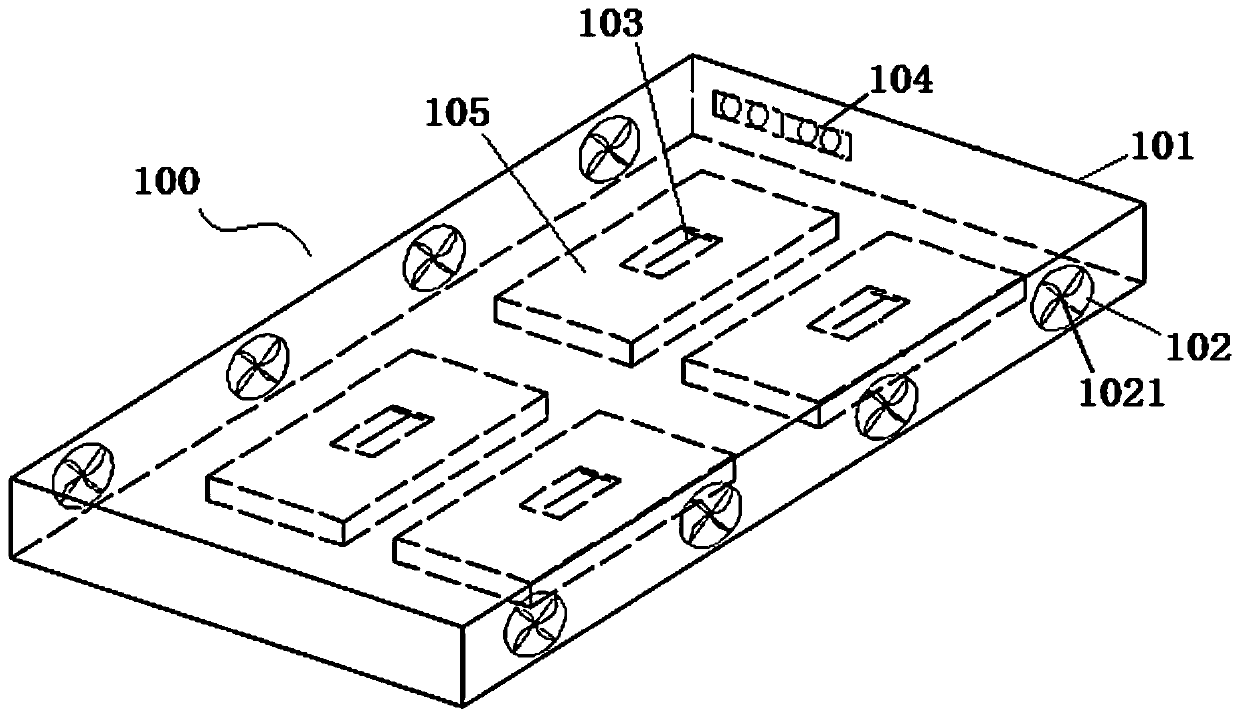

Server and data center

ActiveCN111465301ARapid cooling downEasy to understandCooling/ventilation/heating modificationsCooling towerData center

The invention discloses a server and a data center, belonging to the technical field of cooling of data centers which can be applied to (including but not limited to) cloud computing, cloud storage, big data computing, deep learning, image processing and the like. The server comprises a non-conductive liquid refrigerant filled in a shell and a driving part arranged in the shell. A data center machine room of the data center is provided with a cabinet provided with the server; a spraying device is arranged at a position corresponding to the cabinet; a cooling tower is arranged outside the datacenter machine room; and a liquid supply part of the cooling tower is connected with the spraying device. The server provided by an embodiment of the invention can drive the non-conductive liquid refrigerant to continuously exchange heat with the server under the action of the driving part. Due to the fact that the data center is provided with the server and the spraying device for conducting spraying cooling on the server, heat exchange can be conducted on the interior and the exterior of the server at the same time, and rapid cooling of the server and the whole data center machine room is achieved.

Owner:BEIJING BAIDU NETCOM SCI & TECH CO LTD

Oppositely-opened radiative heating furnace and furnace body

ActiveCN105758182AAvoid dependenceHigh positioning accuracyFurnace typesElectric heating for furnacesEmissivityHearth

The invention provides an oppositely-opened radiative heating furnace and a furnace body, belongs to the field of heating devices used in laboratories and aims at solving the problems of poor rapid heating and cooling performance and low cost performance of existing heating devices used in the laboratories.The furnace body is composed of two sections, wherein each section is provided with a sunken cavity, a wall body of each section is provided with a channel for circulating cooling liquid to flow through, the two cavities form a cylindrical hearth when the two section are oppositely combined together, and the wall face of the cylindrical hearth is a smooth and clean face.The heating furnace comprises a heating element, the furnace body and a temperature controller, wherein the heating element is a radiative heating tube, the furnace body comprises the cylindrical hearth with the smooth and clean wall face, the radiative heating tube is close to the surface of a heated object, and the surface of the heated object is coated with a high-emissivity coating so as to strengthen radiative heating.The furnace body is provided with a gas purging channel to achieve rapid cooling of the hearth, and the circulating cooling liquid flows through the whole furnace wall to ensure cooling of a whole mirror wall.The oppositely-opened radiative heating furnace and the furnace body can be used for a heating tube type reactor.The furnace body is compact and high in performance cost ratio.

