Low-volatility single-component de-ketoxime type silicone rubber for lamps and preparation method of silicone rubber

A low-volatility, ketoxime technology, applied in adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the corrosion damage of PC materials, the limitation of the use of deketoxime silicone rubber, cracking and other problems , to achieve the effect of good adhesion, weather resistance and environmental aging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

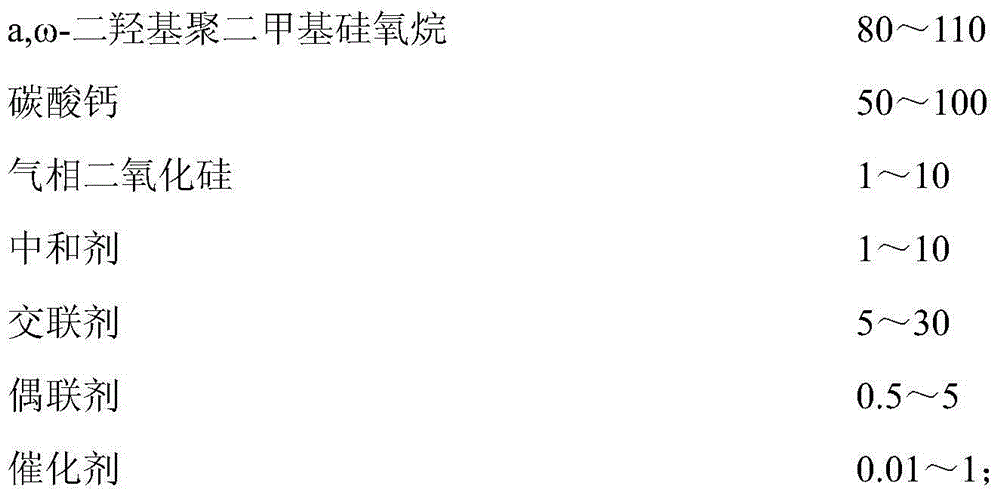

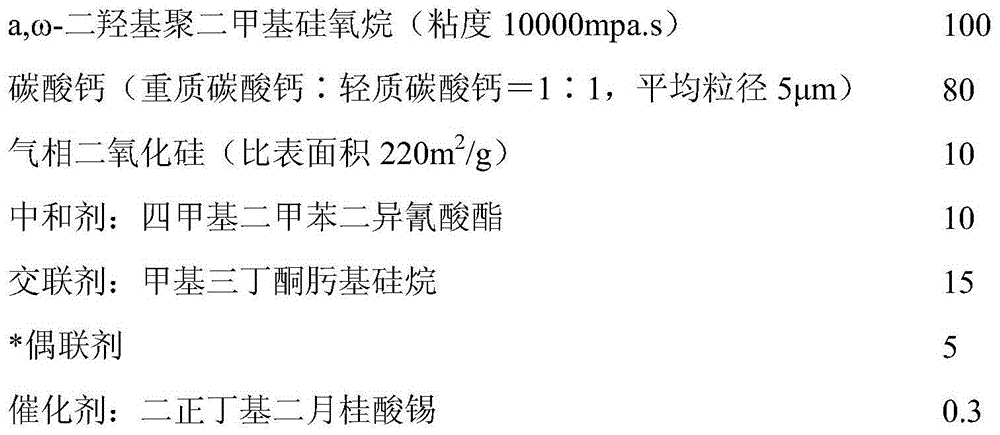

[0017] 1. A low-volatility single-component deketoxime-type silicone rubber for lamps in this embodiment, the raw materials are composed of:

[0018]

[0019] *The coupling agent is: by weight N-(β-aminoethyl)-Y-aminopropyltrimethoxysilane: Y-(2,3-glycidyloxy)propyltrimethoxysilane=3: 1 mixture.

[0020] 2. The preparation method of a low-volatility single-component deketoxime-type silicone rubber for lamps in this embodiment is as follows: mix the above-mentioned raw materials for 30 minutes at a vacuum degree of -0.09Mpa and a stirring speed of 20 Hz, and discharge The product is ready to fill.

Embodiment 2

[0022] 1. A low-volatility single-component deketoxime-type silicone rubber for lamps in this embodiment, the raw materials are composed of:

[0023]

[0024] 2. The preparation method of a low-volatility single-component deketoxime-type silicone rubber for lamps in this embodiment is as follows: mix the above-mentioned raw materials for 30 minutes at a vacuum degree of -0.09Mpa and a stirring speed of 25 Hz, and discharge The product is ready to fill.

Embodiment 3

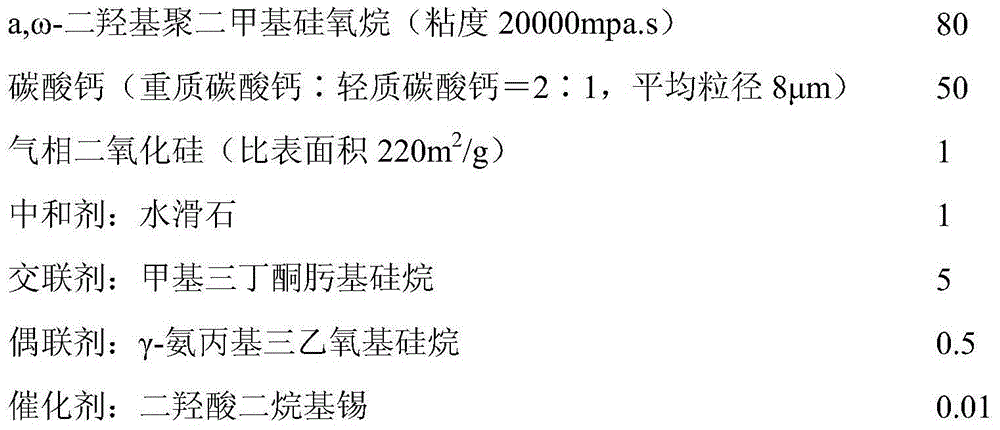

[0026] 1. A low-volatility single-component deketoxime-type silicone rubber for lamps in this embodiment, the raw materials are composed of:

[0027]

[0028] 2. The preparation method of a low-volatility single-component deketoxime-type silicone rubber for lamps in this embodiment is as follows: mix the above-mentioned raw materials for 40 minutes at a vacuum degree of -0.08Mpa and a stirring speed of 25 Hz, and discharge The product is ready to fill.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| tack-free time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com