Patents

Literature

55results about How to "Reduce spare parts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

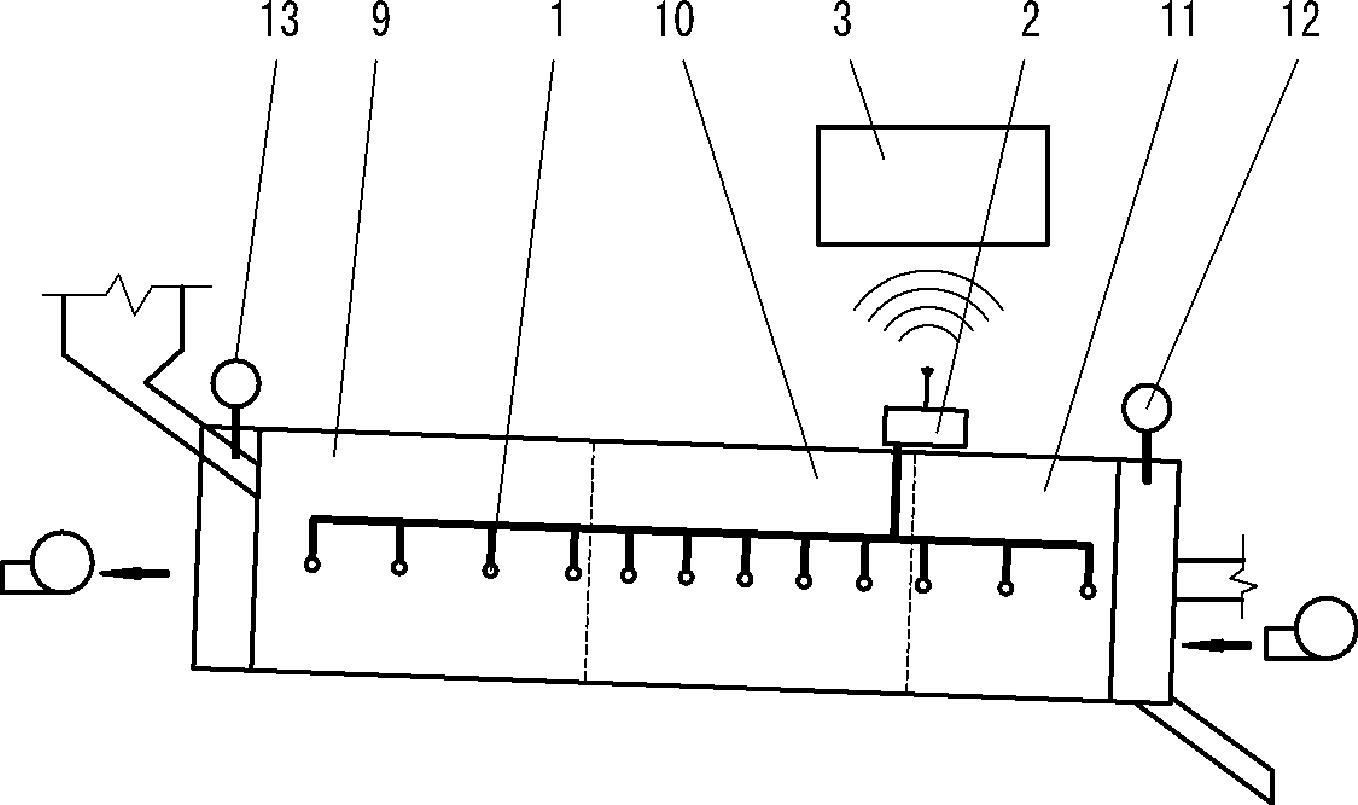

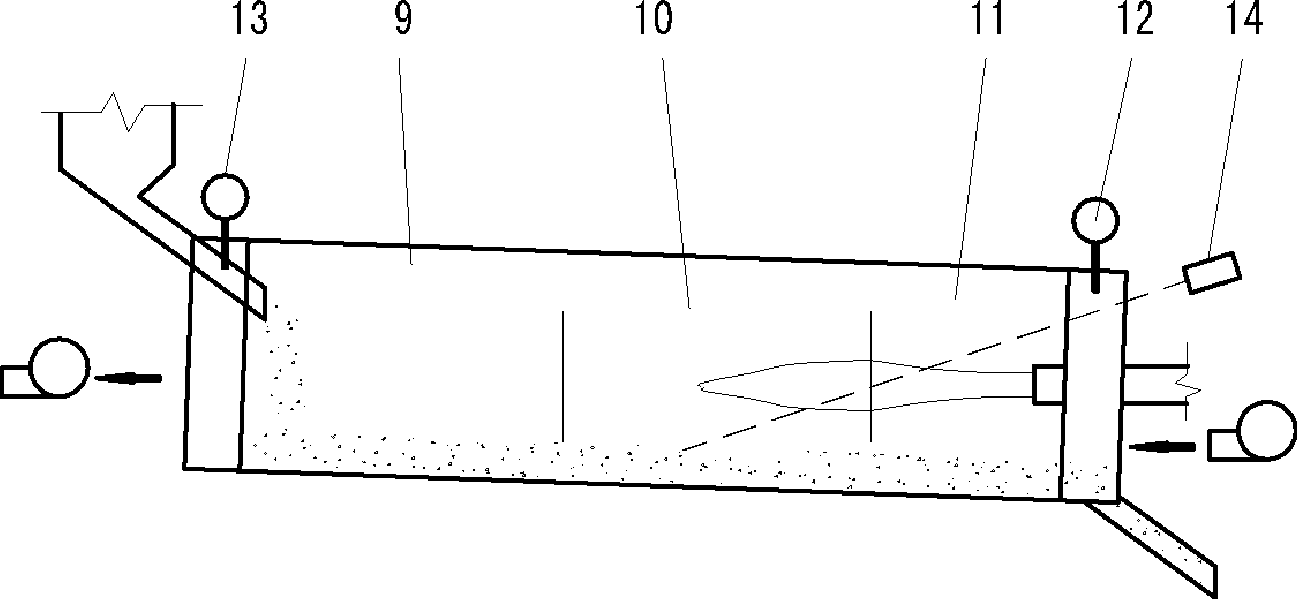

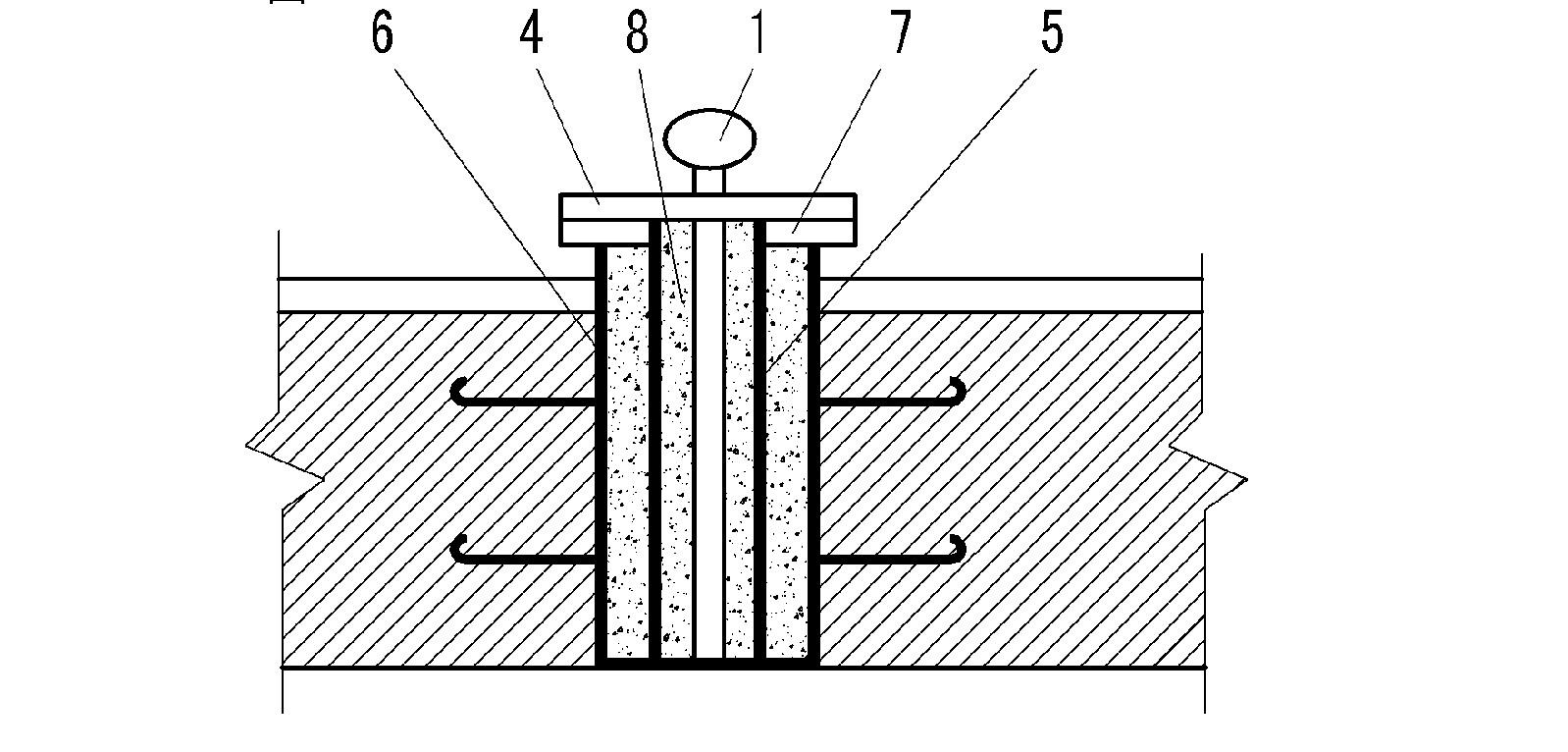

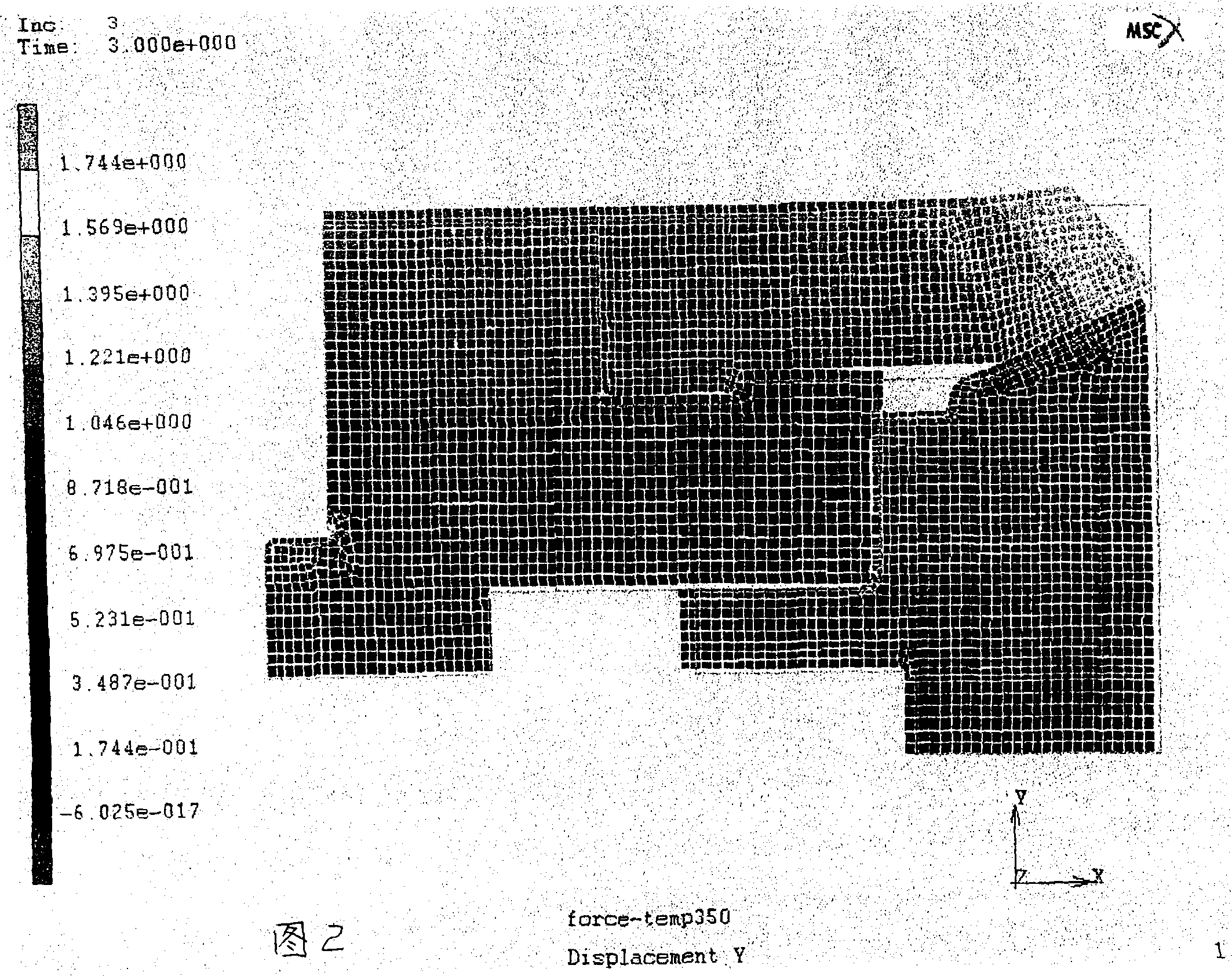

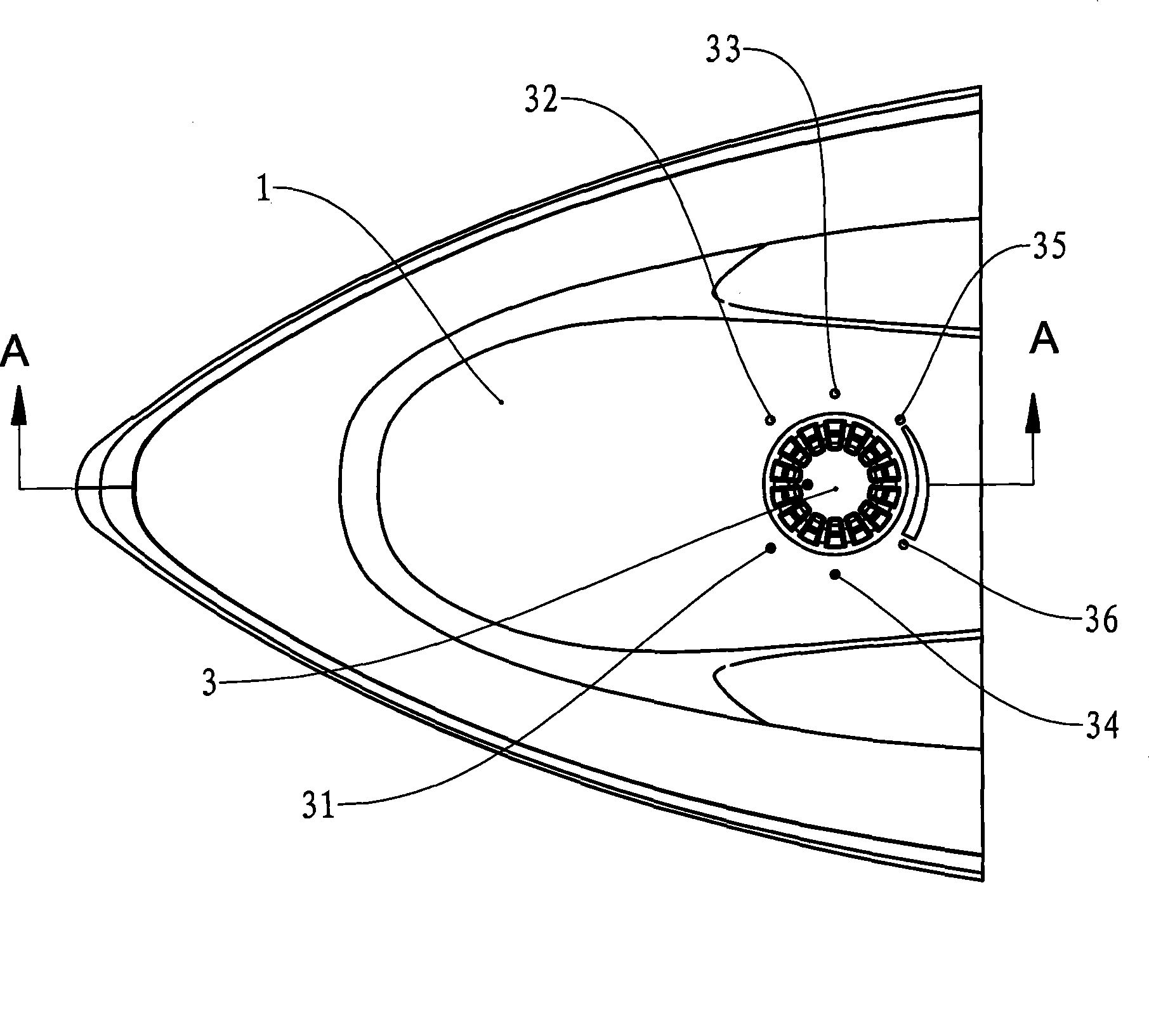

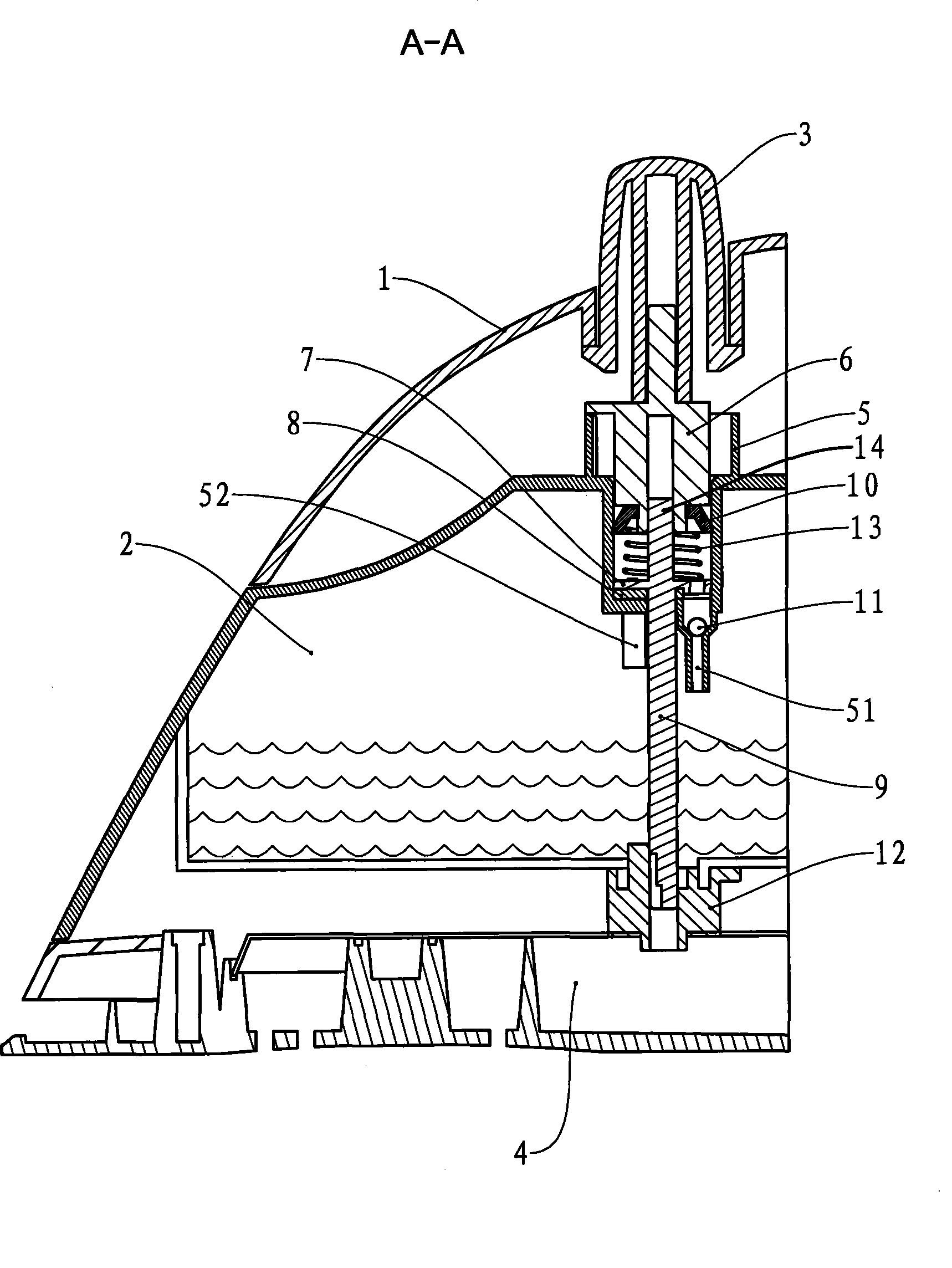

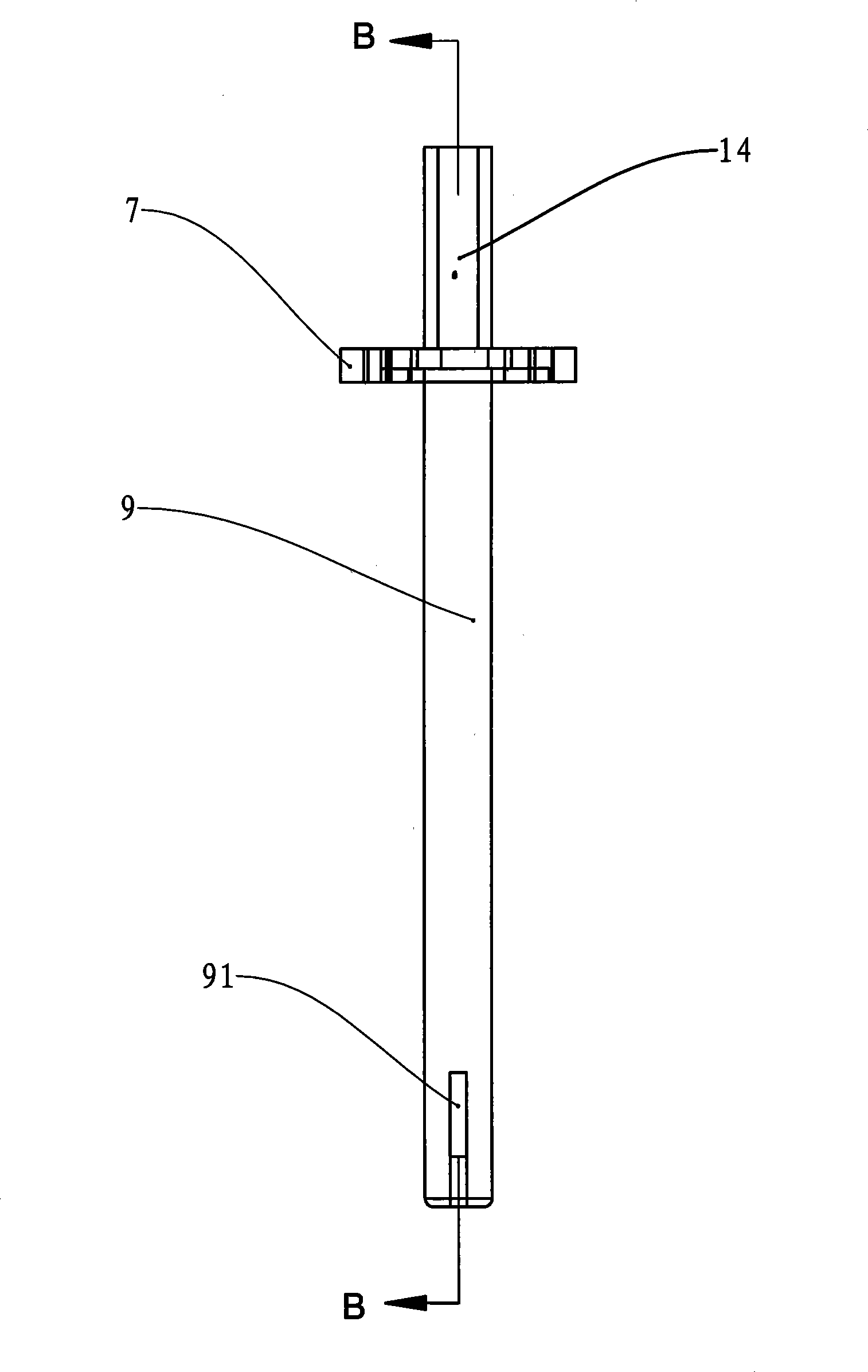

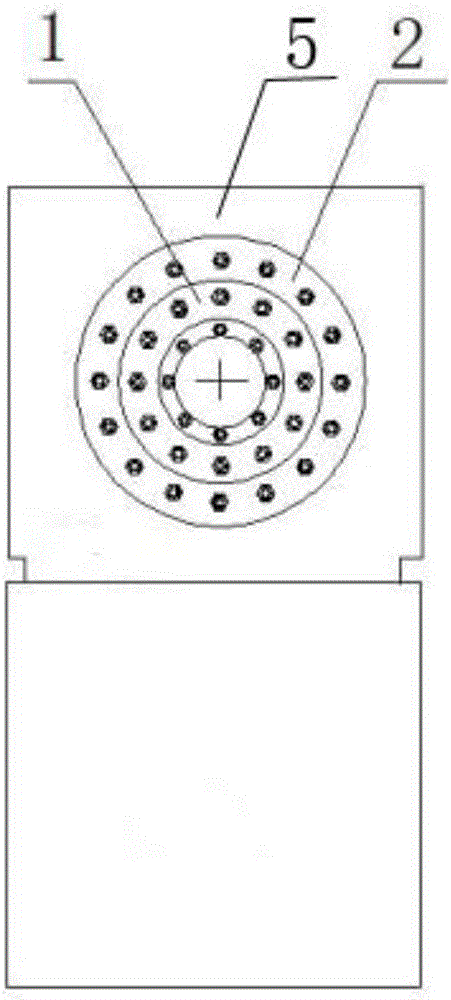

Temperature field detection method and device of calcination rotary kiln

InactiveCN101464093AUndisturbedMeasurement cost input is not affected byTransmission systemsThermometers using electric/magnetic elementsFailure rateEngineering

The invention discloses a method for detecting the temperature field of a calcination rotary kiln and a device thereof. The method comprises the following steps: mounting a group of temperature thermocouples in the inner lining of the kiln body of the calcination rotary kiln in the axial direction of the kiln body; determining the amount and the distribution clearance of the thermocouples according to the requirements for measuring the precision of temperatures on the preheating section, the calcining section and the cooling section of the calcination rotary kiln; and connecting each thermocouple with the wireless communication box mounted on the shell of the calcination rotary kiln body, so that the wireless communication box can transmit the temperature signal of each thermocouple to a computer analysis system on a real-time basis. The invention has the advantages that the real-time measurement of the distribution of the temperature field of the overall rotary kiln is realized; the most authentic material temperatures can be directly measured without being interfered by the flue gas and the flame in the kiln; the construction cost of the complete set of devices is far lower than that of the prior infrared thermometer system; the spare parts are cheap, and the maintenance and the replacement are convenient, therefore, the production cost and the maintenance cost are reduced; and the technical characteristic is reliable, therefore, the failure rate is low. As accurate measurement is realized, the invention provides a calcination control system with strong support for improving the automatization.

