Patents

Literature

716results about How to "Improve rust removal effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pipeline inner wall rust removal device

ActiveCN104723223AAvoid pollutionReduce direct damageGrinding machinesAbrasive machine appurtenancesPneumatic motorPollution

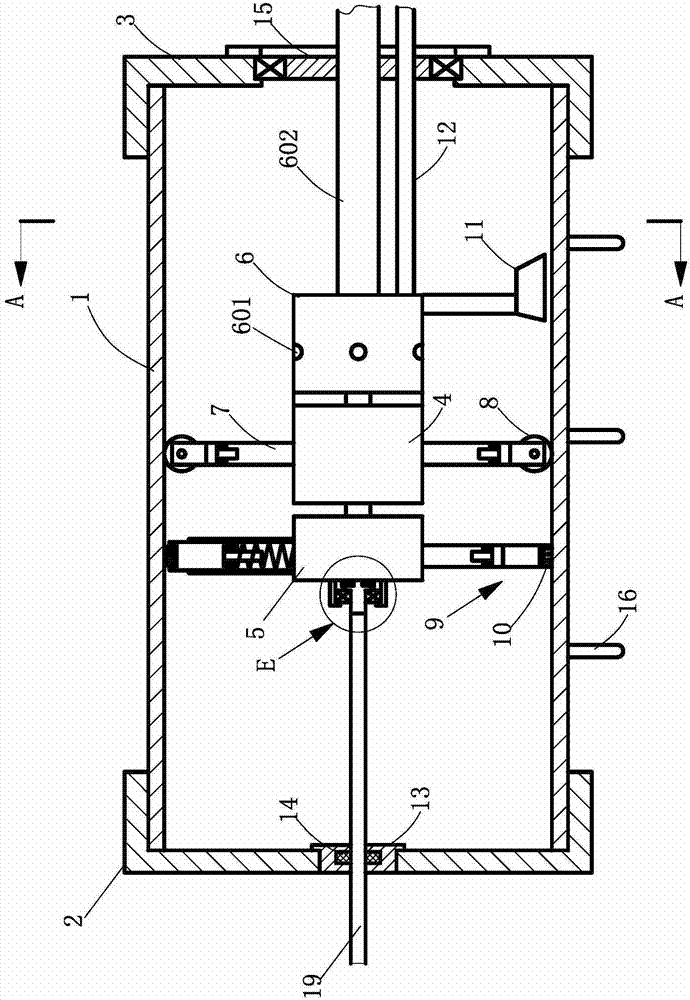

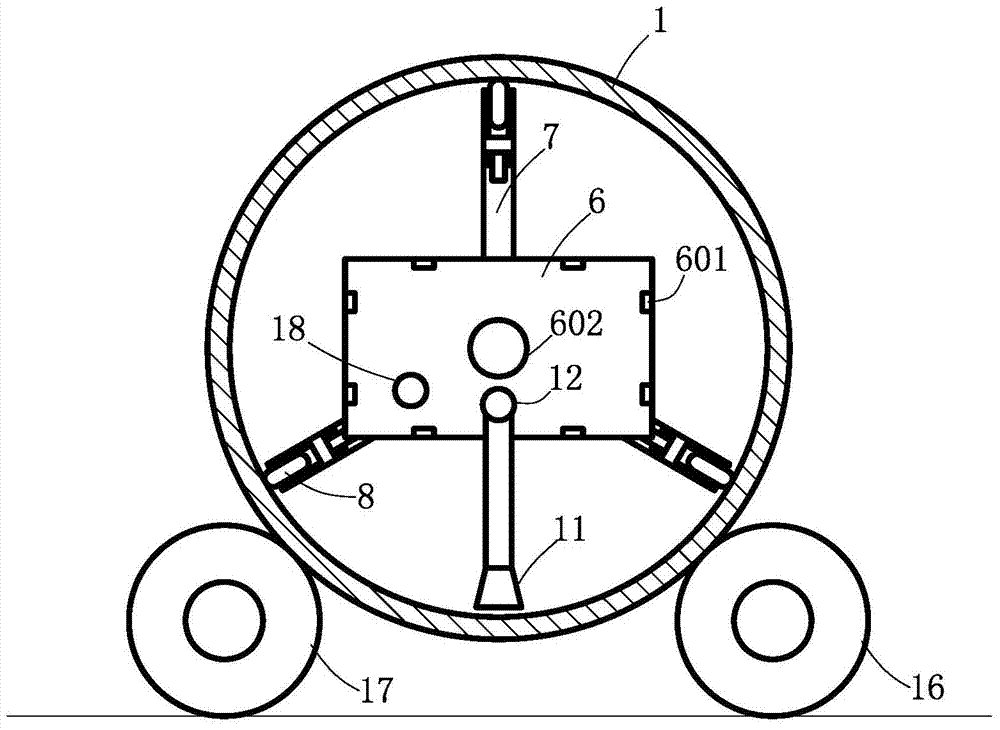

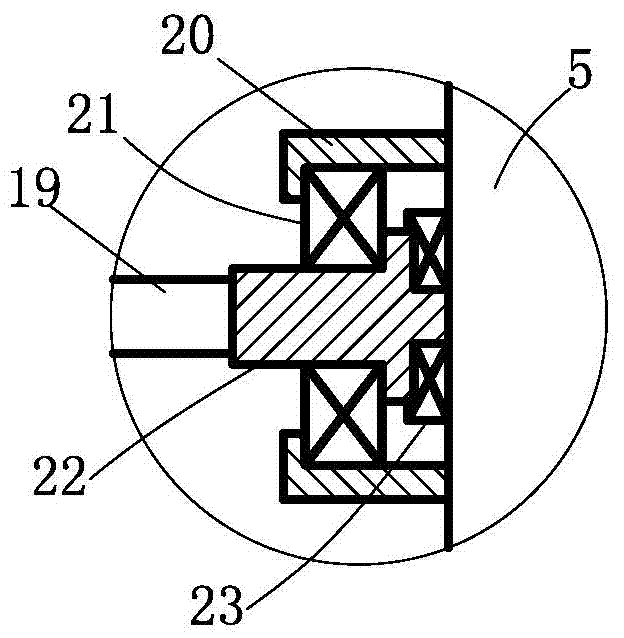

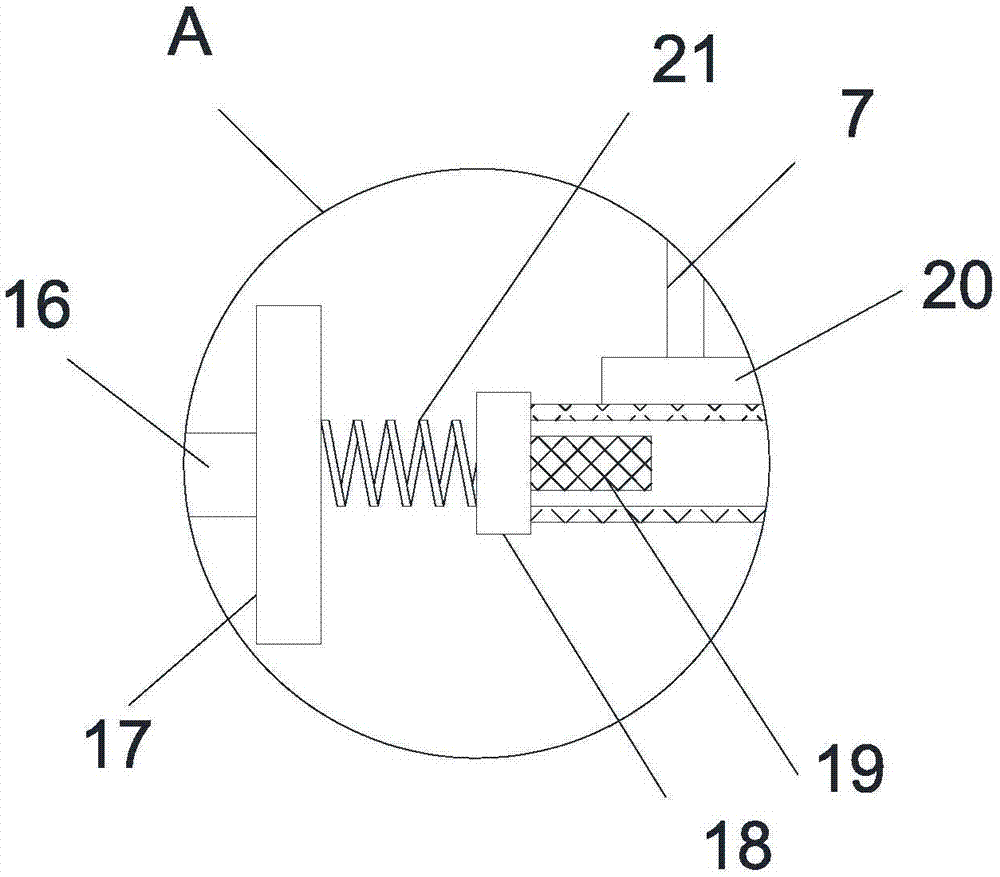

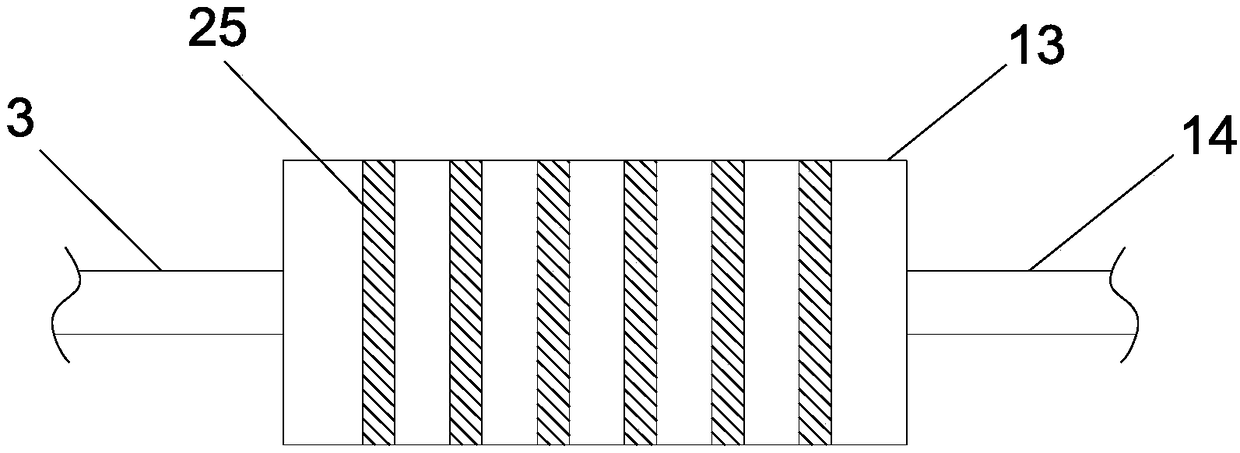

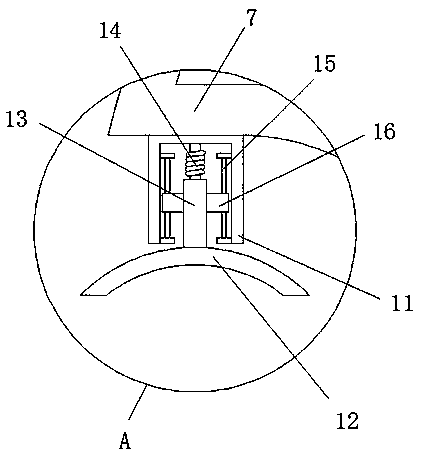

The invention discloses a pipeline inner wall rust removal device, belonging to the technical field of polishing units. The device comprises a first end cover and a second end cover which are hermetically installed at two ends of the pipeline, a rust removal trolley is arranged in the pipeline, the dust removal trolley comprises a pneumatic motor with dual output shafts, a shell of the pneumatic motor is provided with a plurality of support shafts, the end part of each support shaft is provided with a roller wheel, a grinding disc is fixedly installed on the output shaft of the pneumatic motor, close to the first end cover, and is provided with a plurality of support rods in the radial direction, the end part of each support rod is provided with an abrasive disc, the output shaft of the pneumatic motor, close to the second end cover, is connected with a shot-blasting machine in a transmission manner; the end part of the grinding disc is connected with a traction rope, the traction rope extends out of the first end cover, one end of the shot-blasting machine, close to the second end cover, is connected with a shot feeding pipe, the pneumatic motor is connected with a gas inlet pipe, the shot feeding pipe and the gas inlet pipe extend out of the second end cover. The pipeline inner wall rust removal device can be used for solving the technical problems that the pipeline inner wall is serious in rust removal pollution and the rust removal effect is poor, and can be widely applied to pipeline cleaning.

Owner:SHANGHAI HONGPU STEEL STRUCTURE ENG

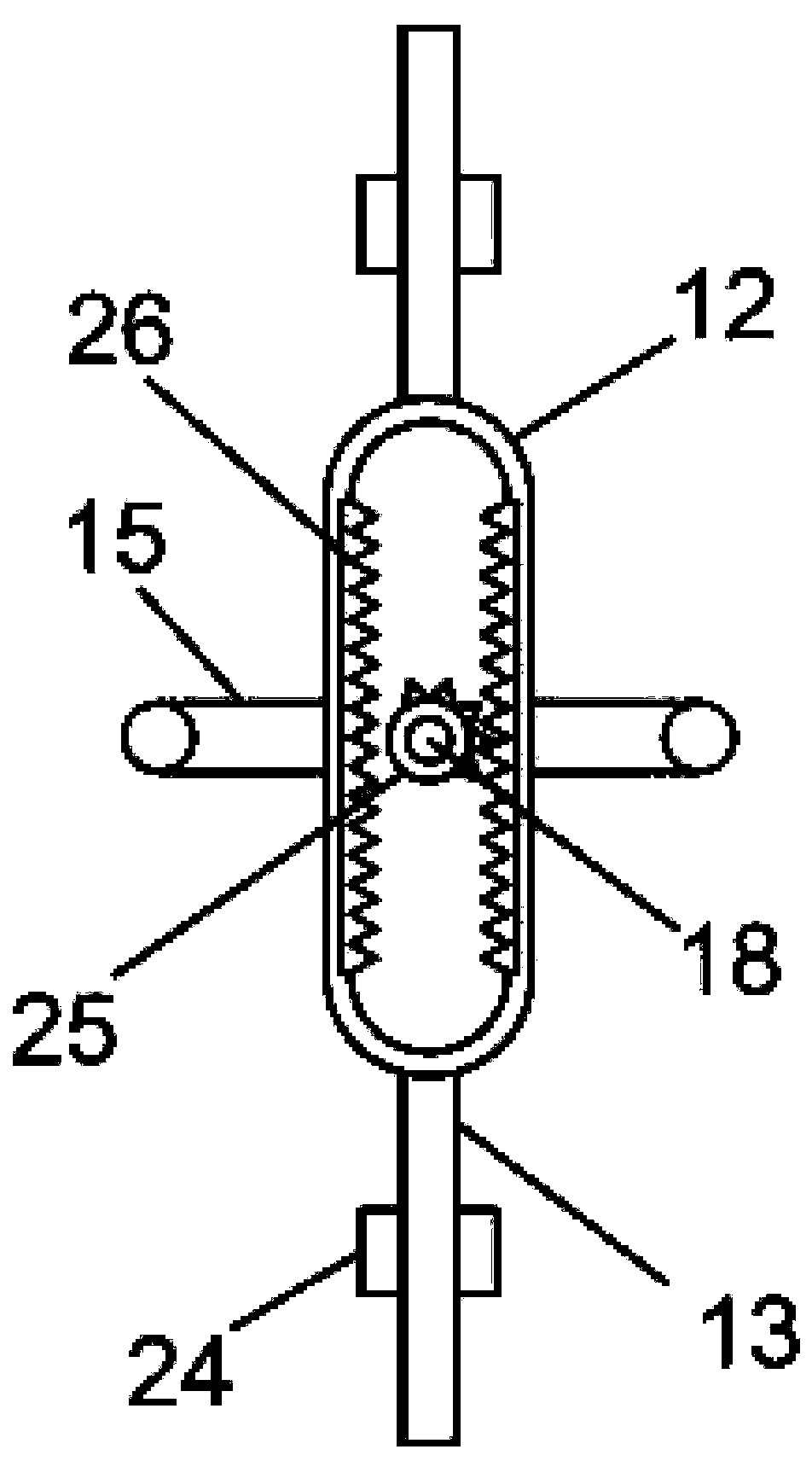

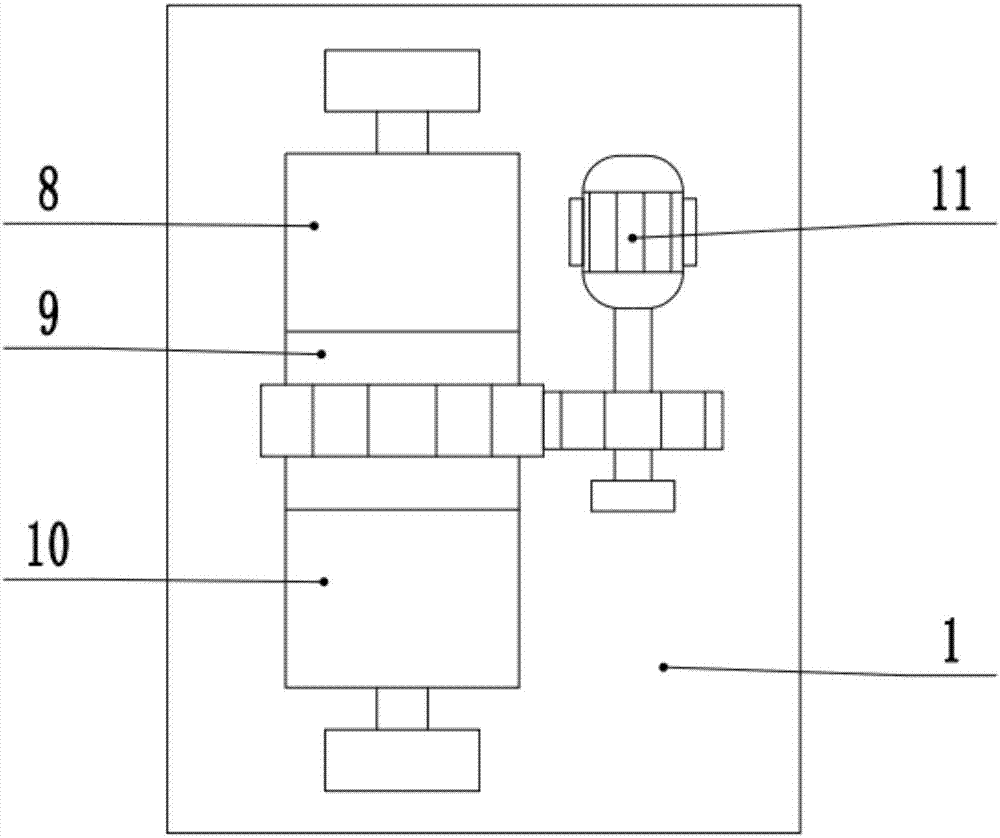

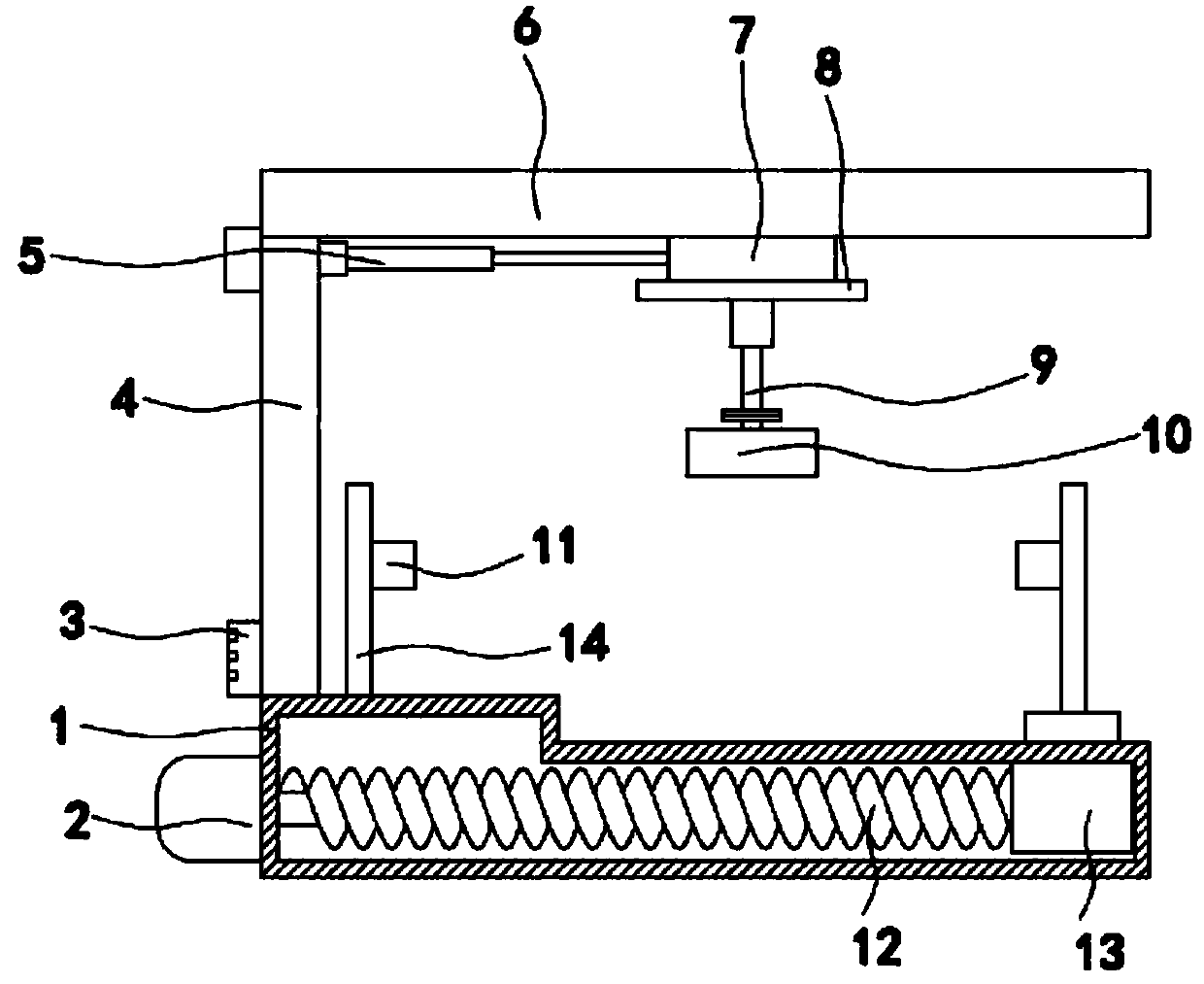

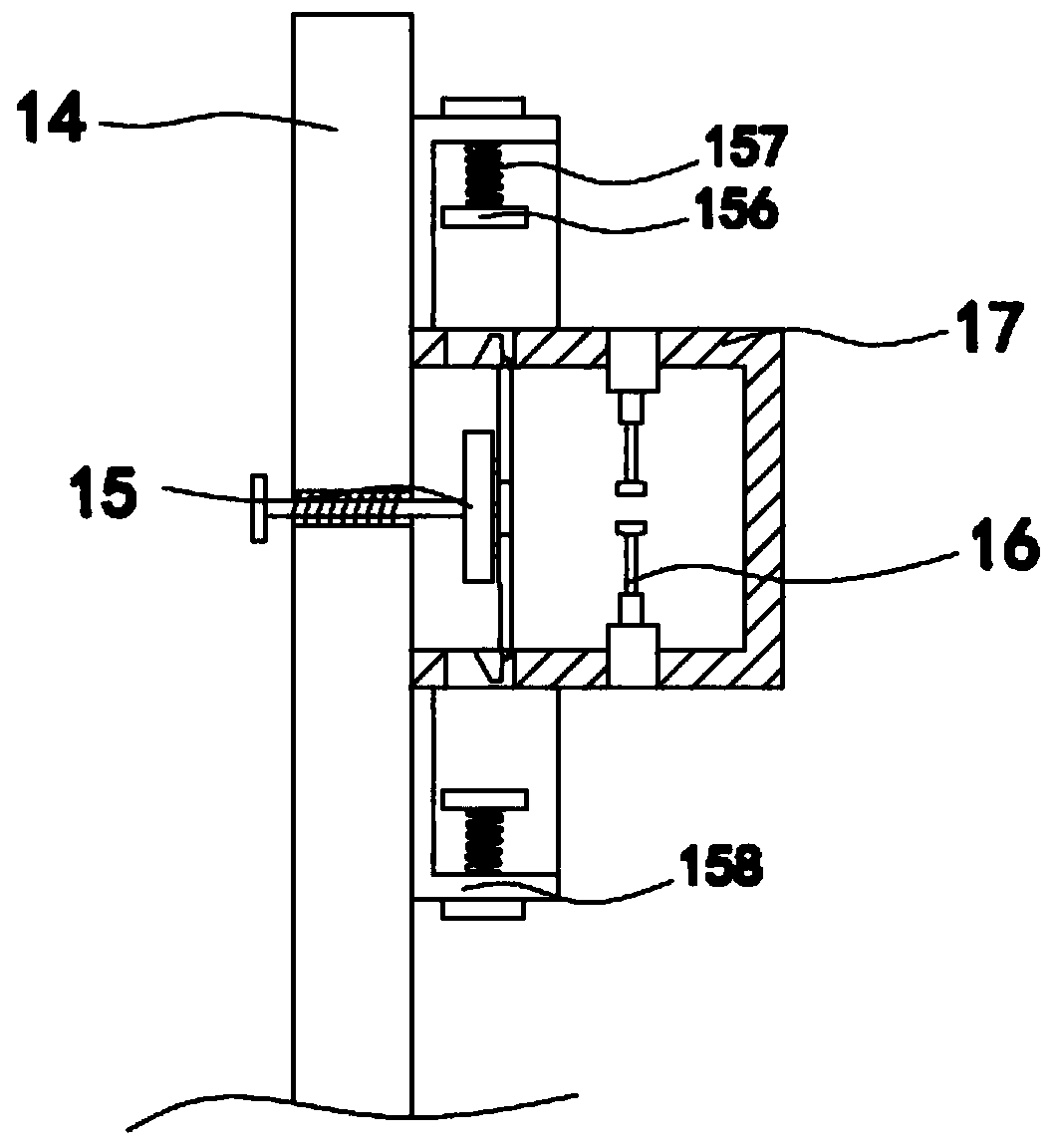

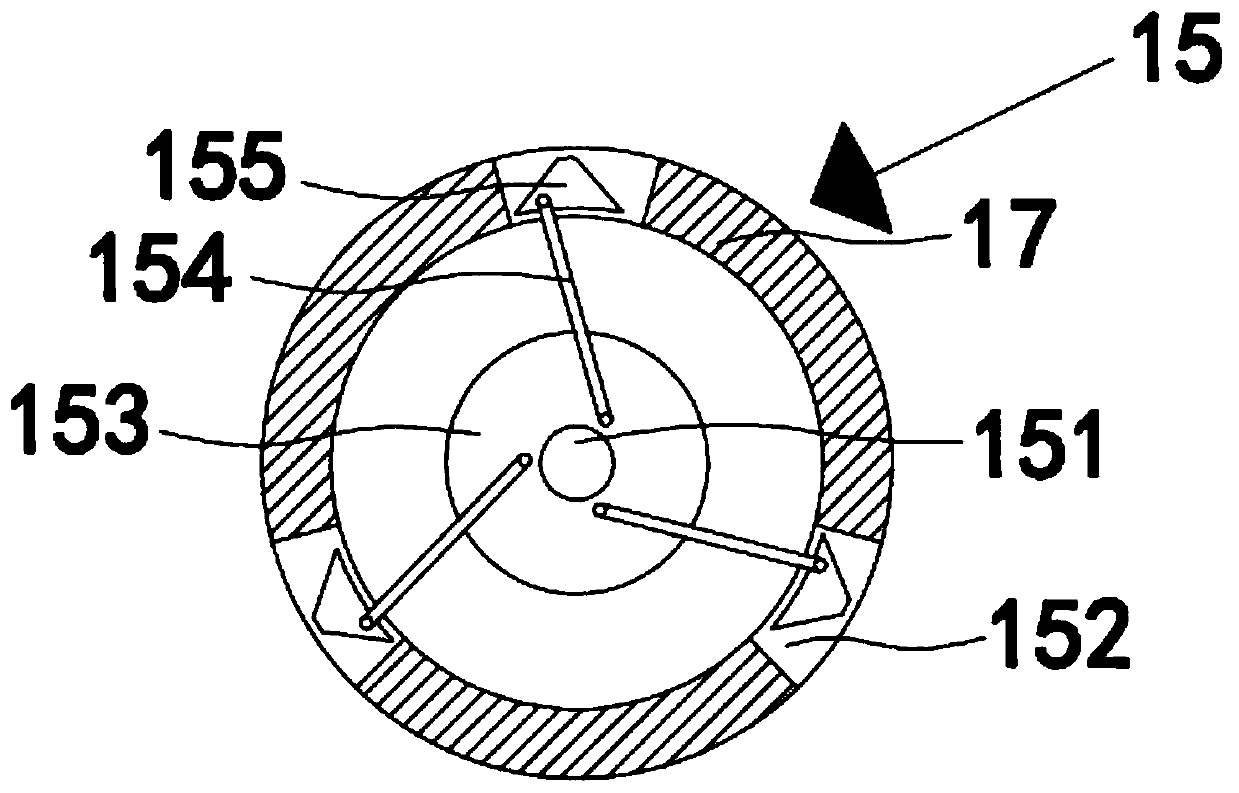

Grinding and rust removing device for chemical pipeline anticorrosion

InactiveCN107962460AGood rust removal effectGrinding speed is fastRevolution surface grinding machinesGrinding drivesReciprocating motionEngineering

