Tower drum maintaining robot and system thereof

A technology of robots and towers, applied in the direction of machines/engines, engines, mechanical equipment, etc., can solve problems such as high risk, low efficiency, and long working cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The content of the present invention will be described below in conjunction with specific embodiments.

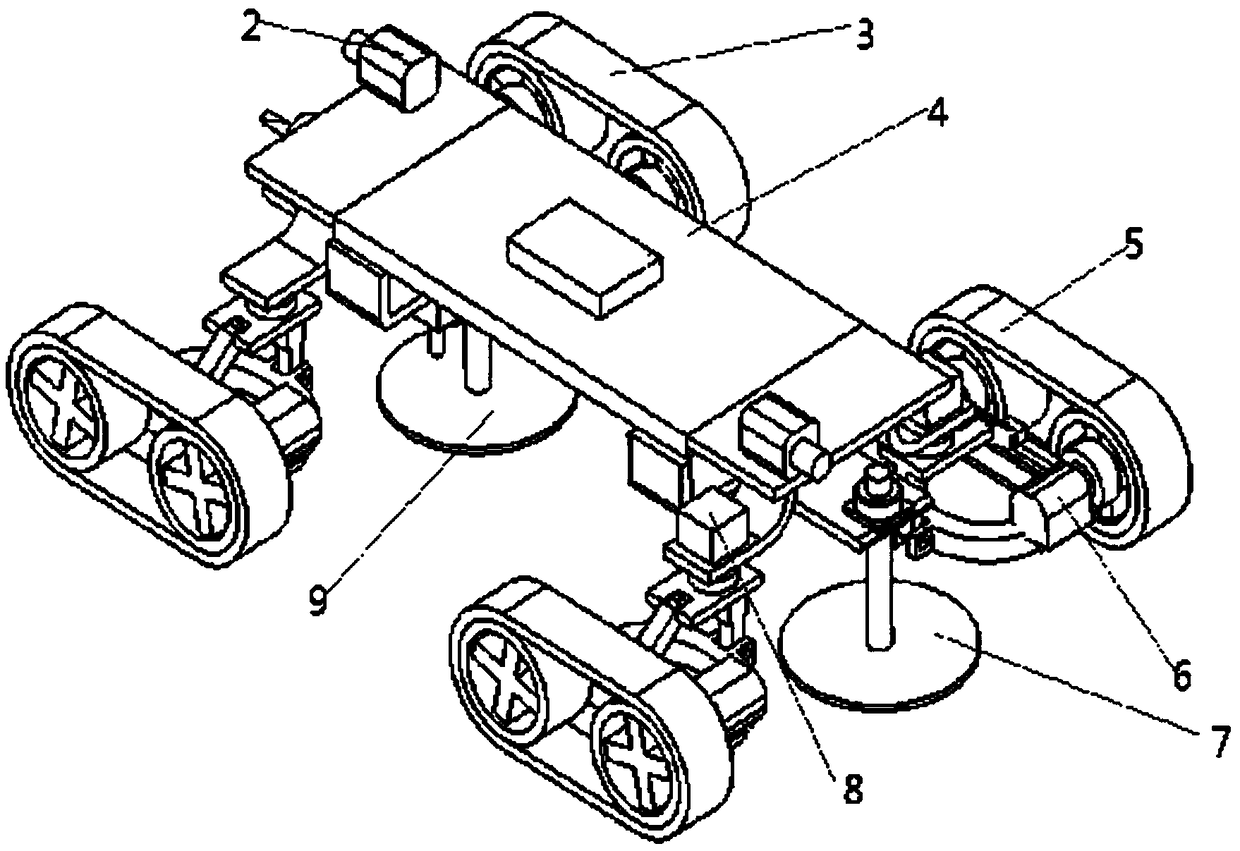

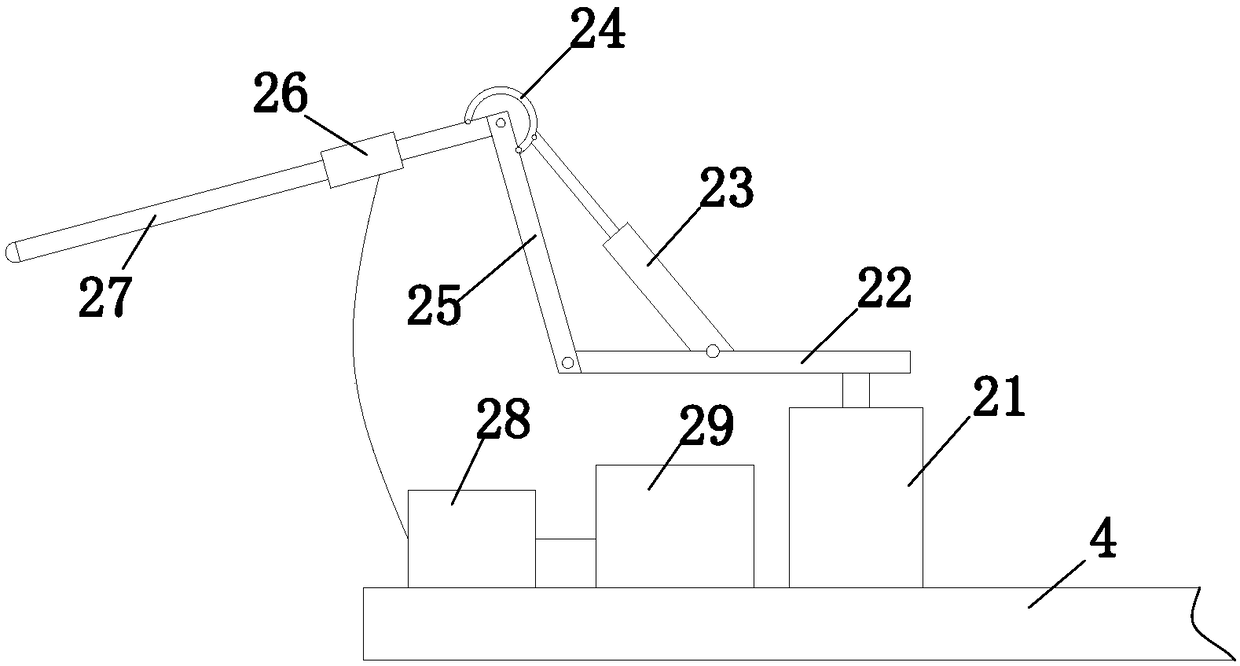

[0020] refer to Figure 1-3 , the present invention proposes a tower tube maintenance robot for removing rust on an iron tower tube, which includes a vehicle frame 4, four crawler walking mechanisms 3 placed on the vehicle frame 4, a rust removal mechanism and a painting mechanism 2 .