Owner:GUIYANG AL-MG DESIGN & RES INST

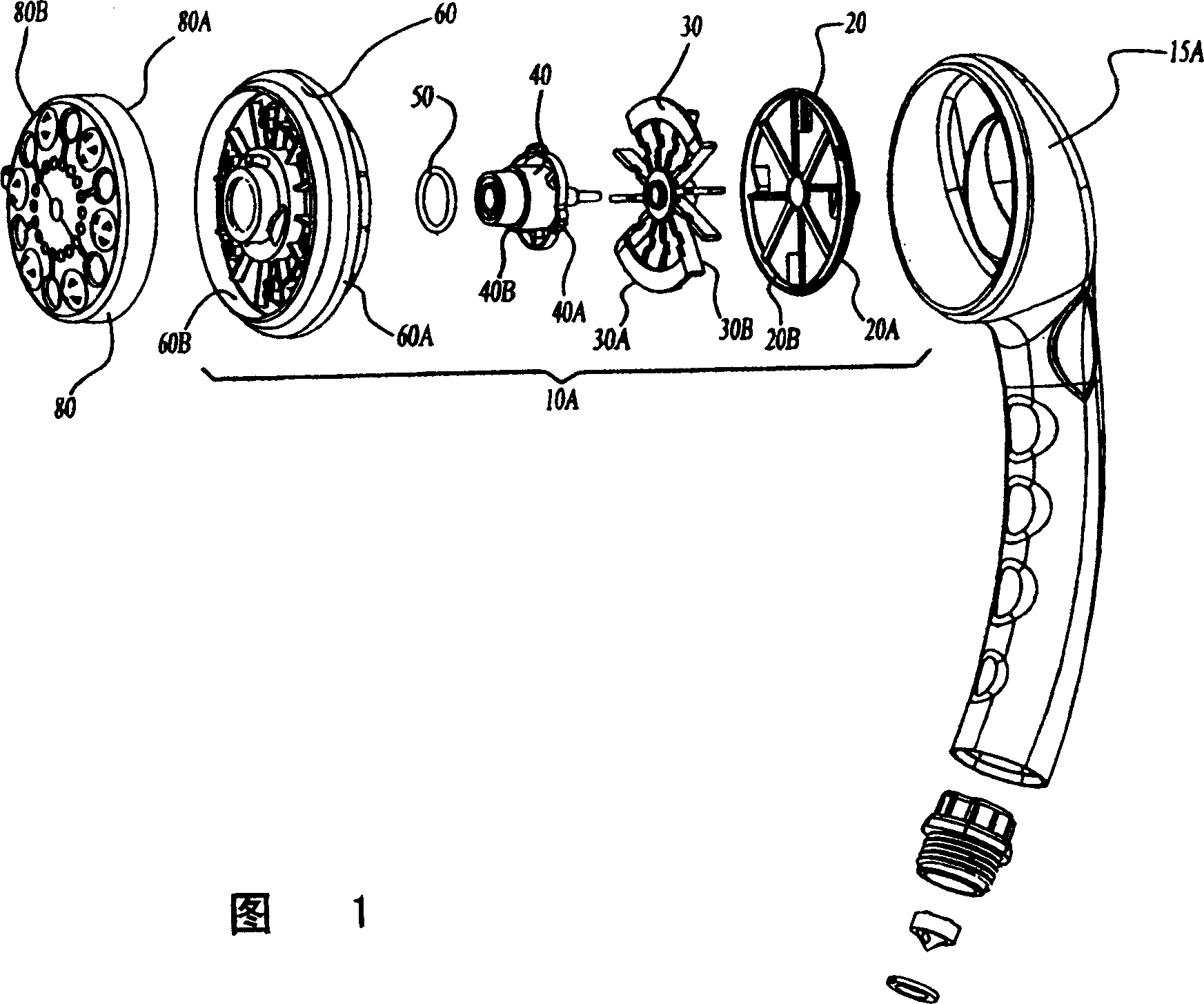

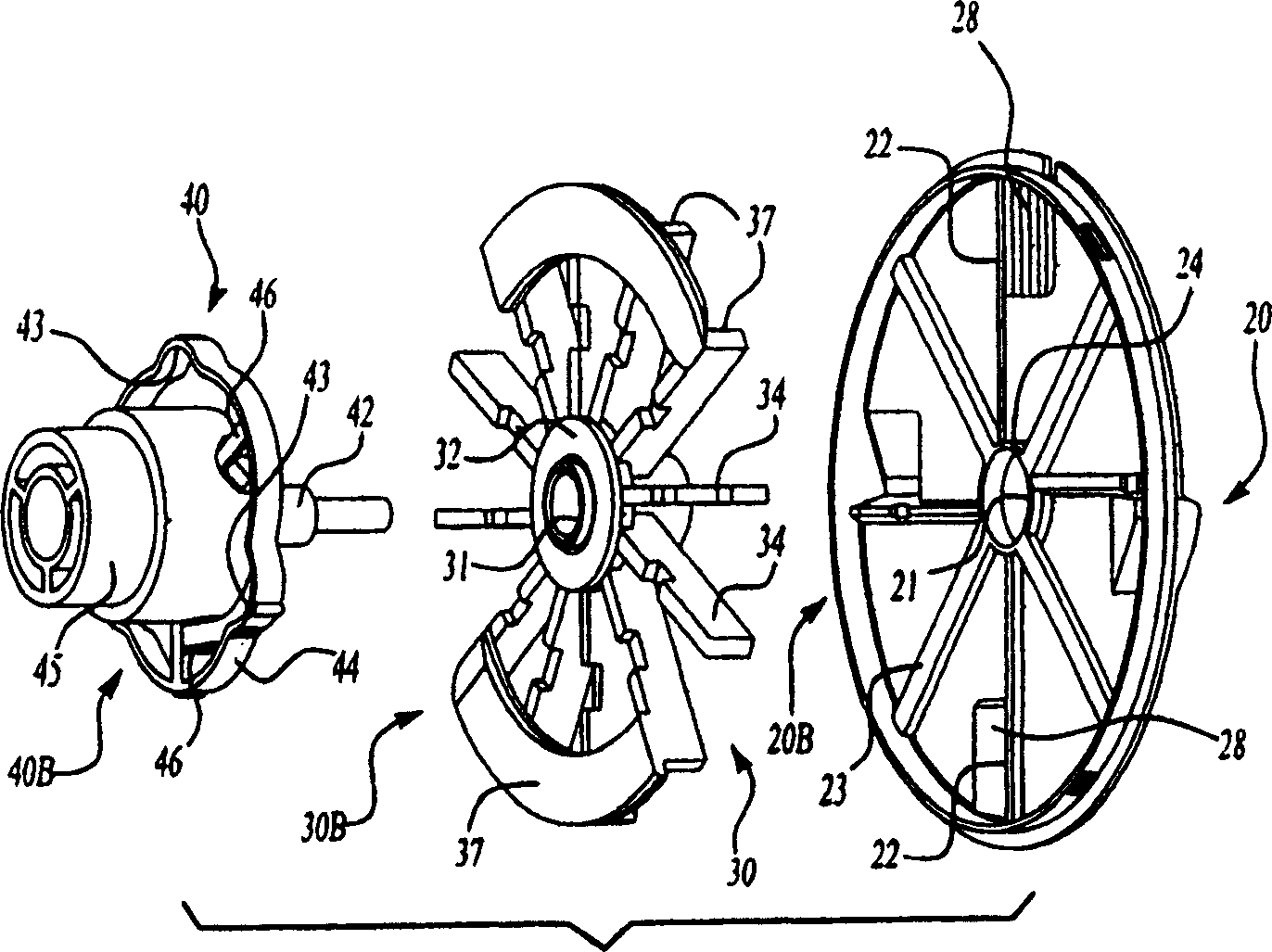

Showerhead engine assembly

The invention relates to a shower ejector, which can supply continuous, deflected, and aerated frog, wherein said invention comprises: static element, rotational element, connector, pressure plate, panel and sealing ring; the pressure plate and the panel are arranged with holes through with liquid; the deflected surface of panel can realize the change between different water flow types; opposite to the static element, the rotator rotates or stops rotation; said static element comprises a couple of stop edges connected and detached with a rotator; when the rotator is detached and rotates freely, the water will pass the channel of rotator to rotate the rotator, to generate vortex and impulse frog.

Owner:ALSONS CORP

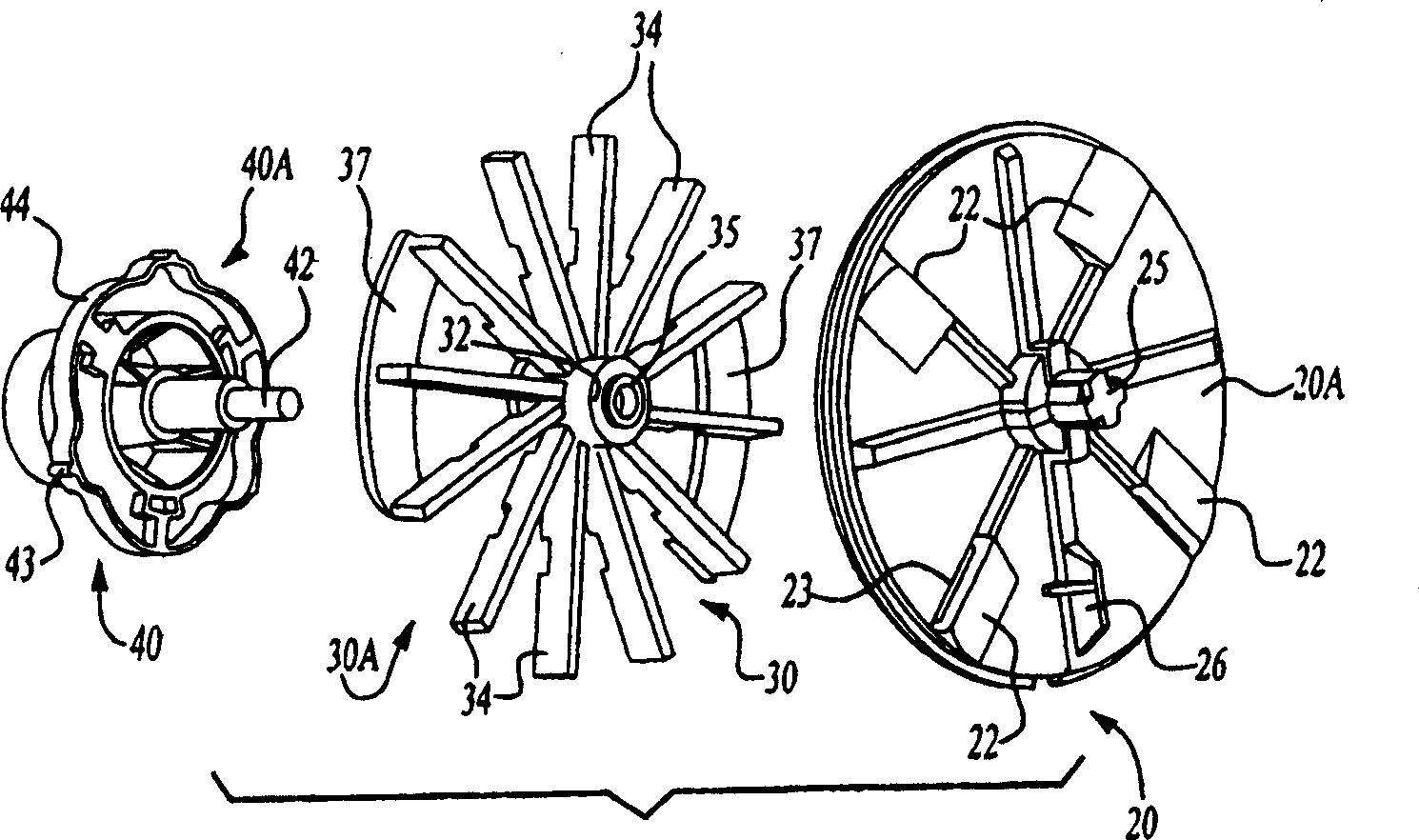

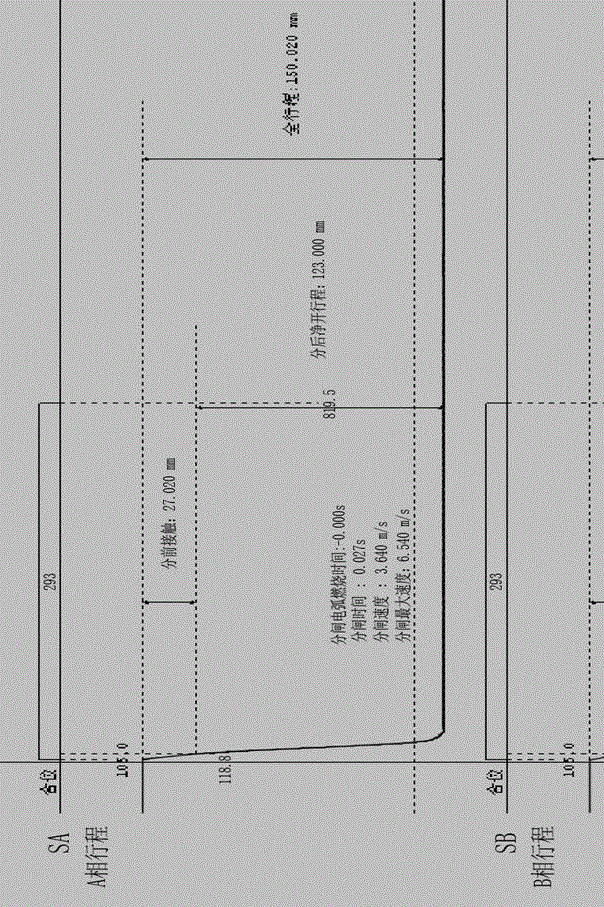

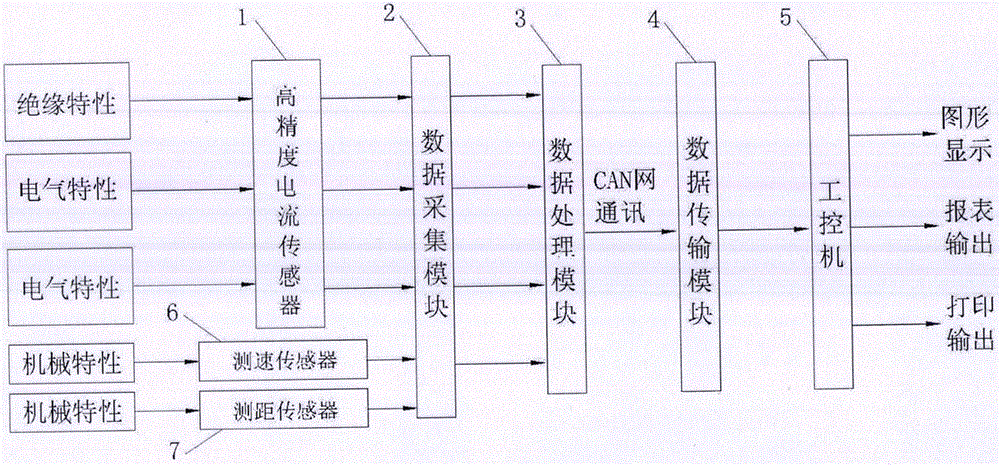

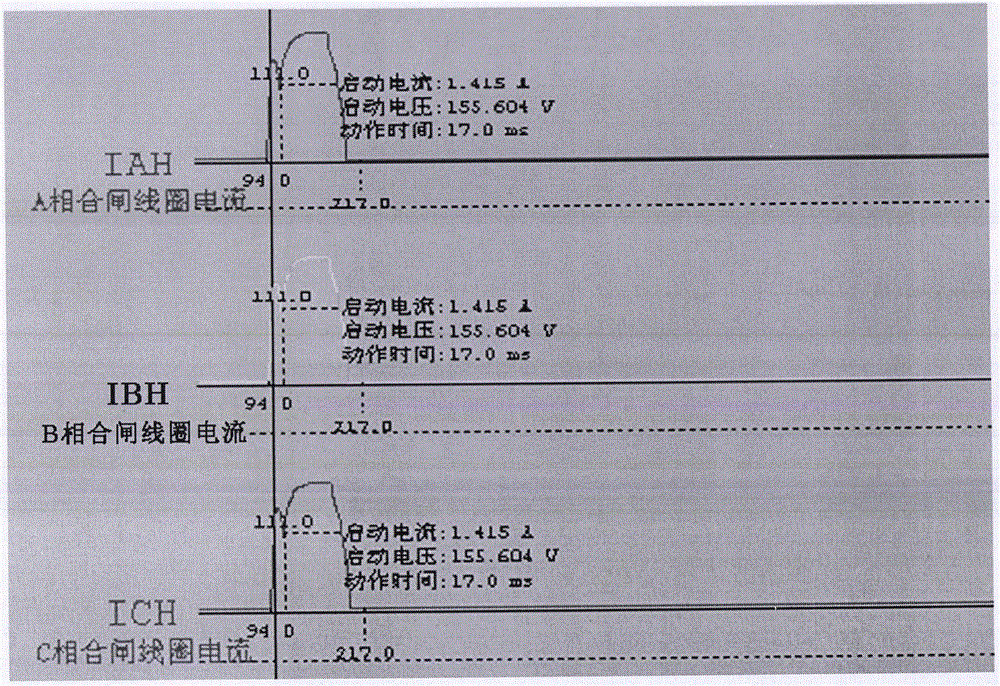

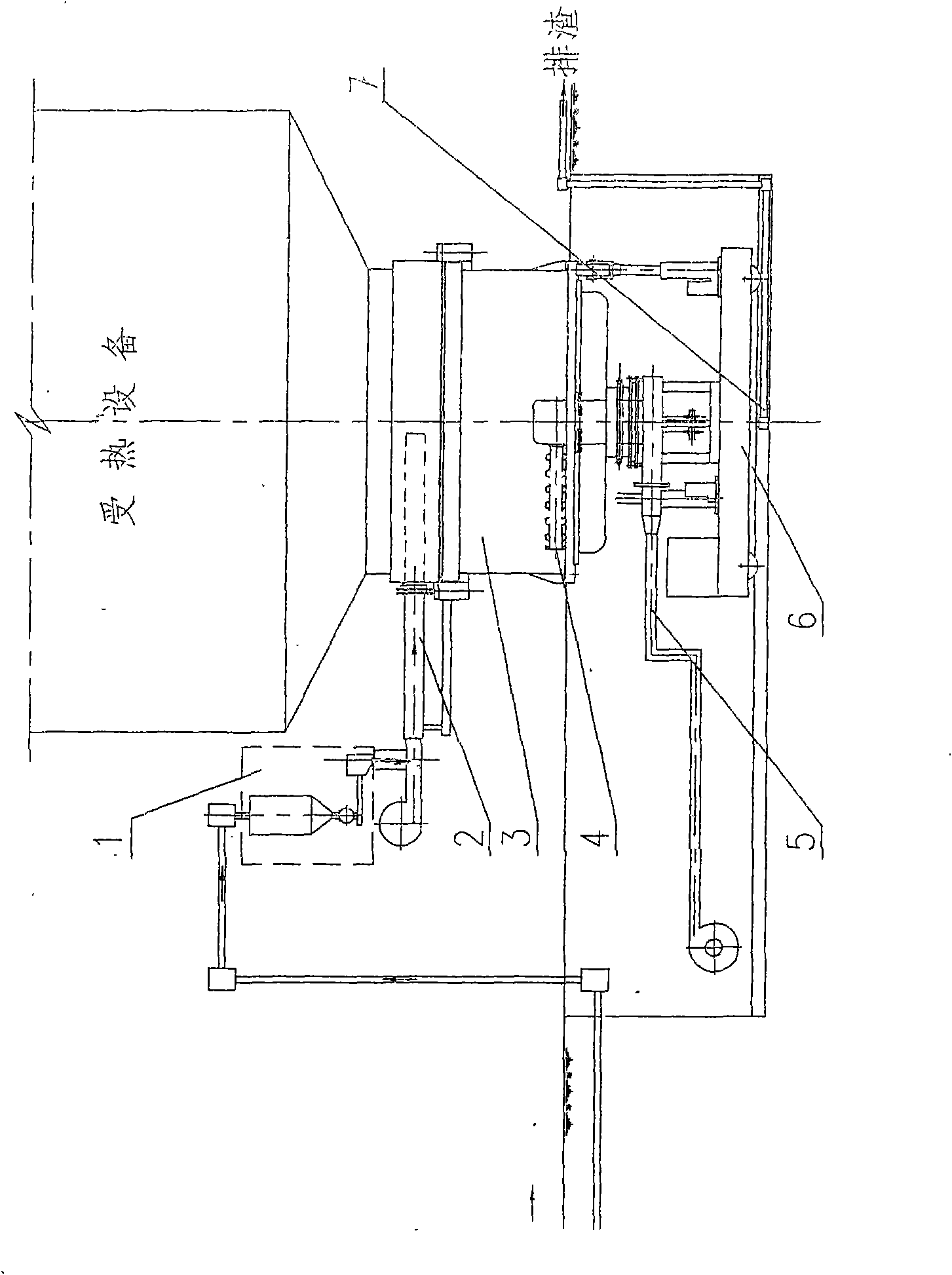

System and method of testing high-voltage circuit breaker

InactiveCN105589030AImprove reliabilityGuaranteed uptimeCircuit interrupters testingCurrent sensorData acquisition

The present invention discloses a system and method of testing a high-voltage circuit breaker. The system comprises a speed measurement sensor, a distance measurement sensor, a current sensor, a data acquisition and processing system and an industrial control computer. The insulation characteristics, the electrical characteristics and the mechanical characteristics, measured by the speed measurement sensor, the distance measurement sensor and the current sensor, of a high-voltage circuit breaker are sent to the industrial control computer through the data acquisition and processing system; the insulation characteristics are the leakage current and the insulation resistor of the high-voltage circuit breaker; the electrical characteristics are the opening and closing current and the measurement current; and the mechanical characteristics are the total motion time, the motion amount and the motion merge-joint direction of the high-voltage circuit breaker, and the accelerated speed, the acceleration time, the uniform motion speed, the uniform motion time, the deceleration process of the motion, the overshoot of the motion and the overshoot time when the motion starts. The system and method of testing a high-voltage circuit breaker are able to discover an abnormal state and predicate a fault period at the early state of the fault so as to fully make a service preparation and provide a technology basis for reasonably making the maintenance plan of a device, therefore the operation reliability of the power grid is improved.

