Transitional flange used between motor and fan

A transitional flange and fan technology, which is applied to parts of pumping devices for elastic fluids, machines/engines, mechanical equipment, etc., can solve the problems of resource occupation and different sizes of fan flanges, and reduce spare parts, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

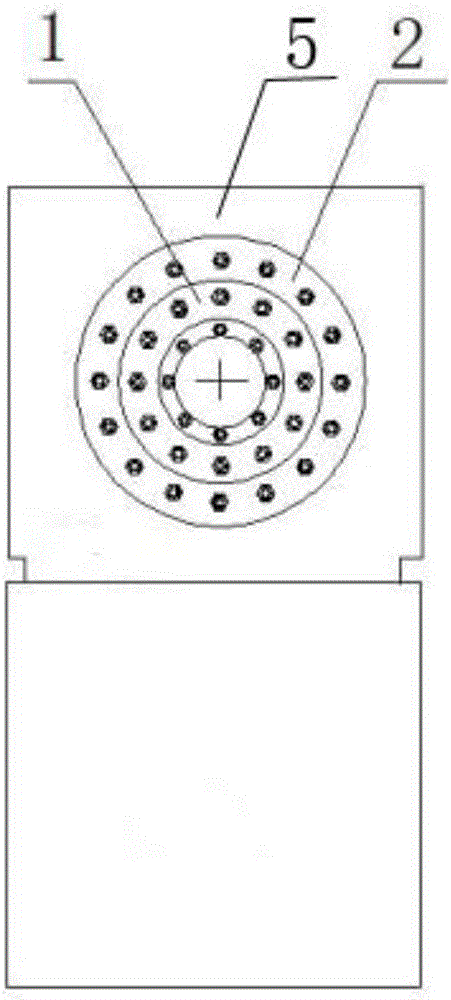

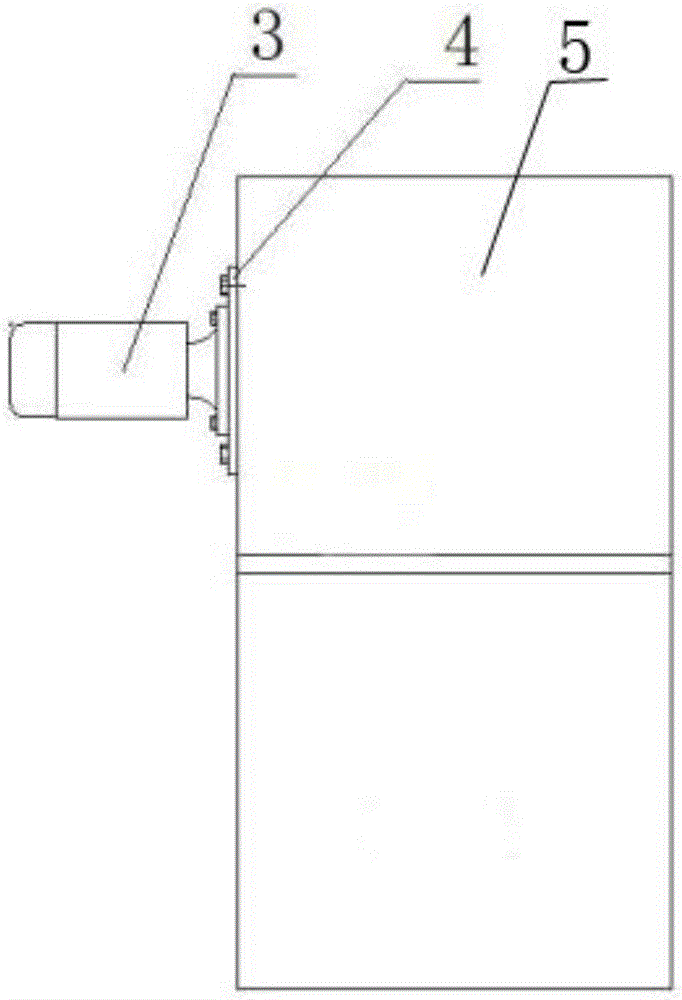

[0012] A transition flange used between the motor and the fan. The transition flange 4 is installed on the fan box body 5, and the motor 3 is installed through the shaft on the transition flange. The transition flange is divided into an inner ring 1 and an outer ring 2. There are screw holes evenly distributed on the circumference of the inner ring. The screw holes are aligned with the screw holes set on the fan box body. The screw hole positions on the outer ring of the transition flange are based on different standards of motor flange Correspondingly, annular screw holes with multiple radii are provided. When replacing the motor, you only need to remove the screws on the motor flange to replace it,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com