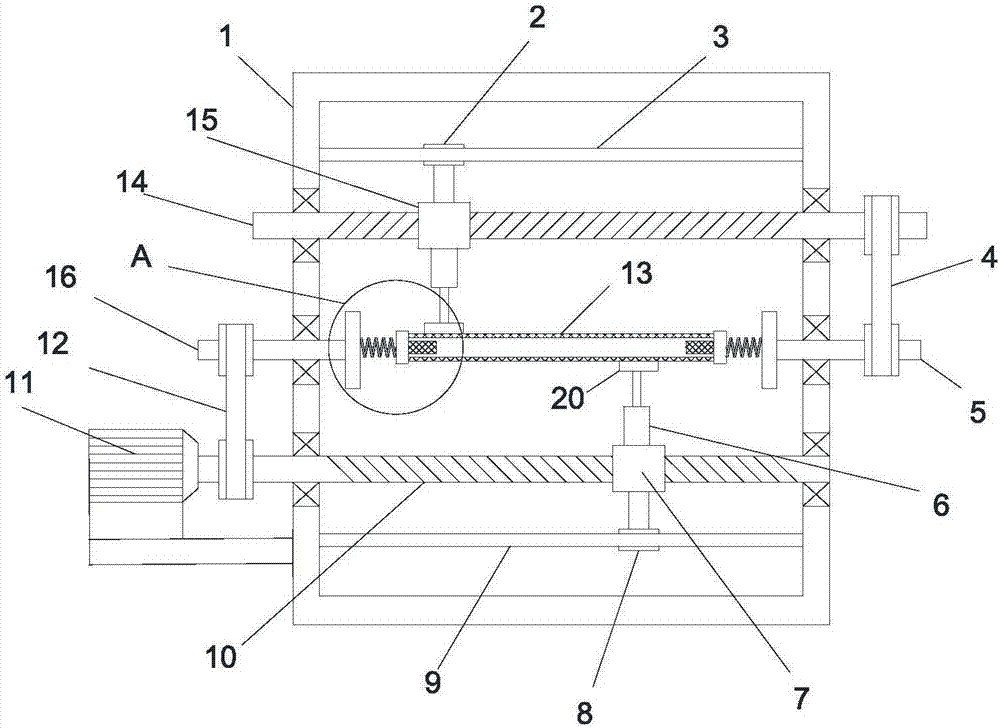

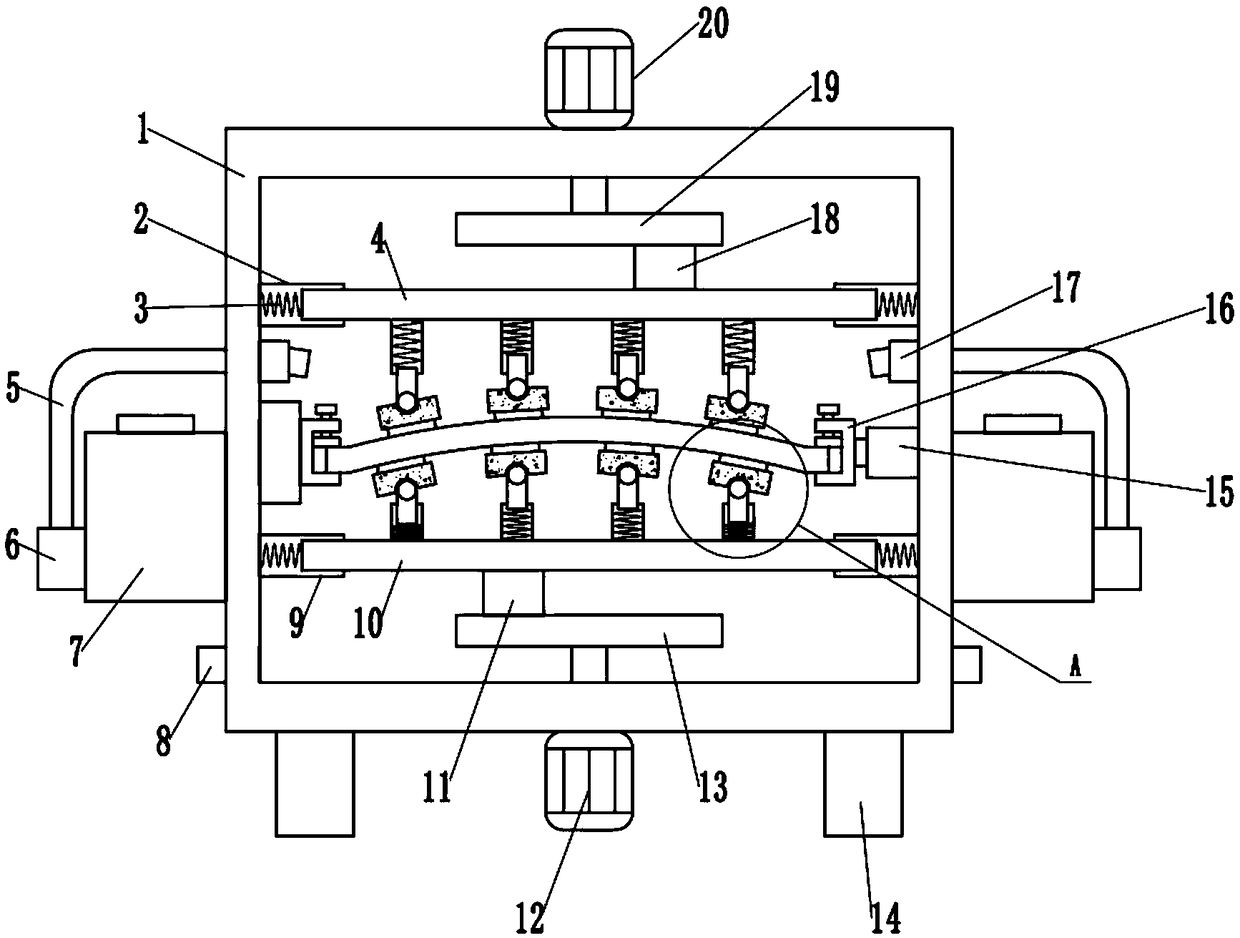

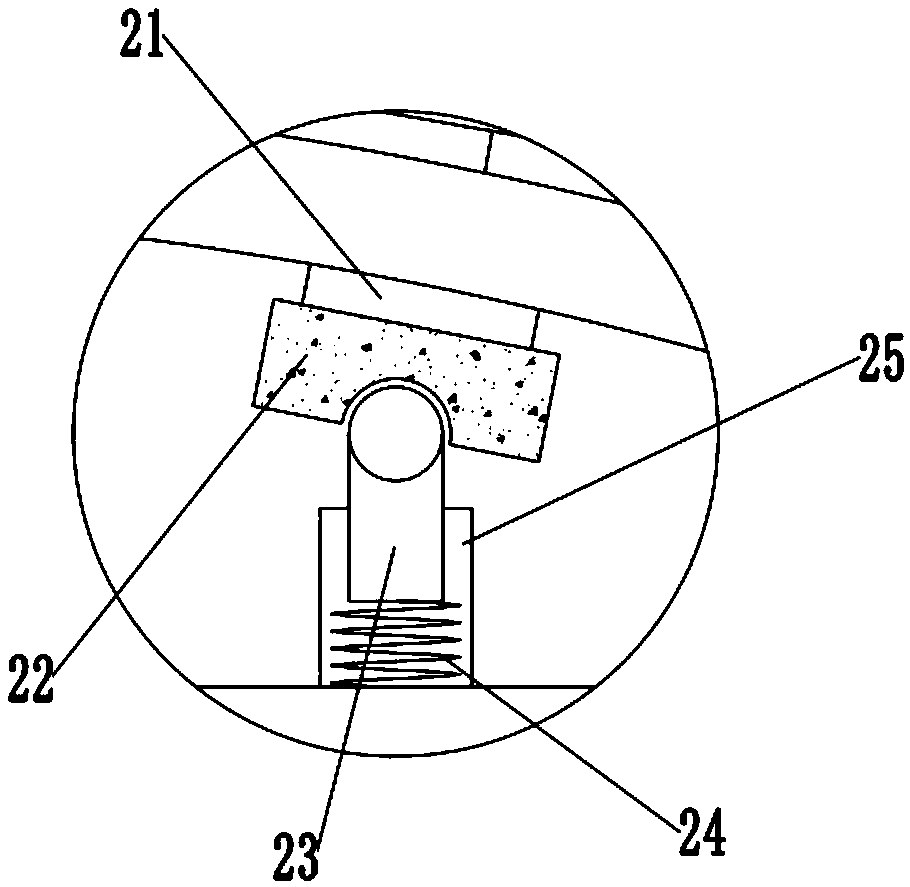

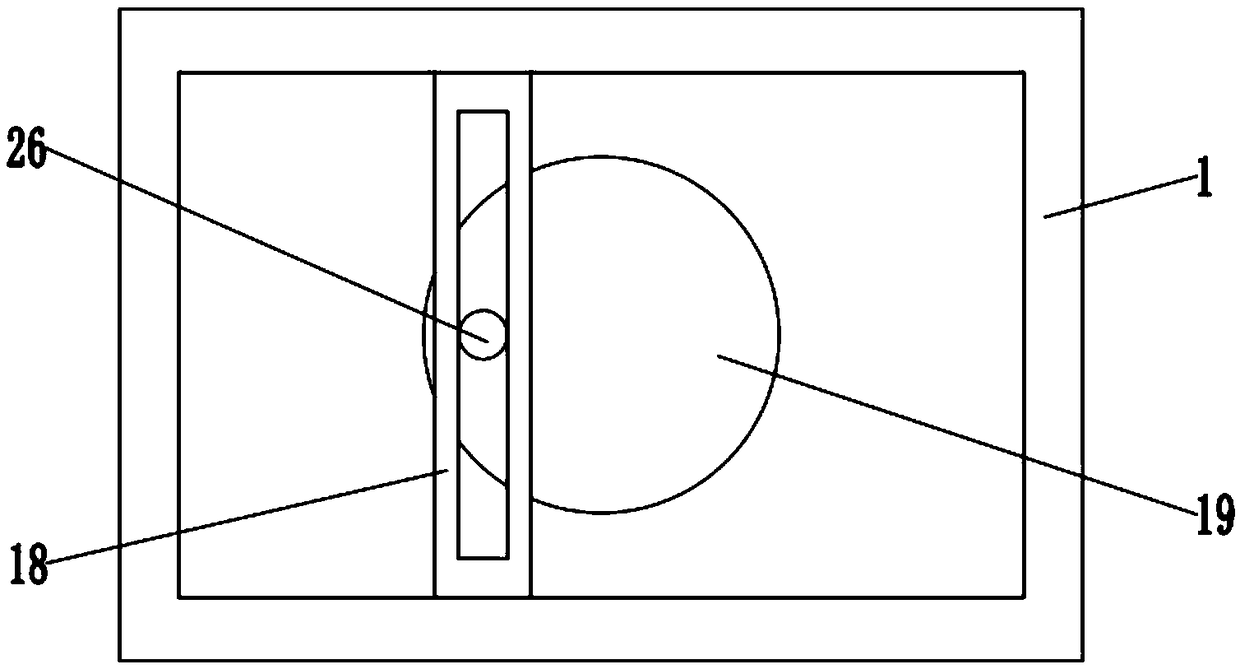

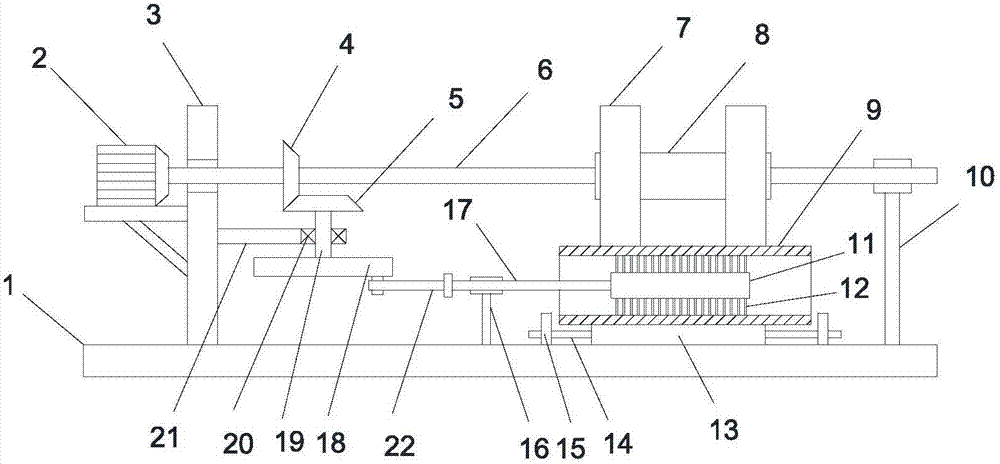

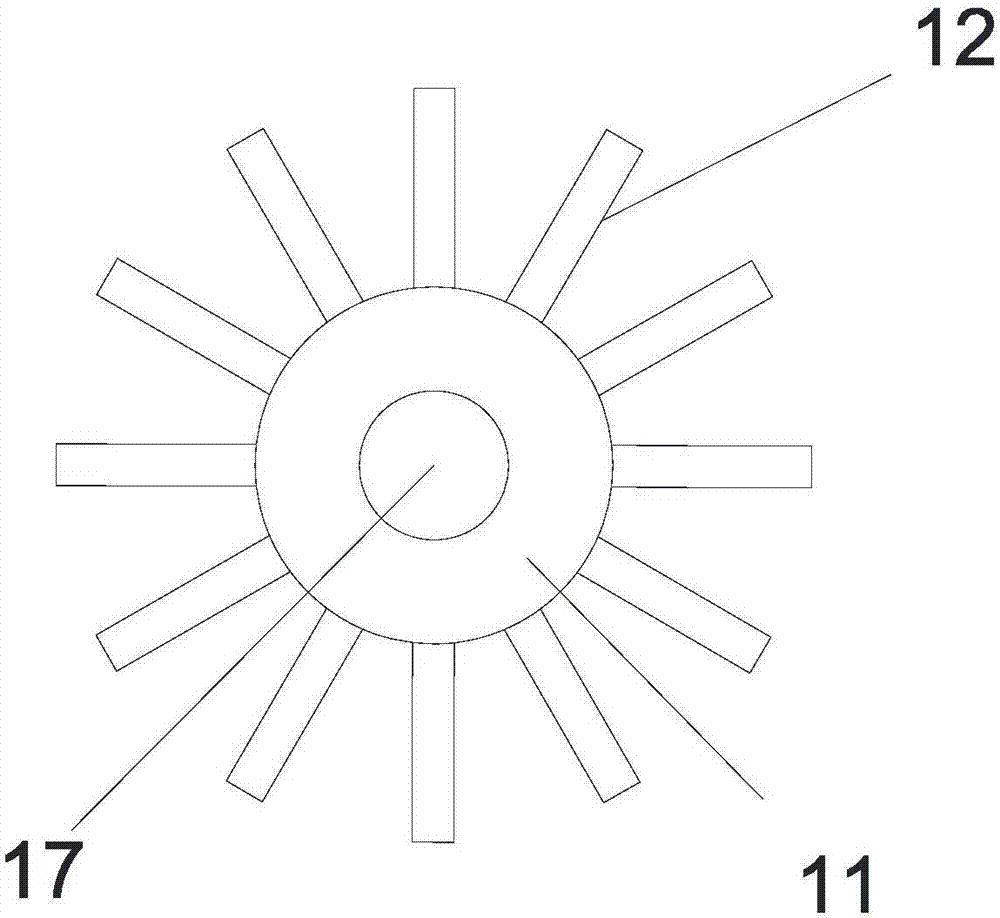

The invention discloses a grinding and rust removing device for chemical pipeline anticorrosion. The grinding and rust removing device for chemical pipeline anticorrosion comprises an operation frame.A first guide rod and a second guide rod are horizontally and fixedly mounted in the operation frame. The first guide rod and the second guide rod are slidably sleeved with an upper sliding sleeve and a second sliding sleeve correspondingly. Grinding heads are fixedly mounted at the ends of telescopic rods correspondingly. A rotary shaft is rotatably arranged on the right sidewall of the operation frame. The rotary shaft is in transmission connection with a second lead screw through a second transmission belt. An output shaft of a forward and reverse rotating motor is coaxially fixed to the second lead screw. According to the grinding and rust removing device, the forward and reverse rotating motor rotates forwards and reversely to drive a first lead screw and the second lead screw to rotate, and then a first threaded sleeve and a second threaded sleeve drive the telescopic rods to do left-right reciprocating motion. Finally, the grinding heads do transverse back and forth motion to grinding the surface of a pipeline. The grinding speed is increased. Meanwhile, the pipeline can rotates along with rotating of the fixed plates so as to be annularly ground. The working efficiency isgreatly improved.