Owner:JINZHOU ELECTRIC POWER SUPPLY COMPANY OF STATE GRID LIAONING ELECTRIC POWER SUPPLY +1

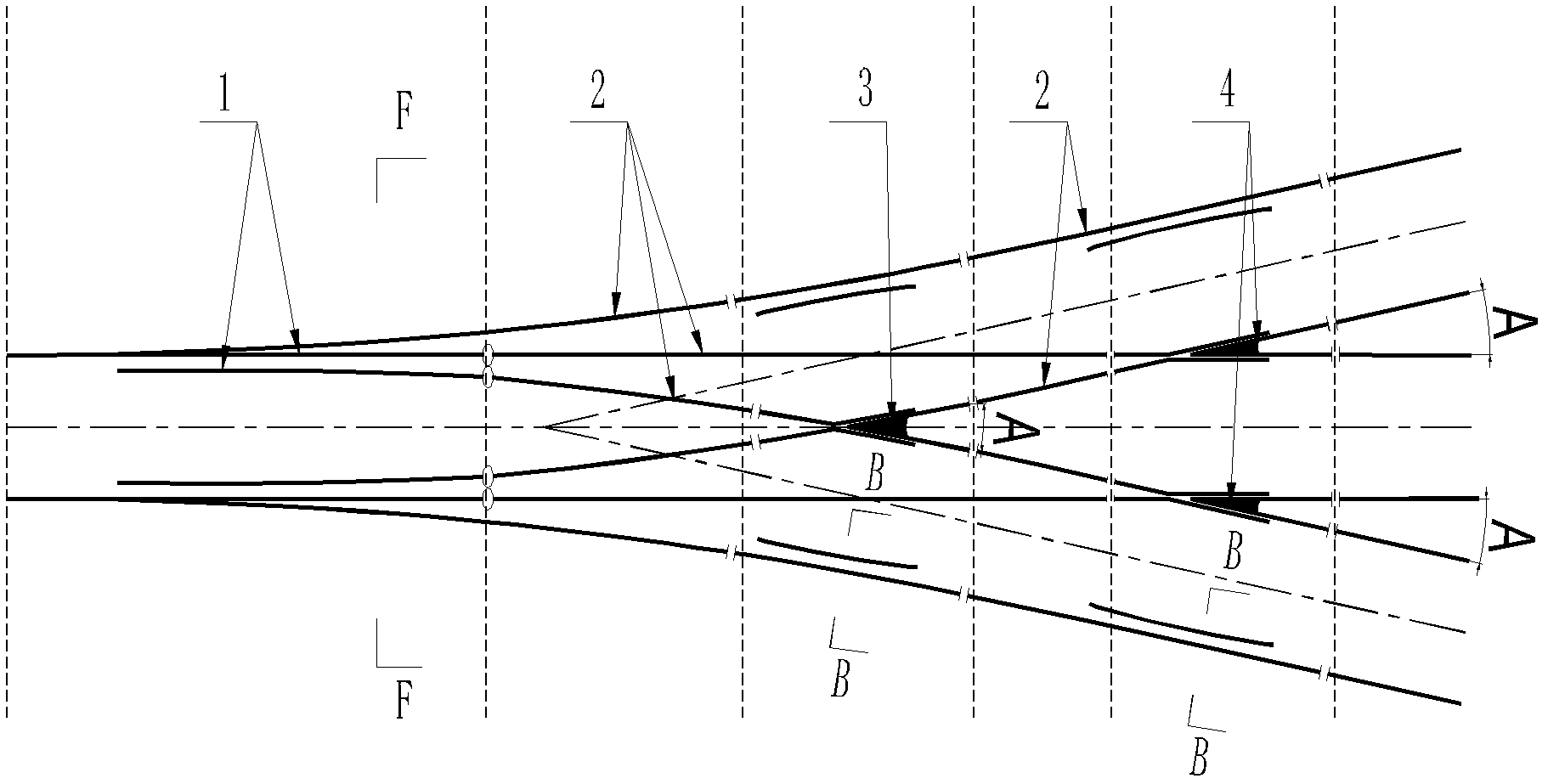

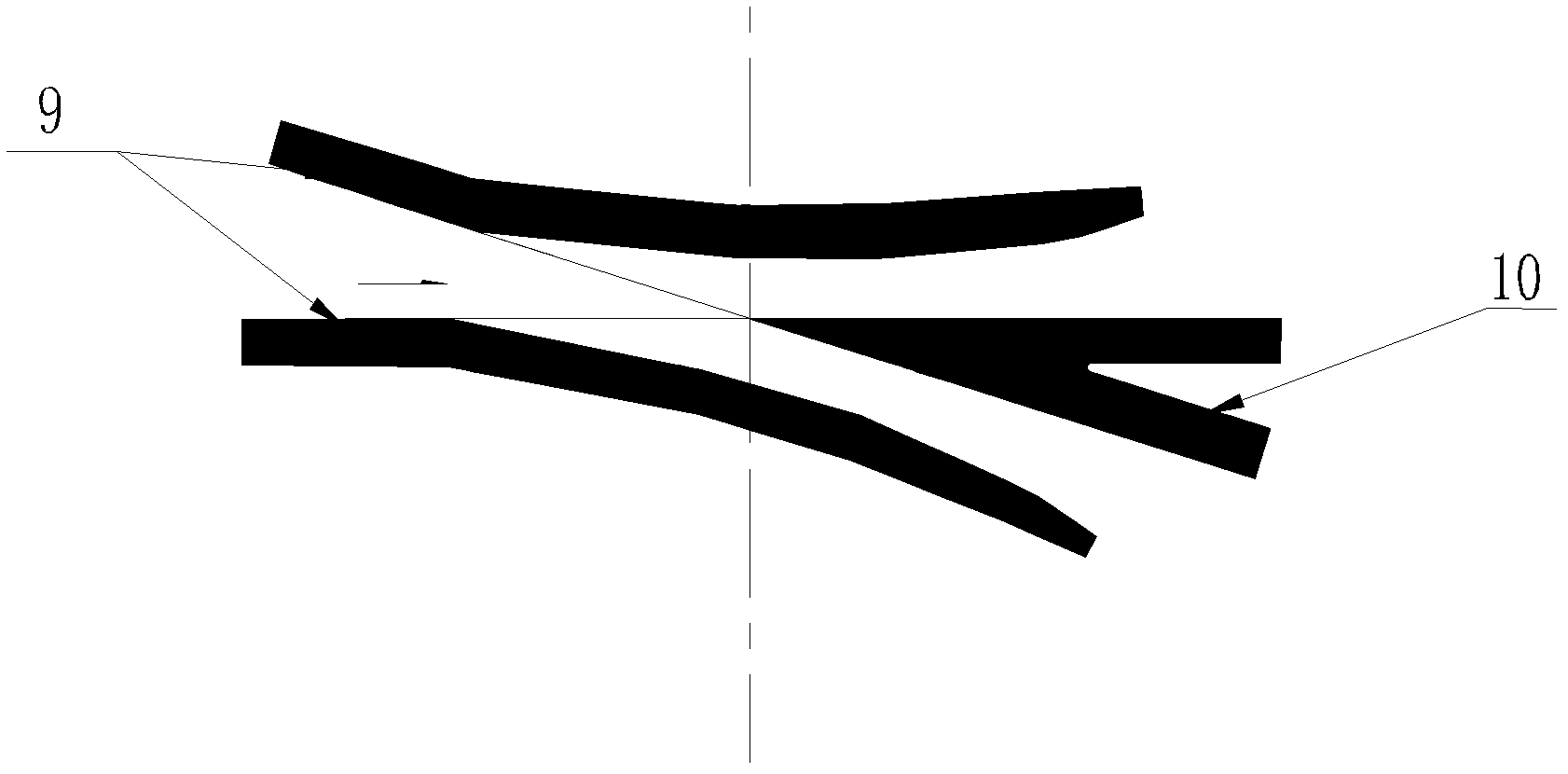

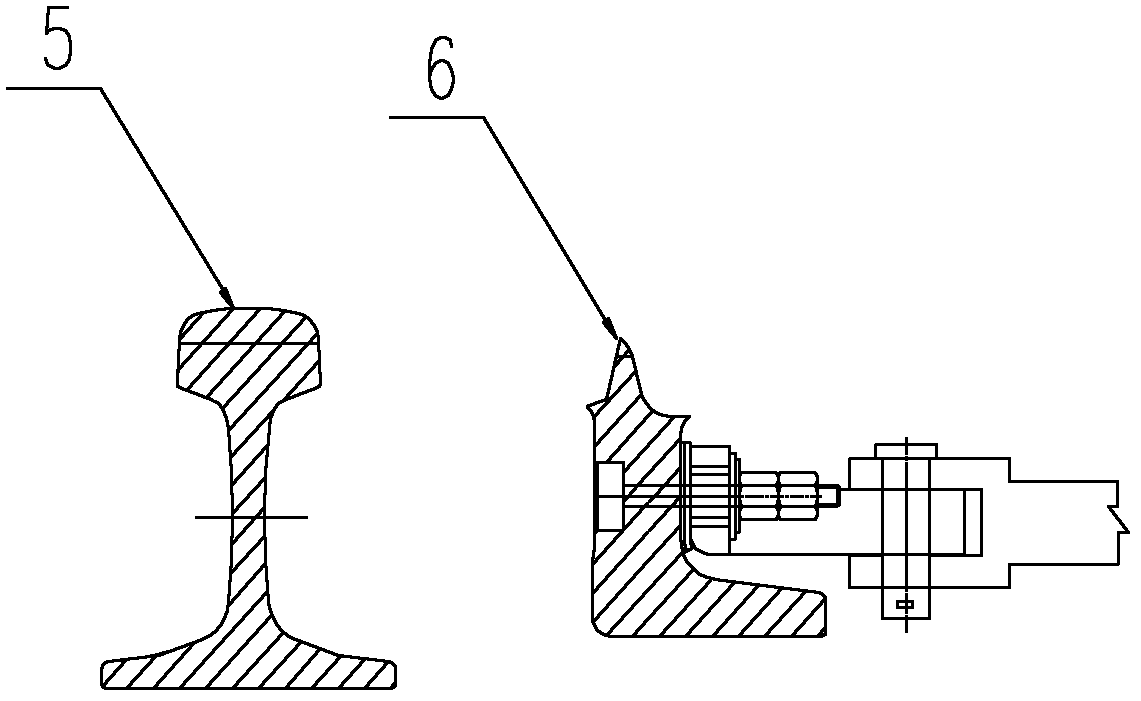

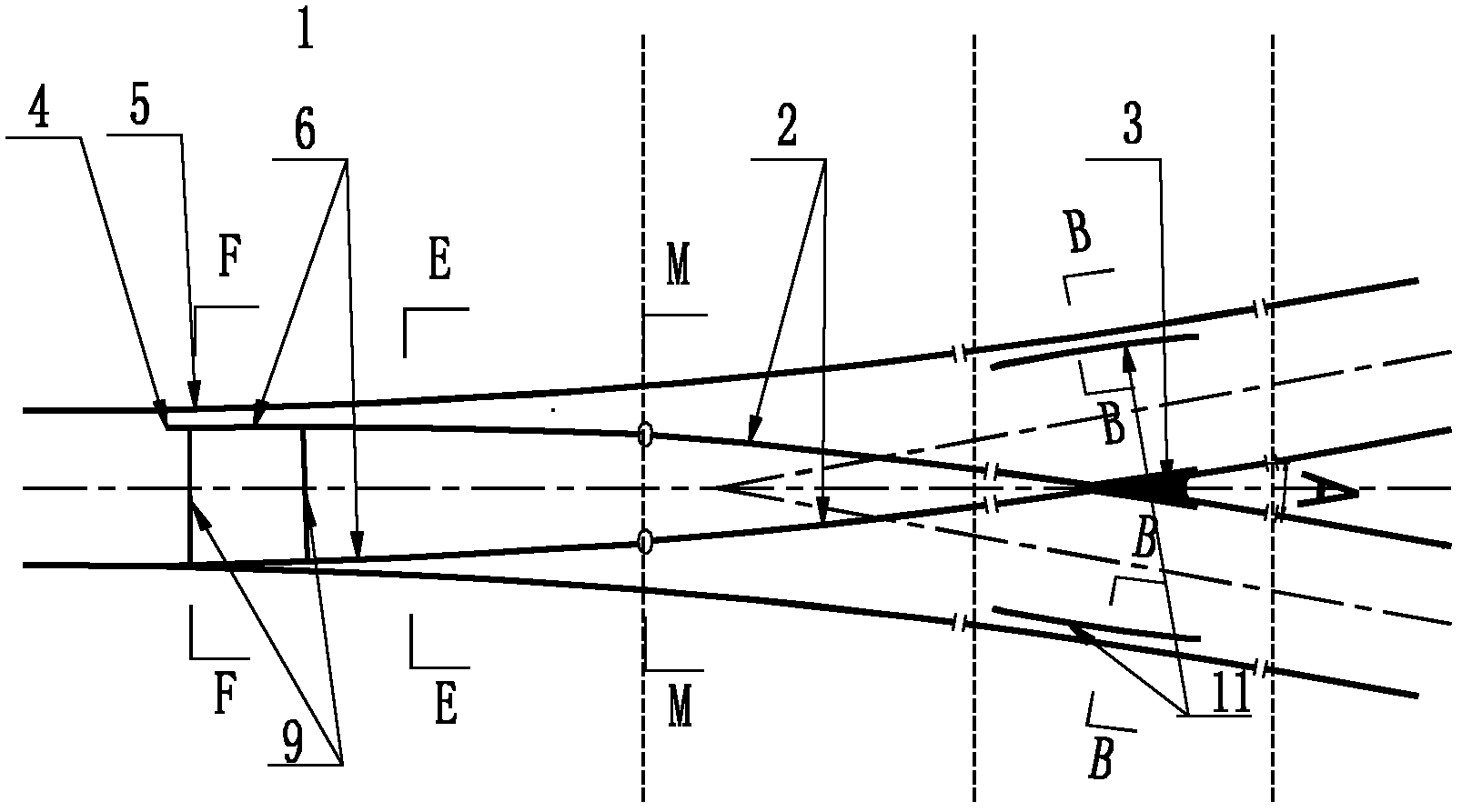

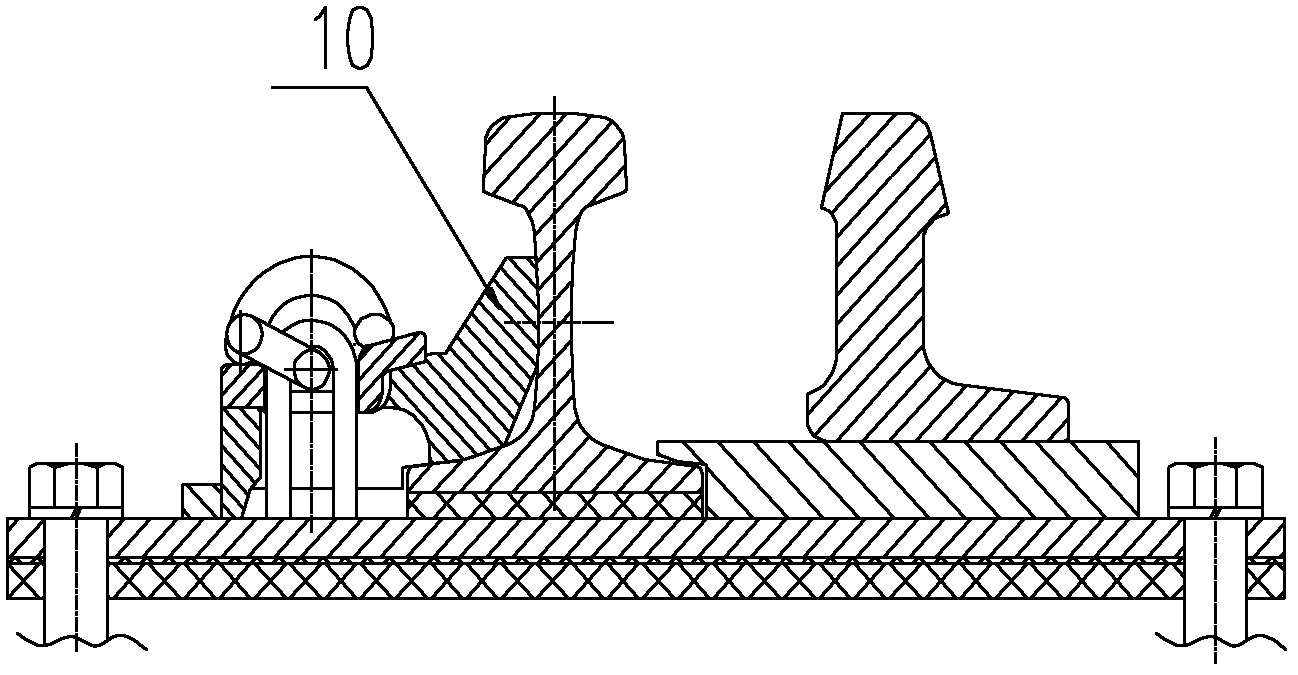

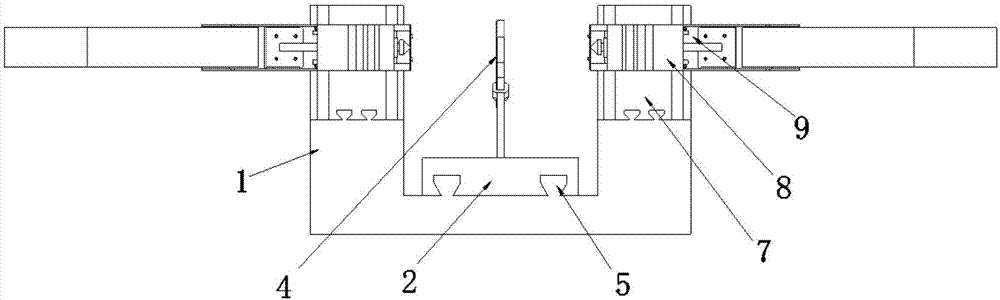

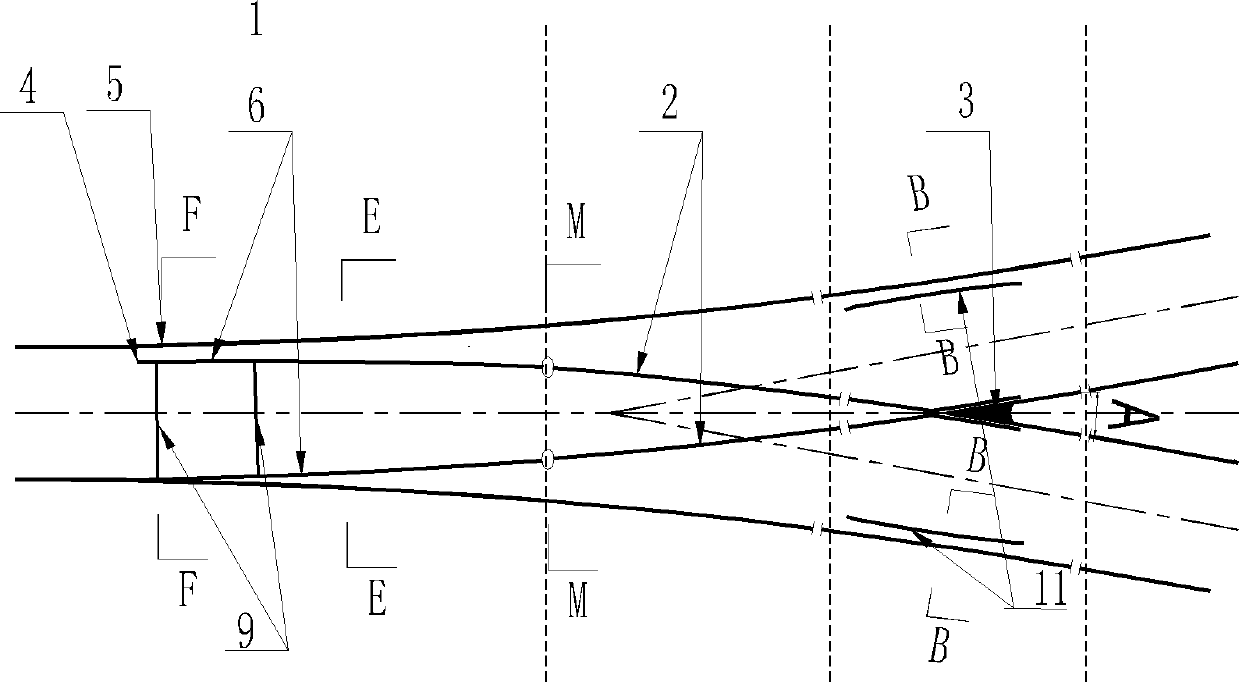

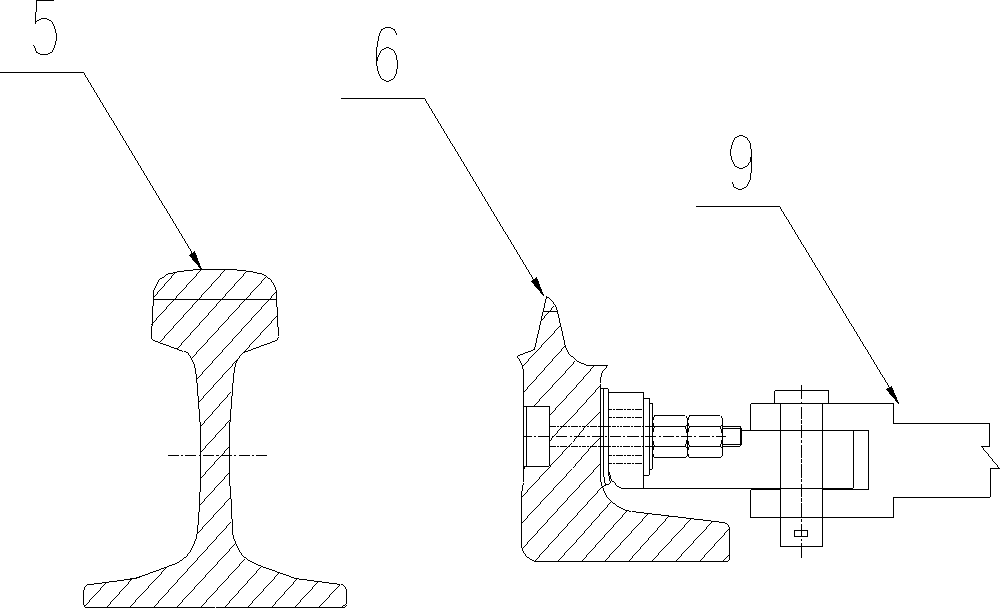

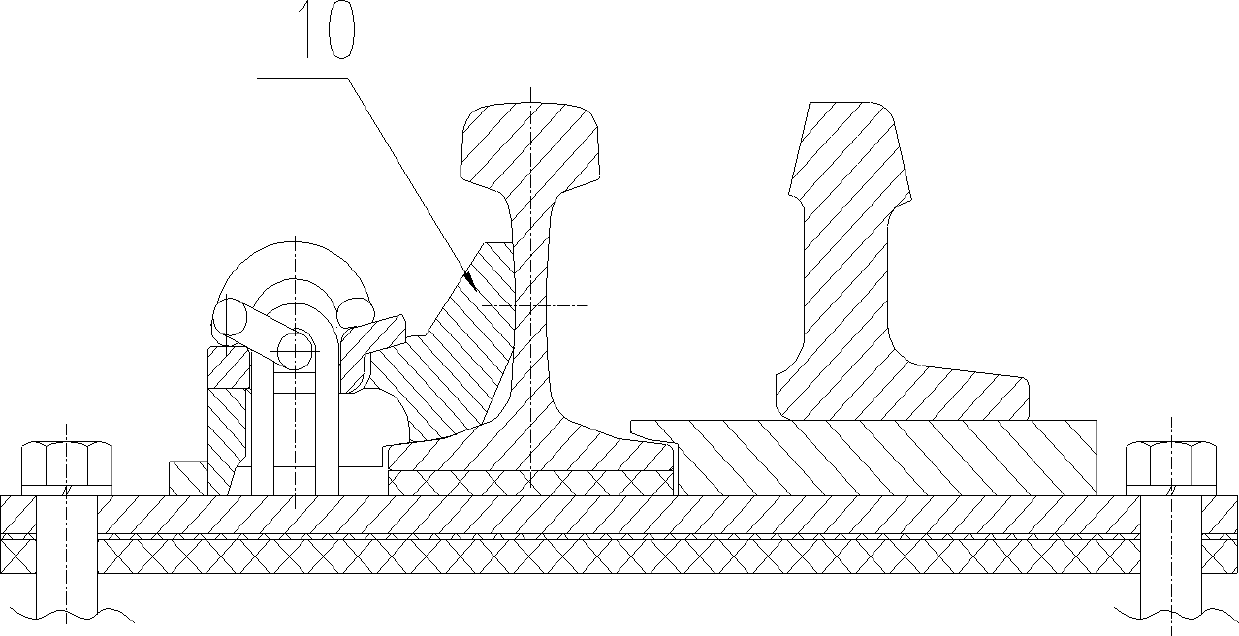

Line rail symmetric three-throw turnout in urban rail traffic engineering

The invention provides a symmetric turnout for line rails No.4 and No.5 in urban rail traffic engineering. The turnout is arranged on a parking line rail of an underground line in an urban rail engineering, the structure of the symmetric turnout comprises a group of railroad switches, a group of frogs and a connecting steel rail, wherein the railroad switches are connected with the frogs by virtue of the connecting steel rail so as to form a symmetric turnout provided with two side rails. The symmetric turnout provided by the invention has the beneficial effects that the turnout ensures a subway and a light rail vehicle to travel safely between a main line and a parking line, related technical standards and safety requirements of the urban rail engineering are met, and the advantages of safety, reliability and convenience in manufacturing, paving, construction and maintenance are realized. By applying the symmetric turnout provided by the invention, turnout investment can be saved, and length of an auxiliary line can be obviously shortened, thus investment of a building project is greatly saved, construction difficulty is reduced, and project risk is reduced.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

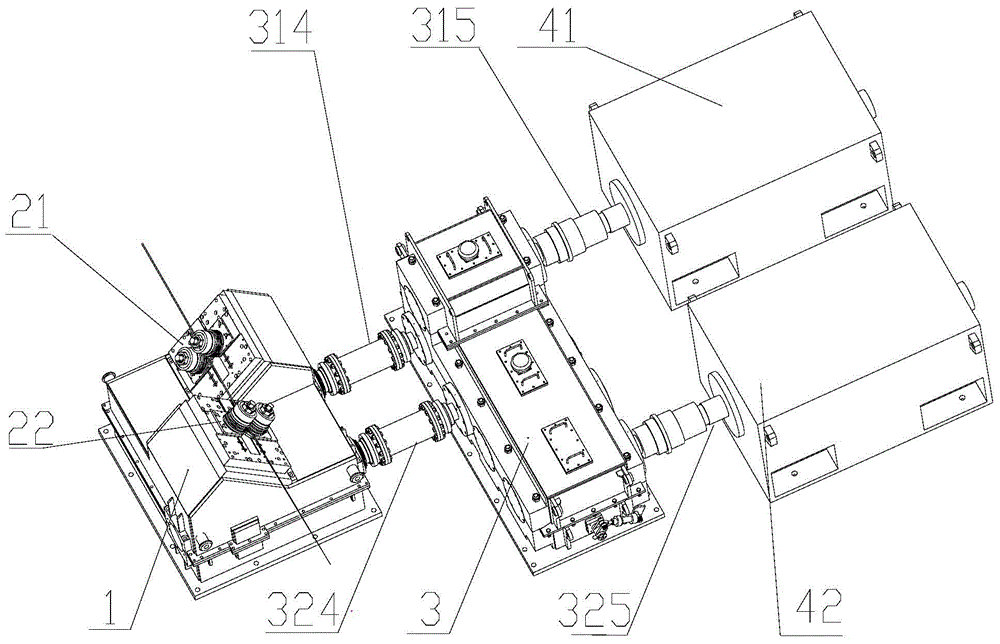

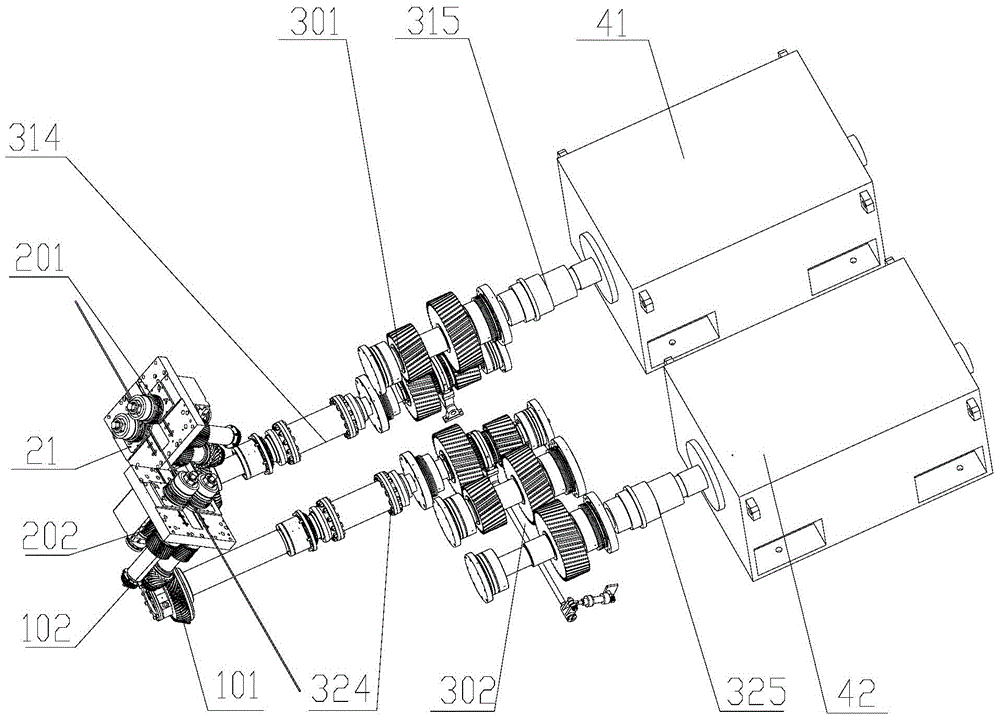

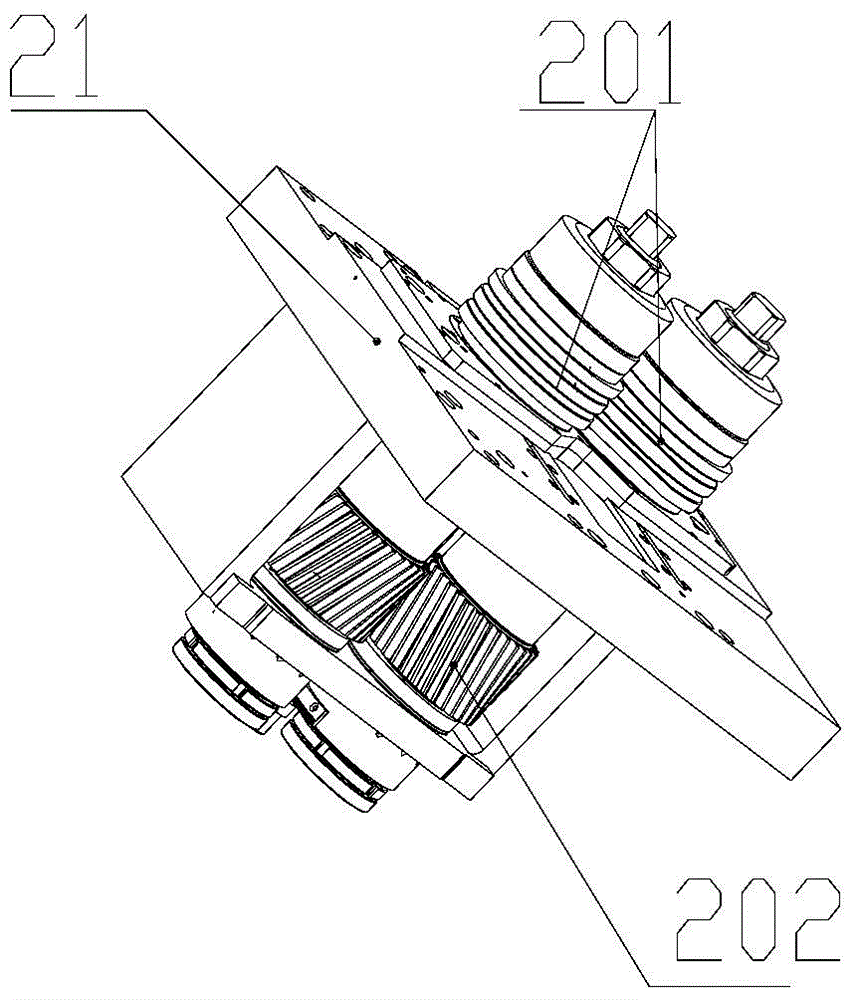

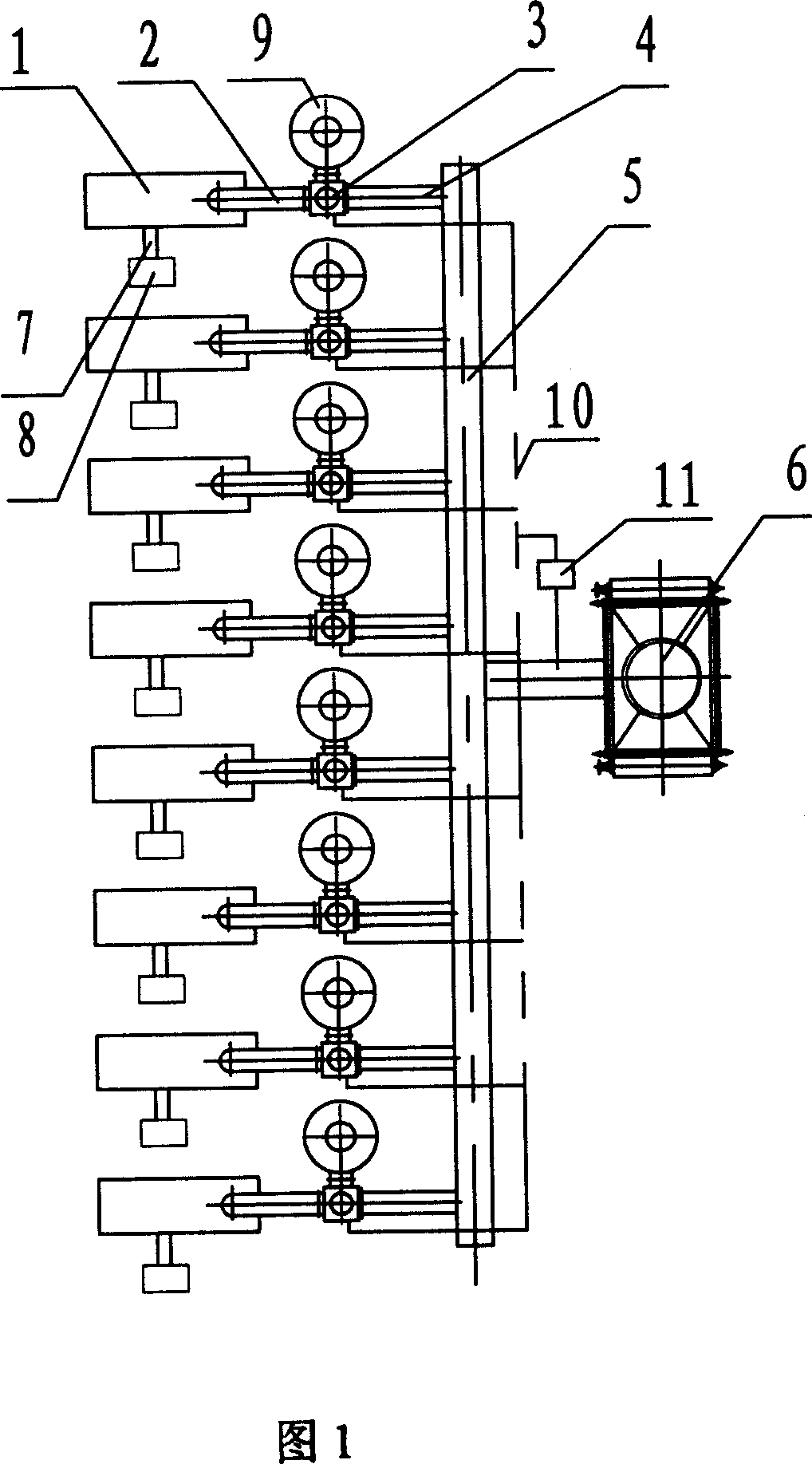

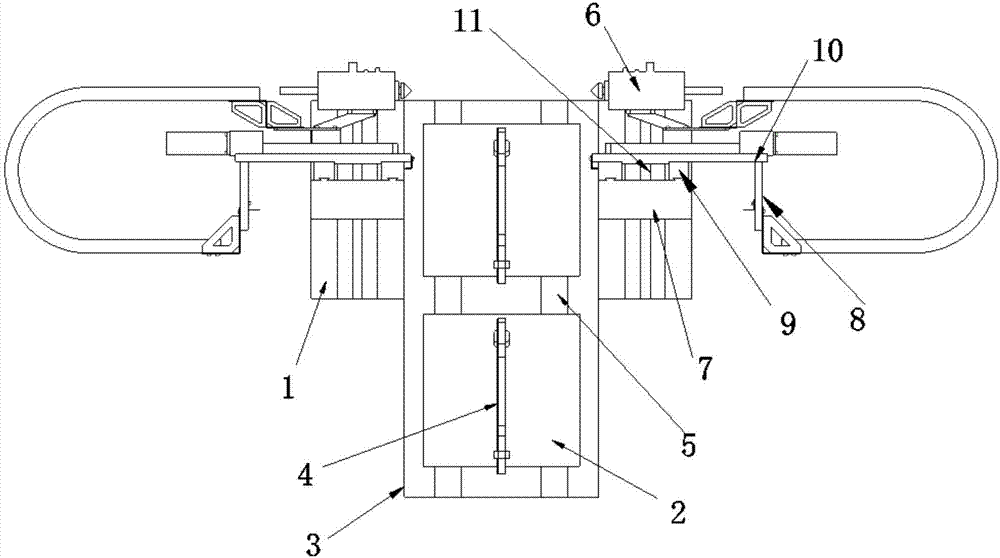

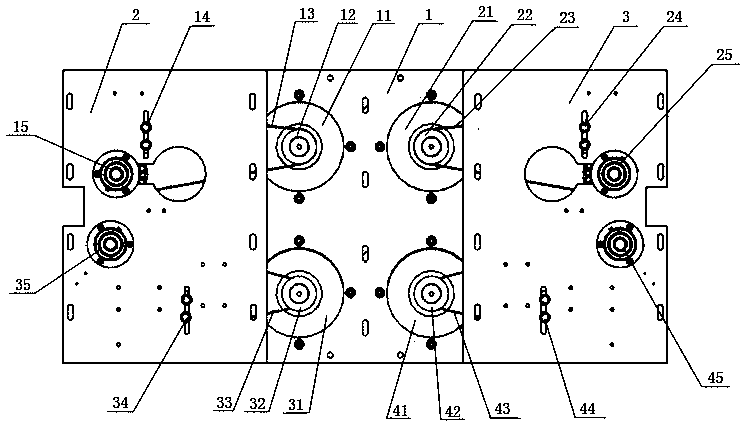

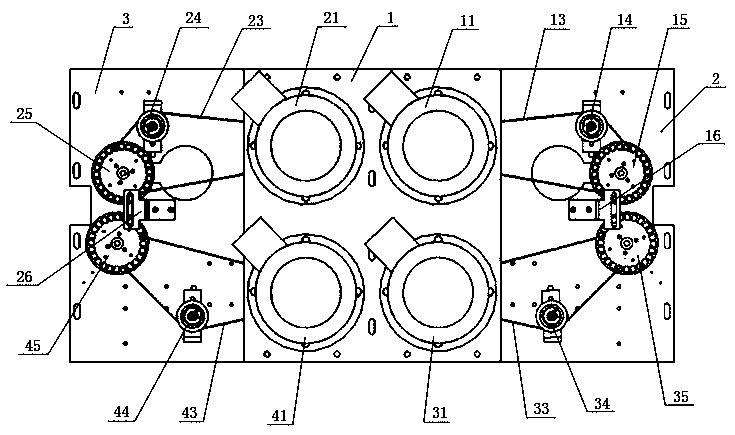

Bar mill

InactiveCN104785530AReduce spacingShorten the pathRolling mill drivesMetal rolling arrangementsDrive shaftTransmission delay

The invention discloses a bar mill which comprises a first transmission device, a second transmission device, a first power device and a second power device. A first driving shaft and a first driven shaft are provided with at least two first gear pairs different in transmission ratio, and the first transmission device is further provided with a first gearing shifting device used for switching different first gear pairs to be fixedly connected with the first driving shaft or the first driven shaft. A second driving shaft and a second driven shaft are provided with at least two second gear pairs different in transmission ratio, and the second transmission device is further provided with a second gearing shifting device used for switching different second gear pairs to be fixedly connected with the second driving shaft or the second driven shaft. The first power device is connected with a first roller box through the first transmission device, and the second power device is connected with a second roller box through the second transmission device. According to the bar mill, each roller box is driven by one independent power device with small power, power transmission is carried out through the gear shifting devices, cost is greatly reduced, and the investment and use maintenance cost is greatly reduced.

