Patents

Literature

80results about How to "No corrosion damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anticorrosive coating for chemical storage tank and construction method thereof

InactiveCN105665258ASolve the technical problem of high failure rate of inner layer corrosion protectionGuaranteed protective effectPretreated surfacesAnti-corrosive paintsChemical storageSand blasting

The invention provides an anticorrosive coating for a chemical storage tank and a construction method thereof. The anticorrosive coating comprises at least two anticorrosive coating units sequentially connected on the inner wall of the chemical storage tank, wherein each anticorrosive coating unit comprises a primer layer and a sprayed polyurea layer, the thickness of the primer layer of each basic anticorrosive coating unit is 10-100 microns, and the thickness of the sprayed polyurea layer is 0.5-1 mm. The inner wall of the chemical storage tank connected with each primer layer is obtained through sand blasting treatment or through sand blasting and acid pickling treatment sequentially. The thickness of each basic anticorrosive coating unit of the anticorrosive coating is small, the anticorrosive coating can be completed through one-time construction, and the polyurea layers are free of joints and tightly combine with the inner wall of the chemical storage tank to form a complete isolation layer. By adding an acid pickling step, tiny sharp corners on the surface subjected to the sand blasting treatment are decreased, the phenomenon that the basic anticorrosive coating cannot completely cover the surface of the inner wall is prevented, and the continuity of the basic anticorrosive coating is ensured.

Owner:TIANJIN DAPURUI TECH CO LTD

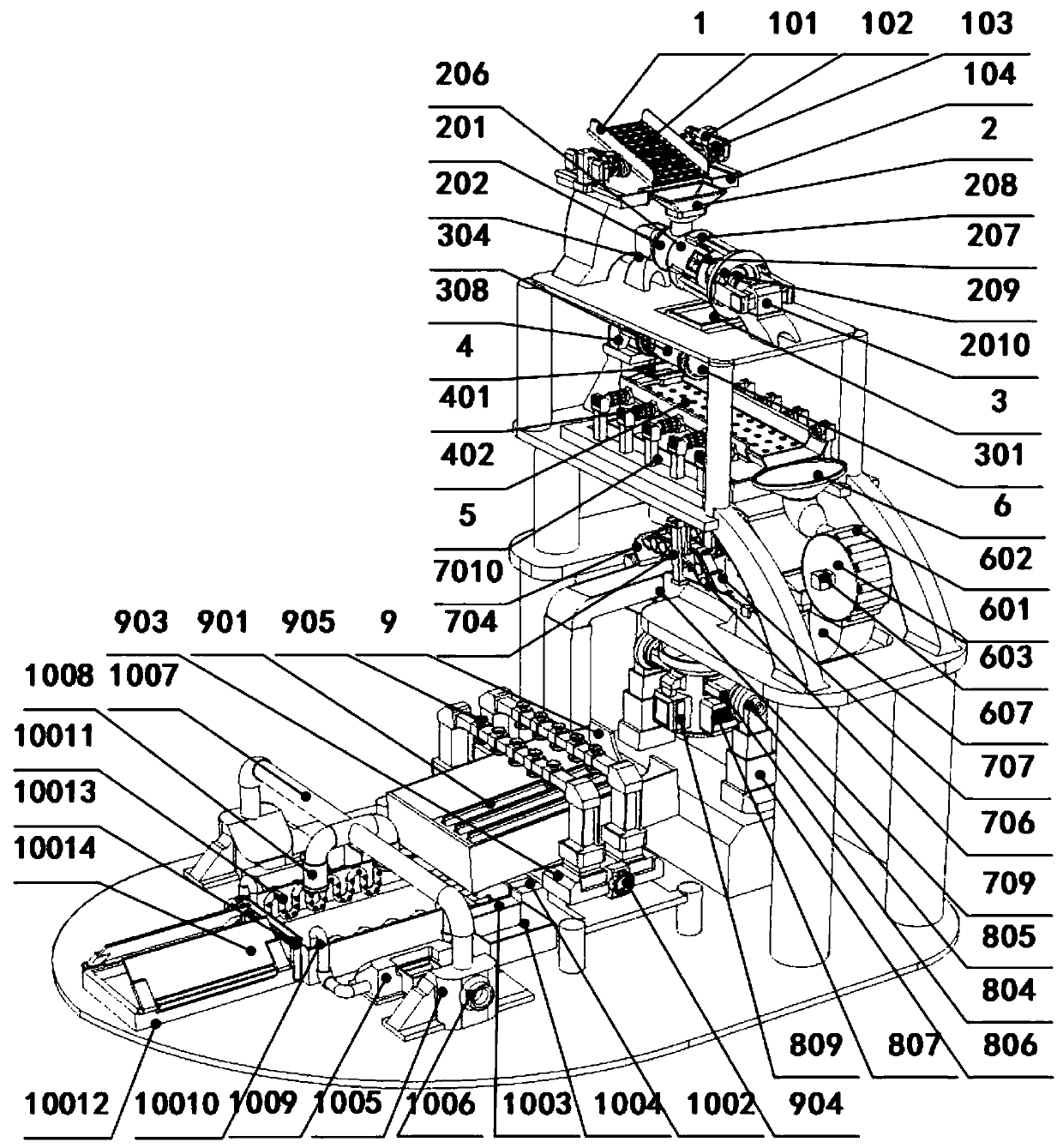

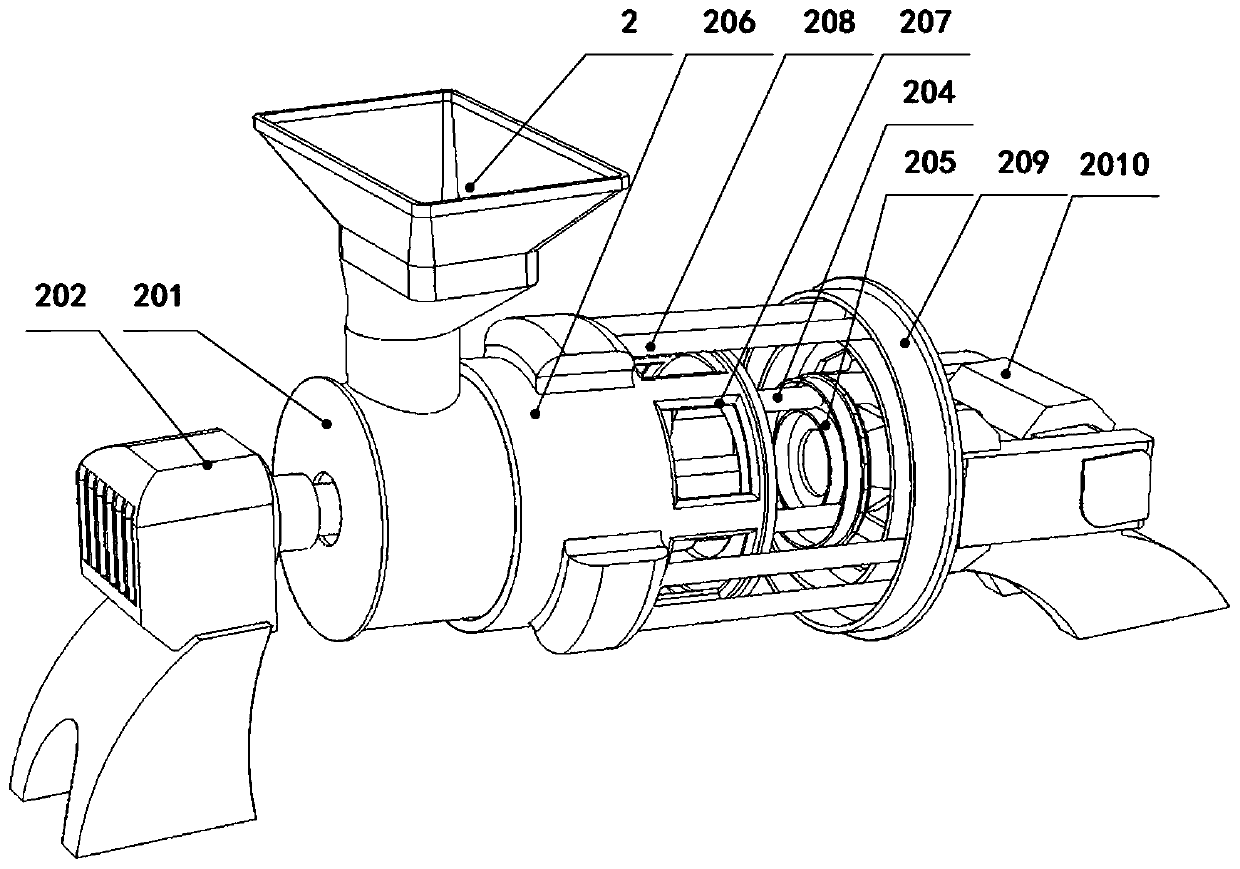

Deep processing device for magnetic iron ore

ActiveCN109894246AGuaranteed purityReduce loss rateMagnetic separationCleaning using liquidsSolid phasesMachining process

The invention relates to a deep processing device for magnetic iron ore. The deep processing device comprises a screening system, a deflection crushing system, a vibrating mill system, a sieving system, a multilayer funnel, a fine grinding system, a solid-phase magnetic separation system, a liquid-phase magnetic separation system, a spray-washing system and a washing system, which are arranged from top to bottom in sequence. Raw material vein ore in mining can be preliminarily screened through the screening system, the deep processing device can ensure that a machine cannot be damaged due to the huge size difference of ore in the following processing process. Moreover, according to a scientific processing order, the ore is successively broken from large size to small size through the deflection crushing system, the vibrating mill system and the fine grinding system in sequence, so the processing effect is good, and the wastage rate of a grinding head or crushing components is reduced.By the cooperative work of the sieving system and crushing operation, the deep processing device can ensure that small-size ore cannot enter a large-size crushing process link to jam or damage the machine.

Owner:承德旭升矿业有限公司

Neutral environment-friendly paint remover

The invention discloses a neutral environment-friendly paint remover. The neutral environment-friendly paint remover is a mixed solution formed by a main solvent, a volatile inhibitor, an activating agent, a cosolvent, an emulsifying agent, a corrosion inhibitor, a penetrating agent, an alkane odor remover and a thickening agent. The main solvent comprises a mixture of two or three of dichloromethane, ethyl acetate and acetone; the volatile inhibitor is liquid paraffin and water; the activating agent is ethanolamine; the cosolvent is ethanol; and the thickening agent is polyethylene glycol. The neutral environment-friendly paint remover comprises, by mass, 70-80% of the main solvent, 0.5-2% of liquid paraffin, 2-5% of water, 4-6% of ethanolamine, 5-10% of ethanol, 3-8% of the emulsifying agent, 0.2-1% of the corrosion inhibitor, 1-3% of the penetrating agent, 0.3-0.7% of the alkane odor remover and 0.5-1.5% of the polyethylene glycol. The neutral environment-friendly paint remover can effectively remove electrophoretic coatings with complex shapes on metal components thoroughly; a paint removal efficiency is higher than or equal to 98%; the neutral environment-friendly paint remover does not corrode metal, wood or cement, and has a wide application scope, no pungent smell, low volatility, and small harm to a human body and an environment. The neutral environment-friendly paint remover has high stability and can be cleaned easily.

Owner:SHANDONG WEIDA MASCH CO LTD

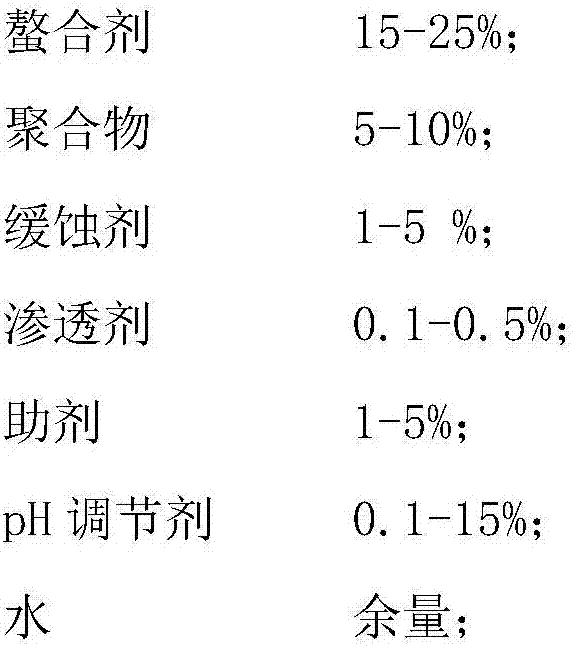

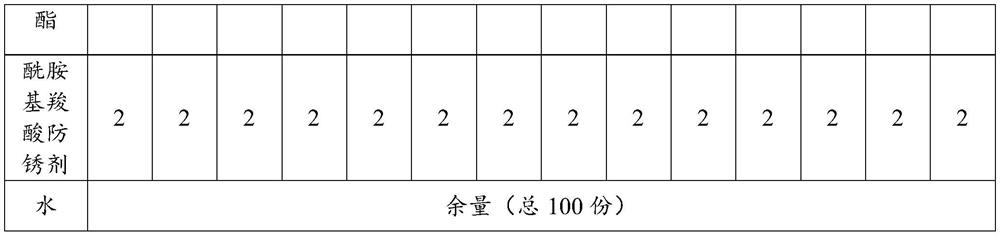

Preparation and application of neutral non-phosphorus rust remover

The invention discloses preparation and application of a neutral non-phosphorus rust remover. The rust remover mainly comprises a chelating agent, a polymer, a corrosion inhibitor, a penetrant, a pH regulator, water and an assistant, and can be applied to phosphorization, chromizing and silanization of coating pretreatment of steel and iron workpieces or zirconium pretreatment and rusty workpiece derusting procedure before chemical conversion coating treatment. According to the rust remover, treatment time is flexible, the rust remover is utilized at the normal temperature, does not need to be heated, can be utilized for treatment in a spraying or impregnation manner, does not contain hazardous substances like phosphorus, and is low in residues and free of scales, after rust removing, a solution is low in bubble and scale, maintenance of a bath solution is simplified, residues and scales are not liable to adhere to the workpieces and pollute the workpieces, the pH of a treating fluid is neutral, workpiece matrixes and operation equipment are not corroded and damaged, the workpieces have good corrosion inhibition and rust protection performance after treatment, and the rust protection problem of the workpieces during the transfer process is solved.

Owner:杭州五源科技实业有限公司

Deoiling agent

InactiveCN1632094AScientific and reasonable compositionEasy to useNon-ionic surface-active compoundsSolventChemistry

The invention relates to an oil expelling agent, comprising the following raw material: water of small necless 300-400portions, fatty acid ethylene oxide addition compound penetrate, arene solvent, compound surface active agent. Its has scientific compounds, without toxicity and pungent odor, is water-soluble, has no pungency to the skin, no influence to people's health and no harm to the subject washed and paint protective film; it is safe, reliable, convenient, rapid and has good cleaning effect, can be widely applied in clearing in the fields such as aviation, train, ship army equipment, oil developing and processing, oil tank, oil pipeline, publishing machine, electric equipment, procession, manufacture and maintenance of chemical equipment the ground of garage and machine house .

Owner:ZIBO XIBEIZI CHEM

Non-destructive waterproof agent for architectural indoor deep penetration curing

The invention discloses a waterproof material which is remarkable in waterproof effect, long in waterproof life, and simple and safe to use, as well as used for performing non-destructive decorative surface leakage treatment aiming at leakages occurring on the decorated unit and home indoor floors; the two components A and B of the waterproof material are in a water-soluble liquid state and can penetrate below the floor through the original leakage channel on the floor, then the two components are reacted in a gap to form a gelled solid so as to thoroughly block the leakage channel, thus realizing non-destructive waterproof treatment on the decorative surfaces. For example, with regard to leakage treatment on bath rooms, toilets, balconies, kitchens and large commercial bathhouses, waterproof leakage treatment can be realized without destruction on the decorative layers of the floors.

