Connecting apparatus for catenary and aluminum guide stem

A technology of connecting device and aluminum guide rod, which is used in transportation and packaging, load hanging components, cranes, etc., can solve the problems of loose aluminum guide rod and hanging trolley, difficult to control the falling of aluminum guide rod, and large maintenance and repair. Achieve the effect of lagging safety benefits and social benefits, preventing the phenomenon of falling off the rod, and ensuring production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

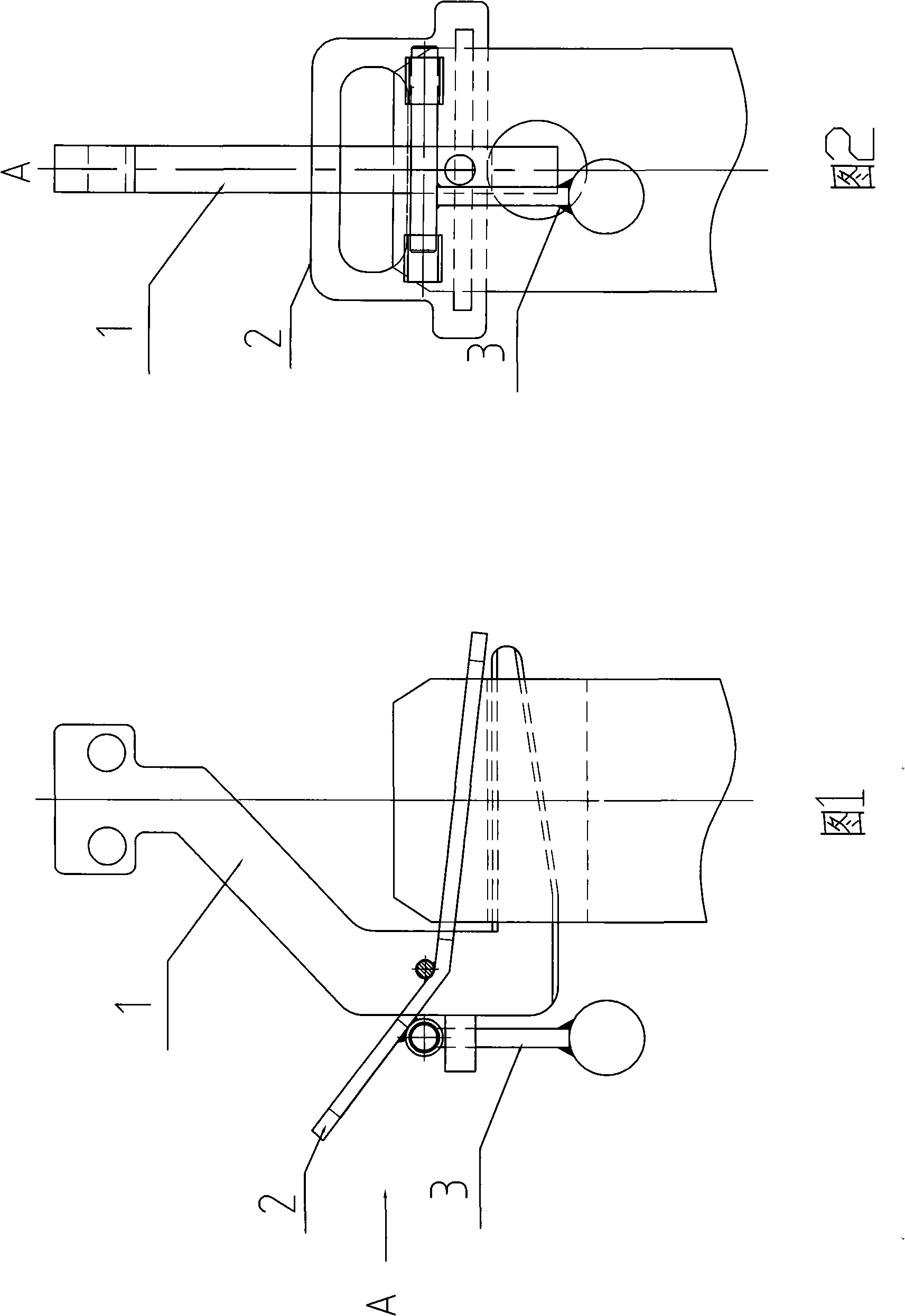

[0032] As shown in Fig. 1 and Fig. 2, the embodiment of the connecting device between the catenary and the aluminum guide rod provided by the present invention is composed of a hook hanger 1, an aluminum guide rod fixing hoop 2 and a safety self-locking pin 3. in:

