Stainless steel GYXTW type optical cable and manufacturing method thereof

A technology of stainless steel tube and production method, which is applied in the directions of light guide, optics, optical components, etc., can solve the problems of environmental pollution of optical cable manufacturing, affecting the protective effect of optical cable, loss of additives, etc., and achieves light weight, compact structure and large span. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

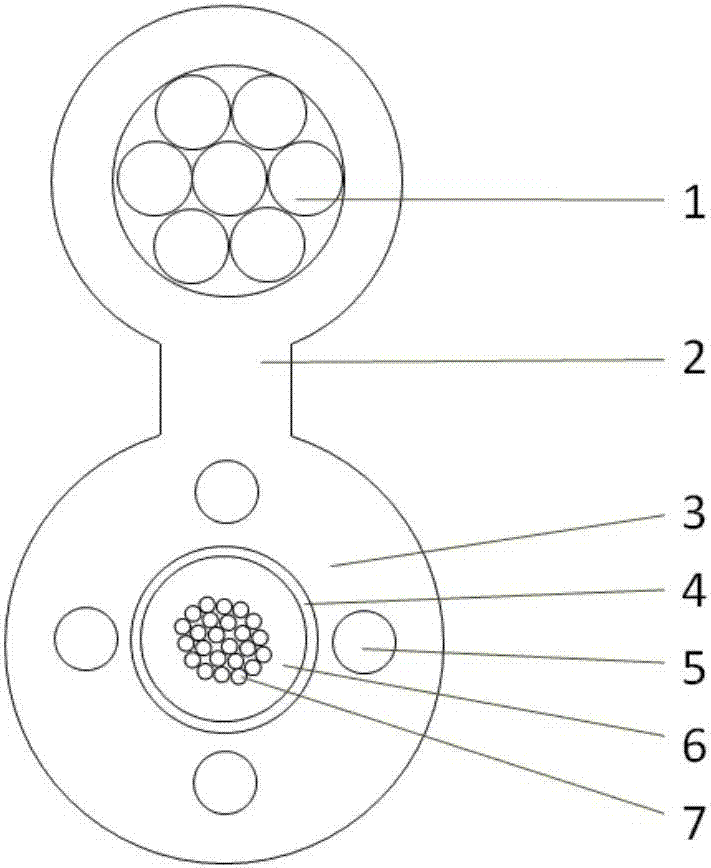

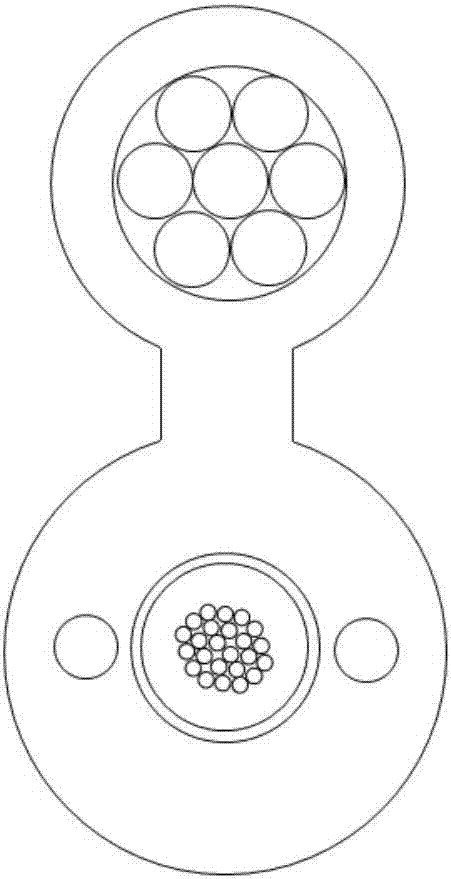

[0072] Such as figure 1Shown is a cross-sectional view of a 24-fiber self-supporting stainless steel center bundle tube cable with four strength elements, which includes strength elements, optical fibers, filler compound, stainless steel tube, outer jacket, hanging neck, and suspension wires. The optical fiber is the B1.3 optical fiber specified in YD / T 9771.1-2008. The number of cores of the optical fiber is 24, of which 12 cores are colored according to the full color spectrum, and the thickness of the colored layer is 5 μm. The remaining 12 cores are colored by the full color spectrum Spray black monochrome ring; the filling compound is thixotropic water-blocking ointment; the outer diameter of the stainless steel tube is Φ2.9mm, and the thickness of the stainless steel tube is 0.18mm; the outer sheath is black high-density polyethylene material and Add a special compatibilizer; the reinforcement is phosphating steel wire, the number is four, symmetrically distributed aroun...

example 2

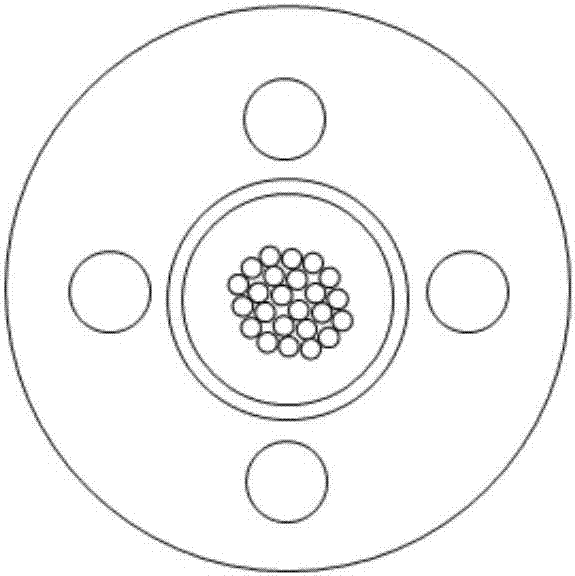

[0074] Such as Figure 4 Shown is a cross-sectional view of a two-strength, non-self-supporting, 24-fiber stainless steel center bundle tube cable consisting of optical fiber, filler compound, stainless steel tube, strength member, and outer jacket. The non-self-supporting stainless steel central beam tube optical cable removes the hanging neck and hanging wire on the basis of the self-supporting stainless steel central beam tube optical cable. The production process follows the self-supporting stainless steel central beam tube optical cable process, but it needs to be removed during production. The mold of the self-supporting optical cable, and the metal hanging wire pay-off device, the non-self-supporting stainless steel central beam tube optical cable has a circular cross-section and an outer diameter of Φ7.0mm. Other technological processes are the same as above.

[0075] The full performance test results of the optical cable of the present invention are given below, as s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| stretching force | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com