Owner:HARBIN INST OF TECH

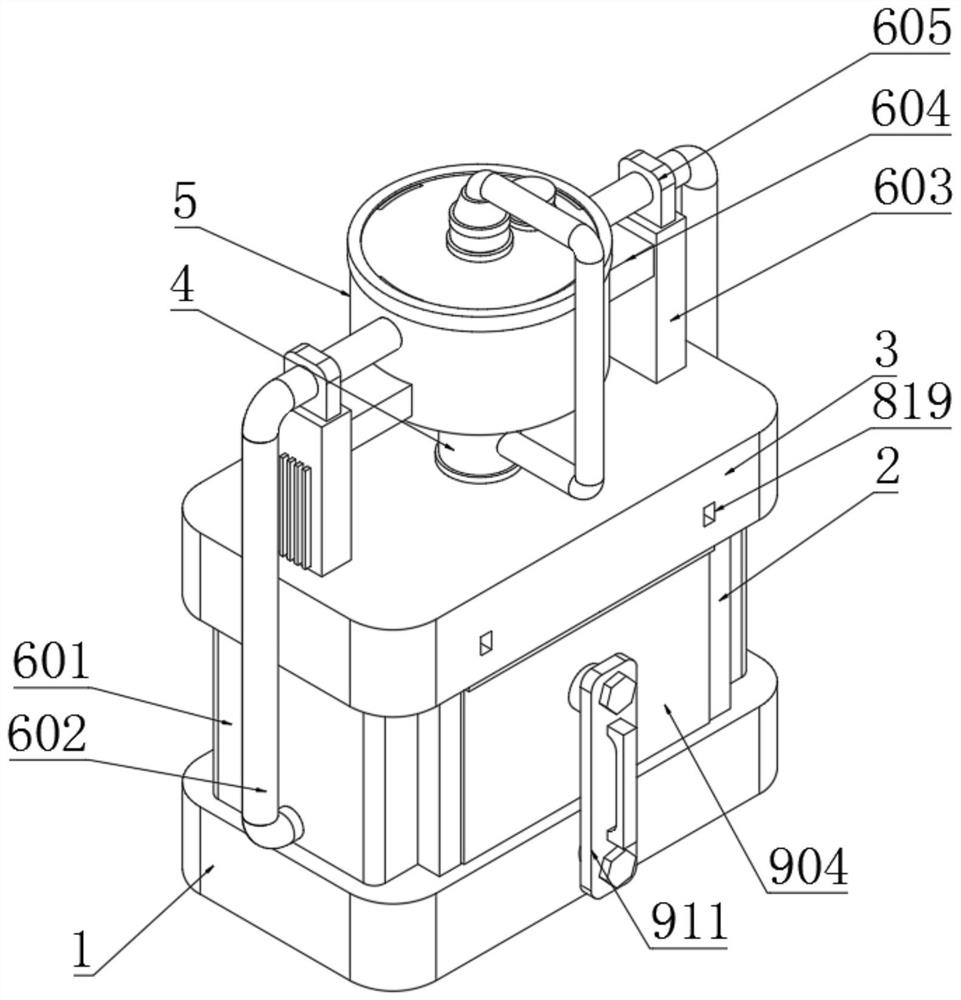

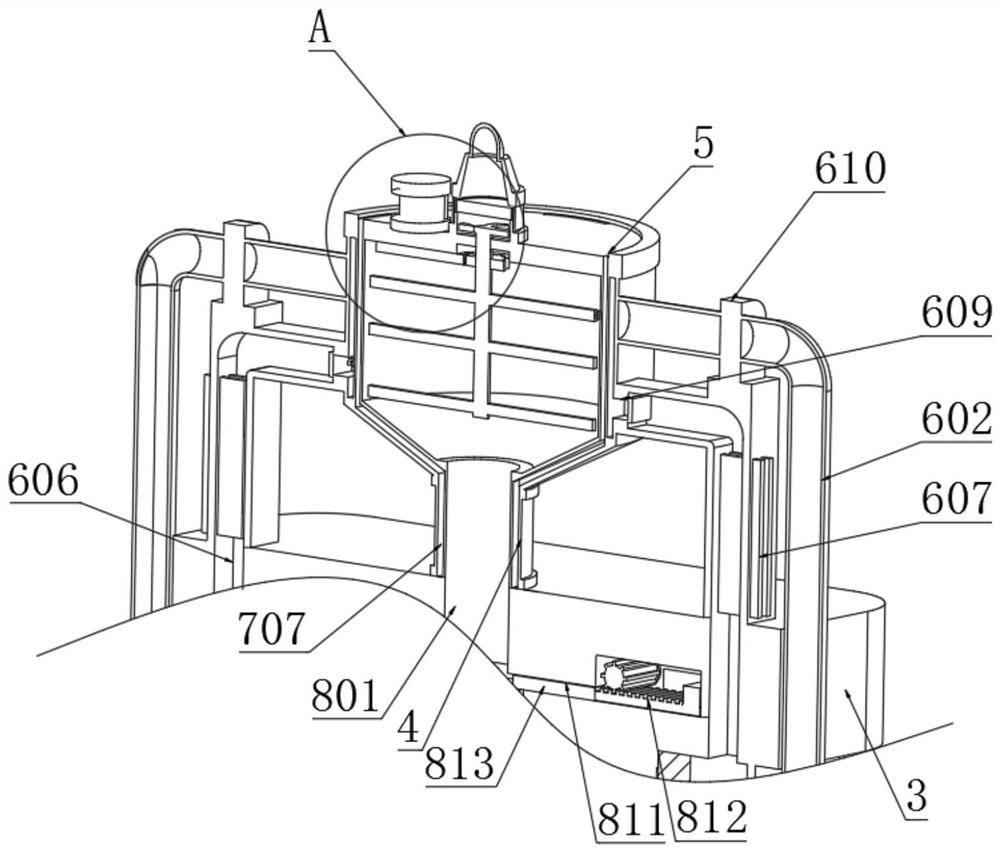

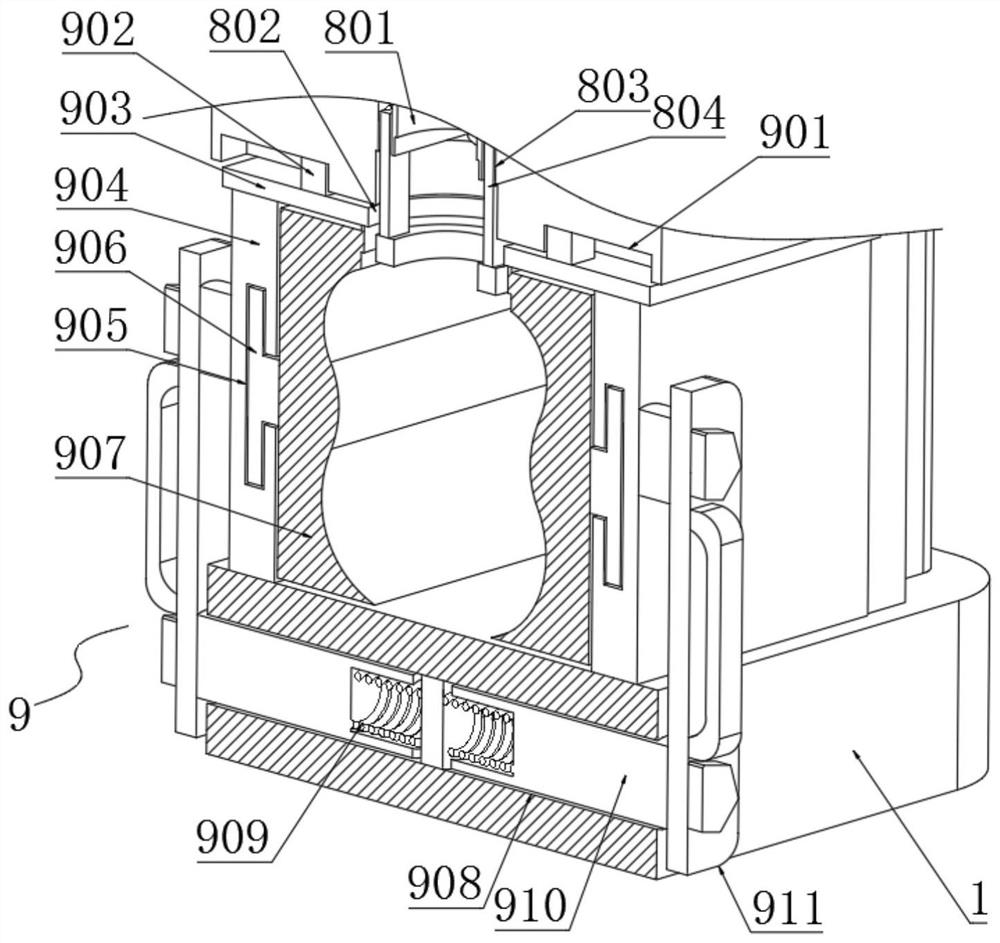