Owner:HENAN SUNSHINE WATERPROOF TECH CO LTD

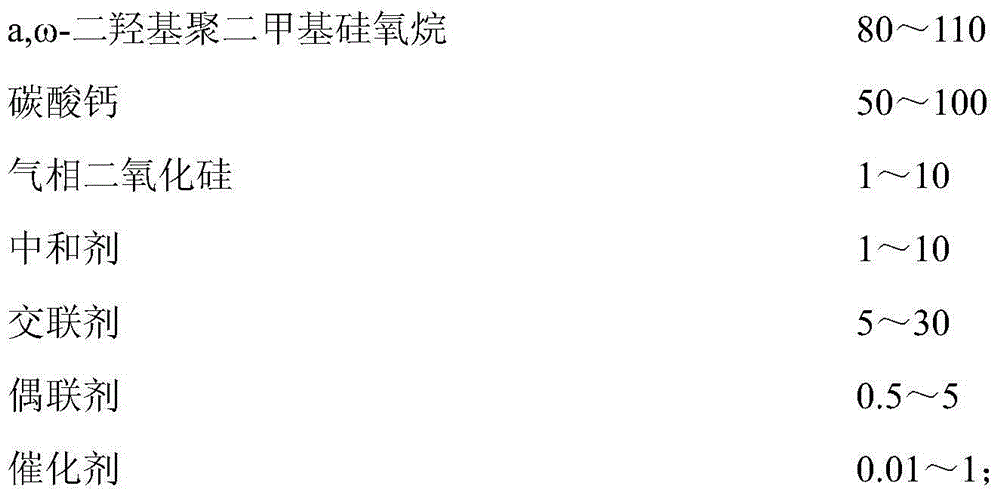

Low-volatility single-component de-ketoxime type silicone rubber for lamps and preparation method of silicone rubber

InactiveCN104371640AReduce or neutralize volatile matterEliminate the effects ofNon-macromolecular adhesive additivesPolymer scienceGas phase

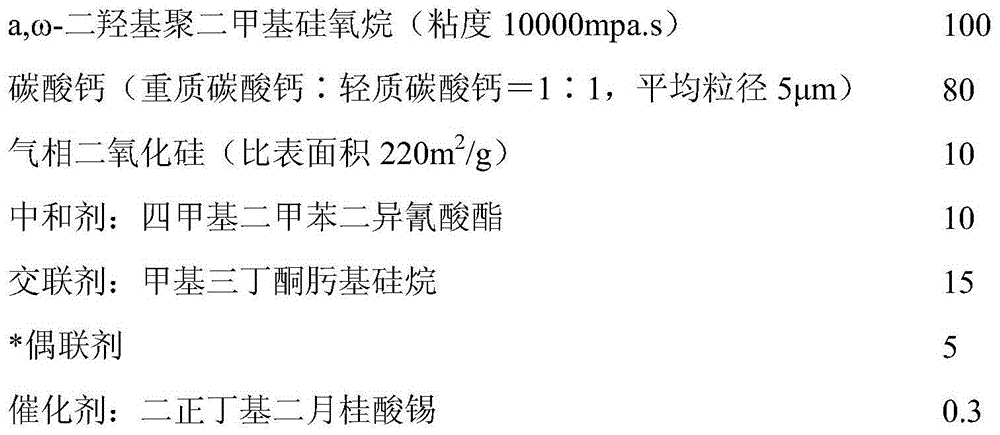

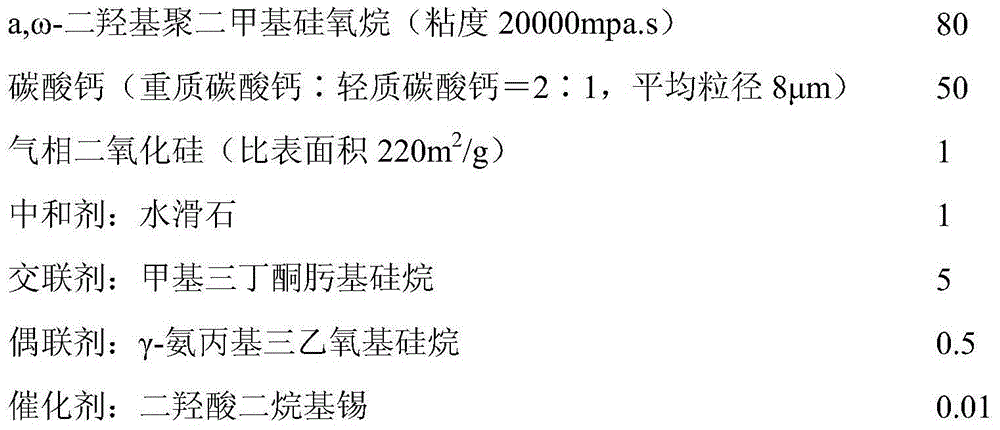

The invention discloses low-volatility single-component de-ketoxime type silicone rubber for lamps. The silicone rubber comprises, by weight, 80-110 parts of a, omega-dyhydroxy polydimethyl siloxane, 50-100 parts of calcium carbonate, 1-10 parts of fumed silica, 1-10 parts of neutralizer, 5-30 parts of cross-linking agent, 0.5-5 parts of coupling agent and 0.01-1 part of catalyst, wherein the neutralizer is one or combination of hydrotalcite, aluminum silicate, magnesium silicate, zeolite, bamboo charcoal powder and organic isocyanate. The silicone rubber has the advantages the influence of ketoxime substances on PC materials is eliminated by lowering volatile content, and the rubber does not generate unpleasant smells during actual application, does not corrode and destroy the PC materials and good in cohesiveness.

Owner:GUANGZHOU HUINA NEW MATERIAL TECH

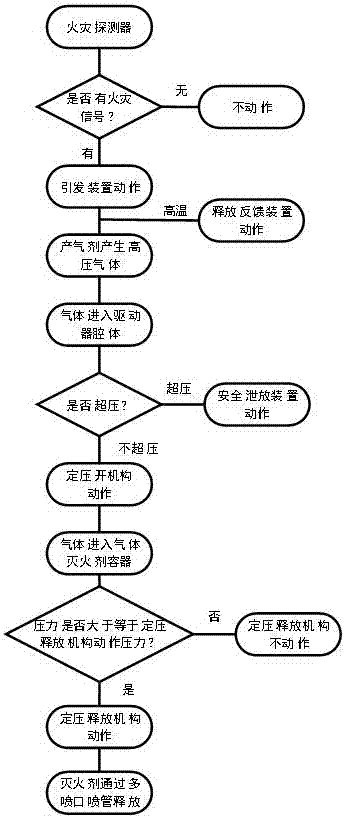

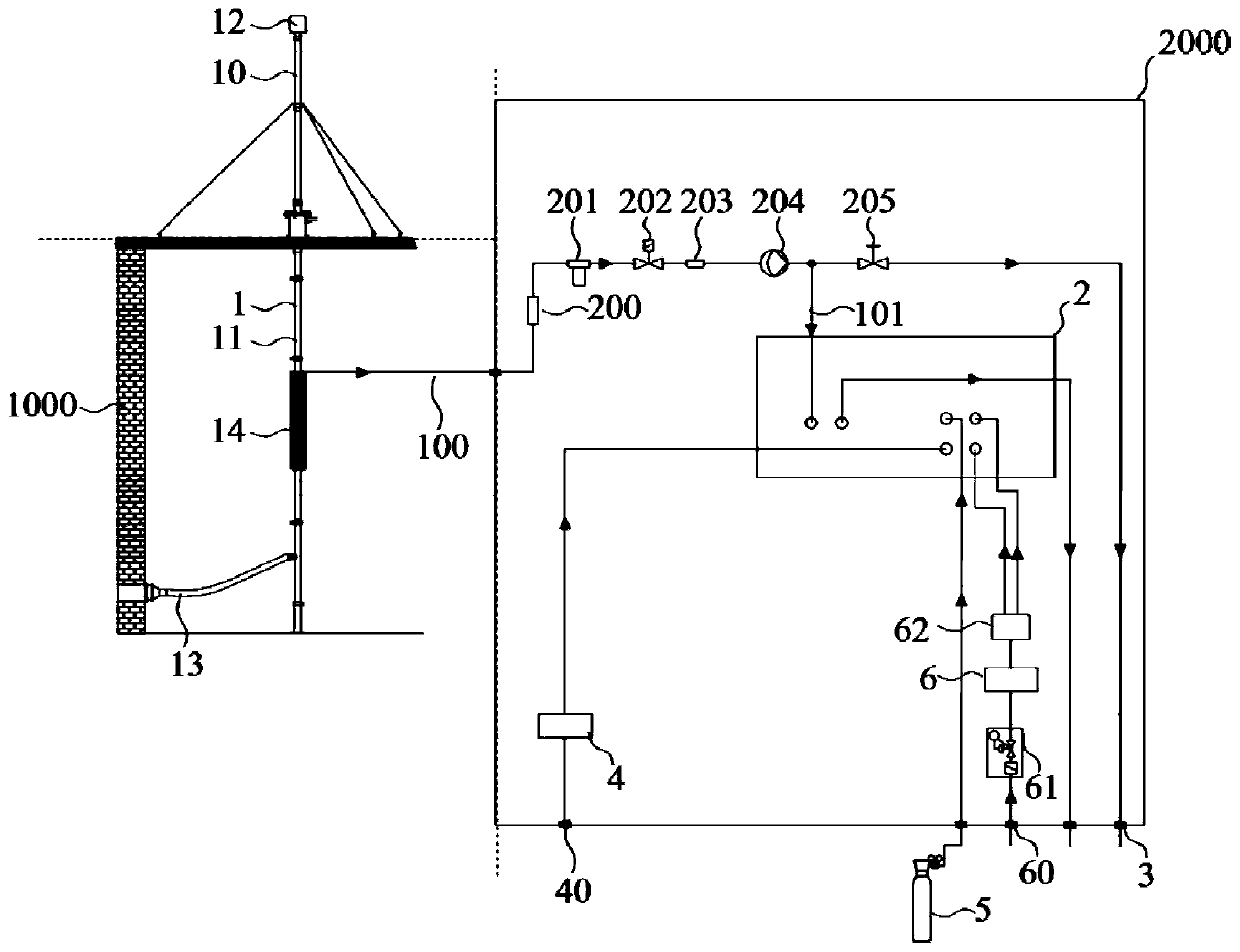

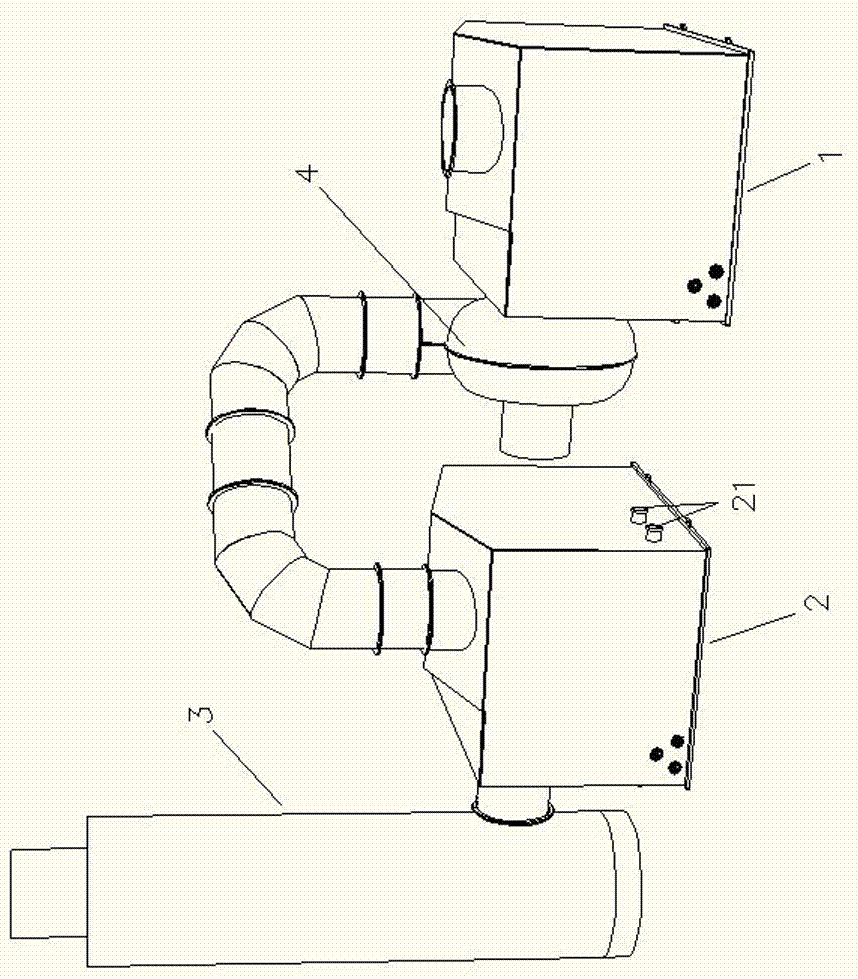

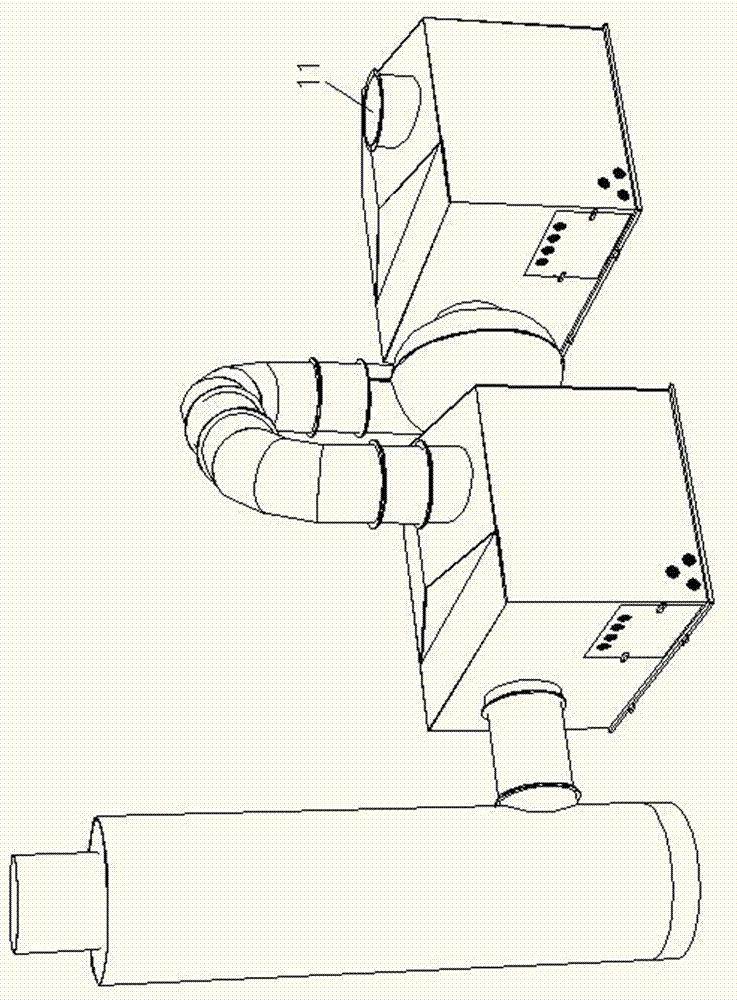

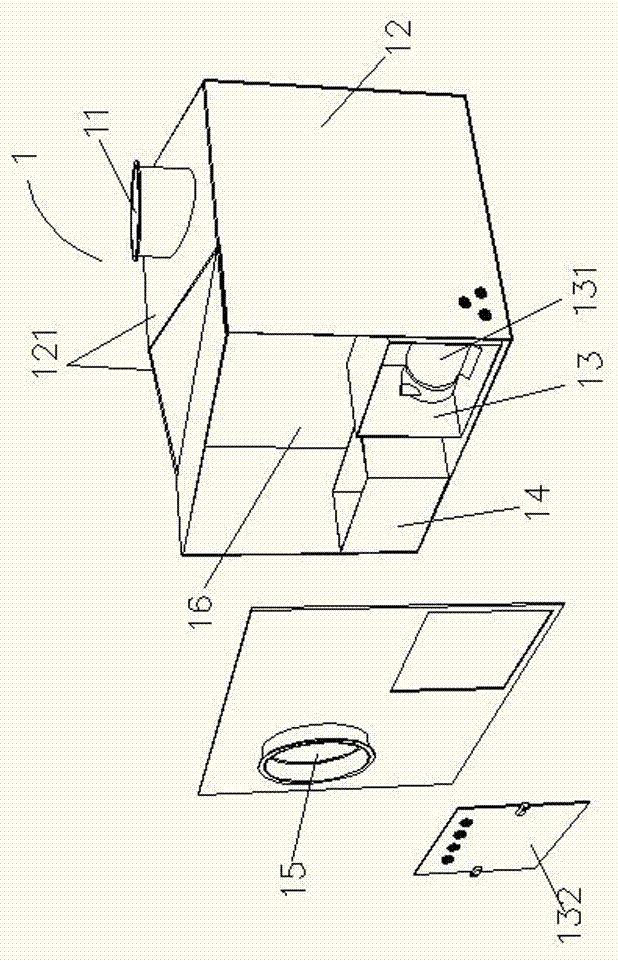

Special gas fire-extinguishing device for lithium-ion battery box and implementation method for fire extinguishing

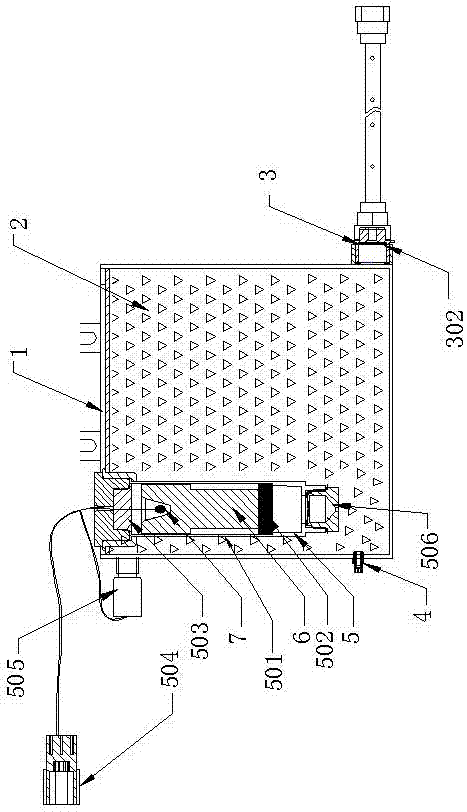

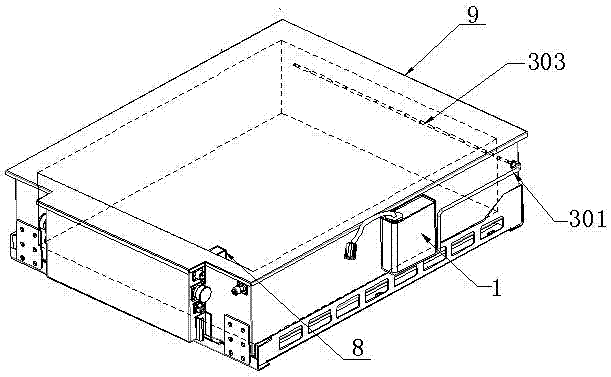

PendingCN107320871ARelieve pressureReduce volumeFire rescueSecondary cells servicing/maintenanceThermal runawayElectrical battery

The invention relates to a special gas fire-extinguishing device for a lithium-ion battery box and an implementation method for fire extinguishing. The device comprises a gas fire-extinguishing agent container, a constant-pressure releasing mechanism, a gas inflowing locking device, a gas producing driver, a gas producing agent, a trigger and a fire detector. The gas producing driver is arranged in the fire-extinguishing agent container and connected with the trigger, the constant-pressure releasing mechanism is arranged at a fire-extinguishing agent releasing opening of the fire-extinguishing agent container, the gas producing agent explodes and is heated up under triggering of the trigger, so that the gas fire-extinguishing agent is changed to be gas from liquid and sprayed out from the constant-pressure releasing mechanism to extinguish fire, and the technical effects are that the size is small, and installation is convenient; and moreover, the internal pressure of the fire-extinguishing agent container is low under normal conditions, the safety and the reliability are achieved, effective fire extinguishing can be implemented on the lithium-ion battery box at first time, no residue is left after the fire-extinguishing agent is released, no corrosion damage is caused, and extension of thermal runaway of a battery is effectively restrained.

