A plant boundary low-concentration benzene series online monitoring system and an online monitoring method

A monitoring system and technology of benzene series, which is applied in the field of low-concentration benzene series on-line monitoring system at the factory boundary, can solve the problems that low-concentration benzene series are difficult to monitor and analyze accurately, so as to improve detection ability and detection accuracy and ensure synchronization , the effect of reducing the failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

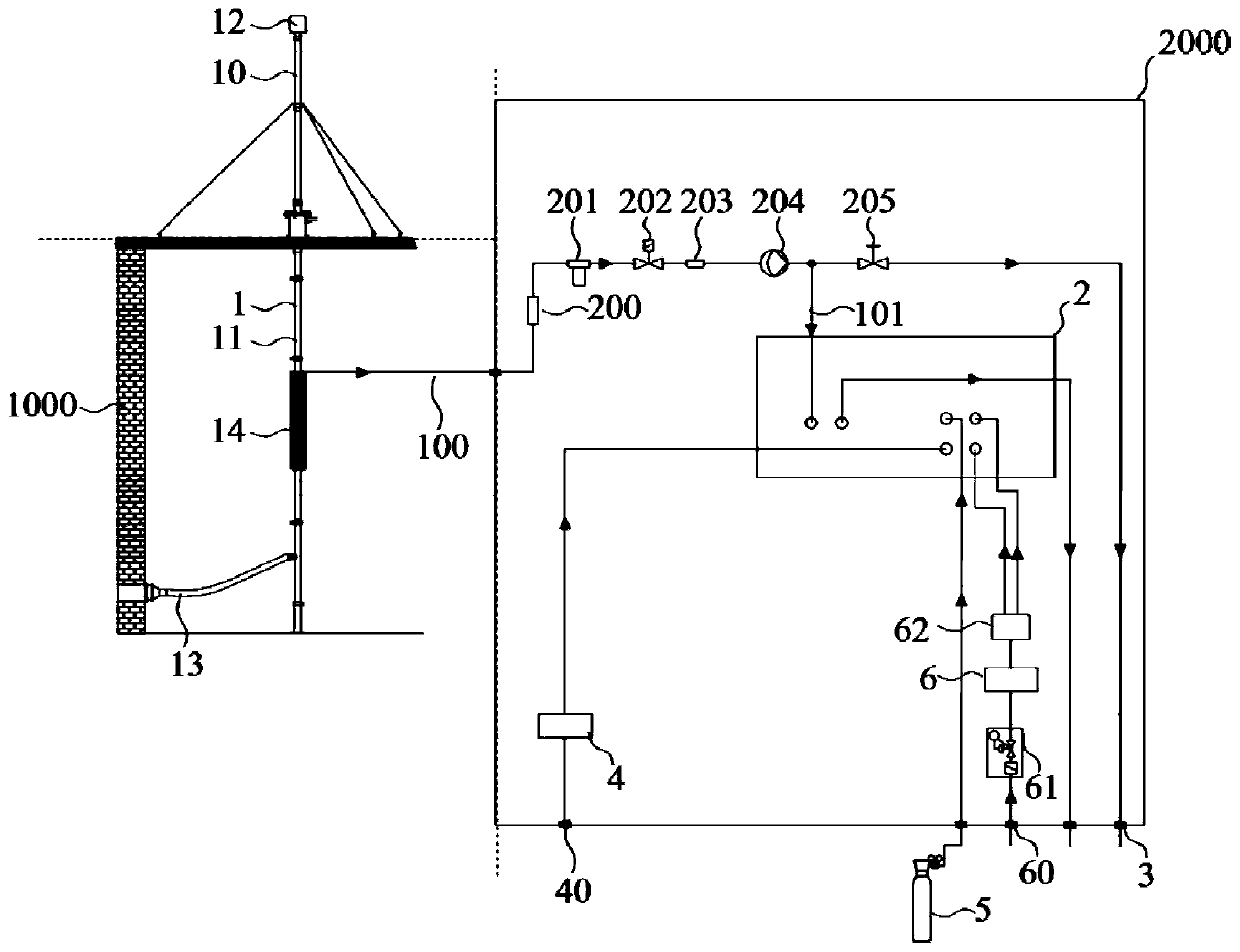

[0064] An on-line monitoring system for low-concentration benzene series at the factory boundary, such as figure 1 shown, including,