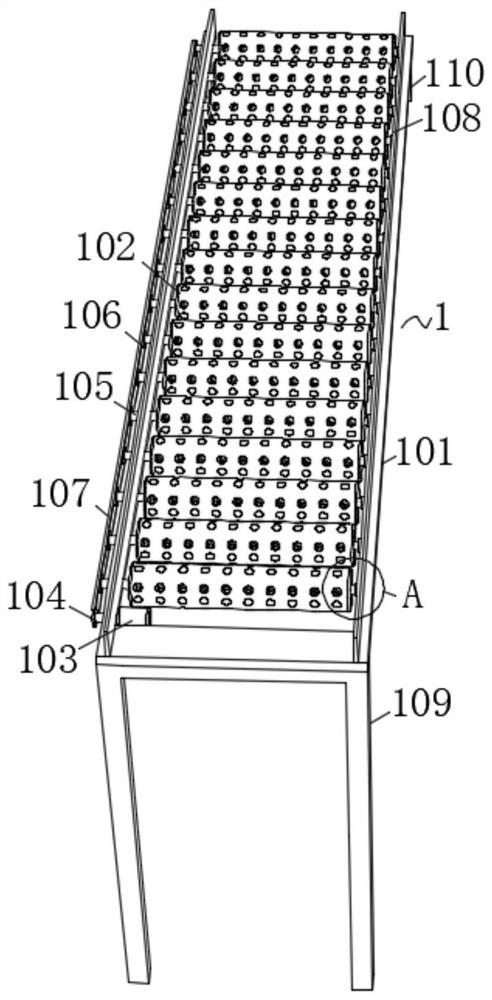

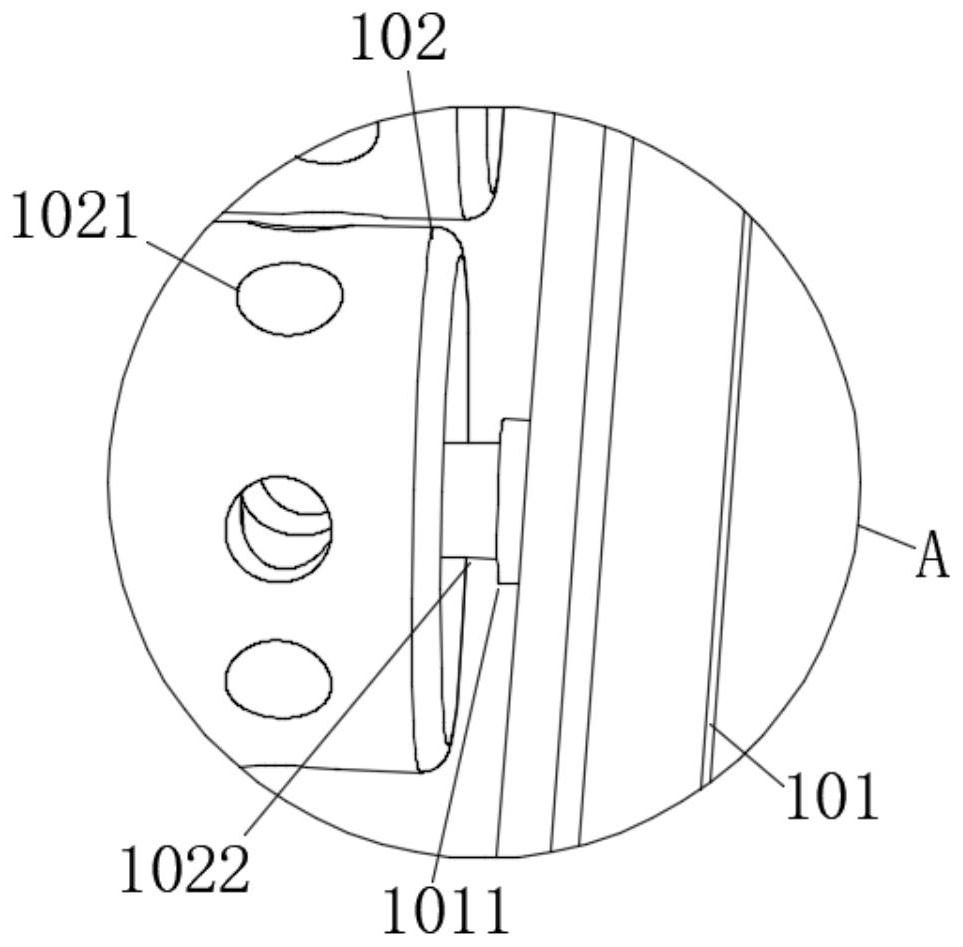

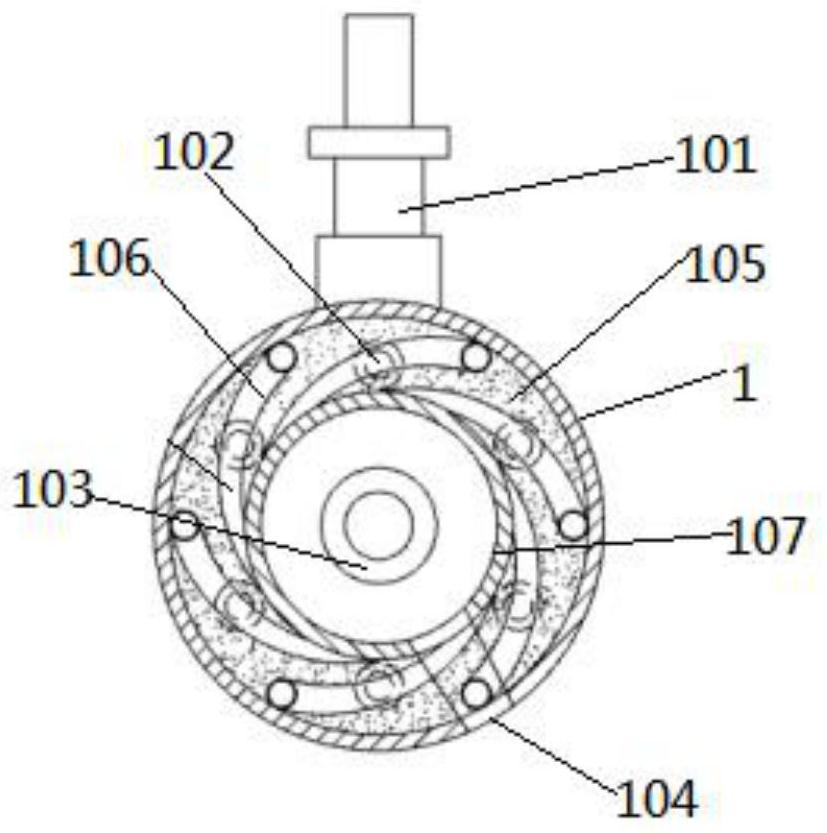