Owner:应急管理部天津消防研究所

Cleaning method of ash pipe in thermal power plant

InactiveCN1337279ANo corrosion damageNo pollution in the processHollow article cleaningSlagSteam power

The present invention relates to a method for cleaning ash pipeline of steam-power plant, which is characterized by that it utilizes slag transferring pump to feed the liquid containing hard granularmaterial into pipeline to make the hard granular material impact against ash scale and make the ash scale fall down, and discharge the ash scale from the pipeline by means of high-speed running liquid containing hard granular material. Said invention does no damage to pipeline, and has no corrosion and has no environmental pollution, and its cleaning cost is low.

Owner:李志杰

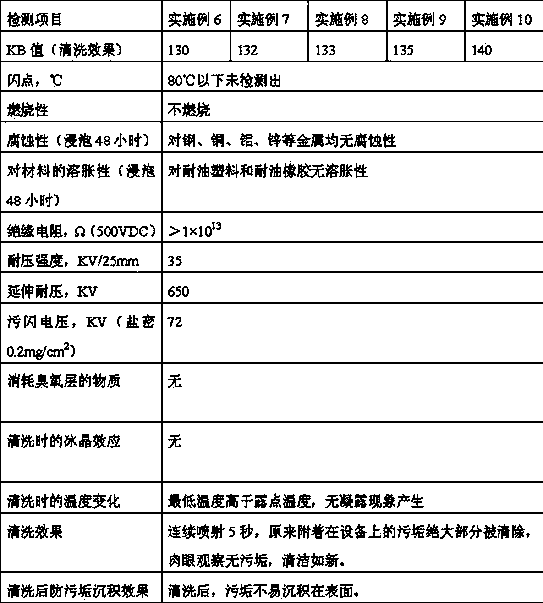

Electrified cleaner for electric appliances and preparation method of electrified cleaner

ActiveCN104212658AReduce cleaning timesExtended service lifeOrganic detergent compounding agentsAnionic-cationic-non-ionic surface-active compoundsEthyleneglycol monobutyl etherTriethanolamine

The invention discloses an electrified cleaner for electric appliances. The electrified cleaner is prepared from the following components, namely 20-30 parts of trichloro ethylene, 15-25 parts of carbon tetrachloride, 15-25 parts of propylene glycol butyl ether, 10-20 parts of triethanolamine, 5-10 parts of N-fatty acyl ethanol glutamate, 1-2 parts of polyvinylpyrrolidone, 1-3 parts of pentaerythritol, 4-6 parts of N-methyl-2-pyrrolidone, 3-5 parts of ethylene glycol monobutyl ether and 1-3 parts of dodecyl dimethyl quaternary ammonium caprolactone. The electrified cleaner is capable of cleaning the electric appliances during normal working and effectively removing oil stains and dust on the surfaces of the electric appliances; oil stains are not easy to deposit again on the cleaned electric appliances so that the cleaning times of the electric appliances are reduced, and therefore, the service lives of the electric appliances can be prolonged; the ice-crystal effect and the condensation phenomena are prevented in the cleaning process, and as a result, the surface insulation values of the appliances do not drop obviously and no corrosion damage is caused to the appliances; the electrified cleaner for electric appliances is safe to use, free of flashing point and does not burn; besides, the electrified cleaner is an environment-friendly material, contains no substance that may deplete the ozone sphere and thus causes no pollution to the environment.