Owner:HENAN GAOSHENG ENTERPRISE MANAGEMENT CONSULTING CO LTD

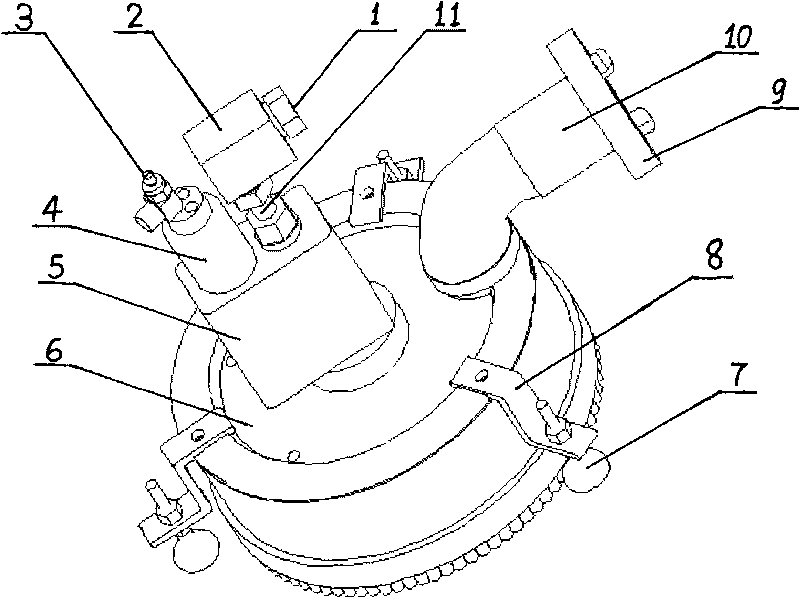

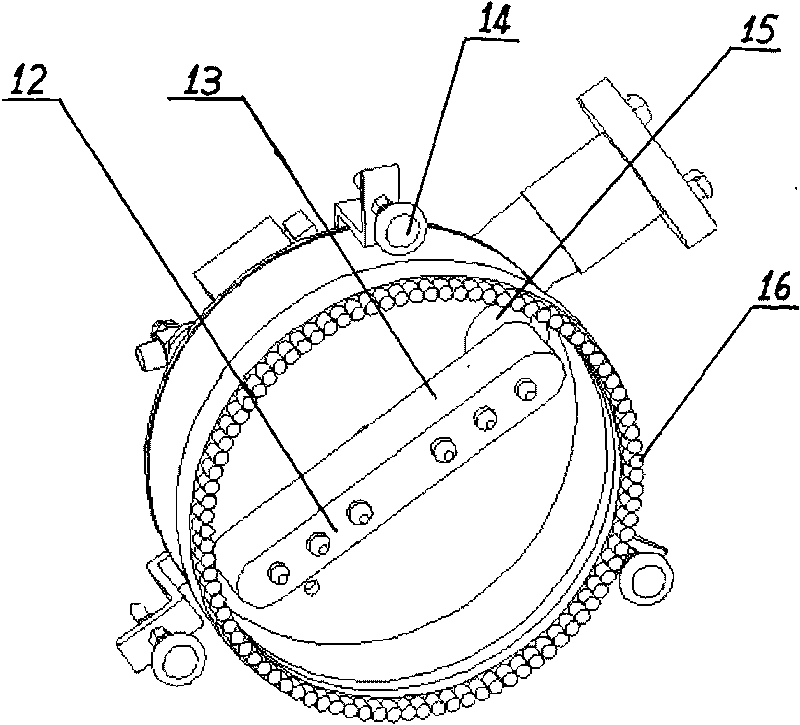

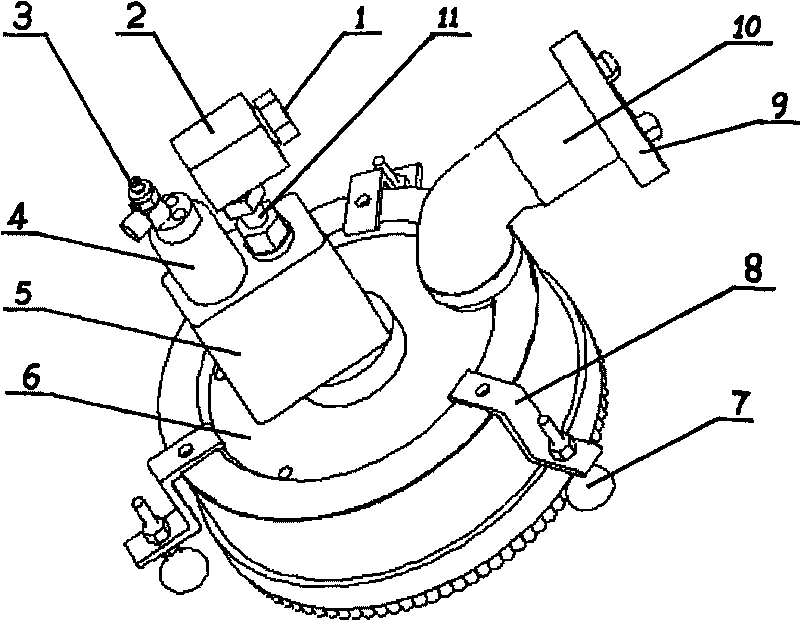

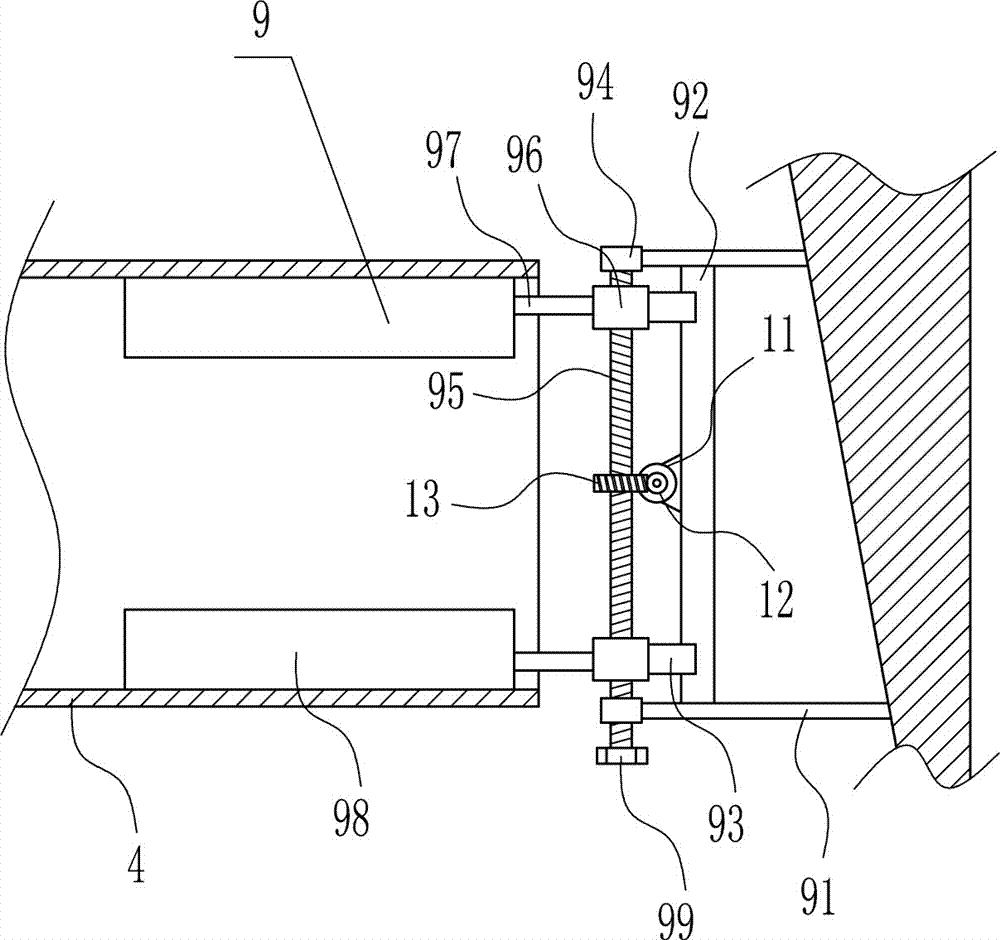

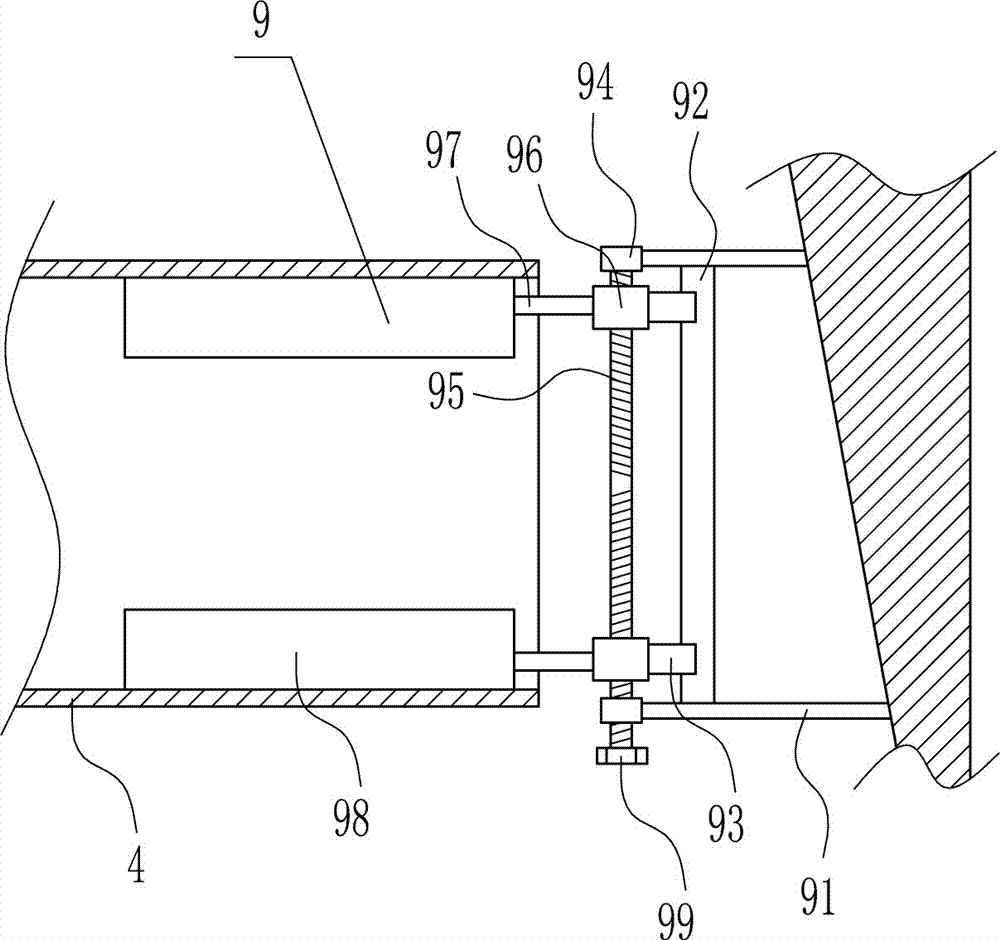

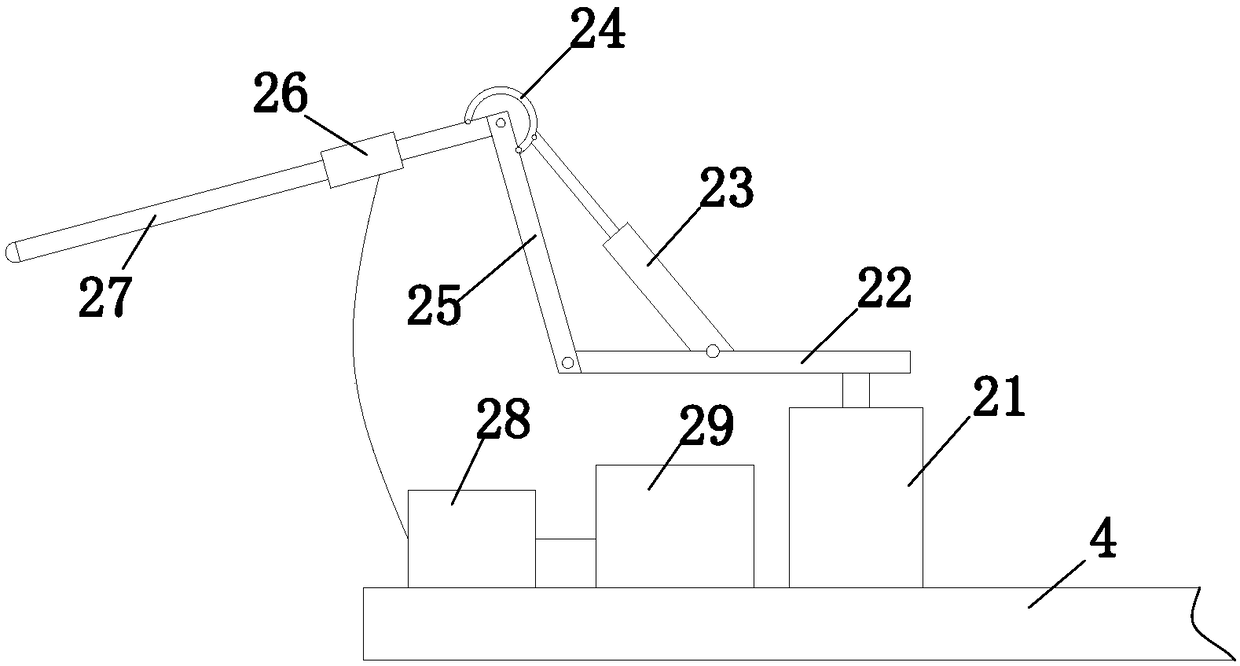

Water jetting washing device and ship wall rust removing wall-climbing robot

The invention is suitable for the technical field of ship rust removing and washing, and provides a water jetting washing device. The water jetting washing device aims at solving the technical problem that the angles of washing nozzles in a ship rust removing and washing device in the prior art can not be adjusted. The water jetting washing device comprises a high-pressure water pipe assembly, a plurality of nozzles and a rotating assembly which is connected to the high-pressure water pipe assembly and used for driving the high-pressure water pipe assembly to rotate. The high-pressure water pipe assembly comprises a main water pipe connected with the rotating assembly and a plurality of branch water pipes communicated with the main water pipe and each provided with at least one nozzle. The water jetting washing device further comprises adjustment assemblies connected between the main water pipe and the branch water pipes to adjust the jetting angles of the branch water pipes relative to the nozzles. According to the water jetting washing device, as the nozzles are arranged on the branch water pipes, and the jetting angles of the nozzles are adjusted through the adjustment assemblies, the nozzles can conduct washing work and rust removing work at any angle, washing work and rust removing work under different working conditions can be achieved, and the washing effect and the rust removing effect are greatly improved.

Owner:SHENZHEN INST OF ADVANCED TECH

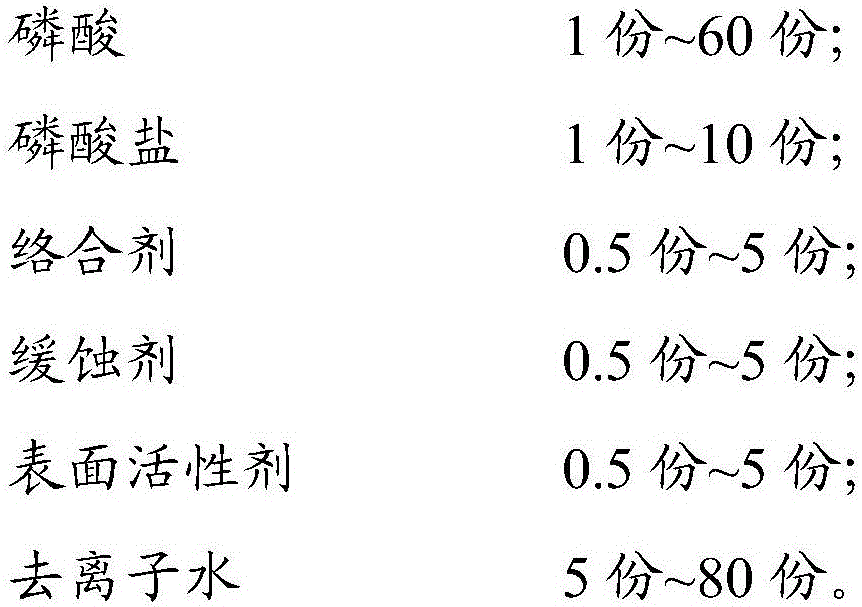

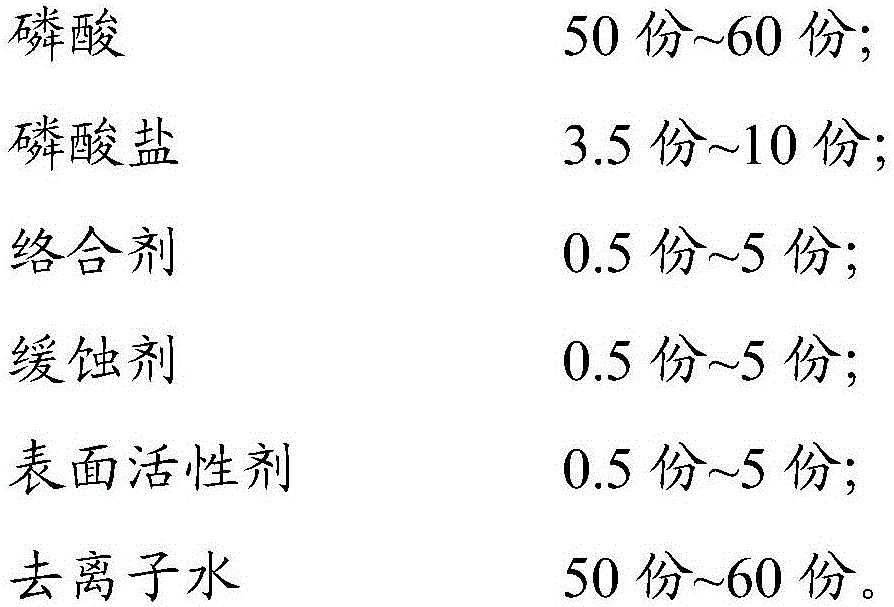

Environment-friendly aluminum cleaning agent and preparation method thereof

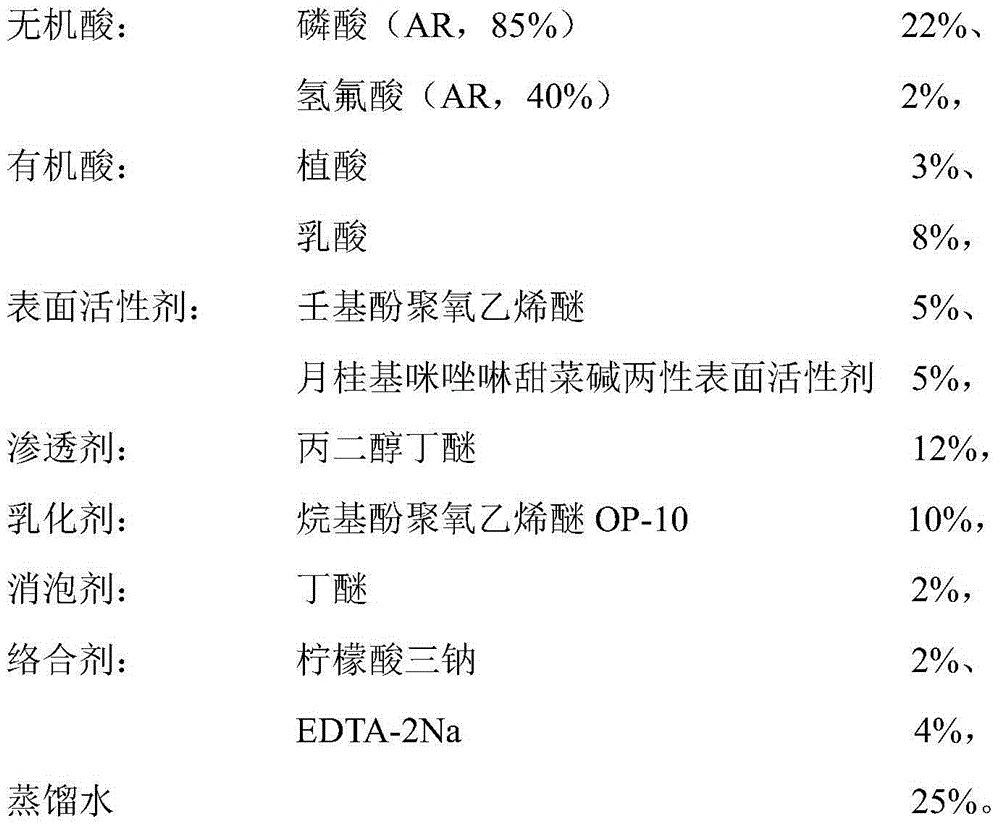

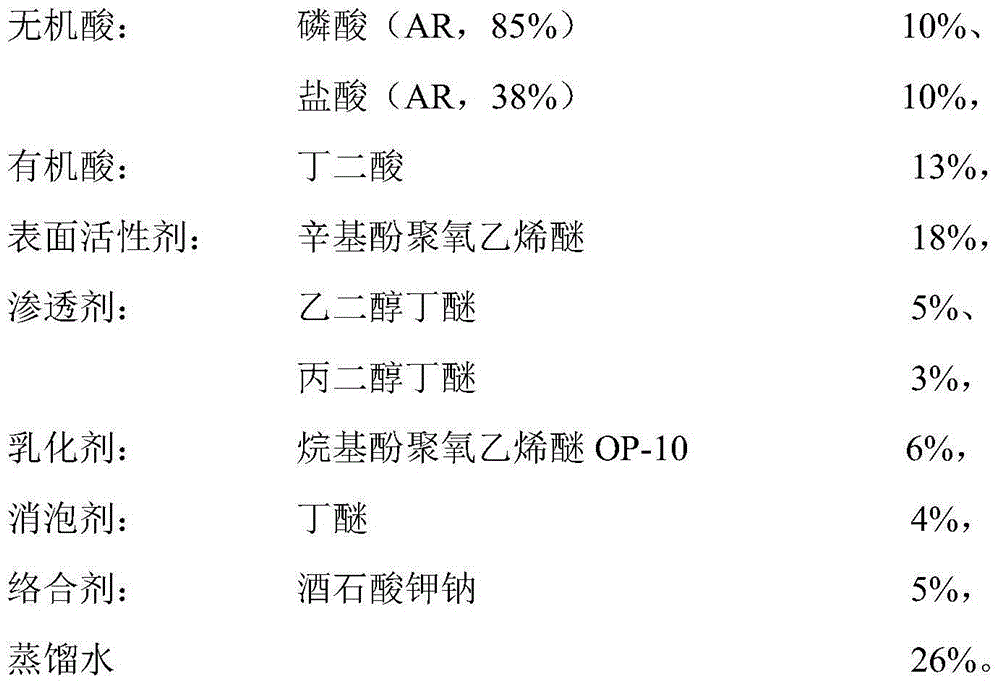

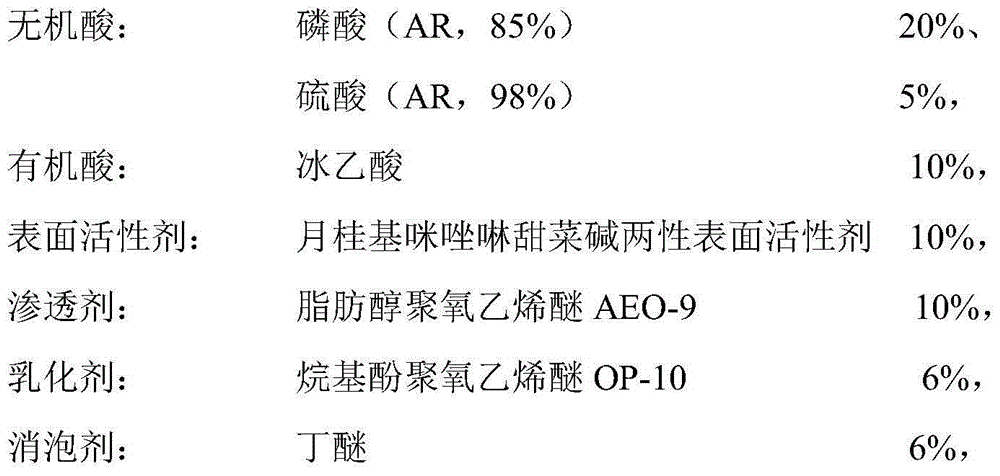

The invention discloses an environment-friendly aluminum cleaning agent and a preparation method thereof. The cleaning agent is composed of the following components in percentage by weight: 20% to 25% of inorganic acid, 10% to 20% of organic acid, 10% to 18% of surfactant, 8% to 15% of osmotic agent, 6% to 18% of emulsifier, 2% to 8% of antifoaming agent, 5% to 8% of complexing agent, and 25% to 30% of water. In the provided cleaning agent, the using amount of hydrochloric acid, sulfuric acid, and nitric acid is reduced, the aluminum parts are washed by medium-strong acids and organic acids, and the cleaning agent has a very good oil stain and rust removing ability. The cleaning agent is acidic, the pH value of the cleaning agent is 2.1 to 5.6, and the cleaning agent can well remove the oxide scale on the aluminum surface. Because the acidity of the organic acids is weak, the over-corrosion on work tools and acid volatilization, which can harm the workers' health, are effectively avoided, and the cleaning effect is not influenced at the same time. Moreover the adopted organic acids are easy to decompose, and thus the cleaning agent is environment-friendly.