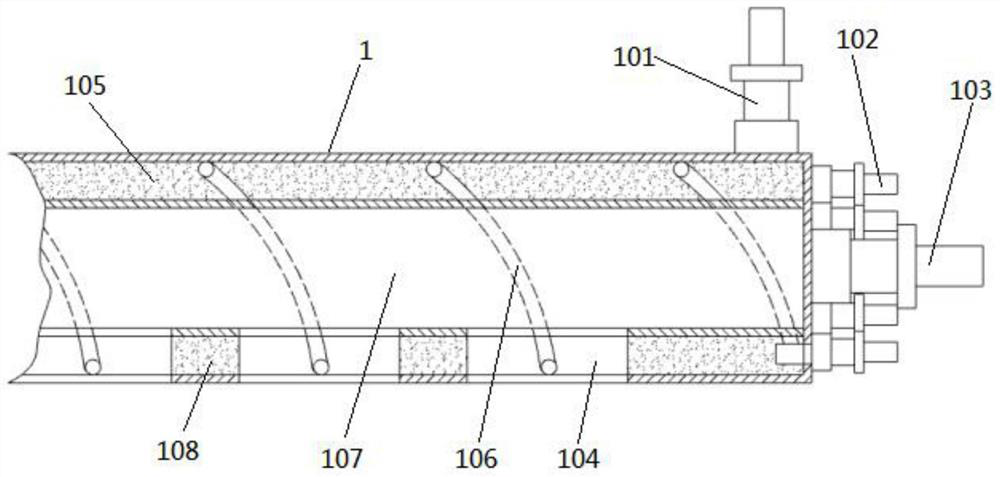

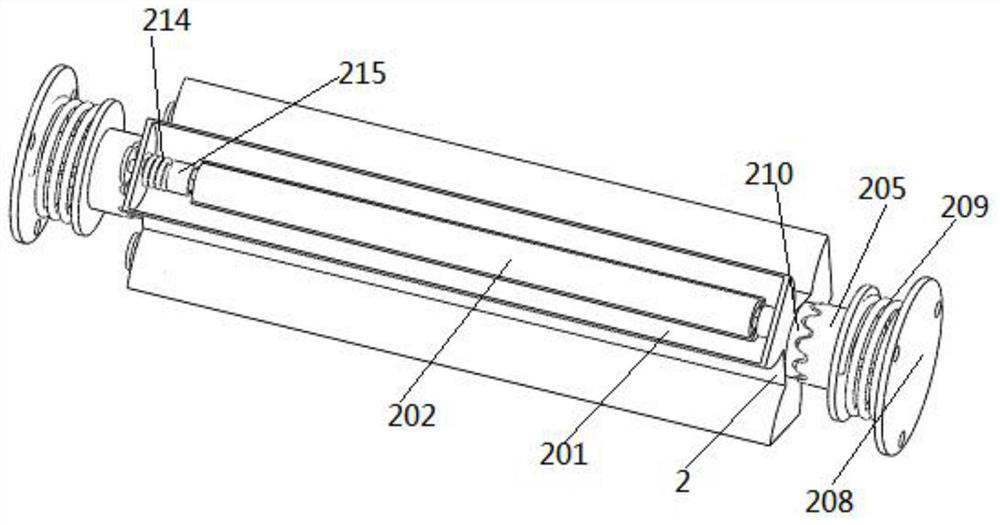

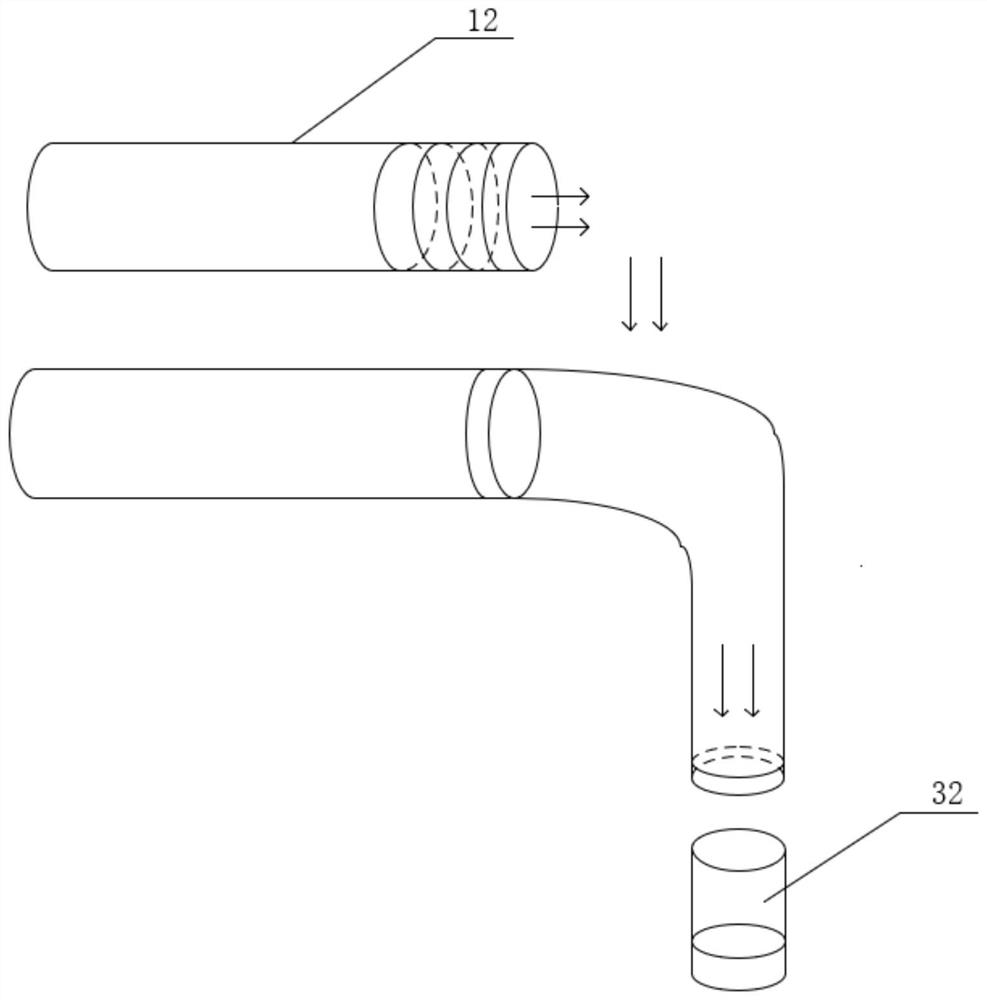

