Energy-saving casting system

An energy-saving, casting mold technology, which is applied in foundry workshops, casting equipment, manufacturing tools, etc., can solve problems that affect the final quality of cast products, unreasonable use of resources, and waste of waste heat in solutions, so as to save manpower and improve the degree of automation , the effect of increasing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

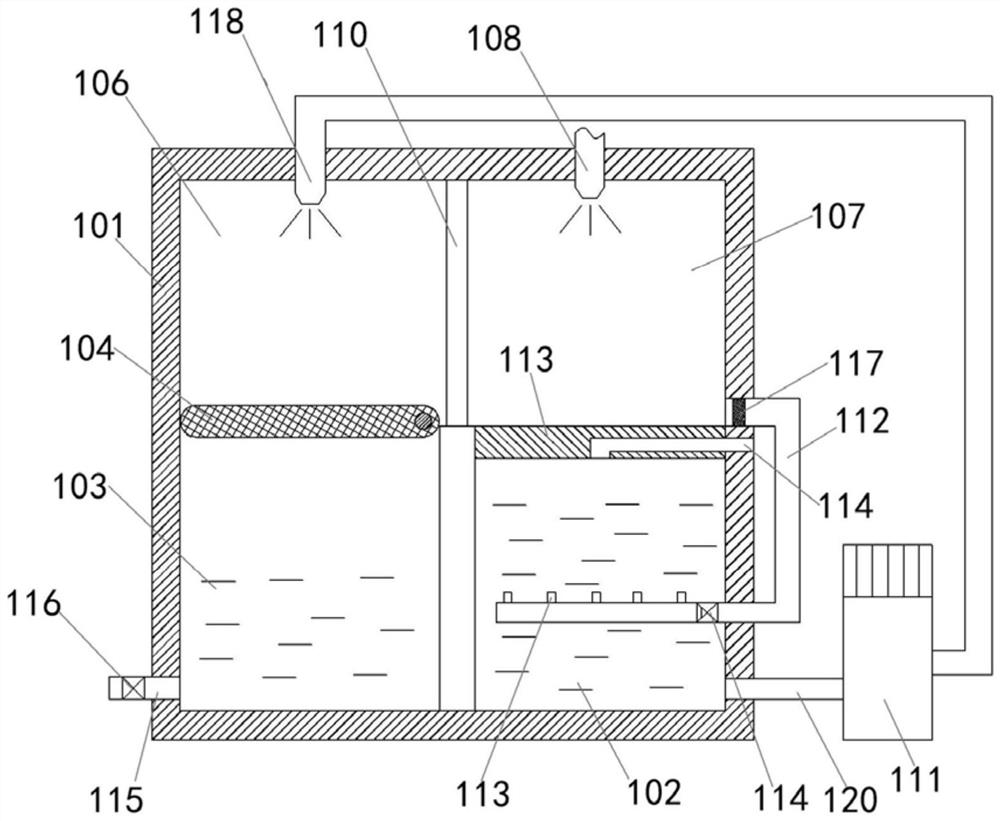

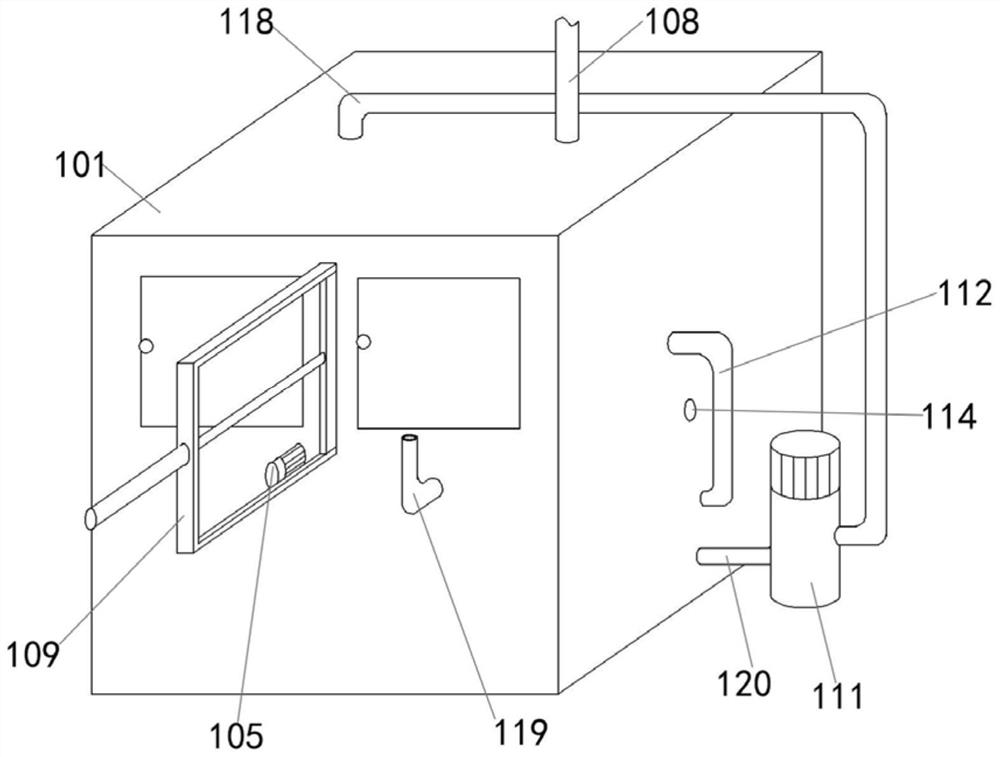

[0038]The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0039] Example: such as Figure 1-4 The energy-saving casting system shown includes a casting material cleaning device 100 and a casting mold 200. After the old metal block to be heated is cleaned by the casting material cleaning device 100, it is sent into the heating cylinder 5 of the casting mold 200 by the operator for heating. Heating and melting (the top of the heating cylinder 5 can be provided with a feeding port that is closed by a cock, and the cleaned old metal block is dropped into the heating cylinder 5 through the feeding port, which is not shown in the figure for clarity of view), casting material cleaning device 100 includes a cleaning housing 101. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com