Owner:PINGGAO GRP +1

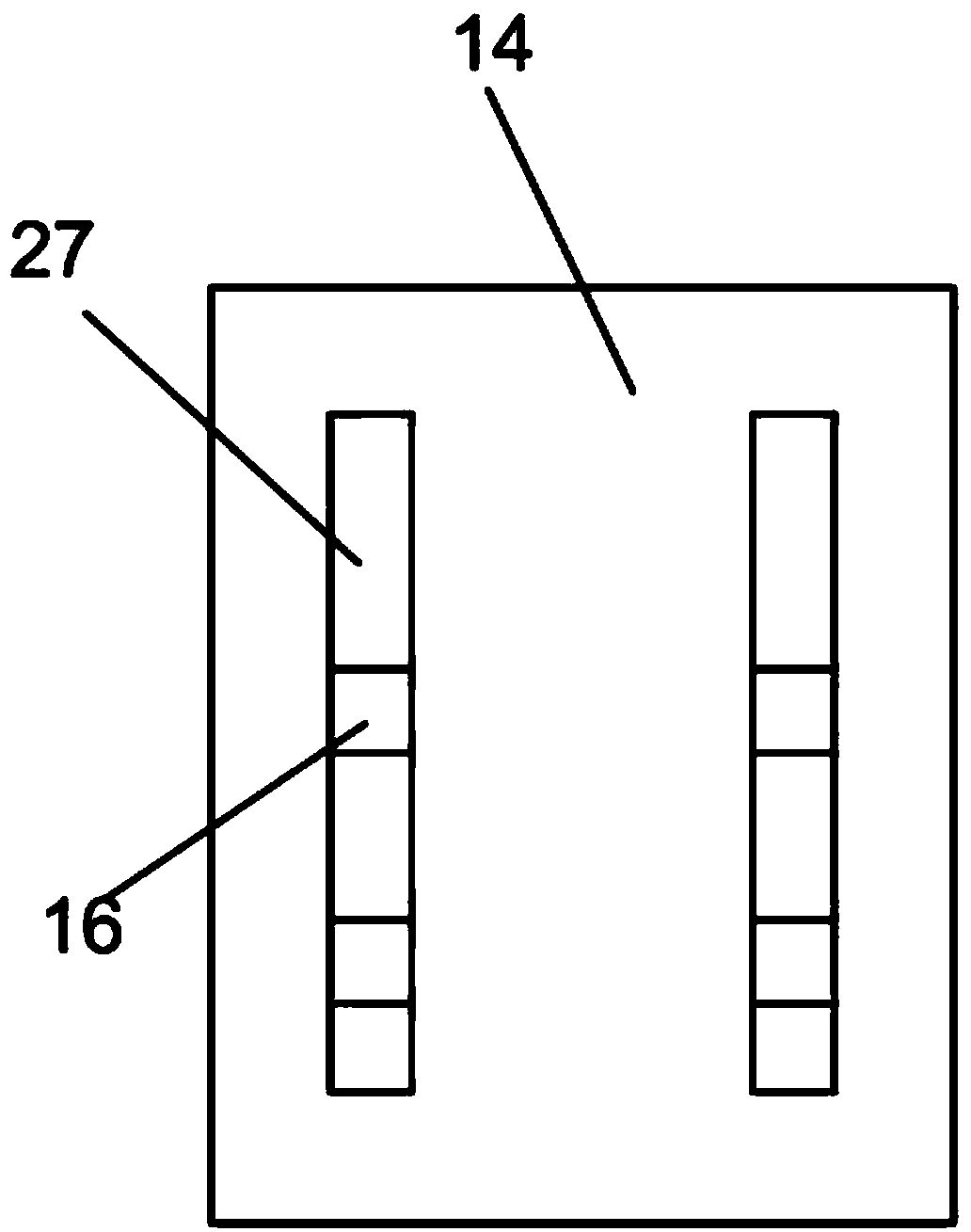

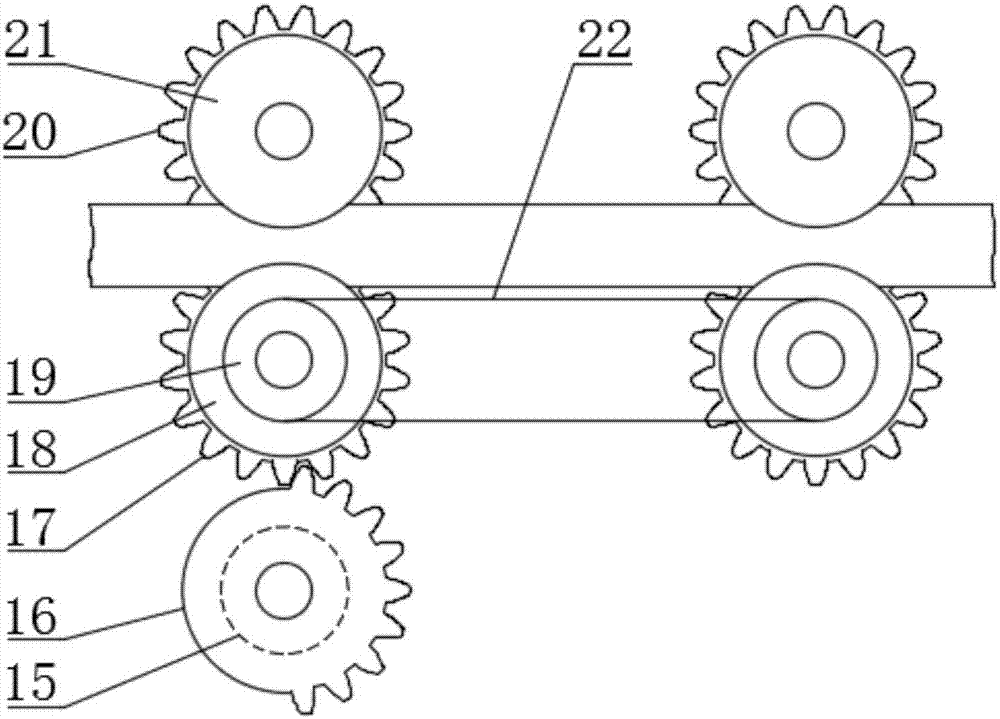

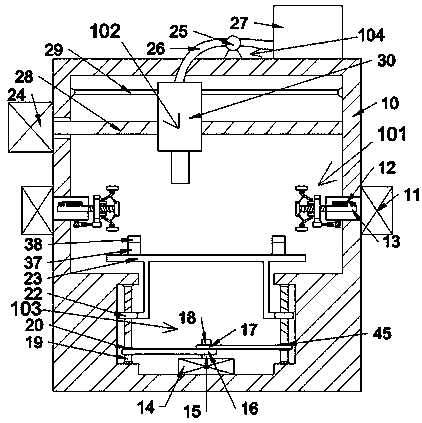

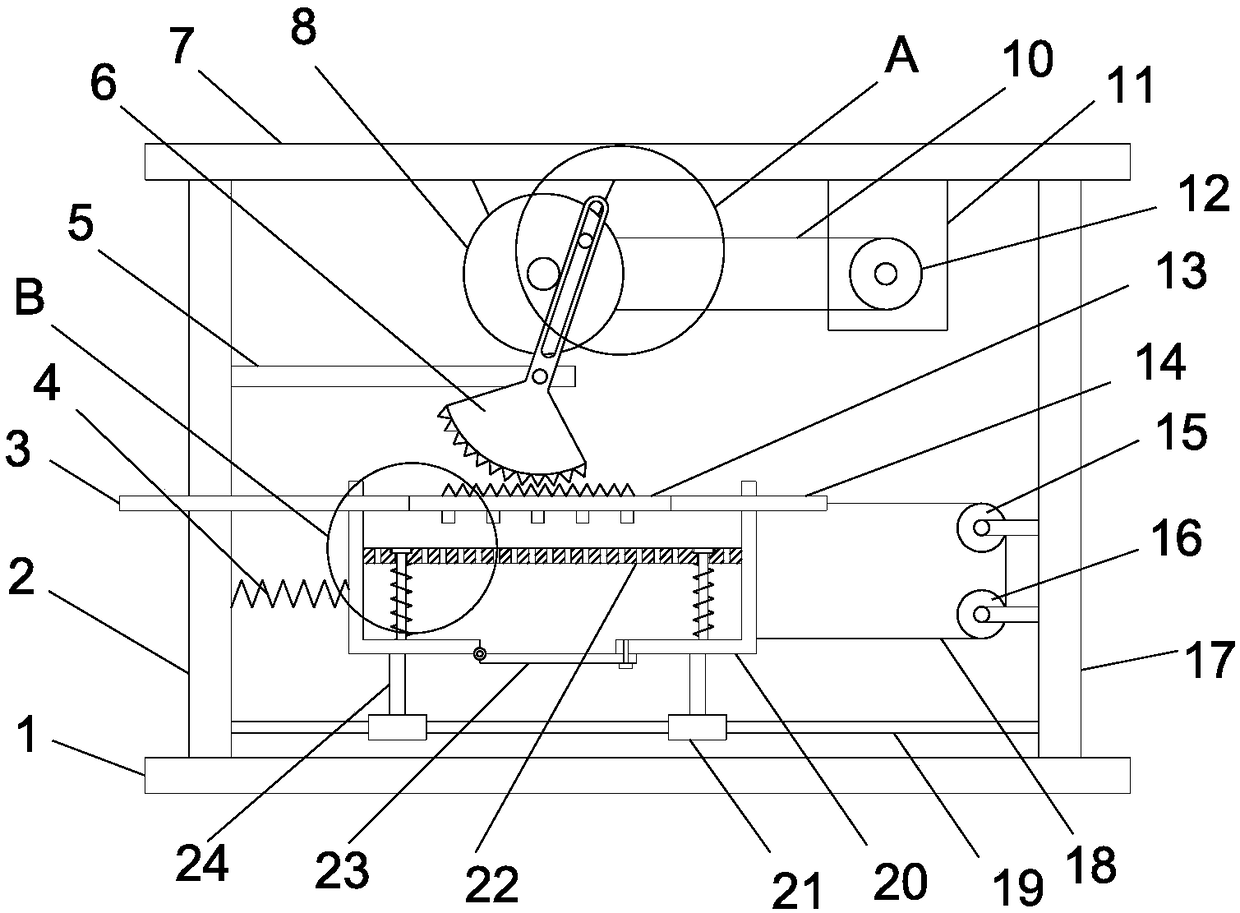

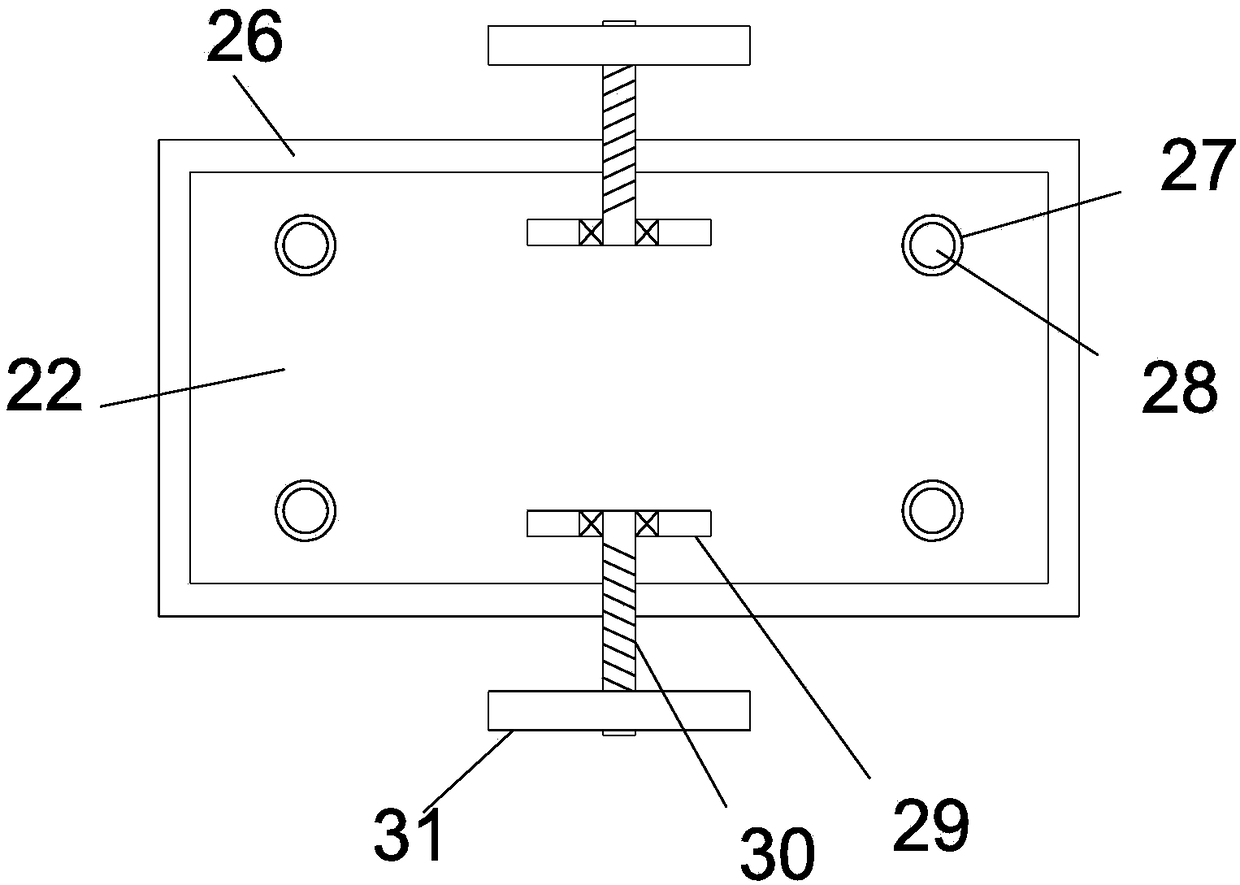

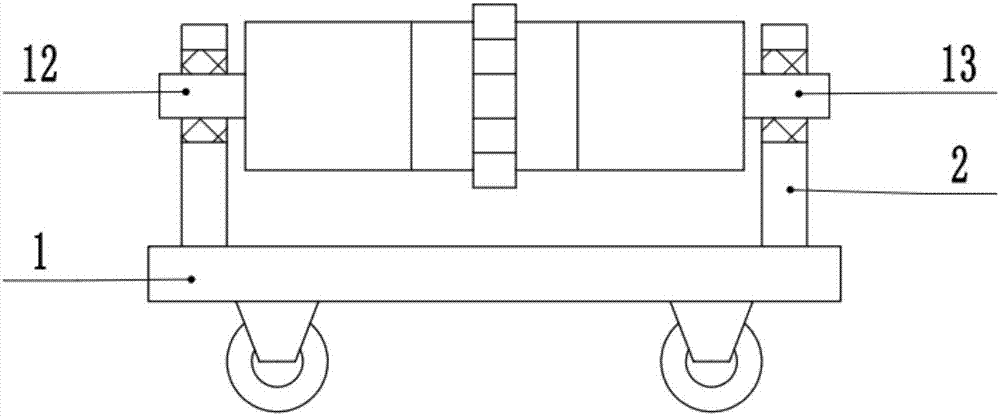

Machining-use efficient derusting device for surface of steel plate

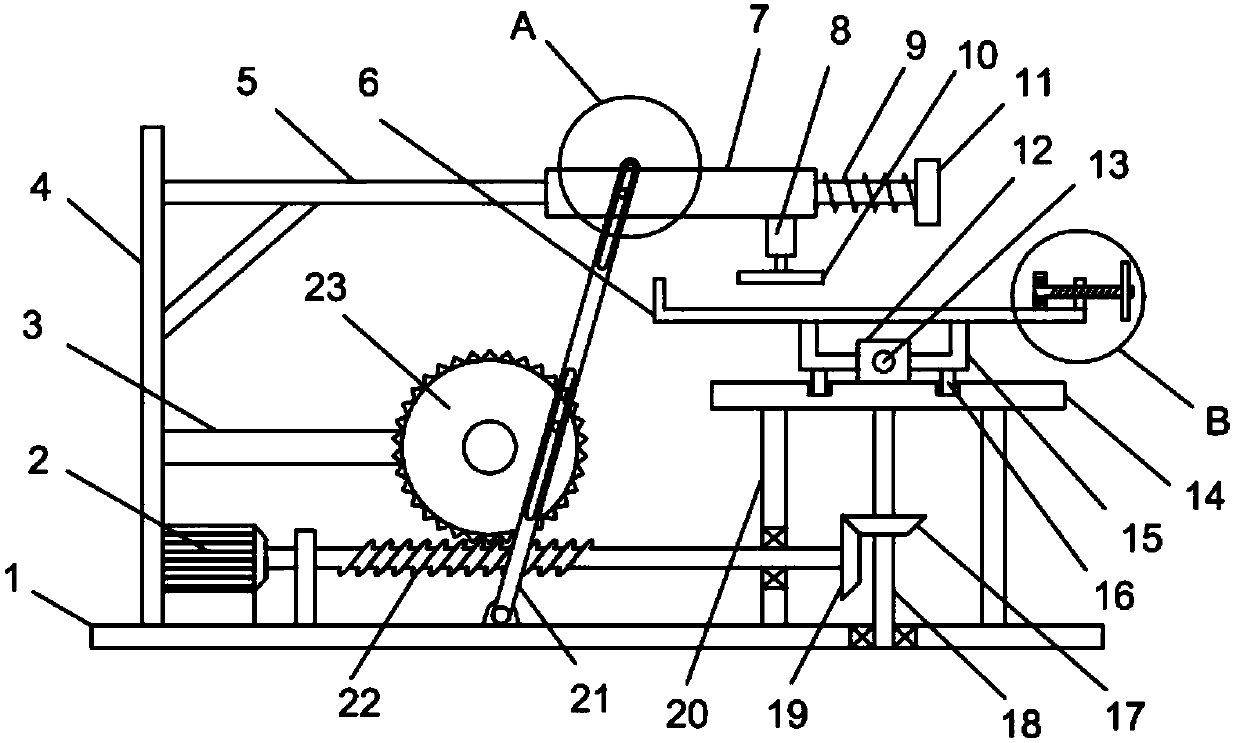

ActiveCN108673318ARealize repeated grinding and derustingGood rust removal effectGrinding machinesGear driveReciprocating motion

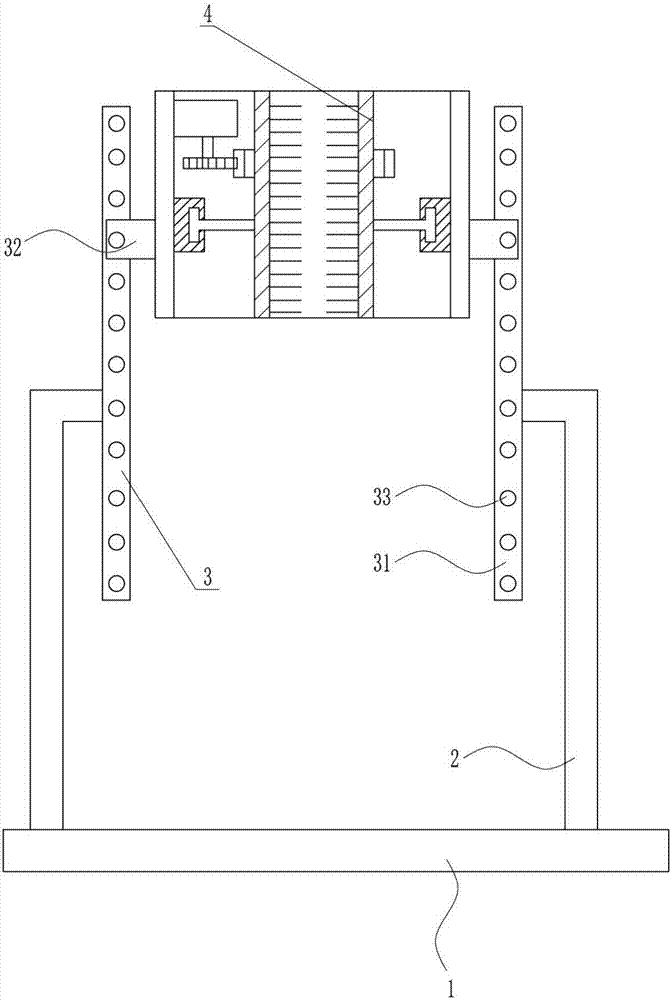

The invention discloses a machining-use efficient derusting device for the surface of a steel plate. The machining-use efficient derusting device comprises a bottom plate. A vertical plate is vertically and fixedly installed on the bottom plate. A guide rod is horizontally and fixedly installed on the right side wall of the vertical plate. Two guide sliding grooves are symmetrically formed in a supporting table. Limiting sliding blocks embedded in the guide sliding grooves in a sliding mode are vertically and fixedly installed at the bottom of a bearing plate. A hand wheel is fixedly installedat the right end of a lead screw. A driving motor serves as power output, a sliding sleeve plate reciprocates left and right along the guide rod through clockwise and anticlockwise alternating swinging of a swinging batten, and then repeated grinding derusting of a grinding disc in the horizontal transverse direction is realized. The rotation of an incomplete gear drives a concentric-square-shaped frame to reciprocate through a transmission inner rack, and the steel plate on the bearing plate reciprocates front and back relative to the grinding disc. Transverse grinding and longitudinal grinding are combined, grinding efficiency is greatly improved, the labor intensity and labor amount are low, and the derusting effect of the steel plate is remarkable.

Owner:日照胜达机械股份有限公司

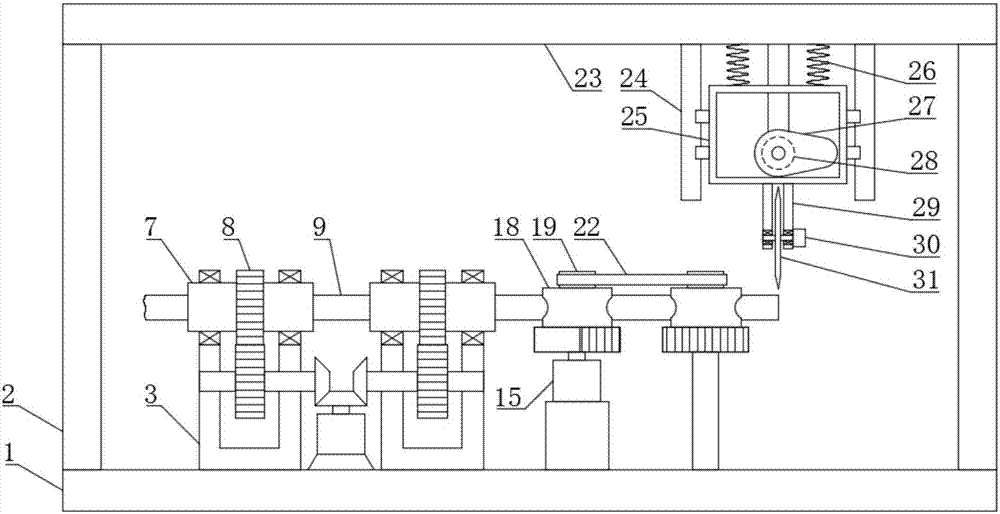

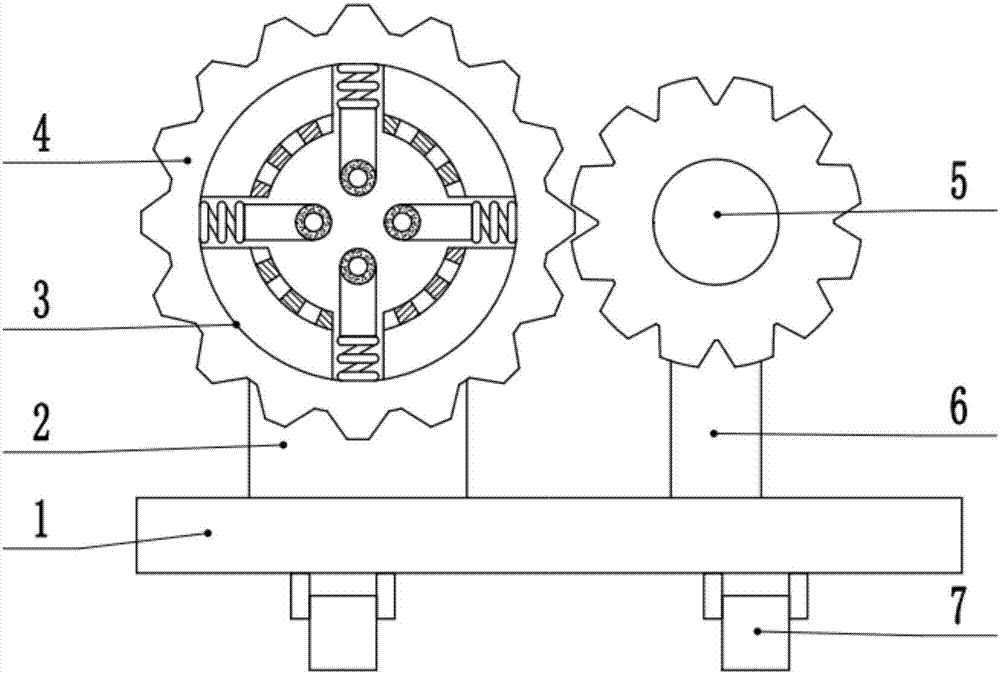

Steel pipe rust removing and cutting integrated machine for building

InactiveCN107234293AImprove processing efficiencyGuaranteed smoothGrinding machinesTube shearing machinesGear wheelArchitectural engineering

The invention discloses an integrated machine for derusting and cutting steel pipes for construction, which comprises a base and a steel pipe. The base is provided with a first U-shaped seat and a second U-shaped seat, and the tops of the first U-shaped seat and the second U-shaped seat respectively pass through the The bearing with seat is rotatably connected with a first derusting cylinder and a second derusting cylinder, and second gears are fixedly installed on the first derusting cylinder and the second derusting cylinder; the first U-shaped seat and the second U-shaped seat also have Rotationally connected with a rotating shaft, the first gear is installed on the rotating shaft, the first gear meshes with the second gear, the right end of the rotating shaft connected with the first U-shaped seat and the left end of the rotating shaft connected with the second U-shaped seat are equipped with the second bevel gear , the base is also provided with a first motor, the motor shaft at the top of the first motor is connected with a first bevel gear, and the first bevel gear meshes with the second bevel gear. The invention rotates the derusting cylinder, and a derusting brush is arranged on the inner wall of the derusting cylinder to derust the steel pipe, and the scope of derusting is wide; there are two derusting cylinders with opposite rotation directions, so that the derusting is more thorough.

Owner:肖进兴

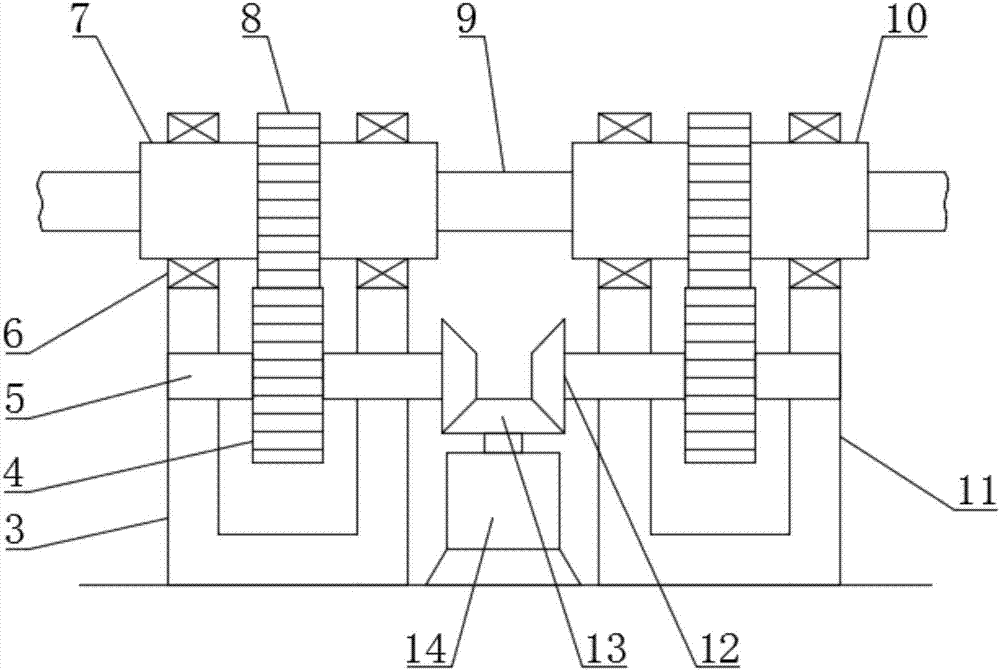

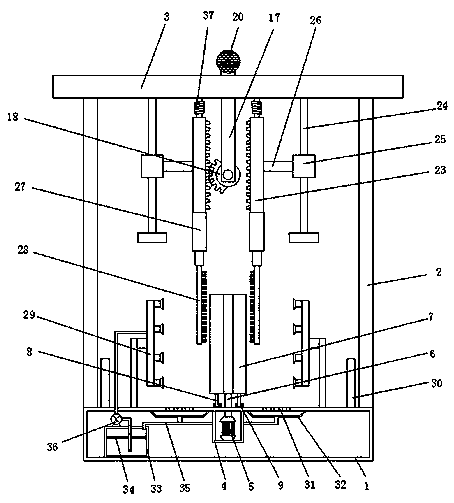

Efficient steel bar rust removing equipment for construction

InactiveCN106944908AComprehensive rust removalImprove rust removal effectGrinding carriagesGrinding drivesArchitectural engineeringEngineering

The invention relates to a derusting device for steel bars for construction, in particular to a high-efficiency derusting device for steel bars for construction. The technical problem to be solved by the present invention is to provide a high-efficiency derusting equipment for building steel bars that does not require a large amount of labor, has short derusting time, and is not easy to be injured during the derusting process. In order to solve the above technical problems, the present invention provides such a high-efficiency derusting equipment for steel bars for construction, which includes a bottom plate, legs, support plates, top plate, first motor, cam, frame, vertical bar, etc.; Outriggers are installed on the sides by bolts, support plates are installed on the left and right sides of the top of the bottom plate by bolts, and a top plate is installed on the top of the support plate by bolts. In the present invention, the first steel wire brush and the second steel wire brush move left and right to double derust the steel bar, so that the derusting effect of the steel bar is better, and at the same time, the rotation of the steel bar is improved.

Owner:孔军玲

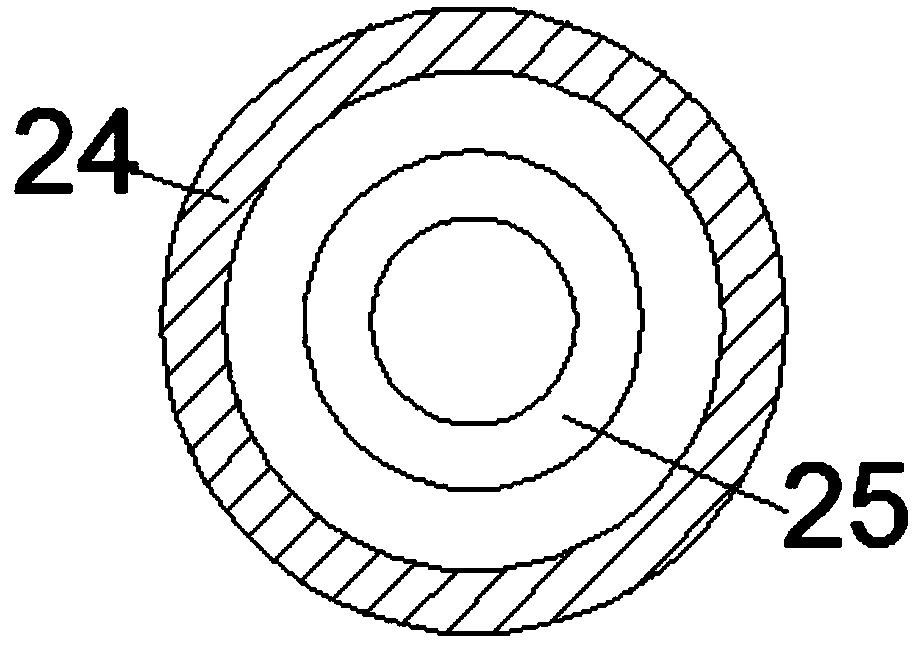

Elastic grinding material for sandblasting treatment

InactiveCN101892014AReduce impact forceReduce harmPolishing compositions with abrasivesElastomerAbrasive blasting

The invention discloses an elastic grinding material for sandblasting treatment. The elastic grinding material is characterized by comprising a rigid grinding material and elastic foam, wherein the elastic foam is coated on the outer part of the rigid grinding material and is generated by a reaction of a polyisocyanate component and a hydroxyl compound and / or an amino compound component; the mass ratio of the rigid grinding material to the elastic foam is from 3:1 to 12:1; the mass ratio of the polyisocyanate component to the hydroxyl compound and / or the amino compound component is from 0.1:99.9 to 99.9:0.1; the hydroxyl compound and / or the amino compound component also comprises other auxiliary agents and pigment filler; and the granularity of the crushed elastic grinding material is 2 to 40 meshes. The elastic grinding material has the advantages of better elasticity, capacity of buffering impact of the grinding material on the surface of a base material, improvement on surface cleanliness, reduction in noise and dust pollution, recyclability, obvious economic benefit and environmental benefit and capacity of being used in closed spaces and environments with severe requirement on environmental and noise pollution control.

Owner:QINGDAO SHAMU INT TRADE

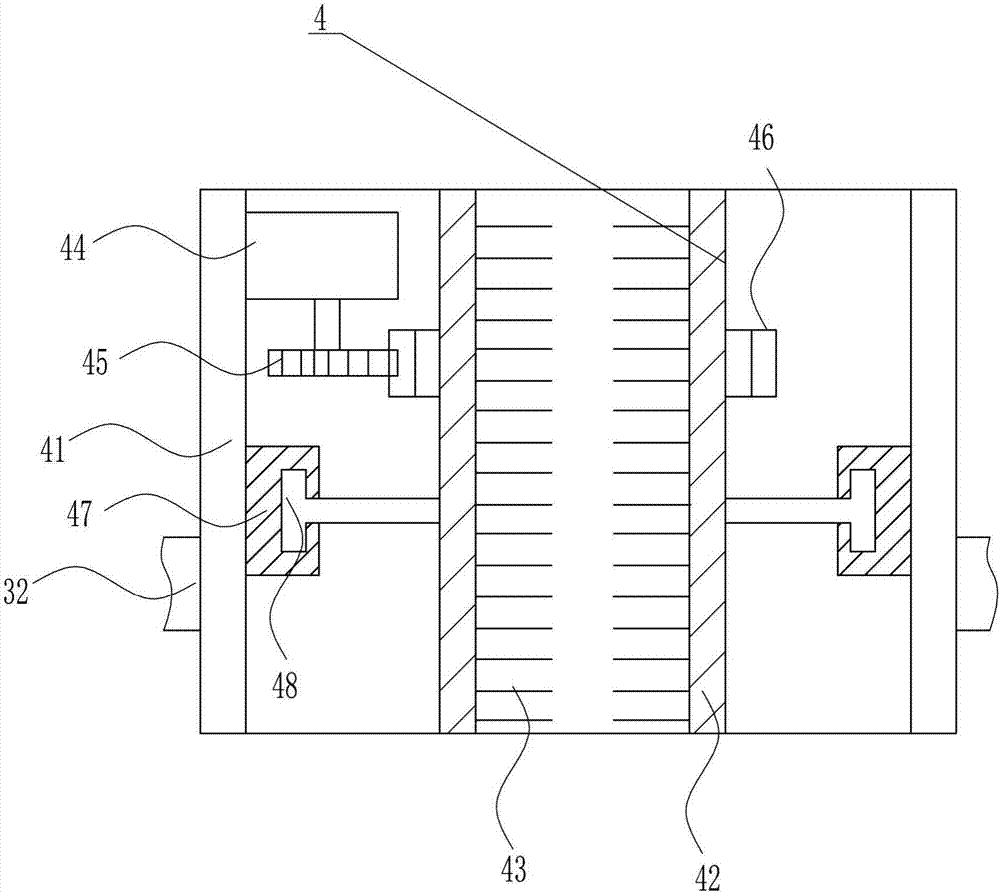

Rust removing and paint spraying device for metal pipes

InactiveCN111167655AEasy to holdNot easy to looseGrinding drivesGrinding machinesMetallurgyElectric machinery

The invention discloses a rust removing and paint spraying device for metal pipes. The rust removing and paint spraying device for the metal pipes comprises a rust removing and paint spraying machinebody arranged on the ground; the rust removing and paint spraying machine body is provided with a fixing rod and a first threaded rod which can be used for installing the rust removing and paint spraying device; a clamping device and a lifting platform are arranged in the rust removing and paint spraying machine body; the clamping device comprises second motors which are symmetrically arranged outside the left side wall and the right side wall; and the lifting platform comprises a third motor which is arranged on the lower portion of the inside of the rust removing and paint spraying machine body. The lifting platform is controlled by the third motor, the metal pipes with different diameters on rollers are collinear with the clamping device, and the clamping effect on the metal pipes is good; and a rust removing device can make a rust removing sheet be in full contact with the metal pipes, and therefore the rust removing effect on the metal pipes is improved; and the metal pipes can besubjected to paint spraying treatment after rust removing is completed, and the production efficiency of the metal pipes is improved.