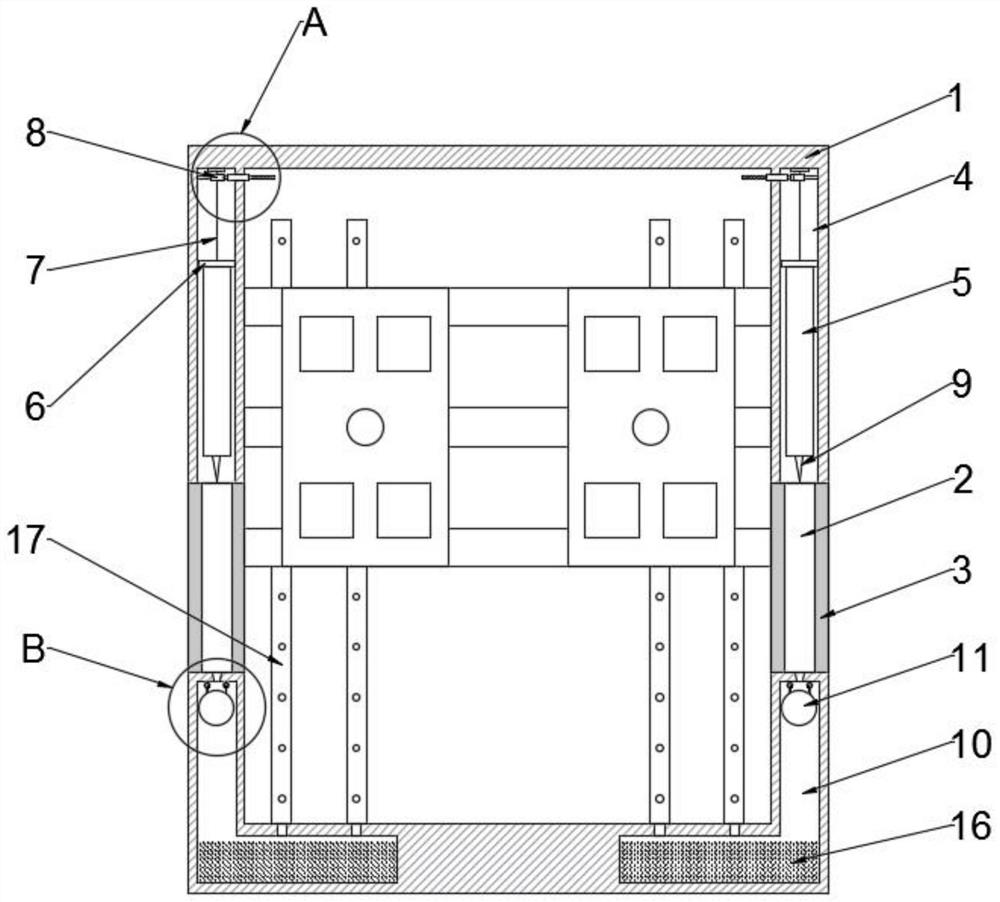

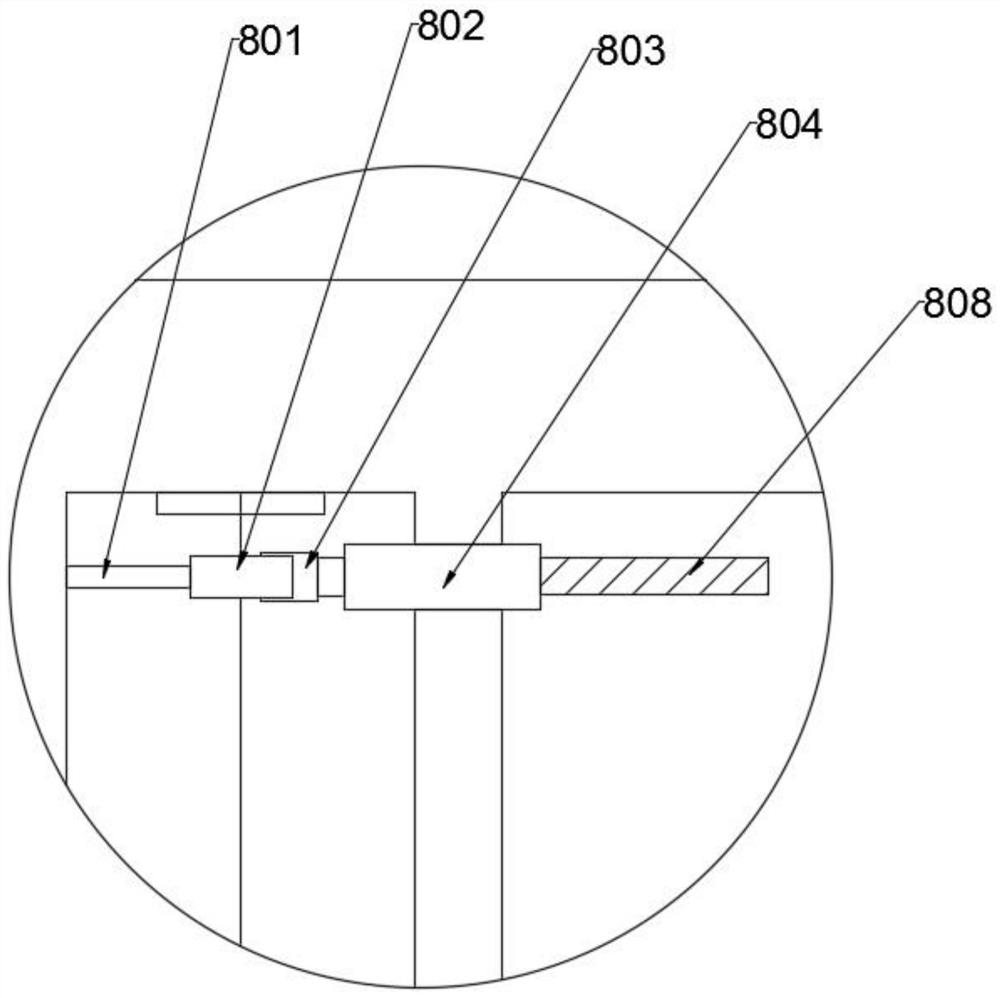

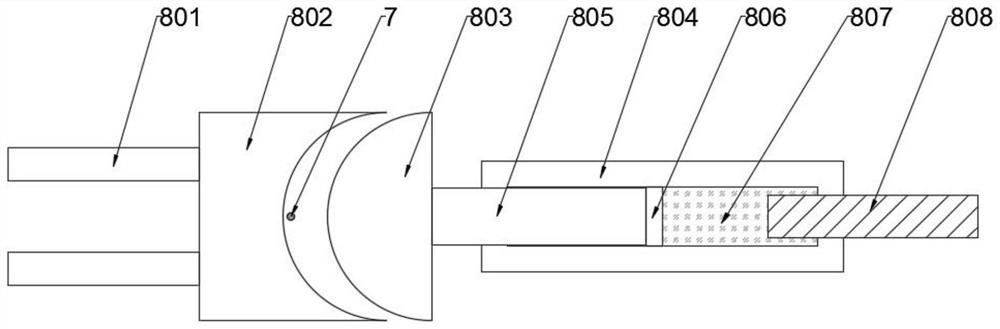