Owner:CHONGQING MAITUO TECH CO LTD

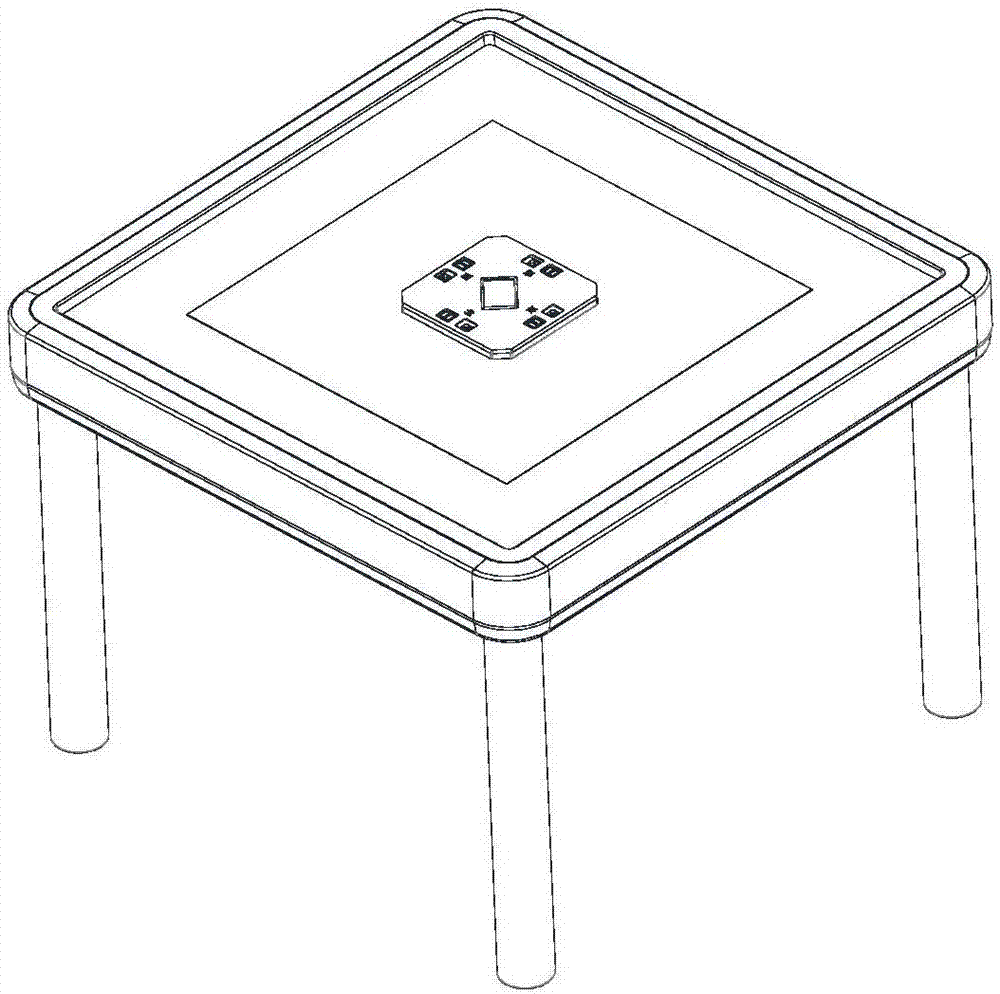

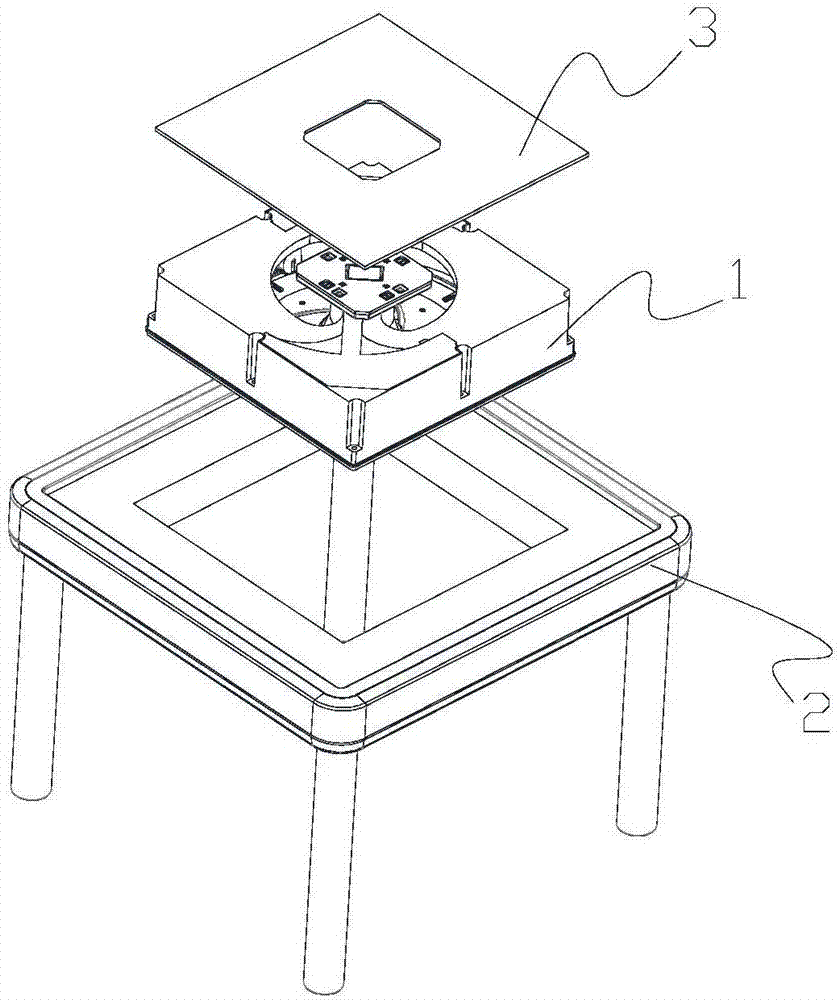

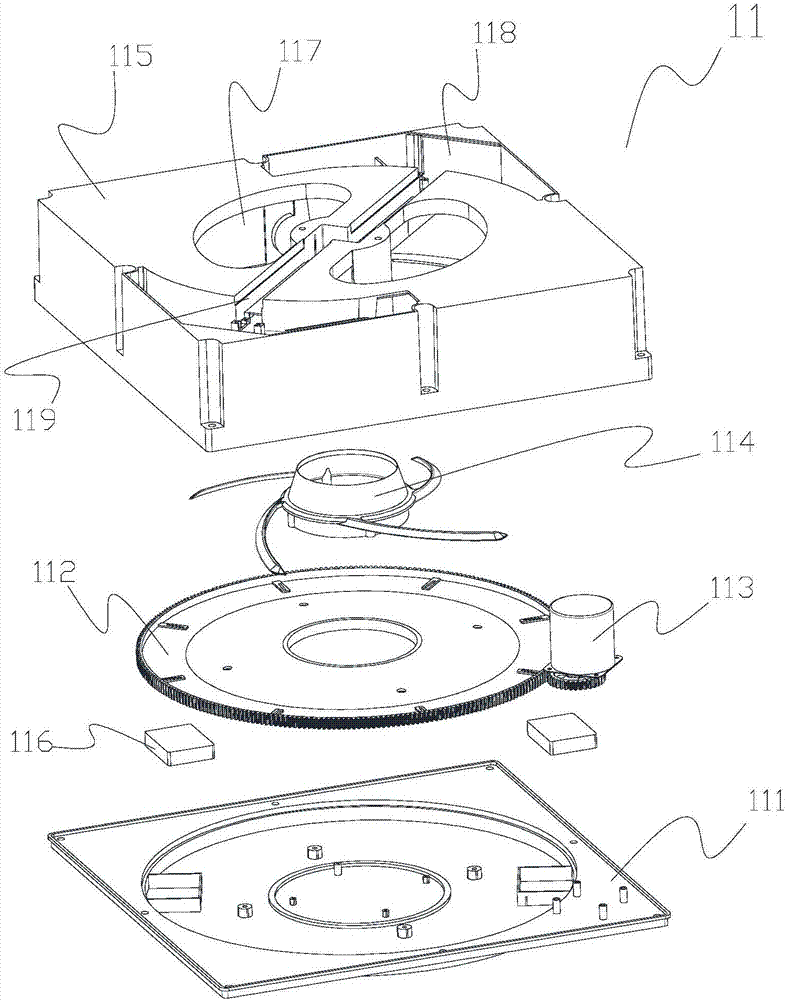

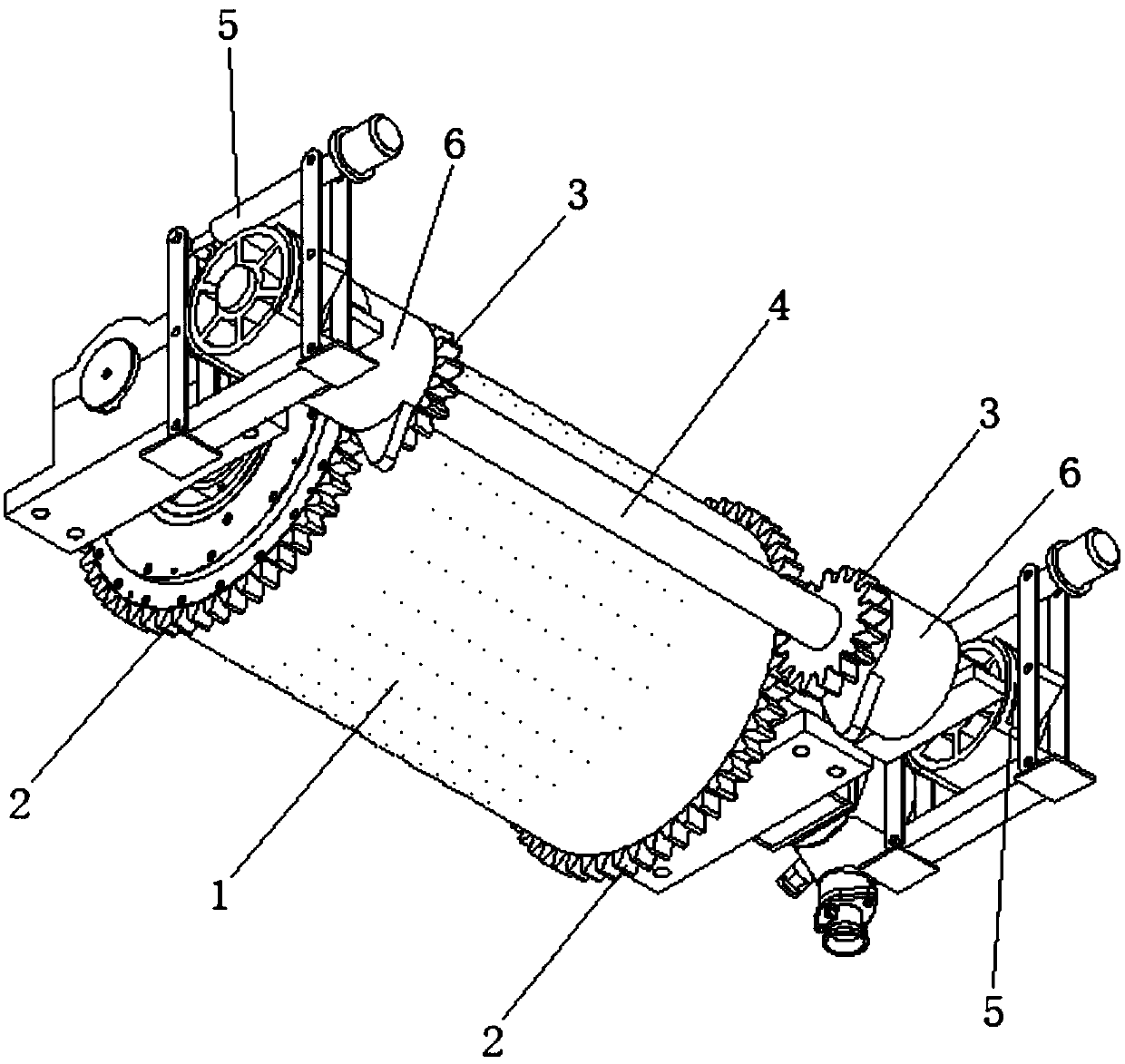

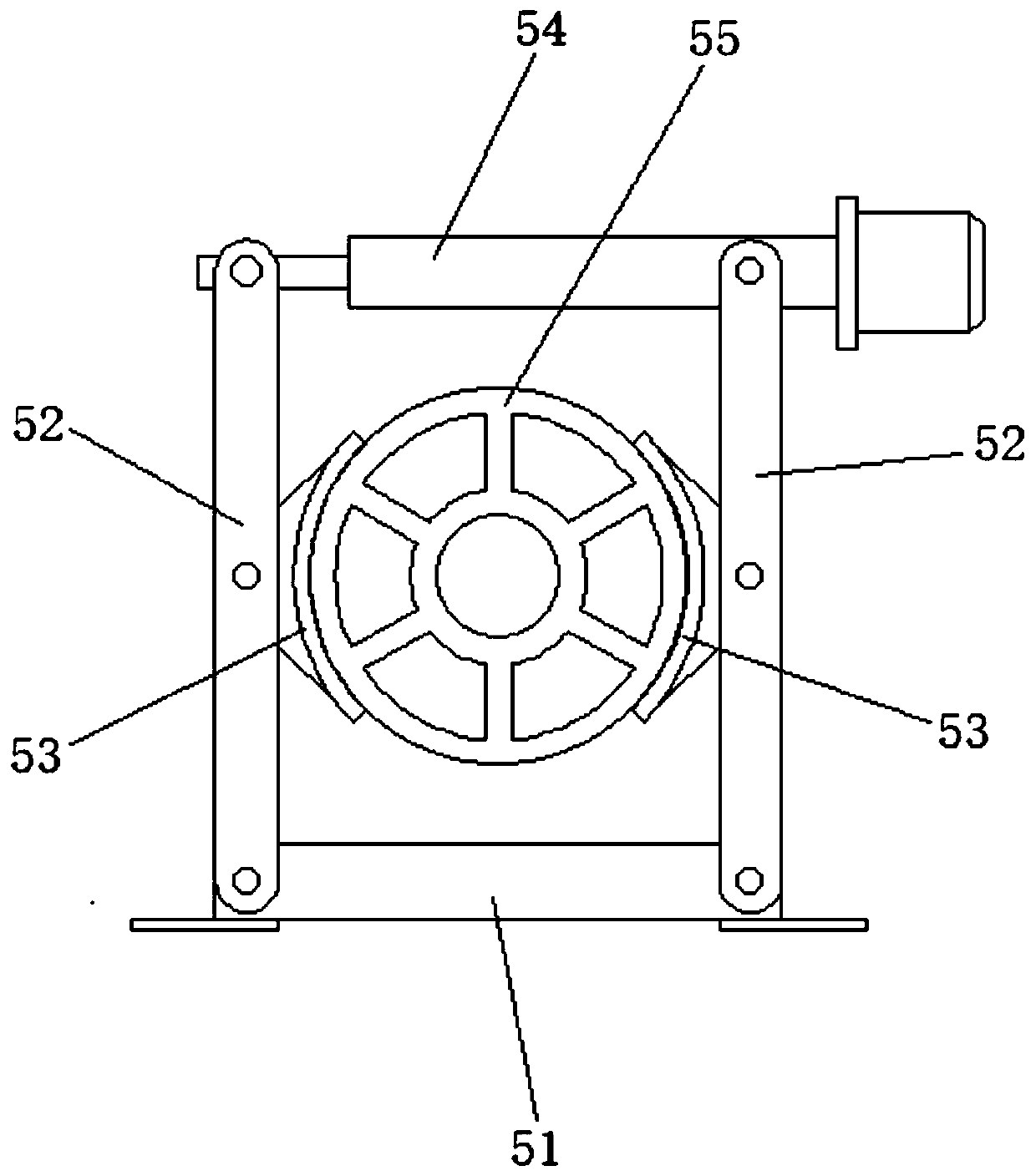

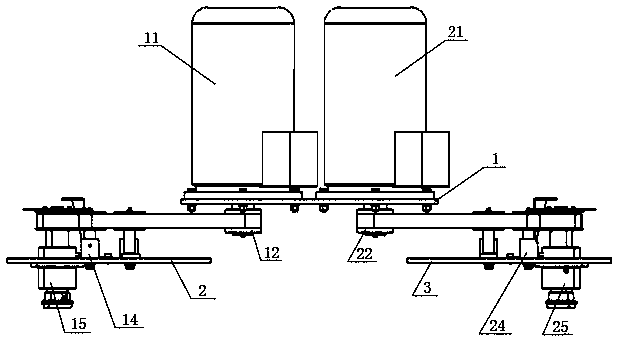

Automatic Mahjong Machine

ActiveCN107376336ASimple structureWill not affect licensing efficiencyIndoor gamesManufacturing cost reductionEngineering

The invention discloses an automatic Mahjong machine. The machine comprises a shuffling mechanism which is installed in a machine body and controlled by a control unit, a tile conveying mechanism, and a tile push-and-lift mechanism; the tile conveying mechanism consists of two sets of oppositely arranged conveying units located on two sides of the tile push-and-lift mechanism; when a tile push lifting platform of the tile push-and-lift mechanism descends, the tile push lifting platform can accept Mahjong tiles coming from conveying units on the two sides at the same time, when the tile push lifting platform rises, the Mahjong tiles on a platform are raised to the center of the table. According to the automatic Mahjong machine, a brand new Mahjong machine is designed by adopting the method of automatically launching mahjong tiles in the middle of the machine body for players to grab, the normal use by the players is satisfied only by one magnetic absorption Mahjong tile, the Mahjong host structure is simplified, the spare parts and occupied space are greatly reduced, the Mahjong machine is lighter, the manufacturing cost can be reduced greatly; additionally the possibility of cheating is completely eliminated, the tabletop of the players is also neat, clean and fresh, and the adjustment of the number of mahjong tiles by different playing methods or even the number of players can be accommodated. The automatic Mahjong machine is an industry subversive innovation, the structure design is simple and reasonable, the Mahjong machine has the advantage of industrialization, low cost, high efficiency, and quantity production, and the market prospect is broad.

Owner:吴凡

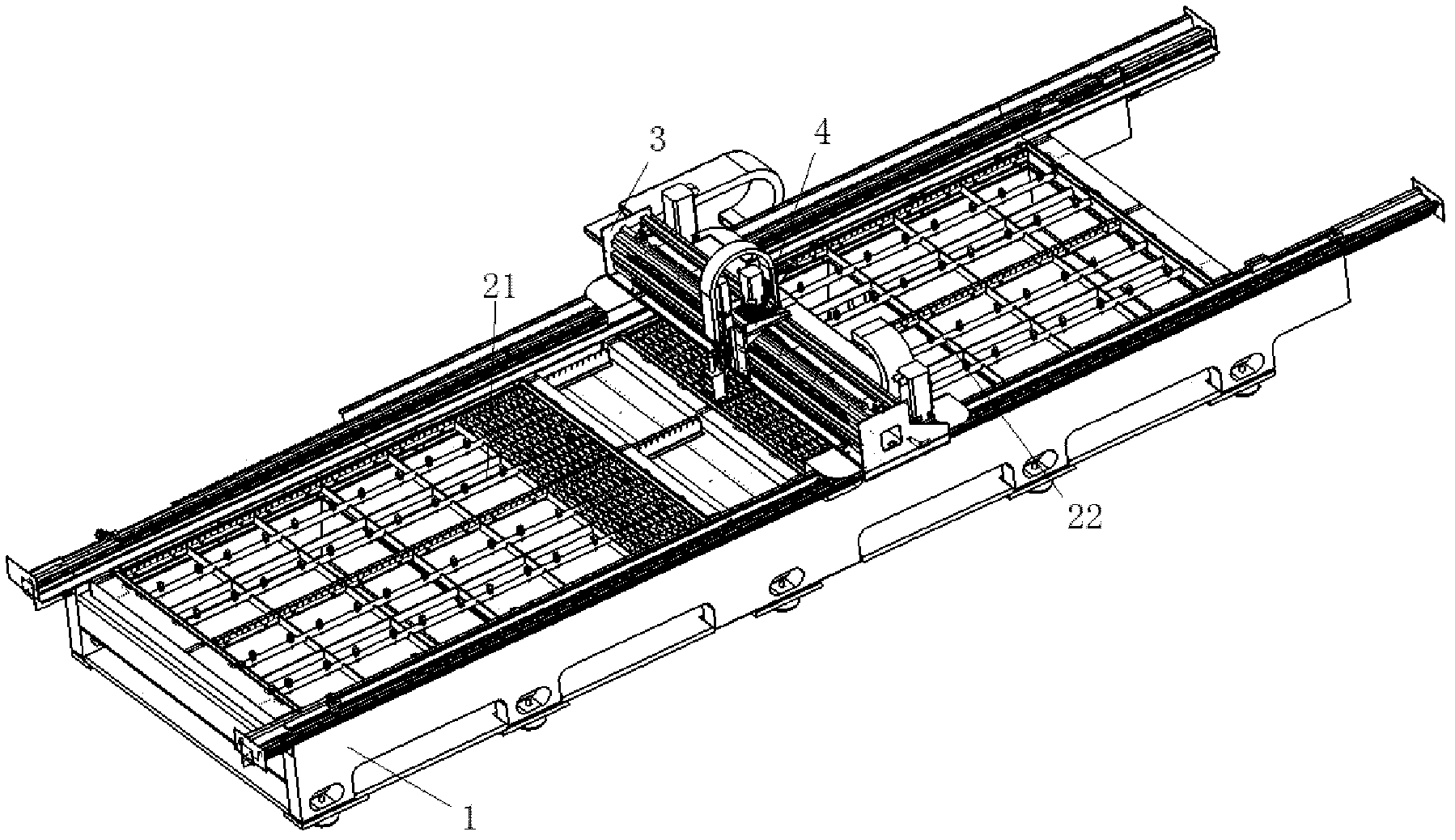

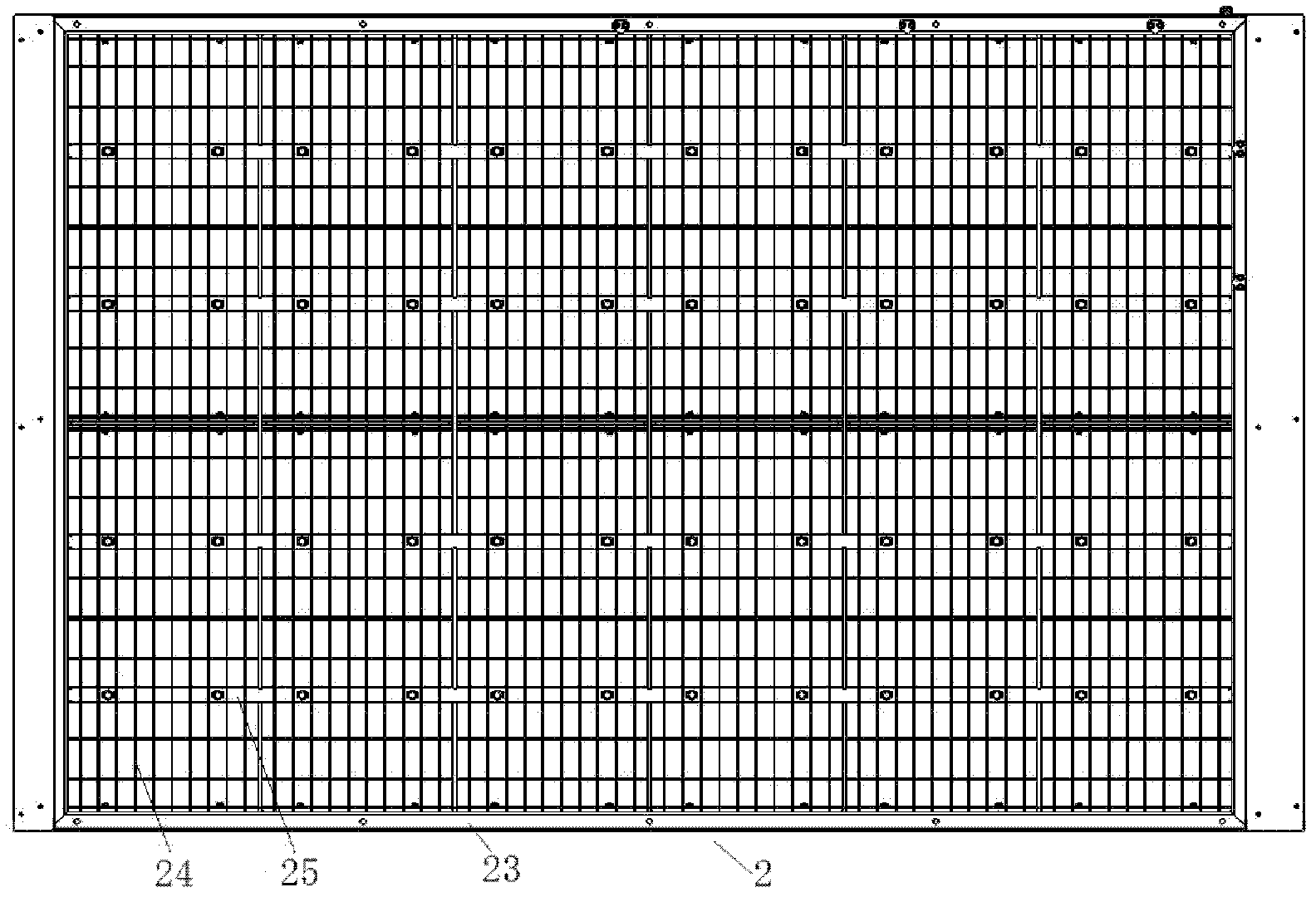

Laser cutting machine

InactiveCN102398115AReduce the number of partsReduced assembly effortLaser beam welding apparatusLaser cuttingMachine tool

The invention discloses a laser cutting machine. The laser cutting machine comprises a lathe bed, an operating platform, a cross beam and a Z shaft, wherein a guide rail is arranged on the lathe bed; the operating platform is arranged on the lathe bed; the cross beam is arranged on the guide rail in a sliding way; the Z shaft is arranged on the cross beam in the sliding way; the operating platform comprises a platform body, a supporting plate strip for supporting workpieces and a plurality of ball supporting oscillating bars for supporting the workpieces and conveying the workpieces; the supporting plate strip is welded on the platform body; the ball supporting oscillating bars are arranged in the slot of the supporting plate strip; the lathe bed is divided into an A operating region and a B operating region; and the A operating region and the B operating region are provided with an operating platform respectively. By the machine, the amount of parts of the conventional exchange operating platform laser cutting machine is reduced; the production period of a machine tool is shortened; the assembling and debugging difficulties of the machine tool are reduced; the fault points of the machine tool are reduced, and the reliability of the machine tool is improved; the amount of reserve parts and spare parts is reduced; and the manufacturing cost and the maintenance cost of the machine tool are substantially reduced.