Owner:PAN AN AIKEN MECHANICAL EQUIP CO LTD

Water jet hull rust remover and operating method thereof

InactiveCN101704004AUniform derustingImprove rust removal effectCleaning using liquidsSlagEvaporation

The invention discloses a water jet hull rust remover and an operating method thereof. The rust remover comprises a high-pressure water tube interface, a high-pressure water tube interface seat, a rust removing disk, a high-pressure water tube interface seat support, a nozzle, and a nozzle rotary frame, and also comprises an air tube interface, an air tube interface seat, an air motor body, a vacuum recycling flange, a vacuum recycling tube, a vacuum recycling opening, and a high-pressure water sealing ring, wherein the vacuum recycling opening is embedded in the rust removing disk and connected with the vacuum recycling tube; the outlet end of the vacuum recycling tube is connected with the vacuum recycling flange; and the upper surface of the rust removing disk is also provided with a height adjusting support. The method comprises steps of height adjustment, rust removal and recycling. In the water jet hull rust remover, the rust removal by the superhigh pressure water jet and pumping and slag discharging by the vacuum system are compatibly designed into one body, the vacuum equipment recycles the rust, the high temperature, which is over 80 DEG C and generated by the water jet action, in the vacuum cavity can cause certain positive effects on the evaporation of water of the bulkhead, the rust removal drying is realized, and the hull is avoided from the return of rust.