[0065] Atmospheric sampling main pipe 1, which is used to collect sample gas in the atmospheric factory boundary;

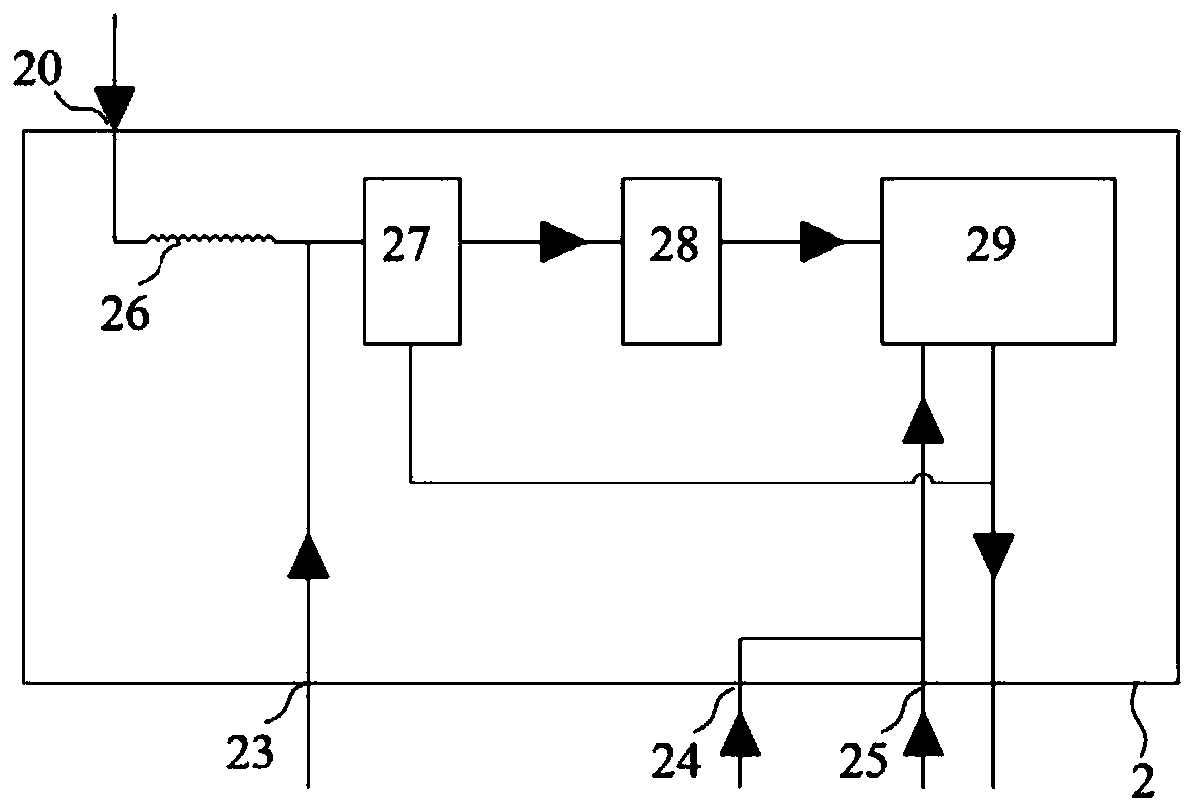

[0066] Chromatography analyzer 2, it is communicated with atmospheric sampling main pipe 1, described chromatographic analyzer 2 is internally equipped with quantitative loop 26, chromatographic column 27 and FID flame ionization detector 29, and described quantitative loop 26 is communicated with atmospheric sampling main pipe 1, The chromatographic column 27 is communicated with the quantitative loop 26, and the FID flame ionization detector 29 is communicated with the chromatographic column 27;

[0067] Gas source unit, it comprises hydrogen generator 4, nitrogen generator 5 and zero gas generator 6, transmits hydrogen, nitrogen and zero gas to chromatography analyzer 2 respectively;

[0068] The chromatographic column 27 is ...

Embodiment 2

[0074] The on-line monitoring system for low-concentration benzene series at the plant boundary of this embodiment is further improved on the basis of Embodiment 1, and the catalyst is a noble metal catalyst.

[0075] Noble metal catalysts and transition metal oxide catalysts are commonly used catalysts for the purification of benzene series in VOCs in industry. Benzene series can be decomposed into CO by heating at 150-600 °C through the catalyst. 2 and H 2 O, the effective removal rate is over 99%.