Owner:SHANGHAI ACL CNC MACHINE TOOL

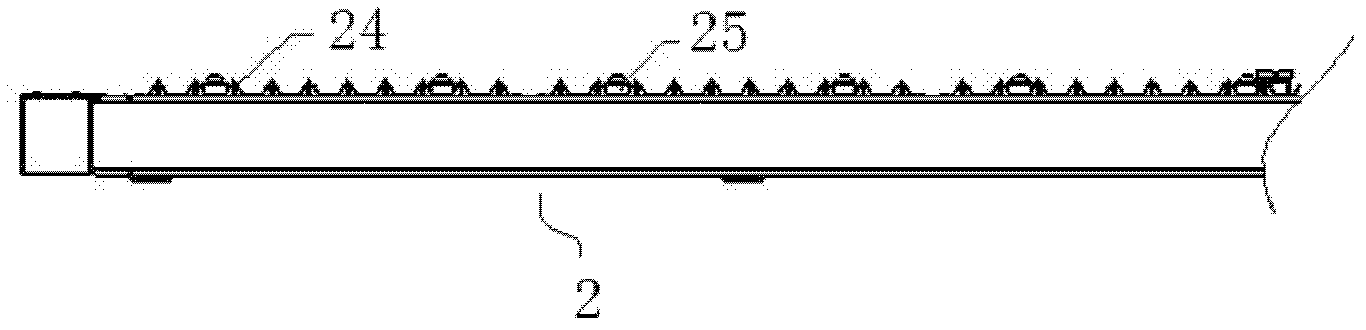

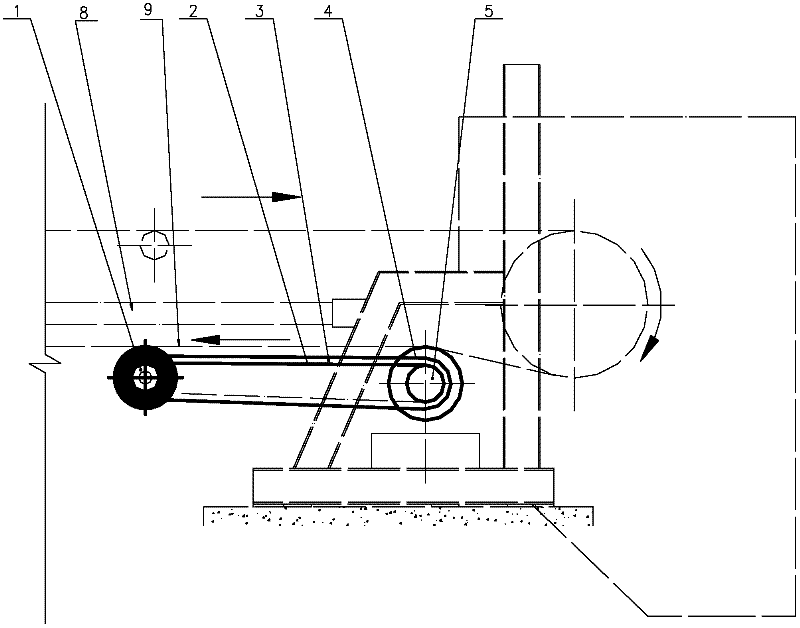

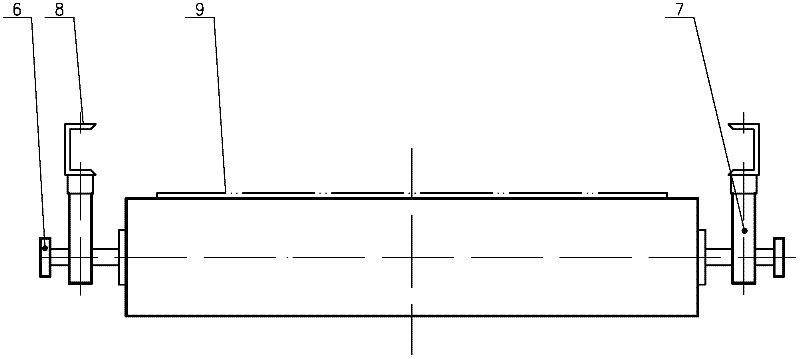

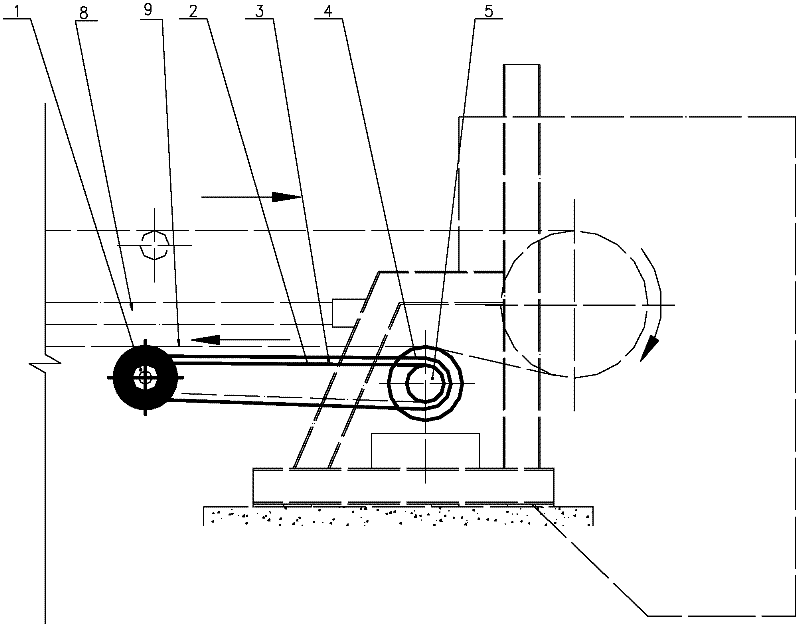

Unpowered rolling brush cleaning device

The invention relates to an unpowered rolling brush cleaning device, which belongs to cleaning equipment of a belt conveyor for bulk materials. The unpowered rolling brush cleaning device is characterized in that a rolling brush is parallel to a turnabout drum of the belt conveyor, a drive mechanism is arranged between a rolling brush extending shaft and a turnabout drum extending shaft, and the turnabout drum drives the rolling brush to rotate through the drive mechanism. The device is simple in structure and is convenient to install, energy consumption is avoided, adhesive tapes are not abraded, equipment and the belt conveyor synchronously run, and manual control is not required; extra power supply and control are not required to be provided, so that the project investment on electric and automatic control is saved; and operation in normal production is simplified, the maintenance workload of daily equipment is reduced, and the unpowered rolling brush cleaning device can be widely applied to the ordinary belt conveyor for bulk material transmission.

Owner:WISDRI ENG & RES INC LTD

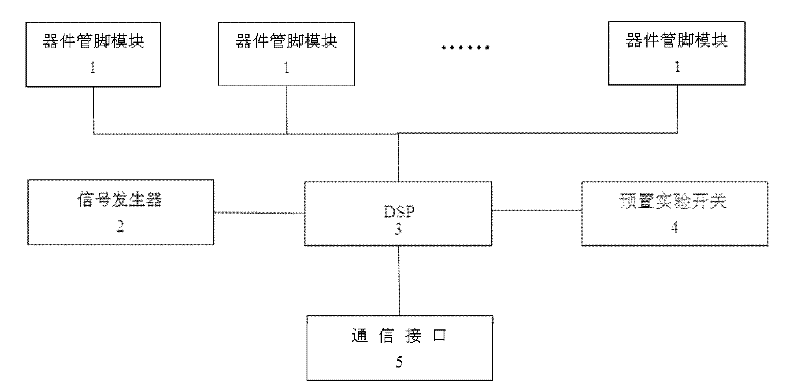

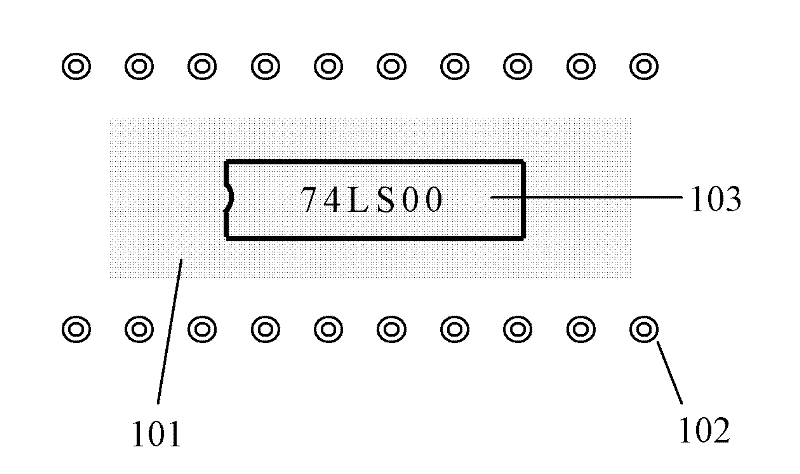

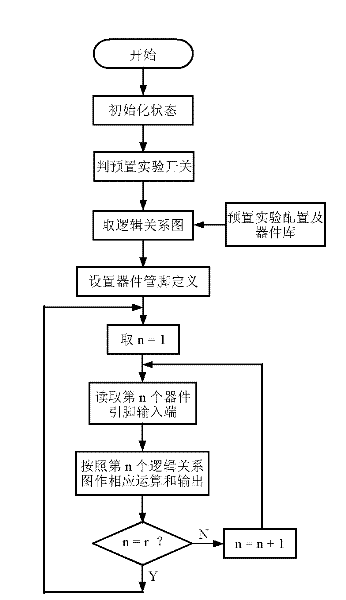

Digital logic device preset type digital circuit experiment device

InactiveCN102542886AReduce restrictionsFlexible changeEducational modelsCommunication interfaceComputer module

The invention relates to a digital logic device preset type digital circuit experiment device, comprising a DSP (Digital Signal Processor), a signal generator, device pin modules, a preset experiment switch and a communication interface, wherein the DSP is connected with the signal generator, the device pin modules, the preset experiment switch and the communication interface respectively. The devices used in each experiment are adopted to establish a logical relation database which is stored as preset experiment configuration, and an experiment number is selected according to the preset experiment; when the device is started, according to the state of the preset experiment switch, the experiment number is confirmed by the DSP; when the logical relation database corresponding to the experiment number, a logical relation graph is read, and the DSP configurates the state definition of the corresponding device pin module according to the logical relation graph; and then, the DSP conducts corresponding logical operation and output according to the preset logical relation of each device pin module. Compared with the prior art, the digital logic device preset type digital circuit experiment device has the advantages that the teaching content is broadened, the teaching cost is reduced, the teaching efficiency is enhanced, and the like.

Owner:SHANGHAI UNIV OF ENG SCI

Line rail symmetric turnout No 4.5 in urban rail transit engineering

The invention provides a line symmetric turnout No. 4.5 in urban rail transit engineering, and the turnout is arrange on parking line rail in underground lines in the urban rail transit engineering. The structure of the symmetric turnout comprises a group of railroad switches, a group of frogs and connecting steel rails, wherein the group of railroad switches is connected with the group of frogs through the connecting steel rails so as to form a symmetric turnout comprising two side rails. The invention has the beneficial effects that the turnout can satisfy the safe running of subway and light rail vehicles between a main line and a stop line, meets relative technical standards and safety requirements of the urban rail transit engineering, highlights the advantages of safety, reliability, convenience in manufacture, laying, construction maintenance and protection and the like. By the adoption of the invention, turnout investment can be reduced, and the length of auxiliary lines can be shortened greatly, and thus civil work investment can be reduced greatly, construction difficulty can be lowered, and construction risk can be decreased.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

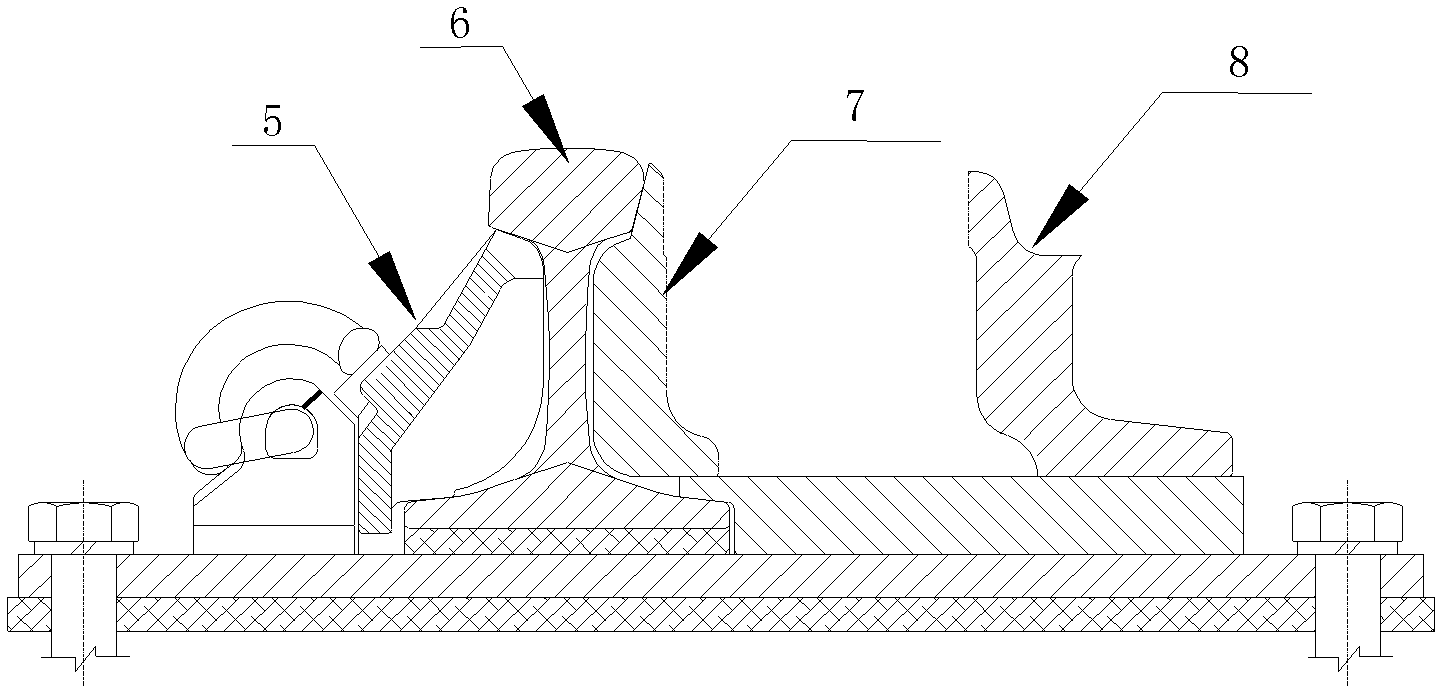

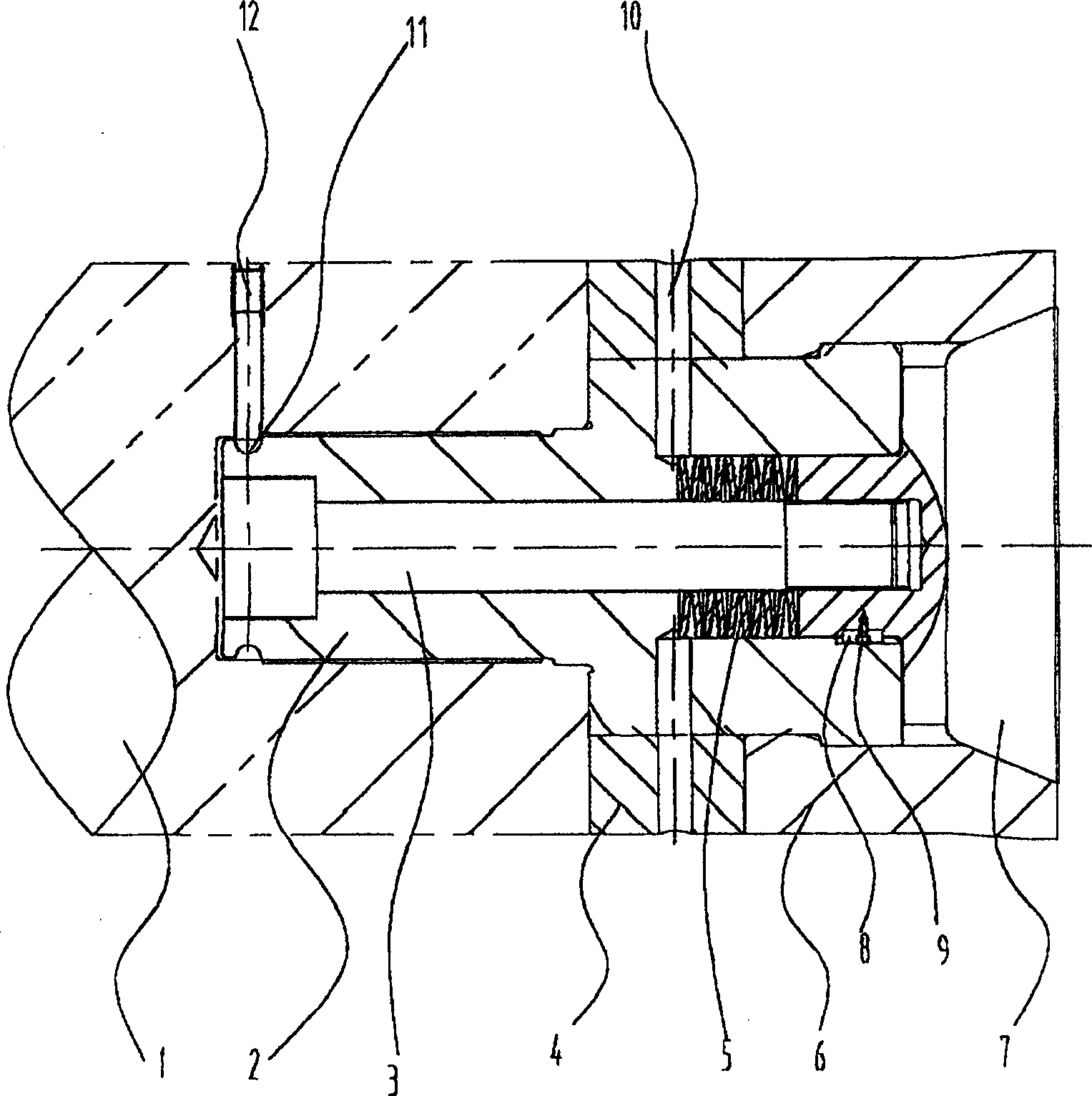

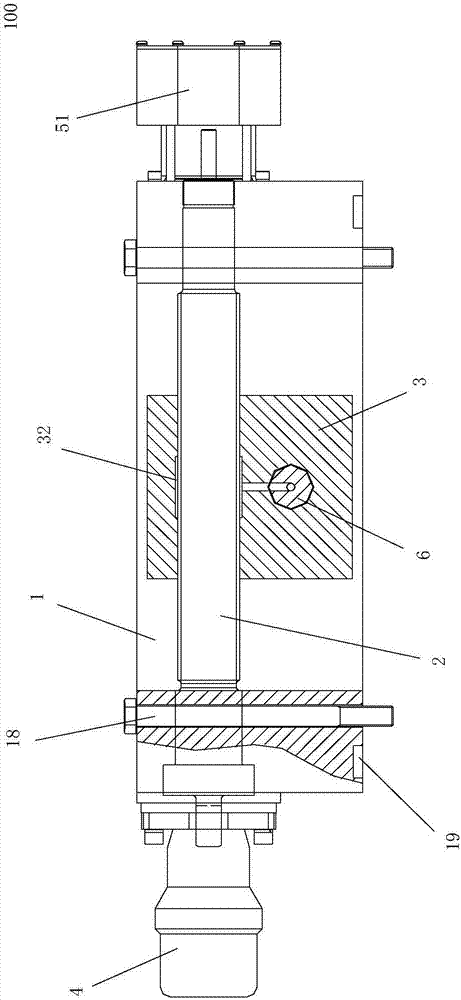

Expanding ring type fixed extrusion pad for aluminium extrusion machine

InactiveCN1293956CImprove reliabilityReduced no-extrusion cycle timeRams/plungersEngineeringAluminium extrusion

A fixed expanding-ring pressing block for the squeezer of aluminium part is composed of main body with spring in its central hole, conic pad, screw bolt for connecting said conic pad with main body, expanding ring with front and back conic surface for maching with said conic pad, pressing rod, ring pad between pressing rod and expanding ring, etc.

Owner:TAIYUAN HEAVY IND

Connecting apparatus for catenary and aluminum guide stem

ActiveCN101274728AImprove securityEliminate the phenomenon of falling off the poleTravelling cranesLoad-engaging elementsSocial benefitsSelf locking

The invention discloses a connection device of a suspension chain and an aluminum guide rod. The device is characterized by consisting of a hooked hanger, a fixing hoop of the aluminum guide rod and a safety self-locking pin, wherein, the fixing hoop of the aluminum guide rod is arranged at the periphery of the hooked hanger and installed in the hoop installation pin hole of the hooked hanger by a hoop connection pin; the safety self-locking pin is connected with the fixing hoop of the aluminum guide rod by a self-locking fixing sleeve and matched with a locking column arranged on the hooked hanger. The connection device of the invention has the advantages of simple manufacturing, convenient operation, high loading and unloading efficiency, safe and reliable connection and extreme low fault rate of operation equipment and is maintenance-free and can correctly and intuitively judge and confirm the firmness degree of the connection between a fixture and the aluminum guide rod so as to effectively avoid and control the occurrence of the falling of the aluminum guide rod; meanwhile, the connection device also has greater value of popularization and application as well as invisible, potential and latent security benefits and social benefits.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

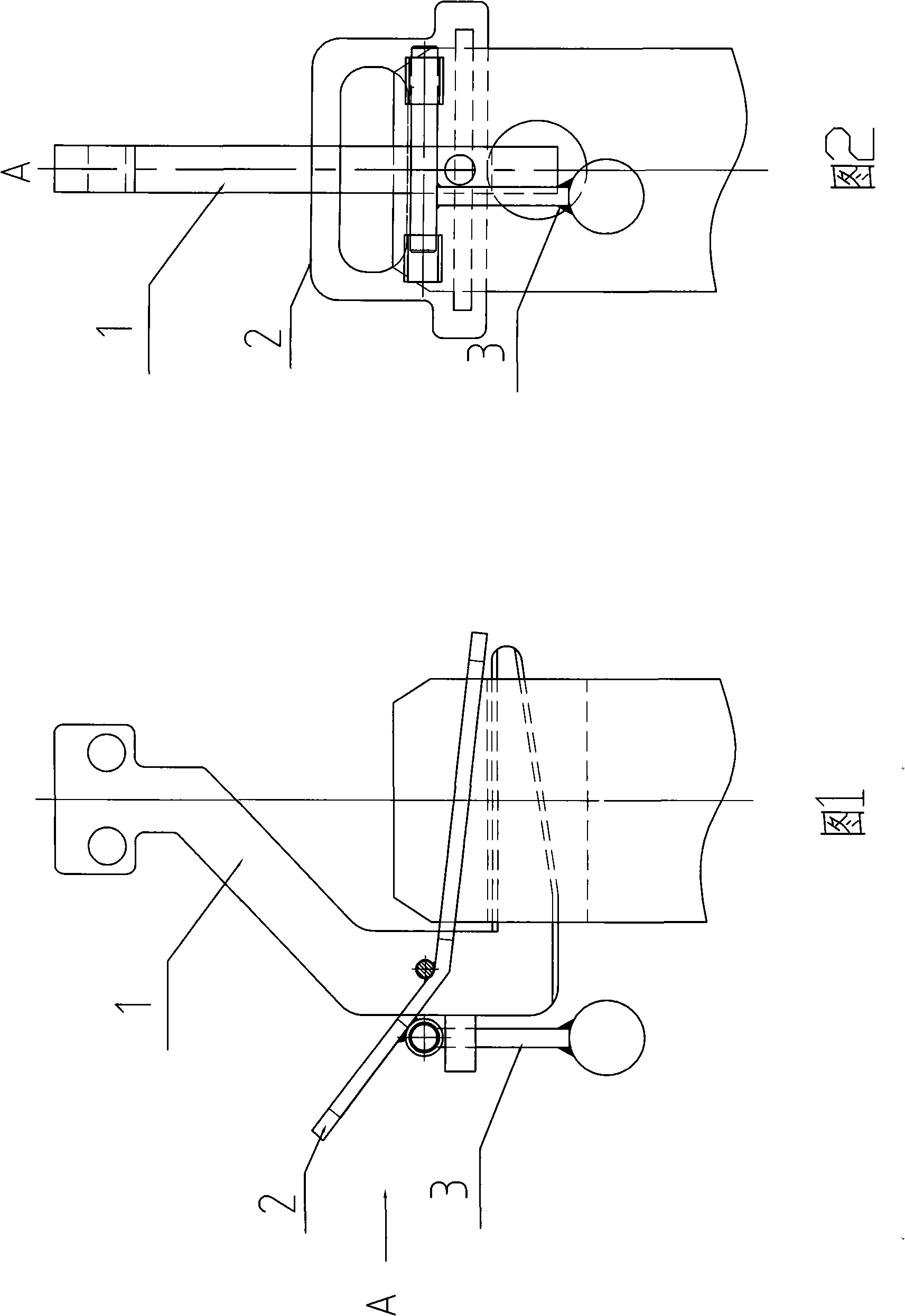

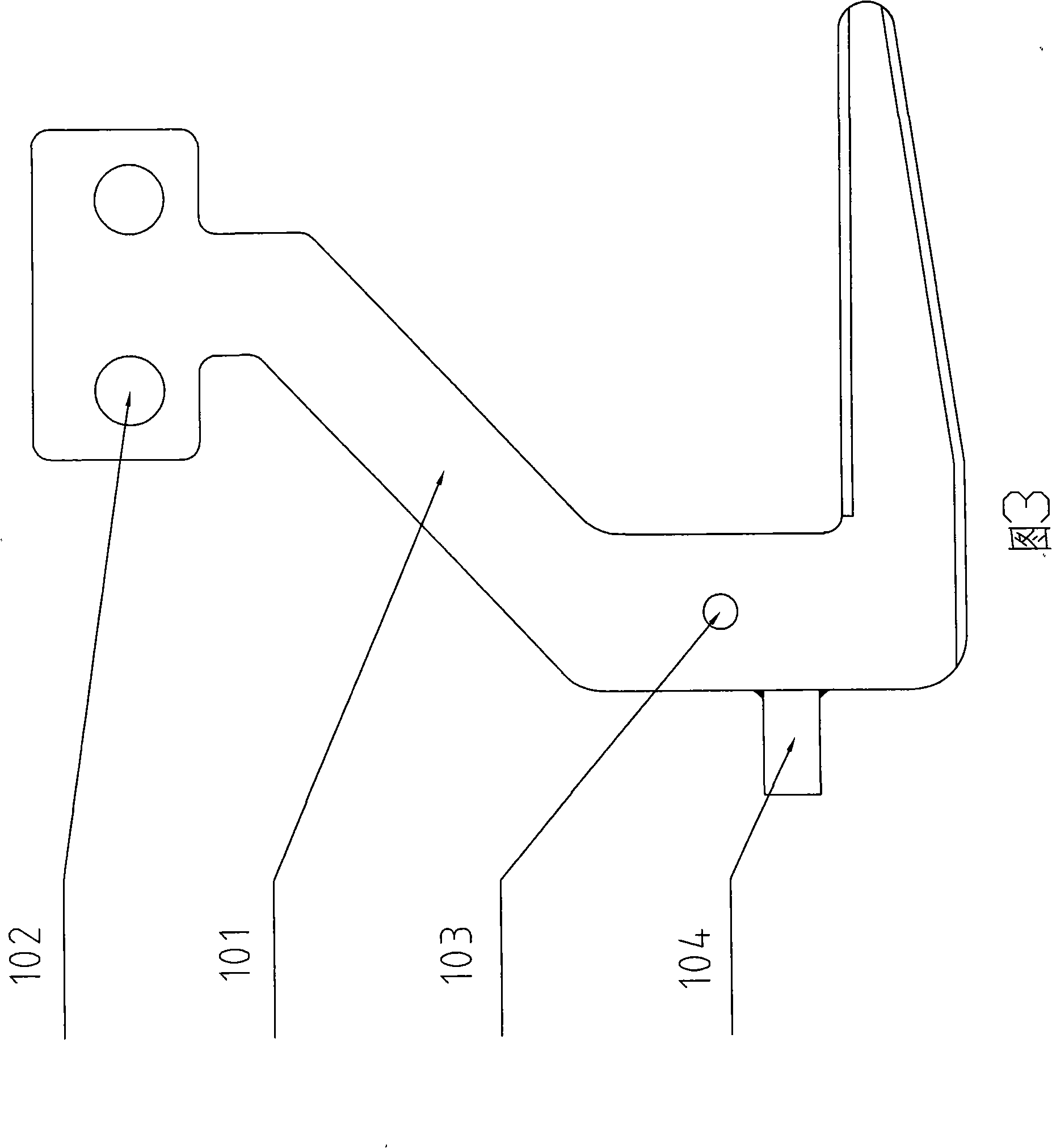

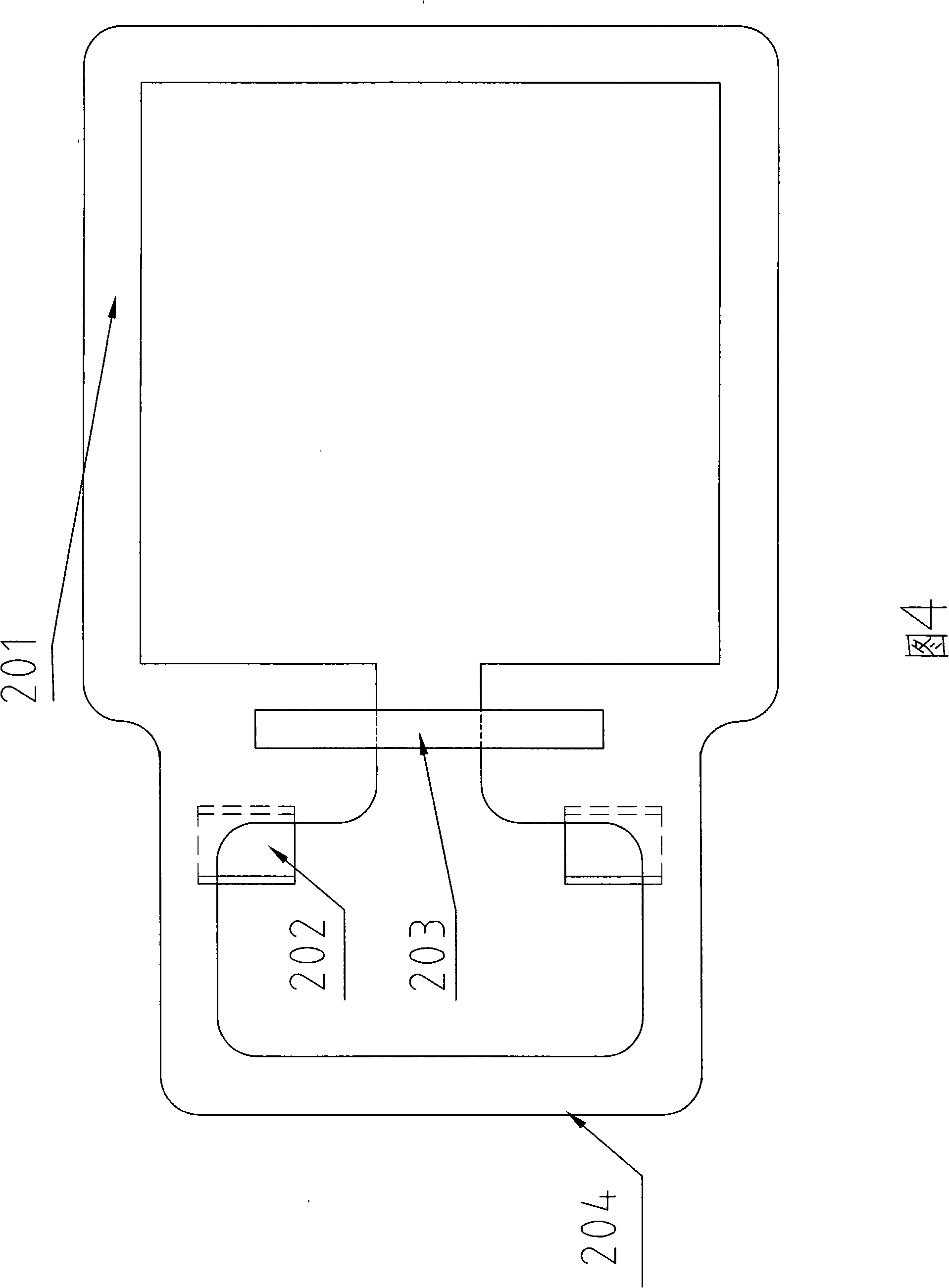

Steam generating iron

InactiveCN101424038AEasy to operateAchieve dry ironingHand ironTextiles and paperTorque transmissionEngineering

The invention relates to a steam iron for realizing functional conversion through a single button. The steam iron comprises a shell, a water tank and a soleplate steam chamber; the steam iron also comprises a pump body, a pump rod, an adjusting rod and a steam nozzle, wherein the pump body is formed on the upper part of the water tank; two grooves are arranged on the outer edge in the circumferential direction; a water inlet pipe, a first water outlet pipe and a second water outlet pipe are arranged on the bottom wall; the pump rod is positioned on the upper part of the pump body; the upper end of the pump rod is fixedly connected with a control button; the lower end of the pump rod and a guide rod can move relatively in axial direction and can be connected in torque transmission; the lower end of the pump rod is fixed with a pump bat which slides in the cylindrical wall of the pump body; the upper end of the pump rod is provided with a convex shoulder which is sunken into two grooves respectively or is laid on the outer edge of an open mouth of the upper end; the adjusting rod comprises a guide rod, a selective sealing part and a steam shaft from top to bottom; the lower end of the steam shaft is provided with a water drop groove; the steam nozzle is fixed between the bottom of the water tank and the soleplate steam chamber; the diameter of an inner hole is the same as that of the steam shaft; and one part of the upper section of the inner hole in circumferential direction is provided with a cutting groove. The steam iron can realize functional conversion through a single button.