Owner:DALIAN MARITIME UNIVERSITY

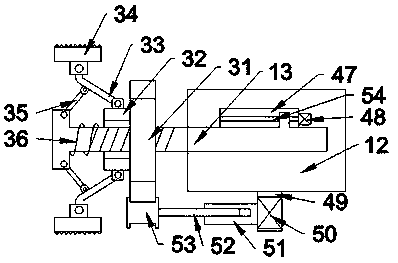

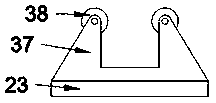

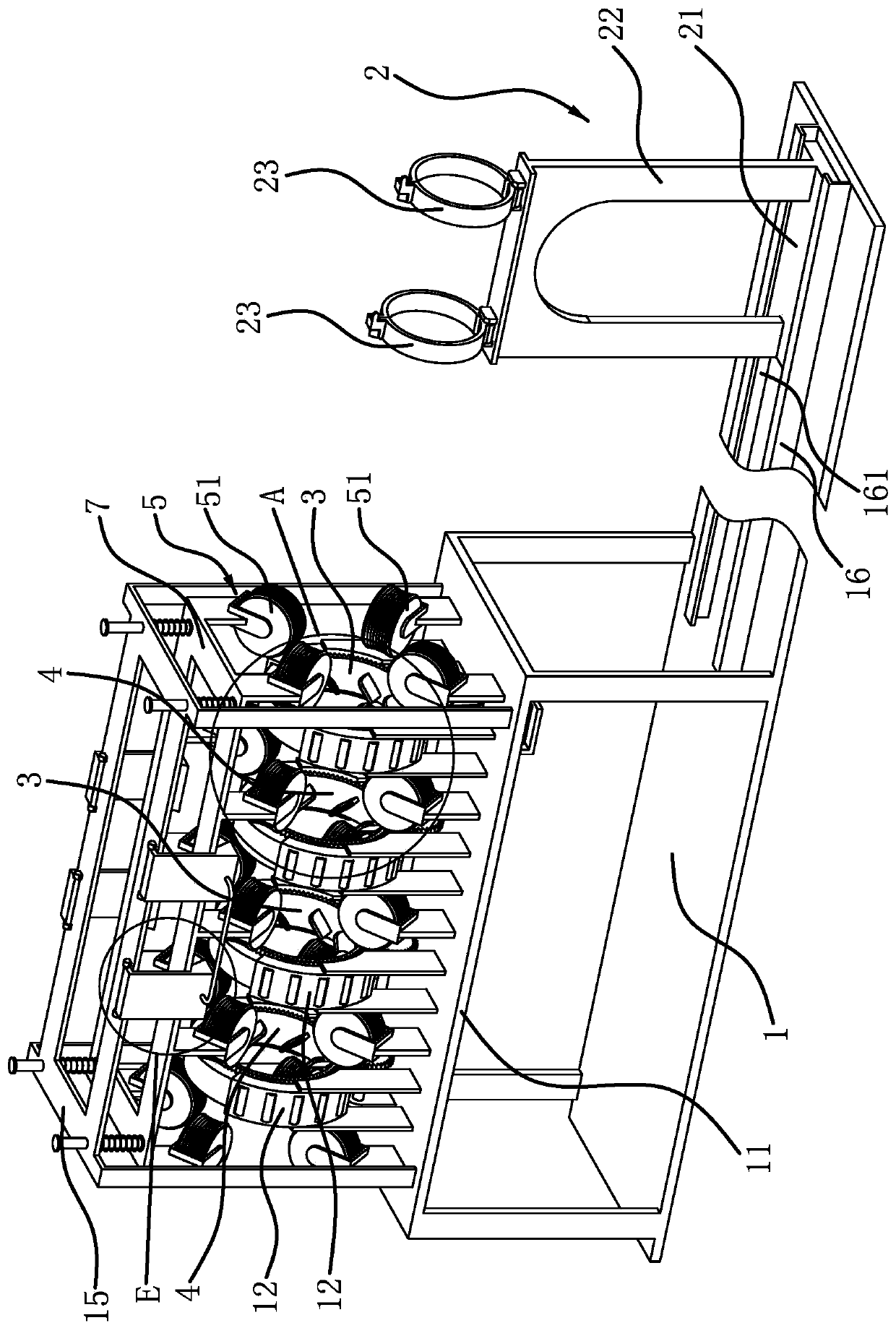

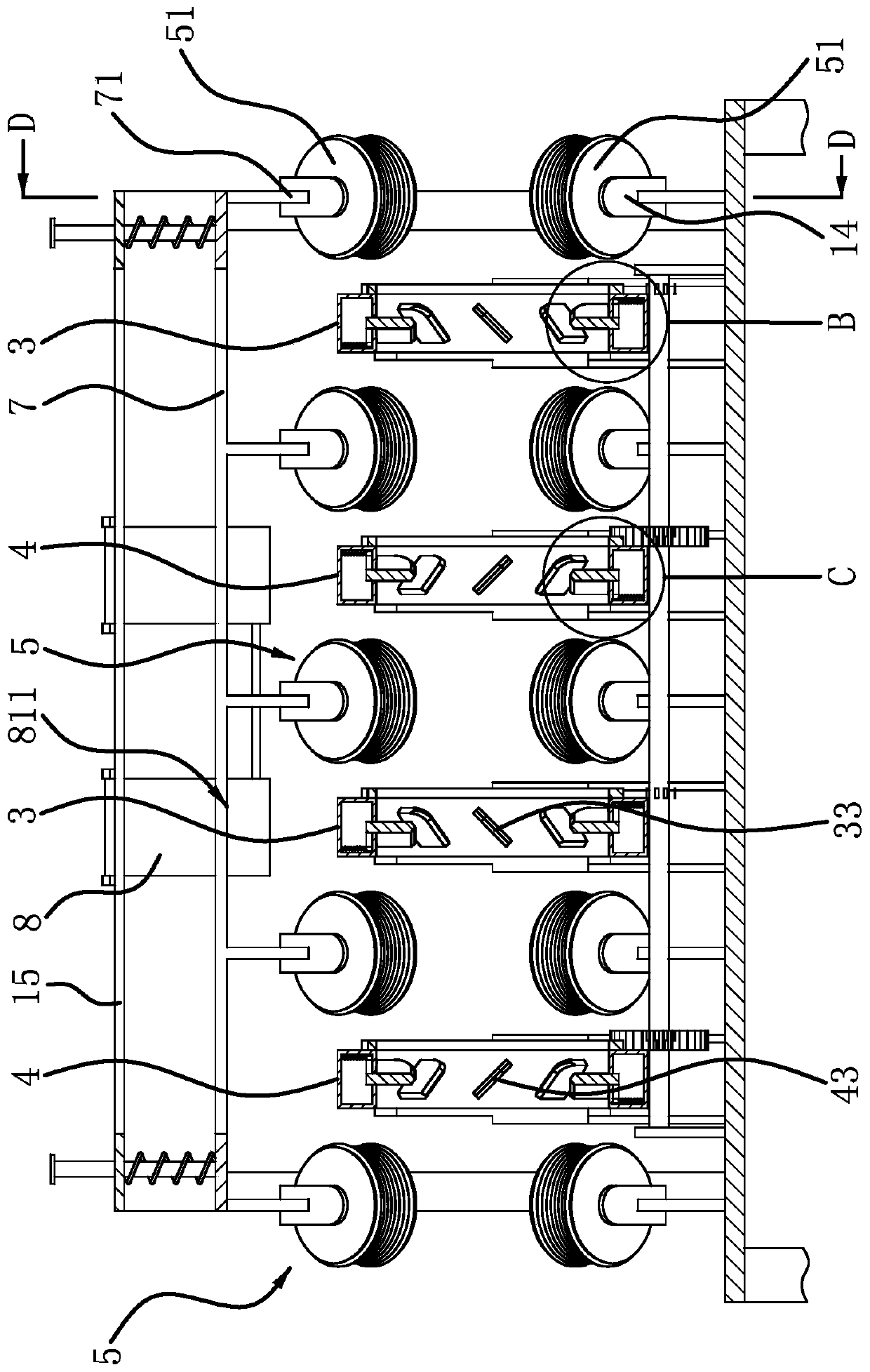

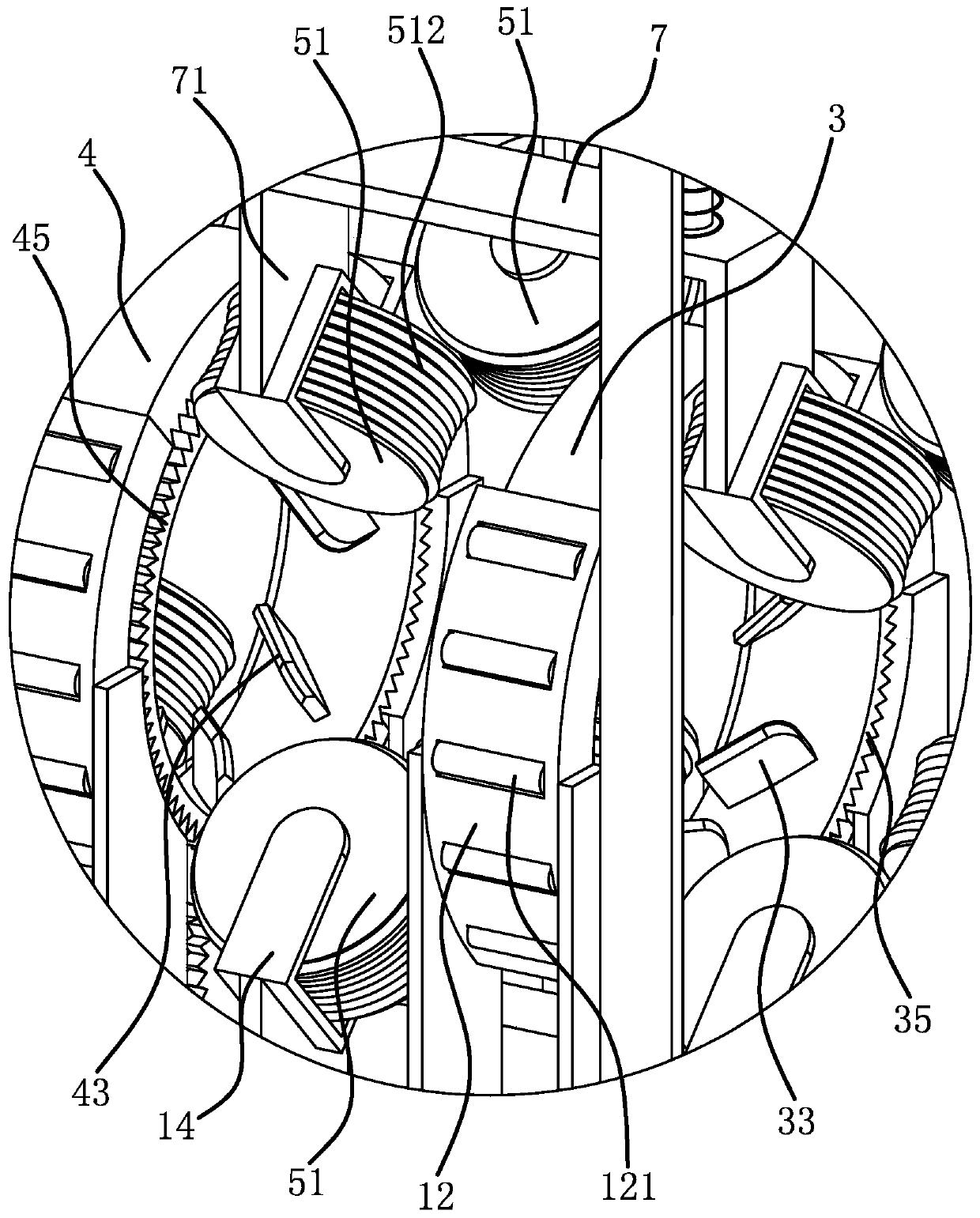

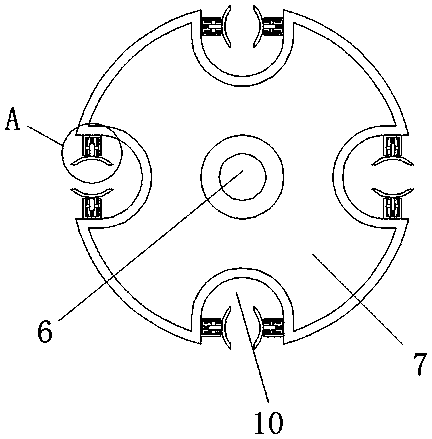

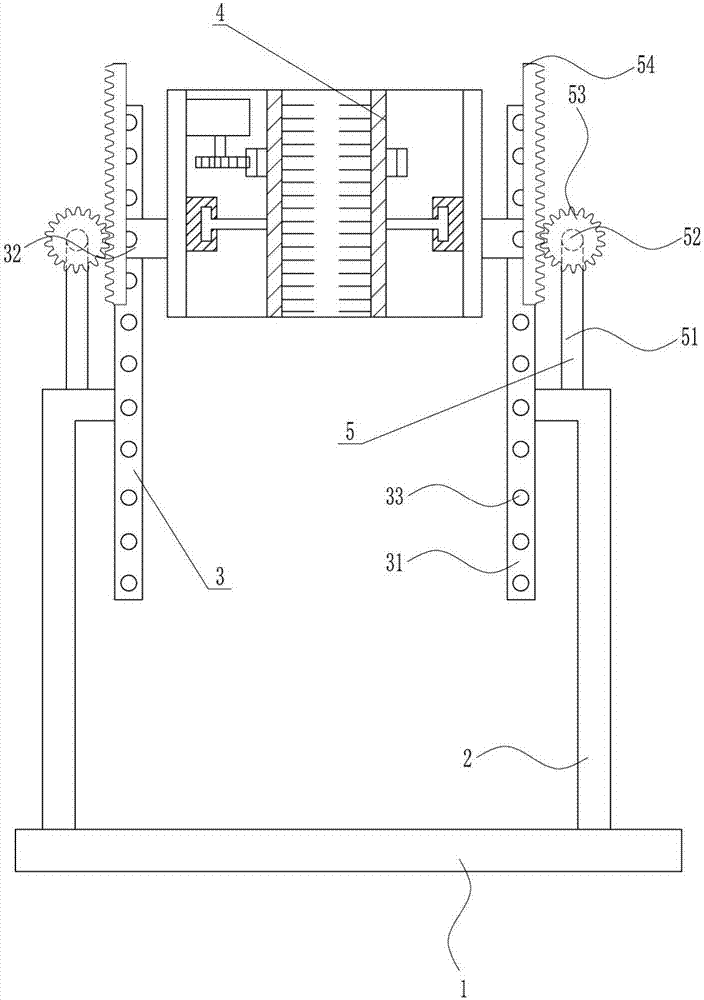

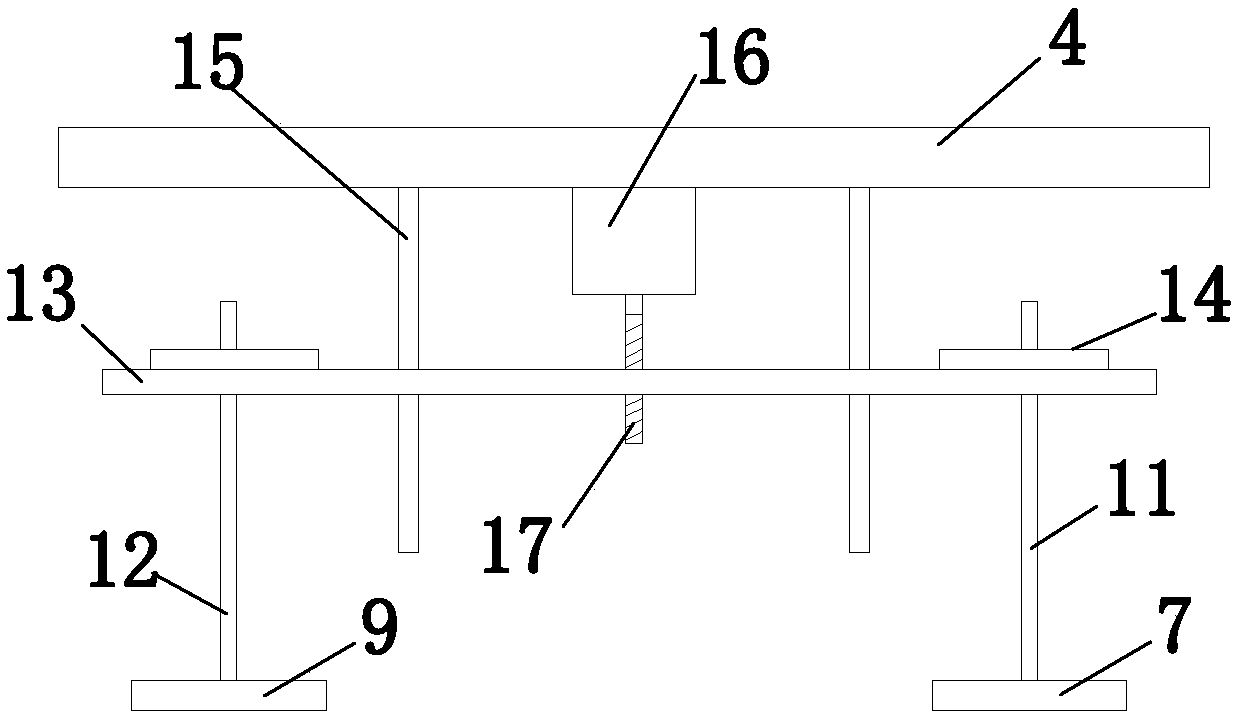

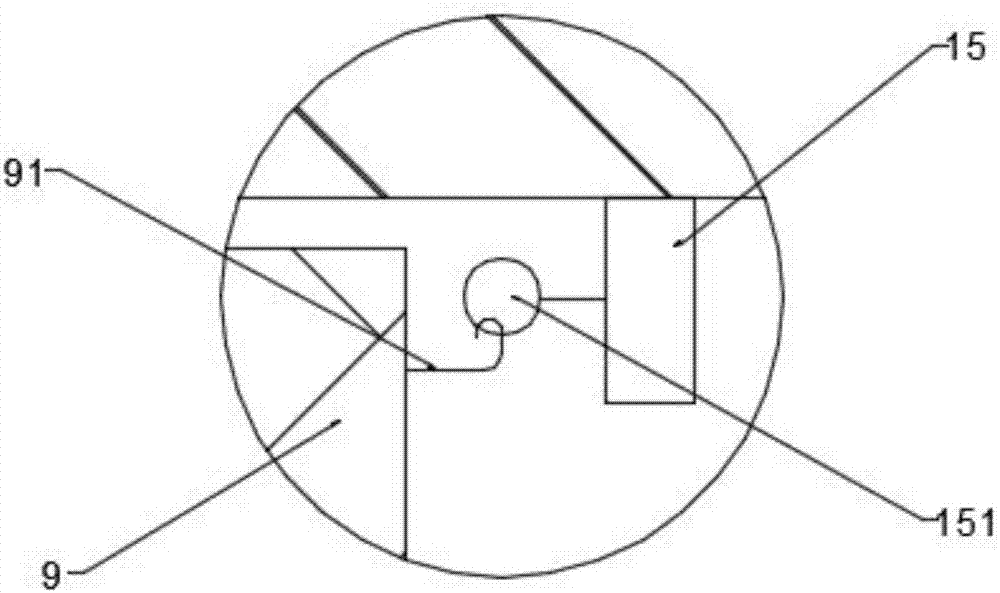

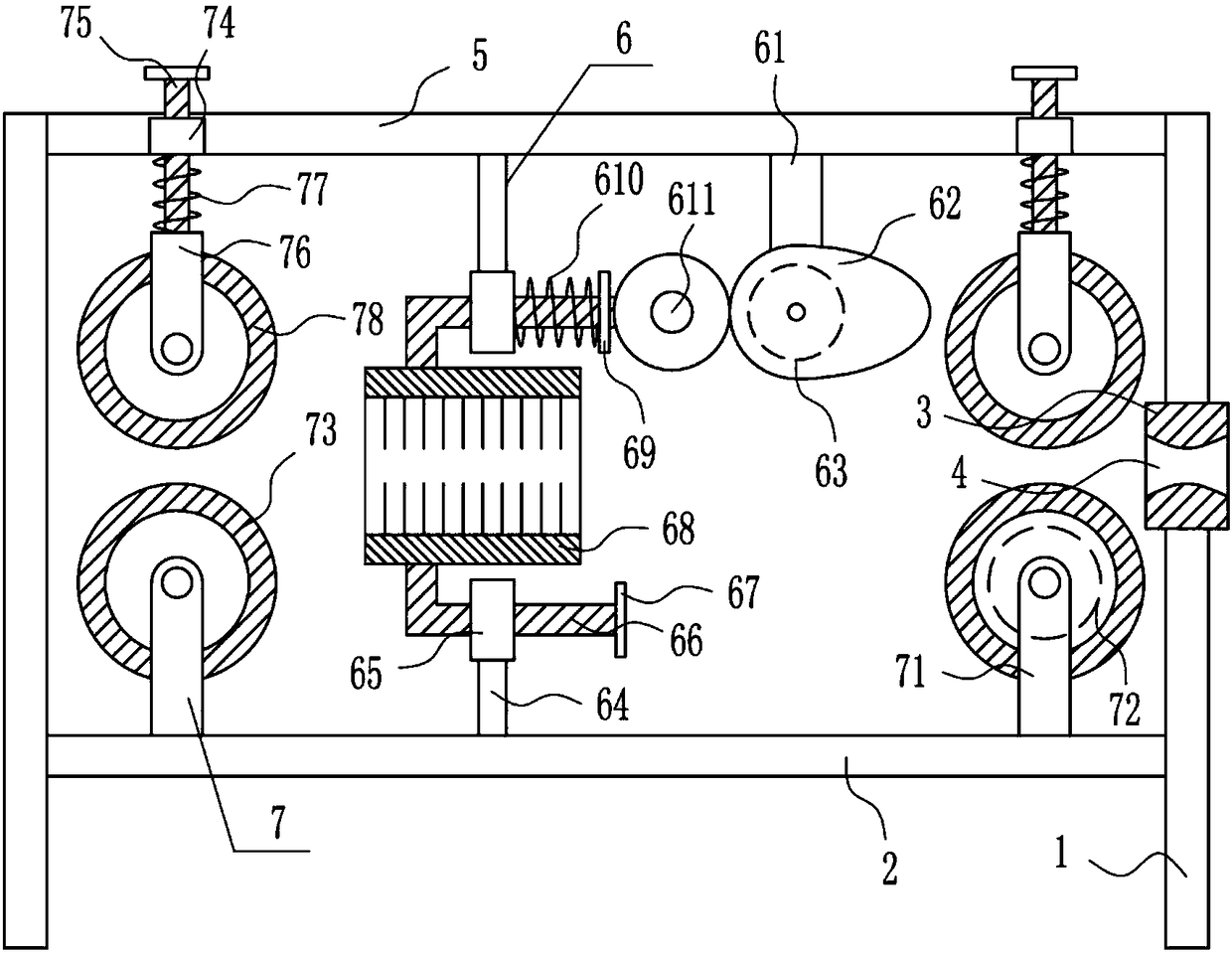

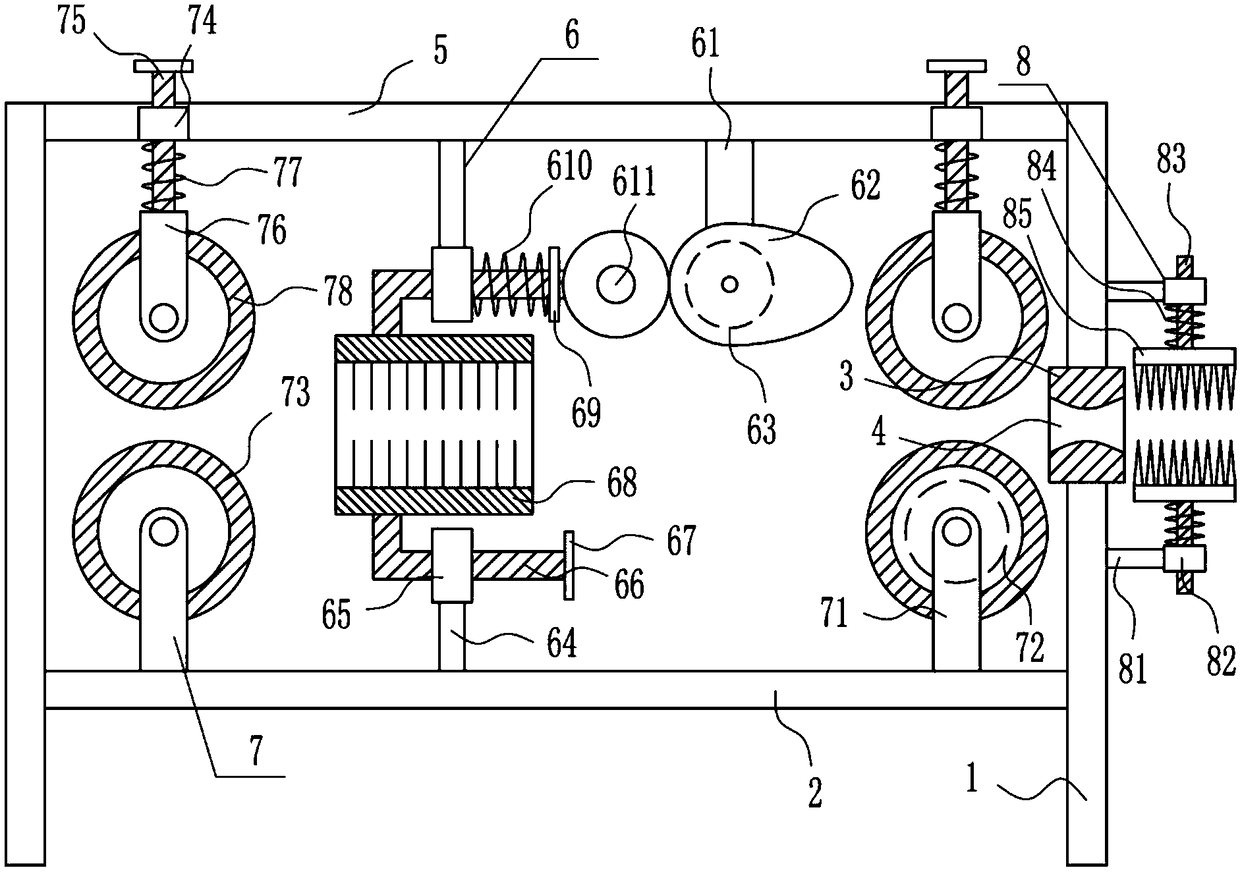

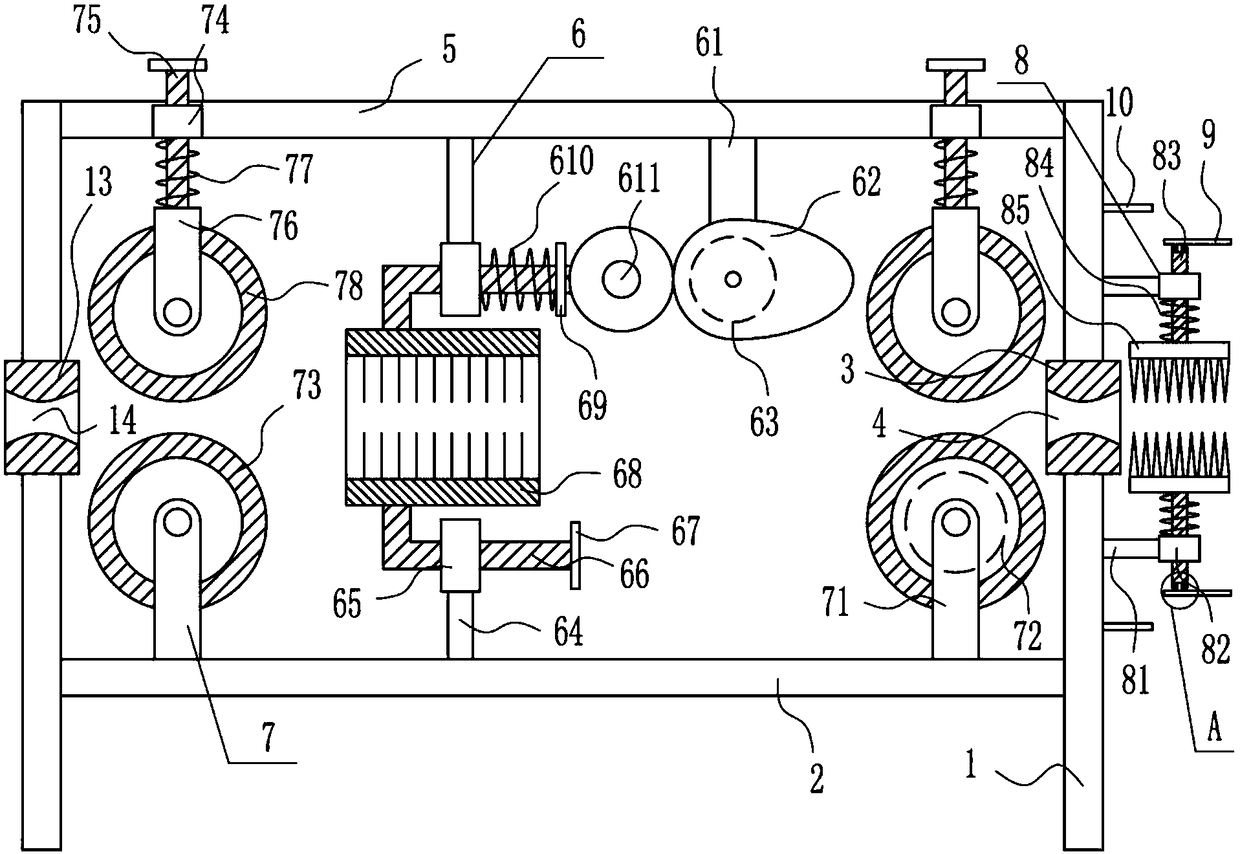

Building scaffold steel pipe rust removal device

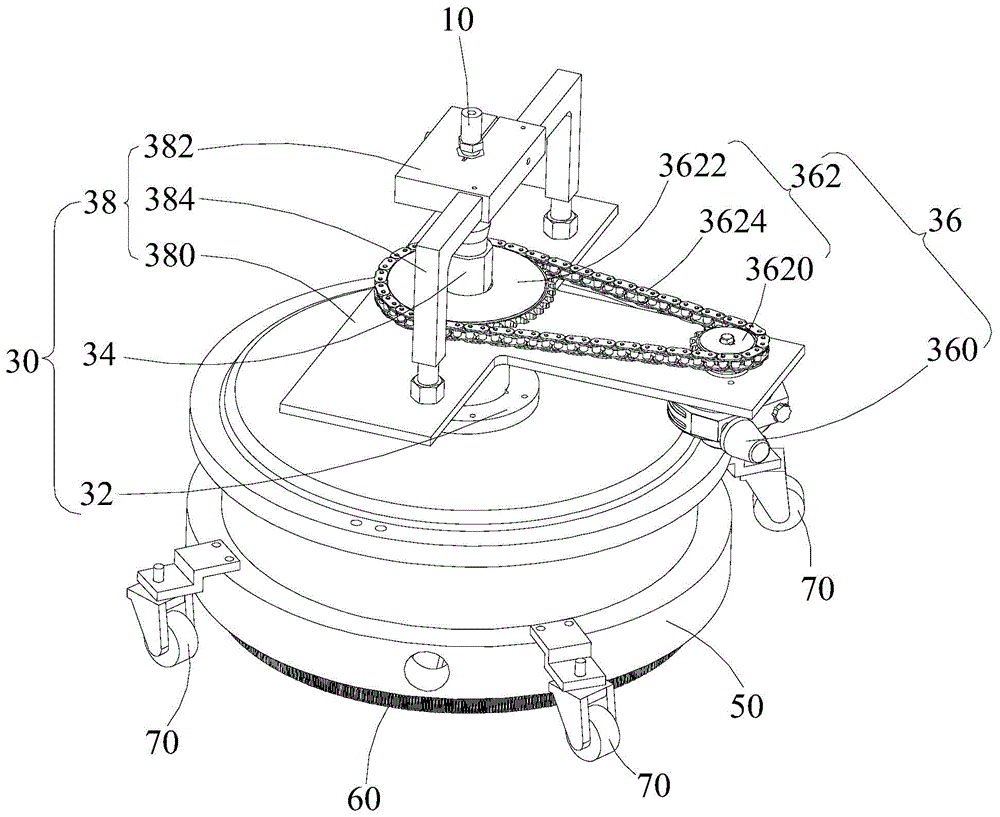

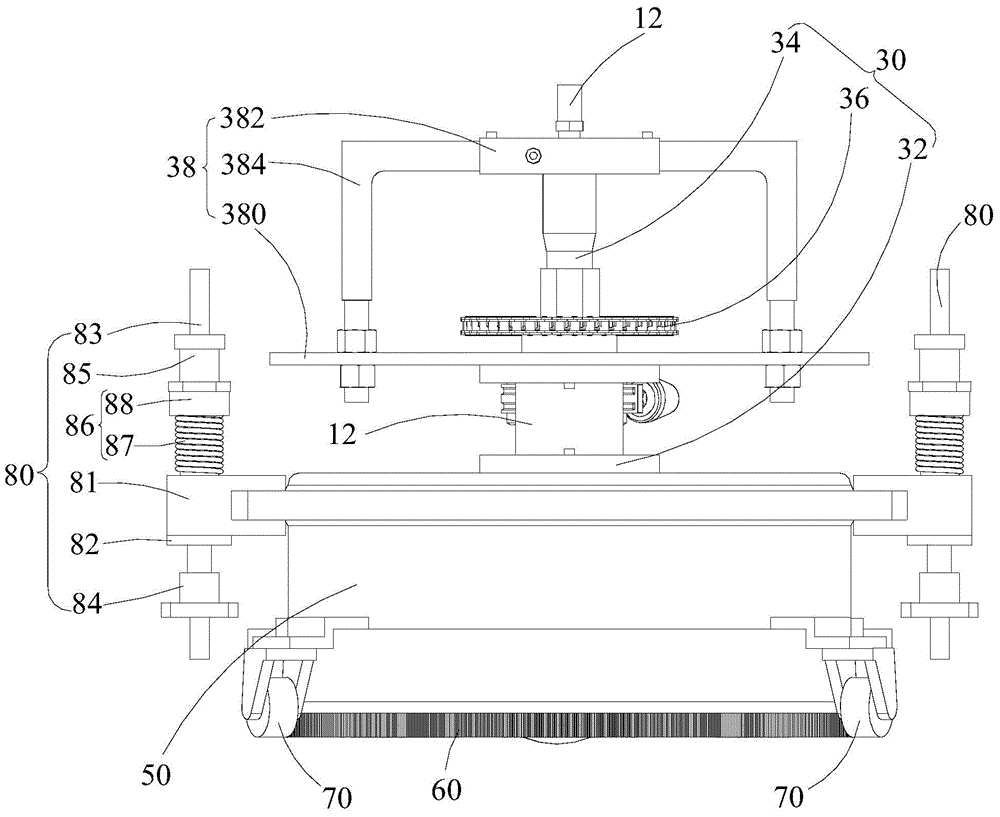

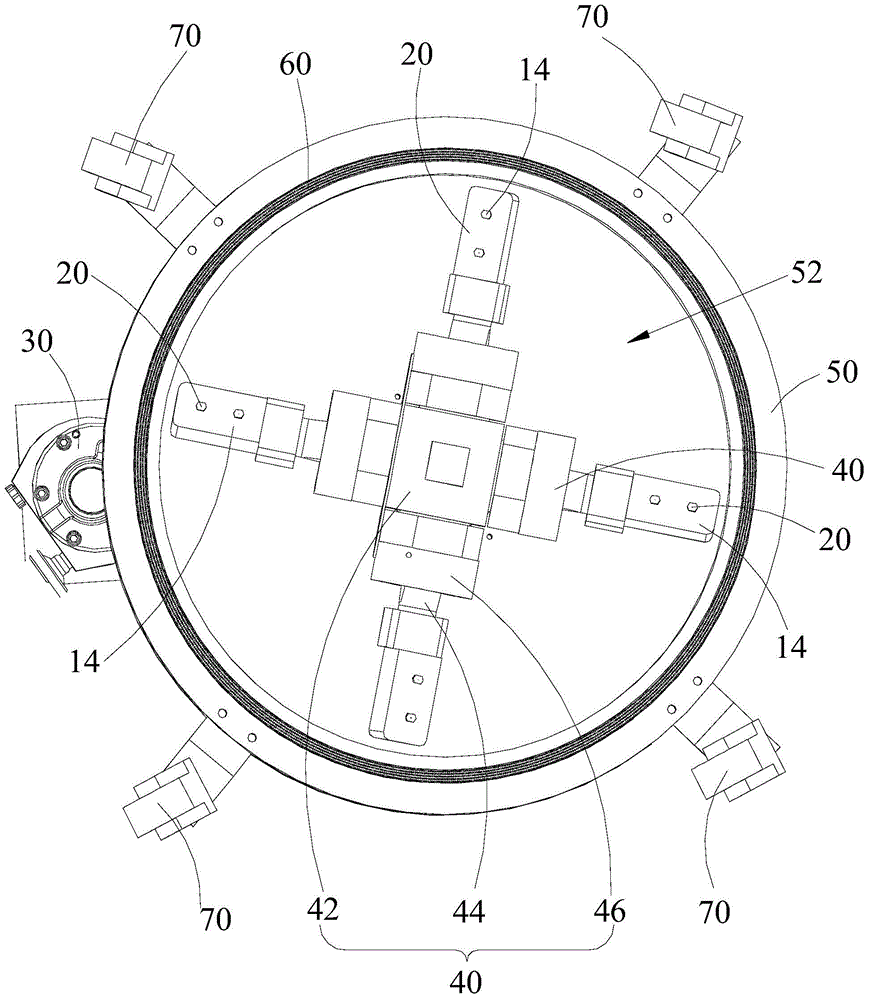

ActiveCN111230222AImprove rust removal effectAvoid the phenomenon of circumferential rotationRevolution surface grinding machinesGrinding drivesWorkbenchSteel tube

The invention provides a building scaffold steel pipe rust removal device, and belongs to the technical field of building equipment. The device solves the problems that an existing scaffold steel pipeis poor in rust removal quality. The building scaffold steel pipe rust removal device comprises a bottom plate and a workbench, wherein a pushing base is arranged on the bottom plate in a sliding mode, a plurality of forward rust scraping rings and a plurality of reverse rust scraping rings are rotationally connected to the workbench, a plurality of forward scrapers are arranged on the inner sideface of each forward rust scraping ring in the circumferential direction, a plurality of reverse scrapers are arranged on the inner side face of each reverse rust scraping ring in the circumferentialdirection, the workbench is provided with a driving piece capable of driving the forward rust scraping rings and the reverse rust scraping rings to synchronously and reversely rotate, the workbench is further provided with a plurality of rolling assemblies, and each rolling assembly comprises at least two rolling wheels used for abutting against and supporting the lower portion of a steel pipe and at least two rolling wheels capable of being pressed on the upper portion of the steel pipe. The building scaffold steel pipe rust removal device is better in rust removal effect and is more labor-saving in manual operation.

Owner:广州耀方脚手架工程有限公司

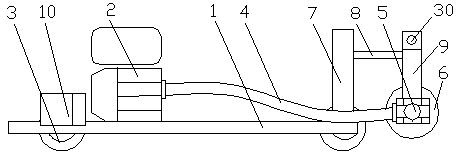

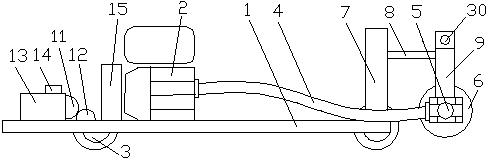

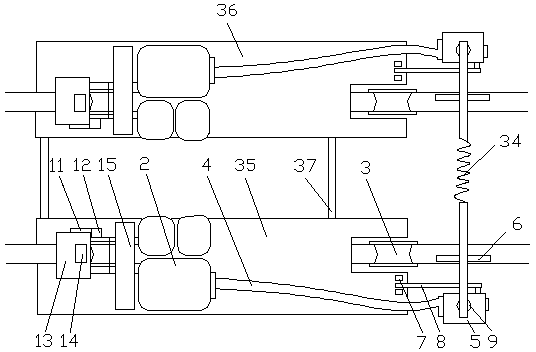

Automatic steel rail duplex rust removing machine

ActiveCN104631234AHard and wear-resistant working surfaceEasy to attachTrack superstructureRailway track constructionCouplingEngineering

The invention discloses an automatic steel rail duplex rust removing machine. The automatic steel rail duplex rust removing machine comprises a rack, engines and wheels connected to the lower portion of the rack, and is characterized in that the two engines are adopted and distributed on steel rails on the two sides respectively, the automatic steel rail duplex rust removing machine further comprises two soft shafts and two steering gears, one ends of the soft shafts are connected with rotating shafts of the engines through couplers, the other ends of the soft shafts are connected with input shafts of the steering gears, output shafts of the steering gears are connected with blade grinding wheels, the rack is fixedly connected with two connecting pieces, vertical adjusting pieces are arranged above the steering gears and elastically connected with the steering gears, connecting rods of the connecting pieces are connected with the vertical adjusting pieces, a transverse spring pull rod is connected between the vertical adjusting pieces of the steel rails on the two sides, and the rack is connected with a drive component. The kinetic energy of the engines is directly transmitted to the blade grinding wheels through the soft shafts, a duplex structure is adopted, synchronous automatic constant-speed rust removing can be carried out on pedal faces of the two steel rails at the same time, and the rust removing quality and efficiency are greatly improved.

Owner:德阳路安恒轨道技术开发有限公司

Double-sided polishing and descaling device for arc-shaped iron plate

InactiveCN108723960APrevent tamperingImprove rust removal effectGrinding carriagesGrinding machinesCircular discUniversal joint

The invention discloses a double-sided polishing and descaling device for an arc-shaped iron plate. The double-sided polishing and descaling device comprises a descaling box, an upper movable plate, awater tank, a lower movable rod and two fixing devices; an electric push rod is fixedly installed on a middle position of the inner wall of the right side of the descaling box, and the two fixing devices are correspondingly and fixedly mounted on a middle position of the inner wall of the left side of the descaling box and the telescopic end of the electric push rod; a plurality of third slidingsleeves are evenly mounted on the lower side of the upper movable plate and the upper side of the lower movable plate, and connecting rods are slidably mounted in the third sliding sleeve; and mounting seats are fixedly connected to one ends of the connecting rods through universal joints, and polishing strips are fixedly mounted on the other sides of the mounting seats. The double-sided polishingand descaling device utilizes two rotating discs to drive a swinging rod to swing left and right, thereby driving the upper movable plate and the lower movable plate to swing left and right, so thatthe polishing strips are driven to polish and descale both sides of the arc-shaped iron plate; and the arc-shaped iron plate is fixed through the arrangement of the fixing devices to prevent the ironplate from swaying during descaling.

Owner:FUJIAN NANAN XIAMEI ELECTRONICS EQUIP FACTORY

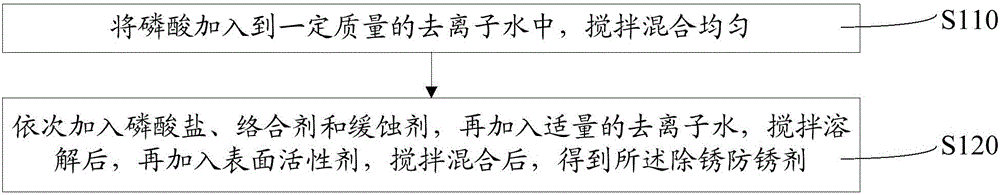

Rust removing and preventing agent

ActiveCN105696001AReduce contentHazard reductionMetallic material coating processesIonization equilibriumHydrogen

Owner:广东东明新材科技有限公司

Rust removal device for natural gas pipeline mounting

InactiveCN107971901AComprehensive rust removalImprove rust removal effectGrinding carriagesGrinding drivesEngineeringRust

The invention relates to a rust removal device, in particular to a rust removal device for natural gas pipeline mounting. In order to achieve the technical aims, the rust removal device for natural gas pipeline mounting saves time and labor, is good in rust removal effect and can remove dust appearing in the rust removal process without influencing the surroundings. To achieve the above technicalaims, the rust removal device for natural gas pipeline mounting comprises a bottom plate, a supporting rod, an arc placement plate, a natural gas pipeline, a supporting plate, first transverse rods and the like; the supporting rod is mounted on the left side of the top of the bottom plate; the arc placement plate is mounted at the top end of the supporting rod; the natural gas pipeline is arrangedin the arc placement plate; and the supporting plate is mounted on the right side of the top of the bottom plate. According to the rust removal device, by means of a fixed rotating device, the natural gas pipeline can be fixed, and the natural gas pipeline can rotate so that rust removal can be more comprehensive; and by means of a dust suction device, the effect that dust appearing in the rust removal process can be removed without influencing the surroundings is achieved.

Owner:广东新网工程技术有限公司

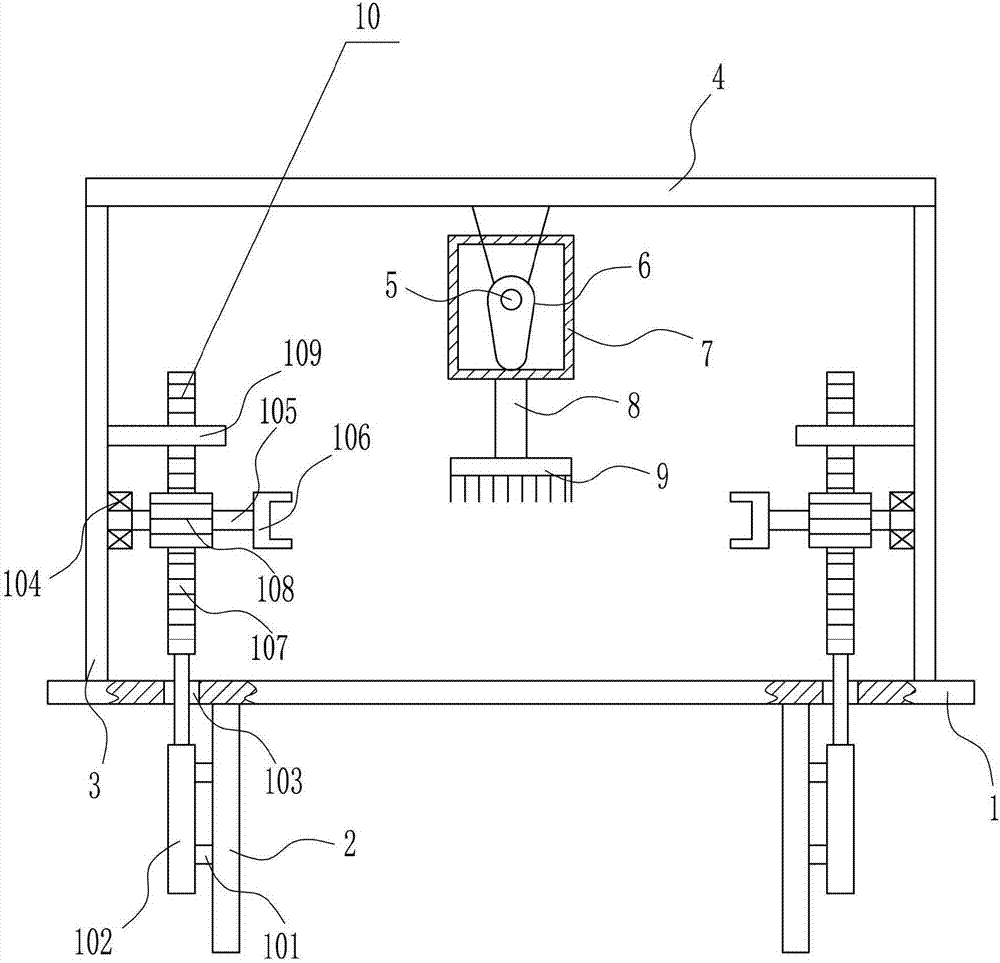

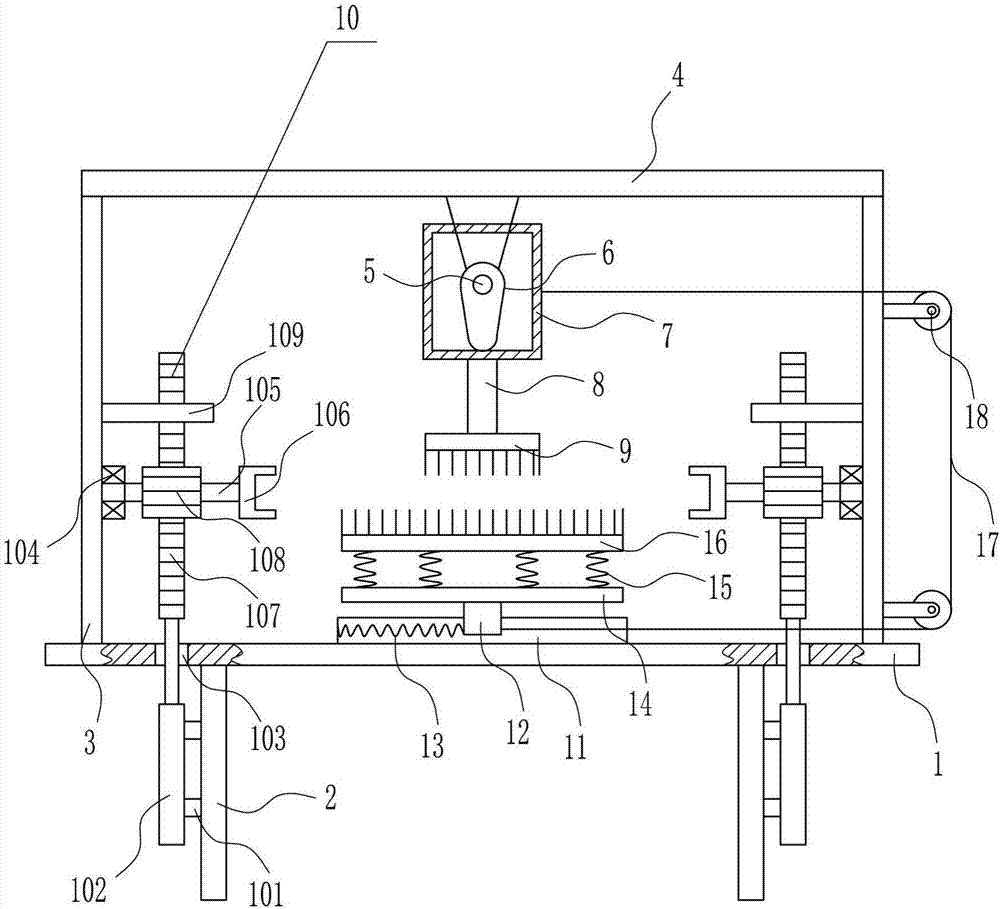

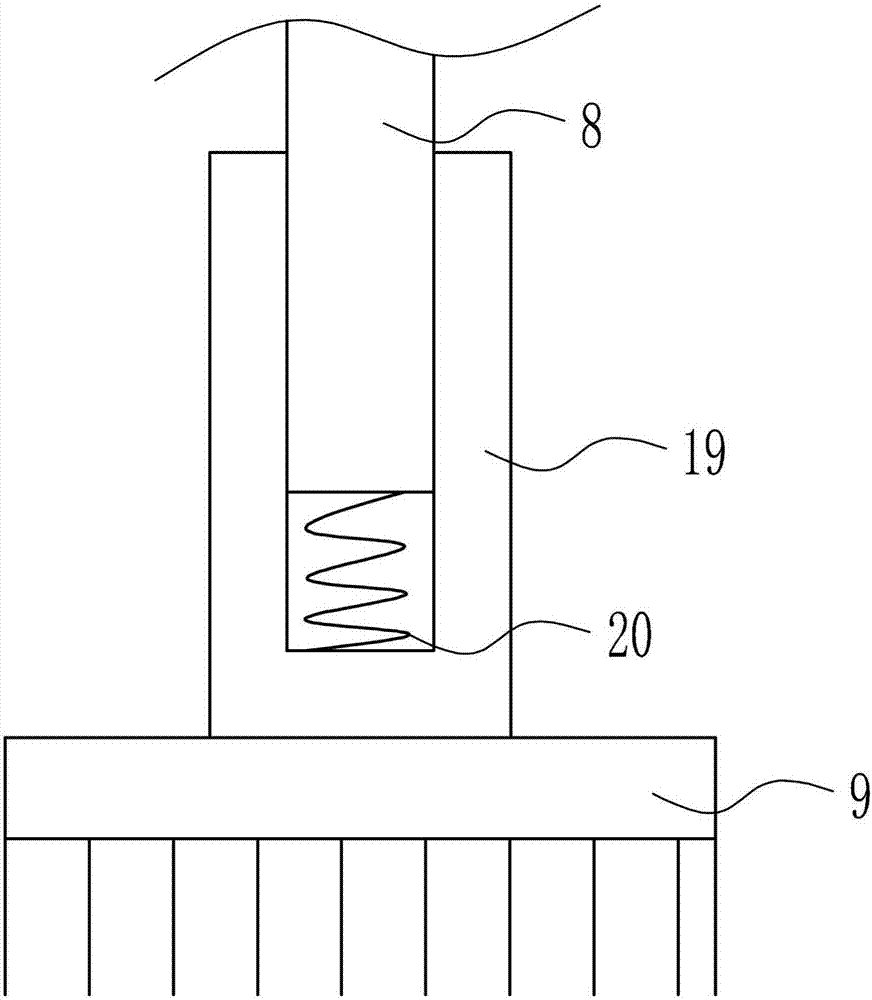

Steel plate surface efficient grinding and rust removing device

InactiveCN108356677AEfficient and rapid rust removalQuality improvementGrinding carriagesGrinding drivesRelative displacementSheet steel

The invention discloses a steel plate surface efficient grinding and rust removing device. The device comprises a bottom plate, wherein a left vertical plate and a right vertical plate are verticallyand fixedly arranged on the bottom plate, a top plate is horizontally and fixedly arranged at the tops of the left vertical plate and the right vertical plate, and a limiting guide rod is horizontallyand fixedly installed between the left vertical plate and the right vertical plate; sliding sleeves sleeve the limiting guide rod in a sliding mode, and supporting columns are vertically and fixedlyinstalled on the sliding sleeves. According to the steel plate surface efficient grinding and rust removing device, the left-and-right and back-and-forth movement of a transmission plate is realized through clockwise and anticlockwise alternate rotation of a fan-shaped teeth, and then grinding strips are driven to carry out back-and-forth grinding on the surface of a steel plate; meanwhile, a pullrope pulls a collecting groove to achieve all reciprocating motion under the elastic acting force of a reset spring, so that the steel plate is driven to move in the left-and-right direction and theback-and-forth direction, the steel plate always moves back to the grinding strips, the relative displacement of the steel plate and the grinding strips is greatly increased, and rust removal of the steel plate is more efficient and rapid; and a bearing plate and the grinding strips clamp the steel plate under the elastic action of damping springs, so that the rust removing quality of the steel plate is effectively improved, and the rust removing effect is remarkable.