Owner:博仕能源江苏有限公司

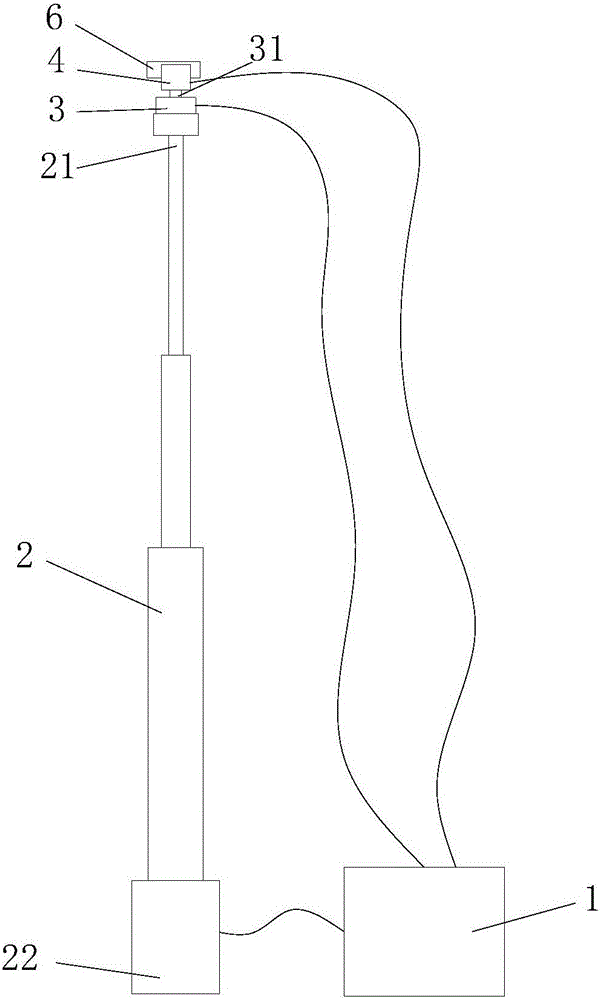

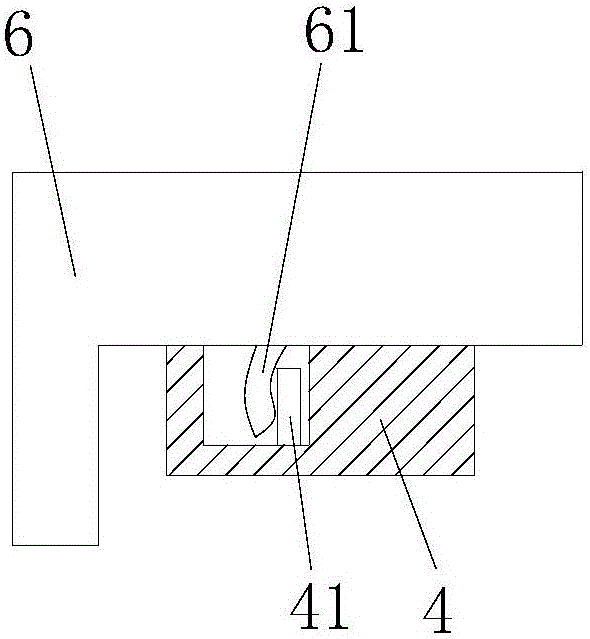

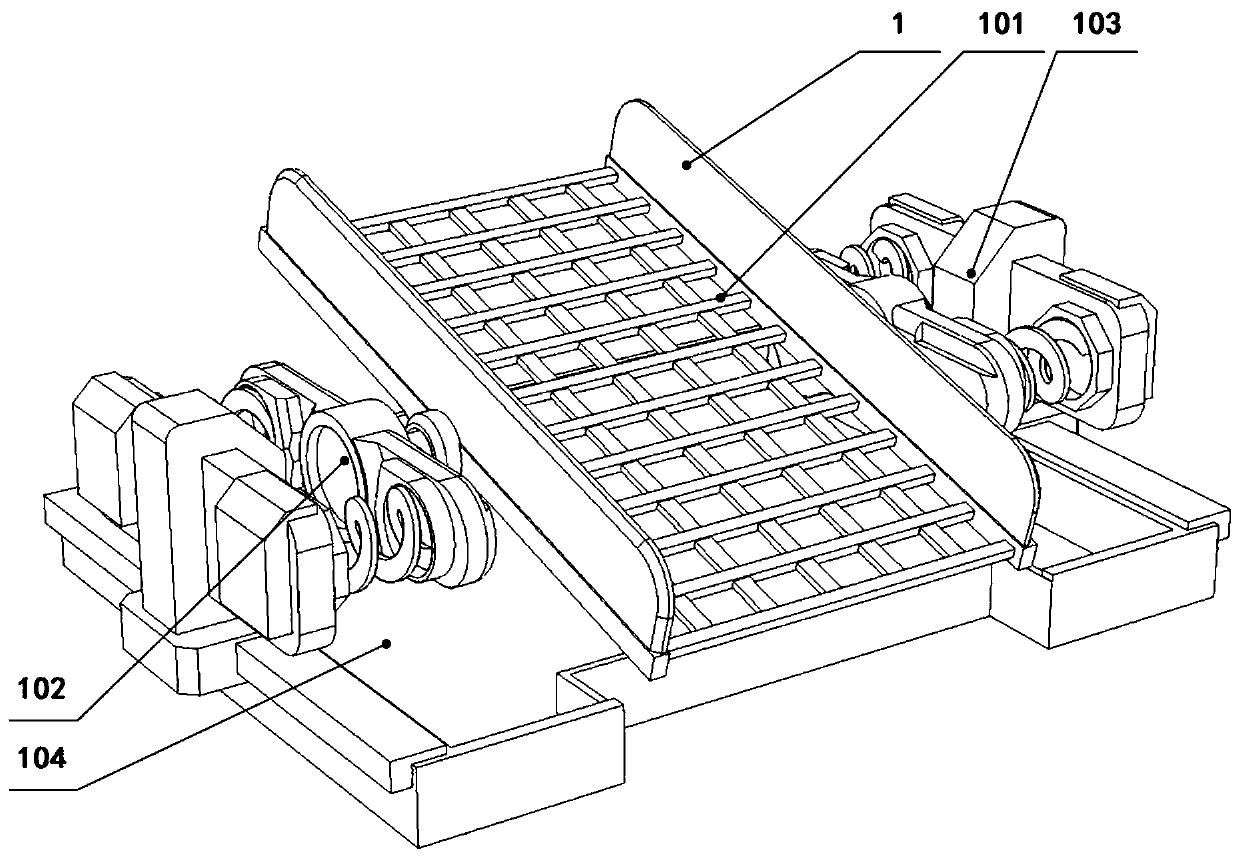

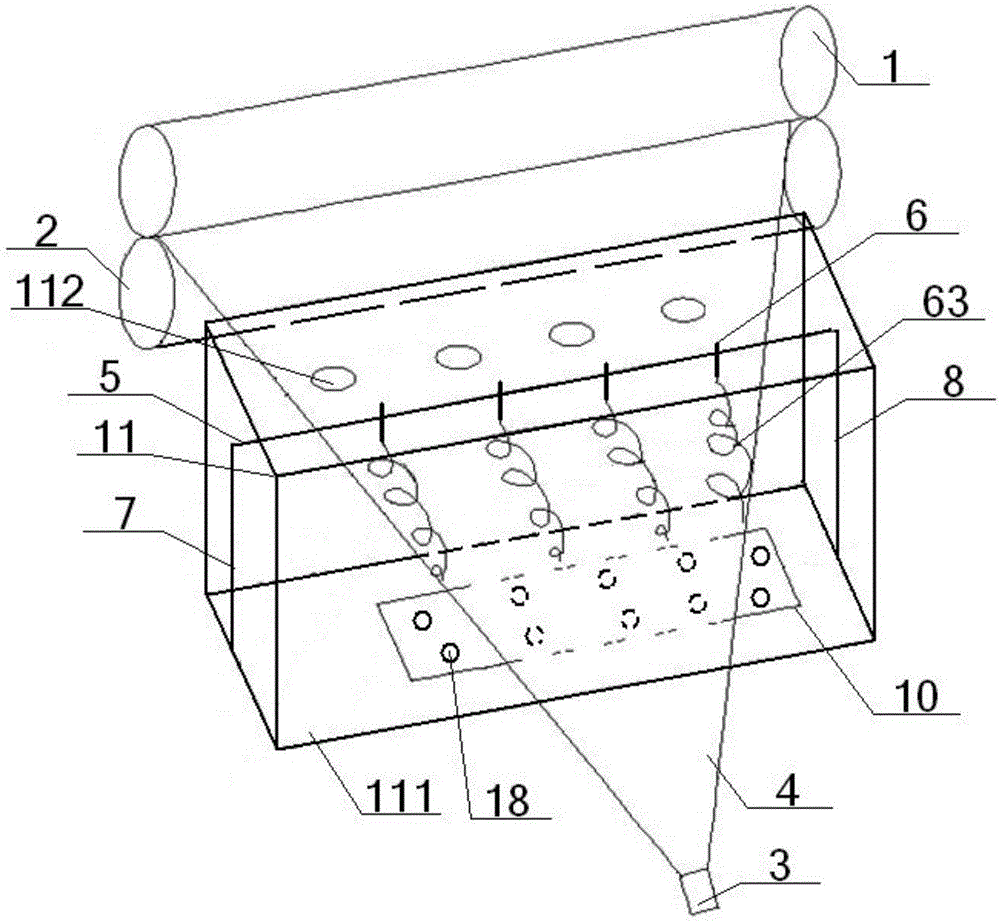

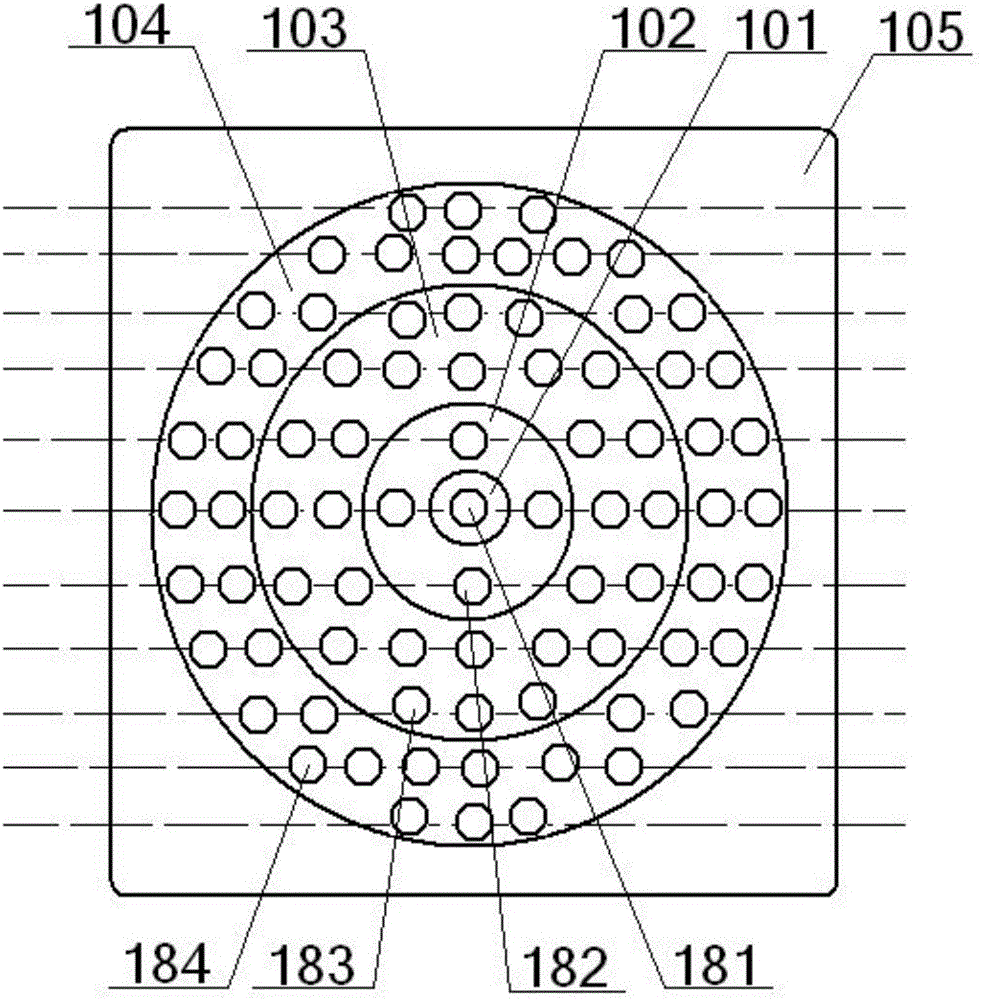

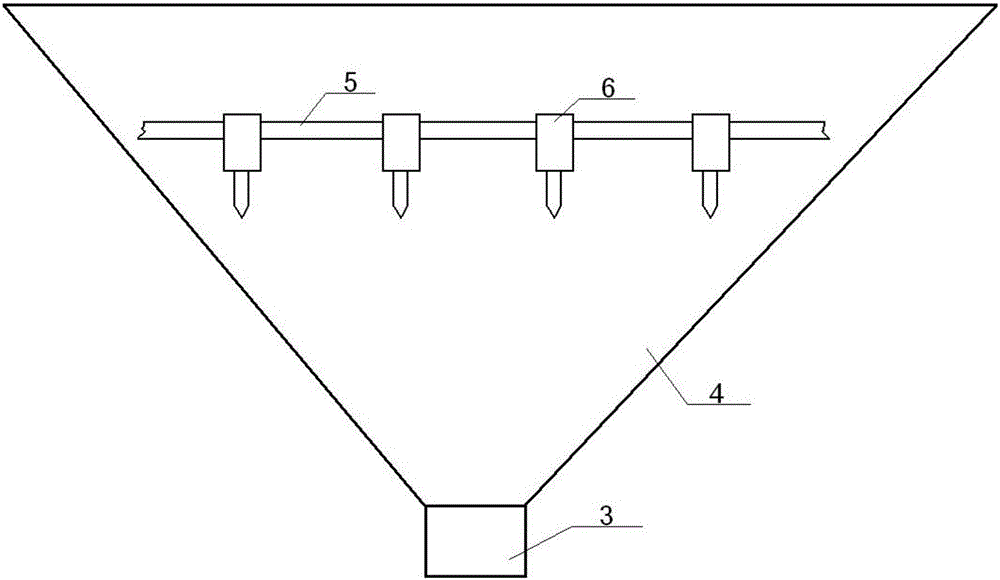

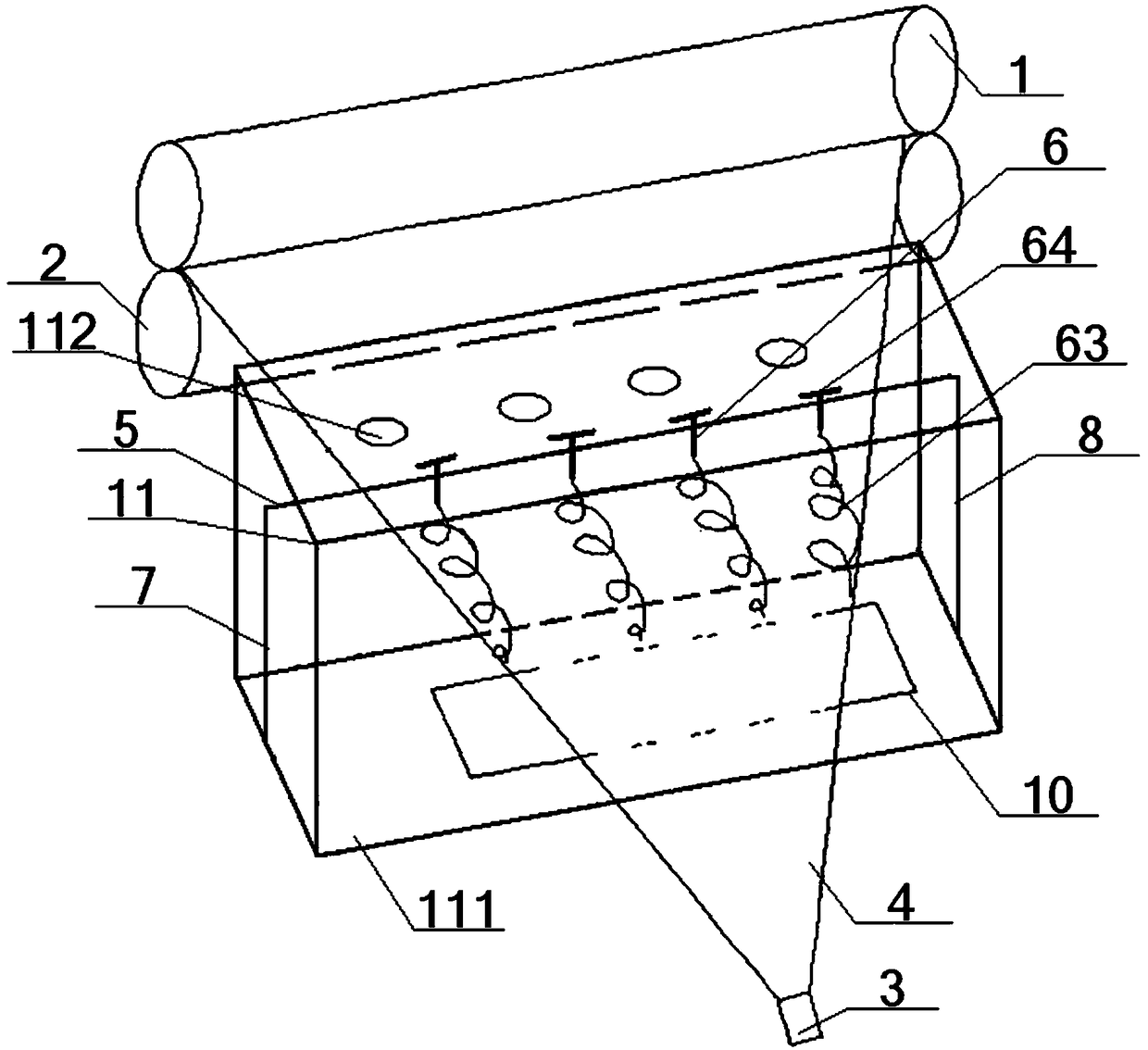

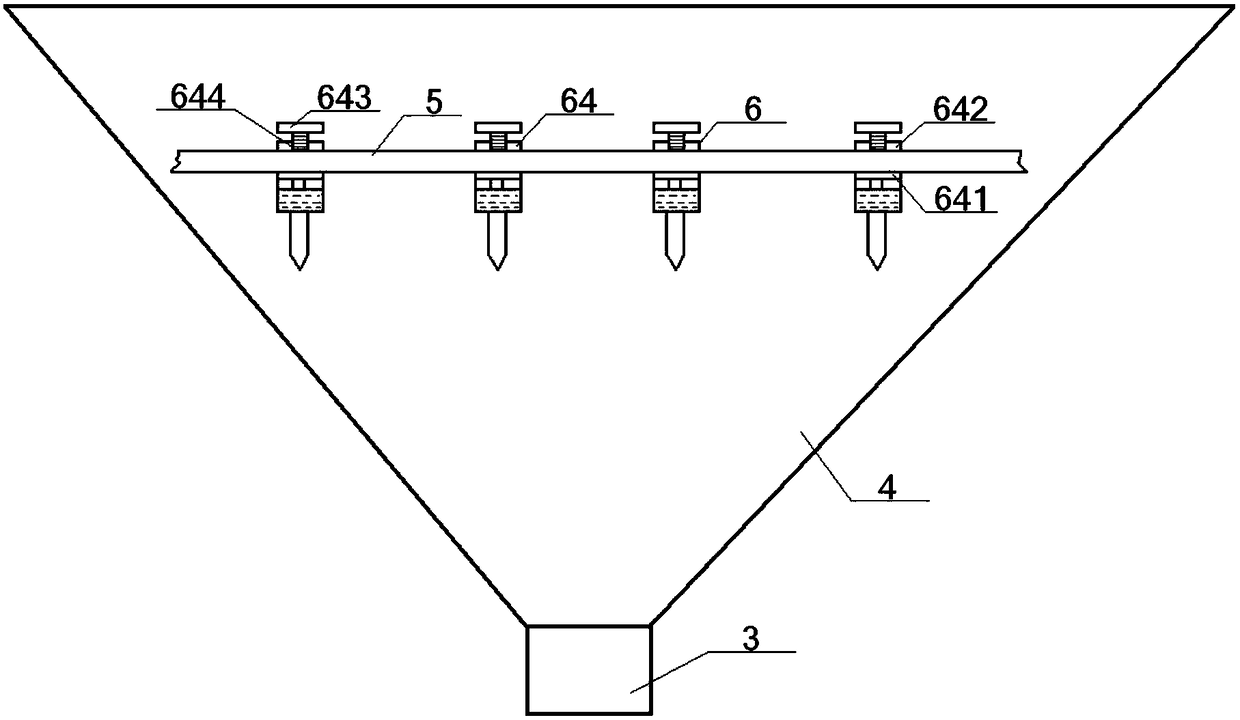

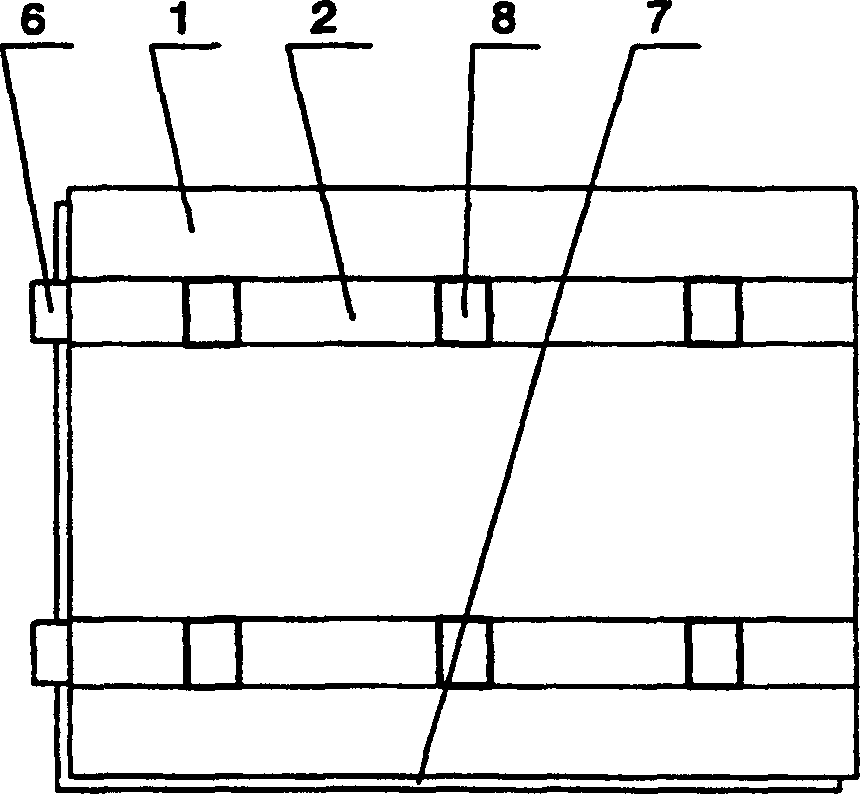

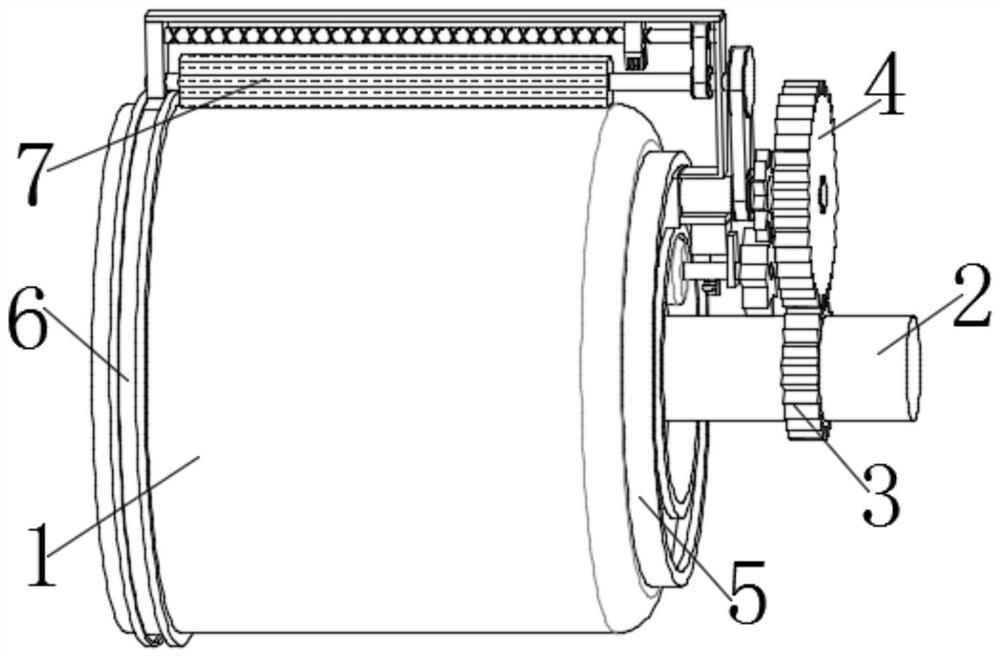

Equipment of improving card silver quality through net supporting plate to guide electrostatic spinning and using method

ActiveCN105926054AGood antistatic effectAccelerateElectro-spinningNon-woven fabricsElectrospinningCarbon nanotube

Equipment of improving card silver quality through a net supporting plate to guide electrostatic spinning comprises an upper roller, a lower roller, a horn mouth and a cotton net. One side of the cotton net penetrates in from a gap in front of the upper or lower roller while the other side of the same penetrates out from the horn mouth, a net supporting plate with a guide air hole is arranged below the cotton net, a transverse fixing rod mounted with multiple electrostatic spinning nozzles is suspended above the cotton net, and two ends of the transverse fixing rod are connected with a vertical adjusting device with a longitudinal moving device arranged at the bottom. When the equipment is in use, the electrostatic spinning nozzles spray electrostatic spinning to realize stacking on the cotton net, the electrostatic spinning is electroconductive nanofiber containing polyaniline, multi-wall carbon nanotube or graphene, height of the nozzles and gaps between the nozzles and the lower roller are adjusted through the vertical adjusting device and the longitudinal moving device, and the guide air hole finishes electrostatic spinning through wind powder to improve uniformity. Due to the design, the phenomenon of static electricity can be solved, card silver quality and subsequent processing are unaffected, and the equipment is high in adjustability, environment-friendliness and static electricity removing efficiency and quite low in cost.