Owner:GOODWAY ELECTRICAL CO LTD

Hot conflux main pipe residual heat reclamation and utilization system using gas medium as hot source

ActiveCN101078534ACompact structureSmall footprintInternal combustion piston enginesExhaust apparatusWaste heat recovery unitSmall footprint

The invention relates to a thermal confluence bus-piping waste heat recovery and utilization system, whose thermal source is air medium. It is characterized in that at least two thermal air sources are connected with the channel of thermal air source respectively; each channel of thermal air source is connected one way of three-way wind door; another channel of three-way wind door is connected with the bus pipe of thermal confluence by connecting pipes; the bus pipe of thermal confluence is connected with the waste heat recovery device; the third way of three-way wind door is connected with by-pass channel; the protection device of generating device of thermal air source can be assigned on the channel of thermal air channel directly; the control equipment of thermal confluence is connected with the generating device of thermal air source, the three-way wind door and controlling and measuring component on the waste heat recovery and utilization device by control circuit. The merit of invention is that multiple thermal air sources are combined to enter into a waste heat recovery and utilization device so that waste recovery is realized easily and it is provided with high recovery efficiency, compact structure, small occupied area, easy assignment, easy running and maintenance and few spare parts.

Owner:SHANGHAI EAGLE NEW TECH ENG

Laser cutting machine

InactiveCN107030394AReduce manufacturing costShorten assembly timeLaser beam welding apparatusLaser cuttingMachine tool

The invention discloses a laser cutting machine which comprises a pedestal, a material feeding platform and a moving platform, wherein a workpiece to be machined is arranged on the material feeding platform; the bottom of the material feeding platform is connected with the moving platform through material feeding platform guide rails in a sliding manner; the moving platform is fixedly arranged on the pedestal; laser cutting systems are separately arranged on two sides of the pedestal; and the laser cutting systems comprise laser devices, X shafts, Y shafts and Z shafts. The laser cutting machine is simple in structural principle; the shortcomings of an original common single-laser-head machine tool are overcome; and a double-laser-head synchronous cutting system and a double-laser-head asynchronous cutting system are integrated. By the use of the characteristics of the laser cutting machine, the original procedures of overturning, clamping and the like are canceled; and meanwhile, by the use of novel material feeding and discharging driving supporting batten devices, a lifting table, a working table and a hydraulic device in the conventional machine are eliminated.

Owner:SHANGHAI EMPOWER AUTOMATION TECH CO LTD

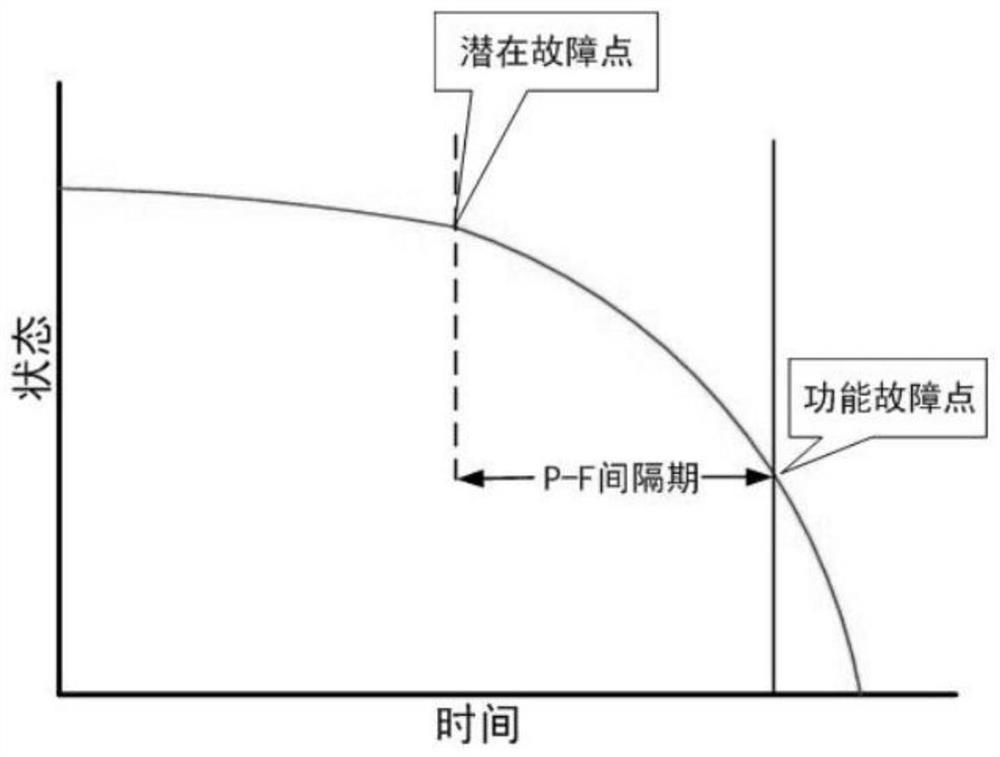

Equipment fault prediction method and system

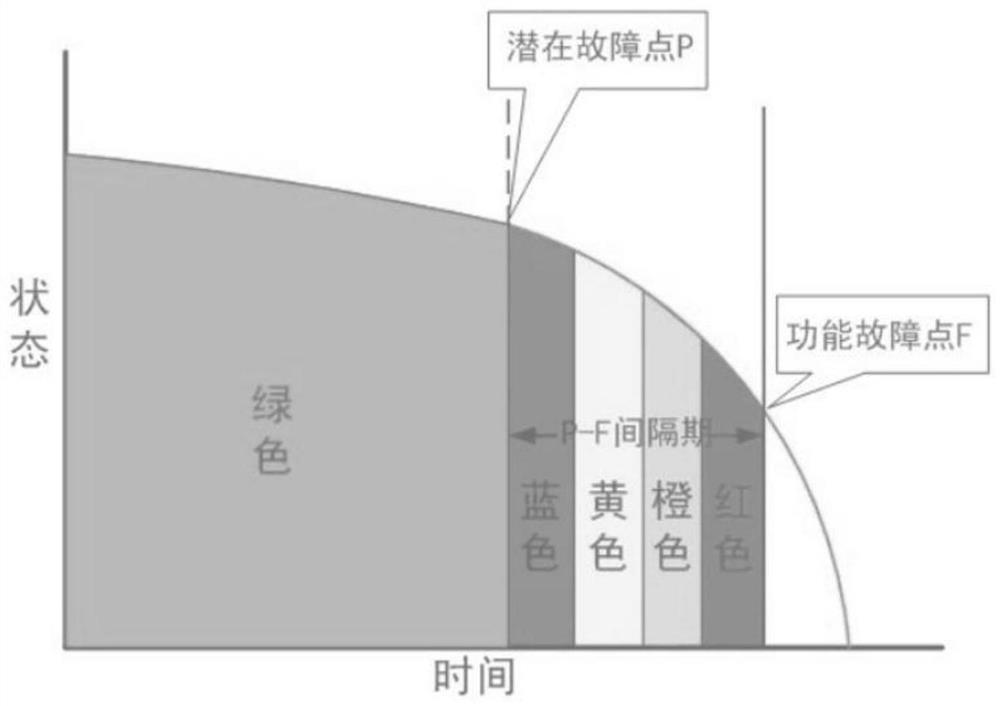

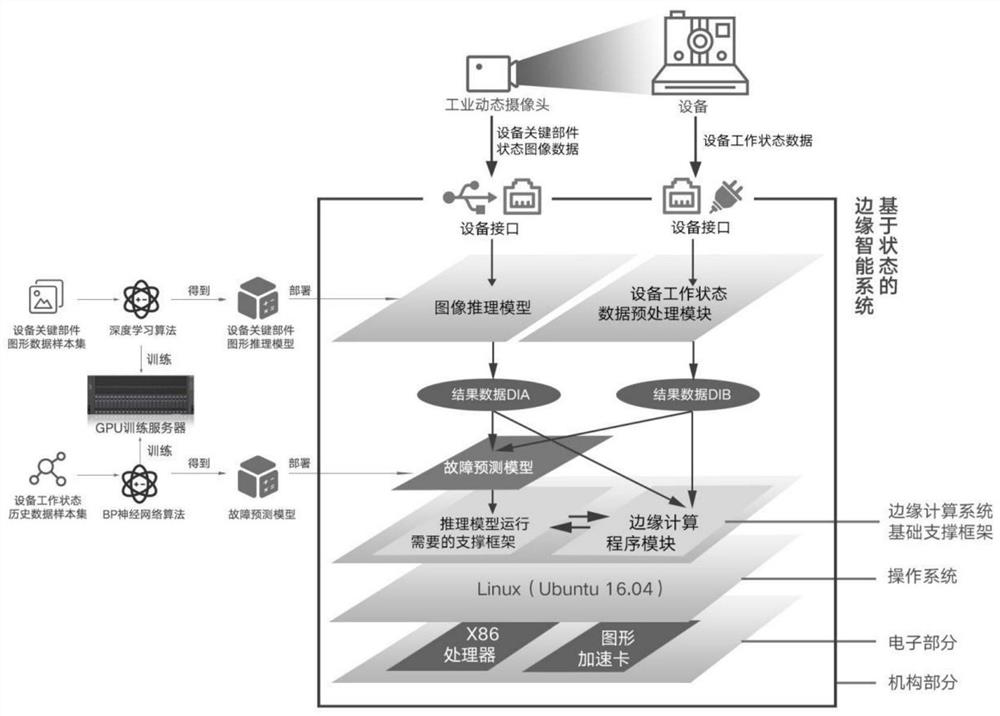

PendingCN112906775AReduce production lossReduce maintenance costsCharacter and pattern recognitionNeural architecturesNetwork modelBayesian network

The invention discloses an equipment fault prediction method. The method comprises the following steps: training is performed by an key component image training sample of equipment; an input training sample set is trained, the training sample set comprises output data of the Bayesian network model and training samples containing a plurality of working parameters, and a neural network model is obtained through training according to the training sample set; an acquisition module acquires working state data of the equipment; a key component image of the equipment is acquired; the obtained image of the key component into a Bayesian network model is input to output data DIA; the working state data of the equipment is preprocessed to obtain data DIB and fault prediction is made by using DIA and DIB according to the neural network model. Fault occurrence prediction and fault occurrence position locking can be provided, so that production loss is reduced, maintenance support cost is reduced, and the equipment perfectness rate and the task success rate are improved; through state monitoring, risks caused by faults in the task process are reduced, and the task success rate is improved.

Owner:深圳市芯聚智科技有限公司

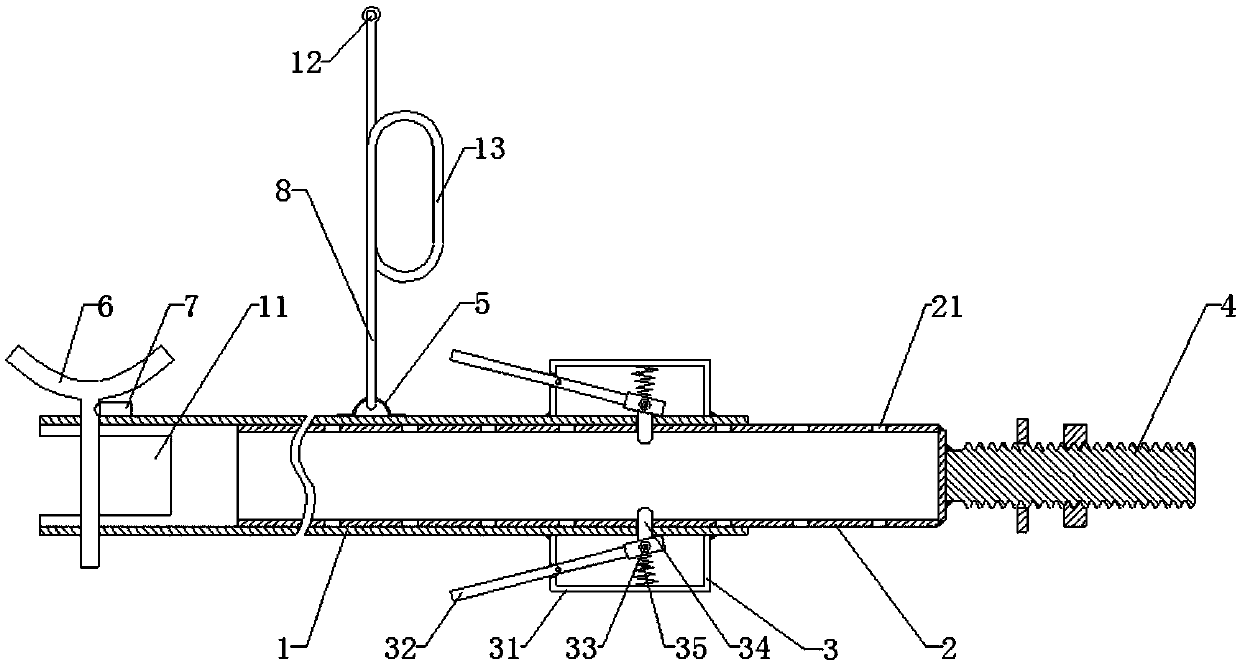

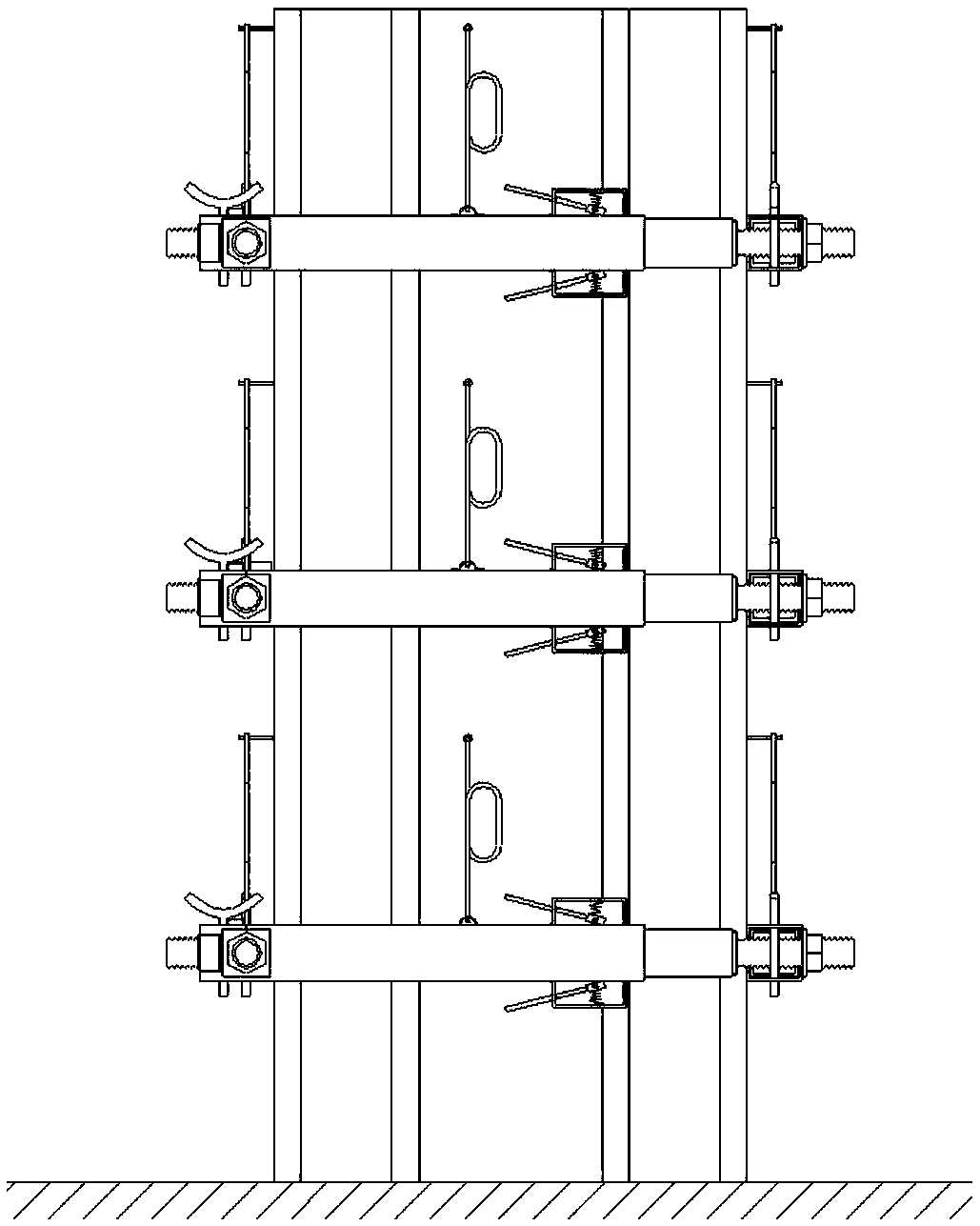

Column formwork clamp and using method thereof

InactiveCN107700838AAdjustable lengthNot easy to scratchForms/shuttering/falseworksLocking mechanismArchitectural engineering

The invention discloses a column formwork clamp and a using method thereof. The column formwork clamp comprises an outer tube, an inner tube, a locking mechanism, a screw rod, a lifting ring and a pinshaft, one end of the inner tube is inserted in the outer tube, and the other end of the inner tube is connected with the screw rod; and the locking mechanism is fixed at one end of the outer tube, the inner tube is connected with the outer tube through the locking mechanism, the lifting ring is fixed at the middle of the outer tube, and the pin shaft is vertically inserted at one end of the outer tube. The column formwork clamp adapts to different construction requirements by adjusting the length of the column formwork clamp, and is less in spare part and can be recycled, the construction cost is reduced, using operation is simple and fast, and the construction efficiency can be enhanced; the column formwork clamp is fixed through the screw rod and nuts, connection is firm and not easy to loose, and protruding parts after installation is less, so that construction personnel is not easy to scratch or stumble; and a suspension device is used for assisting positioning during installation, manpower input during installation can be reduced, the installation efficiency is improved, and the situation the construction personnel are injured after the column formwork clamp is released during detaching is prevented.

Owner:思南县广兴环保建材有限公司

Braking device for permanent-magnet direct-driving roller

The invention provides a braking device for a permanent-magnet direct-driving roller. The braking device for the permanent-magnet direct-driving roller comprises large gears fixedly installed on the roller and small gears meshing with the large gears, a rotation shaft is fixedly connected to the small gears, and brakes are arranged on the rotation shaft. The roller is driven by a belt to achieve transmission to drive the small gears to rotate, low-speed transmission is changed into high-speed transmission, the brakes and backstops are installed on the high-speed shaft, and the braking problemof the permanent-magnet direct-driving roller is effectively solved.

Owner:JIANGSU JIAXUAN INTELLIGENT IND TECH CO LTD

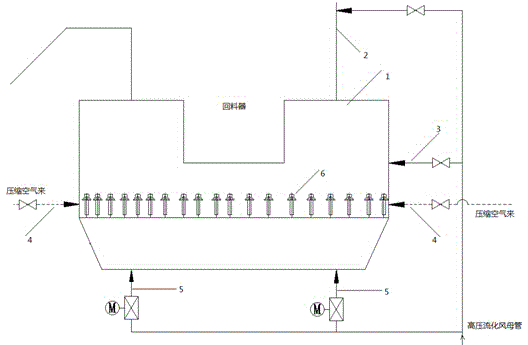

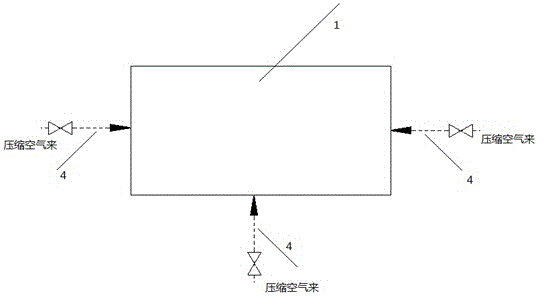

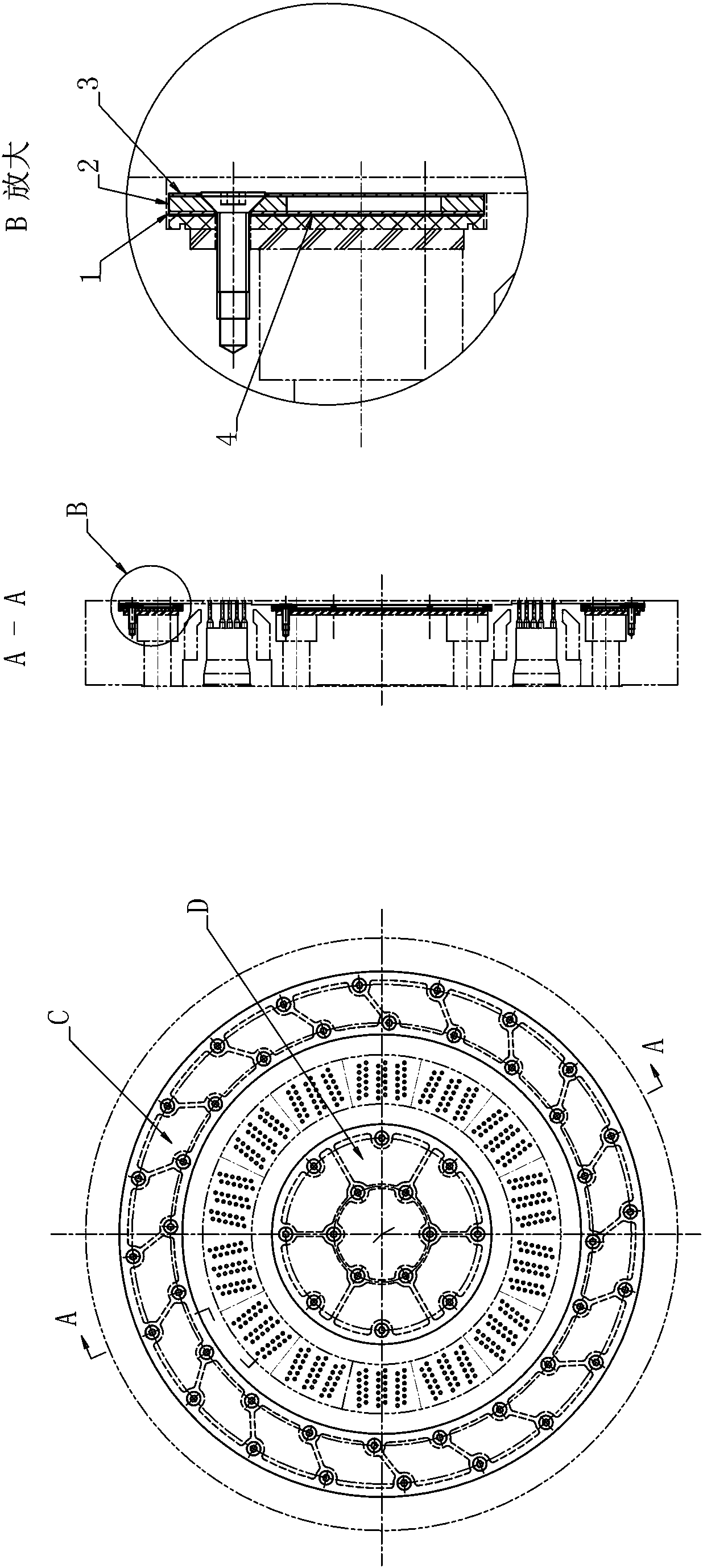

Material return device anti-blocking device for CFB boiler, and operation method thereof

InactiveCN104879749AReduce spare partsLow costFluidized bed combustionApparatus for fluidised bed combustionNormal valuesEngineering

The invention discloses a material return device anti-blocking device for a CFB boiler, and an operation method thereof. The material return device anti-blocking device comprises a material return device, material return device box body vibrating air valves and a material return device wind cap; the at least three vibrating air valves (4) are arranged at the lower part of the box body of the material return device (1) and positioned below the material return device wind cap (6); intercept valves of the vibrating air valves (4) at the lower part of the box body of the material return device are repeatedly closed and opened, and the intercept valves of the vibrating air valves (4) at the lower part of the box body of the material return device are closed till a pressure value of a fluidizing air main pipe is decreased to be a normal value, so that problems that after the automatic fluidization of a material return device of a conventional CFB boiler is destroyed, with the blocking of the material return device, a machine set needs to be restarted after halt cooling, the whole process is long in time consumption, the startup and stop costs of the machine set are high, the great economic loss is caused, the high-pressure fluidizing air system resistance can be increased when the CFB boiler continuously operates after the material return device is blocked, and safety of equipment and the machine set can be affected as two parallelly-operated high-pressure fluidization blowers tack or stall, are solved.