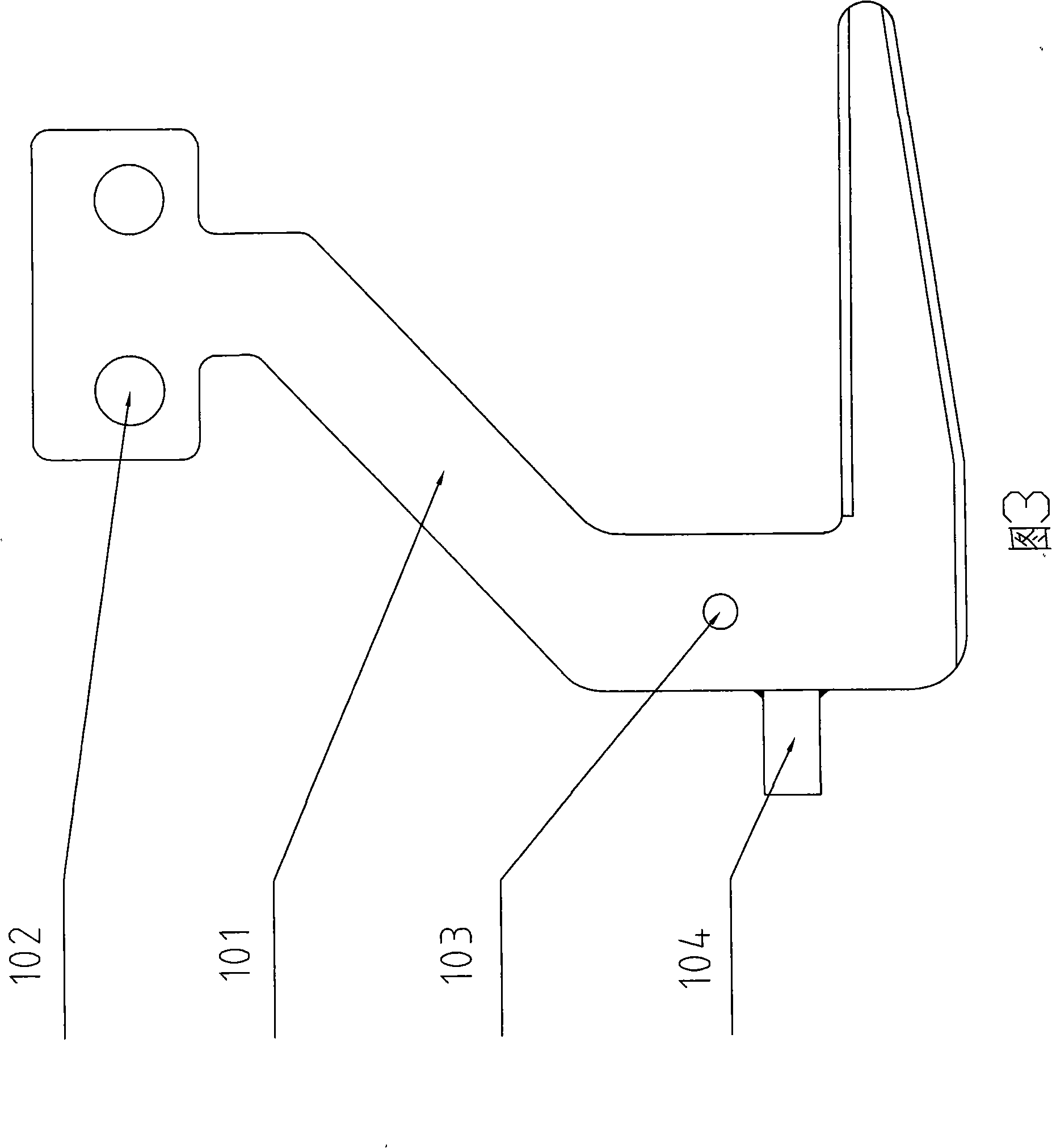

[0033] In Fig. 3: the shape of the hook-like spreader 1 is "B", the upper end of the B-shaped hook 101 has a chain connection pin hole 102, and the transition section of the B-shaped hook 101 has a hoop installation pin hole 103, and the B-shaped hook 101 has a hoop installation pin hole 103. A lock column 104 is provided outside the transition section of the hook 101;