Owner:WUHAN TEXTILE UNIV

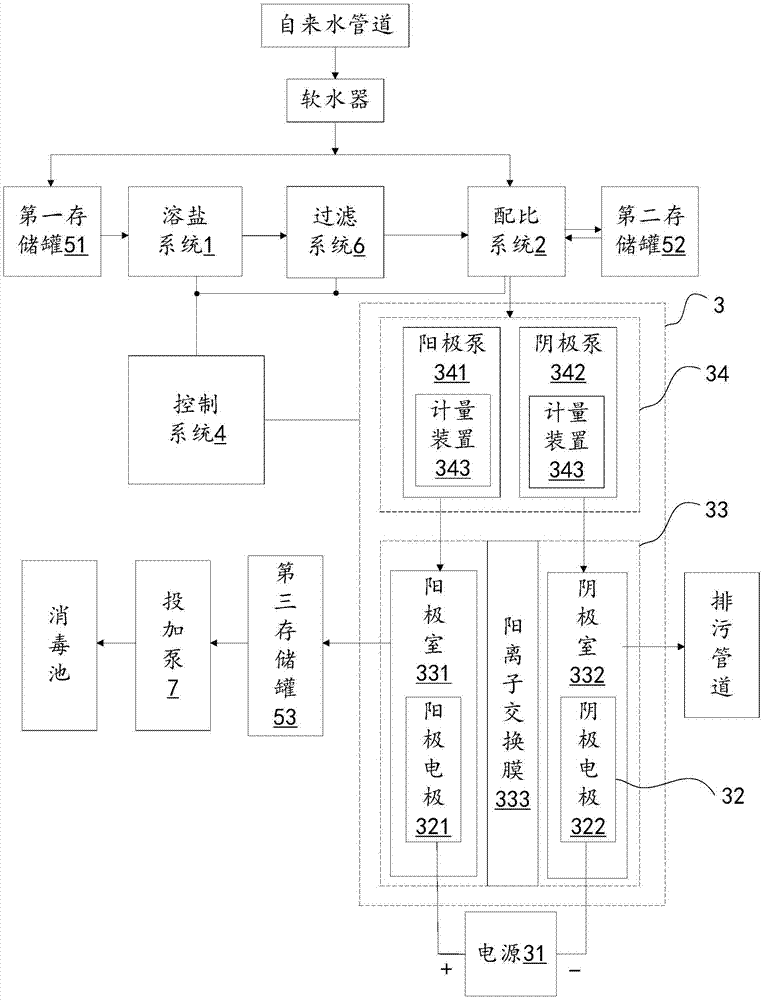

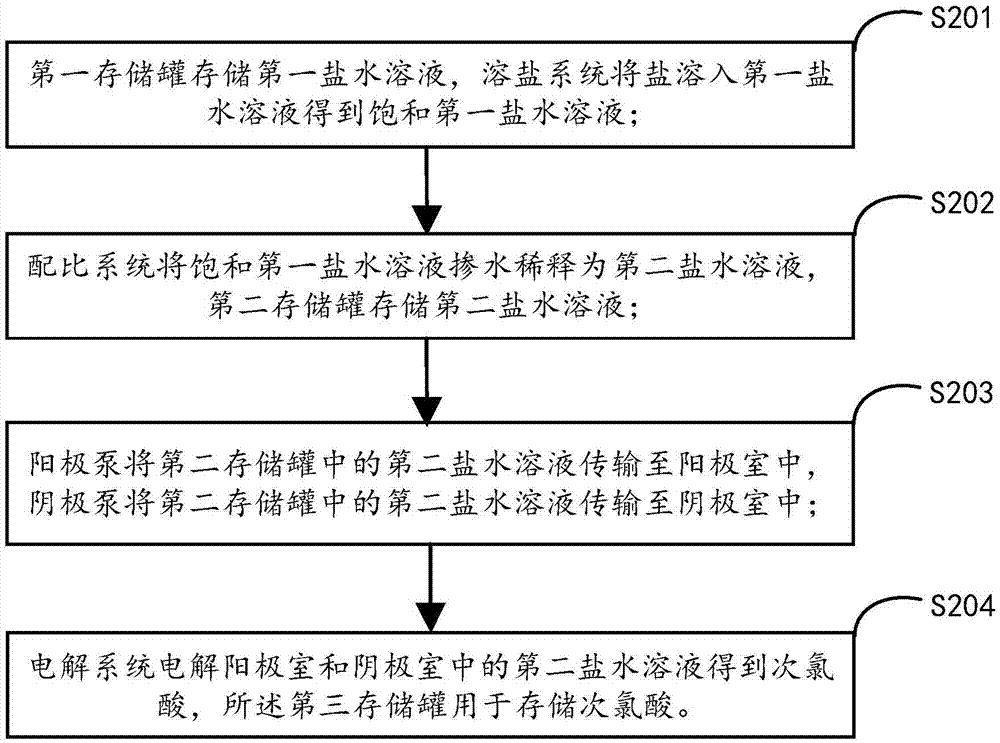

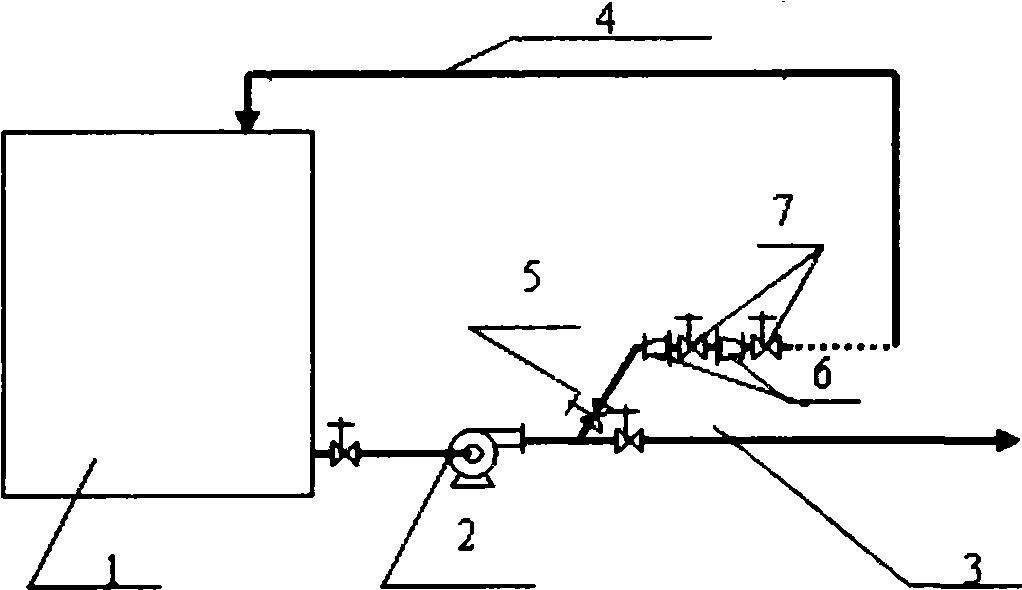

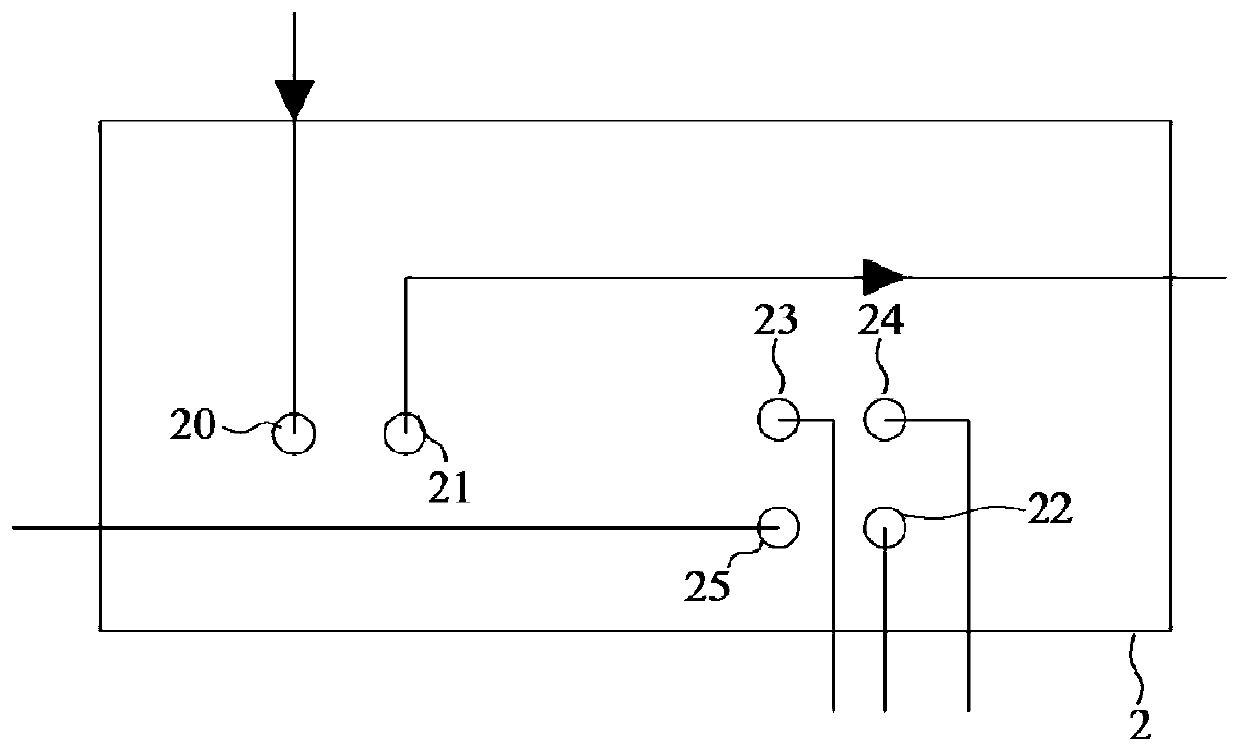

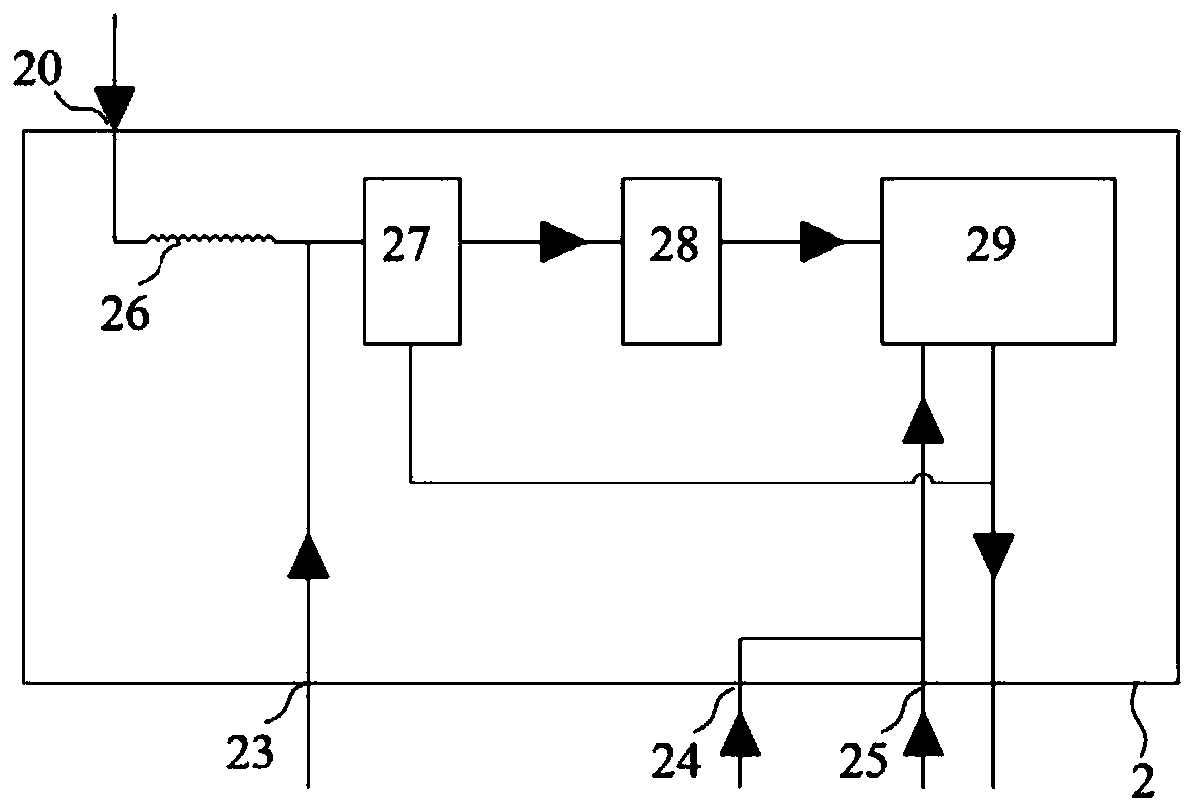

Hypochlorous acid preparation method and device

InactiveCN105441973AThe connection is tight and reasonableReduce volumeElectrolysis componentsChemistryCationic exchange

The invention discloses a hypochlorous acid preparation device which comprises a salt dissolving system, a proportioning system, an electrolysis system, a control system and a storage system. The storage system comprises a first storage tank, a second storage tank and a third storage tank. The electrolysis system comprises a power source, electrodes, an electrolysis cell and pumps. The electrodes comprise the anode electrode and the cathode electrode. The electrolysis cell comprises an anode chamber and a cathode chamber. The pumps comprise the anode pump and the cathode pump. A cation exchange membrane is arranged at the junction of the anode chamber and the cathode chamber. The anode electrode is placed in the anode chamber and connected with the positive pole of the power source. The cathode electrode is placed in the cathode chamber and connected with the negative pole of the power source. The hypochlorous acid preparation device is of an integrated structure, automation and intellectualization are achieved through the control system, operation is simple, the concentration of a hypochlorous acid product is high, and the cost is effectively reduced.

Owner:FUJIAN HADA INTELLIGENCE TECH CO LTD

Cleaning device for valve scaling

ActiveCN101530851ASimple processWash thoroughlyInorganic non-surface-active detergent compositionsCleaning using liquidsEngineeringSpare part

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Multifunctional dirty removing agent for boiler

InactiveCN102863089ANo pollution in the processNo damageScale removal and water softeningSolubilityPropanoic acid

The invention relates to a dirty removing agent, in particular to the dirty removing agent for a boiler. The dirty removing agent is non-toxic and free of pollution, and has descaling and rust removal functions. The dirty removing agent is prepared by the following raw materials in parts by weight: N,N-dimethyldodecylamine-N-oxide sol, triethanolamine, sodium hexametaphosphate, propionic acid, butyric acid, polyacrylic acid, formic acid and water in a ratio of 6-20:3-12:1-10:0.5-5:2-10: 20-30:0.1-0.5:80-100. The dirty removing agent is safe and free of corrosion, low in metal corrosion rate in a washing process, almost free of any corrosion damage on the boiler and high in descaling ratio, is capable of effectively dissolving scales in various types, is strong in water dissolubility capability, and has double functions of descaling and rust removal. Waste liquid has no pollution, the dirty removing agent is non-toxic and free of damage; the washing waste liquid has no damage to animals and plants; and direct discharge of the washing waste liquid cannot pollute the environment.

Owner:刘生力

Forsterite grouting material

InactiveCN101684041AStable in temperature rangeGood early strengthSolid waste managementCeramicwareDecompositionOlivine

The invention provides a forsterite grouting material. The forsterite grouting material is prepared by mixing forsterite aggregate, forsterite powder, fly ash, a water reducing agent, a reinforcing agent, a micro expanding agent, an early strength agent, a flatting agent, a dispersing agent and cement, wherein the forsterite used is a green environmentally-friendly material which is internationally recognized; and the forsterite aggregate is stable in nature in a wider temperature range of between 50 DEG C below zero and 1,000 DEG C and is free from harmful gas or decomposition product generation. The grouting material prepared from the forsterite serving as the main material does not contain chloride ions, does not corrode any construction material and has obvious early strength effect, obvious reinforcing effect and high gravity flowing property; moreover, the grouting material also has the advantages of no weeping, no delamination, high bonding strength, no contraction, guaranteed tight bonding between existing concrete and fresh concrete, oil resistance, water soaking resistance and good durability.