Owner:ELECTRIC POWER SCI RES INST OF GUIZHOU POWER GRID CO LTD

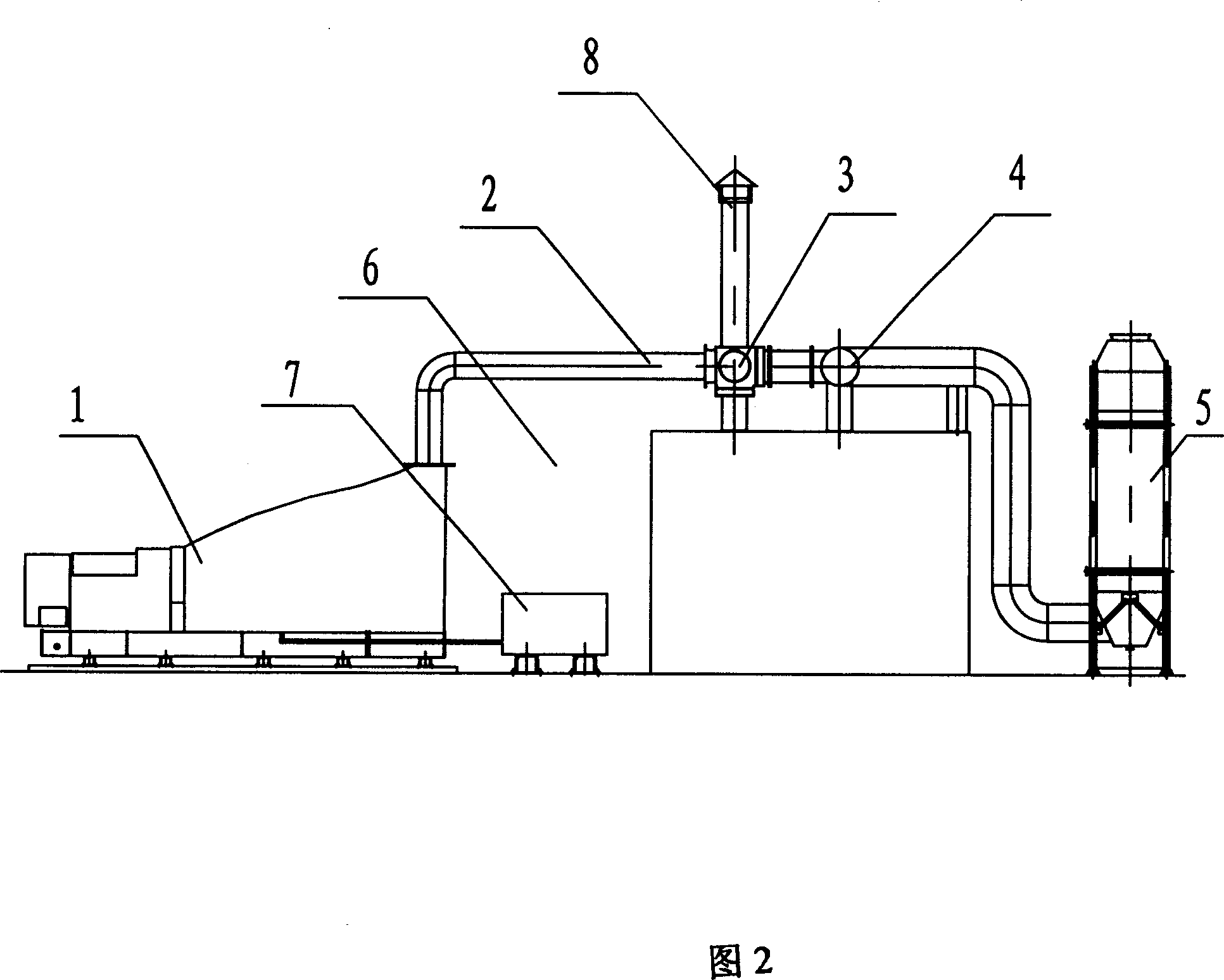

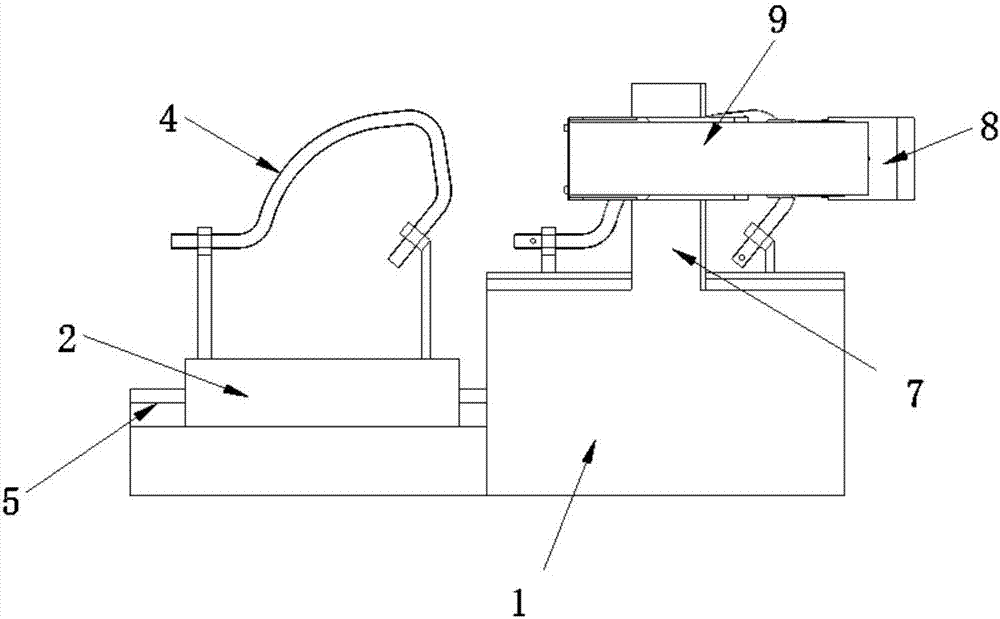

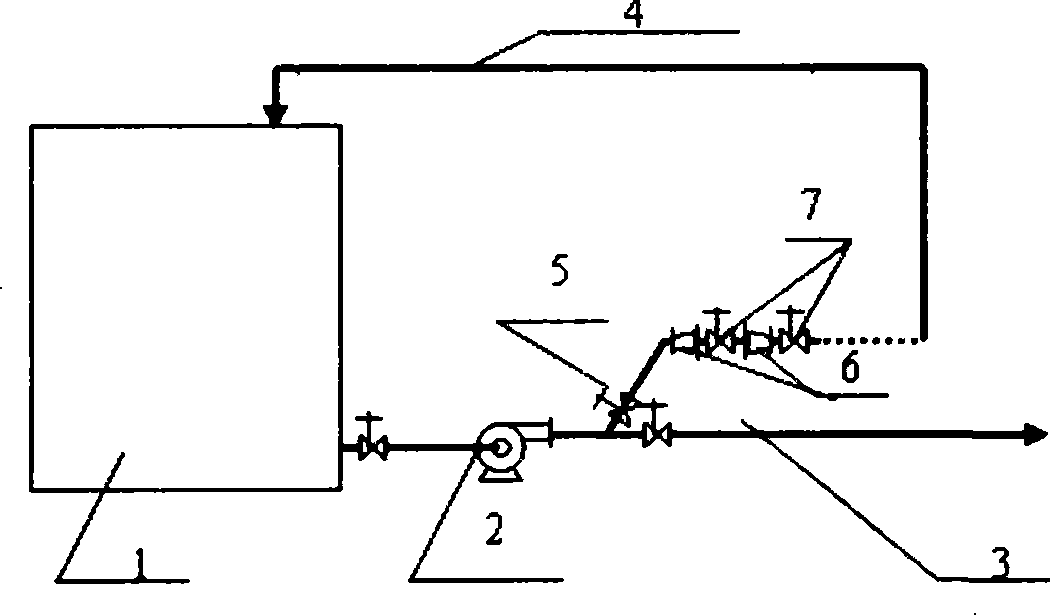

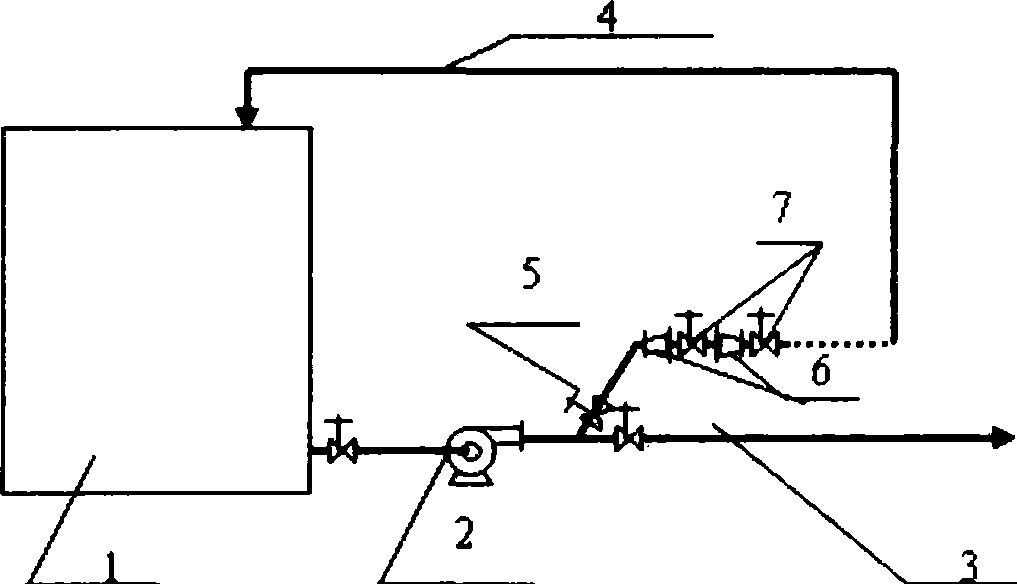

Cleaning device for valve scaling

ActiveCN101530851BScale cleaning thoroughlySimple processInorganic non-surface-active detergent compositionsCleaning using liquidsEngineeringControl valves

The invention discloses a cleaning device for valve scaling, comprising a chemical cleaning solution storage tank (1), a delivery pump (2) and a main pipeline (3); a branch pipeline (4) is connected on the main pipeline (3) for delivering the chemical cleaning solution; a control valve (5) is connected on the branch pipeline (4); various valves (7) with different nominal diameters are connected in series by connecting short pipes (6) with variable diameter on the branch pipeline (4); and then the cleaning solution returns to the chemical cleaning solution storage tank (1). Compared with the prior art, the device has the advantages of simple process, thorough cleaning of the valve scaling, and greatly improving the service life of the valve, thus saving spare parts and spare pieces, reducing production cost and the like.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Dust collection system of air jet loom and method

PendingCN108385247AGuarantee Arrangement StructureAvoid the impact of work performanceLoomsAuxillary apparatusAir-jet loomStop time

The invention belongs to the technical field of an air jet loom, and discloses a dust collection system and method of an air jet loom. The dust collection system comprises an upper dust collection assembly, a lower dust collection assembly and a dust collection box, wherein the upper dust collection assembly comprises an exhaust hole formed in a hemmer and an air exhaust pipe which is communicatedwith the air exhaust hole, and a voltage stabilizing assembly is communicated with an air exhaust pipe close to the air exhaust hole; the lower dust collection assembly comprises a dust collection shell which is arranged at the lower portion of the air jet loom, a dust collection suction pipe which is connected to the dust collection shell and a negative pressure sucking unit. By means of the dust collection system and method of the air jet loom, the energy source can be saved, spare parts are saved, the health of staff is guaranteed, the environment of workshops is improved, the dust removaleffect is good, the problem of hidden safety hazards caused by cotton dust when the air jet loom conducts producing is solved fundamentally, the frequency of cleaning and maintaining a loom platformis reduced, the stopping time for cleaning and maintaining the loom platform is shortened, the yield is increased, and the quality is improved; meanwhile, the using period of the spare parts is prolonged, the equipment performance is improved, and the product quality is improved.

Owner:SHEN MA INDUSTRY CO LTD

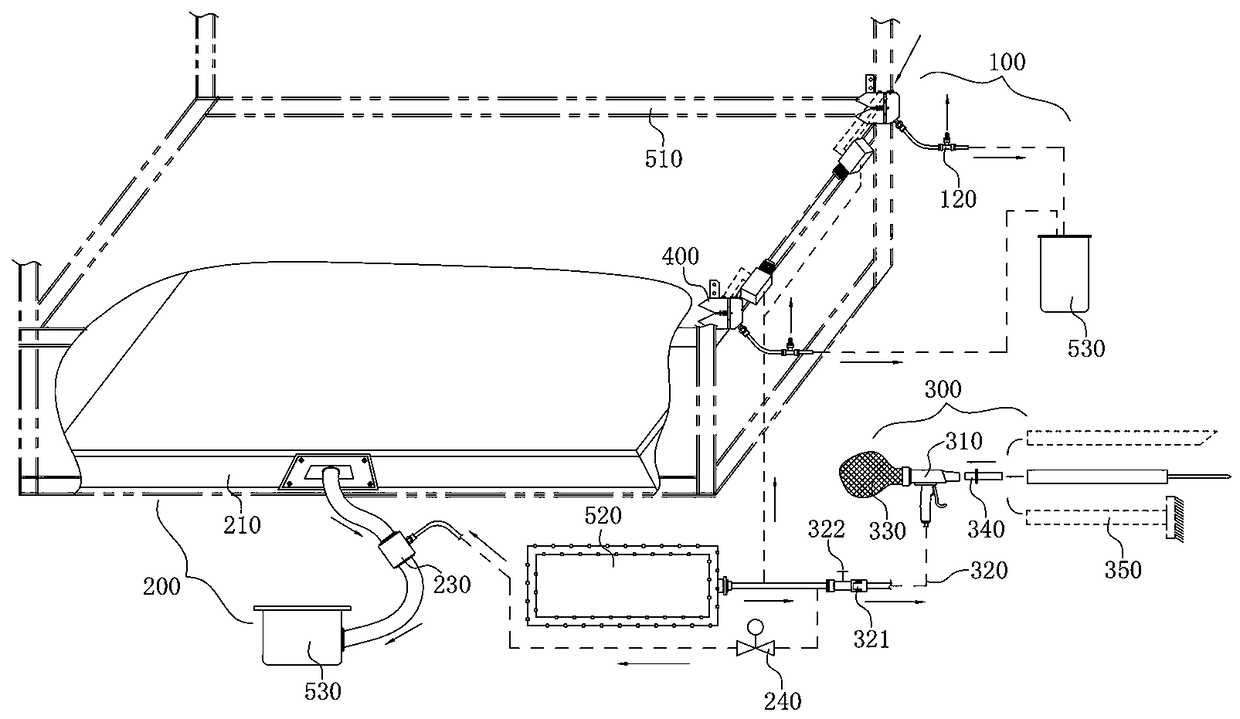

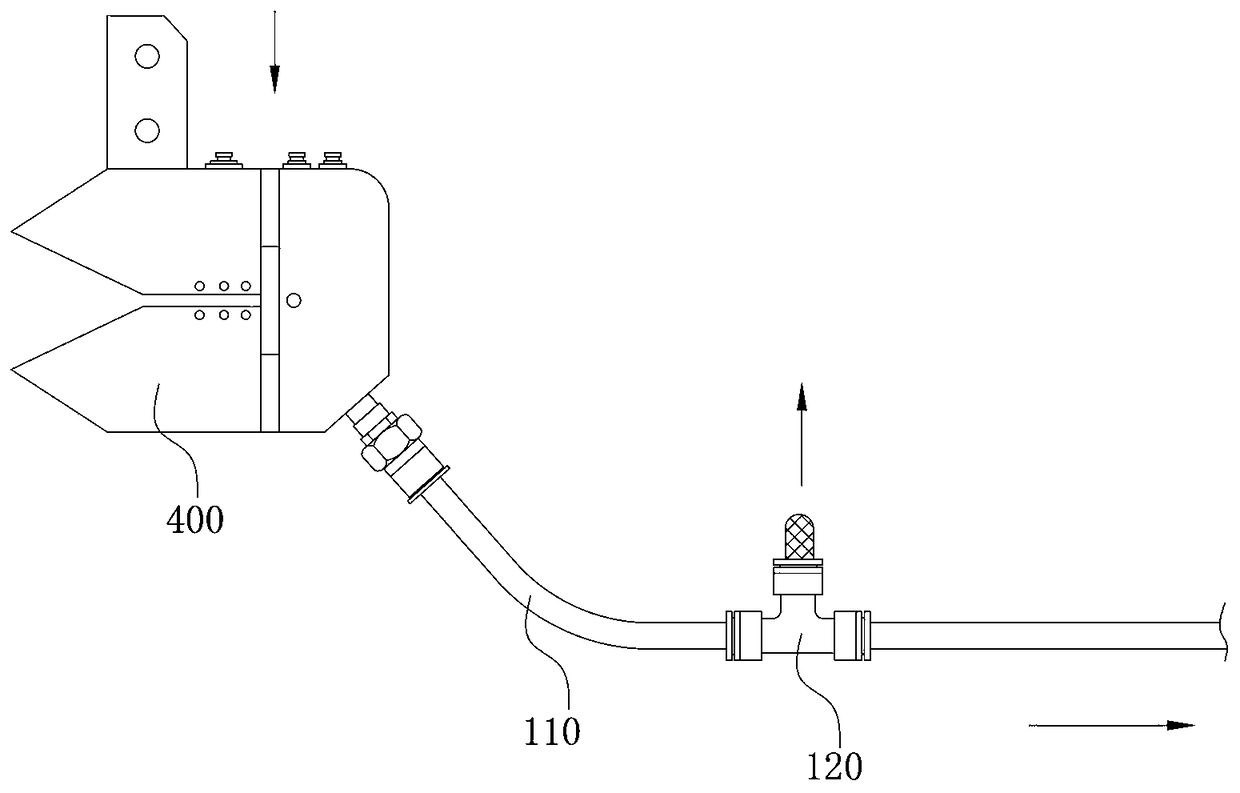

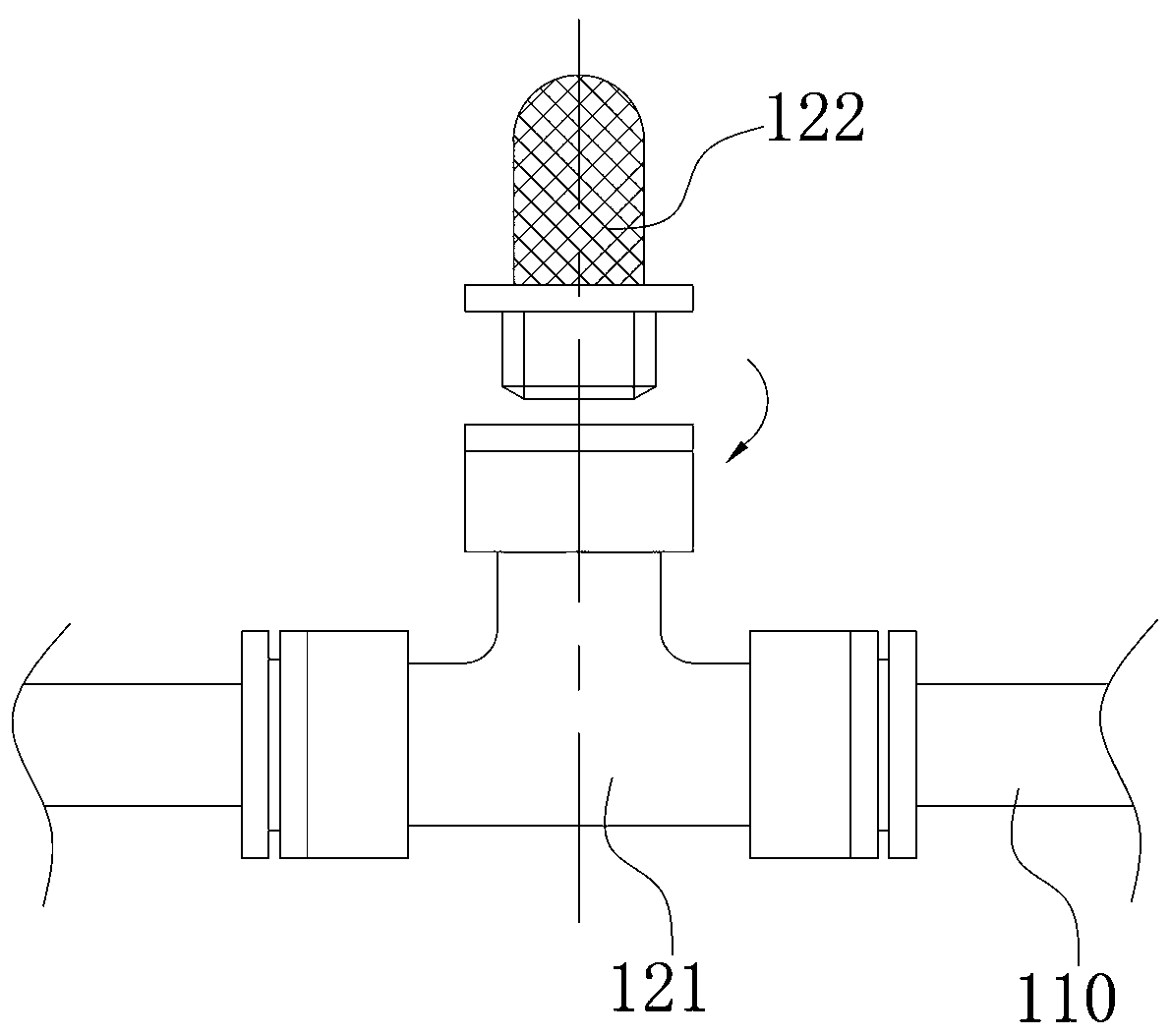

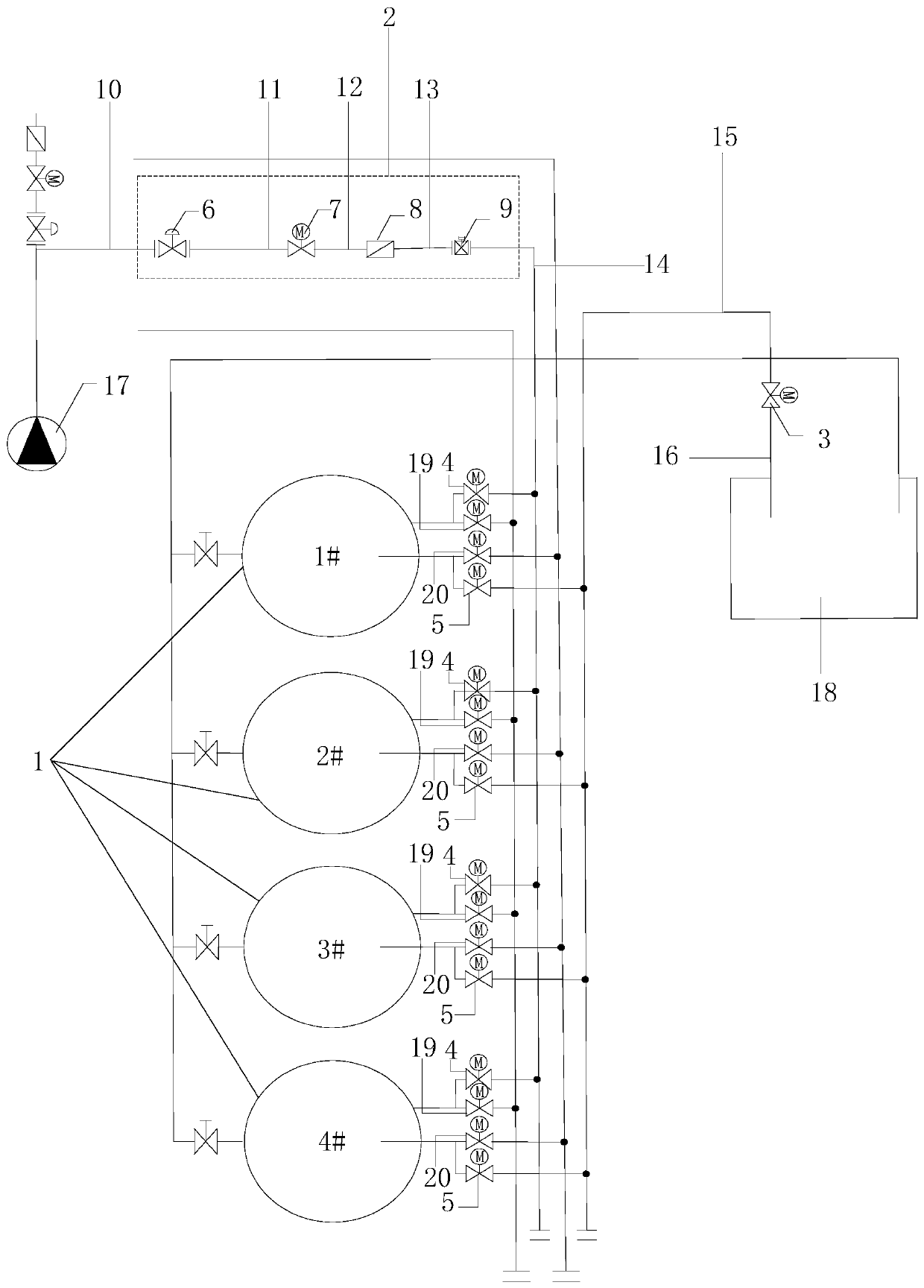

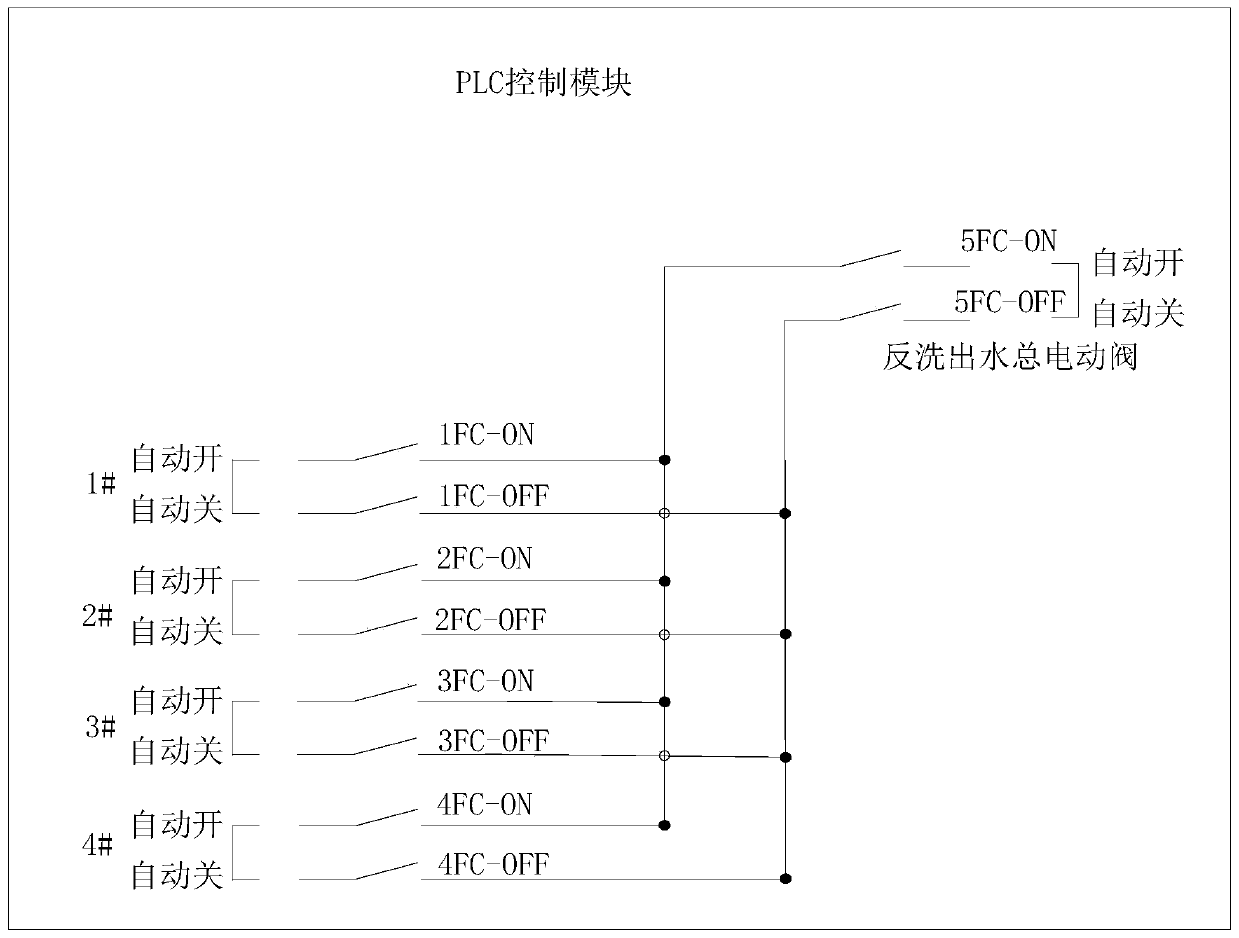

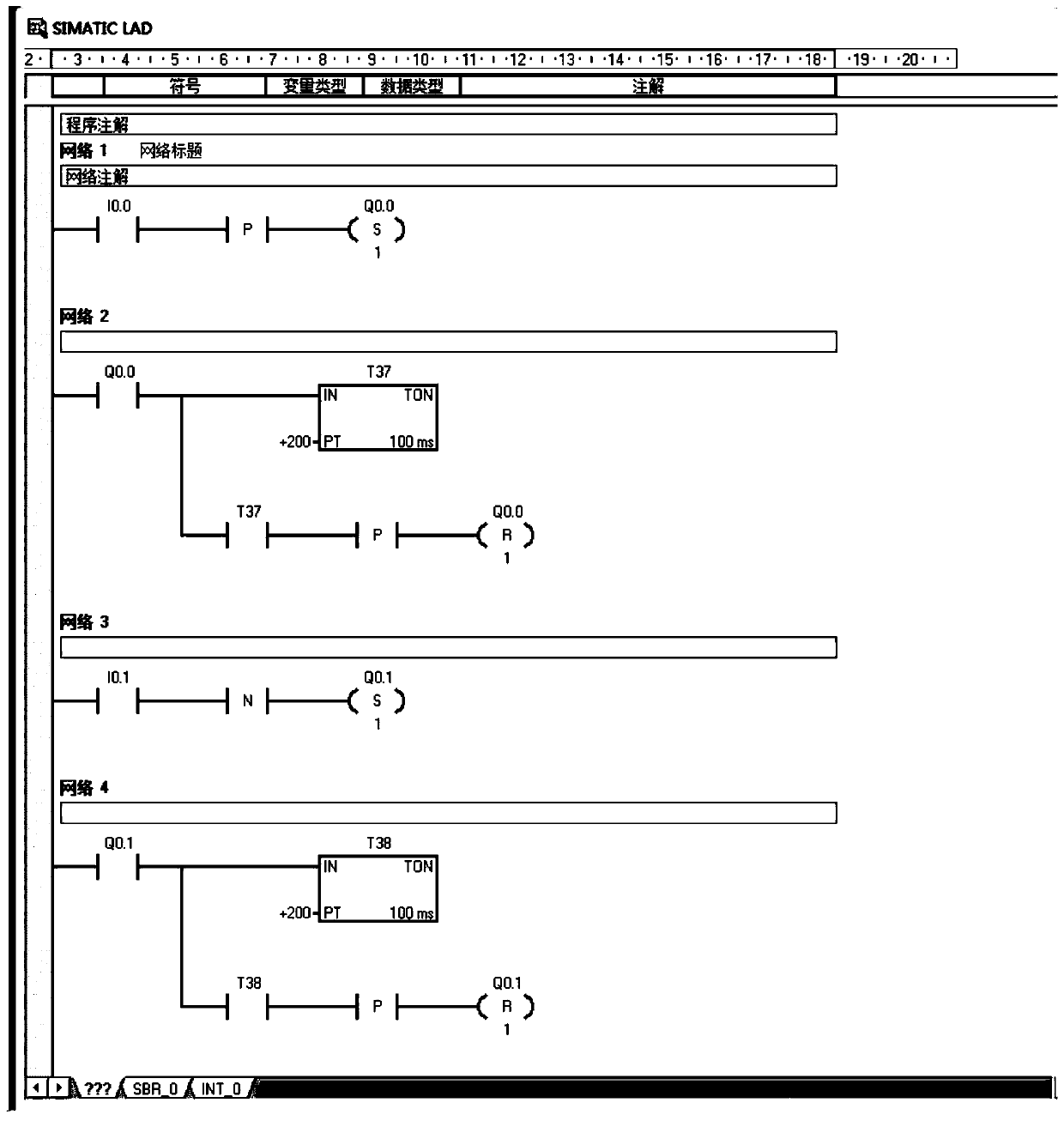

High-speed filter backwashing energy-saving device and use method thereof

PendingCN110482625AThere will be no waste of electricityCircumstances that shorten the service lifeWater treatment parameter controlSpecific water treatment objectivesStart stopControl system

The invention discloses a high-speed filter backwashing energy-saving device and a use method thereof. The device comprises a high-speed filter, a backwashing water inlet start-stop control system anda backwashing water outlet main electric valve; wherein the backwashing water inlet start-stop control system comprises a multifunctional water pump control valve, a backwashing water inlet main electric valve, a backwashing water inlet main manual valve and an electromagnetic flowmeter; two ends of the multifunctional water pump control valve are respectively communicated with the high-level water tank water supply pump and the water inlet end of the backwashing water inlet main electric valve; the water outlet end of the backwashing water inlet main electric valve is communicated with the water inlet end of the backwashing water inlet main manual valve, the water outlet end of the backwashing water inlet main manual valve is communicated with the water inlet end of the electromagnetic flowmeter, the water outlet end of the electromagnetic flowmeter is communicated with the backwashing water inlet end of the high-speed filter, and two ends of the backwashing water outlet main electric valve are respectively communicated with the backwashing water outlet end of the high-speed filter and the sewage tank. The problems that a backwashing pump wastes electric energy and is short in service life due to frequent starting and stopping are solved, and meanwhile the problems of sealing leakage of a backwashing water outlet electric butterfly valve and waste caused by frequent replacement of electric valve spare parts are solved.