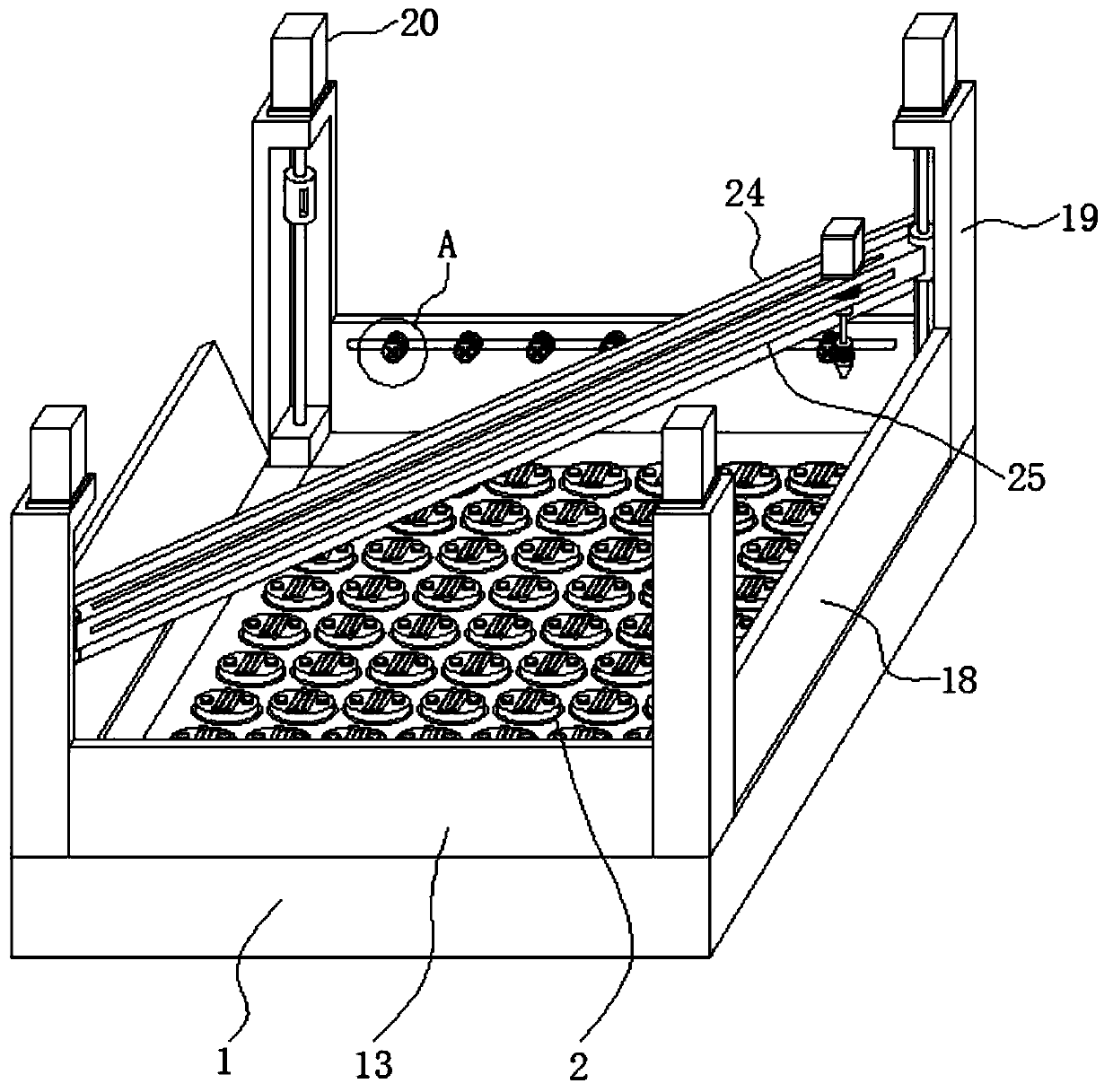

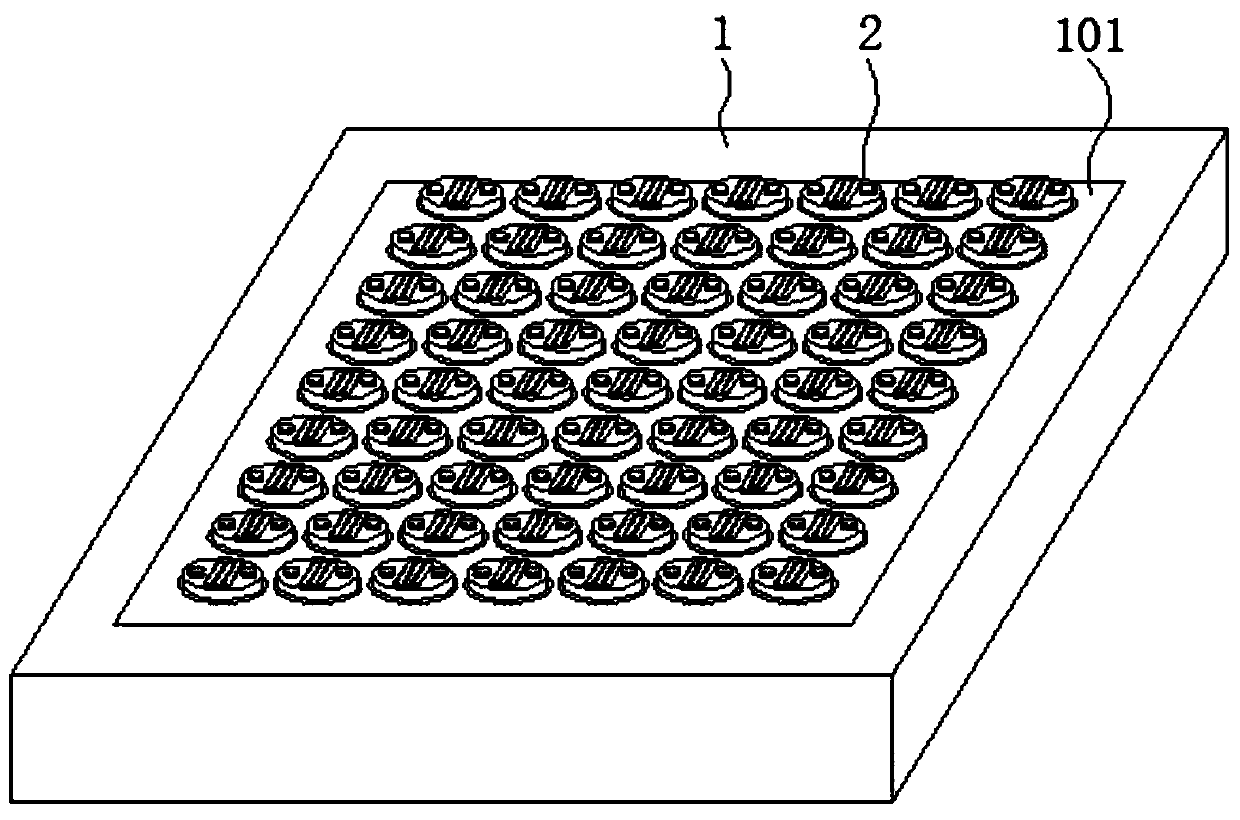

Metal film evaporation equipment for film capacitor processing

ActiveCN110205601BRealize winding and pullingGuaranteed normal processingVacuum evaporation coatingSputtering coatingThin membraneEngineering