Owner:YICHANG PENGBO FORSTERITE

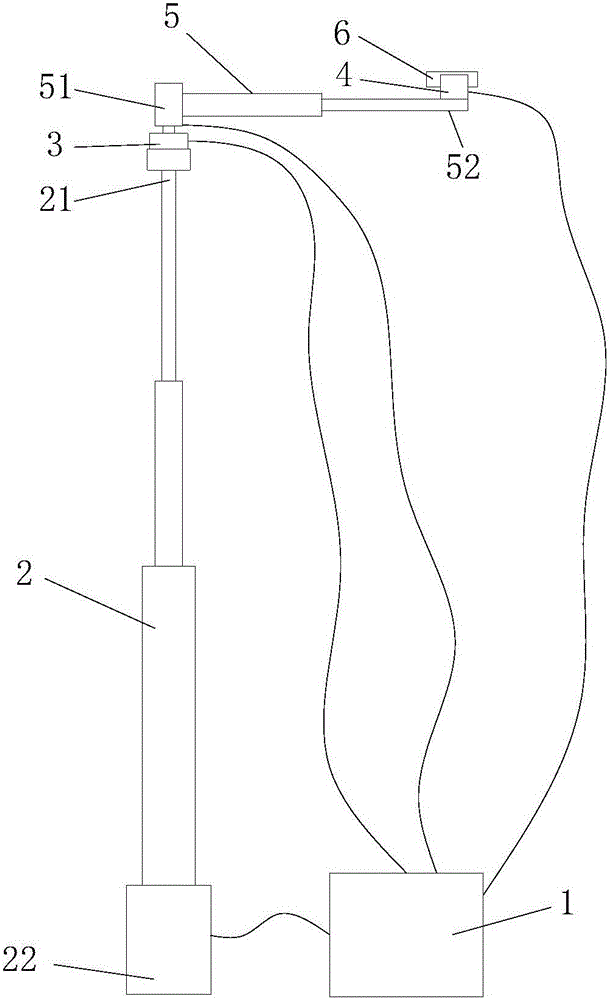

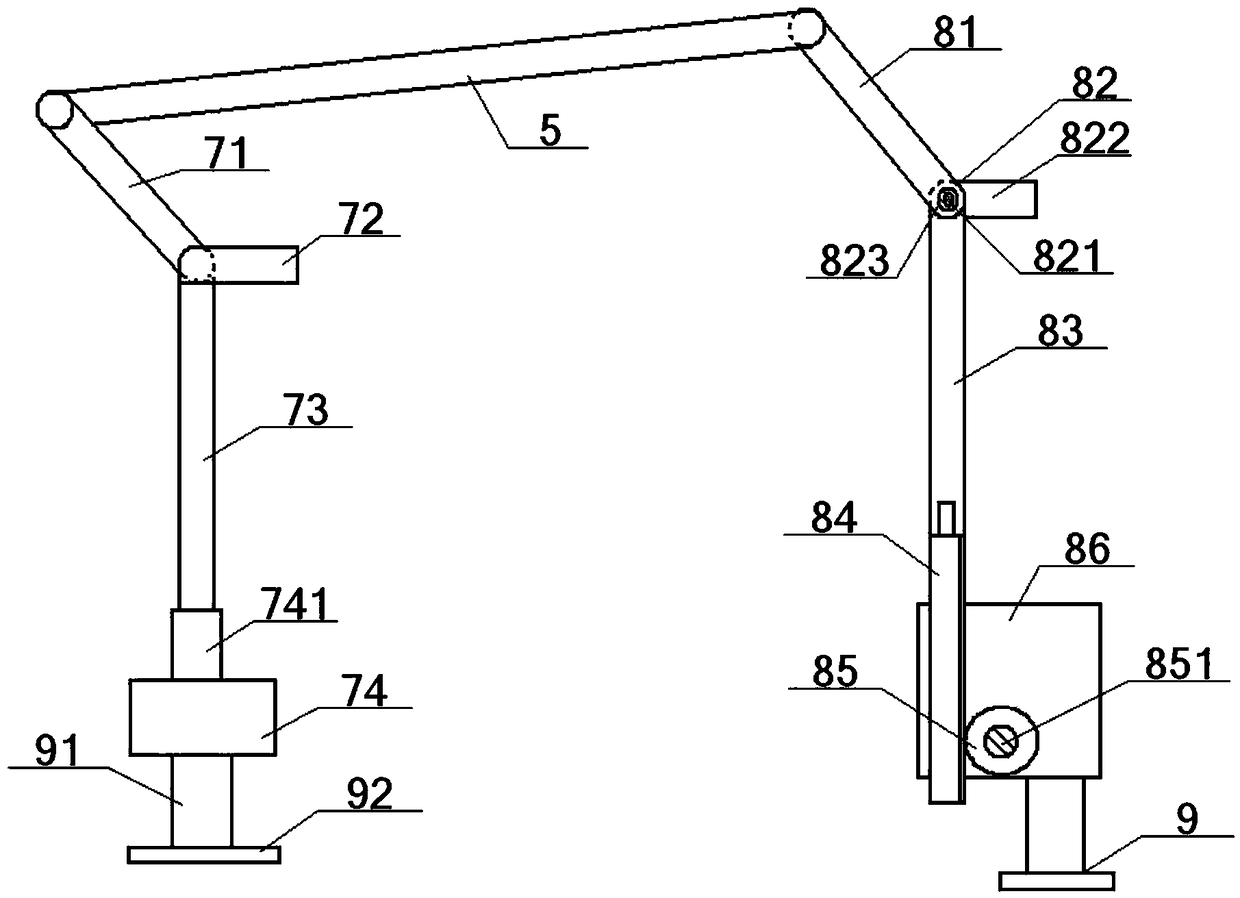

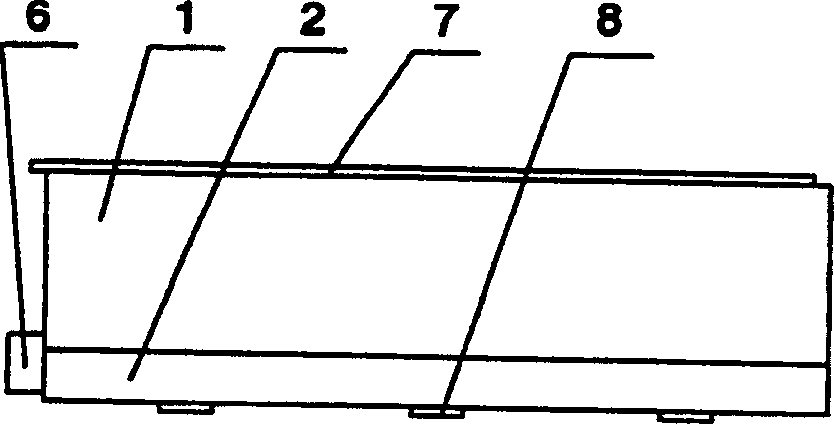

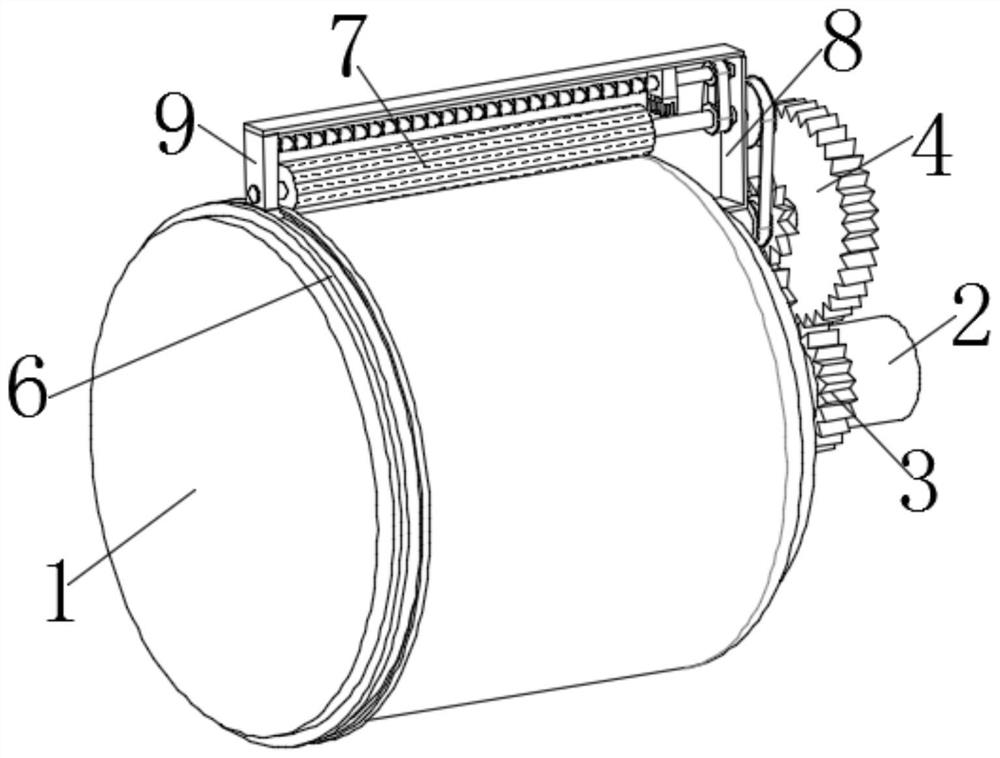

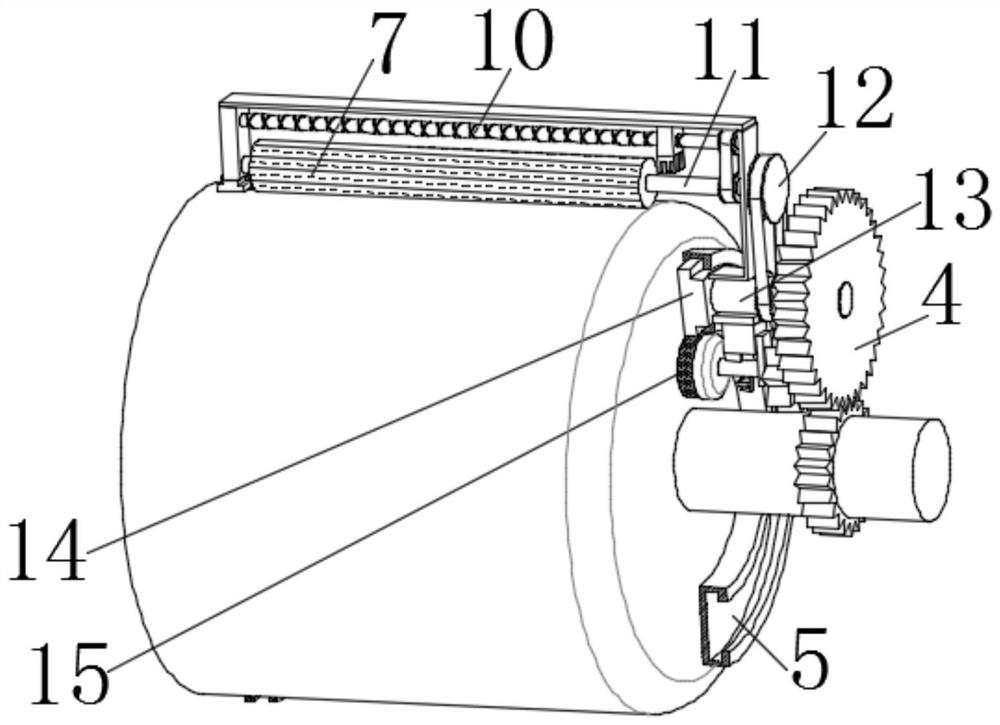

Equipment and method for improving card sliver quality by single-row nozzle mobile electrospinning method

ActiveCN105926088BStatic electricity quickly dissipatesHigh speedFilament/thread formingLap forming devicesElectrospinningNanofiber

Equipment of improving card silver quality through a single-row-nozzle moving type electrostatic spinning method comprises an upper / lower roller, a horn mouth and a cotton net. One side of the cotton net penetrates in from a gap in front of the upper / lower roller while the other side of the same penetrates out from the horn mouth, a transverse fixing rod suspended above the cotton net is connected with multiple electrostatic spinning nozzles through a nozzle connecting device, and two ends of the transverse fixing rod are connected with a vertical adjusting device with a longitudinal moving device arranged at the bottom. When the equipment is in use, the electrostatic spinning nozzles spray electrostatic spinning to realize stacking on the cotton net, the electrostatic spinning is electroconductive nanofiber containing polyaniline, multi-wall carbon nanotube or graphene, and spraying angle, degree of freedom and height of the nozzles and gaps between the nozzles and the roller are adjusted through the nozzle connecting device, the vertical adjusting device and the longitudinal moving device. Due to the design, the phenomenon of static electricity can be solved, card silver quality and subsequent processing are unaffected, and the equipment is high in adjustability, environment-friendliness and static electricity removing efficiency and quite low in cost.

Owner:HUBEI FENGSHU THREAD MFG

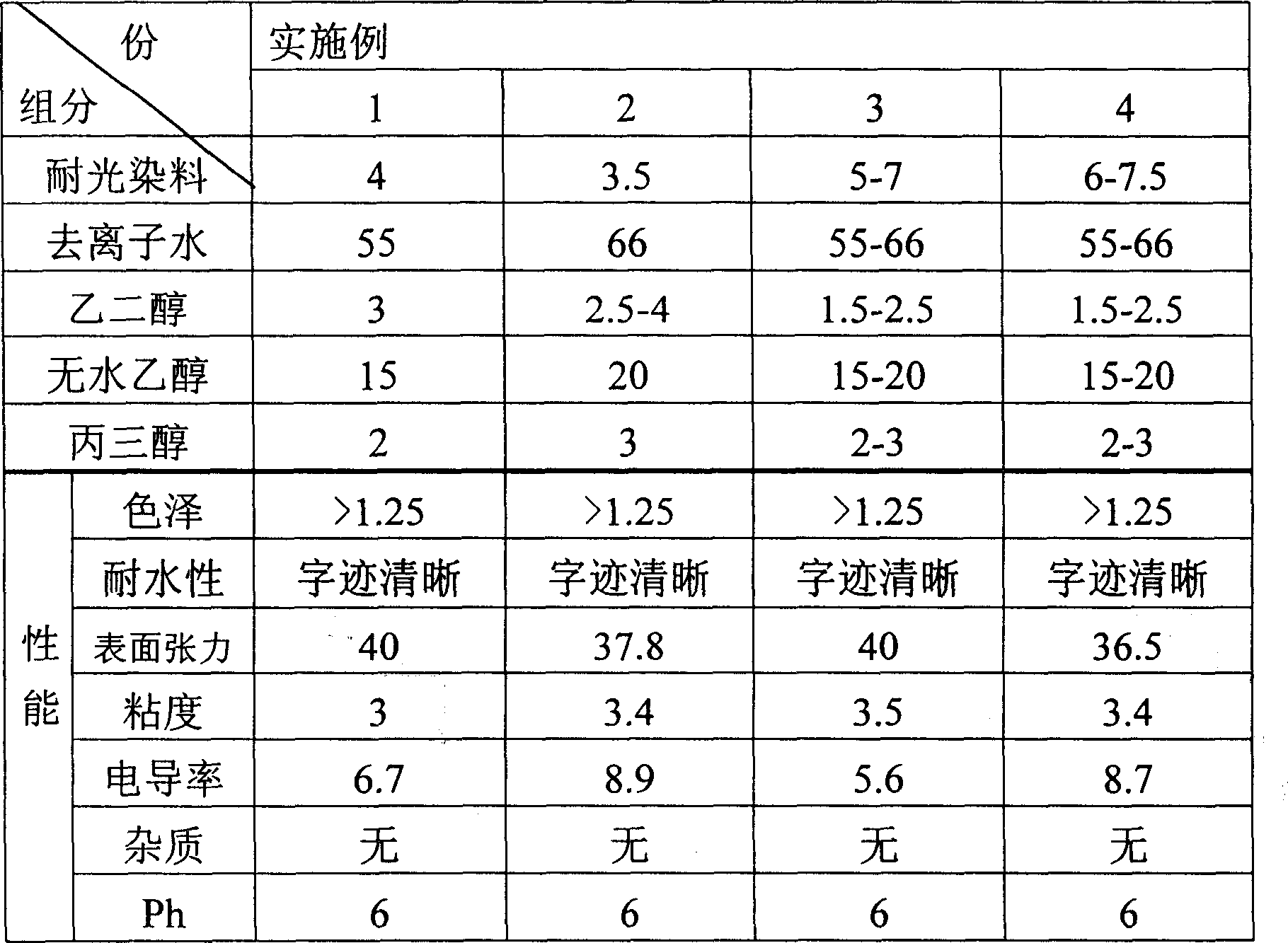

Colour ink-jet ink and its preparing method

The invention discloses a method to manufacture colorful jet printing ink that includes the constituent of color nm light resistance dye 3.5-7.5 portions, deionized water 55-66 portions, ethylene glycol 1.5-4 portions, anhydrous alcohol 15-20 portions and glycerin 2-3 portions. It has the features of water endurance, light endurance, no-precipitation and fastness. It could be widely used in kinds of different series of jet printer.

Owner:ZHEJIANG UNIV

Insect repellant

InactiveCN103155955AReduces pungent odorsNo pollution in the processBiocidePest repellentsIrritationFennel Oil

The invention disclose insect repellant, and relates to a method of eliminating injurious insects. When cockroaches contact with or smell out the insect repellant, the cockroaches can rapidly flee, so the insect repellant reduces breeding of the cockroaches, prevents the cockroaches from reappearing at places where the insect repellant is used, and achieves the effects of continuously preventing and controlling the cockroaches. The insect repellant is characterized by containing fennel oil, boric acid, stabilizer, preservative and slow release formulations. The prepared insect repellant has the advantages of being small in pungent smell, and nontoxic, belongs to physical control, does not pollute environment, and has no corrosive and destructive effects on the surfaces of objects. The slow release formulations are added in the insect repellant, so the duration of pesticide effects can reach 4-6 months. The insect repellant not only can eliminate the cockroaches, but also can eliminate ants, moths and other injurious insects. The method for eliminating the injurious insects is simple in procedures and convenient to operate, and facilitates large-scale popularization and application.

Owner:王玉雪

Liquid-state CO2 washing method of petroleum industry oil dirt equipment and facilities

PendingCN109465250AWide variety of sourcesEasy to liquefyCleaning using liquidsEnvironmental resistanceLiquid state

The invention discloses a liquid-state CO2 washing method of petroleum industry oil dirt equipment and facilities. Liquid-state CO2, a storing device, a conveying pipeline, a spraying device and an oil receiving groove bag are involved in the method. The method is characterized in that the characteristics of ultralow viscosity, ultra-strong mobility, ultra-strong permeability and ultra-strong adsorption property of the liquid state CO2 are utilized, and the flexible conveying pipeline and the spraying device strip and eliminate oil dirt rapidly and thoroughly at a time and collects and recycles the oil dirt for fixed or movable oil dirt oil field equipment or devices in the manner of extending in the single direction from top to bottom and from inside to outside. Compared with the prior art, oil dirt waste is not generated in the washing process, sewage containing oil and chemical agent and needing secondary treatment is not generated, new toxic and harmful substance is not generated,contaminant does not fall to the ground, the cleaning effect is thorough, fallen oil can be recycled, operation is simple, the cost is low, and the method is safe and environmentally friendly and hasgood application and popularization value.

Owner:董恬纲

Cockroach expelling medicament and preparation method thereof

The invention discloses a cockroach expelling medicament and a preparation method thereof. The cockroach expelling medicament is prepared from the following components in percentage by weight: 88%-73% of potatoes, 10%-25% of boric acid and 2% of sodium benzoate. The cockroach expelling medicament has a special smell to which cockroaches are extremely sensitive, and the cockroaches rapidly escape to outdoors after smelling, so that propagation of the cockroaches is avoided indoors; meanwhile, the cockroach expelling medicament is environmentally friendly, the steps of the operation method are simple, the operation is convenient, and large-scale popularization and application are facilitated.

