Preparation and application of neutral non-phosphorus rust remover

A rust remover and neutral technology, which is applied in the preparation and application field of neutral phosphorus-free rust remover, can solve the problems of secondary attachment to contaminated workpieces, high labor intensity, and large dust pollution, and achieve simplified bath maintenance, Reduce secondary pollution, good rust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

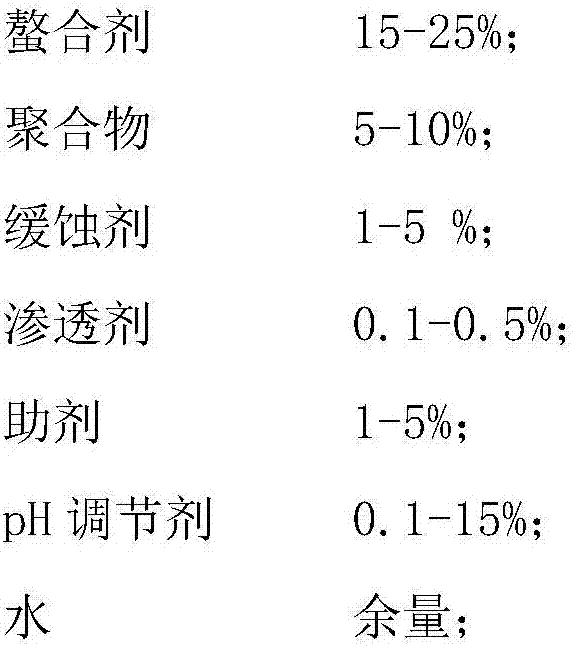

Method used

Image

Examples

Embodiment 1

[0021] A) Based on 100 parts by weight, add 70 parts of water to the stirring tank, dissolve and mix tartaric acid and potassium sodium tartrate mixture (the two are mixed at 10:1, 15 parts), sodium polyacrylate (7.5 parts), Monoethanolamine (1 part), 2-imidazolidinone (0.2 part) and thiourea (1 part), after stirring and clarification, adjust the pH value of the solution to 6.5 with 0.2 part of sodium bicarbonate, and finally add the remaining water and stir evenly.

[0022] B) The neutral phosphorus-free rust remover prepared in step A) is used to treat the barrel of the rusty filter by immersing it at room temperature (37°C) for about 0.5-1.5min; the floating rust on the surface (including processing Hand sweat during the process will cause rust).

Embodiment 2

[0024] A) Based on 100 parts by weight, add 50 parts of water to the stirring tank, dissolve and mix citric acid (25 parts), maleic acid-acrylic acid copolymer (10 parts), monoethanolamine, triethanolamine and triethanolamine respectively as required Borate ester mixture (the three are mixed at a ratio of 1:1:6, 5 parts), N,N-dimethylallyl urea (0.5 part) and sodium gluconate (5 parts), after stirring and clarification, use 12.5 parts of hydroxide Adjust the pH value of the solution to 6.1 with sodium, and finally add the remaining water and stir evenly.

[0025] B) The neutral phosphorus-free derusting agent prepared in step A) is used to treat rusty steel sheet metal parts by immersing them at room temperature (5°C) for about 15-20 minutes; the rust on the surface can be removed, and the workpiece can be processed and produced No secondary corrosion phenomenon.

Embodiment 3

[0027] A) Based on 100 parts by weight, add 60 parts of water to the stirring tank, dissolve and mix oxalic acid (20 parts), polyaspartic acid (5 parts), monoethanolamine (3 parts), and dimethylimidazole respectively as required Linone (0.1 part) and sodium gluconate (2 parts), after stirring and clarification, adjust the pH value of the solution to 6.7 with 9.5 parts of sodium carbonate, and finally add the remaining amount of water and stir evenly.

[0028] B) The neutral phosphorus-free derusting agent prepared in step A) is used to treat the rod-shaped steel workpiece with rust by spraying it at room temperature (25°C) for about 1.0-1.8min; the rust on the surface can be removed, and the subsequent descaling There is no secondary corrosion on the workpiece in the oil process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com