[0021] The four crawler running mechanisms 3 are respectively arranged at the four corners of the vehicle frame 4 , and the crawler belt running mechanisms 3 include a first motor 6 and two magnetic wheels. The two magnetic wheels are connected through a crawler belt 5, and the magnetic wheels are at least partially made of magnetic materials. The first motor 6 is connected with the magnetic wheel for driving the magnetic wheel to rotate.

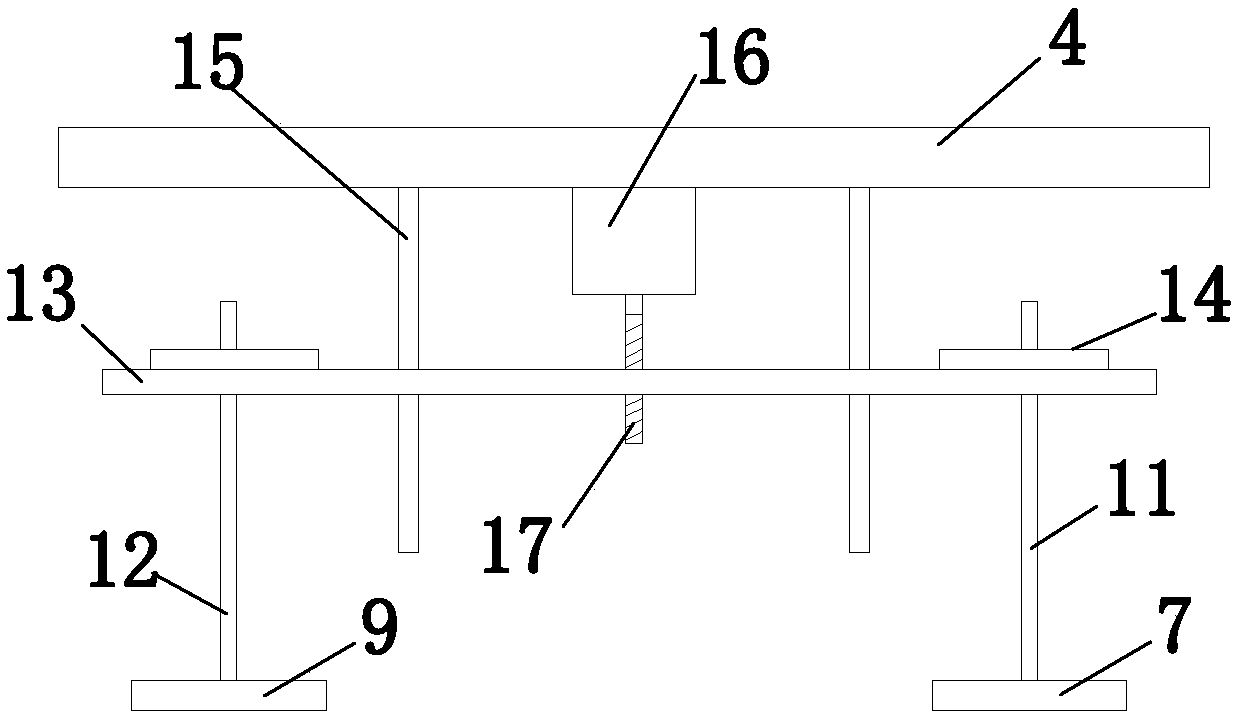

[0022] refer to image 3 , The derusting mechanism includes a hard brush wheel 7, a soft brush wheel 9, a support seat 13 and a driving mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com