Owner:郭宝聪

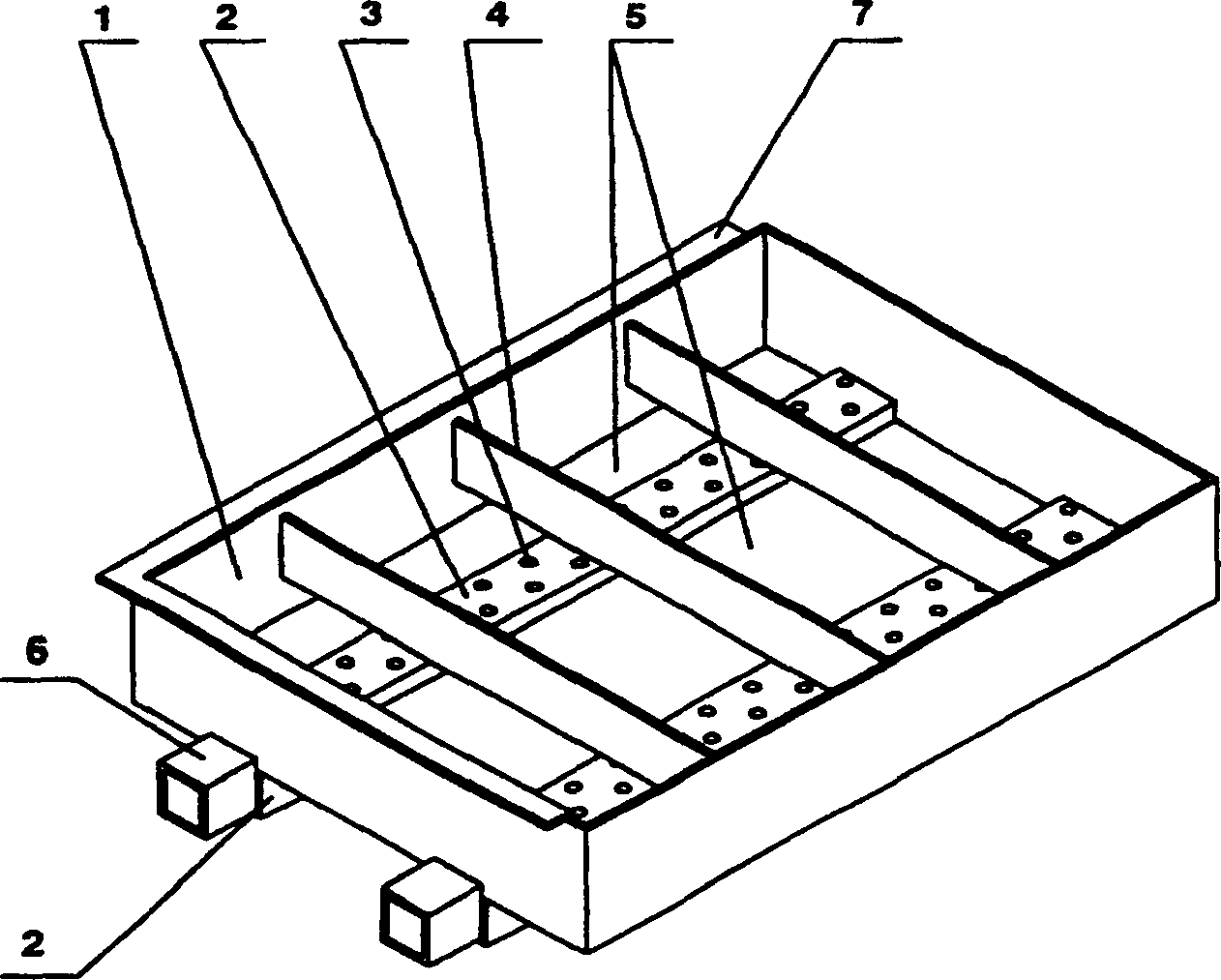

Ecotype slope-style planting container

InactiveCN1262167CImprove breathabilityNo corrosion damageRoof improvementClimate change adaptationPondingEngineering

The invention relates to an ecotypic sloing planting container with the container, drain-vent pipe set at the bottom of the container, vent hole set on the inner side of the drain-vent pipe, and at least a piece of baffle set in the container. The bottom of the container doesn't leak hydrops not to corrode and damage the ground, is well ventilated, and especially when applied to the roofs of buildings, can insulate the heat; can prevent the planting or cultivating base material from leaking, which keeps environmental sanitation outside the container and also ensures storing some water; can stop the plants on the roof and the planting base material sliding in the container not to pile and lose.

Owner:SHANGHAI ZHONGHUI ECO TECH

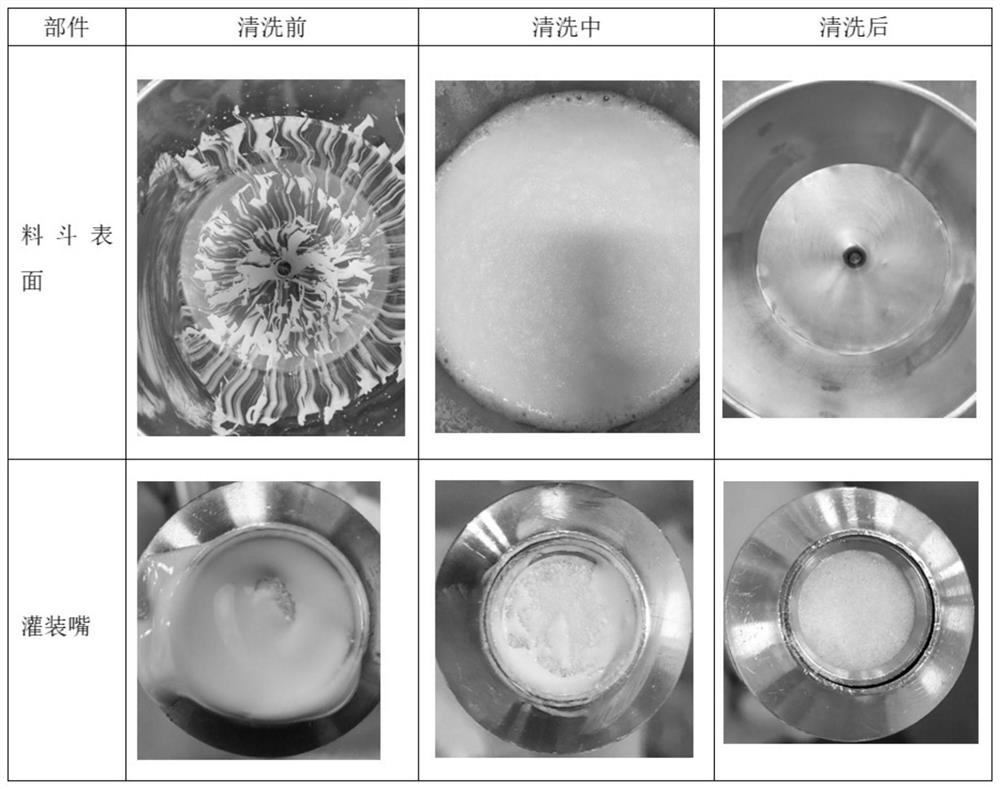

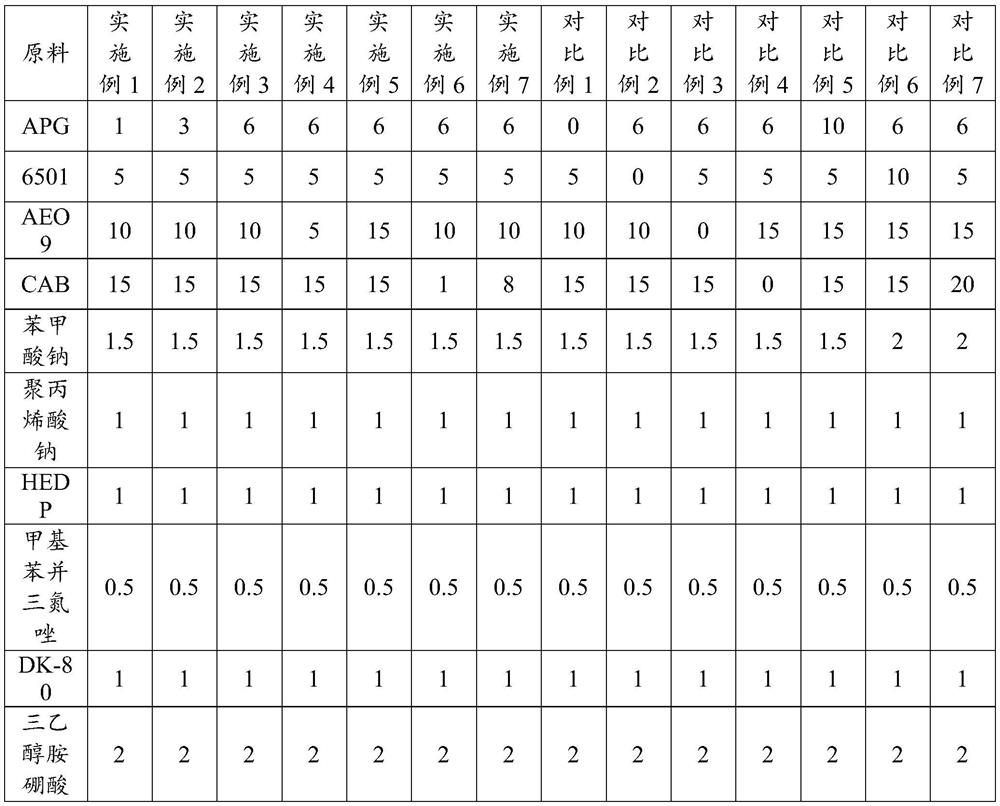

Neutral cleaning agent for water-in-oil cosmetics and preparation method of neutral cleaning agent

ActiveCN113150887ANo negative impactStrong targetingNon-ionic surface-active compoundsOrganic detergent compounding agentsActive agentBiochemical engineering

The invention discloses a neutral cleaning agent for water-in-oil cosmetics and a preparation method of the neutral cleaning agent, belonging to the field of cleaning supplies. In the components of the neutral cleaning agent disclosed by the invention, a specific nonionic surfactant and a specific ampholytic surfactant jointly exert permeation, emulsification and stripping effects on the water-in-oil cosmetics, so the effect of effectively treating the residual water-in-oil cosmetics in production equipment is achieved; the addition of a penetrant can further assist the surfactants in improving cleaning efficiency; and the produced neutral cleaning agent does not contain VOC substances, nonyl phenol or other heavy metal toxic substances, is safe and environment-friendly, is neutral, and does not cause corrosion damage to clean equipment. The invention also provides the preparation method of the neutral cleaning agent. The preparation method has the advantages of simple operation steps, low requirements on production equipment, and realization of industrial large-scale production. The invention further provides application of the neutral cleaning agent to instrument and equipment cleaning.

Owner:完美(广东)日用品有限公司 +1

Filtering cloth detergent and cleaning method thereof

InactiveCN110079398AExtended service lifeImprove transmittanceInorganic/elemental detergent compounding agentsSludge treatment by de-watering/drying/thickeningOXALIC ACID DIHYDRATEDecomposition

The invention discloses a filtering cloth detergent and a cleaning method thereof. The filtering cloth detergent comprises the following raw materials in percentage by mass: 2-15% of hydrochloric acid, 2-8% of oxalic acid, 1-15% of sodium dodecyl sulfate and the balance of water. In a mode of low-pressure internal circulation mode of a filter press, filtering cloth sticking substances are washed off with the filtering cloth detergent in an active decomposition manner, the liquid permeation rate can be increased, the service life of filtering cloth can be prolonged, the energy consumption can be reduced, and the productivity can be improved.

Owner:宁波汇土环保科技有限公司

Novel liquid fuel and preparation method thereof

InactiveCN104611074AGood combustion continuityGood miscibilityLiquid carbonaceous fuelsLiquid fuelSolvent

The invention relates to the field of fuel preparation, particularly to a novel liquid fuel and a preparation method thereof. The novel liquid fuel provided by the invention is prepared from the compounding of a main material and three kinds of auxiliary solvents, the auxiliary solvents are successively mixed, the obtained mixed auxiliary solvent has good intersolubility, and no other impurities are generated; the mixed and dissolved auxiliary solvent is added in the main material so as to mutually dissolve with the ingredients in the main material, as a result, the ingredients can sufficiently react, the ingredients cooperate with one another, the prepared novel liquid fuel effectively solves the problem that the octane values of most standard fuels are substandard, and the anti-detonating quality enhancing effect is excellent; the problem of cold ignition boot is solved; the novel liquid fuel has the characteristics of energy conservation, emission reduction, high effects, environmental protection and easiness in use, the novel liquid fuel can be singly used in a large amount for a long time, and also can be mixed with conventional commercial gasoline, such as number 97, 93, in any proportion, bad influences cannot be generated, engines and the like do not need to be washed, and the novel liquid fuel has relieving and supplementing effects for the current domestic situation of resource shortage to some extent.