Owner:王芳

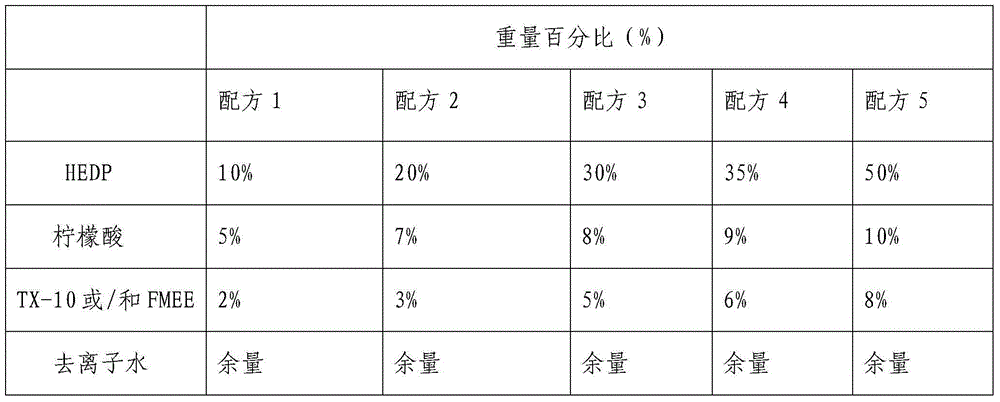

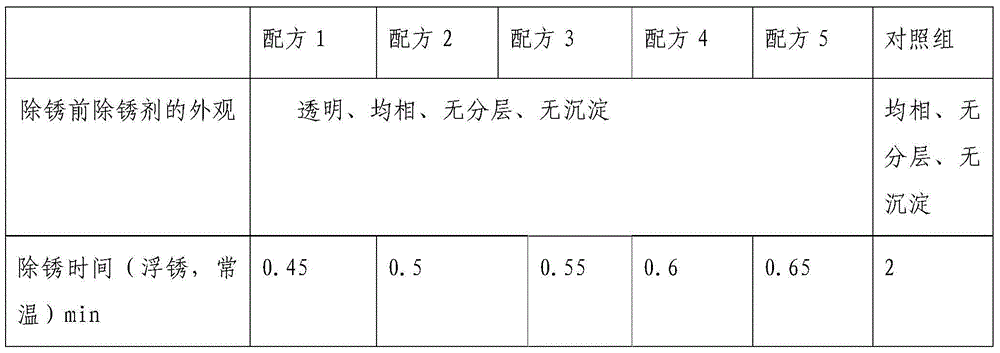

A steel environmental rust remover

The invention discloses a steel environmental rust remover. The rust remover comprises the following components by weight percentage: 10-50 % of organic phosphonic acid, 5-10 % of citric acid, and 3-5% of surfactant, with the balance being water. The surfactant is one of TX-10 and FMEE or a mixture of both. By adopting the technical solution of the invention, good rust removing effect can be achieved, the rust removing process is gentle and does not damage the surface of a steel article, and the use and manufacturing cost is low.

Owner:赵理奎

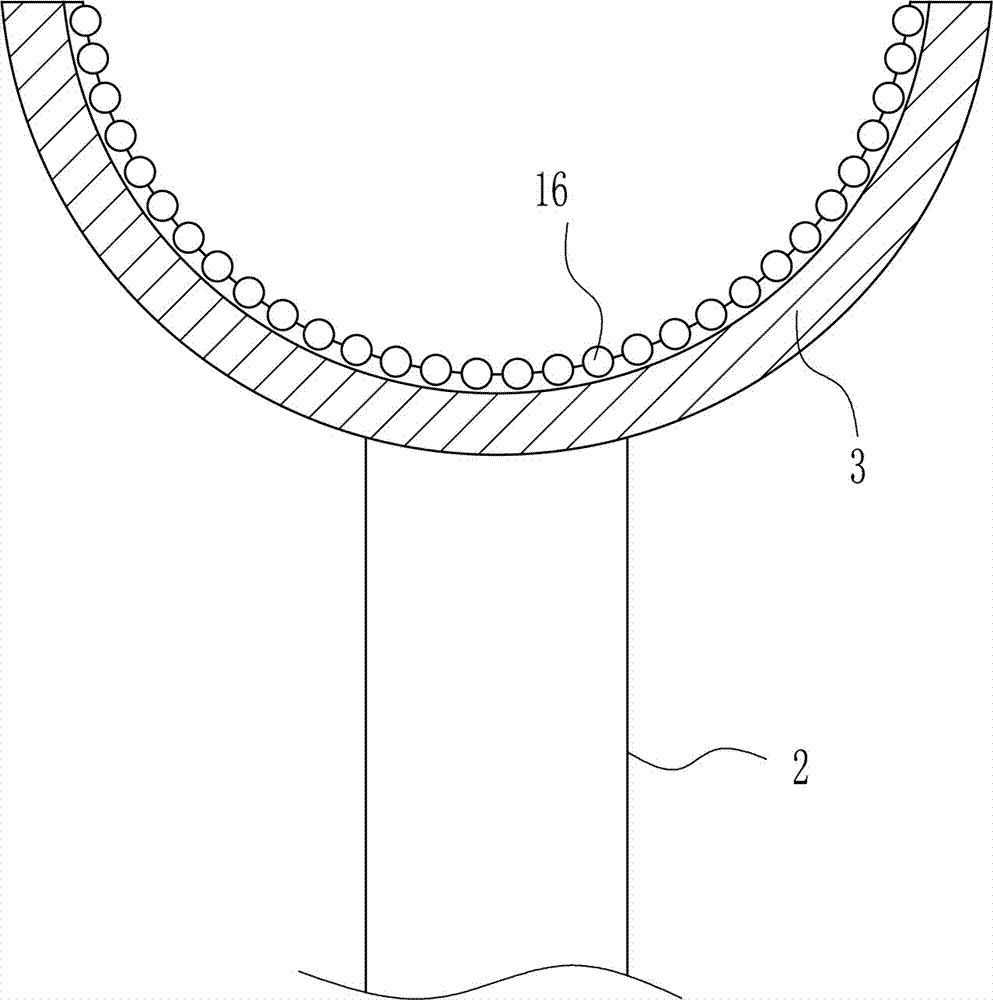

Rebar rust removal trolley for construction site

InactiveCN107378715AEffective sandingEasy to cleanEdge grinding machinesPolishing machinesEngineeringRebar

The invention discloses a rebar rust removal trolley for a construction site. The rebar rust removal trolley comprises a base, a rust removal bucket and a driving gear. The rust removal bucket is internally provided with a polishing layer, a cleaning layer and a drying layer which are sequentially arranged in the rebar feeding direction. The polishing layer is of a round ring structure and is internally and symmetrically provided with four slide grooves, a connection rod is slidably installed in each slide groove, one end of each connection rod is fixedly connected with the inner wall of the polishing layer through a spring, and the other end of the connection rod is rotationally provided with a polishing ball. The cleaning layer is also of a round ring structure, and a cleaning disc is arranged in the middle of the cleaning layer. According to the rebar rust removal trolley provided by the invention, the rust removal bucket is internally provided with the polishing layer, the cleaning layer and the drying layer, the structure is simple, using is convenient, and carrying and transporting are facilitated; and moreover, rebars can be effectively polished, cleaned and dried, and the rust removal effect is excellent.

Owner:伍超群

Iron rod rust removal device for hardware production

InactiveCN109048610AMeet production needsImprove work efficiencyGrinding carriagesGrinding drivesEngineeringRust

The invention provides an iron rod rust removal device for hardware production, and relates to the field of hardware machining. The iron rod rust removal device comprises a base. Supporting columns are fixedly mounted on the two sides of the top of the base. A top beam is fixedly mounted at the tops of the supporting columns. A sealing box is fixedly mounted in the middle of the top of an inner cavity of the base. A clamp motor is fixedly mounted in the sealing box. A clamp shaft is arranged at the top of the clamp motor. The clamp shaft penetrates through the base and extends to the upper portion of the base. A clamp is fixedly mounted at the top of the clamp shaft. Four semicircular grooves are formed on the outer side of the clamp. According to the iron rod rust removal device for hardware production, the round clamp is arranged to cooperate with the four semicircular grooves, the rust removal device can carry out rust removal on four iron rods at the same time, the work efficiencyis greatly improved, and the production requirements of enterprises can be effectively met; and the clamp shaft is arranged to cooperate with drive of the clamp motor, the clamp can rotate, and four iron rod raw materials can be subjected to rust removal at the same time.

Owner:JIANGYIN CHANGJING CAR & SHIP ACCESSORY

Large-inside-diameter steel pipe inner wall derusting device for machining

InactiveCN107263288AAchieve rust removalReasonable designRevolution surface grinding machinesGrinding drivesGear wheelDrive shaft

The invention discloses a large-inside-diameter steel pipe inner wall derusting device for machining. The device comprises a bottom plate, wherein a first shaft support is vertically and fixedly mounted on the bottom plate and is movably connected with a right end of a driving shaft; a first bevel gear is coaxially and fixedly mounted on the driving shaft; a second bevel gear is coaxially and fixedly mounted on an upper end of a driven shaft and is connected with the first bevel gear in a meshed manner; a rotating wheel is coaxially and fixedly mounted at a lower end of the driven shaft; a second shaft support is vertically and fixedly mounted on the bottom plate; a first connecting rod is horizontally arranged on the second shaft support in a horizontal sliding manner; a limiting roller is coaxially and fixedly mounted on the rotating shaft; a steel pipe for derusting is placed on the limiting roller; a derusting roller is fixedly mounted on the first connecting rod; steel wire brushes are uniformly arranged on a surface of the derusting roller; guiding wheels are fixedly mounted on the rotating roller in a sleeving manner and are pressed against an outer surface of the derusting roller. According to the device disclosed by the invention, axial and annular derusting effects on the inner wall of the steel pipe can be realized at the same time, so that the derusting effect on the inner wall of the steel pipe is preferable.

Owner:深圳市海帮国际商务服务有限公司

Steel bar rust removal device used for power station construction

InactiveCN107116437AImprove rust removal efficiencyEasy to operateGrinding machinesPower stationArchitectural engineering

The invention belongs to the technical field of power station construction, and particularly relates to a steel bar rust removal device used for power station construction. The steel bar rust removal device used for power station construction is easy to operate, good in rust removal effect and high in working efficiency. The steel bar rust removal device used for power station construction comprises a base plate and the like. Supports are connected to the left and right sides of the top of the base plate in a bolted mode correspondingly. An adjusting device is installed on the top of the inner side of each support. A rust removal device is arranged on the inner sides of the adjusting devices. The steel bar rust removal device can move up and down through a lifting device so that the bust removal device can remove rust for a steel bar all the time, and simple in operation, a good bust removal effect and high work efficiency are achieved.

Owner:徐宗林

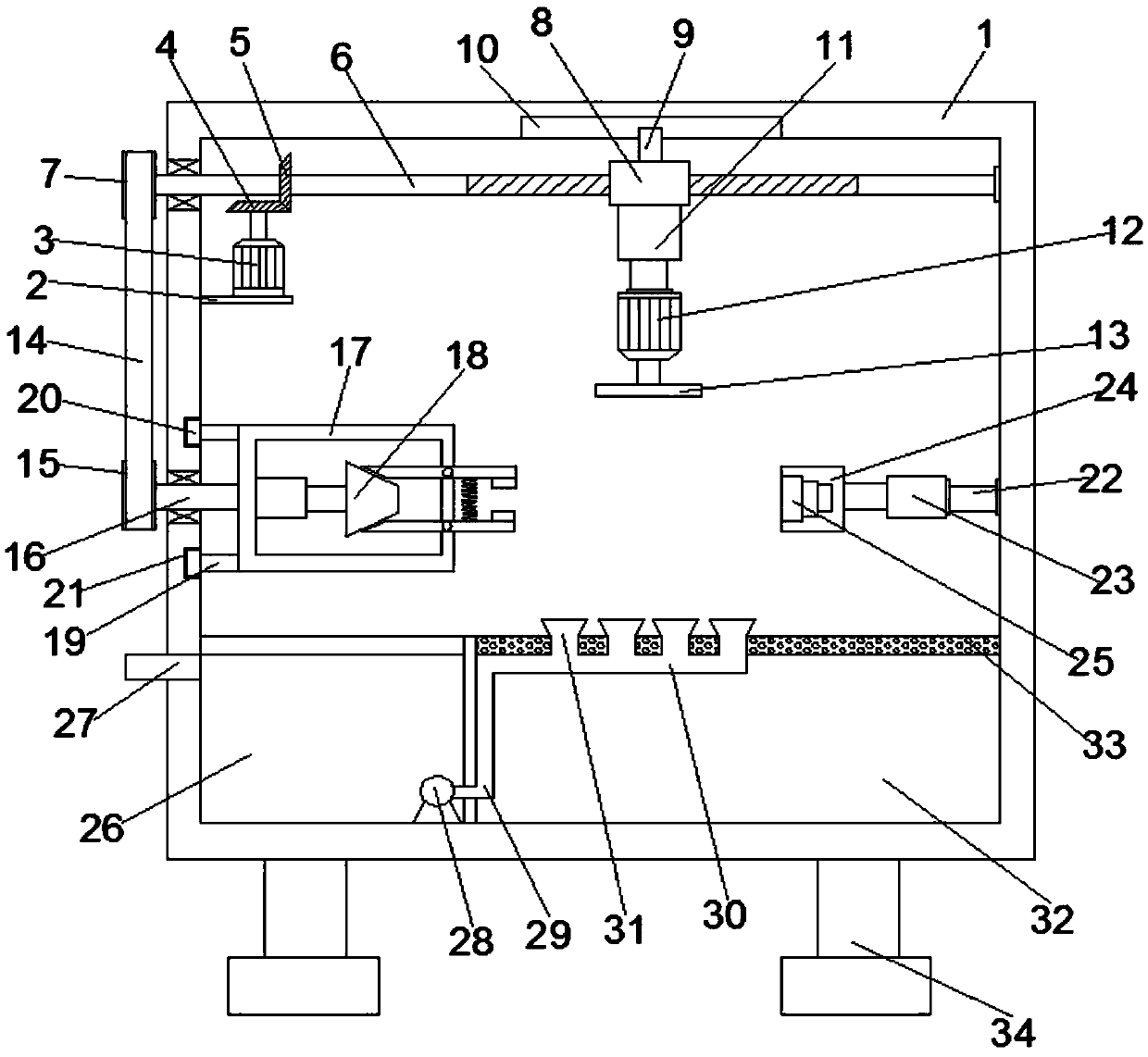

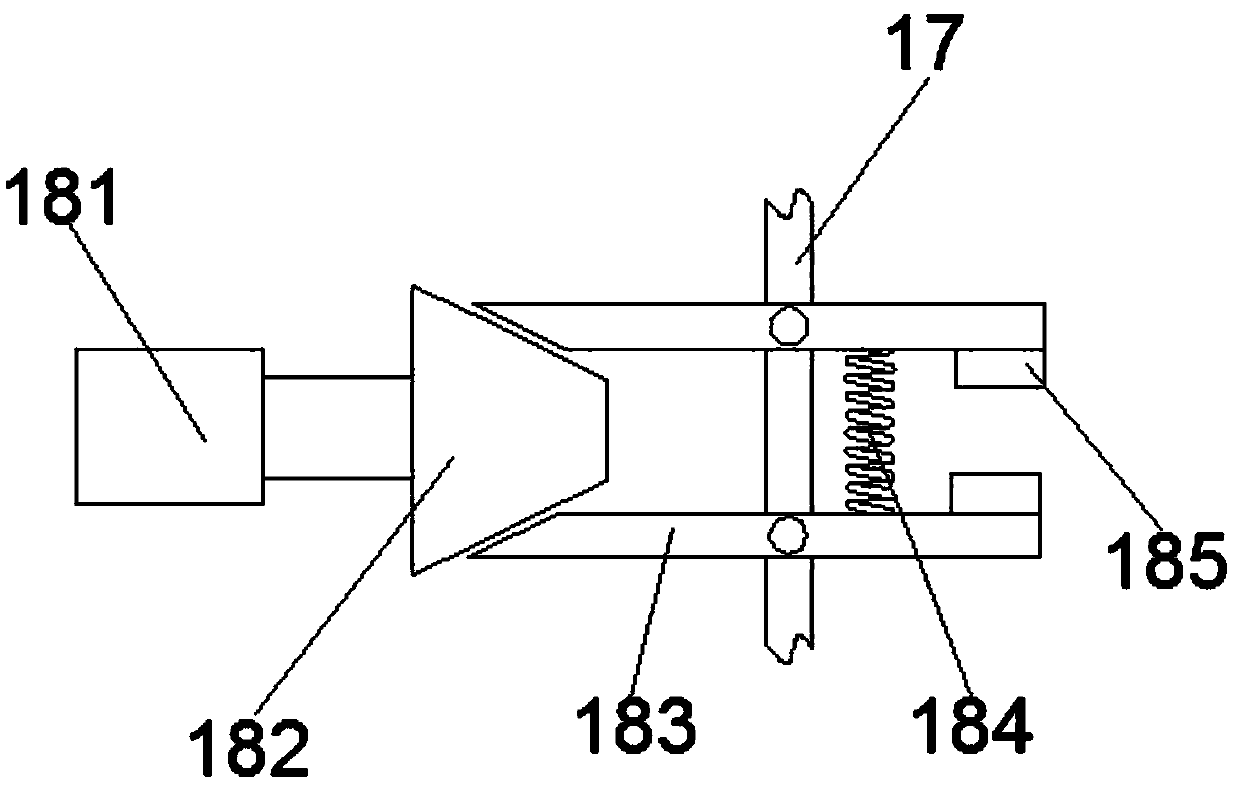

Multifunctional drainage pipeline rust removing and paint spraying equipment

InactiveCN111346761AReduce work intensityImprove stabilitySpraying apparatusGrinding machinesReciprocating motionElectric machine

The invention relates to the technical field of drainage devices, in particular to multifunctional drainage pipeline rust removing and paint spraying equipment which comprises a main box. A fixing plate is arranged on the upper portion of the left side of an inner cavity of the main box, a first driving motor is installed on the fixing plate, a first bevel gear is arranged on the front side of anoutput shaft of the first driving motor and engaged with a second bevel gear, and the second bevel gear is arranged on the left side of a lead screw. According to the multifunctional drainage pipelinerust removing and paint spraying equipment, a pipeline can be clamped and treated under the action of a clamping mechanism and a groove, stability is high, and adaptability is high; and through left-right reciprocating motion of a grinding wheel and forward and reverse rotation of the pipeline, the pipeline can be thoroughly derusted, the derusting efficiency is further improved, the pipeline does not need to be manually turned over, and the automation degree is high; and meanwhile, under the action of a spray head and cooperation of forward rotation and reverse rotation of the pipeline, spraying is more uniform, and the spraying efficiency is better.

Owner:张欣欣

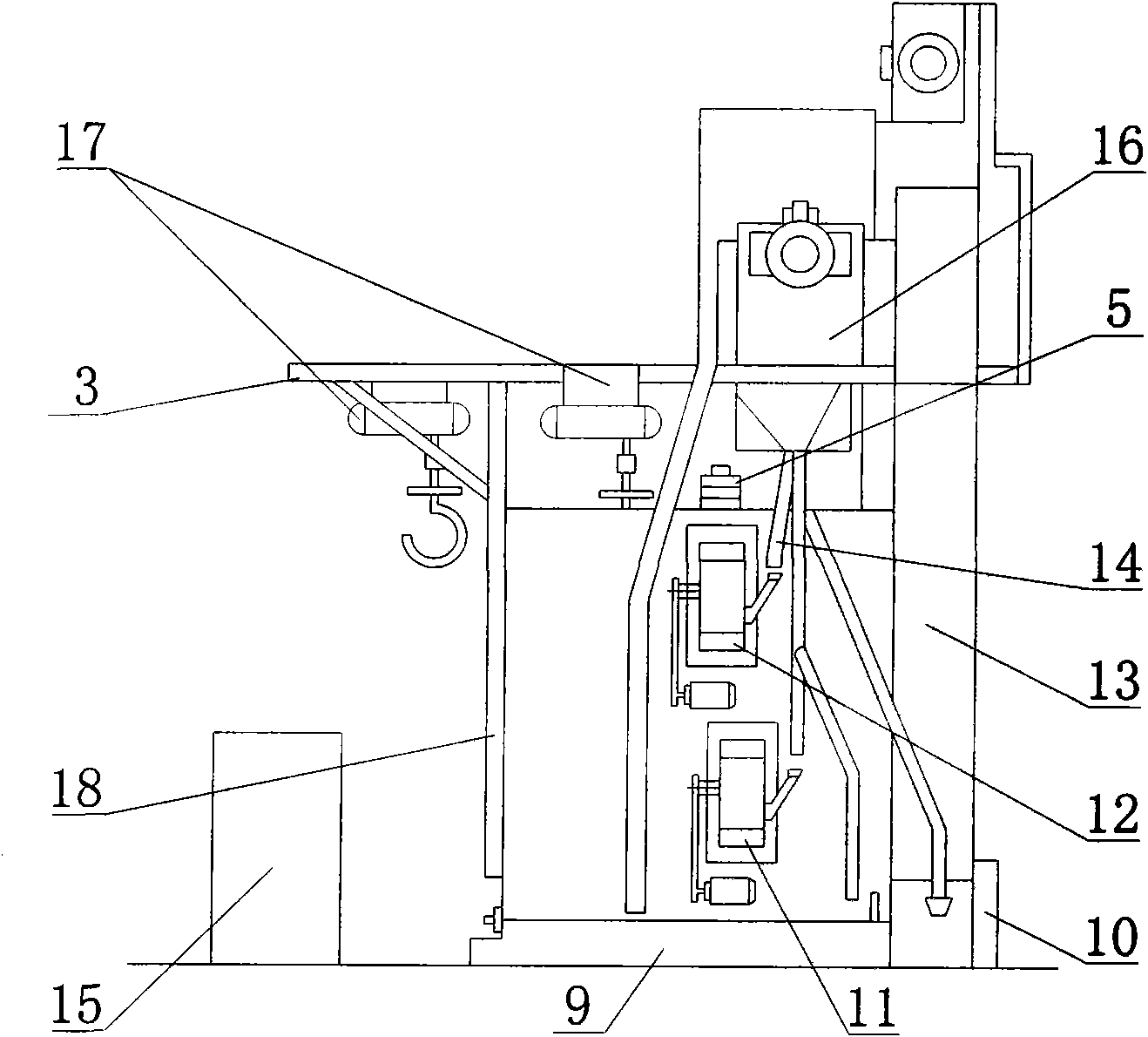

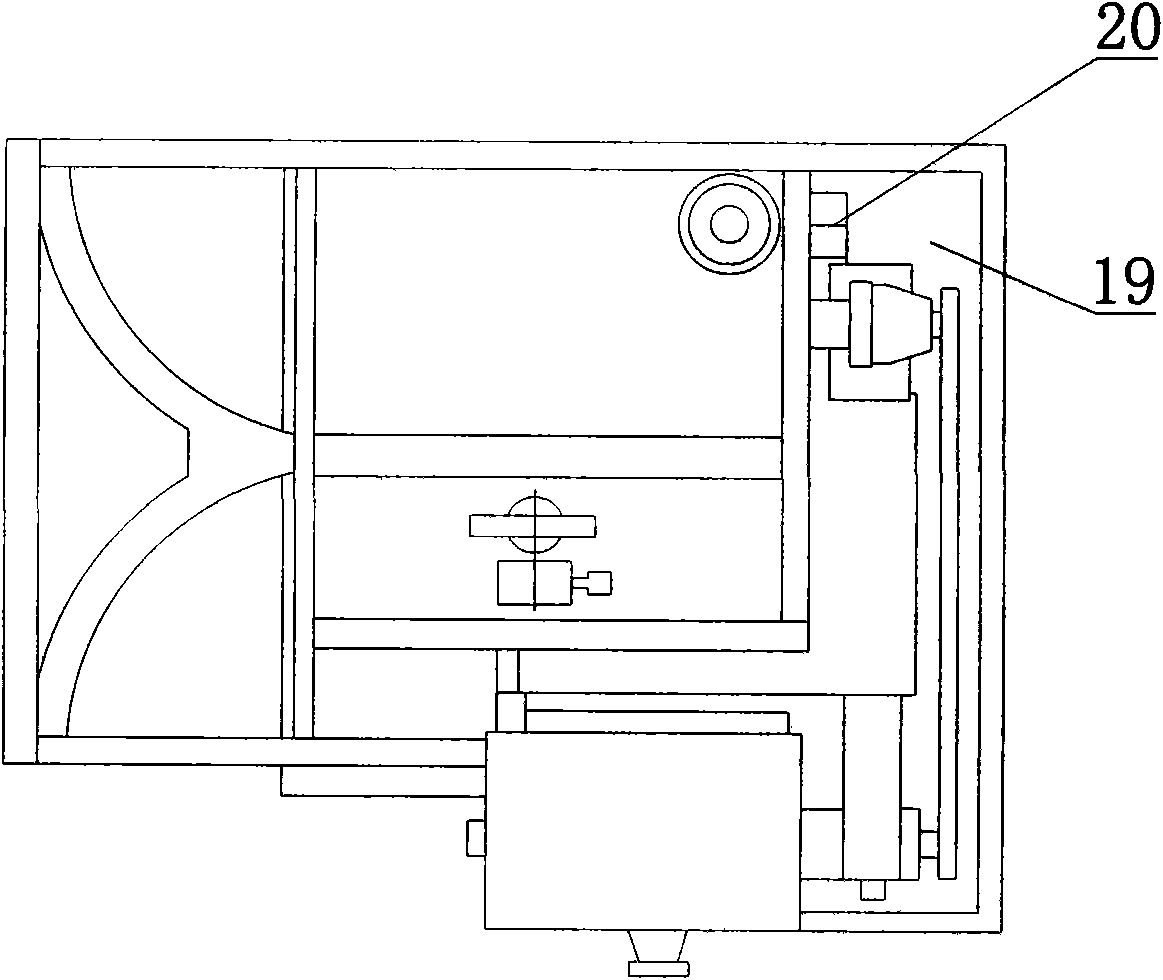

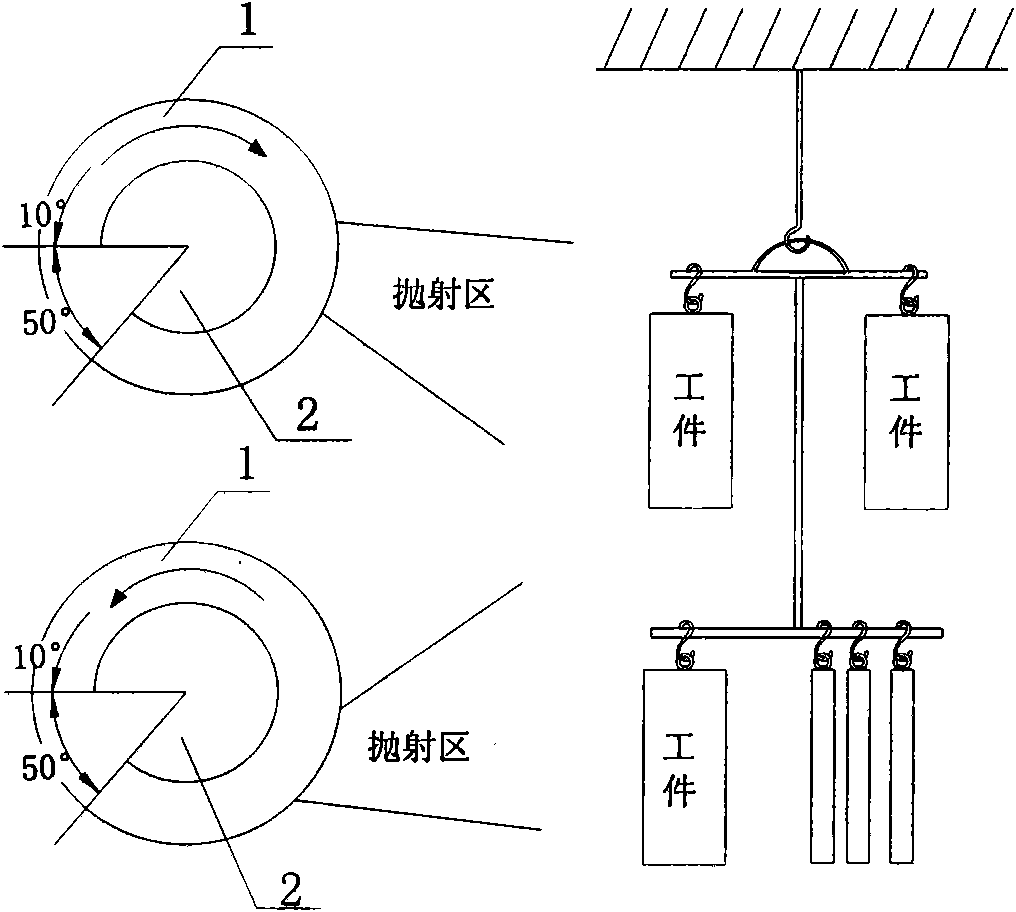

Method and device for sanding and descaling mining explosion-proof type shell

InactiveCN101670555AAchieve production effectUniform derustingAbrasive machine appurtenancesAbrasive blasting machinesEngineeringSmall footprint

