Corrosion-resisting fuel tank with double-layer structure

A double-layer structure and corrosion-resistant technology, which is applied in the field of space navigation and its aircraft or equipment, can solve problems such as tank damage, coating peeling, and inner layer erosion of the tank, so as to reduce the impact of stress concentration and improve service life , the effect of reducing residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

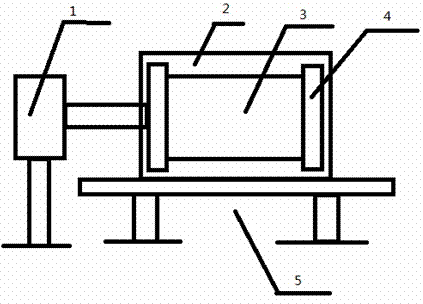

[0016] Below in conjunction with accompanying drawing, the present invention is described in further detail:

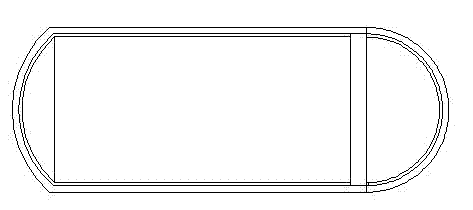

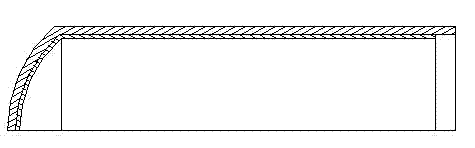

[0017] As shown in the figure: a corrosion-resistant double-layer structure fuel tank, including an inner tank and an outer tank, the inner tank is made of anti-corrosion materials, and the outer tank is made of high-strength materials As a result, the inner tank is evenly attached to the inner wall of the outer tank. The outer storage tank is formed by segmental pressing and welding; the inner storage tank is formed by centrifugal processing.

[0018] The strong corrosion-resistant material of the inner layer is aluminum alloy material, and the outer layer is made of aluminum alloy series material with higher strength.

[0019] The outer structure of the storage tank adopts the segmental pressing and welding forming method of the general storage tank.

[0020] Such as figure 2 As shown in Fig. 1, after the section processing of the outer structure of the storage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com