Owner:SICHUAN DIBIAO NEW ENERGY TECH CO LTD

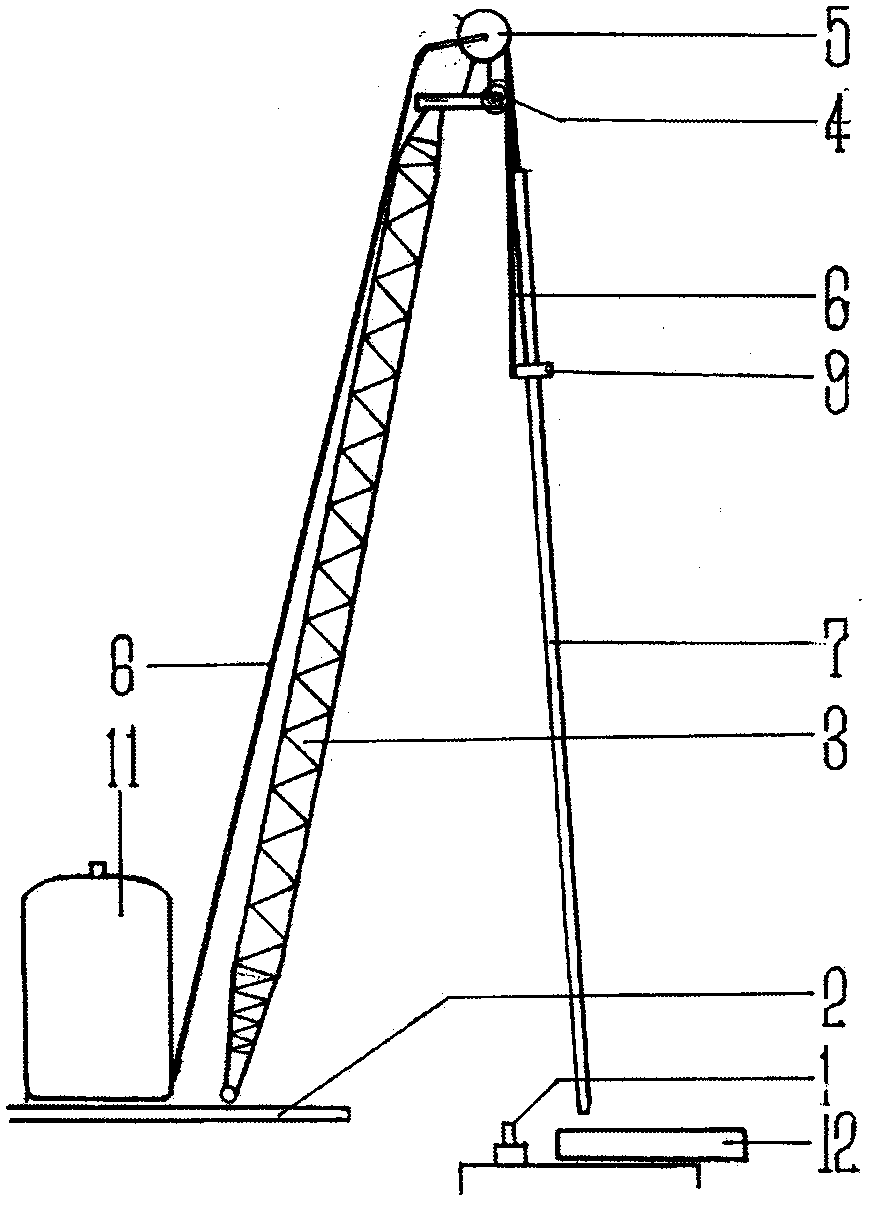

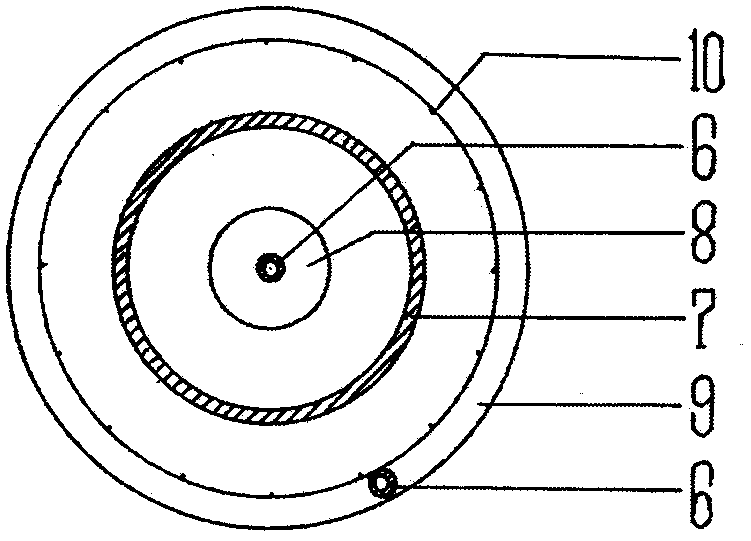

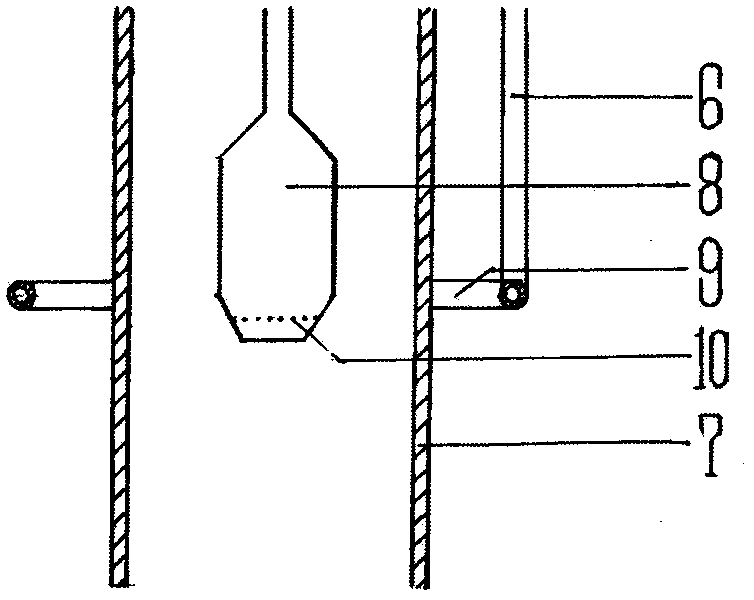

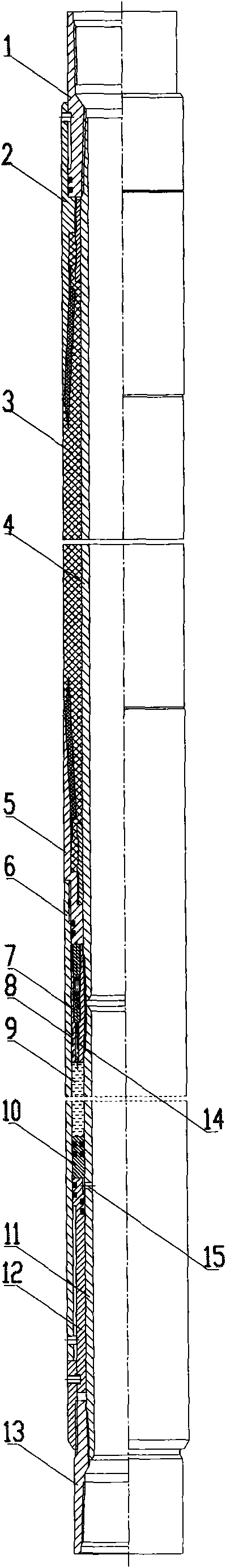

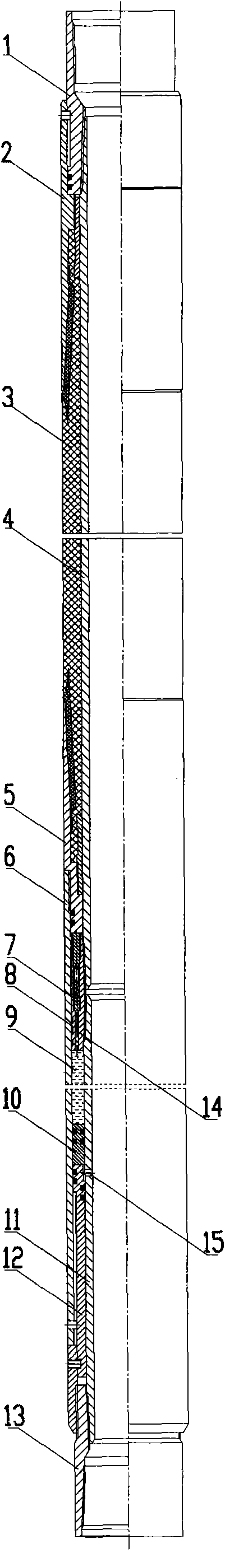

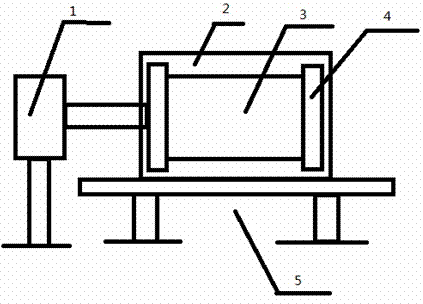

Open hole well packer

InactiveCN102094592ANo corrosion damageWork effectively for a long timeSealing/packingUpper jointPiston

The invention relates to an open hole well packer, a rubber tube is sheathed outside an upper inner tube, an upper joint, the upper inner tube, a combined valve body, a lower inner tube and a lower joint are sequentially connected, the lower part of an upper rubber tube sheath covers the upper part of the rubber tube, the upper part of the upper rubber tube sheath is sheathed outside the upper joint, the upper part of a lower rubber tube sheath covers the lower part of the rubber tube, the upper part of a sealing sleeve is connected with the lower part of the lower rubber tube sheath, the lower part of the sealing sleeve is sheathed outside the combined valve body, an upper piston and a lower piston are mounted between the sealing sleeve and the lower inner tube, preset solution is perfused above the upper piston, the lower piston is arranged below the upper piston, a communicating hole is arranged on the upper piston, the communicating hole is positioned between the upper piston and the lower piston, a vertical pore canal is arranged on the combined valve body, a one-way valve is mounted at the upper part of the vertical pore canal, the one-way valve is designed for enabling the rubber tube to be in expansion state permanently, the rubber tube is expanded by the preset solution, and the one-way valve can not be corroded and damaged, so that the rubber tube can work effectively for a long time and meet the requirement on permanent blocking of the well bottom of an open hole well in an oilfield.

Owner:东营市兆鑫工贸有限责任公司

A plant boundary low-concentration benzene series online monitoring system and an online monitoring method

PendingCN110286172ANot corrosiveGuaranteed synchronicityComponent separationNitrogen generatorHelium ionization detector

The invention discloses a plant boundary low-concentration benzene series online monitoring system and an online monitoring method, and belongs to the field of environmental monitoring. The plant boundary low-concentration benzene series online monitoring system comprises the following parts: an atmospheric sampling header pipe; a chromatographic analyzer communicated with the atmospheric sampling header pipe, wherein a quantitative loop, a chromatographic column and an FID flame ionization detector are arranged in the chromatographic analyzer; a gas source unit that comprises a hydrogen generator, a nitrogen generator and a zero gas generator which are used for respectively transmitting hydrogen, nitrogen and zero gas to the chromatographic analyzer. The chromatographic column is used for separating and conveying benzene series in the sample gas; the chromatographic analyzer further comprises a catalytic tube which is a heating tube with a built-in catalyst, one end of the catalytic tube is communicated with the chromatographic column, and the other end of the catalytic tube is communicated with the FID flame ionization detector and used for catalytically decomposing the benzene series into methane. The catalytic tube is additionally arranged in the chromatographic analyzer, the benzene series to be detected are catalytically decomposed into the methane component for detection, so the detection difficulty of the low-concentration benzene series is reduced, the detection result synchronism is high, and the detection analysis result accuracy is high.

Owner:马鞍山市桓泰环保设备有限公司

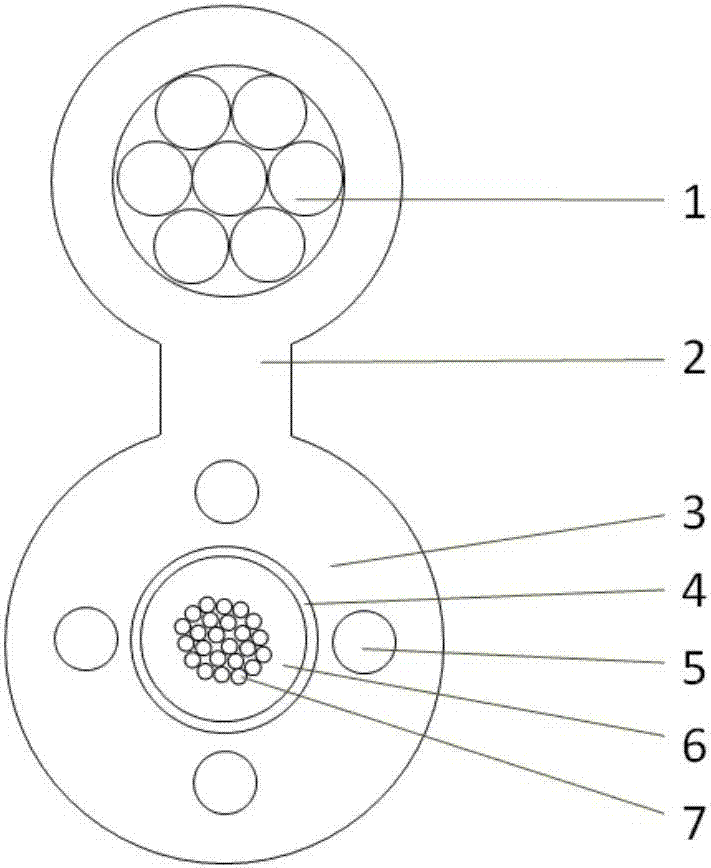

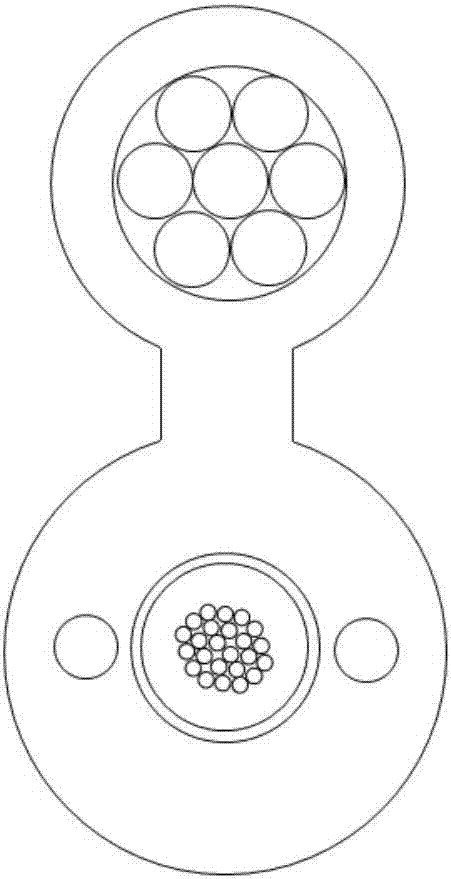

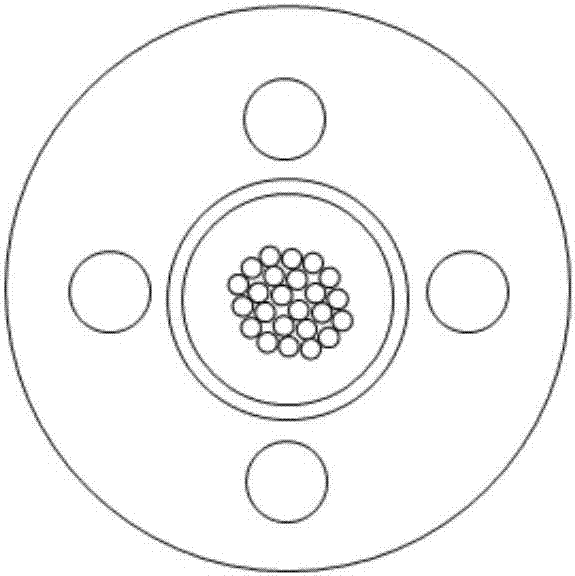

Stainless steel GYXTW type optical cable and manufacturing method thereof

InactiveCN107167889ALow costReduce in quantityFibre mechanical structuresSteel pipelineUltimate tensile strength

The invention discloses a stainless steel GYXTW type optical cable and a manufacturing method thereof. The method includes the following steps: 1. coloring optical fibers; 2. moulding a stainless steel pipe optical fiber unit; 3. manufacturing the stainless steel GYXTW type optical cables; and 4. testing overall properties of the optical cables. The optical cable herein includes an external sheath and suspension wires which are connected through a neck. The external sheath is provided thereon with at least two reinforcement pieces and is provided therein with a stainless steel pipeline. The stainless steel pipeline is provided therein with a filling composite and optical fibers. Each suspension wire is provided therein with a steel strand which is made by twisting galvanized steel wires. The stainless steel GYXTW type optical cable uses stainless steel GYXTW, has the advantages of small external diameters, high strength and strong biological protection. The stainless steel GYXTW type optical cable can effectively address large pollution in the environment due to manufacturing optical cables in the prior art, prevents additives from being washed away by rainfall or other environment factors after construction and ensures protection effects of the optical cables.

Owner:FURUKAWA ELECTRIC XIAN OPTICAL COMM

Three-acid waste gas purifying machine

InactiveCN107029518AImprove purification efficiencySimple structureGas treatmentDispersed particle separationPlastic materialsEngineering

The invention relates to a three-acid waste gas purifying machine. The three-acid waste gas purifying machine comprises a three-acid gas purifying device, a vapor condensation apparatus and a vapor drying device, the three-acid gas purifying device is composed of a purifier housing, a housing separator plate, an impact curved slab, a high-pressure spray pipe group, an air-water mixing layer, a water-replenishing tank, a water pump case, an exhaust gas air-inlet pipe and a purifier outlet duct; the vapor condensation apparatus and the three-acid gas purifying device have a same structure; the vapor drying device comprises a a drying device housing, an inner cylinder, an intermediate cylinder, a drying device air inlet pipe, a drying device exhaust pipe, a water-stop sheet and a support plate. The three-acid waste gas purifying machine has high purifying efficiency, the gas discharged in atmosphere has no peculiar smell, the structure is simple and requires no maintenance, the equipment cost is low, and the three-acid waste gas purifying machine is convenient for popularization and application. the device with passed vapor is prepared by corrosion-resistant plastic materials, corrosivity is strong, corrosion damage can be avoided, and purifying quality can be guaranteed for long-term.

Owner:董降龙

Brushless submersible motor for anti-erosion self-cleaning through motor driving

ActiveCN113285550AImprove self-cleaning functionNot prone to corrosionClimate change adaptationCleaning using toolsMotor driveMarine engineering

The invention discloses a brushless submersible motor for anti-erosion self-cleaning through motor driving, which relates to the technical field of brushless submersible motors. The brushless submersible motor comprises a submersible motor body and a motor output shaft installed on the submersible motor body, and the end part of the submersible motor body is fixedly provided with a built-in ring. The built-in ring and the motor output shaft are located on the same central axis, and the built-in ring is provided with a motor side part cleaning part used for self-cleaning the side part of the submersible motor body and a motor end part cleaning part used for self-cleaning the end part of the submersible motor body. According to the brushless submersible motor, the structure is reasonable, when the brushless submersible motor works, dirt on the end portion and the side portion can be brushed and swept in time, the brushless submersible motor has a good self-cleaning function, the brushless submersible motor is not prone to corrosion, the service life of the brushless submersible motor is longer, and the stability of the brushless submersible motor is better when the brushless submersible motor is used.

Owner:深圳市恒然电机有限公司

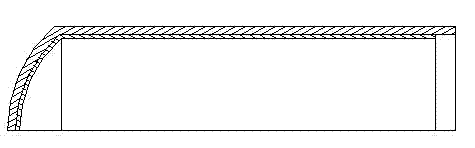

Corrosion-resisting fuel tank with double-layer structure

InactiveCN102788245AImprove corrosion resistanceReduces the effects of corrosion damageContainer filling methodsNon-pressured vesselsFuel tankHigh intensity

The invention relates to a corrosion-resisting fuel tank with a double-layer structure, belonging to the field of astronavigation and aircrafts or equipment used in astronavigation. The fuel tank comprises an inner layer tank and an outer layer tank, wherein the inner layer tank is made from anti-corrosion materials, the outer layer tank is made from high strength materials, and the inner layer tank is uniformly adhered on the inner wall of the outer layer tank. According to the invention, the inner structure is made from anti-corrosion materials, and the outer structure is made from high strength materials; the inner structure has high corrosion resistance but bears small load, the outer structure is used for bearing most loads and is separated from fuels, thus the outer structure can not be corroded, and the influence caused by fuel corrosion and damage can be effectively reduced, thus the service life of the fuel tank is prolonged.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com