The invention relates to a method and a device for sanding and descaling a mining explosion-proof type shell, belonging to the technical field of sanding cleaning. The method for sanding and descalingthe mining explosion-proof type shell is characterized in that steel shot sanding and descaling is carried out on the explosion-proof type shell by adopting a way of throwing steel shots through a shot-blasting machine. The device for sanding and descaling the mining explosion-proof type shell comprises the shot-blasting machine, a track and a cleaning room, wherein the shot-blasting machine is arranged in the cleaning room; and the track is arranged above the cleaning room and provided with a shell hanger of lifting hanger explosion-proof type. The invention has the advantages of simple technique, small floor area, convenient use, safety and reliability, no discharging of polluted liquid, environmental protection, high production efficiency, low labor intensity, good sanding and descaling effects, and the like.

Owner:天津市天矿电器设备有限公司

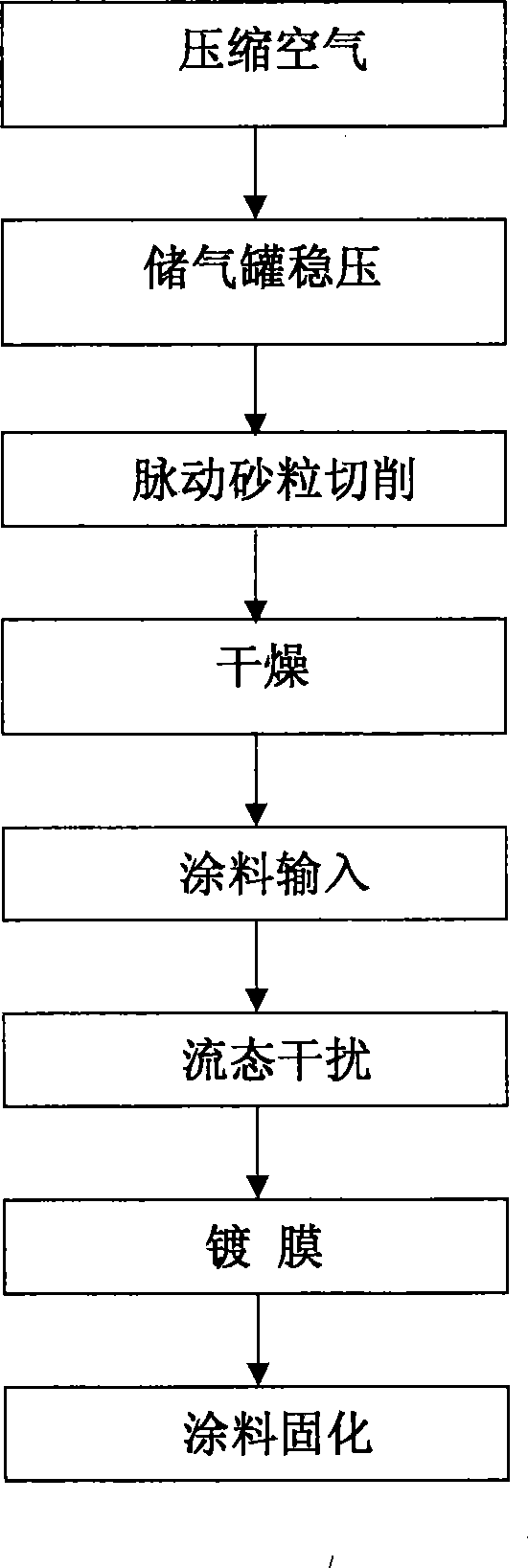

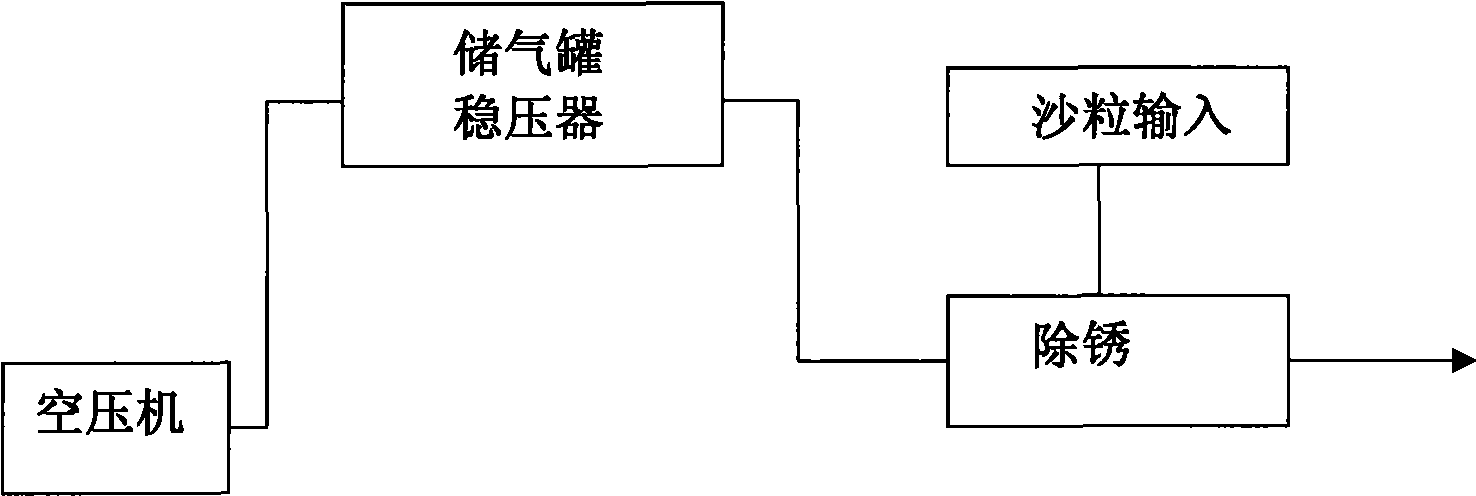

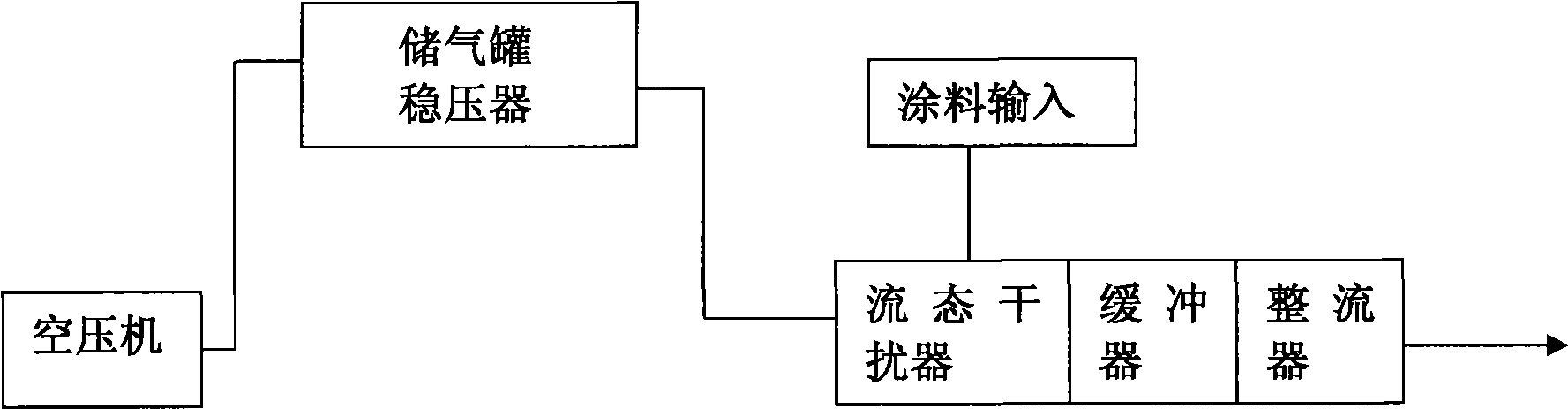

Method and device for clearing rust-dirt and performing anticorrosion coating on metal pipelines

InactiveCN101518773AGood rust removal effectGood surface smoothnessPretreated surfacesCoatingsWater qualityEngineering

The invention provides a method and a device for clearing rust-dirt and performing anticorrosion coating on metal pipelines. The method is characterized in that a soft-body pipeline clearing device is arranged in the ends of a pipeline; a soft-body plugging device is pushed to move by compressing air so as to push pasty sewage and a large amount of accumulated water poor in adhesion out of the pipeline; natural sand or red steel sand is blown into the pipeline by compressing the air so as to remove strong-adhesion hard rust dirt; a reinforced soft-body plastic dryer is pushed to move by compressing the air so as to dry the pipeline in cooperation with compressed-air exhaust; tangential wind and straight wind of the compressed air are blown into the pipeline, and an air gate of a fluid-state interference unit is opened; anticorrosive paint is carried by airflow to enter the fluid-state interference unit; the paint is sprayed in the fluid-state interference unit; the wall of the pipeline is evenly coated with the paint in a laminar-flow fluid state; and the paint is blown and cured. The invention has the advantages of realizing good rust-dirt clearing effects without replacing the pipeline with new pipelines in the whole course, realizing nontoxic anticorrosive coating, uniform thickness, smooth surface and good quality, prolonging the service lifespan of old pipelines, solving the problem of secondary rusting, saving a large quantity of funds, improving pipeline channels and solving the problem of the long-term poor water quality of old water-supply pipelines.

Owner:李常胜

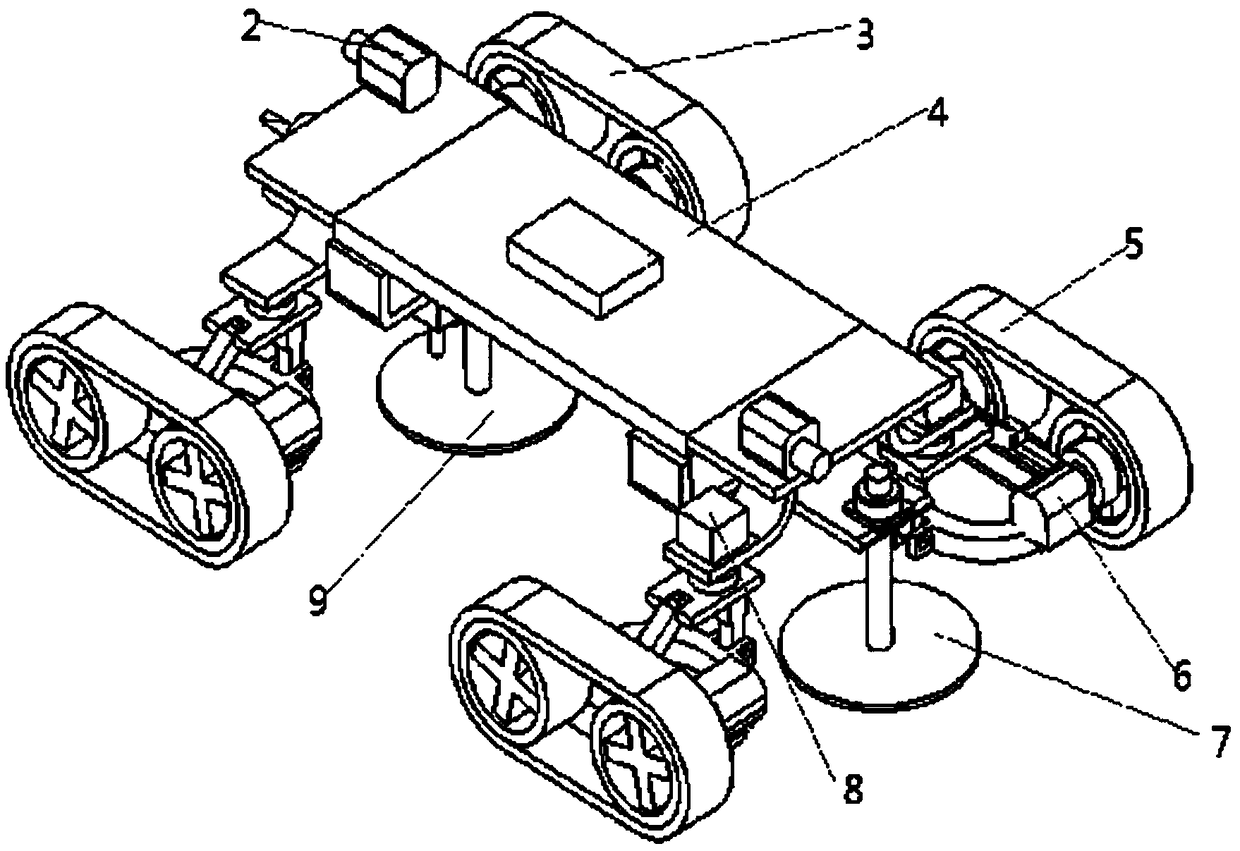

Tower drum maintaining robot and system thereof

PendingCN108488047AReduce erosionExtended service lifeSpraying apparatusMachines/enginesAgricultural engineeringTower

The invention relates to a tower drum maintaining robot which is used for removing rust on an irony tower drum. The tower drum maintaining robot comprises a frame, four caterpillar band walking mechanisms installed on the frame, a rust removing mechanism and a paint spraying mechanism; the four caterpillar band walking mechanisms are arranged at the four corners of the frame, and each caterpillarband walking mechanism comprises a first motor and two magnet wheels, wherein the two magnet wheels are in transmission connection through a caterpillar band, at least parts of the magnet wheels are made of magnetic materials, and the first motor is connected with the magnetic materials and used for driving the magnetic materials to rotate; the rust removing mechanism comprises a hard brush brushing wheel, a soft brush brushing wheel, a bearing base and a driving mechanism, the driving mechanism can drive the hard brush brushing wheel and the soft brush brushing wheel to rotate and can drive the bearing base to drive the hard brush brushing wheel and the soft brush brushing wheel to get close to or be far away from the tower drum; and the paint spraying mechanism comprises a paint storingbox, a spraying rod and a centrifugal pump.

Owner:HEBEI UNIV OF TECH

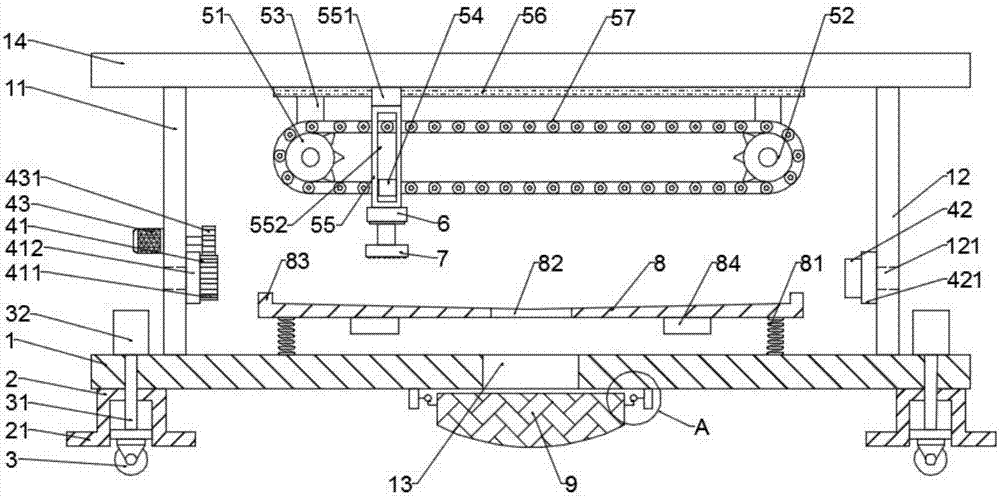

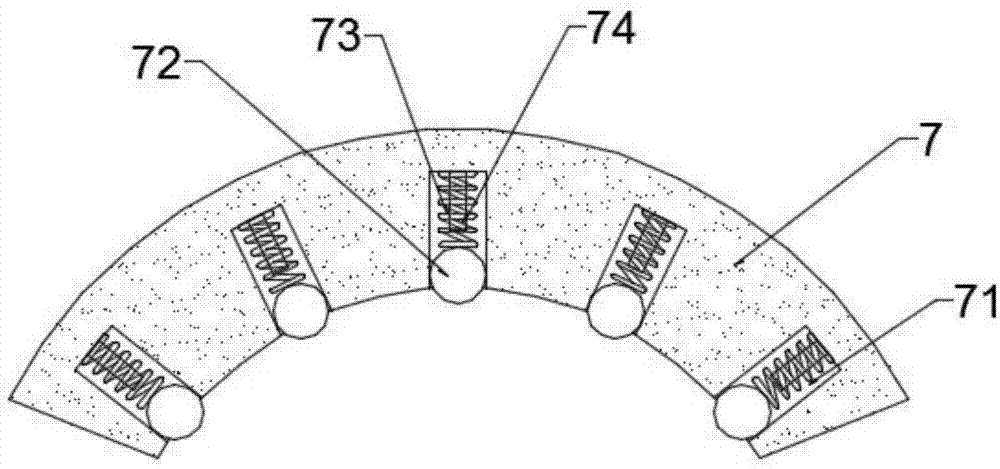

Portable efficient steel bar rust removing device

InactiveCN107471052ARust removal achievedAvoid pollutionGrinding carriagesGrinding drivesArchitectural engineeringRebar

The invention discloses a portable efficient steel bar rust removing device. The portable efficient steel bar rust removing device comprises a base, fixing assemblies, a walking assembly and a rust removing disc. A left support and a right support are symmetrically fixed to the two sides of the top of the base. Column legs are arranged at the bottom of the base and are designed to be hollow, and wheels capable of ascending and descending are arranged in the column legs. The fixing assemblies are arranged in the left support and the right support and can fix steel bars and drive the steel bars to rotate. The walking assembly can drive the rust removing disc to reciprocate left and right. The rust removing disc is in an arc shape and is provided with elastic floating type rust removing balls. A waste scrap table is arranged below the walking mechanism, a waste scrap collecting frame is arranged below the base, and waste scrap collection can be finished through cooperative usage of the waste scrap table and the waste scrap collecting frame. The steel bar rust removing device is good in portability and excellent in rust removing effect; and meanwhile, the structure is reasonable, operation is convenient and fast, and the portable efficient steel bar rust removing device is worthy of popularization and usage.

Owner:广西综改咨询服务有限公司

Steel bar rust-removing equipment for bridge construction

ActiveCN108527109ARust cleanNot easy to get hurtGrinding carriagesGrinding machinesArchitectural engineeringRebar

The invention relates to rust removing equipment, in particular to steel bar rust-removing equipment for bridge construction. The invention aims to provide the steel bar rust-removing equipment for the bridge construction which can achieve the effects that the time and the labor are saved, the rust removing effect is good, manual rust removing operation is not needed, and hands are not prone to behurt. In order to achieve the effects, the steel bar rust-removing equipment for the bridge construction comprises supporting legs and the like; the supporting legs are arranged on the left side surface and the right side surface of a transverse plate, a transverse rod is installed at the top ends of the supporting legs on the left side and the right side, a first fixing block is installed on theupper portion of the front side of the supporting leg on the right side, a first trumpet-shaped through hole is formed in the middle of the first fixing block, a conveying device is arranged betweenthe top of the transverse plate and the transverse rod, and a rust removing device is arranged between the middle of the top of the transverse plate and the bottom of the transverse rod. According tothe equipment, through a scraping device, a steel bar can preliminarily undergo rust removing, so that the steel bar is subjected to rust removing more completely, and the effects that the time and the labor are saved, the rust removing effect is good, the manual rust removing operation is not needed, and the hand is not prone to be hurt are achieved.

Owner:浙江雅迪世纪汽车内饰件有限公司

Metal cleaner

The invention discloses a metal cleaner, which relates to the field of chemical articles. The compositional ratio of a formula of the metal cleaner is as follows: 16 percent to 20 percent of hydrochloric acid, 2 percent to 4 percent of stabilizer, 1 percent to 2 percent of reducer, 1 percent to 2 percent of synergist, 1 percent to 2 percent of chelator, 1 percent to 2 percent of corrosion inhibitor and 60 percent to 70 percent of water. The metal cleaner has the advantages of good rust removal effect, high speed, low cost, convenience in use, non-ignition, non-explosion, no pollution to the environment, no irritation or damage to human bodies or metal, safety, non-toxicity and no volatilization.

Owner:ZHENJIANG XINTAI CHEM MATERIAL

Rapid and efficient rust removal device and method

ActiveCN111230682AEasy to removeImprove rust removal efficiencyAbrasive feedersGrinding machinesIron powderRebar

The invention discloses a rapid and efficient rust removal device and method. The device comprises a base, a left side plate is welded to the upper portion of the left side of the base, a transversely-arranged sliding rail is connected to the top of the left side plate, a sliding block is movably connected to the lower portion of the sliding rail, the left side end of the sliding block is connected with the movable end of an electric extendable rod, and the fixed end of the electric extendable rod is connected with the left side plate; and an air cylinder is installed on the bottom face of thesliding block through an installation plate, the movable end of the air cylinder is connected with a rust removal assembly through a flange, supporting plates are symmetrically arranged above the base, and fixing assemblies are installed on the side faces of the supporting plates. According to the device, the rust removal efficiency of a steel pipe and a steel bar is improved through multiple motion states of the rust removal assembly, iron powder can be effectively removed and collected, the collected iron powder can be circularly sprayed to the surface of the steel pipe and the surface of the steel bar, the rust removal effect can be further enhanced in cooperation with rotation of a rust removal wheel, and it can be guaranteed that the surrounding environment is friendly all the time in the working state.

Owner:迁安市仁泰金属制品有限公司

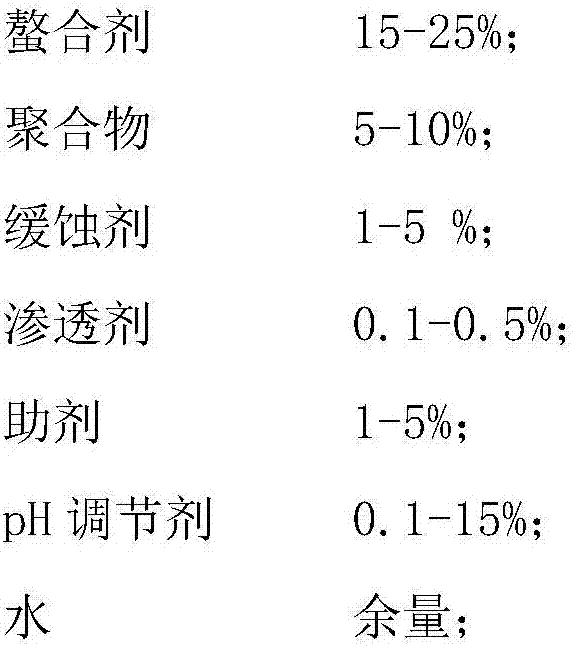

Preparation and application of neutral non-phosphorus rust remover

The invention discloses preparation and application of a neutral non-phosphorus rust remover. The rust remover mainly comprises a chelating agent, a polymer, a corrosion inhibitor, a penetrant, a pH regulator, water and an assistant, and can be applied to phosphorization, chromizing and silanization of coating pretreatment of steel and iron workpieces or zirconium pretreatment and rusty workpiece derusting procedure before chemical conversion coating treatment. According to the rust remover, treatment time is flexible, the rust remover is utilized at the normal temperature, does not need to be heated, can be utilized for treatment in a spraying or impregnation manner, does not contain hazardous substances like phosphorus, and is low in residues and free of scales, after rust removing, a solution is low in bubble and scale, maintenance of a bath solution is simplified, residues and scales are not liable to adhere to the workpieces and pollute the workpieces, the pH of a treating fluid is neutral, workpiece matrixes and operation equipment are not corroded and damaged, the workpieces have good corrosion inhibition and rust protection performance after treatment, and the rust protection problem of the workpieces during the transfer process is solved.

Owner:杭州五源科技实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com