The invention relates to capacitor processing equipment, and provides metal thin film evaporation equipment for processing a thin film capacitor. The equipment aims to solve the problems that when a traditional evaporation device is used for evaporation of a thin film, an evaporation source is uniformly heated, the evaporation thickness is not uniform, layering is not uniform, the evaporation efficiency is low and the production efficiency of the thin film capacitor is affected. The equipment comprises an outer box, a plurality of supporting legs arranged at the lower end of the outer box anda box door arranged on the front wall of the outer box, and a vacuumizing machine is arranged at the upper end of the outer box. A vacuumizing pipe is arranged at the input end of the vacuumizing machine, and the lower end of the vacuumizing pipe extends to the lower part of an inner cavity of the outer box. A thin film roll is arranged in the inner cavity of the outer box, and a thin film is wound on the thin film roll. The other end of the thin film sequentially passes through a cleaning assembly, two steering rollers and a cooling assembly and is wound on a film winding roller. The equipment is especially suitable for high-efficiency evaporation processing of the metallized thin film, and has relatively high commercial prospects.

Owner:TONGLING CITY START ELECTRONICS MFG

Energy-saving production device for emulsified asphalt

InactiveCN108854744AQuick mixWell mixedTransportation and packagingRotary stirring mixersWater bathsEmulsion

The invention discloses an energy-saving production device for emulsified asphalt. The energy-saving production device comprises a base; two symmetrical support plates are arranged on the upper side of the base, and an emulsification box is arranged between the support plates; an annular fixing boss is arranged on one outer side of the emulsification box; a second servo motor is arranged in the lower middle position of the emulsification box; an output shaft of the second servo motor is connected with one end of a main shaft through a coupler, and the other end of the main shaft extends into the emulsification box and is connected with a shaft connecting plate through a bearing. The energy-saving production device has the advantages that asphalt and emulsions can be rapidly and uniformly mixed through interaction between a first spiral stirring rib and a second spiral stirring rib; the annular fixing boss is internally provided with an annular water-bath tube which can guarantee the temperature environment during mixing; the mixed emulsified asphalt can be quickly and conveniently taken out through interaction between a first servo motor and an arc-shaped support plate.

Owner:杨洁磊

Cooling device used in automobile part machining process

InactiveCN110116481ARapid cooling downIncrease productivityDomestic articlesEngineeringMachining process

The invention relates to the technical field of cooling devices and discloses a cooling device used in the automobile part machining process. The cooling device comprises a base, a cooling tank and aconveying belt. The cooling tank is fixedly arranged on the upper surface of the base, and openings are formed in the left side and the right side of the cooling tank correspondingly. The conveying belt is fixedly arranged on the upper surface of the base and transversely penetrates the interior of the cooling tank. Cooling water is arranged at the bottom of an inner cavity of the cooling tank. Afirst hollow plate is longitudinally arranged on the top of the inner cavity of the cooling tank, and two first connecting rods are symmetrically and fixedly arranged on the upper surface of the firsthollow plate. The upper ends of the two first connecting rods are fixedly connected with the inner wall of the top of the cooling tank, and multiple water spraying pipes which are evenly distributedcommunicate with the lower surface of the first hollow plate in the length direction of the first hollow plate. By means of the cooling device, parts on the conveying belt can be rapidly cooled, the production efficiency of the parts is improved, and meanwhile water on the surfaces of the parts can be blown dry.

Owner:安徽佰尧电子科技有限公司

Plastic injection mold convenient to cool and demold

The invention relates to the technical field of plastic injection molding, in particular to a plastic injection mold convenient to cool and demold. The plastic injection mold comprises a concave moldand a convex mold matched with the concave mold, wherein a first cooling cavity and a second cooling cavity are respectively arranged in the concave mold and the convex mold; a first branch pipe and asecond branch pipe are fixedly connected to one end, away from a liquid storage tank, of a water outlet pipe; the first branch pipe is fixedly connected and communicated with the concave mold; the second branch pipe is fixedly connected and communicated with the convex mold; pressure stabilizing tanks are arranged on the other side of the concave mold and the other side of the convex mold; a circulating water pump is fixedly connected to the water outlet pipe, heating assemblies are arranged on the first branch pipe and the second branch pipe; and a water pressure demolding assembly is arranged in the convex mold. According to the plastic injection mold, cooling and demolding actions can be conveniently remembered, the cooling is sufficient; the demolding effect is good; the cooling effect is guaranteed for the demolding ejection position, and thus, the damage is reduced; and meanwhile, the mold can be kept at a certain temperature during injection molding, so that uneven injection molding caused by the cold mold is avoided.

Owner:孙超月

Drying system with cooling function

InactiveCN106196920AAvoid uneven heatingEasy dischargeDrying solid materials with heatDrying gas arrangementsCold airElectricity

The invention discloses a drying system with a cooling function. The drying system comprises an infrared drying chamber and a containing frame arranged in the infrared drying chamber; the infrared drying chamber comprises a drying body, a plurality of infrared heating lamp tubes are arranged in the drying body, an exhaust pipe is arranged at the top of the drying body, and a draught fan is arranged in the exhaust pipe; and the containing frame comprises a base arranged at the bottom of the drying body, a motor is arranged in the base, a rotating shaft is connected to the power output end of the motor, and a shoe body containing plate is arranged on the rotating shaft. A temperature sensor and a humidity sensor are arranged in the drying body, a display screen electrically connected with the temperature sensor and the humidity sensor is arranged on the outer wall of the drying body, and an air inlet pipe is further arranged on the drying body and communicated with a dry cold air storage tank. The drying system solves the problem that the drying efficiency is low due the fact that an existing drying manner is used; and meanwhile, the cooling function is achieved, and a dried shoe body can be rapidly cooled to the normal temperature.

Owner:CHENGDU LIXIN SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com