Cleaning device for valve scaling

A technology for cleaning devices and valves, which is applied to liquid cleaning methods, cleaning methods and utensils, and inorganic non-surface-active cleaning compositions, etc., which can solve the problems of increased and reduced production costs, valves that are easily damaged by washing, and use pressure levels, etc. , to achieve the effect of low cleaning cost, simple process and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the invention:

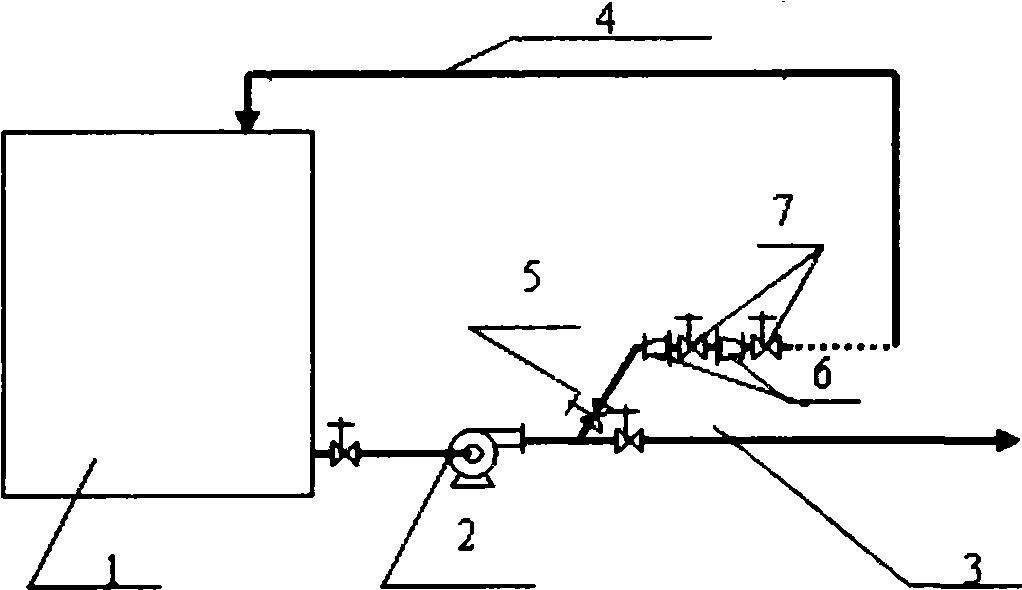

[0018] The caustic alkali solution purchased by alumina production is prepared into a caustic alkali solution with a concentration of 320g / l, which is used as a chemical cleaning solution to clean large equipment and tanks. Control the temperature of the chemical cleaning solution to 65°C. Install a branch pipeline 4 on the main pipeline 3 that transports the clear liquid, and connect the valves 7 with diameters of 100mm, 150mm, 200mm, and 250mm in series through a variable-diameter connecting short pipe 6 on the branch pipeline, and then branch the pipeline 4 Return to the chemical cleaning liquid storage tank 1 to form a closed loop.

[0019] A control valve 5 is connected to the branch pipeline 4 . When the chemical cleaning liquid is sent to clean large-scale equipment and tanks through the main pipeline 3 by the delivery pump 2, the control valve 5 is opened, and the chemical cleaning liquid enters the branch pipeline 4. Because t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com