Owner:SHANDONG IRON & STEEL CO LTD

Line rail symmetric turnout No 4.5 in urban rail transit engineering

The invention provides a line symmetric turnout No. 4.5 in urban rail transit engineering, and the turnout is arrange on parking line rail in underground lines in the urban rail transit engineering. The structure of the symmetric turnout comprises a group of railroad switches, a group of frogs and connecting steel rails, wherein the group of railroad switches is connected with the group of frogs through the connecting steel rails so as to form a symmetric turnout comprising two side rails. The invention has the beneficial effects that the turnout can satisfy the safe running of subway and light rail vehicles between a main line and a stop line, meets relative technical standards and safety requirements of the urban rail transit engineering, highlights the advantages of safety, reliability, convenience in manufacture, laying, construction maintenance and protection and the like. By the adoption of the invention, turnout investment can be reduced, and the length of auxiliary lines can be shortened greatly, and thus civil work investment can be reduced greatly, construction difficulty can be lowered, and construction risk can be decreased.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

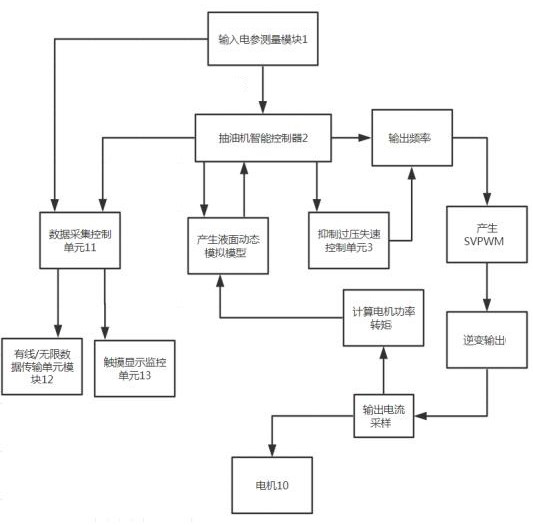

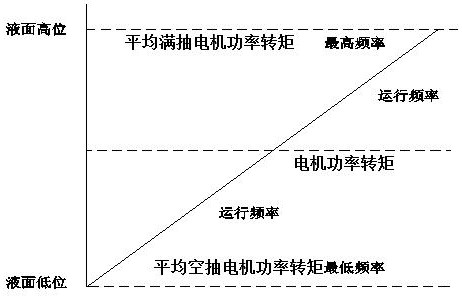

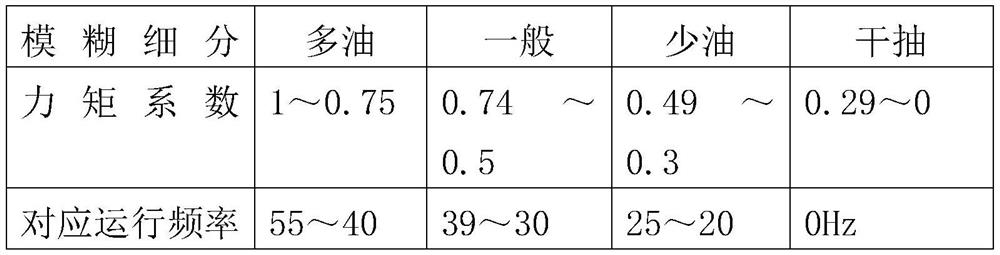

A Control Method of Pumping Unit Based on Motor Power Torque

ActiveCN111884557BAvoid empty pumping, etc.Reduce energy consumptionConstructionsSoftware algorithm controlMachine controlElectric machine

The invention discloses a control method for a pumping unit based on the power torque of a motor, which comprises the following steps. In the second step, the intelligent controller of the pumping unit gives the motor an output frequency, the output frequency is modulated to generate SVPWM, and the SVPWM drives the motor to operate after outputting through the inverter; the third step is to input electric parameters to measure The module samples the output current of the inverter output to obtain the output current change signal, and calculates the motor power torque from the output current change signal, and the intelligent controller of the pumping unit adjusts the output frequency, thereby adjusting the motor operating frequency and changing the pumping speed . Through the real-time change of the current / torque of the motor, the output speed required in real time can be obtained to achieve better energy-saving effects, achieve a balance between supply and production, improve the efficiency of mechanical production, and reduce the energy consumption of pumping units during oil production.

Owner:PETROCHINA CO LTD

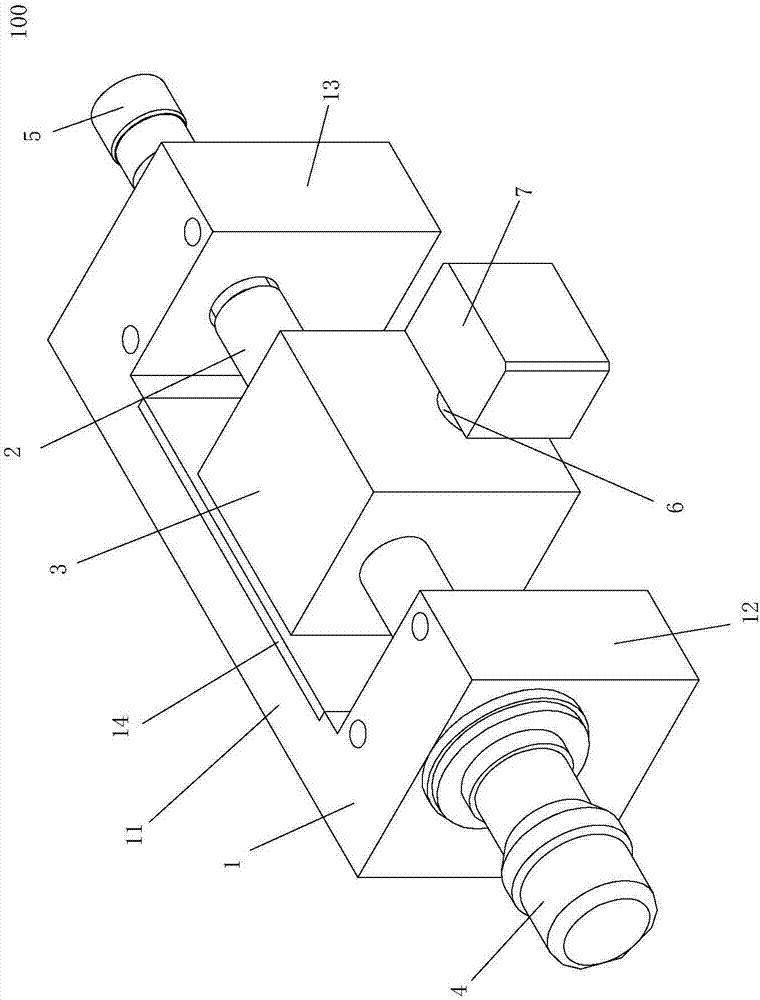

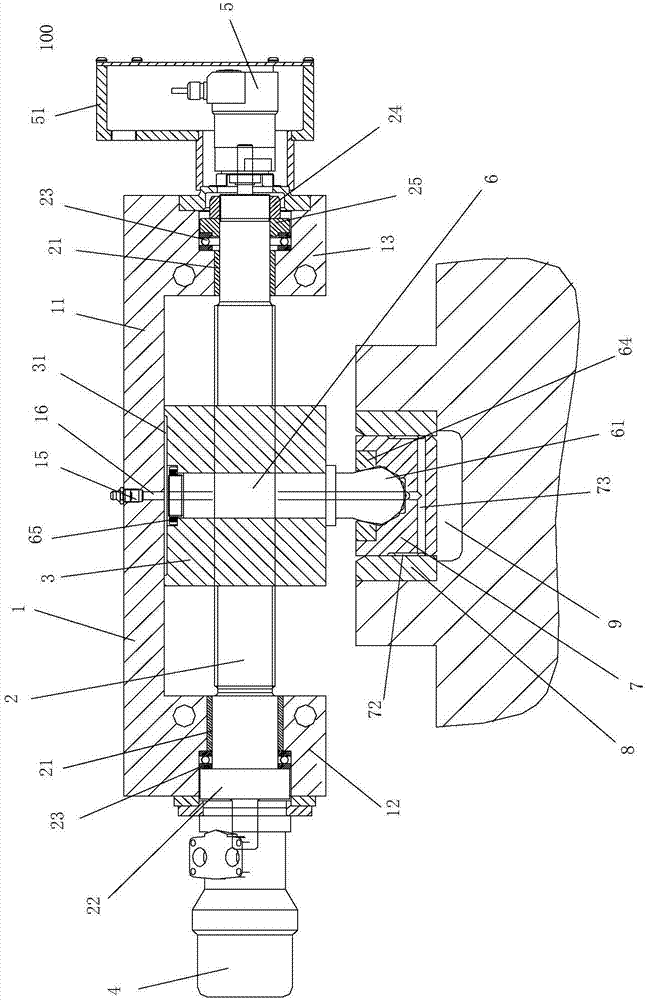

Cross-rolling feed angle adjustment device

ActiveCN106216410BCompact and practicalReliable adjustmentMetal-working feeding devicesMetal rolling stand detailsEngineeringSpare part

The invention provides a skew rolling feed angle adjusting device. The device comprises a base, wherein a rotating screw passes through the base; a slider capable of axially moving along the screw is arranged on the screw in a rotary manner; a driving device is connected at one end of the screw and a coder is connected at the other end of the screw; an extended driving lever is fixedly arranged in the slider; a connection block is hinged at the extended end of the driving lever. The skew rolling feed angle adjusting device has a practical and compact structure, is accurate and reliable in adjustment and convenient and fast to change, can achieve off-line removal and installation and complete change, can achieve the effects of reducing the operation time, the spare parts and the maintenance cost, can replace adjusting mechanisms with complex structures and has the effect of solving the problem that the product quality is affected because some structures easy to wear cause errors.

Owner:BEIJING JINGCHENG RUIXINCHANGCAI ENG TECH +1

Method for rotary burning of thin coal layer

ActiveCN101659873AAvoid messBurn fullyEnergy inputIndirect heating destructive distillationCoal measuresCombustion

The invention belongs to the field of raw coal burning, and particularly relates to a method for burning coal particles arranged in a rotary burning chamber provided with a high temperature fire bed. The method comprises the following steps: the coal particles are input into a coal measure feeder and are fed into a wind power coal feeding pipe arranged in a coal feeding rod; a coal output end of the coal feeding rod is arranged above the cavity of a rotating furnace and reciprocates along the radius of the furnace cavity, and the coal particles are fed into the furnace cavity by wind power; under the reciprocating action of the coal feeding rod and the rotating action of the furnace cavity, the coal particles form a uniform coal layer on the surface of the fire bed; under the rotating actions of the furnace cavity and a slag extractor, the coal layer ignites and burns by the combination with oxygen in combustion air; and the coal layer rotates in the furnace cavity, the slag extractorrotates, crashes and collects slag, and the slag falls in a slag discharging pipe and is discharged. The method has the advantages of the rotary burning of the thin coal layer, the combustion supporting of secondary air, reasonable and scientific coal burning, and adequate and complete burning, improves the thermal efficiency and reduces the coal consumption by 30%. The used equipment has the advantages of compact and reasonable structure, low manufacturing cost, safety, reliability and low operation cos. The defects that burning machines are dirty, disorderly and bad and pollute the environment are avoided.

Owner:MAANSHAN EME INNOVATION TECH CO LTD

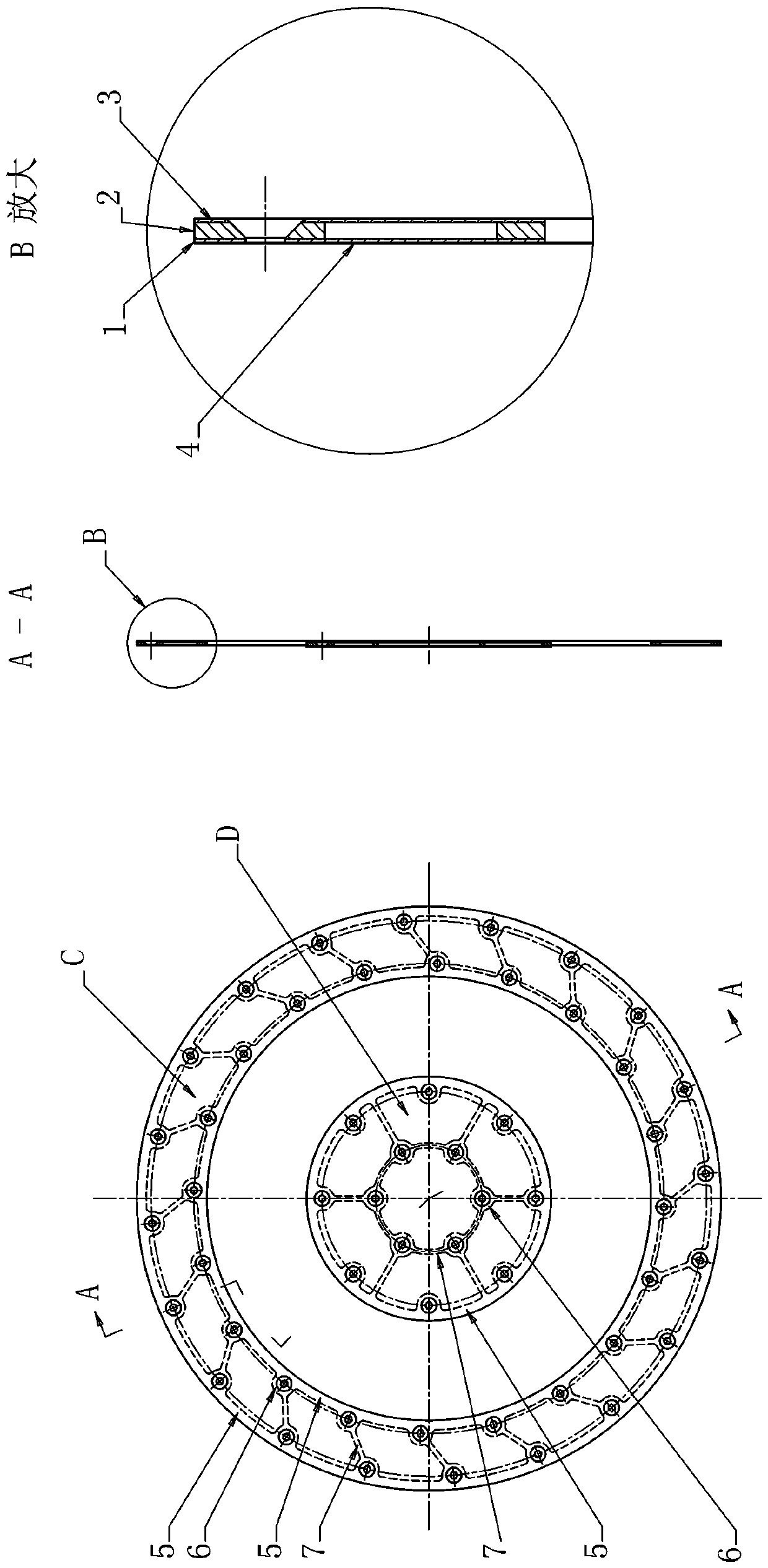

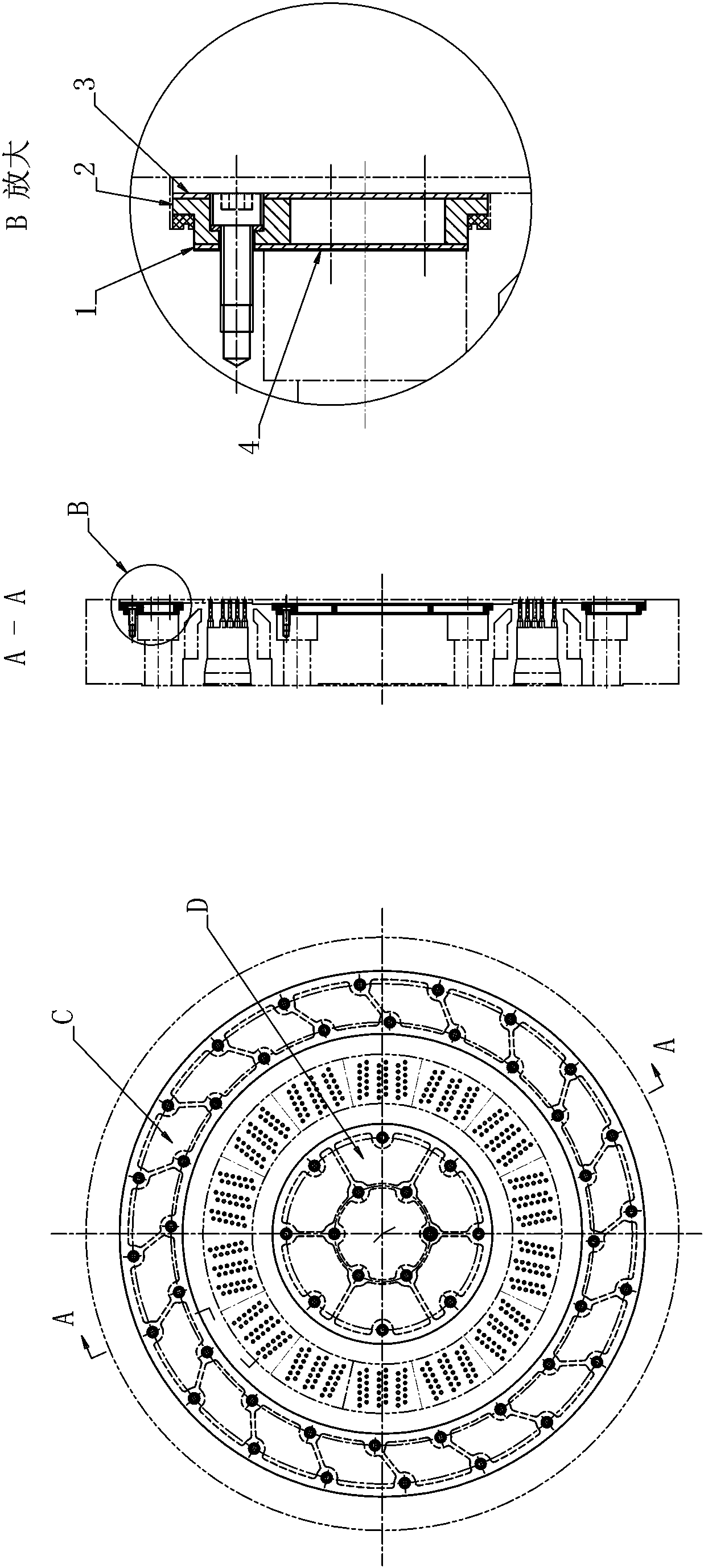

Vacuum heat insulation cover plate for granulation template

The invention relates to an underwater granulator granulation template, in particular to a vacuum heat insulation cover plate for the granulation template. The vacuum heat insulation cover plate provided by the invention is arranged on the surfaces of an inner ring and an outer ring of the granulation template to be capable of insulating heat conduction, convection and radiation in these portions,the heat-preservation and heat-insulation performance of the portions is improved, the transmitting speed of temperature dropping generated by inner ring and outer ring areas under the action of cooling water towards the edge of a template granulation band is reduced, the temperature difference between the edge of the template granulation band and the central portion is reduced, and the granulation quality is improved. The vacuum heat insulation cover plate for the granulation template comprises a lower cover plate, a middle support grid plate, an upper cover plate and a high-temperature resistant heat insulation coating. According to the vacuum heat insulation cover plate for the granulation template, a main body area of the vacuum heat insulation cover plate is provided with a pluralityof independent vacuum cavities which do not communicate with each other, the inner side of the lower cover plate is provided with the high-temperature resistant heat insulation coating, and the outward convection, conduction and radiation loss of internal heat of the granulation template is insulated.

Owner:大连市锐耐特刀具有限公司

Transmission mechanism of spinning motor

PendingCN110923863AReduce work intensityLess varietyTextile/flexible product manufactureContinuous wound-up machinesYarnDrive shaft

The invention relates to a transmission mechanism of a spinning motor. The transmission mechanism comprises a main wallboard, a first small wallboard, a second small wallboard, variable frequency motors, synchronous belt wheels, synchronous belts, tensioning mechanisms, winding combination mechanisms, yarn guiding combination mechanisms and sensor supports, wherein the number of the variable frequency motors, the synchronous belt wheels, the synchronous belts and the tensioning mechanisms is four separately; the number of the winding combination mechanisms, the yarn guiding combination mechanisms and the sensor supports is two separately, wherein the four variable frequency motors are uniformly and symmetrically arranged on the main wallboard; the synchronous belt wheels are arranged on the variable frequency motors; the winding combination mechanisms and the yarn guiding combination mechanisms are arranged on the first small wallboard and the second small wallboard in different columns; and the tensioning mechanisms are arranged on the first small wallboard and the second small wallboard in different columns. The synchronous belts are adopted to drive a winding and yarn guiding transmission shaft to rotate, and variable frequency control of the motors is carried out, so that precise adjustment of the spinning process is achieved, and the transmission mechanism is simple and compact in structure and small in occupied space.

Owner:JINGWEI INTELLIGENT TEXTILE MACHINERY CO LTD

Transitional flange used between motor and fan

The invention relates to a transitional flange used between a motor and a fan. The transitional flange is mounted on a fan box body; a motor is mounted on the transitional flange through a shaft; the transitional flange is divided into an inner ring and an outer ring; screw holes are formed in the inner ring circumferentially at the same interval; and a plurality of annular screw holes with different radius are formed in the outer ring of the transitional flange correspondingly according to the hole positions of the motor flange screw holes with different modes. According to the transitional flange provided by the invention, when the motor is replaced, the motor can be replaced only by disassembling screws of the motor flange and without replacing the transitional flange; and when spare parts are prepared, the spare parts can be effectively reduced and the cost is reduced.

Owner:天津市新宇彩板有限公司

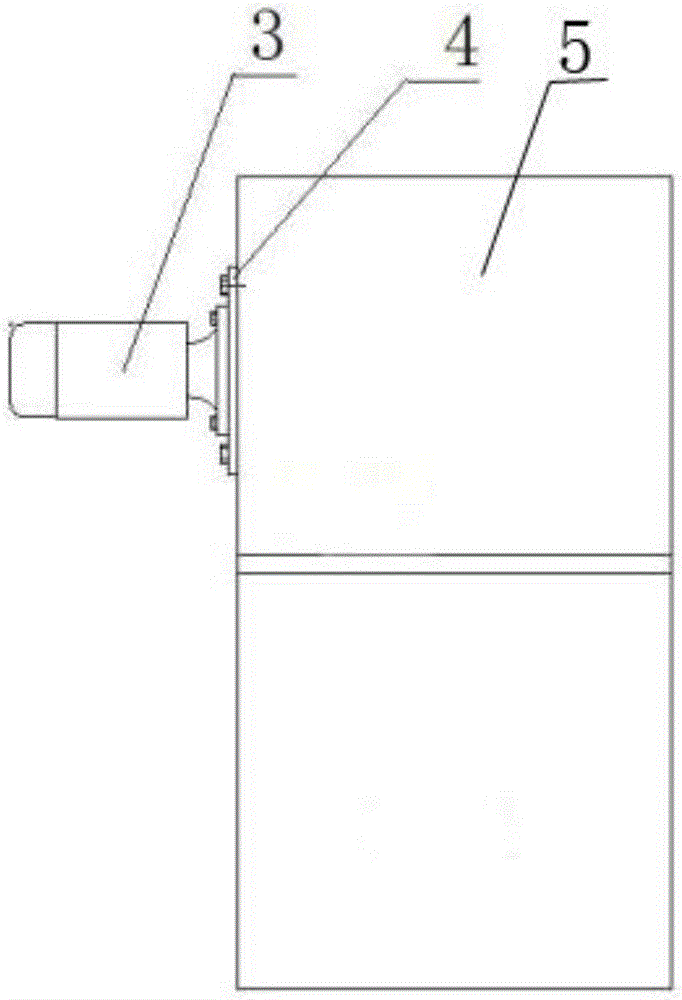

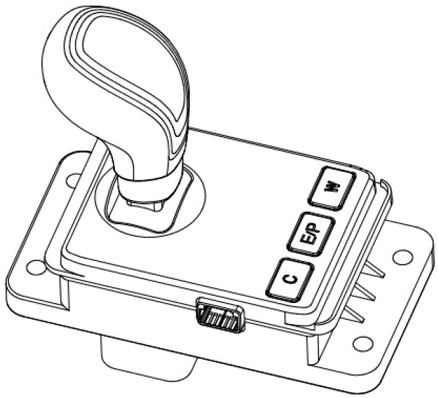

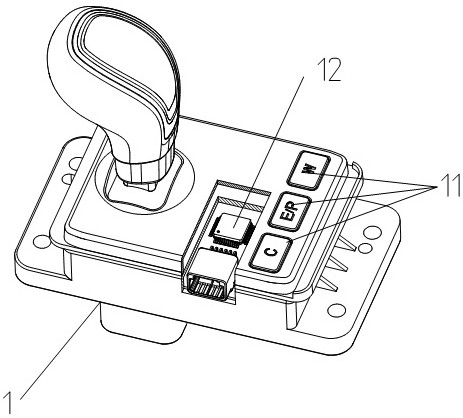

Electronic shifter with active initialization function, active initialization method of electronic shifter and vehicle

InactiveCN111897597AReduce the number of varietiesAvoid custom settingsGearing controlProgram loading/initiatingIn vehicleControl engineering

The invention relates to an electronic shifter with an active initialization function, an active initialization method of the electronic shifter and a vehicle. The electronic shifter comprises built-in active initialization software; in the software active initialization, a special and unoccupied key combination on an electronic shifter is set as a trigger point; triggering is continued until settime is up, different Baud rates of different built-in vehicle models are tried to be used for being communicated with the whole vehicle; when the proper Baud rate of the whole vehicle is matched, theBaud rate is recorded and written into an EEPROM of the electronic gear shifter, and initialization is ended. If different built-in APPs need to be started according to different vehicle types, afterBaud rate matching is completed, the successfully matched Baud rate is used for communicating with the whole vehicle, the vehicle type code of the whole vehicle is read and written into an EEPROM ofan electronic shifter, and it is determined that the built-in APP of the corresponding vehicle type is started according to the code. The same electronic shifter is used for different vehicle types and configurations to the maximum extent, the number of part varieties is reduced, inventory and waste are reduced, and user-defined settings are prevented from being unexpectedly and forcibly initialized to factory settings.

Owner:SHIYAN DAFENG FLEXIBLE CONTROL CABLES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com