[0076] During the experiment, the applicant found that by using a noble metal catalyst, a small amount of benzene series can pass through the catalyst, stay for a short time, and after heating at a certain temperature, the benzene series can be decomposed into methane. Concentration benzene series on-line monitoring system, the specification of quantitative loop 26 is 1ml in the present embodiment, after being separated by chromatographic column 27, the volume of benzene series...

Embodiment 3

[0081] The on-line monitoring system of low-concentration benzene series in the factory boundary of this embodiment is further improved on the basis of embodiment 2. The main pipe 1 is connected; the main pipeline 101 is provided with an air pump 204 .

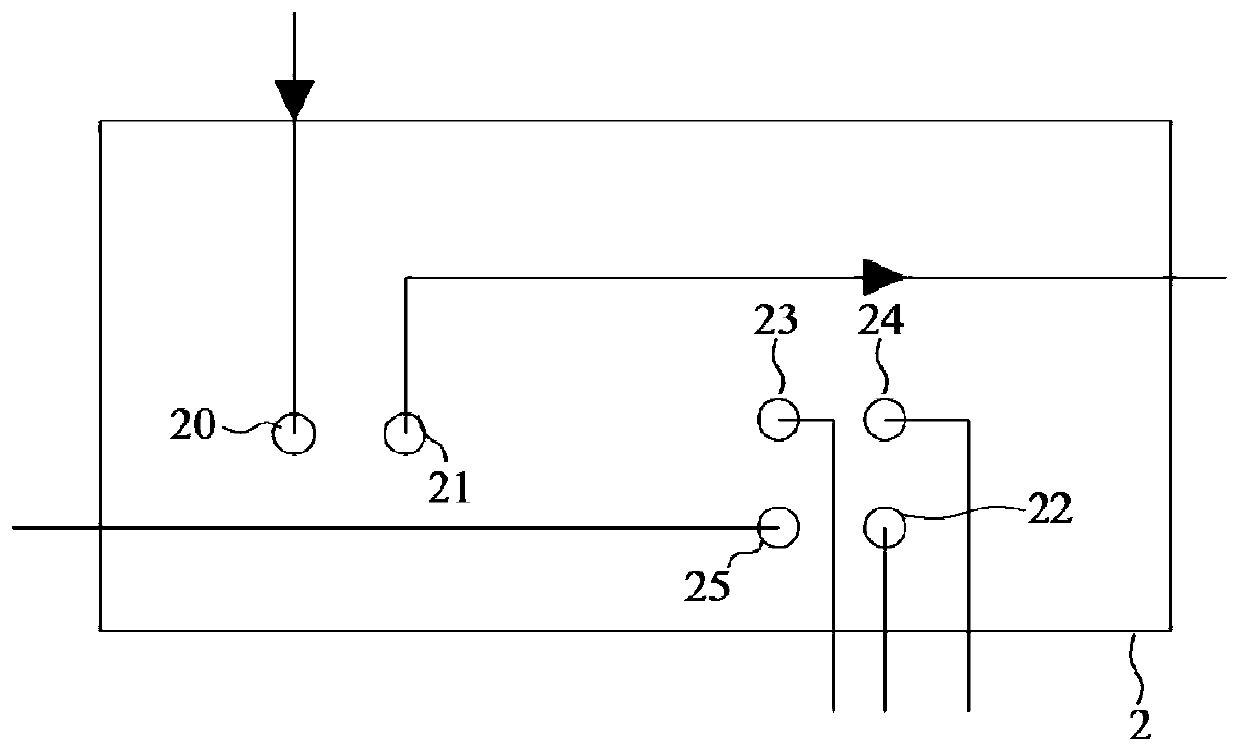

[0082] Such as figure 2 As shown, the chromatographic analyzer 2 includes a sample gas inlet 20 , a sample gas outlet 21 , a zero gas inlet 22 , a carrier gas inlet 23 , a driving gas inlet 24 , and a hydrogen gas inlet 25 . The sample gas inlet one 20 is communicated with the main road pipeline 101, the carrier gas inlet 23 is communicated with the nitrogen generator 5 through the pipeline, the driving gas inlet 24 is communicated with the zero gas generator 6 through the pipeline, and the hydrogen inlet 25 is communicated through the pipeline and The hydrogen generator 4 communicates, the zero gas inlet 22 communicates with the zero gas generator 6 through a pipeline, and the sample gas outlet 22 communicates with the outs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com