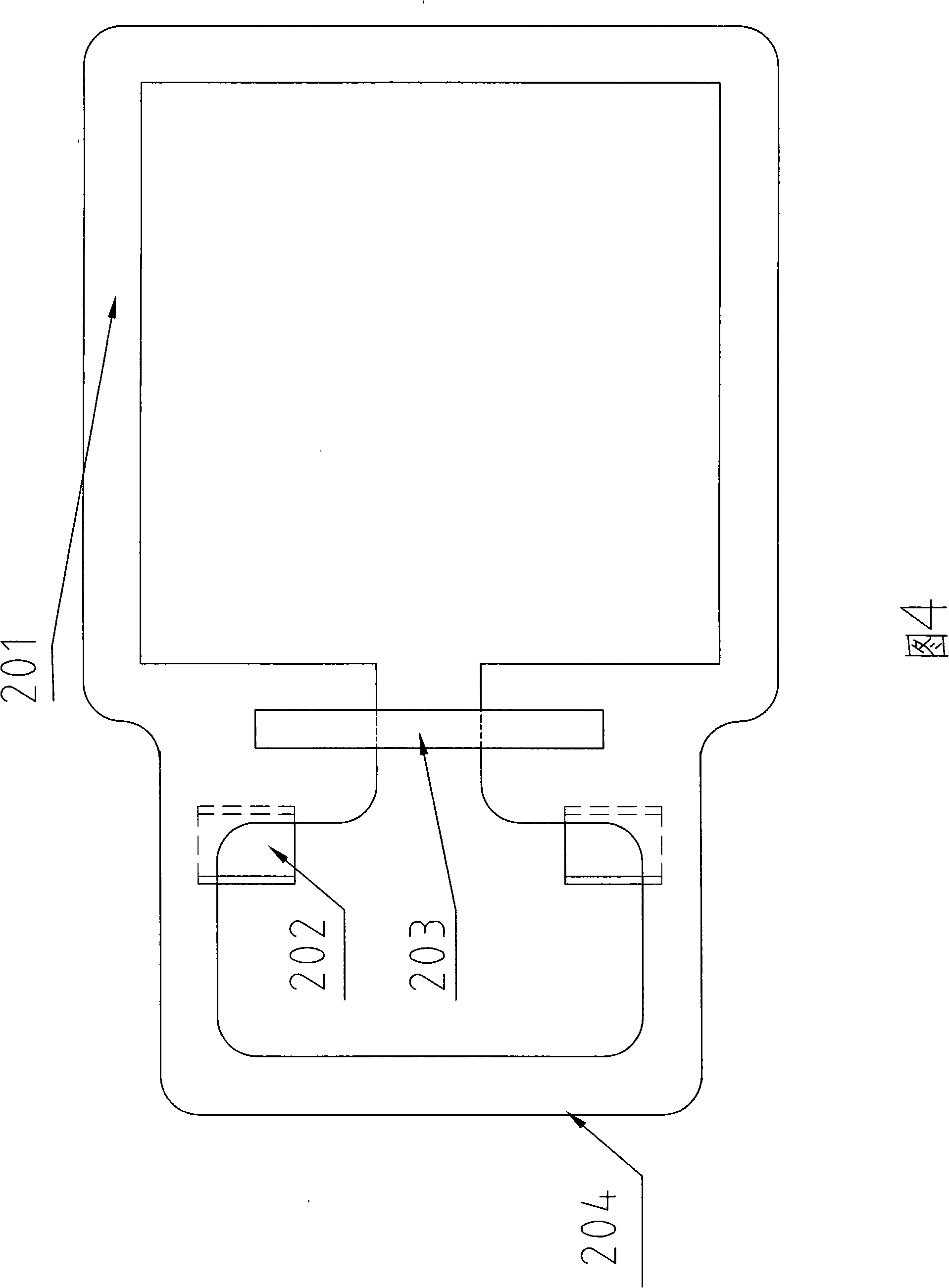

[0034] In Fig. 4: the hoop of the aluminum guide rod fixing hoop 2 is a square steel ring suitable for the outer shape and size of the aluminum guide rod, and an opening is left in the center of one side of the hoop, and the opening is in the assembly When the hook hanger 1 is welded with the hoop connecting pin 203, the side of the hoop also exte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com